Huntron Instruments HTR 1005B-1JS, HTR 1005B-1ES, HTR 1005B-1S User Manual

, ,

, "

OPERATOR

FOR MODELS

HTR 1005B·18 .

MANUAL

HTR 1005B·1

E8

HTR 1005B·1J8

HUNTRON INSTRUMENTS. INC

.•

15123

Hwy.

99

North.

Lynnwood. WA

98037.

(800)426-9265 • (206)743-3171 • Telex 152951

TABLE OF CONTENTS

SECTION 1 - GENERAL INFORMATION

1.1

ABOUT THIS MANUAL

1.2 TRACKER DESCRIPTION ,

1.3 PRINCIPLESOFTRACKER OPERATION ,

1.3,1 Tracker Test Signal , , , ,

1.3.2 Horizontal and Vertical Deflection of the Display " ,

1.3.3 Short and Open Circuit Displays

.",'

, ,

SECTION 2 - TRACKER OPERATION

2.1 GENERAL , , , ,

2.2 CONTROLS AND INDICATORS ,..,.,

2.3 ALTERNATE MODE OPERATION , 2-3

2.4

FUSE REPLACEMENT , ' , ' 2-3

,

SECTION 3 - TESTING DIODES

3.1

THE

SEMICONDUCTOR DIODE AND ITS CHARACTERISTICS

3.1.1 Diode Symbol and Definition

3.1.2 The Volt-Ampere Characteristic , , , 3-2

3.2 SILICON RECTIFIER

3.2.1 Patternsofa Good Diode 3-2

3.2.2 Patterns

3.3

HIGH

3.4

RECTIFIER BRIDGES , , 3-5

3.5 LIGHT-EMITTING DIODES 3-8

3.6

ZENER DIODES 3-8

ofa

VOLTAGE SILICON DIODES , , 3-3

DIODES.

Defective Diode , " 3-3

.,

, , , 3-2

, ,

1-1

1-3

1-3

1-3

1-4

2-1

2-1

3-1

3-1

SECTION 4 - TESTING TRANSISTORS

4.1 BIPOLAR JUNCTION TRANSISTORS , , , , , , , , , ,

4,2 NPN BIPOLAR TRANSISTORS

4,2.1 B-E Junction Testing

4.2.2

C-E Connection Testing , , 4-2

4.2.3

C-B Junction Testing ,

4.3

PNP

BIPOLAR TRANSISTORS , , , 4-4

4.4

POWER TRANSISTORS - NPN OR PNP 4-5

4.5 DARLINGTON TRANSISTORS

4.6

JFET TRANSISTORS , , 4-8

4.7 MOSFET TRANSISTORS , , , , , , . , ' , , , . , , 4-9

4.7. I General , , , , 4-9

4.7.2

Depletion Mode MOSFET ,

4.7.3

Enhancement Mode MOSFET 4-11

4.7.4

MOSFET with Protection Diode 4-12

4.8

UNIJUNCTION TRANSISTORS (UJT) 4-15

,'

.,

,.,.., ,

, ,

,.,

".,

',.,.,

'"

,.,

' 4-2

,.4-10

SECTION 5 - RESISTORS, CAPACITORS, AND INDUCTORS

5.1 RESISTORS

5.

1.1

General

5.1.2 Low Range 5-1

5.1.3 Medium Range 5-2

5.1.4

High Range ,

5.2 CAPACITORS 5-3

5.3 INDUCTORS , 5-3

5.4

TOROID INDUCTORS , 5-6

4-1

4-1

4-3

4-5

5-1

5-1

,.

5-2

SECTION 6 - TESTING MULTIPLE COMPONENT CIRCUITS

6.1 TRACKER DIAGNOSTIC PRINCIPLES

6.2

DIODE/RESISTOR CIRCUIT 6-2

6.2.1 Diode in Parallel with Resistor 6-2

6.2.2 Diode in Series with Resistor 6-4

6.3 DIODE AND CAPACITOR PARALLEL COMBINATION 6-5

6.4

RESISTOR AND CAPACITOR PARALLEL COMBINATION 6-7

6.5 INDUCTOR WITH DIODE 6-8

SECTION 7 - TESTING INTEGRATED CIRCUITS

7.1 INTRODUCTION

7.1.1 Integrated Circuit Technology

7.1.2 Integrated Circuit Testing Techniques 7-2

7.2 LINEAR OPERATIONAL AMPLIFIERS 7-2

7.3 LINEAR VOLTAGE REGULATORS _ 7-5

7.3.1 The 7805 Regulator 7-5

7.3.2 The 7905 Regulator 7-7

7.4

555 TIMERS 7-9

7.5 TTL DIGITAL INTEGRATED CIRCUITS 7-12

7.5.1 General 7-12

7.5.2 TTL Devices 7-13

LS

7.5.3

7.5.4

7.6

CMOS INTEGRATED CIRCITS 7-17

7.7 MICROPROCESSORS 7-19

TTL Devices 7-14

Tri-State

TTL

Digital Devices 7-15

6-1

7-1

7-1

SEC1"ION

8.1 SILICON CONTROLLED RECTIFIERS

8.2 TRIAC DEVICES 8-3

8 - TESTING RECTIFIERS

SECTION 9 - TESTING POWER SUPPLIES

9.1 GENERAL

9.2

TESTING PROCEDURE 9-2

SECTION 10 - TESTING COMPONENTS BY COMPARISON

10.1 INTRODUCTION

10.2 SETUP PROCEDURES

10.3 HIGH VOLTAGE TRANSISTOR (TIP-50) _ 10-2

10.3.1 TIP-50 B-E Junction 10-2

10.3.2 TIP-50 C-E Junction 10-3

10.4 HIGH VOLTAGE DIODE HV-15F 10-4

lOOuF

10.5

10.6 1458 DUAL OP-AMP 10-5

10.7 7905 NEGATIVE REGULATOR 10-8

25V ELECTROLYTIC CAPACITOR 10-4

SECTION11- SOLVING BUS PROBLEMS

11.1 INTRODUCTION

11.2 STUCK WIRED-OR BUS

11.3 DEFECTIVE WAVESHAPE ON BUS

11.4 MEMORIES

SECTION 12 - TROUBLESHOOTING TIPS

8-1

9-1

10-1

10-1

11-1

11-1

11-1

11-1

APPENDIX A

APPENDIX B

AI

AS

ii

SECTION 1

GENERAL

INFORMATION

1.1

ABOUT

This manualisprovided for the operatorofthe Huntron

Tracker. The information contained within this manual

familiarizes the reader first with the tracker and its principles

of

operation. and then with its specific uses. A working

knowledge

assists the user

when using the instrument for troubleshooting purposes.

The manual

information pertinent to a certain application

sections contain the following information.

Section I

This section provides a description

lists its specifications.

on which the tracker operates. using a pure resistance

and a diode as examples.

Section 2

This section describes the front panel controls

tracker.

testing feature.

THIS

of

the tracker's operating principles greatly

in

is

divided into sections. Each section contains

- GENERAL INFORMATION

- TRACKER OPERATION

It

MANUAL

evaluating the tracker's display. especially

of

of

the tracker and

It

also describes the principles

also describes the tracker's comparative

the unit. The

of

the

across) circuits containing the following devices: NPN

PNP

and

transistors,

transistors.

Section 5 - PASSIVE COMPONENTS

This section describes and illustrates tracker displays

produced when the test leads are connected to capacitive, inductive, and resitive circuits

Section 6

This section covers the testing

nations. diode/capacitor combinations. and capacitor/resistor combinations.

Section 7

This section discusses integrated circuit technology

followed

as operational amplifiers and voltage regulators. Testing information

as

well

Section 8 - TESTING RECTIFIERS

transistors, Darlington pairs, germanium

MOSFET's,

- TESTING MULTIPLE COMPONENT CIRCUITS

- TESTING INTEGRATED CIRCUITS

by

testing information for linear devices such

is

also provided for the LM555 Timer

as TTL. LS TTL, and CMOS devices.

J-FET's,

and unijunction

or

devices.

of

diode/resistor combi-

Section 3 - DIODE TESTING

This section describes the characteristics

(showing

essential to understanding the tracker display. This

section also illustrates and describes tracker displays

produced when the test leads are connected to (or

across) circuits containing the following devices: silicon diodes. high voltage silicon diodes, zener diodes,

bridging diodes. and light-emitting diodes.

Section 4

This section illustrates and describes tracker displays

produced when the test leads are connected to (or

its

voltage-to-current relationship). which

-

TRANSISffiR

TESTING

of

the diode

This section describes the testing

rectifiers and TRIAC devices.

Section 9 - TESTING POWER SUPPLIES

is

This describes how to use the tracker

transformer/full-wave bridge type'power supply.

Section

10

-TESTINGCOMPONENTSBYCOMPARISON

This section provides tracker displays for defective

components as compared to known good devices. The

tracker

voltage transistor. a high voltage diode, an electrolytic

capacitor, an op-amp, and a regulator.

is

used in the alternate mode to check a high

of

silicon-controlled

to

test the typical

1-1

SECfION11- SOLVING BUS PROBLEMS

This section contains information that may be helpful

when attempting to isolate faults caused

devices connected to a common bus.

SECfION12- TROUBLESHOOTING TIPS

by

defective

Table I-I. Specifications

of

This section contains a series

troubleshooting suggestions and information that should assist the user

when using the tracker.

TEST SIGNAL

DATA

Waveform Type sinusoidal

Frequency 80Hz

Voltage/Current Characteristics

Open Circuit Voltage (peak-to-peak)

- Low Range

20

Short Circuit Current (mA rms) 64

Power (mW rms)

Power (mW peak)

Short Circuit Current (mA peak)

81

161

170

Voltage/Current Characteristics - Medium Range

Open Circuit Voltage (peak-to-peak)

40

Short Circuit Current (mA rms) 0.27

Power (mW rms) 0.23

Power (mW peak) 0.45

Short Circuit Current (mA peak)

0.7

Voltage/Current Characteristics - High Range

Open Circuit Voltage (peak-to-peak)

120

Short Circuit Current (mA rms) 0.29

Power (mW rms) 0.26

Power (mW peak) 0.52

Short Circuit Current (mA peak) 0.8

of

NOTE: All power ratings are conditions existing across a single silicon diode in the test terminals

the tracker.

CRT SCREEN SIZE 7cm diagonal

CRT ACCELERATION POTENTIAL

1350Y

regulated

INPUT PROTECTION

Protection provided against damage caused

by

touching probestoline voltages.

TRACE ALTERNATE MODE

Alternates display between channel A and B inputs at o.8Hz rate

POWER REQUIREMENTS

HTR l005B-IS

HTR

l005B-1

ES 220/240V, SO/60Hz

HTR l005B-IJS

IOOY,

50/60Hz

117V,60Hz

WEIGHT 5 pounds, 5 ounces

DIMENSIONS (inches)

3

8-

/4

W X

(21.9 em x 7.4

3-1/2

H X

emx24.2cm)

AMBIENT TEMPERATURE

Operating . zero to + 50 degrees Celsius

Storage -50 to

+60

degrees Celsius

SHOCK AND VIBRATION

Will withstand shock and vibration encountered

in

commerical shipping and handling

1·2

(2.4 kg)

11-1/2

D

1.2 TRACKER DESCRIPTION

The tracker is a general purpose troubleshooting test instrument. It qualitatively evaluates digital, analog, and hybrid

semiconductor devices, as well as capacitive and inductive

devices, in or out ofcircuit,

operates

circuit under test and displaying the resultant current and

voltage levels and their phase relationship. The tracker display indicates any component leakage, shorts, opens, noise,

plus any combination of these problems. Table

specifications ofthe tracker.

by

providing an ac stimulus to the component or

in

a power off state. The tracker

I-I

lists the

causes current to flow through the device and a voltage drop

to appear across

causes vertical deflection

voltage drop across the device causes horizontal deflection

the tracker display.

The test signal is selected for appl ication to a device

under test

high. The open-circuit voltage values for each range are

listed

each range for complete protection

under test.

in

in

Table

it.

The current flow through the device

of

the tracker display while the

oneofthree available ranges;

1-1.

Note that current-limitingisprovided on

low,

of

the deviceorcircuit

or

circuit

medium, and

of

Included with each tracker is a set

test leads. These test leads plug into the front panel test jacks

of

the tracker and have special tips that allow contact with

very small component terminals and printed circuit board

traces without the danger

leads and terminals.

Also included with the tracker is a special common test lead

that allows the connection oftracker common to two components. This test lead

tion.

of

is

usedinthe alternate modeofopera-

of

Huntron Micro Probe

touching adjacent component

1.3 PRINCIPLES OF TRACKER OPERATION

1.3.1 Tracker Test Signal

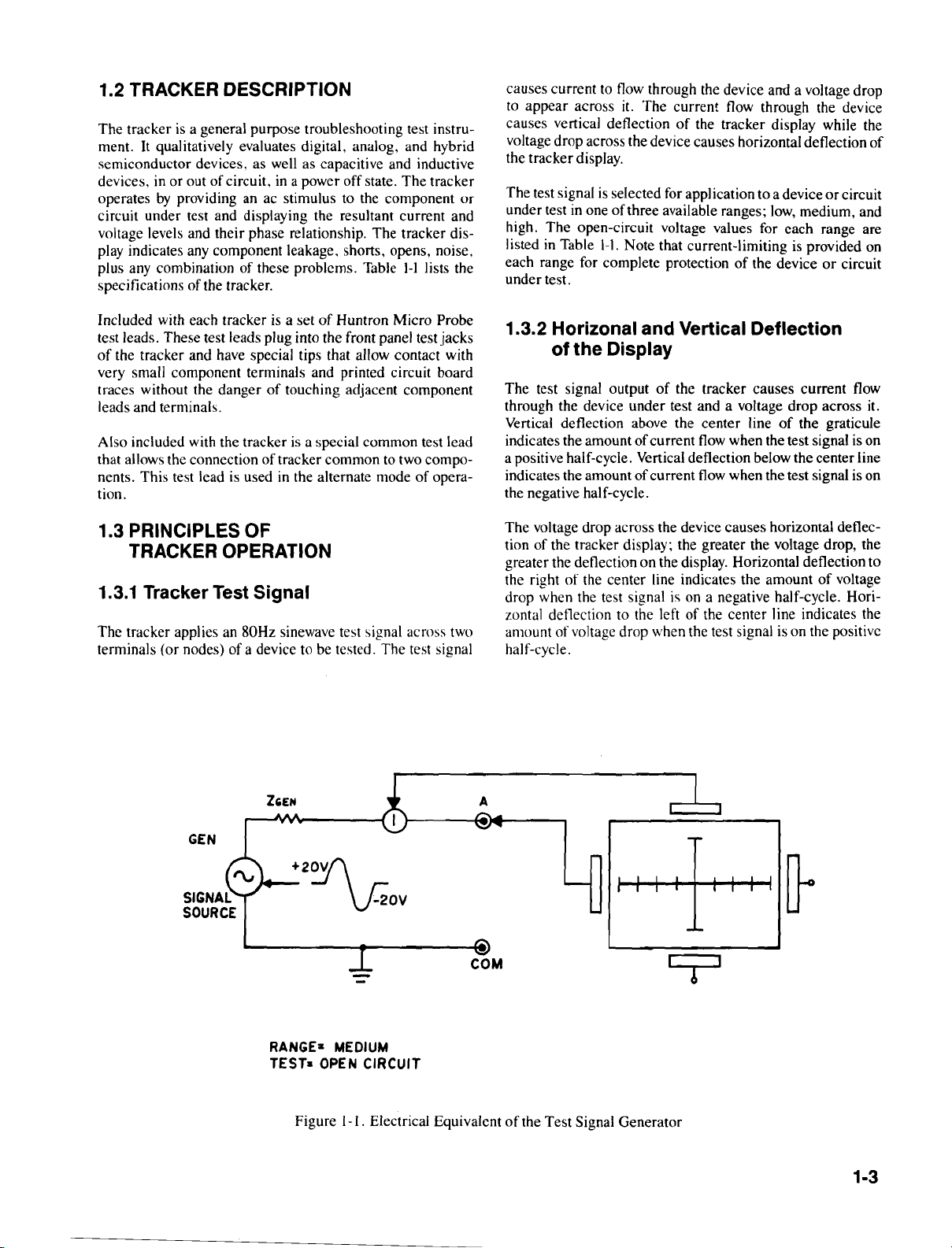

The tracker applies an 80Hz sinewave test signal across two

terminals (or nodes) of a device to be tested. The test signal

1.3.2 Horizonal and Vertical Deflection

of

the

Display

The test signal outputofthe tracker causes current flow

through the device under test and a voltage drop across it.

Vertical deflection above the center line

indicates the amount

a positive half-cycle. Vertical deflection below the center line

indicates the amount

the negative half-cycle.

The voltage drop across the device causes horizontal deflec-

of

the tracker display; the greater the voltage drop, the

tion

greater the deflection on the display. Horizontal deflection to

the right

drop when the test signal is on a negative half-cycle. Horizontal deflection

amount of voltage drop when the test signal is on the positive

half-cycle.

of

the center line indicates the amountofvoltage

of

current flow when the test signal is on

of

current flow when the test signal is on

to

the left of the center line indicates the

of

the graticule

GEN

ZiEN

+25"\_

RANGE-

TEST-

OPEN

Figure

V~20V

COM

MEDIUM

CIRCUIT

I-I.

Electrical Equivalentofthe Test Signal Generator

1-3

Figure

generator within the tracker and

voltage drop across the test terminals provide vertical and

horizontal deflectionofthe display. The 80Hz test signal is

providedbythe signal generator and

(Zgen). All current that passes through the test terminals to

the device under test, also passes through a current sensing

point (I). The vertical deflection plates receive deflection

voltage from this current sensing point. The amount

deflection voltage provided to the vertical deflection plates is

proportional to the amountofcurrent flowing through the

device under test.

The voltage appearing across the test terminals (and the

device undertest)isalso applied across the horizontal deflection plates. The amountofvoltage provided to the horizontal

deflection plates is proportional to the voltage drop across the

device under test.

I-I

shows the electrical equivalentofthe test signal

how

the current through and

its

series impedance

1.3.3 Short and Open Circuit Displays

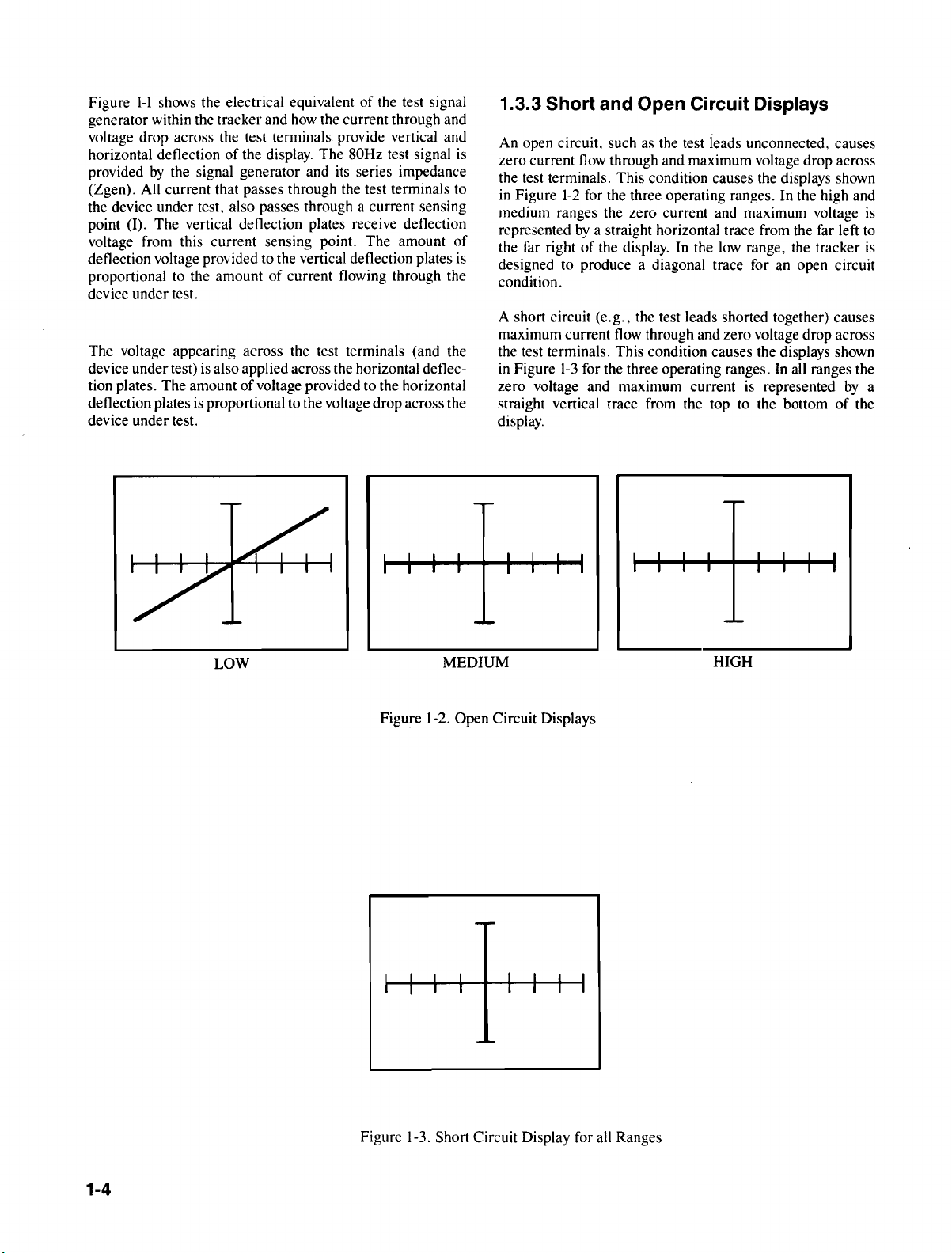

An open circuit, such as the test ieads unconnected, causes

zero current flow through and maximum voltage drop across

the test terminals. This condition causes the displays shown

in

Figure

1-2

for the three operating ranges.Inthe high and

medium ranges the zero current and maximum voltage

representedbya straight horizontal trace from the far left

of

the far right of the display.Inthe low range, the tracker

designed to produce a diagonal trace for an open circuit

condition.

A short circuit (e.g., the test leads shorted together) causes

maximum current

the test terminals. This condition causes the displays shown

in

Figure

1-3

zero voltage and maximum currentisrepresented

straight vertical trace from the top to the bottomofthe

display.

flow

through and zero voltage drop across

for the three operating ranges.Inall ranges the

by

is

to

is

a

LOW

Figure 1-2.

MEDIUM

Open

Circuit Displays

HIGH

1-4

Figure 1-3. Short Circuit Display for all Ranges

GEN

320

PEAK

JAQ

A

+---

+2~

'

20-

"V

SIGNAC

SOURCE

COM

RANGE:MEDIUM

TEST: 33K

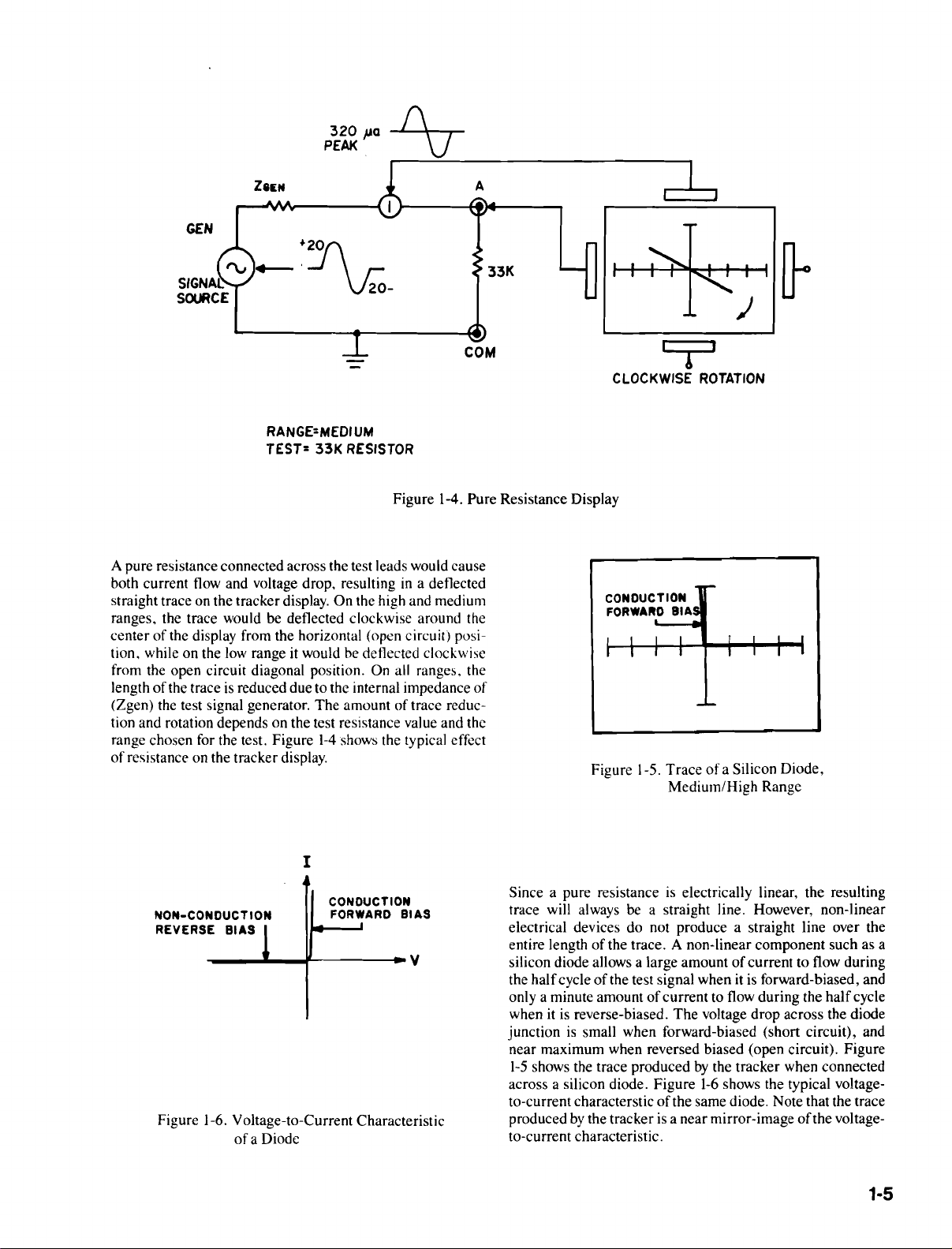

A pure resistance connected across the test leads would cause

both current flow and voltage drop, resulting

straight trace on the tracker display. On the high and medium

ranges, the trace would be deflected clockwise around the

center

of

the display from the horizontal (open circuit) position, while on the low range it would be deflected clockwise

from the open circuit diagonal position. On

of

length

(Zgen) the test signal generator. The amount of trace reduction and rotation depends on the test resistance value and the

range chosen for the test. Figure

of

the traceisreduced due tothe internal impedance

resistance on the tracker display.

RESISTOR

Figure 1-4. Pure Resistance Display

in

a deflected

all

ranges, the

1-4

shows the typical effect

of

33K

CLOCKWISE

T

Figure 1-5. Trace

Medium/High Range

)

ROTATION

of

a Silicon Diode,

I

CONDUCTION

NON-CONDUCTION

REVERSE

Figure 1-6. Voltage-to-Current Characteristic

--

BIAS

ofa

....

-(------..v

Diode

FORWARD

BIAS

Since a pure resistanceiselectrically linear, the resulting

be

trace will always

electrical devices do not produce a straight line over the

entire length

silicon diode allows a large amount

the halfcycle

only a minute amount

when

junction

near maximum when reversed biased (open circuit). Figure

1-5

shows the trace producedbythe tracker when connected

across a silicon diode. Figure

to-current characterstic

produced

to-current characteristic.

of

of

itisreverse-biased. The voltage drop across the diode

is

small when forward-biased (short circuit), and

by

the trackerisa near mirror-imageofthe voltage-

a straight line. However, non-linear

the trace. A non-linear component such as a

of

current to flow during

the test signal when itisforward-biased, and

of

current to flow during the halfcycle

1-6

shows the typical voltage-

of

the same diode, Note that the trace

1·5

NOTES:

1-6

2.1

GENERAL

2.2

CONTROLS

SECTION 2

TRACKER

OPERATION

AND

INDICATORS

Components are testedbythe tracker using a two terminal

system, where two test leads are placed across the component

is

under test. All testing

tions for the component/equipment under test. The tracker

tests components while in-circuit, even when bridged

other components. Included with each trackerisa set of

Huntron Micro Probe test leads. Also included with the

is

tracker

tion

usedinthe alternate modeofoperation.

a special common test lead that allows the connec-

of

tracker common to two components. This test lead

performed under power-off condi-

by

1

2

3

+

Operationofthe tracker, for the mostpart, amounts to deter-

of

mining the significance

display. While the tracker

panel contoIs to assist

of

these controlsisnecessary to during actual useofthe

use

2-1

tracker. Table

and Figure

sis on tracker operation is on the determination

displays. For this reason, the majority

is

in

tained

4

this documentisrelative to tracker displays.

5

lists and describes the front panel controls,

2-1

shows the control,although the main empha-

6

the trace(s) appearing on the

is

equipped with several front

in

optimizing displays, only limited

of

information con-

7

8

9

10

of

tracker

15 14

Figure 2-1. LocationofFront Panel Controls

13

12

11

2·1

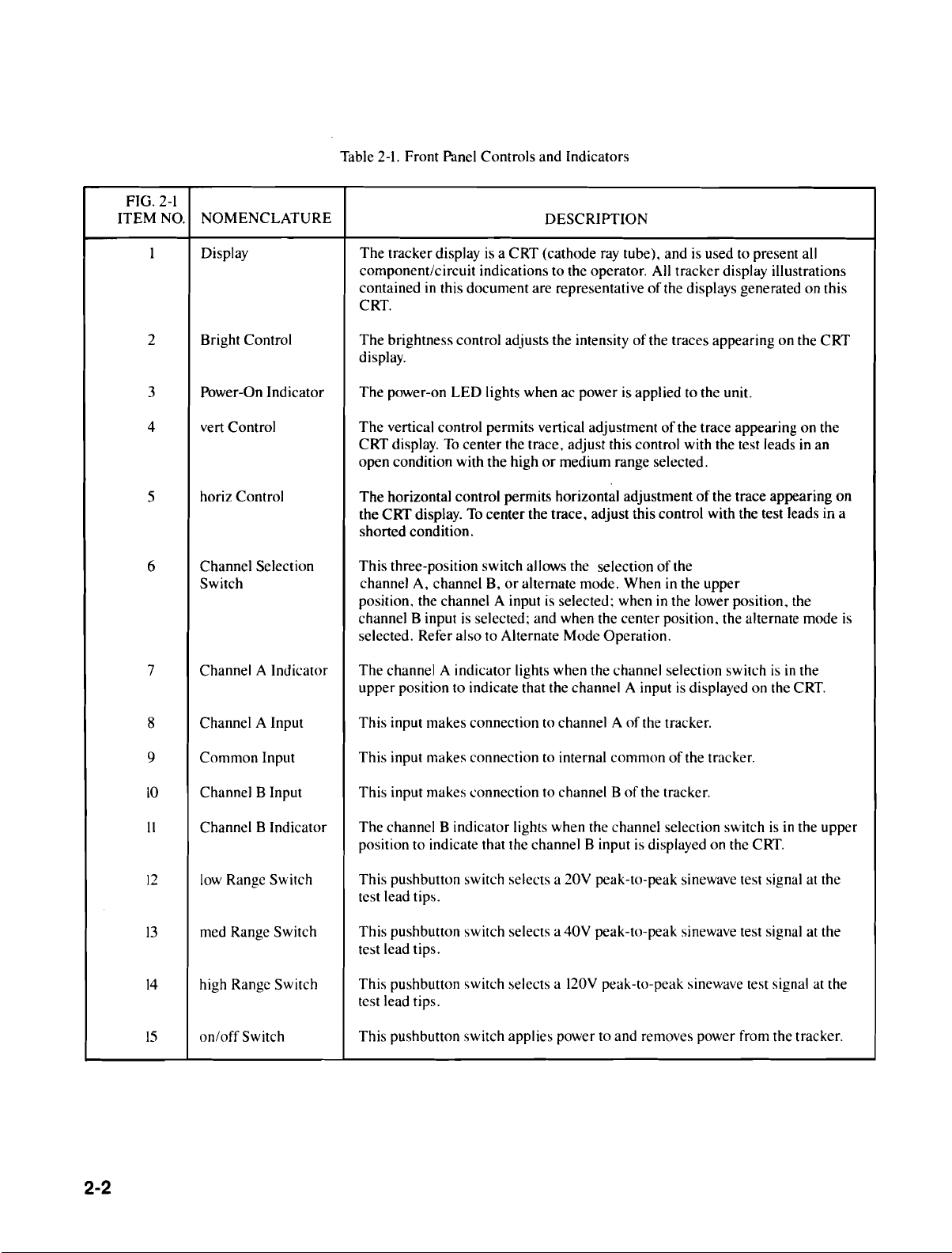

Table

2-1.

Front Panel Controls and Indicators

FIG.

2-1

ITEM

NO.

NOMENCLATURE

DESCRIPTION

1 Display The tracker display is a CRT (cathode ray tube), and is used to present all

component/circuit indications to the operator. All tracker display illustrations

of

contained in this document are representative

CRT.

the displays generated on this

2

3 Power-On Indicator The power-on

4 vert Control

5

6

7

8

9

10

Bright Control

horiz Control

Channel Selection This three-position switch allows the selectionofthe

Switch

Channel A Indicator

Channel A Input

Common

Channel B Input

Input

The

brightness control adjusts the intensityofthe traces appearing on the CRT

display.

The

vertical control permits vertical adjustmentofthe trace appearing on the

CRT display.

open condition with the high

The

horizontal control permits horizontal adjustmentofthe trace appearing on

the CRT display.

shorted condition.

channel A, channel B,

position, the channel A input

channel B input

selected. Refer also to Alternate Mode Operation.

The

channel A indicator lights when the channel selection switchisin

upper position to indicate that the channel A input

This input makes connection to channel A

This input makes connection to internal common

This input makes connection to channel B

LED

lights when ac power is applied to the unit.

To

center the trace, adjust this control with the test leads in an

or

medium range selected.

To

center the trace, adjust this control with the test leads in a

or

alternate mode. When in the upper

is

selected; when in the lower position, the

is

selected; and when the center position, the alternate mode

is

displayed on the CRT.

of

the tracker.

of

the tracker.

of

the tracker.

is

the

2-2

11

12

13

14

15

Channel B Indicator

low Range Switch

med Range Switch

high Range Switch

on/off

Switch

is

The channel B indicator lights when the channel selection switch

position to indicate that the channel B input

This pushbutton switch selects a 20Y peak-to-peak sinewave test signal at the

test lead tips.

This pushbutton switch selects a 40Y peak-to-peak sinewave test signal at the

test lead tips.

This pushbutton switch selects a 120Y peak-to-peak sinewave test signal at the

test lead tips.

This pushbutton switch applies power to and removes power from the tracker.

is

displayed on the CRT.

in the upper

2.3

ALTERNATE MODE OPERATION

2.4

FUSE REPLACEMENT

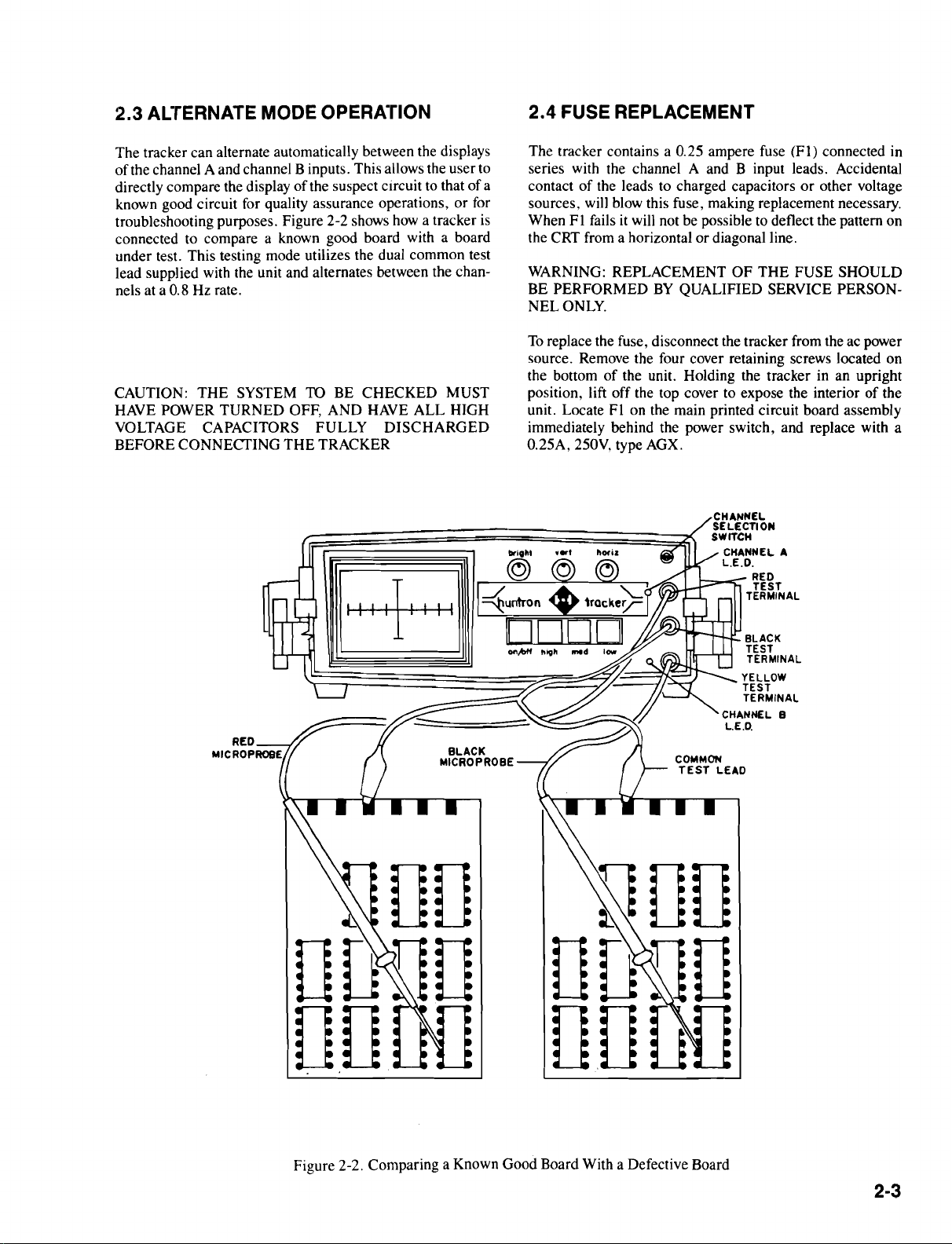

The tracker can alternate automatically between the displays

of

the channel A and channel B inputs. This allows the user to

of

directly compare the display

known good circuit for quality assurance operations,

troubleshooting purposes. Figure 2-2 shows how a tracker

connected to compare a known good board with a board

under test. This testing mode utilizes the dual common test

lead supplied with the unit and alternates between the channels at a 0.8 Hz rate.

THE

CAUTION:

HAVE POWER

VOLTAGE CAPACITORS

BEFORE CONNECTING

SYSTEM m BE

TURNED

the suspect circuit to thatofa

CHECKED

OFF,

AND

HAVE

ALL

THE

FULLY

TRACKER

DISCHARGED

or

for

MUST

HIGH

The tracker contains a 0.25 ampere fuse

series with the channel A and B input leads. Accidental

contact

sources, will blow this fuse, making replacement necessary.

is

When FI fails

the CRT from a horizontal

WARNING: REPLACEMENT

BE PERFORMED

NELONLY.

To

replace the fuse, disconnect the tracker from the ac power

source. Remove the four cover retaining screws located on

the bottom

position, lift off the top cover to expose the interior

unit. Locate

immediately behind the power switch, and replace with a

0.25A, 250V, type AGX.

(Fl)

connected in

of

the leads to charged capacitorsorother voltage

it

will not be possible to deflect the pattern on

or

diagonal line.

OF

THE

FUSE SHOULD

BY

QUALIFIED SERVICE PERSON-

of

the unit. Holding the tracker in an upright

Fl

on the main printed circuit board assembly

CHANNEL

SELECTION

SWITCH

CHANNEL A

L.E.D.

RED

TEST

TERMINAL

of

the

+

BLACK

MICROPROBE

BLACK

TEST

TERMINAL

YELLOW

TEST

TERMINAL

CHANNEL B

L.E.D.

Figure 2-2. Comparing a Known Good Board With a Defective Board

2·3

NOTES:

2-4

SECTION 3

TESTING DIODES

3.1

THE

SEMICONDUCTOR DIODE

AND ITS CHARACTERISTICS

3.1.1

Diode Symbol and Definition

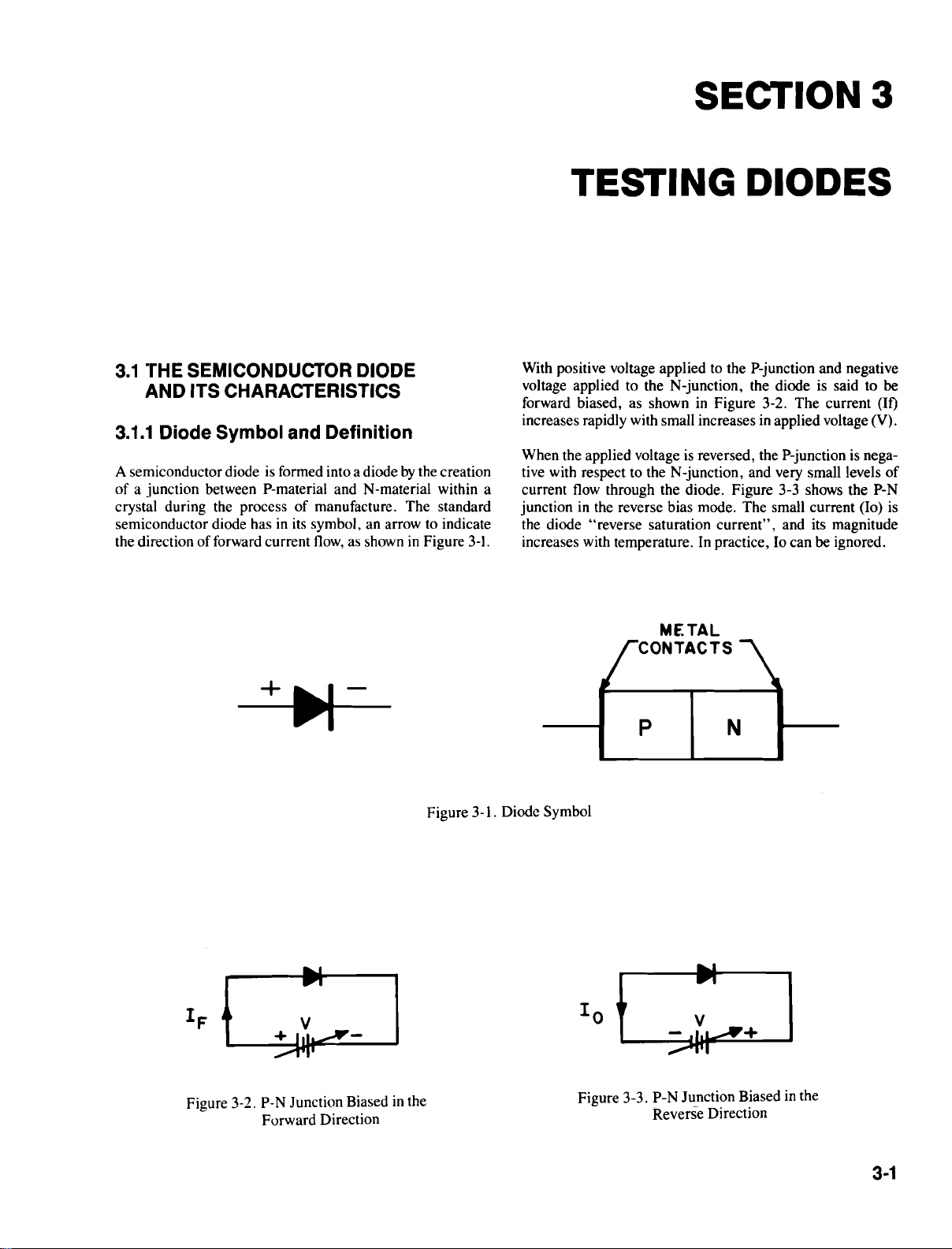

A semiconductor diode is formed into a diodebythe creation

of

a junction between P-material and N-material within a

of

crystal during the process

semiconductor diode has in its symbol, an arrow to indicate

of

the direction

forward current

manufacture. The standard

flow,

as showninFigure

3-1.

+~-

Figure 3-1. Diode Symbol

With positive voltage applied to the P-junction and negative

voltage applied to the N-junction, the diodeissaid to be

forward biased, as shown in Figure 3-2. The current (It)

increases rapidly with small increases in applied voltage (V).

When the applied voltage is reversed, the P-junction is negative with respect to the N-junction, and very small levels

current flow through the diode. Figure 3-3 shows the P-N

junction in the reverse bias mode. The small current

the diode "reverse saturation

increases with temperature.

current",

In

practice,10can be ignored.

and its magnitude

(10) is

METAL

CONTACTS

p

N

of

Figure 3-2. P-N Junction Biased in the

Forward Direction

+

Figure 3-3. P-N Junction Biased

Reverse Direction

in

the

3·1

3.1.2

The

Volt-Ampere Characteristic

3.2 SILICON RECTIFIER DIODES

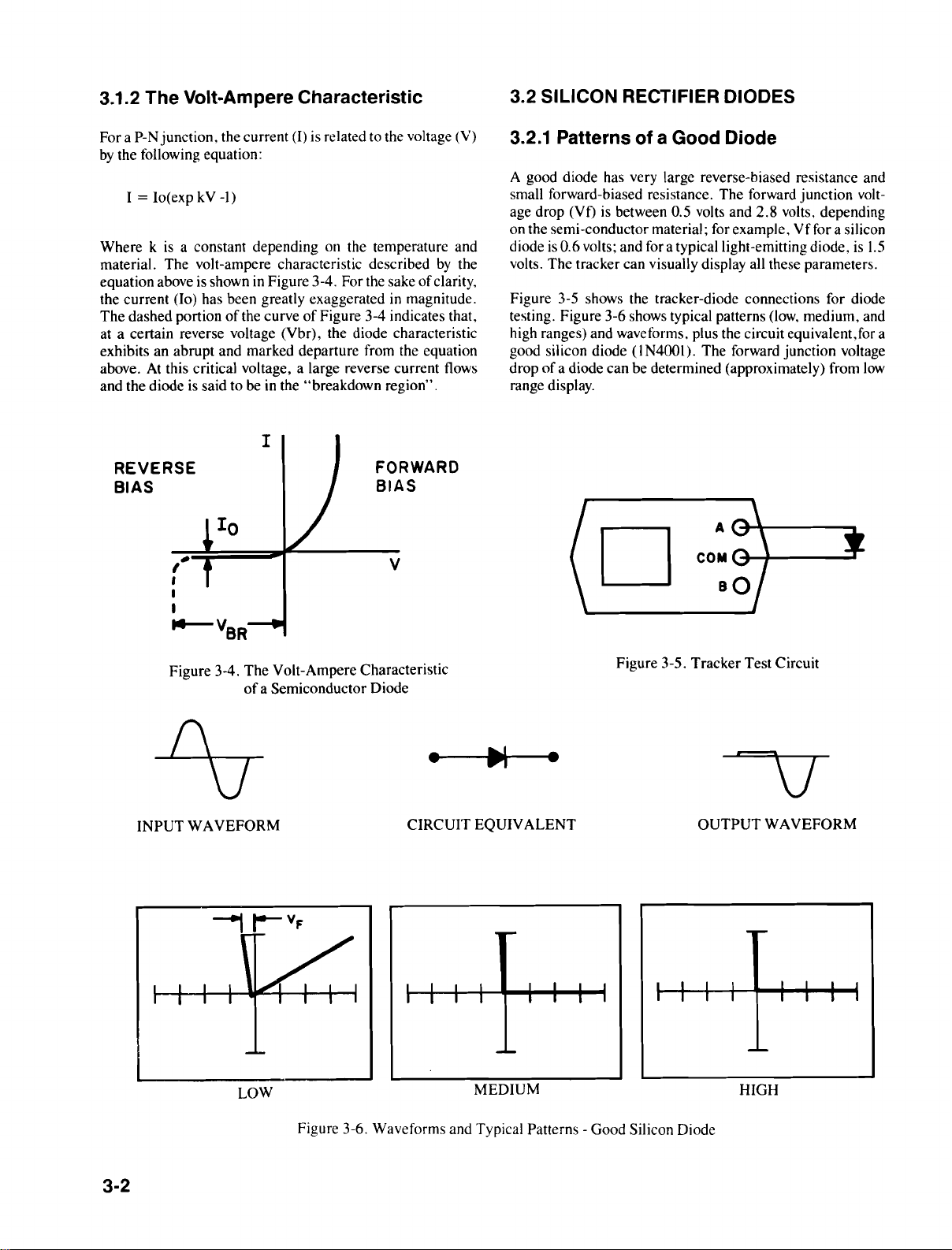

Fora P-N junction, the current (I)isrelated to the voltage (V)

by

the following equation:

= lo(exp

I

Where kisa constant depending on the temperature and

material. The volt-ampere characteristic described

equation above

the current

The dashed portion

at a certain reverse voltage (Vbr), the diode characteristic

exhibits an abrupt and marked departure from the equation

At

above.

and the diode

REVERSE

BIAS

kV

-1)

by

the

is

showninFigure 3-4. For the sake of clarity,

(10) has been greatly exaggerated

of

the curveofFigure 3-4 indicates that,

this critical voltage, a large reverse current flows

is

said tobein

the "breakdown region" .

I

in

magnitude.

FORWARD

BIAS

V

Patternsofa Good Diode

3.2.1

A good diode has very large reverse-biased resistance and

small forward-biased resistance. The forward junction volt-

is

age drop (Vf)

on the semi-conductor material; for example, Vf for a silicon

is

diode

volts. The tracker can visually display all these parameters.

Figure 3-5 shows the tracker-diode connections for diode

testing. Figure 3-6 shows typical patterns

high ranges) and waveforms. plus the circuit equivalent,for a

good silicon diode

drop

range display.

0.6 volts; and for a typical light-emitting diode,is1.5

of

a diode can be determined (approximately) from

between 0.5 volts and 2.8 volts, depending

(low,

medium, and

(I

N4OOl).

The forward junction voltage

A

(-J*-----.

COM

low

D

Figure 3-4. The Volt-Ampere Characteristic

of

a Semiconductor Diode

INPUT WAVEFORM

LOW

..

--~..-

CIRCUIT EQUIVALENT

MEDIUM

.....

Figure 3-5. Tracker Test Circuit

r=v

OUTPUT WAVEFORM

HIGH

3-2

Figure 3-6. Waveforms and Typical Patterns - Good Silicon Diode

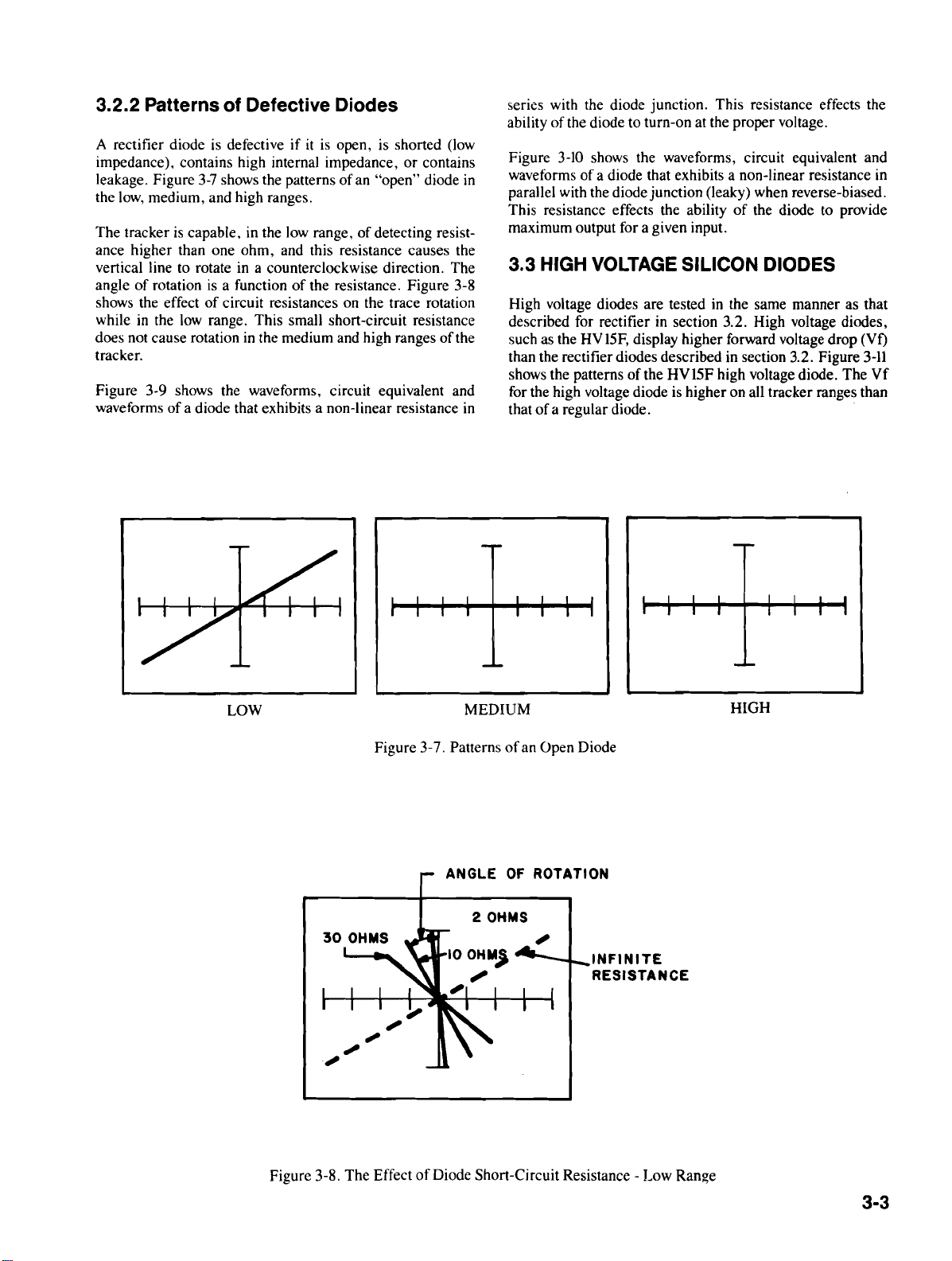

3.2.2 Patterns of Defective Diodes

A rectifier diodeisdefectiveifitisopen,isshorted (low

impedance), contains high internal impedance, or contains

3-7

leakage. Figure

the

low,

medium, and high ranges.

The tracker

ance higher than one ohm, and this resistance causes the

vertical line to rotate in a counterclockwise direction. The

angle

of

rotationisa functionofthe resistance. Figure 3-8

shows the effect

in

while

does not cause rotation in the medium and high ranges

tracker.

Figure

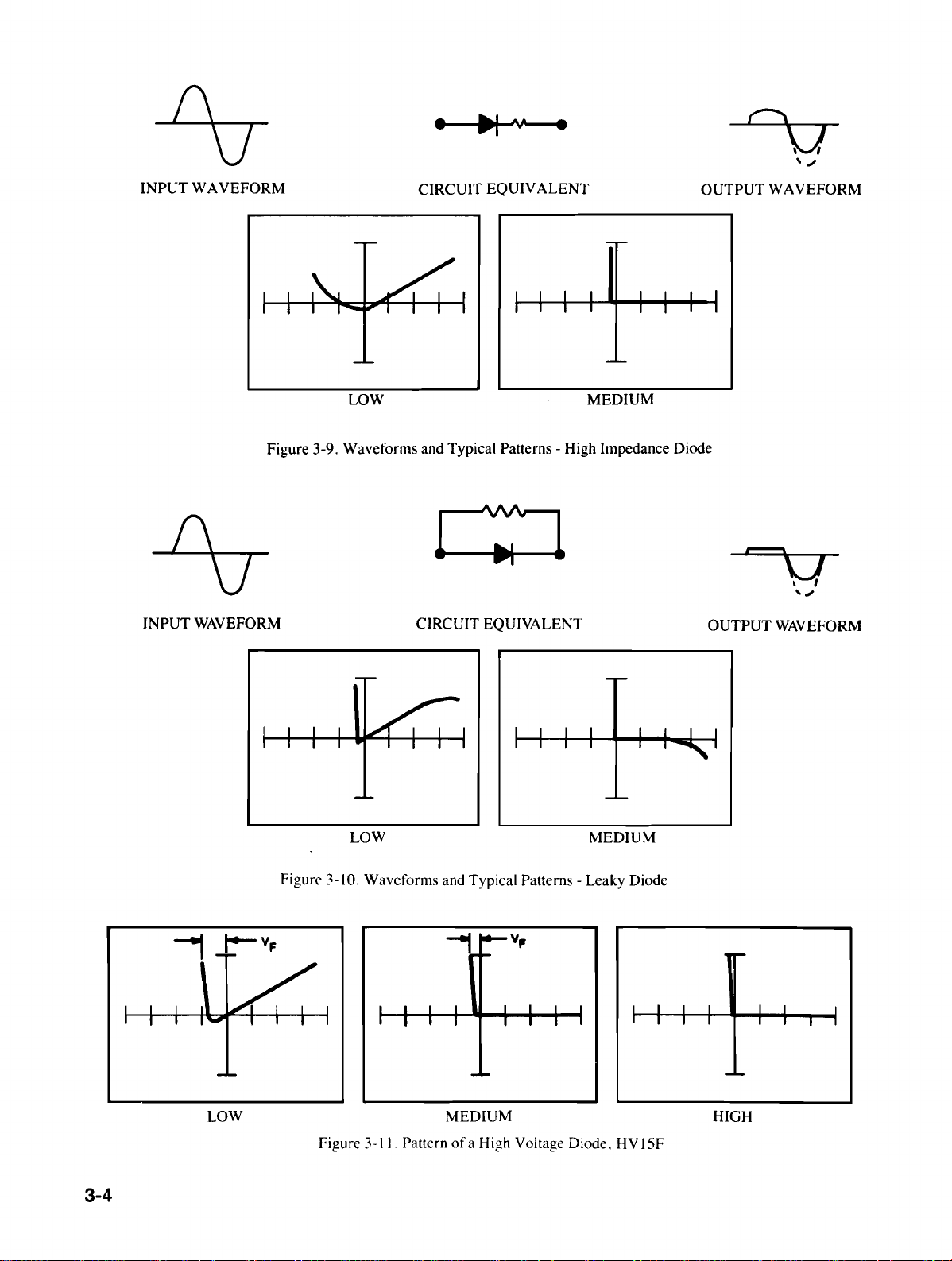

waveforms

the low range. This small short-circuit resistance

3-9 shows the waveforms, circuit equivalent and

of

shows the patterns ofan "open" diode

is

capable, in the low range, ofdetecting resist-

of

circuit resistances on the trace rotation

of

a diode that exhibits a non-linear resistance in

the

series with the diode junction. This resistance effects the

ability ofthe diode to turn-on at the proper voltage.

3-10

Figure

waveforms ofa diode that exhibits a non-linear resistance

in

parallel with the diodejunction (leaky) when reverse-biased.

This resistance effects the ability

maximum output for a given input.

3.3

HIGH

High voltage diodes are tested in the same manner as that

described for rectifier in section 3.2. High voltage diodes,

such as the HV l5F, display higher forward voltage drop (Vf)

than the rectifier diodes described in section

shows the patterns of the HV15F high voltage diode. The

for the high voltage diode is higher on all tracker ranges than

that

of

shows the waveforms, circuit equivalent and

of

the diodetoprovide

VOLTAGE

a regular diode.

SILICON DIODES

3.2. Figure

in

3-11

Vf

LOW

Figure

MEDIUM

3-7. Patterns

ANGLE

of

an Open Diode

OF

ROTATION

HIGH

INFINITE

RESISTANCE

Figure 3-8. The EffectofDiode Short-Circuit Resistance - Low Range

3-3

INPUT WAVEFORM

Figure 3-9. Waveforms and Typical Patterns - High Impedance Diode

CIRCUIT EQUIVALENT

LOW MEDIUM

OUTPUT WAVEFORM

,..........

\.T

'-'

INPUT WAVEFORM

CIRCUIT EQUIVALENT

LOW

3-10. Waveforms and Typical Patterns - Leaky Diode

Figure

I I I I

I I I I

I I I I

I I I I

-'-

MEDIUM

OUTPUT

WAVEFORM

3-4

LOW

Figure 3-11. Pattern

MEDIUM

ofa

High Voltage Diode. HV15F

HIGH

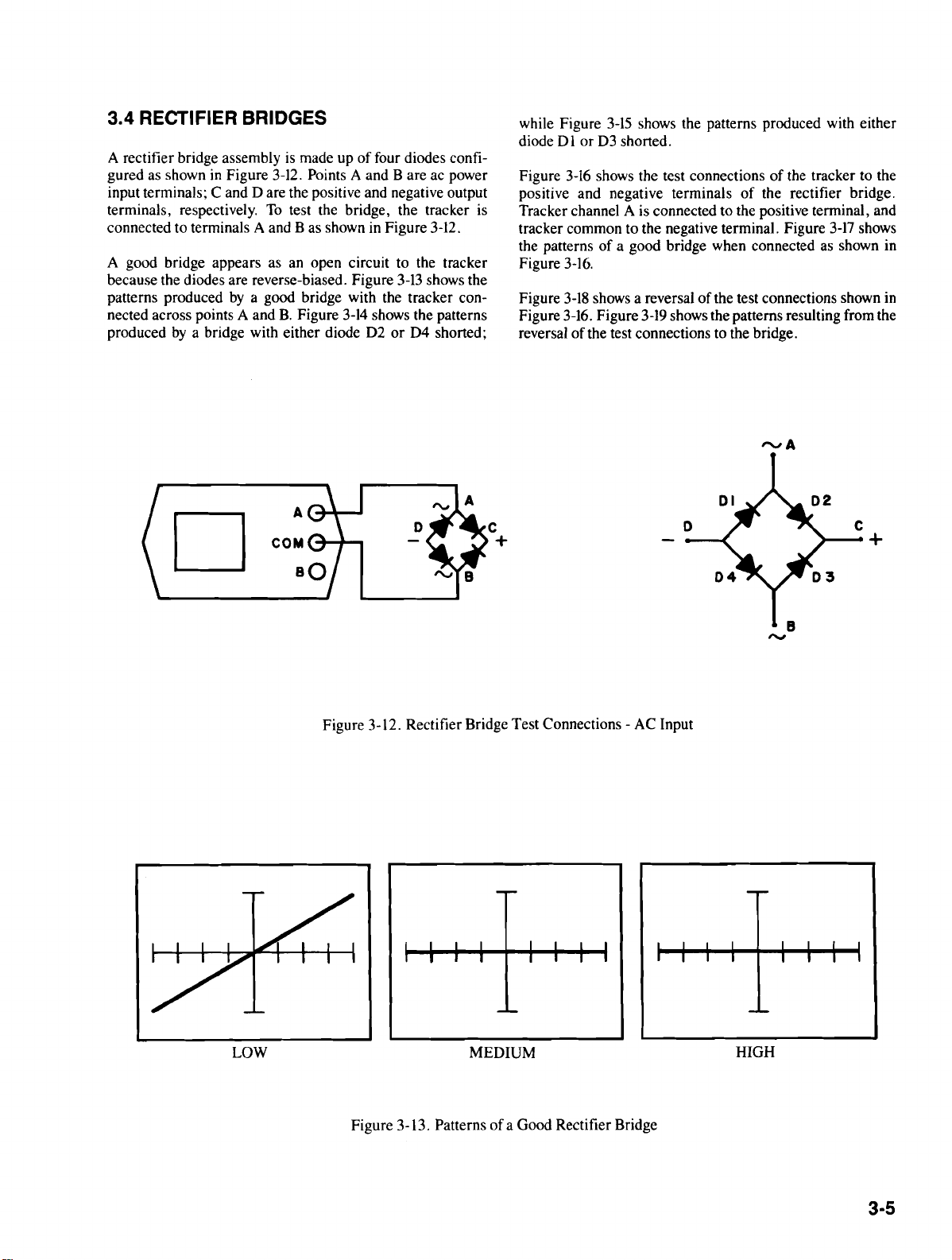

3.4 RECTIFIER BRIDGES

A rectifier bridge assembly is made upoffour diodes confi-

in

Figure

3-12.

gured as shown

input terminals; C and D are the positive and negative output

terminals, respectively.

connected to terminals A and B as shown in Figure 3-12.

A good bridge appears as an open circuit to the tracker

because the diodes are reverse-biased. Figure

patterns produced

nected across points A and

produced

by

by

a good bridge with the tracker con-

a bridge with either diode D2orD4 shorted;

Points A and

To

test the bridge, the tracker is

B.

Figure

3-14

Bare

ac power

3-13

shows the

shows the patterns

while Figure

diode

DIorD3 shorted.

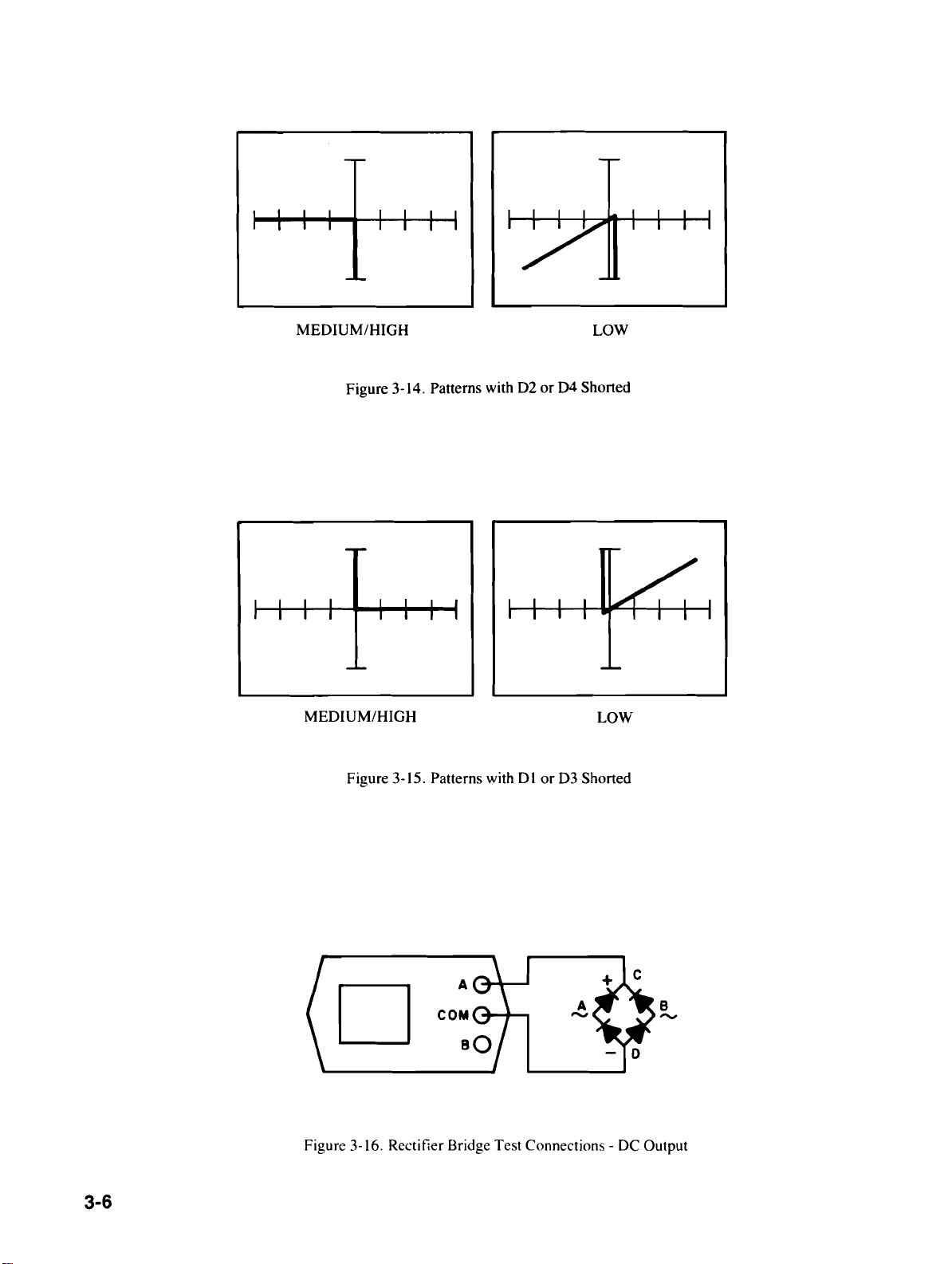

Figure

positive and negative terminals

Tracker channel A is connected to the positive terminal, and

tracker common to the negative terminal. Figure

the patterns

Figure

Figure

Figure

reversal

3-15

shows the patterns produced with either

3-16

shows the test connectionsofthe tracker to the

of

the rectifier bridge.

of

a good bridge when connected as shown in

3-16.

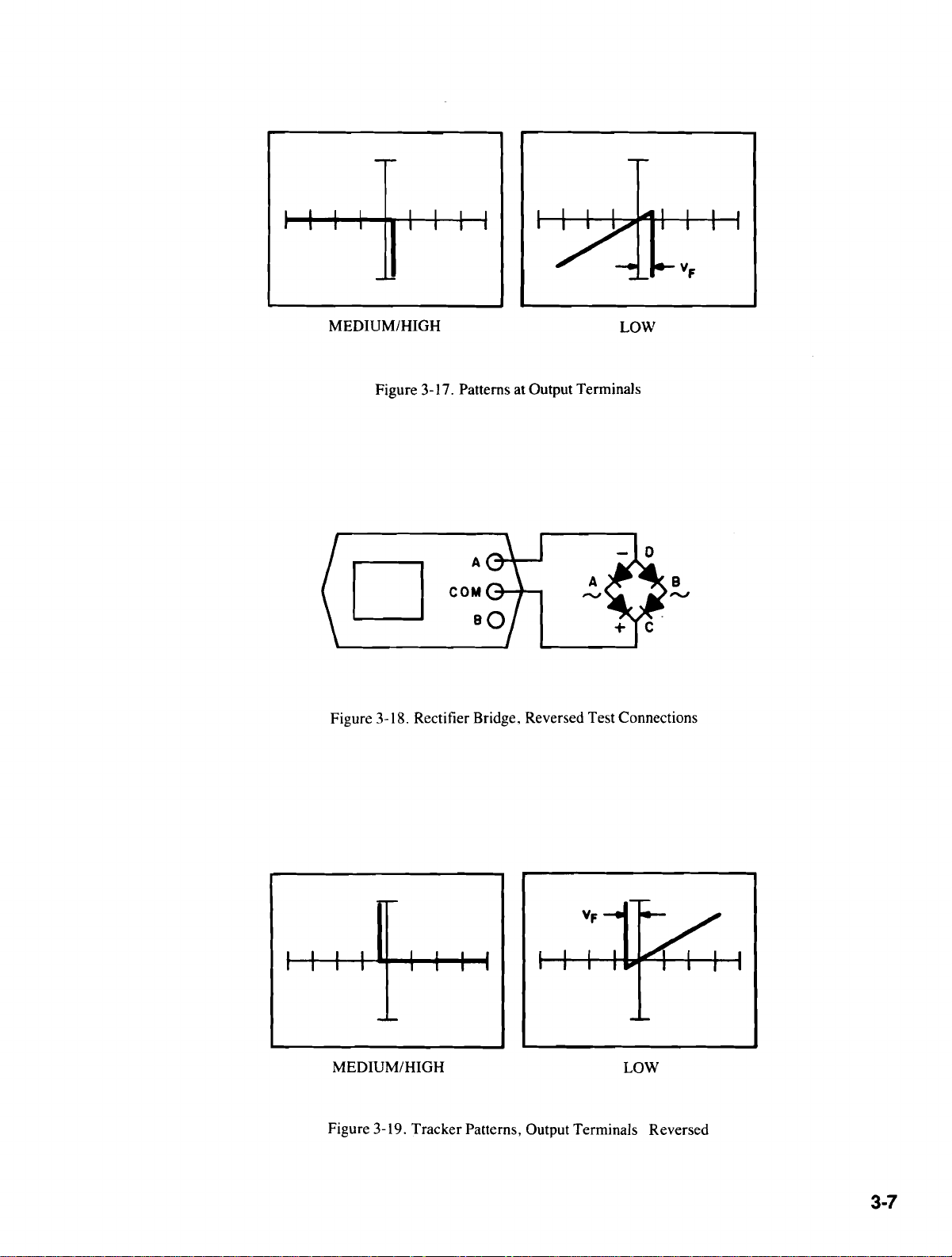

3-18

shows a reversalofthe test connections shown in

3-16.

Figure

3-19

shows the patterns resulting from the

of

the test connections to the bridge.

"'VA

3-17

shows

D

A

D

COM

Figure 3-12. Rectifier Bridge Test Connections - AC Input

LOW

MEDIUM

Figure 3-13. Patternsofa Good Rectifier Bridge

3·5

MEDIUM/HIGH

LOW

Figure 3-14. Patterns with D2orD4

MEDIUM/HIGH

Figure 3-15. Patterns with D 1orD3 Shorted

Shorted

LOW

3-6

A

COM

D

Figure 3-16. Rectifier Bridge Test Connections - DC Output

MEDIUM/HIGH

Figure 3-17. Patterns at Output Terminals

A

R--\--'

COM

LOW

D

Figure 3- I8.Rectifier Bridge, Reversed Test Connections

MEDIUM/HIGH

Figure 3-19. Tracker Patterns, Output Terminals Reversed

LOW

3-7

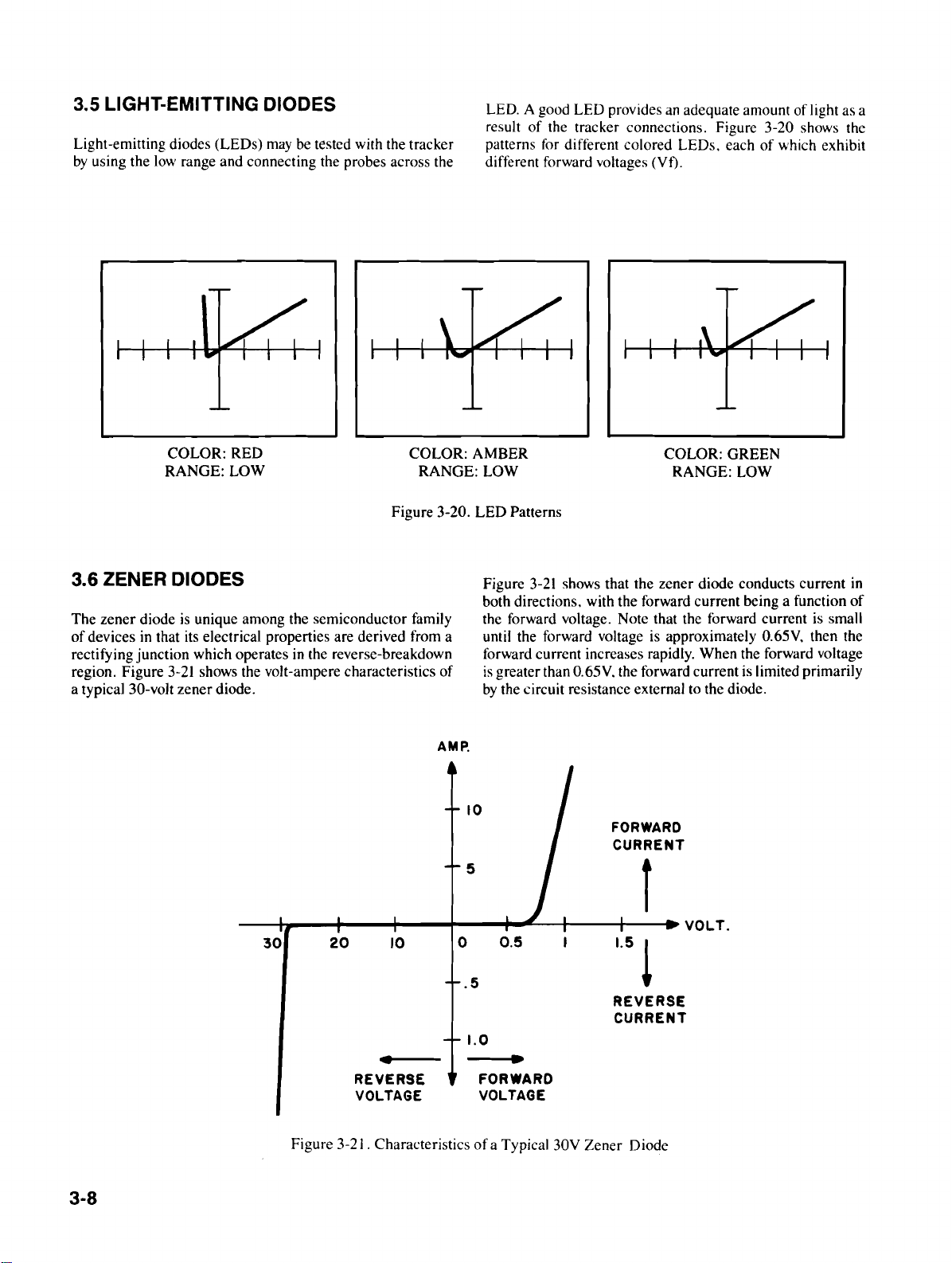

3.5 LIGHT-EMITTING DIODES

Light-emitting diodes (LEDs)

by

using the low range and connecting the probes across the

may

be tested with the tracker

an

LED. A good LED provides

of

result

patterns for different colored LEDs, each

different forward voltages (VD.

the tracker connections. Figure 3-20 shows the

adequate amount oflight as a

of

which exhibit

COLOR: RED

RANGE: LOW

COLOR: AMBER

RANGE: LOW

Figure 3-20. LED Patterns

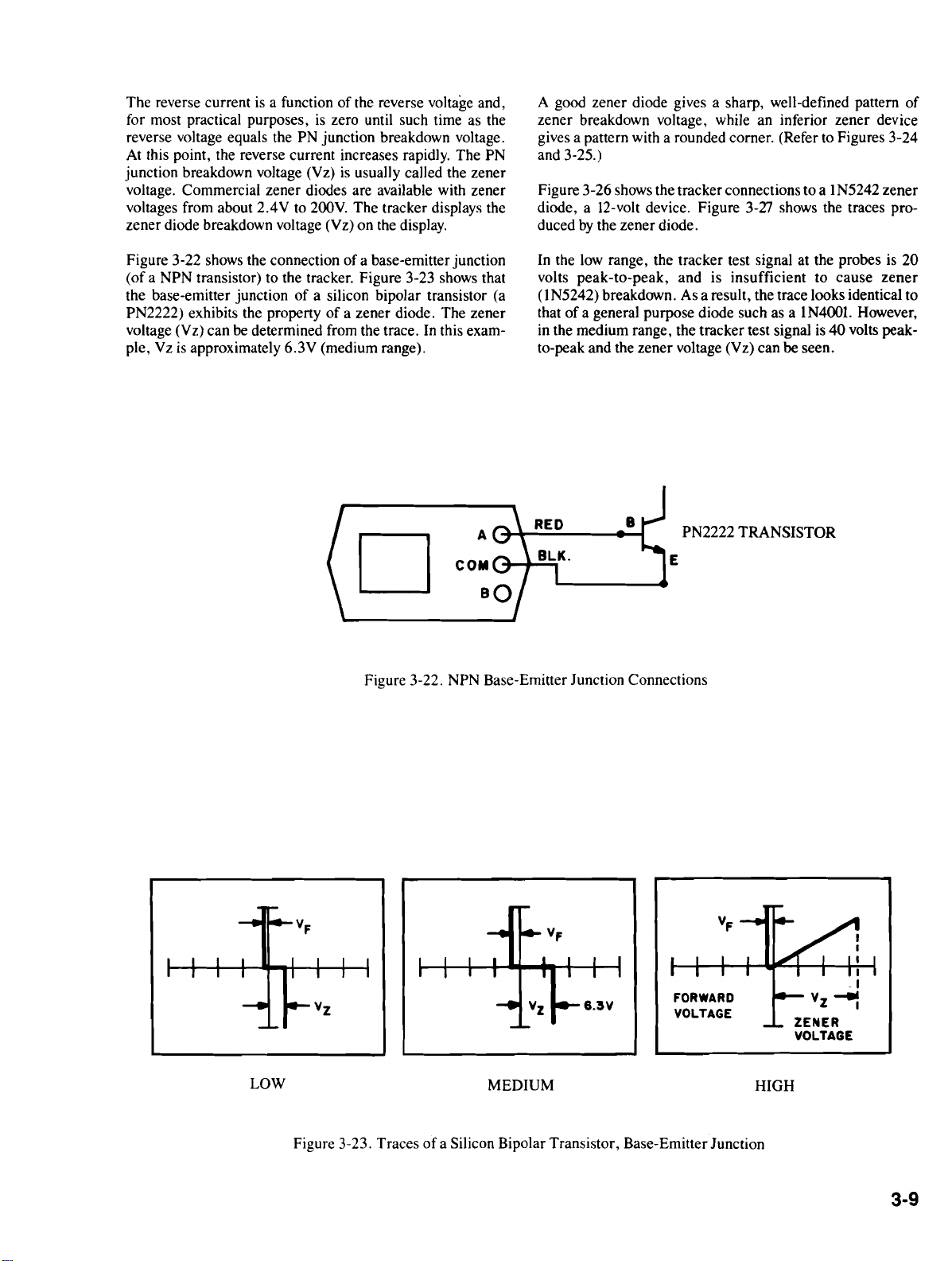

3.6 ZENER DIODES

The zener diodeisunique among the semiconductor family

of

devicesinthat its electrical properties are derived from a

rectifying junction which operates

region. Figure

a typical 30-volt zener diode.

3-21

shows the volt-ampere characteristics

in

the reverse-breakdown

COLOR: GREEN

RANGE: LOW

Figure

both directions, with the forward current being a function

the forward voltage. Note that the forward currentissmall

of

by

AMP.

10

3-21

shows that the zener diode conducts current

is

until the forward voltage

forward current increases rapidly. When the forward voltage

is

greaterthan0.65V, the forward currentislimited primarily

the circuit resistance external to the diode.

approximately

FORWARD

CURRENT

5

O.65V,

in

of

then the

3-8

o

30

20

10

REVERSE

VOLTAGE

Figure 3-21. Characteristicsofa Typical 30V Zener Diode

0.5

.5

1.0

FORWARD

VOLTAGE

REVERSE

CURRENT

The reverse current is a functionofthe reverse voltage and,

for most practical purposes, is zero until such time as the

reverse voltage equals the PN junction breakdown voltage.

At this point, the reverse current increases rapidly. The PN

junction breakdown voltage (Vz) is usually called the zener

voltage. Commercial zener diodes are available with zener

2.4V

voltages from about

zener diode breakdown voltage (Vz) on the display.

to 200V. The tracker displays the

A good zener diode gives a sharp, well-defined pattern

zener breakdown voltage, while an inferior zener device

gives a pattern with a rounded comer. (Refer to Figures 3-24

and 3-25.)

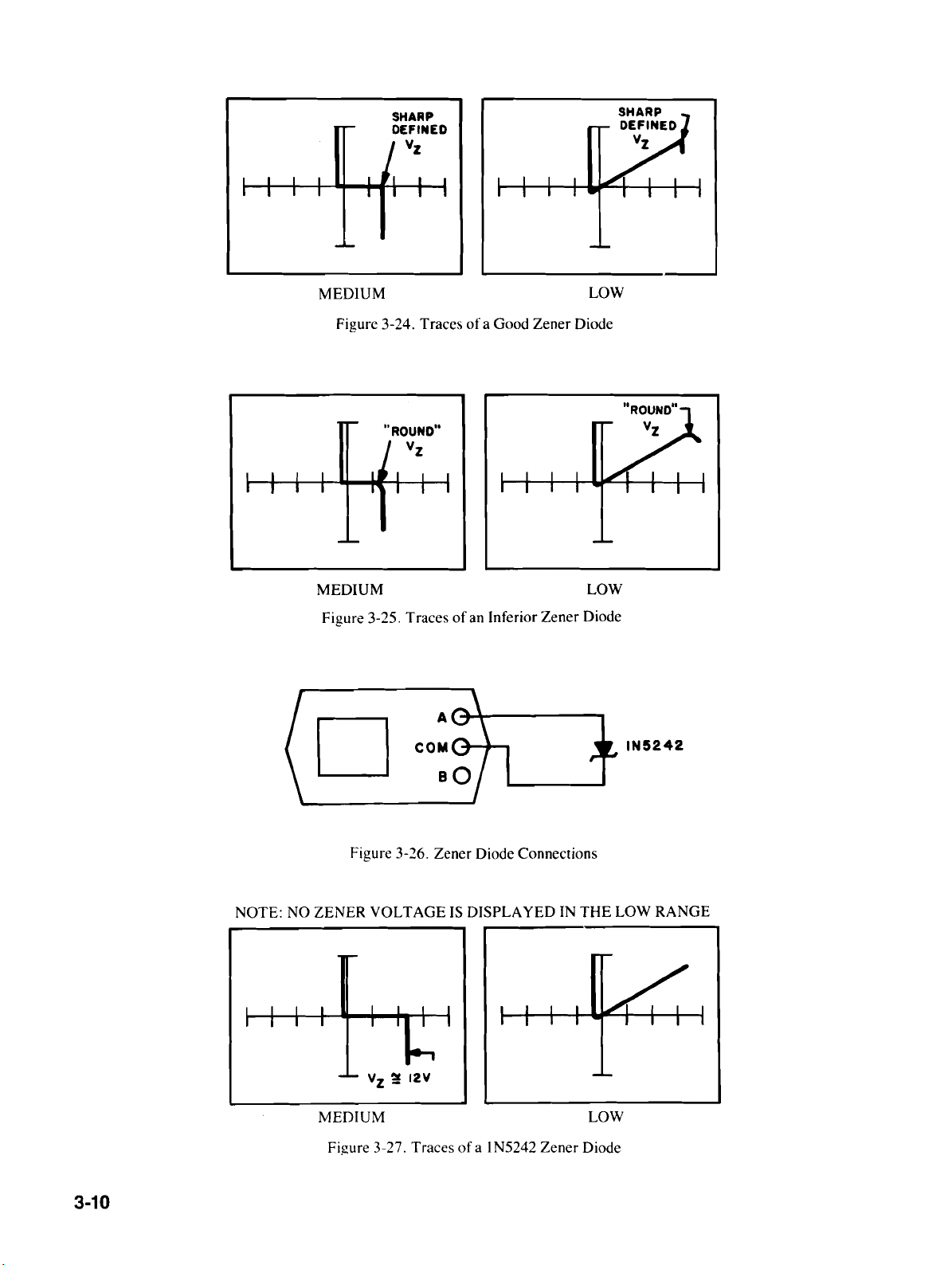

Figure 3-26 shows the tracker connections to a 1N5242 zener

diode, a 12-volt device. Figure

duced

by

the zener diode.

3-Zl shows the traces pro-

of

Figure 3-22 shows the connectionofa base-emitterjunction

(of a NPN transistor) to the tracker. Figure 3-23 shows that

of

the base-emitter junction

PN2222) exhibits the property

voltage (Vz) can be determined from the trace. In this example, Vz is approximately 6.3V (medium range).

a silicon bipolar transistor (a

of

a zener diode. The zener

A

COM

D

Figure 3-22. NPN Base-Emitter Junction Connections

In the low range, the tracker test signal at the probes is

volts

peak-to-peak,

(1

N5242) breakdown. As a result, the trace looks identical to

that

of

a general purpose diode such as a IN4001. However,

in the medium range, the tracker test signal is

to-peak and the zener voltage (Vz) can

8

and

is insufficient to cause

be

PN2222 TRANSISTOR

E

seen.

40

volts peak-

zener

20

LOW

Figure 3-23. Traces

FORWARD

VOLTAGE

MEDIUM

of

a Silicon Bipolar Transistor, Base-Emitter Junction

HIGH

VZ~

ZENER

VOLTAGE

I

I

3·9

SHARP

DEFINED

V

z

MEDIUM

Figure 3-24. Traces

"ROUND"

V

z

MEDIUM

Figure 3-25. Traces

COM

D

of

a Good Zener Diode

of

an Inferior Zener Diode

A

LOW

LOW

IN!5242

3-10

Figure 3-26. Zener Diode Connections

NOTE: NO ZENER VOLTAGE

V

~

12V

z

MEDIUM

Figure 3-27. Traces

IS

DISPLAYED IN THE LOW RANGE

LOW

ofa

IN5242 Zener Diode

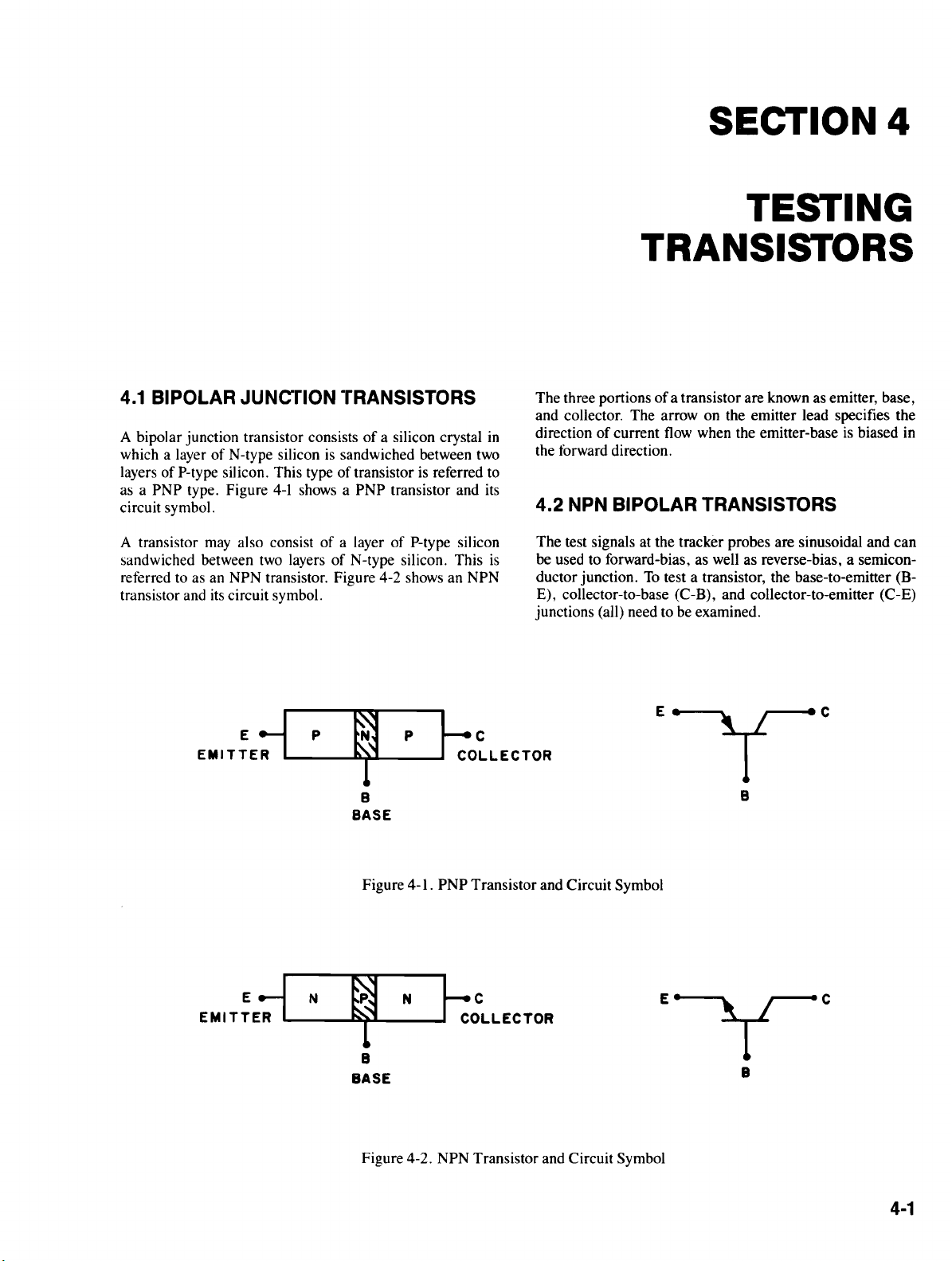

4.1

BIPOLAR JUNCTION TRANSISTORS

A bipolar junction transistor consistsofa silicon crystal

which a layerofN-type siliconissandwiched between two

layers of P-type silicon. This type

as a PNP type. Figure

circuit symbol.

4-1

of

transistorisreferred to

shows a PNP transistor and its

SECTION 4

TESTING

TRANSISTORS

of

The three portions

and collector. The arrow on the emitter lead specifies the

direction

in

the forward direction.

4.2 NPN BIPOLAR TRANSISTORS

of

current

a transistor are known as emitter, base,

flow

when the emitter-baseisbiased in

may

A transistor

sandwiched between two layers

referred to as an NPN transistor. Figure 4-2 shows an NPN

transistor and its circuit symbol.

also consistofa layer of P-type silicon

of

N-type silicon. This

~

BASE

P

__

~~O~LECTO"

B

Figure 4-1. PNP Transistor and Circuit Symbol

The test signals at the tracker probes are sinusoidal and can

be used to forward-bias, as well as reverse-bias, a semicon-

is

ductor junction.

E), collector-to-base (C-B), and collector-to-emitter (C-E)

junctions (all) need to be examined.

To

test a transistor, the base-to-emitter (B-

E

.....

-'\...

~-.c

B

E

'"

T~E-;1~_N_

.....

~~_N_""'~~LLECTO"

B

BASE

Figure 4-2. NPN Transistor and Circuit Symbol

B

4-1

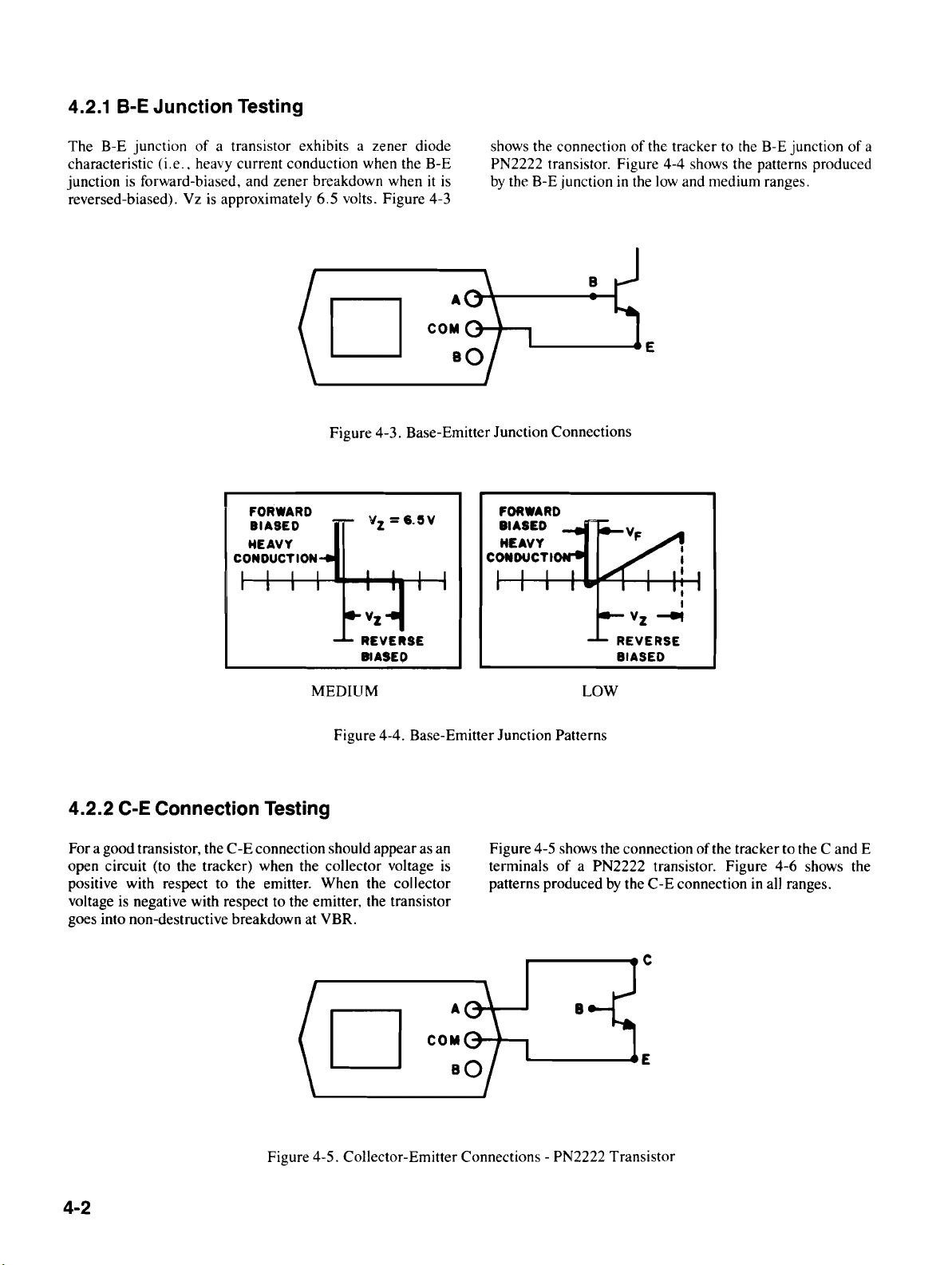

4.2.1 B-E Junction Testing

The B-E junction of a transistor exhibits a zener diode

characteristic (i.e.. heavy current conduction when the B-E

is

junction

reversed-biased). Vzisapproximately 6.5 volts. Figure 4-3

forward-biased. and zener breakdown when it

COM

D

Figure 4-3. Base-Emitter Junction Connections

FORWARD

BIASED

HEAVY

I CONDUCTION

V

=

6.15V

z

shows the connection

PN2222 transistor. Figure 4-4 shows the patterns produced

is

by

the B-E junctioninthe low and medium ranges.

A

P\o-\-----~

'------

of

the tracker to

B

..

E

the

B-E junction of a

Vz

REVERSE

BI

ASE

0

MEDIUM

Figure 4-4. Base-Emitter Junction Patterns

4.2.2

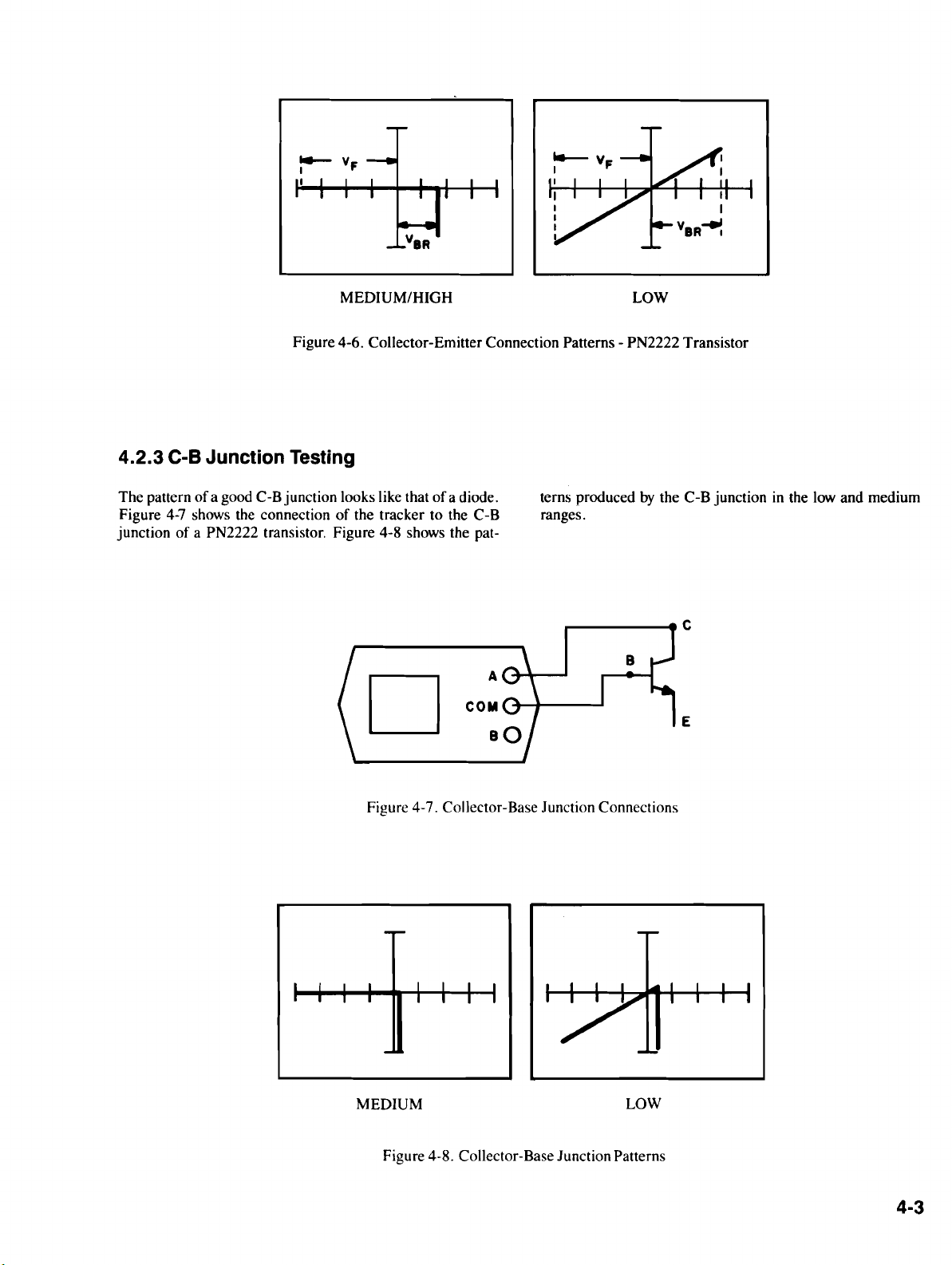

Fora good transistor, the C-Econnection should appear as an

open circuit (to the tracker) when the collector voltage

positive with respect to the emitter. When the collector

voltage is negative with respect to the emitter, the transistor

goes into non-destructive breakdown at VBR.

C-E Connection Testing

COM

D

Figure 4-5 shows the connection ofthe tracker to the C and E

is

terminals

patterns produced

A

of

r-----

"'------

V

z

REVERSE

BIASED

LOW

a PN2222 transistor. Figure 4-6 shows the

by

the C-E connection in all ranges.

..... C

8

...

E

4-2

Figure 4-5. Collector-Emitter Connections - PN2222 Transistor

MEDIUM/HIGH LOW

Figure 4-6. Collector-Emitter Connection Patterns - PN2222 Transistor

4.2.3

The patternofa good C-B junction looks like thatofa diode.

Figure 4-7 shows the connection

junction

C-B Junction Testing

of

the tracker to the C-B

of

a PN2222 transistor. Figure 4-8 shows the pat-

COM

D

Figure 4-7. Collector-Base Junction Connections

terns produced

ranges.

,..-----

A

by the C-B junction

..

C

E

in

the low and medium

MEDIUM

Figure 4-8. Collector-Base Junction Patterns

LOW

4-3

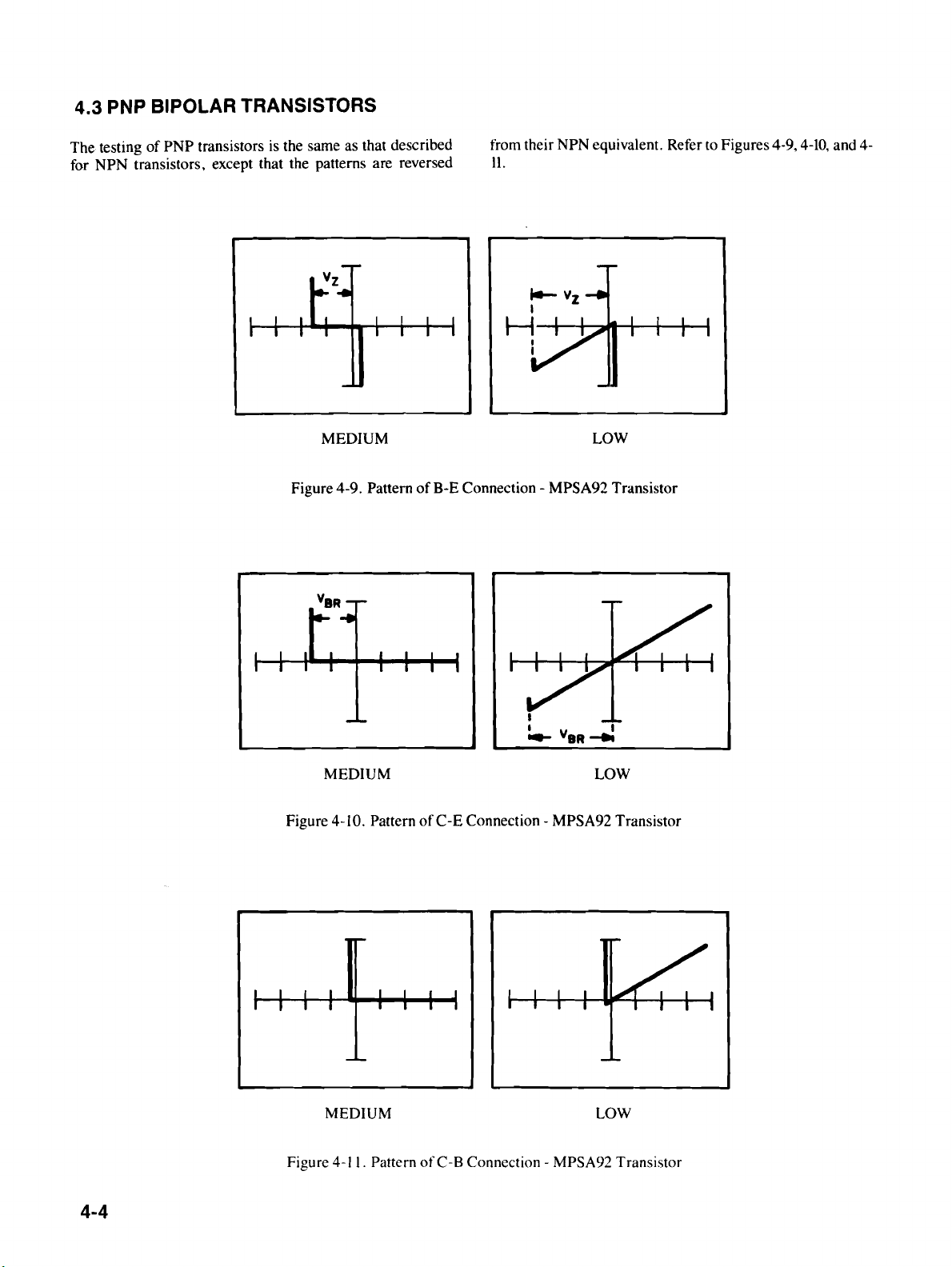

4.3 PNP BIPOLAR TRANSISTORS

The testingofPNP

for NPN transistors, except that the patterns are reversed

transistorsisthe same as that described

MEDIUM

Figure 4-9. PatternofB-E Connection - MPSA92 Transistor

from their NPN equivalent. Refer to Figures 4-9,4-10, and 4-

ll.

LOW

4-4

MEDIUM

Figure 4-10. PatternofC-E

MEDIUM

Figure 4-11. Pattern

ofC-B

LOW

Connection - MPSA92 Transistor

LOW

Connection - MPSA92 Transistor

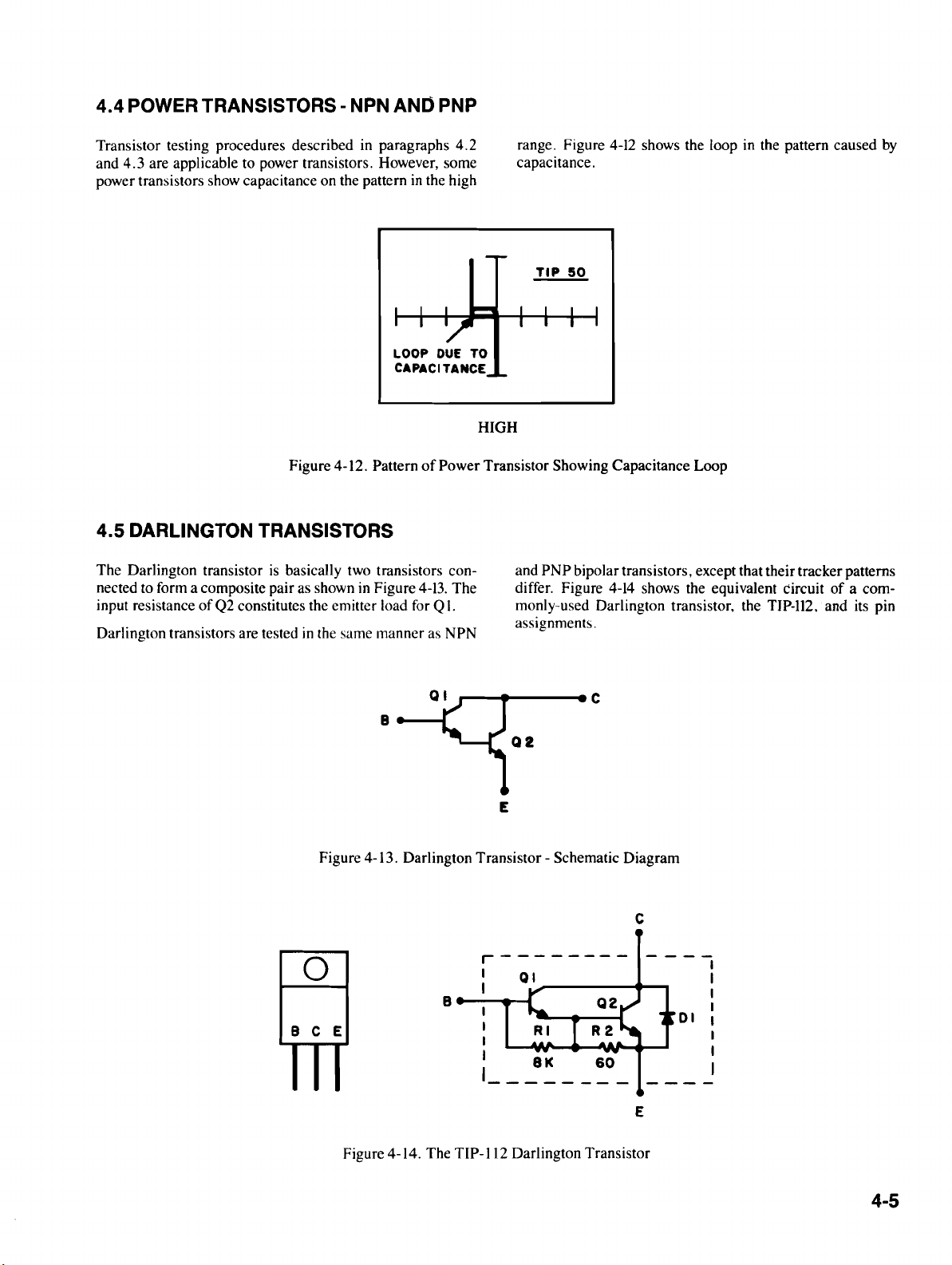

4.4

POWER TRANSISTORS - NPN ANO PNP

Transistor testing procedures described in paragraphs 4.2

and 4.3 are applicable to power transistors. However, some

in

power transistors show capacitance on the pattern

Figure 4-12. PatternofPower Transistor Showing Capacitance Loop

4.5

DARLINGTON TRANSISTORS

The Darlington transistorisbasically two transistors connected to form a composite pair as shown in Figure

of

input resistance

Darlington transistors are testedinthe same manner as NPN

Q2 constitutes the emitter load for Q

the high

LOOP

DUE

CAPACITANCE

4-13.

The

I.

range. Figure

capacitance.

TIP

TO

50

4-12

shows the loop in the pattern caused

HIGH

and PNP bipolartransistors, except that theirtrackerpatterns

differ. Figure

monly-used Darlington transistor, the TIP-Il2, and its pin

assignments.

4-14

shows the equivalent circuit of a com-

by

r---

.....

--

...... c

B

----I

Q2

E

Figure 4-13. Darlington Transistor - Schematic Diagram

r--------

o

BeE

Figure 4-14. The TIP-I12Darlington Transistor

B

....-....

I

QI

I

..

~----

-f

BI<

60

C

..........

01

E

4-5

To

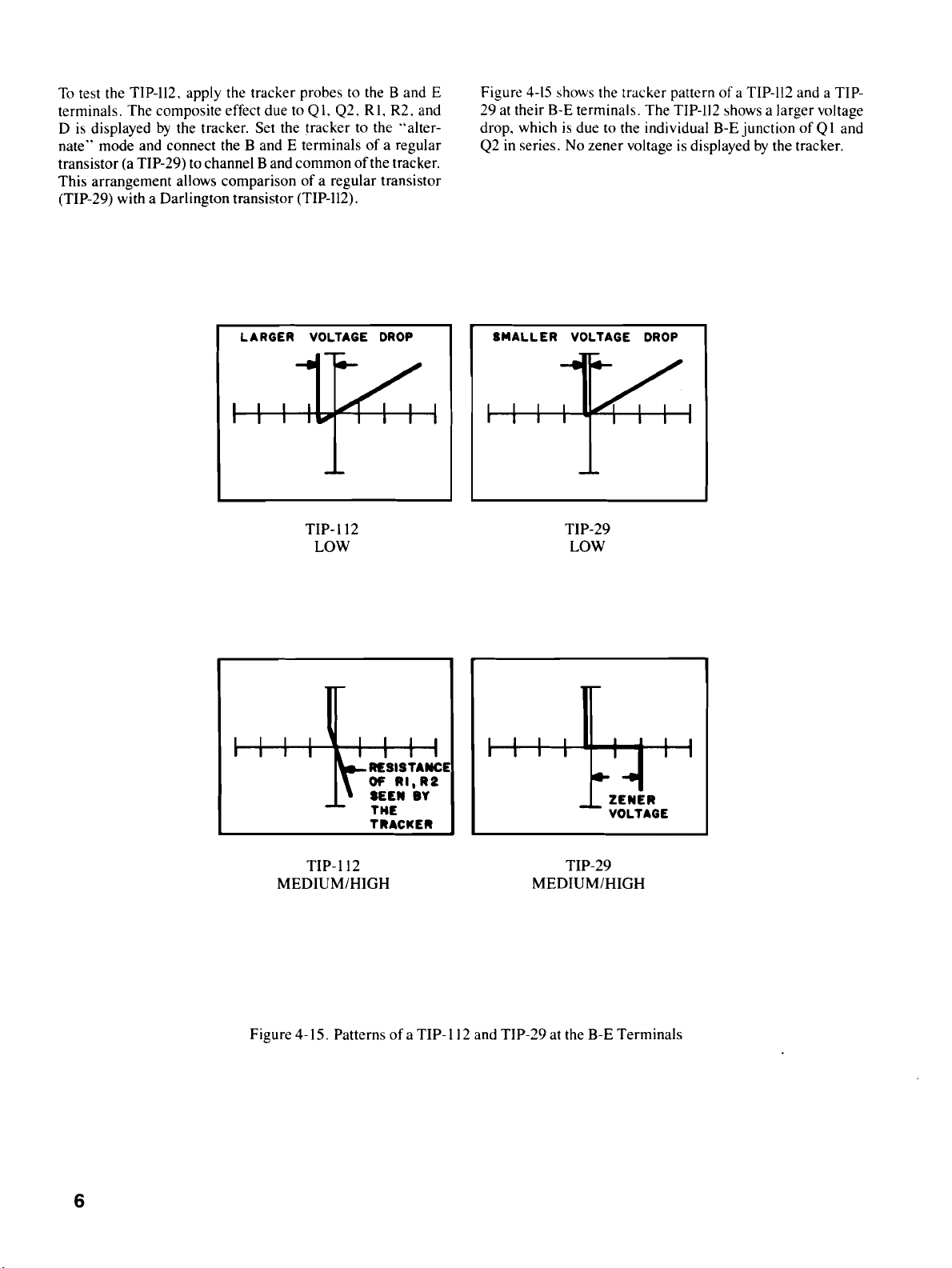

test the TIP-lI2. apply the tracker probes to the

terminals. The composite effect due to

D is displayed

nate"

mode and connect the

by

the tracker. Set the tracker to the "alter-

Band

QI,

Q2. RI. R2, and

E terminalsofa regular

transistor (a TIP-29) to channel B and common

This arrangement allows comparison

of

a regular transistor

(TIP-29) with a Darlington transistor (TIP-Il2).

ofthe

Band

tracker.

Figure

4-15

E

shows the tracker patternofa TIP-lI2 and a TIP29 at their B-E terminals. The TIP-Il2 shows a larger voltage

drop, which

Q2 in series. No zener voltage

is

due to the individual B-E junctionofQ I and

is

displayedbythe tracker.

LARGER VOLTAGE

TIP-I

12

LOW

DROP

RESISTANCE

otr

RI,

tEEN IV

TRACKER

R2

THE

SMALLER

VOLTAGE

TIP-29

LOW

DROP

TIP-Il2

MEDIUM/HIGH

Figure 4-15. Patternsofa

TIP-I12and TIP-29 at the B-E Terminals

TIP-29

MEDIUM/HIGH

6

Loading...

Loading...