Huntleig

h

HEALTHCARE

Mini Pump

Service Manual

Issue 2

SER0004 Nov 2001

Mini Pump Service Manual Contents

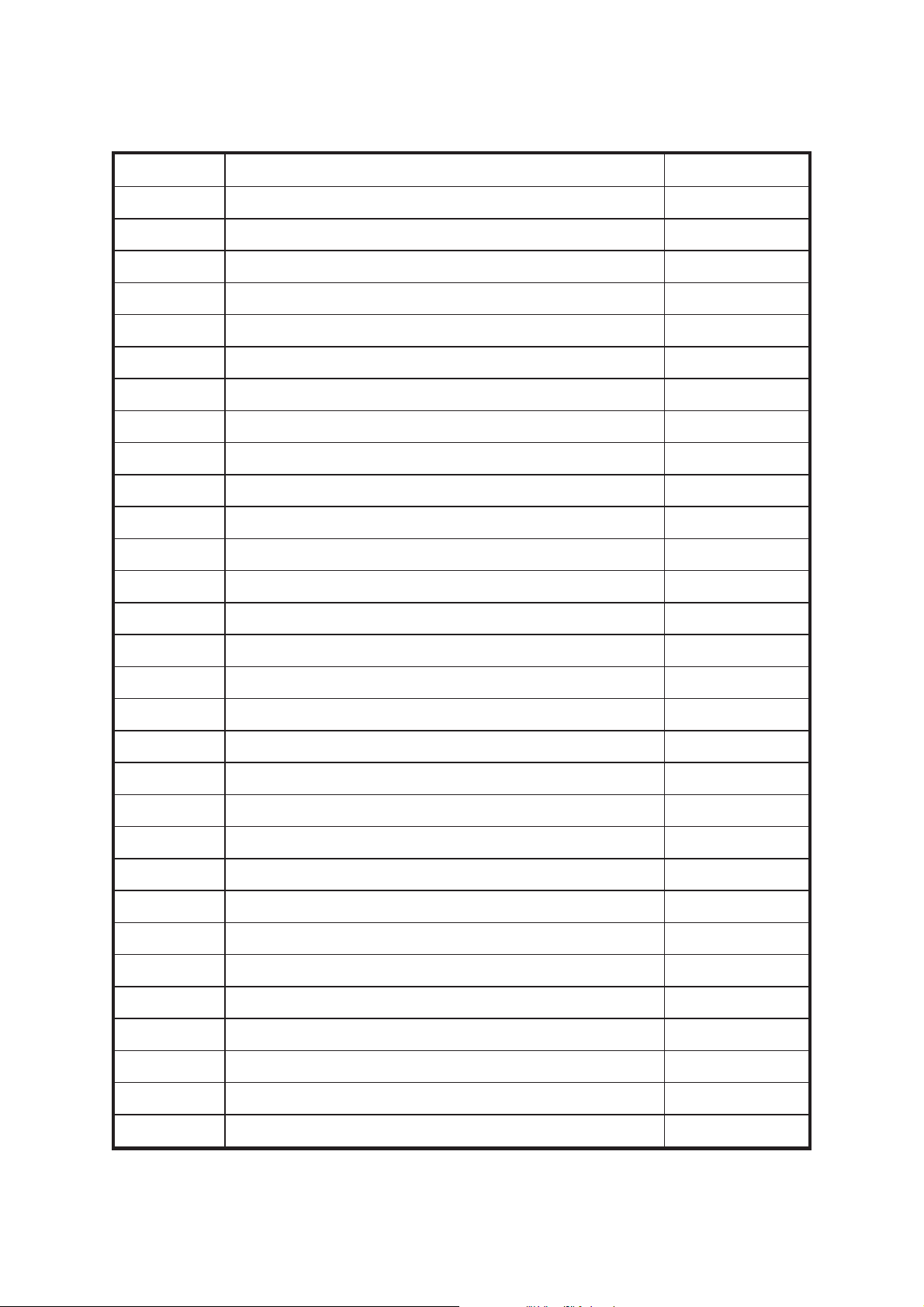

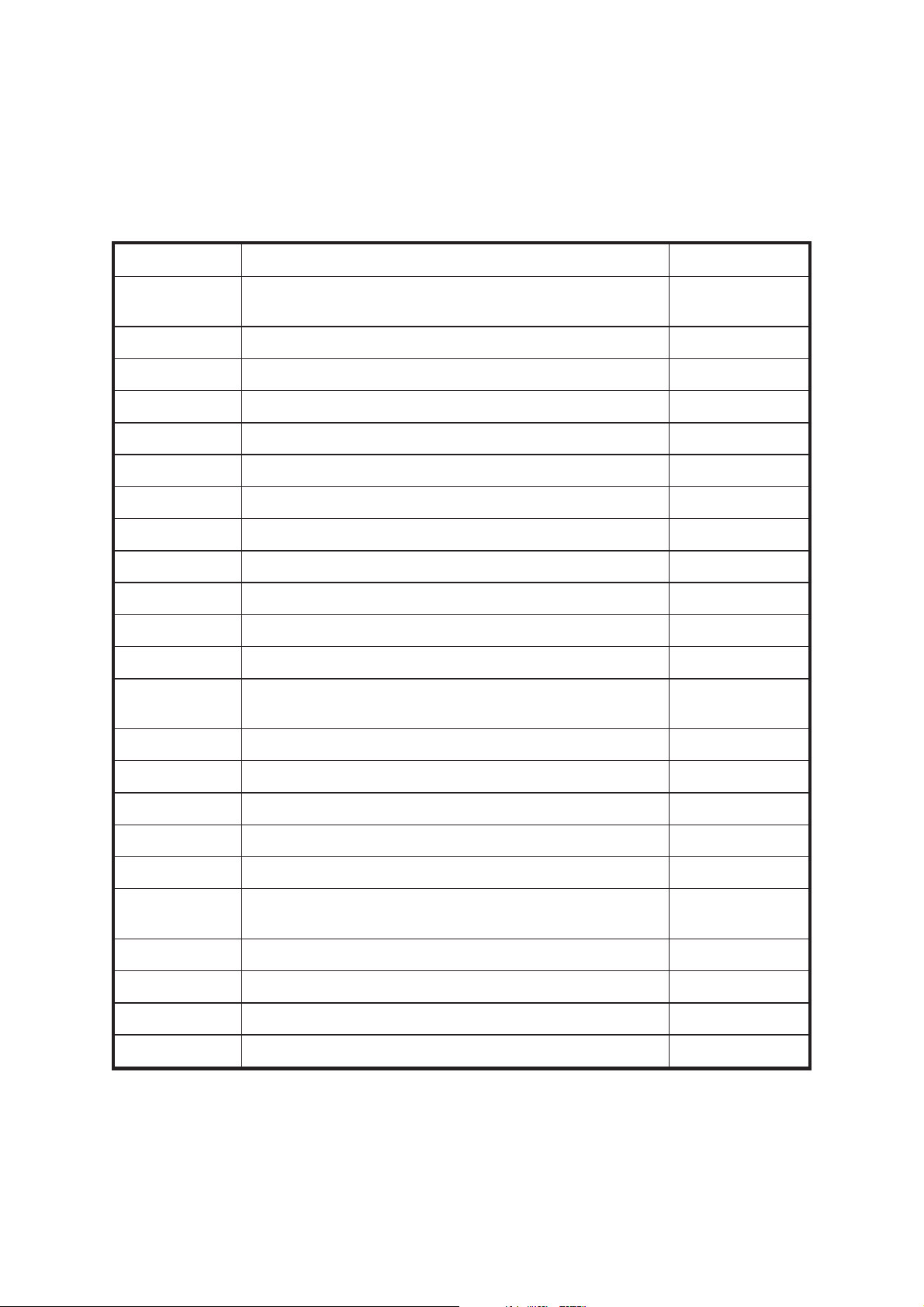

AMENDMENT RECORD

Amendment Incorporated by Date

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Issue 2 Contents

Nov 2001 SER0004 Page (i)

Contents Mini Pump Service Manual

Contents Issue 2

Page (ii) SER0004 Nov 2001

Mini Pump Service Manual Contents

Contents

CHAPTER 1

Introduction ....................................1

About This Manual ......................................1

Warnings, Cautions and Notes ............................2

Technical Description .....................................3

Operating Principle...................................3

System Start Up Sequence ..............................5

Low Pressure Alarm (Electronic Units Only) ......................6

Low Pressure Alarm (All Units) ............................6

Low Pressure Alarm Protocol (Electronic Units Only) .................6

Power Failure Alarm (Electronic Units Only)......................6

Battery Management (Electronic Units Only) .....................7

CHAPTER 2

Maintenance ...................................1

Pump Maintenance Checks .................................1

Pump Soak/Break-in Times..................................2

Pump Service .........................................2

CHAPTER 3

Pump Repair ...................................1

General ............................................1

Removing the Pressure Control Knob ............................3

Installing the Pressure Control Knob .............................3

Disassembling the Pump Filter ................................5

Assembling the Pump Filter .................................5

Disassembling the Rear Case ................................5

Assembling the Rear Case ..................................5

Disassembling the New Style Bed Hook ...........................7

Installing the New Style Bed Hook ..............................7

Removing the Old Style Bed Hook ..............................9

Installing the Old Style Bed Hook...............................9

Removing the Compressor Inlet Filter............................11

Installing the Compressor Inlet Filter ............................11

Removing the New Style AV Mounts ............................13

Replacing the New Style AV Mounts ............................13

Removing the Old Style AV Mounts .............................15

Issue 2 Contents

Nov 2001 SER0004 Page (i)

Contents Mini Pump Service Manual

Installing the Old Style AV Mounts .............................15

Removing the Compressor Mounting Bracket........................17

Installing the Compressor Mounting Bracket ........................17

Removing the Compressor Bump Stops ..........................17

Installing the Compressor Bump Stops ...........................18

Replacing the Compressor Silencer Bag ..........................19

Replacing the Bellows Armature Assemblies and Pivots ..................21

Replacing the Compressor Armature Pivots ........................21

Replacing the Compressor Valve Bodies ..........................23

Replacing the ‘E’ Stack Assembly..............................25

Replacing the Coil Assembly ................................25

Replacing the Compressor Assembly ............................25

Replacing the Pressure Control Module...........................27

Replacing the Alarm Monitoring PCB ............................29

Changing the Battery ....................................31

Replacing the Neon Indicator Light .............................33

Replacing the Microswitch..................................35

Replacing the Terminal Block ................................35

Replacing the Pressure Control Flaps and Air Bag .....................37

Replacing the Pressure Control Assembly .........................39

Replacing the Synchronous Motor (Gearbox), Rotor Stator Assembly ...........41

Replacing the Side Panel Mains/Power On/Off Switch ...................43

Replacing the Side Panel Mains/Power Lead ........................43

Replacing the Fuses.....................................43

Replacing the Snap-lock Connectors ............................45

Removing the Front Case ..................................46

Installing the Front Case ..................................46

Pump Label Sets ......................................47

CHAPTER 4

Troubleshooting .................................1

General ............................................1

Low Pressure fault indicated (checks without dismantling the pump) ............2

Loss of Output Pressure (checks by dismantling the pump) .................3

Low Pressure Alarm Fault ..................................4

Air Not Alternating (continuous pressure fault) ........................4

Loss of Electrical Power ...................................4

Contents Issue 2

Page (ii) SER0004 Nov 2001

Mini Pump Service Manual Contents

Circuit Diagrams .......................................5

CHAPTER 5

Testing ......................................1

Pump Flow, Pressure and Function Test ...........................1

Electrical Testing .......................................5

PCB Functional Tests (Electrical Units Only) .........................6

Functional Tests (Mechanical Units Only) ..........................7

CHAPTER 6

Technical specification..............................1

CHAPTER 7

Parts list ......................................1

CHAPTER 8

Service Contact Details .............................1

Issue 2 Contents

Nov 2001 SER0004 Page (iii)

Contents Mini Pump Service Manual

Contents Issue 2

Page (iv) SER0004 Nov 2001

Mini Pump Service Manual Introduction

CHAPTER 1

INTRODUCTION

1 About This Manual

Huntleigh Healthcare strongly recommend that their equipment is only serviced by trained

personnel and provide courses for customers who wish to become licensed to service their

own equipment. In no event will Huntleigh Healthcare be responsible for any service

performed by customers or third parties.

This manual contains information on maintenance, servicing, repair, troubleshooting and testing for

the range of pressure regulated pump units; pump models within the range are as follows:

AlphaXcell (Electronic)AlphaXcell (Mechanical)

•

AlphaRelief (Electronic)

•

Aura (Electronic)

•

AlphaTrancell (Mechanical)

•

AlphaBed (Mechanical)

•

AlphaCare (Mechanical)

•

Pump models are available for use world wide – model codes are shown in Table 1, while for country

codes and power supply details refer to Table 2.

Table 1 - Product Range Distribution

Model Code Country Code

AlphaXcell (Electronic) ALX 01 to 10

AlphaXcell (Mechanical) ALX 11

AlphaRelief ALR 01 - 10

Aura ALS 01 - 10

AlphaTrancell ALT 01 - 10

AlphaBed ALB 01 - 10

AlphaCare ALC 01 - 10

Issue 2 Chap 1

Nov 2001 SER0004 Page 1

Introduction Mini Pump Service Manual

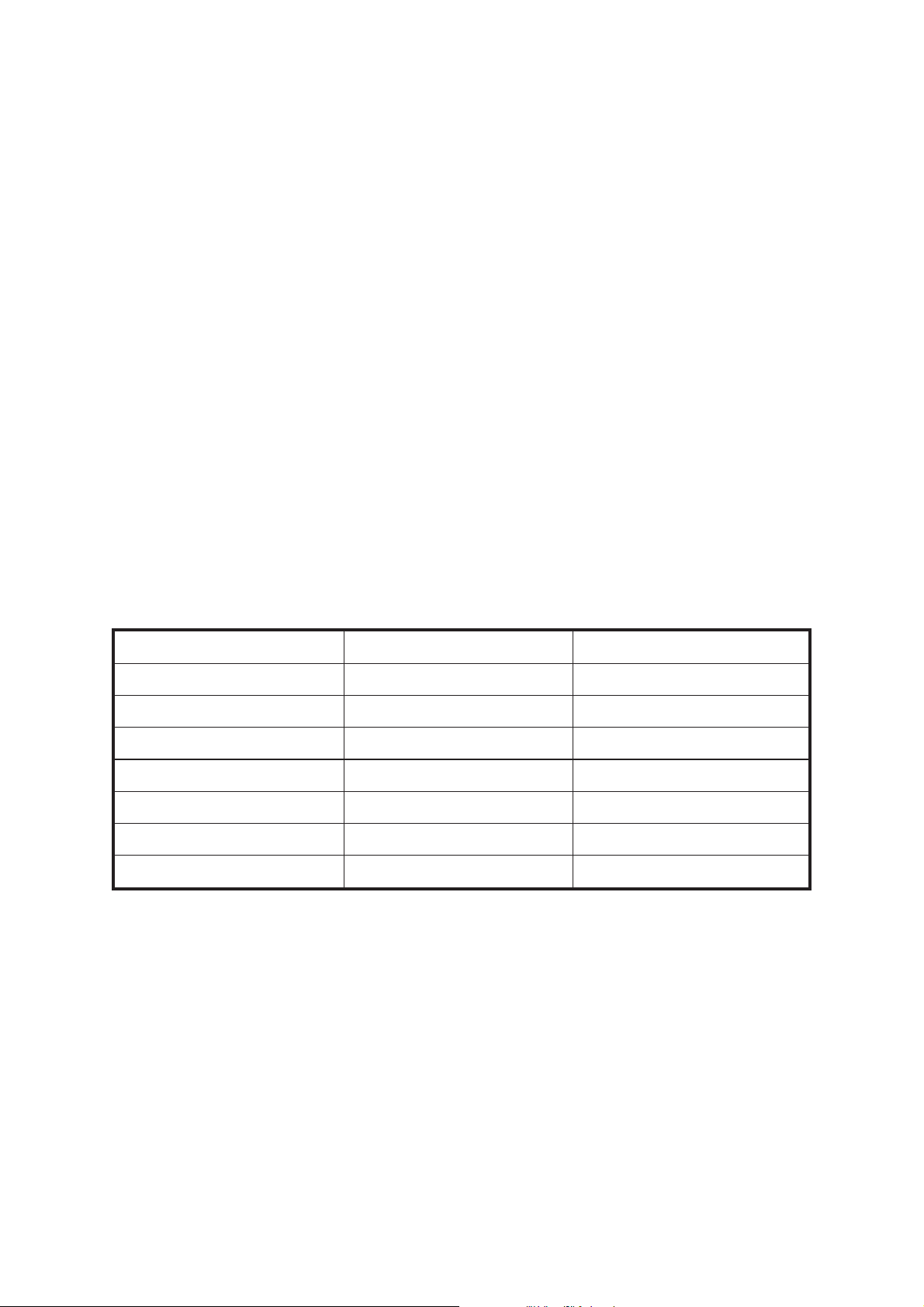

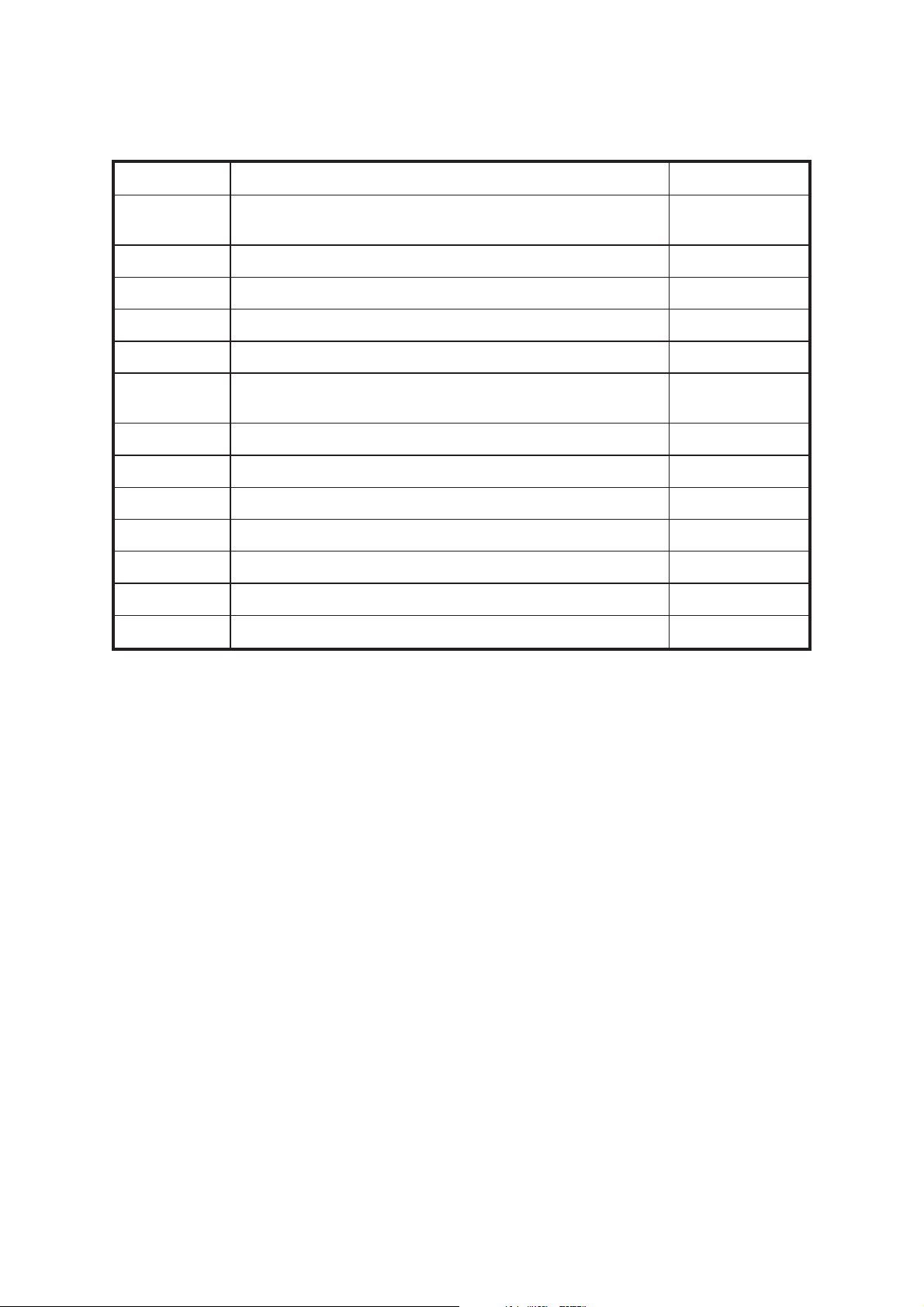

Table 2- Country Codes/Power Supplies

Mains Power

Country Code Country

Voltage (Volts AC) Frequency (Hz)

01 UK 220 - 240 50

02 Germany 220 - 240 50

03 USA 110 - 120 60

04 Euro 220 - 240 50

05 France 220 - 240 50

06 Japan 100 50/60

07 Italy 220 - 240 50

08 Australia 220 - 240 50

09 Rest of World 220 - 240 50

10 Holland 220 - 240 50

11 Rest of World 110 - 120 60

Warnings, Cautions and Notes

WARNINGS given in this manual identify possible hazards in procedures or conditions which, if not

correctly followed, could result in death, injury or other serious adverse reactions.

Cautions given in this manual identify possible hazards in procedures or conditions which, if not

correctly followed, could result in equipment failure or damage.

Notes given in this manual are used to explain or amplify a procedure or condition.

WARNINGS:

BEFORE PERFORMING ANY SERVICE OR MAINTENANCE PROCEDURES,

ENSURE THAT THE EQUIPMENT HAS BEEN ADEQUATELY

DECONTAMINATED.

VOLTAGES IN EXCESS OF 30 VOLTS RMS OR 50 VOLTS DC CAN, IN

CERTAIN CIRCUMSTANCES, BE LETHAL. WHEN WORKING ON

EQUIPMENT REQUIRING EXPOSURE TO LIVE, UNPROTECTED

CONDUCTORS WHERE SUCH VOLTAGES ARE PRESENT, EXTREME CARE

MUST BE EXERCISED.

WHEN AN UNSERVICEABLE MAINS LEAD/POWER CORD FITTED WITH A

NON-REWIREABLE PLUG IS REMOVED FROM THIS EQUIPMENT, THE

LEAD/CORD AND THE PLUG MUST BE DESTROYED AND DISPOSED OF

SAFELY. TO AVOID THE DANGER OF ELECTRIC SHOCK THE PLUG MUST

NEVER BE INSERTED IN ANY POWER OUTLET.

Chap 1 Issue 2

Page 2 SER0004 Nov 2001

Mini Pump Service Manual Introduction

2 Technical Description

The pressure regulated pump units listed in section 1 provide pressurised air for alternating pressure

mattress systems which are used in aiding the prevention, treatment and management of pressure

ulcers.

Pressurised air is fed to a range of support systems, mattresses, seat cushions etc., which support

patients at risk of developing pressure ulcers.

All pumps are self-contained units powered by the single phase mains/power supply. Low air

pressure and power failure alarm functions are included in some models, and pump output pressure

is adjustable by means of a rotary control mounted on the unit front panel.

Operating Principle

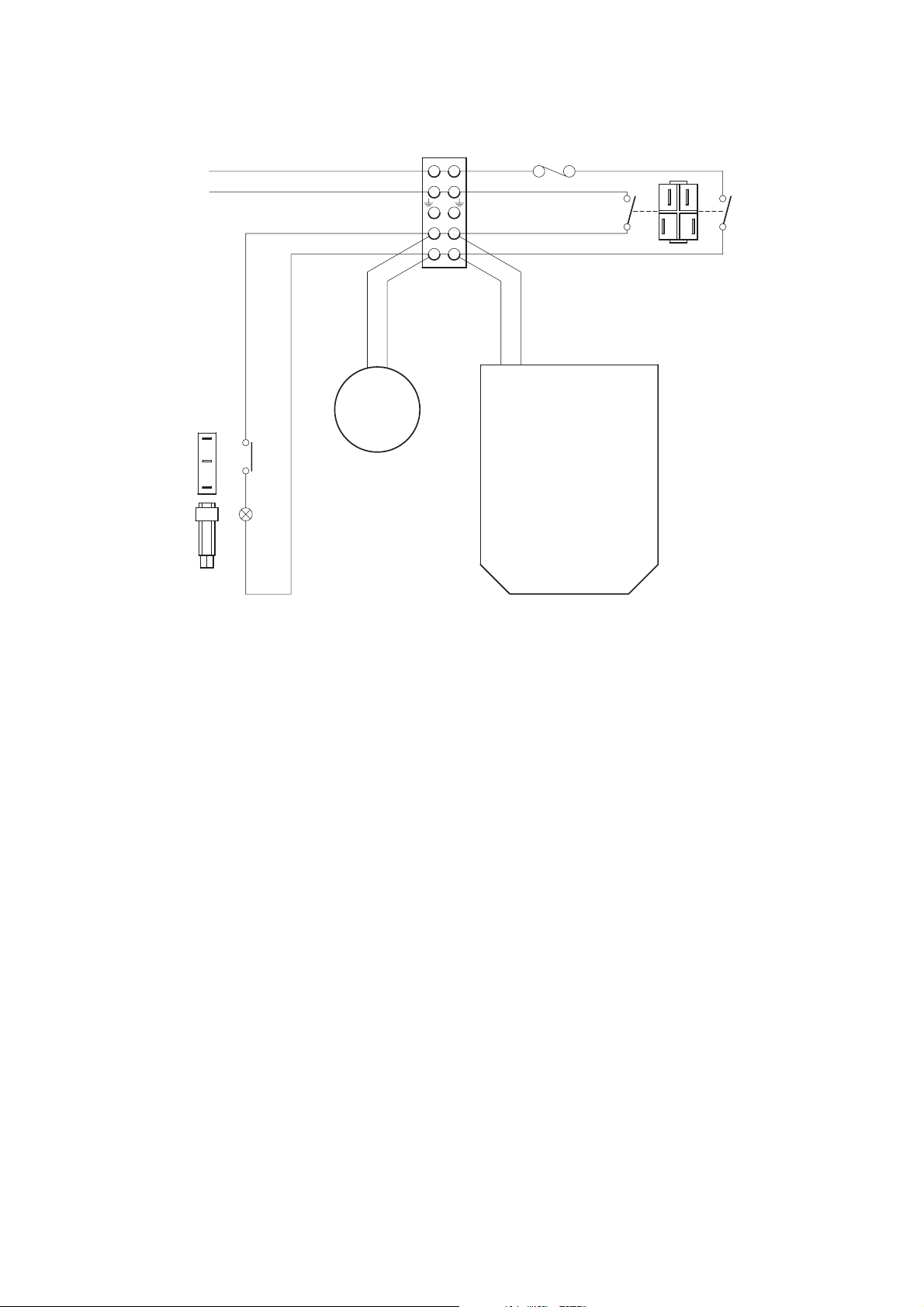

Refer to Figure 1 for details of the pneumatic circuit. All pumps have two pressurised air outlets, air

from the outlets is fed to separate cells or groups of cells in the mattress or cushion via a rotary valve.

The support cells are continuously inflated and deflated utilising a ten minute cycle. During the cycle,

air is pumped from one outlet for 4 minutes 10 seconds, there is then a period of 50 seconds where

air is pumped from both outlets. Air is then pumped from the other outlet for 4 minutes 10 seconds,

followed by a 50 second period where air is supplied from both outlets. During the period when air is

suppled from a single outlet to one group of cells, the opposing outlet is vented to atmosphere,

deflating the corresponding cells.

Issue 2 Chap 1

Nov 2001 SER0004 Page 3

Introduction Mini Pump Service Manual

COMPRESSOR

PRESSURE

CONTROL

PRESSURE

CONTROL

MODULE

MICROSWITCH

ALTERNATING CELLS

1

A

A

A

A

A

B

B

B

A2

A

A

B

B

A3

A

B

B

A4

A

B

B

EXCEPTION:

Aura has 9 alternating cells but no static cells.

A

B

A

A

B

A

A

B

A

B

B

A

A

B

B

A

A

B

B

A

A

B

B

ROTOR/

STATOR

OUTLET

PORTS

M

HEAD

SECTION

(STATIC)

A

B

B

C

C

C

A

B

B

C

C

C

A

B

B

C

C

C

A

B

B

C

C

C

KEY

= INFLATED

= DEFLATED

Figure 1 - Pneumatic Diagram and Pressure Variations

For the Aura mini pump small adjustments can be made to cell pressure using the comfort control

knob on the pump unit. This is a patient comfort feature to make small adjustments to the softness or

firmness of the support cells. All other mini pumps have a pressure adjustment control that must be

set to the patient weight in accordance with the instructions given in the relevant user manual and/or

the pump labels.

The range of air pressure delivered by the series of pumps varies, as does the achievable flow rate.

One extreme of pressure range can be adjusted by obtaining access to a screw under the pressure

control knob; see Table 3 for details of pressure variations. The range achievable is fixed by the

pressure control spring, only the set pressure can be reset.

Chap 1 Issue 2

Page 4 SER0004 Nov 2001

Mini Pump Service Manual Introduction

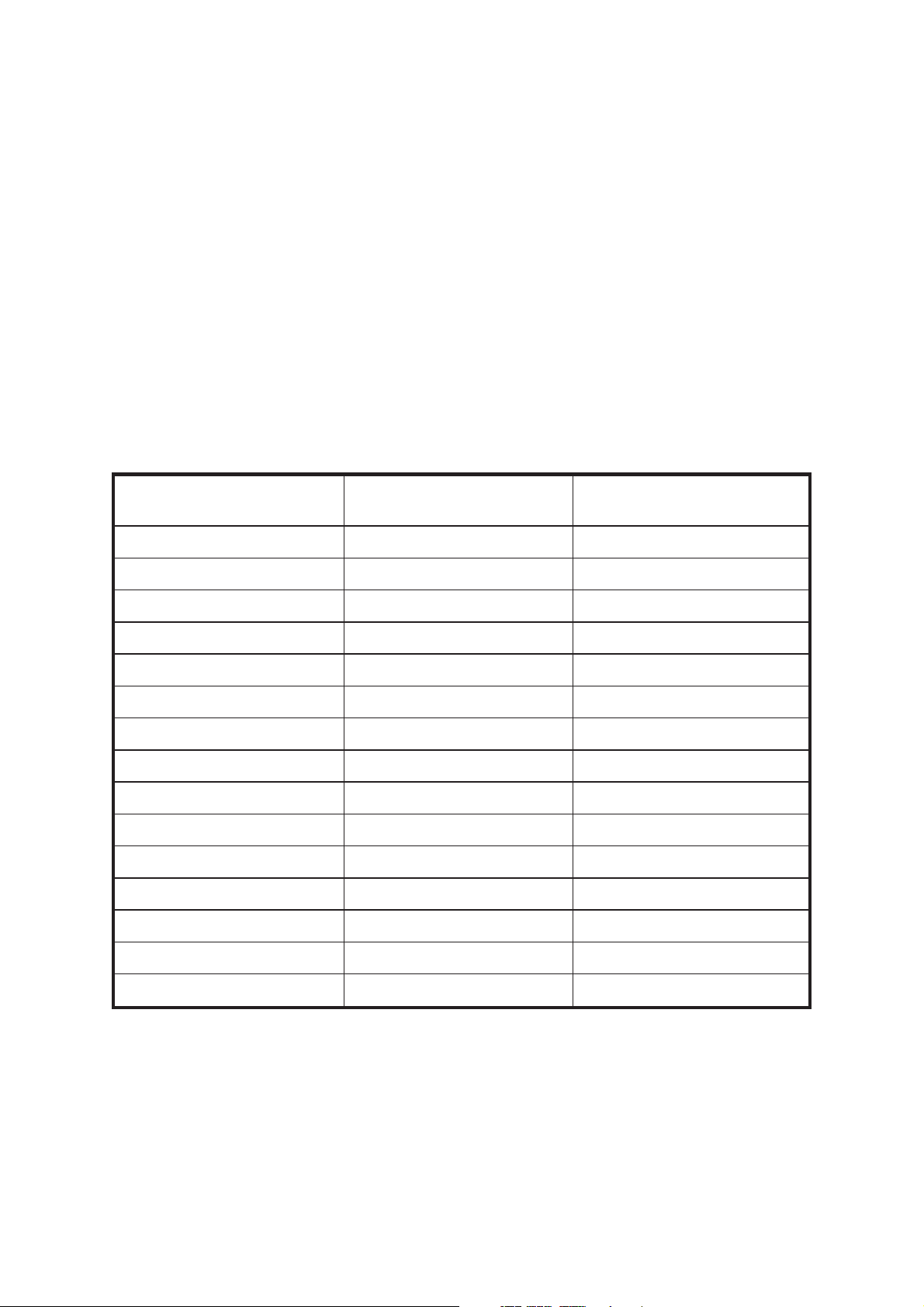

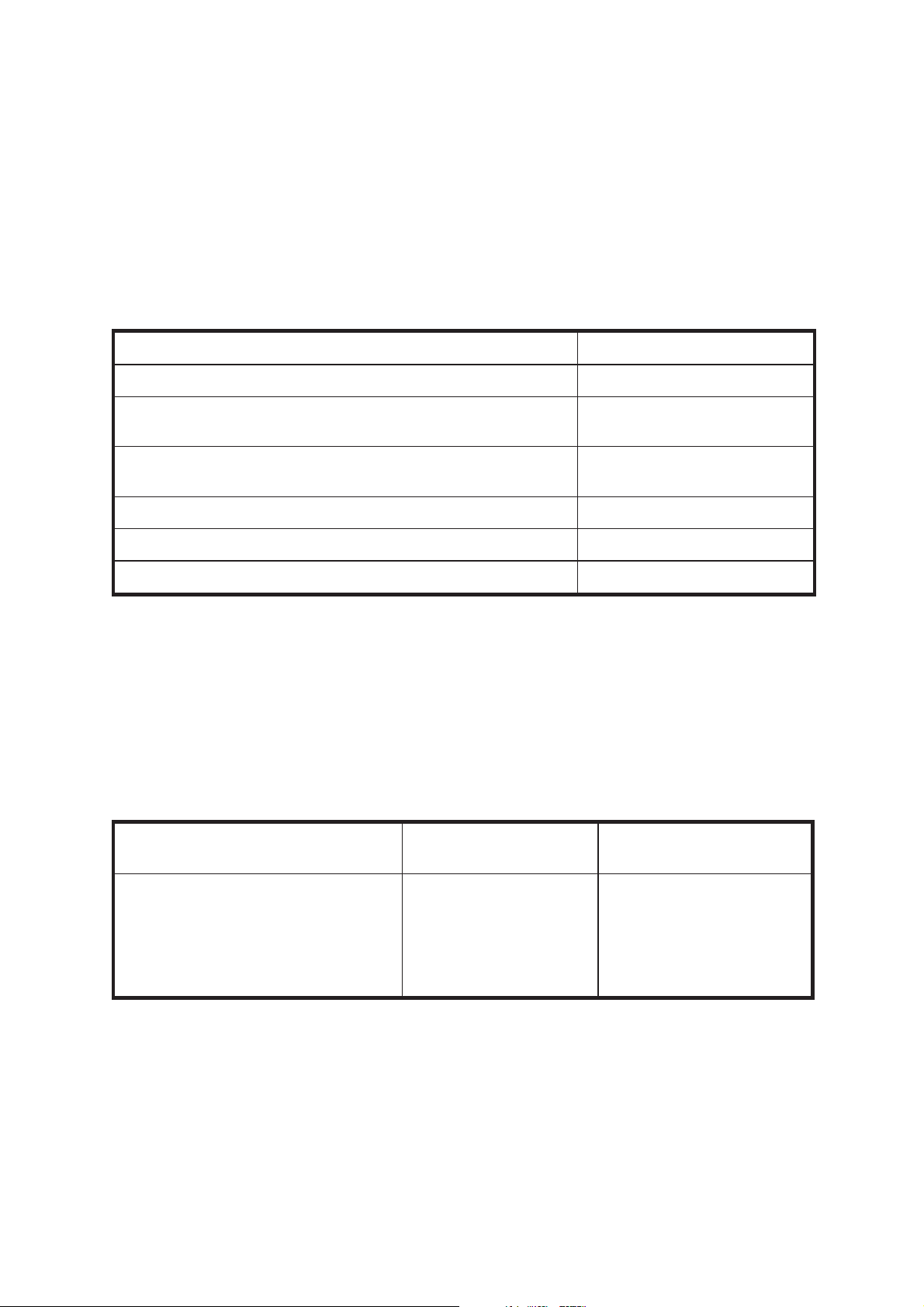

Table 3 - Air Pressure/Flow Rates

Pump

Model

ALX 20-24 57-73 Yes 6 3

ALR 20-24 72-92 Yes 6 3

ALS 83-87 Less than 110 Comfort

ALT 25-35 65-81* Yes 6 3

ALB 25-35 80-100 Yes 6 3

ALC 25-35 80-100 Yes 6 3

* Holland pumps (ALT10) only - max pressure is 80-100 mmHg

Pump units may be divided, into two types, Mechanical and Electronic. Major differences between

the two types of pump unit are as follows:

Alarm indicators - mechanical type has a neon indicating low air pressure, also an illuminated

•

mains/power on/off switch. The electronic type incorporates an alarm monitoring PCB driving a

number of LED indicators and audible warning sounder. See Table 4 for visual indicator

details.

Minimum

Pressure

(mmHg)

Maximum

Pressure

(mmHg)

Adjustable

Pressure

Range

control only

Minimum Flow

Rate at 20 mmHg

back pressure

(litres/minute)

3.25 2.25

Minimum Flow

Rate at 50

mmHg

(litres/minute)

• Air outlets - mechanical type has simple push-on connectors (except ALX11 which has

snap-lock type connectors). The electronic type utilises snap-lock type connectors.

Table 4 - Product Visual Indicators

Model Code ALB ALC ALT ALR ALX ALX ALS

Mechanical (M)

or

Electrical (E)

Indicator

Illuminated Mains/Power Switch X X X X

On X X X

Wait X X

Low Pressure X X XXXXX

Power Fail X X X

System Start Up Sequence

All pump types must be connected to the appropriate mains/power supply via a suitable plug.

After a mechanical pump is switched on the start up sequence is as follows:

MMME EME

•

The ON/OFF switch lever will be illuminated green.

Issue 2 Chap 1

Nov 2001 SER0004 Page 5

Introduction Mini Pump Service Manual

The red ‘low pressure’ indicator will be illuminated. When operating pressure is achieved, the

•

low pressure indicator will be extinguished automatically.

After an electronic pump is switched to ‘Run’ the start up sequence is as follows:

The unit performs a diagnostic self test, illuminating all LED indicators and sounding the

•

audible alarm. If an internal fault is sensed or a problem with the wiring of the mains/power

sense switch, the pump will remain in this state. If the self test is successful then the start up

sequence will proceed.

On start up, the low pressure alarm will be inhibited until one minute after the low pressure

•

signal is deactivated. The amber WAIT indicator will be illuminated while the low pressure

alarm is inhibited. (See Low pressure Protocol) Other functions will work as normal.

Note: Aura (ALS) model has no WAIT indicator; apart from this one difference, however, the Aura

pump performs the same as the other electronic pump units.

Low Pressure Alarm (Electronic Units Only)

When the alarm is activated, the red LOW PRESSURE indicator will flash, in combination with an

audible warning which increases in pitch with time. The alarm can be reset by momentarily switching

the pump to ‘Stand by’ and then back to ‘Run’. Alternatively, the alarm will automatically reset after

15 minutes provided that the low pressure switch is not activated during this time. If however the low

pressure switch is activated (for more than 15 seconds) during this time, the timer will reset to zero

and the alarm will continue for a further 15 minutes.

Low Pressure Alarm (All Units)

On all pump units except the ALS model the low air pressure alarm will be activated on or before

5 mmHg and deactivated before the pressure reaches 17 mmHg.

For the ALS model only, the low air pressure alarm will be activated on or before 50 mmHg and

deactivated at or before 82 mmHg.

Low Pressure Alarm Protocol (Electronic Units Only)

The low pressure alarm will be activated only when the requirements of the low pressure alarm

protocol have been met by a sequence of low pressure signals. The system is designed to detect low

pressure fault conditions without responding to spurious signals due to patient movement, mattress

cell crossover, short term tube disconnection etc.

In order to generate a low pressure alarm the system must detect three low pressure switch closure,

of 15 seconds duration each, within a 25 minute period. There will be a 2 minute lockout between the

first and second switch closures as well as between second and third switch closures. The lockout

period is to allow temporary disconnection of tubing.

In addition to the above, a wait period of 25 minutes is allowed on start up. During this time the low

pressure alarm is inhibited to allow inflation of the mattress to operating pressure. If, during this wait

period, the low pressure switch is activated (i.e., the system is up to pressure), the wait period will be

terminated 1 minute later, and normal protocol is obeyed thereafter.

Power Failure Alarm (Electronic Units Only)

In the event of a power failure, the red POWER FAIL indicator will flash in combination with an

audible warning which increases with time.

If the power supply is restored, the audible alarm will stop, but the indicator will remain illuminated

(continuously) until the system is reset. Resetting, by switching the pump to ‘Stand by’ and then back

to ‘Run’, will clear all alarm indications.

Chap 1 Issue 2

Page 6 SER0004 Nov 2001

Mini Pump Service Manual Introduction

The power failure alarm is initiated by the removal of the mains/power supply from the unit for a

period of more than 5 seconds, by a means other than operation of the ‘Run/Standby’ switch. A drop

in the supply voltage below the minimum supply specification will be interpreted as a supply failure. If

power is restored within 5 seconds, no alarm is given and normal operation is resumed.

A battery backup supply provides power to operate the visual and audible alarm.

Battery Management (Electronic Units Only)

On switching the pump to ‘Run’, the processor automatically initiates a standard charge sequence

(3 mA) for a predetermined period. On completion of the standard charge period, a trickle charge

(0.9 mA) will be applied to the battery for the remainder of the operating period.

When discharging during a power failure alarm, the battery supply will be shut down in a controlled

manner if the terminal voltage falls below 4.6 V before the alarm duration has expired.

Issue 2 Chap 1

Nov 2001 SER0004 Page 7

Introduction Mini Pump Service Manual

Chap 1 Issue 2

Page 8 SER0004 Nov 2001

Mini Pump Service Manual Maintenance

CHAPTER 2

MAINTENANCE

1 Pump Maintenance Checks

If any parts are found to be damaged they must be replaced in accordance with Chapter 3, Pump

Repair.

1.1 Visually inspect the following for damage, wear and potential faults:

Note : If any parts require repairing or replacing then refer to the Huntleigh Healthcare service

manual.

1.1.1 Check outer casings for damage.

1.1.2 Functionally check switches and control knobs.

1.1.3 Ensure hanging brackets are secure and located.

1.1.4 Check outlet ports and connecting points for damage.

1.1.5 Ensure feet are secure and present.

1.1.6 Check fuses are satisfactory.

1.1.7 If a gauge is fitted ensure the glass is not cracked or damaged.

1.1.8 Check that there is no damage to the mains/power connector if fitted.

1.1.9 Check labels are present, located correctly and legible.

1.1.10 Ensure LED’s are not cracked.

1.2 Remove the compressor lid (Refer to Chap. 3, Section 22) and visually inspect the following for

damage, wear, and potential faults:

Note : If any parts require repairing or replacing then refer to Chap 3, Pump Repair.

1.2.1 Coil/’E’ stack assembly.

1.2.2 Elbows and connectors.

1.2.3 Bellows.

1.2.4 Security of compressor.

1.2.5 Integrity of filters and gaskets.

1.2.6 Valve body assembly.

1.2.7 Armature blades.

1.2.8 Pivot points.

1.2.9 Silencer bags.

1.2.10 Valve shuttle assembly.

Issue 2 Chap 2

Nov 2001 SER0004 Page 1

Maintenance Mini Pump Service Manual

Once the compressor has been visually inspected connect to a power supply and run, this is to

ensure the compressor is working and that there is flow/pressure at the outlet port of the pump.

Check for any excessive noise and vibration.

2 Pump Soak/Break-in Times

2.1 A pump must be soaked/broken-in for the following reasons:

Note : Soaking/breaking-in consists of running the pump with the outlet ports blocked.

To ensure that the pump is at normal running temperature prior to pneumatic performance

•

tests being carried out.

To stress test major/critical parts which have been replaced or repaired.

•

2.2 All pumps should be soaked/broken-in for a period of 30 to 60 minutes prior to any pneumatic

performance test being carried out. This is because the compressor bellows need to warm up

to reach normal output.

2.3 If any of the following major/critical components have been replaced or repaired, then it is

recommended that the pump be soaked/broken-in for 12 hours prior to being tested:

Valve body.

•

Silencer Bag.

•

Printed Circuit Boards (PCB) if applicable.

•

Compressor.

•

Rotary Valve Assembly.

•

3 Pump Service

A pump should be serviced every 12 months. To carry out a service on the pump, do the following:

3.1 Carry out the Pump Maintenance Checks (Section 1).

3.2 Replace the following components:

3.2.1 Silencer bag (Refer to Chapter 3, Section 22).

3.2.2 Pivot points (Refer to Chapter 3, Section 24).

3.2.3 Bellow assemblies (Refer to Chapter 3, Section 23).

3.2.4 Valve bodies (Refer to Chapter 3, Section 25).

3.2.5 Compressor filter (Refer to Chapter 3, Section 12).

3.2.6 Compressor gasket (Refer to Chapter 3, Section 22).

3.2.7 Pump case filter (Refer to Chapter 3, Section 4).

3.2.8 AV mounts (Refer to Chapter 3, Section 14 - new style, Section16 - old style).

3.2.9 Internal rechargeable battery (Refer to Chapter 3, Section 31).

Chap 2 Issue 2

Page 2 SER0004 Nov 2001

Mini Pump Service Manual Maintenance

3.3 Reassemble the pump and soak/break-in for the recommended time (Refer to Section 2).

3.4 Carry out a flow, pressure and function test on the pump in accordance with Chapter 5.

3.5 Carry out electrical tests on the pump in accordance with Chapter 5.

Issue 2 Chap 2

Nov 2001 SER0004 Page 3

Maintenance Mini Pump Service Manual

Chap 2 Issue 2

Page 4 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

CHAPTER 3

PUMP REPAIR

1 General

This chapter details repair procedures for the range of pump units listed in Chapter 1, Page 1,

Table 1. All repairs should be carried out by Huntleigh approved service personnel.

After carrying out a service or any repairs, the pump must be soak tested/broken-in for the

recommended time (Refer to Chapter 2) and tested for serviceability. The table below defines the test

requirements which must be carried out following certain repairs:

To carry out a flow, pressure and function test on the pump refer to Chapter 5.

To carry out the electrical tests on the pump refer to Chapter 5.

Table 5- Repair to Testing Requirements

Components / Assemblies

Compressor Yes Yes

Pressure Control Yes Yes

Rotors & Stators Yes Yes

Silencer Bag Yes No

Coils Yes Yes

Elbows & Connectors Yes No

AV Mounts Yes Yes

PCB Yes Yes

Front Casing Yes No

Rear Casing No No

Battery No Yes

Switches No Yes

Fuse No Yes

Flow/Pressure & Function

Test

Electrical Safety

Electrical Connectors No Yes

Mains/Power Lead No Yes

Issue 2 Chap 3

Nov 2001 SER0004 Page 1

Pump Repair Mini Pump Service Manual

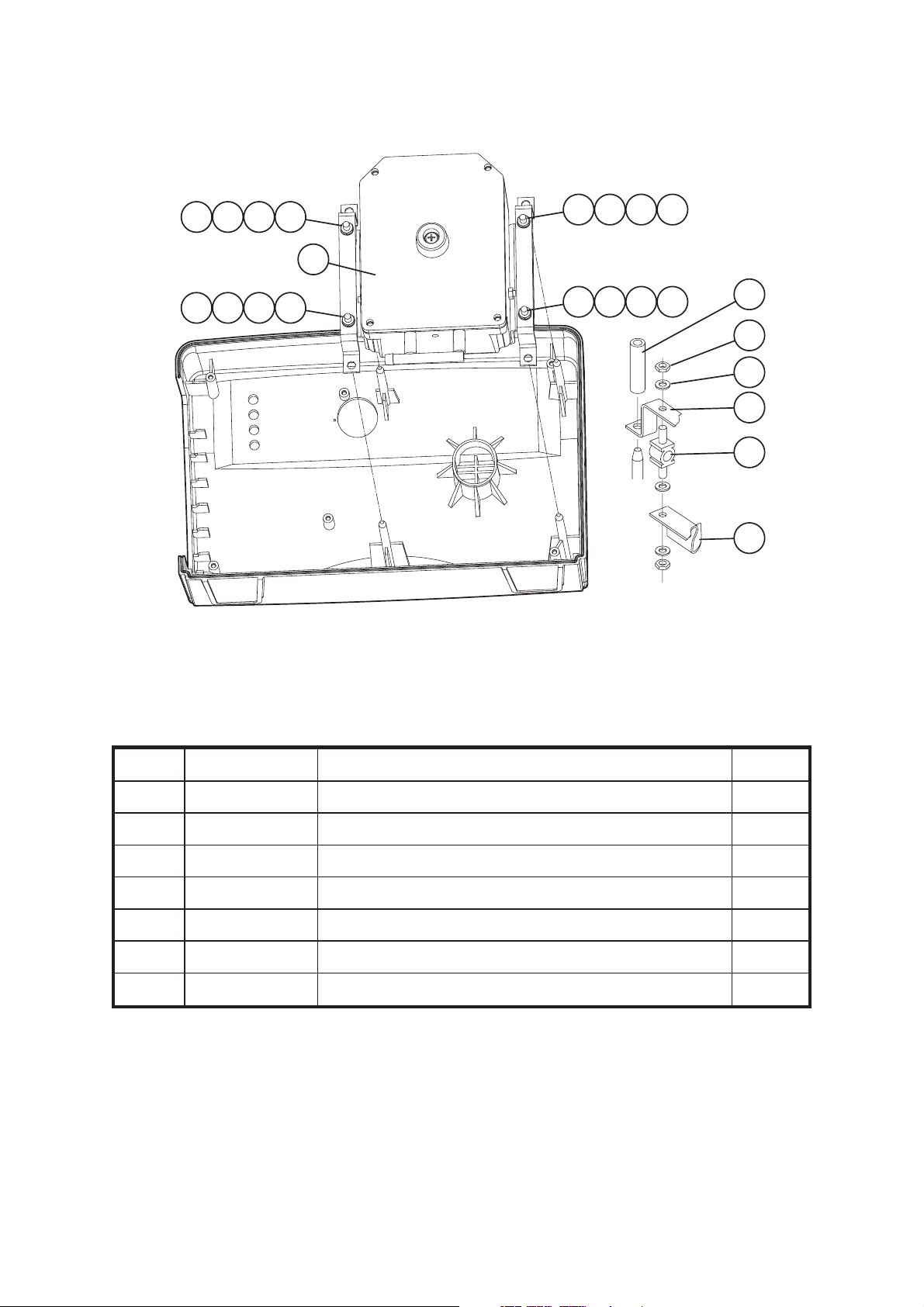

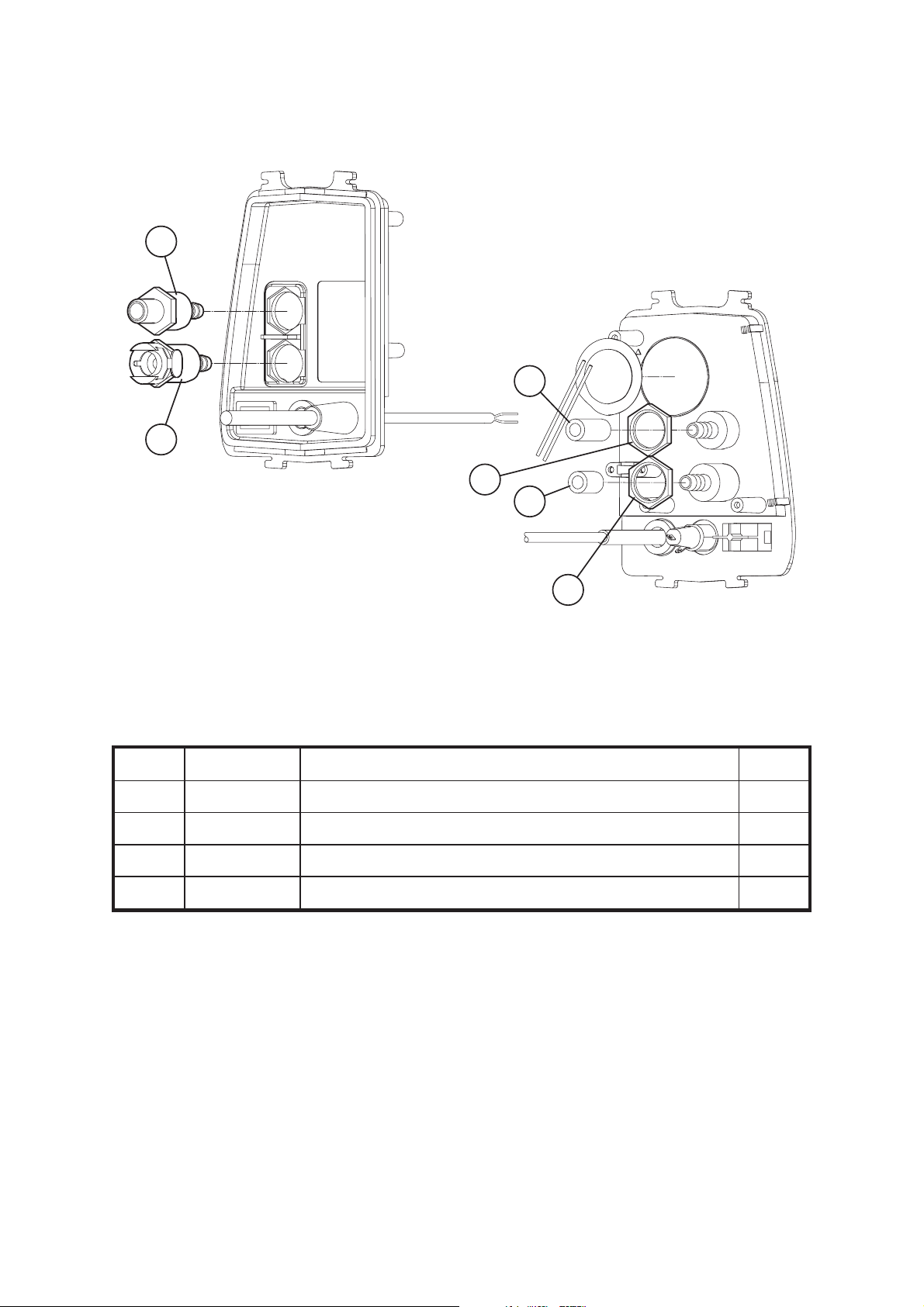

20

10

30

Pin (if fitted)

40

Figure 2 - Removing the Control Knob

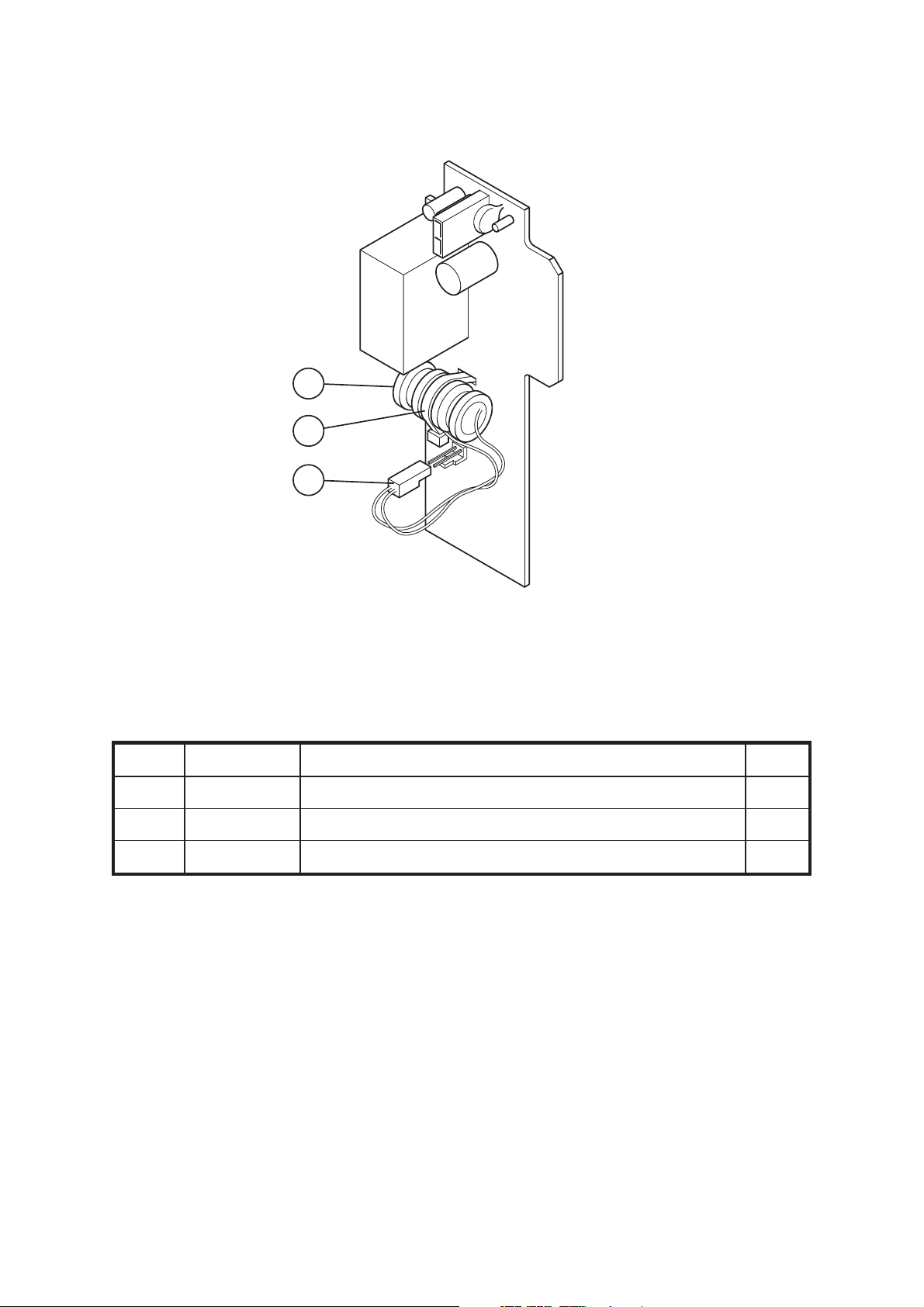

Table 6 - Control Knob Part List

Item Part Number Description Qty

10 500484 Control Knob (MK2) 1

20 500304 Knob Arbour 1

30 500318 Pin (if fitted) 1

40 500316 Front Case 1

Note : The obsolete MK1 control knobs are fully interchangeable with the MK2 control knobs. If the

MK1 control knob needs replecing, replace it with the MK2 version.

Chap 3 Issue 2

Page 2 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

2 Removing the Pressure Control Knob

Note : Removing the control knob avoids possible damage and allows the pump to sit on a flat

surface without rocking.

2.1 Locate the slot at the rear of knob (Fig 2, Item 10) and inserta3mmflatpoint screwdriver.

2.2 Lever the screwdriver upward to lift the knob off the three retaining prongs.

3 Installing the Pressure Control Knob

Note : When installing the pressure control knob, ensure that the small prong sits in its own housing.

Then, the two larger prongs will line up correctly.

Aura (Pin fitted)

Turn knob arbour clockwise to it’s full extent. Fit control knob in the position shown below.

ENSURE

90° MOVEMENT

SMALL PRONG

AlphaRelief / AlphaBed / AlphaCare / AlphaTrancell ALT10 (No pin fitted)

Turn knob arbour counter-clockwise to it’s full extent. Fit control knob in the position shown below.

ENSURE

SMALL PRONG

270° MOVEMENT

AlphaXcell / AlphaTrancell ALT01-09 (Pin fitted)

Turn knob arbour counter-clockwise to it’s full extent. Fit control knob in the position shown below.

ENSURE

SMALL PRONG

180° MOVEMENT

3.1 Carefully position the knob (Fig 2, Item 10) so that the prongs are correctly aligned with the

recesses in the knob arbour (Fig 2, Item 20)

3.2 Press the knob into place on the arbour and ensure that it is correctly seated.

Issue 2 Chap 3

Nov 2001 SER0004 Page 3

Pump Repair Mini Pump Service Manual

10

50

20

40

30

Figure 3 - Removing and Replacing the Pump Filter

Table 7 - Pump Filter Part List

Item Part Number Description Qty

10 500340 Felt Filter 1

20 500327 Filter Plate 1

30 500317 Rear Case 1

40 FAS223 Pan Head Screw PT 3 Dia x 10 Pozi 1

50 FAS225 Pan Head Screw PT 3 Dia. x 16 Pozi 4

Chap 3 Issue 2

Page 4 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

4 Disassembling the Pump Filter

4.1 Remove the centre screw (Fig 3, Item 40) retaining the filter plate (Fig 3, Item 20) in the rear

case (Fig 3, Item 30).

4.2 Carefully remove the filter plate and felt filter (Fig 3, Item 10) from the rear case. Discard the

old filter.

5 Assembling the Pump Filter

5.1 Install a new filter (Fig 3, Item 10) in the filter plate (Fig 3, Item 20) ensuring that the curved

edge is at the top.

5.2 Ensure that the filter is correctly positioned over the boss in the filter plate then fit the filter plate

to the rear case (Fig 3, Item 30) and secure with the screw (Fig 3, Item 40).

6 Disassembling the Rear Case

Note : It is necessary to remove the rear case from the front case to allow access to all internal pump

connections.

6.1 Remove the front panel control knob (Refer to Page 3, Section 2).

6.2 Place the pump on a flat, clean surface with the case front face down.

6.3 Unscrew and remove the four corner screws (Fig 3, Item 50).

6.4 Carefully remove the rear case assembly (Fig 3, Item 30) from the case front.

7 Assembling the Rear Case

7.1 Assembly of the rear case is in the reverse order of disassembly.

Issue 2 Chap 3

Nov 2001 SER0004 Page 5

Pump Repair Mini Pump Service Manual

10

50

20

30

40

Figure 4 - Replacing the New Style Bed Hook

Table 8 - New Style Bed Hook Part List

Item Part Number Description Qty

10 500495 Bed Hook (New Style) 1

20 500496 Hook Plate (Left Hand) 1

30 500497 Hook Plate (Right Hand) 1

40 FAS223 Pan Head screw PT 3 Dia. x 10 8

50 500381 Rubber foot 8

Chap 3 Issue 2

Page 6 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

8 Disassembling the New Style Bed Hook

8.1 Remove the pressure control knob from the pump (Refer to Page 3, Section 2).

8.2 Remove the pump rear case (Refer to Page 5, Section 6).

Note : The bed hook brackets are right and left handed.

8.3 Hold a hook plate (Fig 4, Item 20 or 30) in position and remove the four securing screws (Fig 4,

Item 40) from the inside of the pump rear case. Release the hook plate from the rear case and

lift clear.

8.4 If necessary repeat Section 8.3 to remove the other hook plate and bed hook (Fig 4, Item 10).

9 Installing the New Style Bed Hook

Note : Replacement Old Style Bed Hooks are no longer available. The Old Style Rear Case

assembly will not accommodate the New Style Bed Hook so where Old Style Bed Hooks must

be replaced it will be necessary to obtain all the parts listed in Table 8, plus the rear case (Item

30 in Table 6).

Note : For step 9.2, remember to place the left-hand bracket on the right and the right-hand bracket

on the left, since their relative positions will be reversed when they are presented to the rear

case assembly.

9.1 Assembly of the new Pump Filter is in the reverse order of disassembly. Make sure the slots in

the Filter Housing Plates (Fig 4, Item 20) are uppermost in the positions shown in Fig 4.

9.2 Lay the left-hand (Fig 4, Item 20) and the right-hand (Fig 4, Item 30) brackets on a hard flat

surface with their rubber pads face down and their shaped heads pointing inward.

9.3 Ensure the bed hook (Fig 4, Item 10) is correctly placed to the left-hand and right-hand slots

where the coating has been removed. Firmly press home the bed hook until it clicks into place.

9.4 Lay the rear case assembly, on a hard flat surface, with its back uppermost. Turn over the bed

hook subassembly and place into the rear case assembly.

9.5 Position one bracket and press it firmly until it clicks into place. Repeat this process for the

other bracket.

9.6 Turn over the rear case assembly and fit four securing screws to each bracket.

9.7 Assemble the rear case to the pump (Refer to Page 5, Section 7).

9.8 Install the pressure control knob (Refer to Page 3, Section 3).

Issue 2 Chap 3

Nov 2001 SER0004 Page 7

Pump Repair Mini Pump Service Manual

10

30

20

30

40

Figure 5 - Replacing the Old Style Bed Hooks

Chap 3 Issue 2

Page 8 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

Table 9 - Old Style Bed Hook Part List

Item Part Number Description Qty

10 N/A Bed Hook - Left Hand 1

20 N/A Bed Hook - Right Hand 1

30 N/A Hook Plate 1

40 N/A Pan Head screw PT 3 Dia. x 10 Pozi 6

Note :The old bed hook bracket assemblies are left and right handed. Replacements are no longer

available.

10 Removing the Old Style Bed Hook

10.1 Remove the pressure control knob from the pump (Refer to Page 3, Section 2).

10.2 Remove the pump rear case (Refer to Page 5, Section 6).

10.3 Hold a hook plate (Fig 5, Item 30) in position and remove the three securing screws (Fig 5,

Item 40) from the inside of the rear case.

10.4 Carefully remove the hook plate and its bed hook (Fig 5, Item 10 or 20).

10.5 Repeat Section 10.3 and 10.4 for the other hook plate and bed hook if required.

Note : The above procedure will not be necessary when changing the old bed hooks for the new bed

hook which needs the new rear case assembly.

11 Installing the Old Style Bed Hook

11.1 When refitting the old bed hook brackets, replacement is the reversal of the above procedure.

11.2 Ensure correct orientation of the left and right-handed assemblies. (The spring on the right

hand assembly is colour coded red).

11.3 Position the hook and spring assembly on the rear case, install the hook plate and hold it in

place while inserting the three securing screws from the inside of the rear case.

11.4 Assemble the rear case to the pump (Refer to Page 5, Section 7).

11.5 Install the pressure control knob (Refer to Page 3, Section 3).

Issue 2 Chap 3

Nov 2001 SER0004 Page 9

Pump Repair Mini Pump Service Manual

10

20

30

40

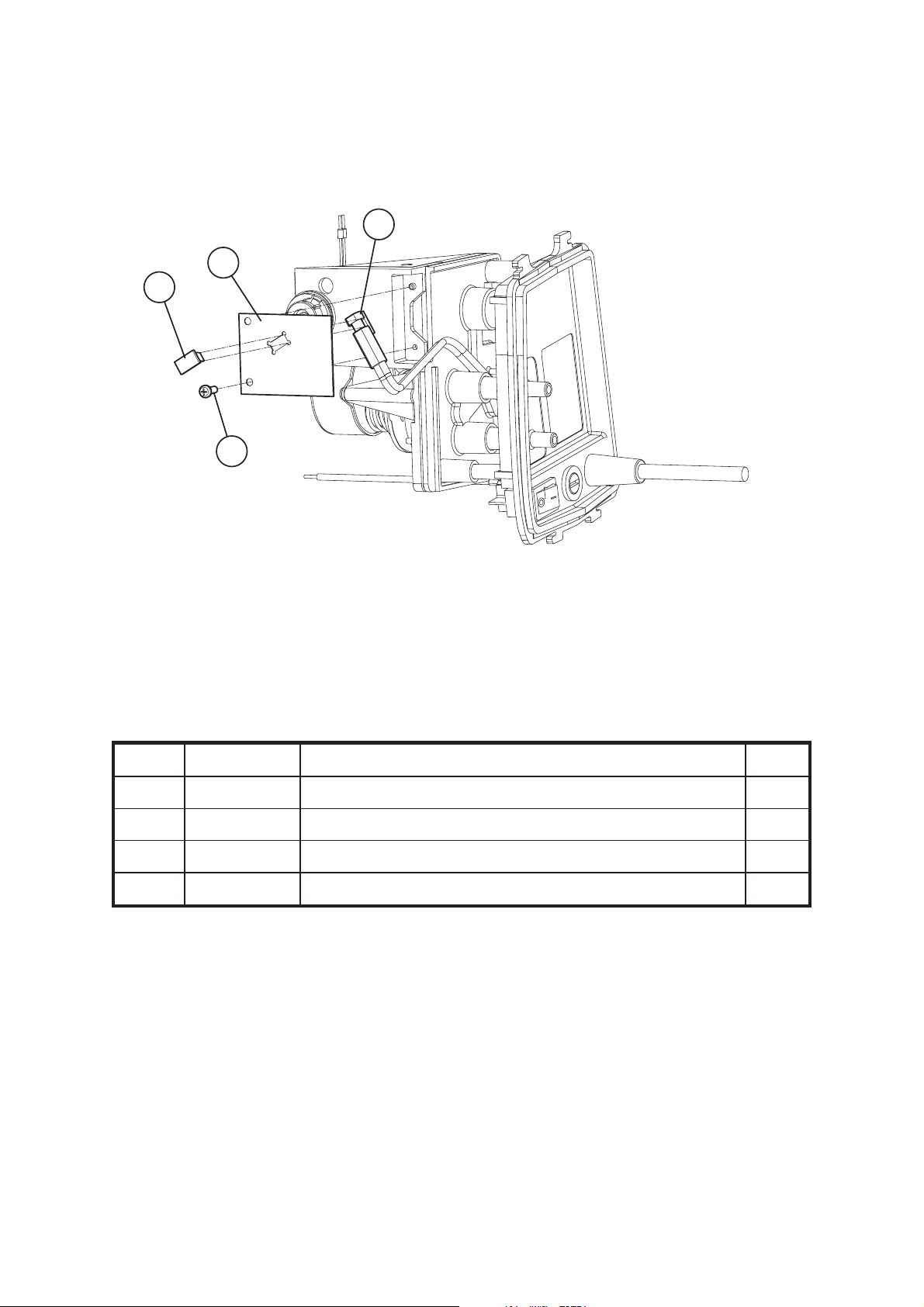

Figure 6 - Replacing the Compressor Filter Assembly

Table 10 - Compressor Filter Assembly Part List

Item Part Number Description Qty

10 502003 Compressor Assy 230V 50Hz 11K/T 1

502002 Compressor Assy 110V 60Hz 5K/T (USA) 1

502007 Compressor Assy 100V 50/60Hz 4.5K/T (Japan) 1

20 500320 ‘F’ Tube Connector REF

30 500410 Filter Retaining Clip 1

40 500417 Inlet Filter 1

Chap 3 Issue 2

Page 10 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

12 Removing the Compressor Inlet Filter

12.1 Remove the pressure control knob from the pump (Refer to Page 3, Section 2).

12.2 Remove the rear case assembly (Refer to Page 5, Section 6).

12.3 Carefully pull the filter retaining clip (Fig 6, Item 30) from the ‘F’ tube connector (Fig 6, Item 20).

12.4 Remove and discard the old inlet filter (Fig 6, Item 40).

13 Installing the Compressor Inlet Filter

13.1 Locate a new inlet filter (Fig 6, Item 40) over the air intake hole in the case of the compressor

assembly (Fig 6, Item 10).

13.2 Carefully reposition the filter retaining Clip (Fig 6, Item 30) on the ‘F’ tube connector (Fig 6,

Item 20) to retain the inlet filter (Fig 6, Item 40). Make sure the clip is fitted with the longer arm

downward if appropriate.

13.3 Assemble the rear case to the pump (Refer to Page 5, Section 7).

13.4 Install the pressure control knob from the pump (Refer to Page 3, Section 3).

Issue 2 Chap 3

Nov 2001 SER0004 Page 11

Pump Repair Mini Pump Service Manual

20 20

10

20 20

30

Figure 7 - Replacing the New Style AV Mounts

Table 11 - New Style AV Mounts Part List

Item Part Number Description Qty

10 500124 Compressor Mounting Bracket 1

20 500416 AV Mount 4

30 N/A Mounting Pins 4

Chap 3 Issue 2

Page 12 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

14 Removing the New Style AV Mounts

14.1 Remove the pressure control knob from the pump (Refer to Page 3, Section 2).

14.2 Remove the rear case assembly (Refer to Page 5, Section 6).

14.3 Carefully lift the compressor, mounting bracket (Fig 7, Item 10) and AV mounts (Fig 7, Item 20)

from the mounting pins (Fig 7, Item 30).

14.4 Remove the AV mounts from the mounting bracket and discard them.

15 Replacing the New Style AV Mounts

15.1 Fit new AV mounts (Fig 7, Item 20) of the same type to the mounting bracket (Fig 7, Item 10).

15.2 Carefully fit the compressor, mounting bracket and AV mounts to the mounting pins (Fig 7,

Item 30) in the pump case. Ensure that all four AV mounts are correctly located on the

mounting pins.

15.3 Assemble the rear case to the pump (Refer to Page 5, Section 7).

15.4 Assemble the pressure control knob to the pump (Refer to Page 3, Section 3).

Issue 2 Chap 3

Nov 2001 SER0004 Page 13

Pump Repair Mini Pump Service Manual

10

20

30

40

50

10

20

30

40

40

30

10

20

Figure 8 - Replacing the Old Style AV Mounts

Table 12 - Old Style AV Mounts Part List

10

20

30

40

70

30

40

10

20

60

Item Part Number Description Qty

10 N/A AV Mounting Bracket 2

20 198375 AV Mount 4

30 N/A AV Mount Nut 8

40 N/A Washer 12

50 Ref Table 14 Compressor 1

60 N/A Compressor Mounting Bracket (Part) 1

70 N/A Spacers 4

Chap 3 Issue 2

Page 14 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

16 Removing the Old Style AV Mounts

Note : Replacements are not available for the old style AV mounts.

16.1 Remove the pressure control knob from the pump (Refer to Page 3, Section 2).

16.2 Remove the rear case assembly (Refer to Page 5, Section 6).

16.3 Remove the securing spacers (Fig 8 Item 70) and carefully lift the compressor (Fig 8, Item 50)

and AV bracket assembly (Fig 8, Items 10, 20, 30, 40, 60) from the mountings.

16.4 Release the to AV mount nuts (Fig 8, Item 30) and washers (Fig 8, Item 40) and remove the

two AV mounting brackets (Fig 8, Item 10) from the AV mounts (Fig 8, Item 20).

16.5 Release the bottom AV mount nuts and washers and remove the four AV mounts from the

compressor mounting bracket (Fig 8, Item 60).

17 Installing the Old Style AV Mounts

17.1 Fit four replacement AV mounts (Fig 8, Item 20) to the compressor mounting bracket (Fig 8,

Item 60) and secure with washers (Fig 8, Item 40) and nuts (Fig 8, Item 30).

17.2 Fit the two AV mounting brackets (Fig 8, Item 10) to the AV mounts and secure with washers

and nuts.

17.3 Carefully fit the compressor (Fig 8, Item 50) and AV bracket assembly (Fig 8, Items 10, 20, 30,

40, 60) to the mountings in the pump case and fit securing spacers (Fig 8 Item 70).

17.4 Assemble the rear case to the pump (Refer to Page 5, Section 7).

17.5 Install the pressure control knob (Refer to Page 3, Section 3).

Issue 2 Chap 3

Nov 2001 SER0004 Page 15

Pump Repair Mini Pump Service Manual

10

40

50

50

30

60

20

40

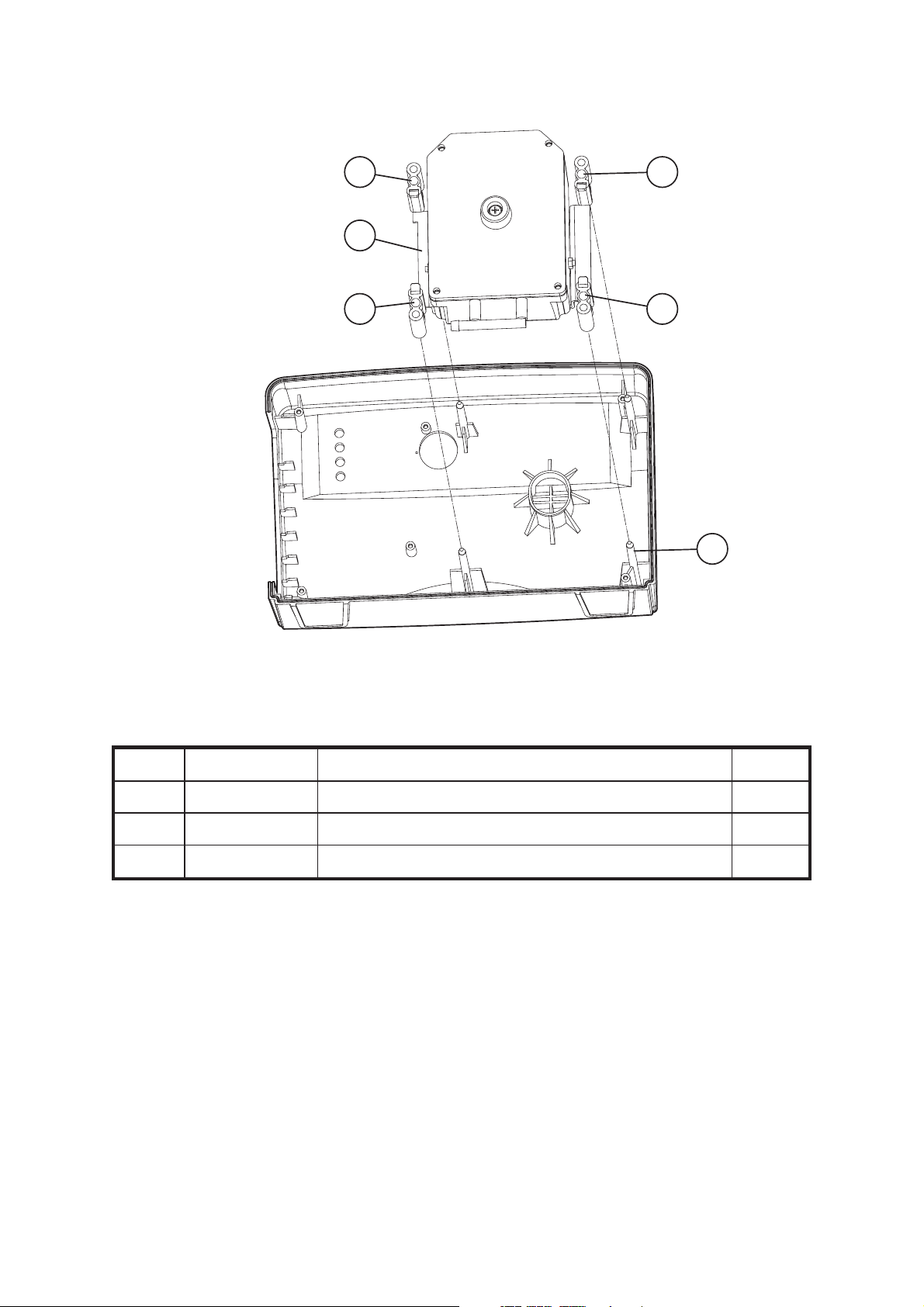

Figure 9 - Replacing Mounting Brackets and Bump Stops

Chap 3 Issue 2

Page 16 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

Table 13 - Compressor Mounting Brackets and Bump Stops Part List

Item Part Number Description Qty

10 165310 Upper Bump Stop 1

20 165310 Lower Bump Stop 1

30 500124 Compressor Mounting Bracket (New Style) 1

N/A Compressor Mounting Bracket (Old Style) 1

40 FAS160 Washer M4 Plain 2

50 FAS051 Screw Pan Head Pozi M4x6mm 2

60 FAS095 Screw Pan Head Pozi M4 x 10 mm 3

18 Removing the Compressor Mounting Bracket

18.1 Remove the compressor/AV bracket assembly from the pump case and disassemble AV

mounts as described on Page 13, Section 14 (new style AV mounts) or Page 15, Section 16

(old style AV mounts. Section 16.4 should be omitted if old style AV mounts are not to be

replaced.

Note : Figure 7 Illustrates the new style AV mount system. Compressor mounting bracket to

compressor assembly methods are the same for both old and new style AV mount systems.

18.2 Remove screw, washer and lower bump stop (Fig 9, Items 50, 40, 20) from the compressor

mounting bracket (Fig 9, Item 30).

18.3 Remove three screws (Fig 9, Item 60) and detach the mounting bracket from the compressor.

19 Installing the Compressor Mounting Bracket

19.1 Fit replacement mounting bracket (Fig 9, Item 30) same type (if required) to the compressor.

Ensure that the four pegs are correctly located and secure the mounting bracket to the

compressor with three screws (Fig 9, Item 60).

19.2 Fit the screw, washer and lower bump stop (Fig 9, Items 50, 40, 20) to the mounting bracket.

19.3 Assemble AV mounts and fit the compressor/AV bracket assembly into the pump case as

described in Section 15 (new style AV mounts) or Section 17 (old style AV mounts). Section

17.2 may be omitted.

20 Removing the Compressor Bump Stops

20.1 Remove the compressor/AV bracket assembly from the pump case as described in Section

14.1, 14.2 and 14.3 (new style AV mounts) or Section 16.1, 16.2 and 16.3 (old style AV

mounts).

Note : Figure 7 illustrates the new style AV mount system. Bump stop to compressor and bump stop

to compressor mounting bracket assembly methods are the same for both old and new style

AV mount systems.

20.2 Remove screw, washer and upper bump stop (Fig 9, Items 50, 40, 10) from the compressor lid.

Issue 2 Chap 3

Nov 2001 SER0004 Page 17

Pump Repair Mini Pump Service Manual

20.3 Remove screw, washer and lower bump stop (Fig 9, Items 50, 40, 20) from the compressor

mounting bracket.

21 Installing the Compressor Bump Stops

21.1 Fit screw, washer and replacement upper bump stop (Fig 9, Items 50, 40, 10) to the

compressor lid.

21.2 Fit screw, washer and replacement lower bump stop (Fig 9, Items 50, 40, 10) to the

compressor mounting bracket.

21.3 Refit the compressor/AV bracket assembly to the pump case as described in Page 13, Section

15.2, 15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style

AV mounts).

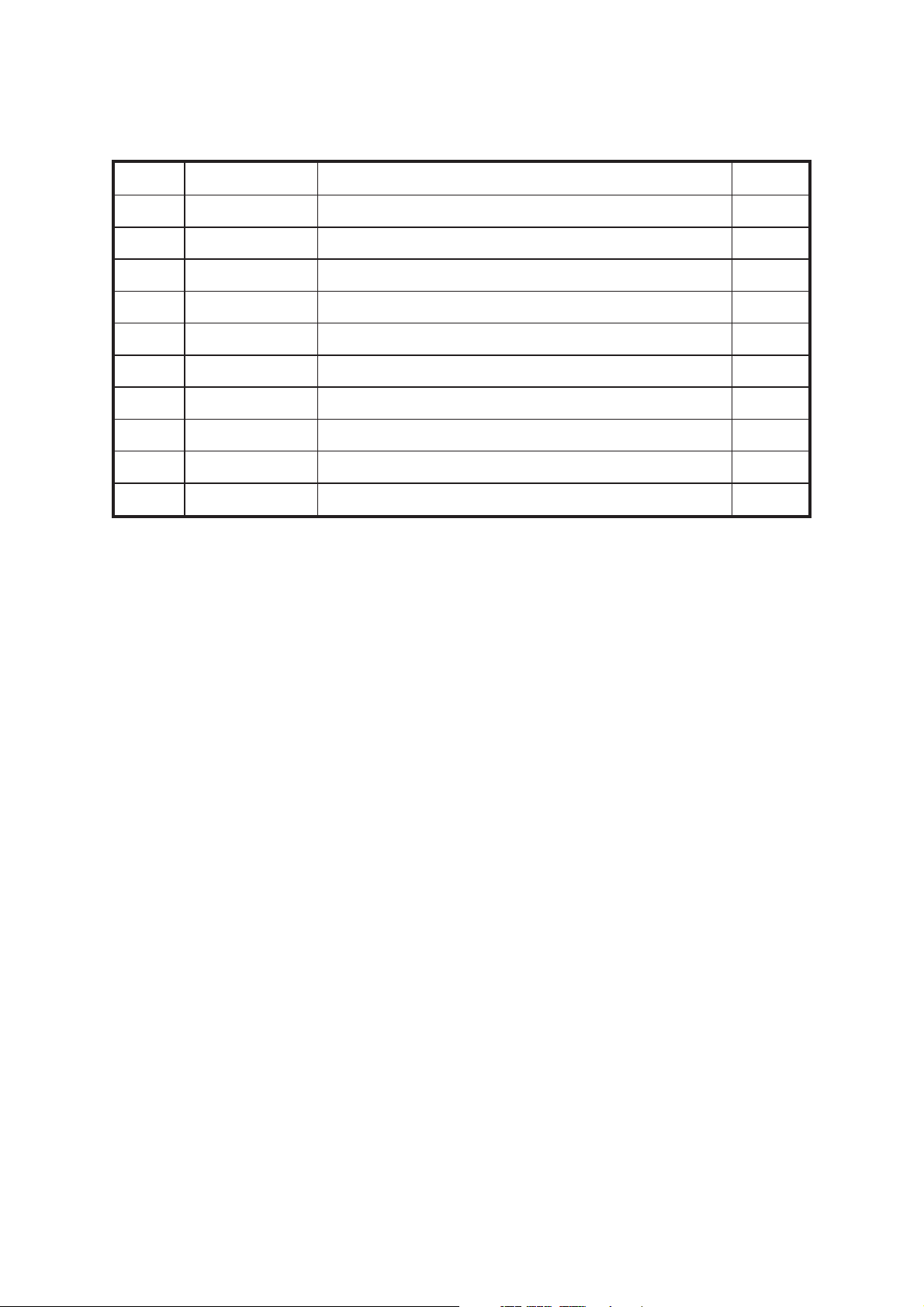

30

20

60

40

10

70

50

80

Figure 10 - Compressor Silencer Bag

Chap 3 Issue 2

Page 18 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

Table 14 - Compressor Silencer Bag Part List

Item Part Number Description Qty

10 502003 Compressor Assy 230V 50Hz 11K/T 1

502002 Compressor Assy 110V 60Hz 5K/T (USA)

502007 Compressor Assy 100V 50/60Hz 4.5K/T (Japan)

20 502301 Compressor Lid 1

30 FAS054 Screw Countersunk Pozi M4 x 12 mm 4

40 BP032 Compressor Gasket 1

50 502055 Silencer Bag 1

60 500320 ‘F’ Tube Connector 1

70 N/A Silencer Bag Outlet Tubes REF

80 N/A Silencer Bag Inlet Tubes REF

22 Replacing the Compressor Silencer Bag

22.1 Remove the compressor/AV bracket assembly from the pump case (Refer to Page 13, Section

14.1, 14.2 and 14.3 (new style AV mounts) or Page 15, Section 16.1, 16.2 and 16.3 (old style

AV mounts)).

22.2 Remove four screws (Fig 10, Item 30) and carefully lift off the compressor lid (Fig 10, Item 20)

and gasket (Fig 10, Item 40) from the compressor assembly (Fig 10, Item 10). Discard the

gasket.

22.3 Disconnect the outlet tubes (Fig 10, Item 70) of the silencer bag (Fig 10, Item 50) from the ‘F’

tube connector (Fig 10, Item 60).

22.4 Disconnect the inlet tubes (Fig 10, Item 80) of the silencer bag from the valve bodies.

22.5 Fit a new silencer bag and gasket, then replace the compressor lid by reversing operations

detailed in Section 22.4, 22.3 and 22.2.

22.6 Refit the compressor/AV bracket assembly to the pump case (Refer to Page 13, Section

15.2,15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style

AV mounts)).

Issue 2 Chap 3

Nov 2001 SER0004 Page 19

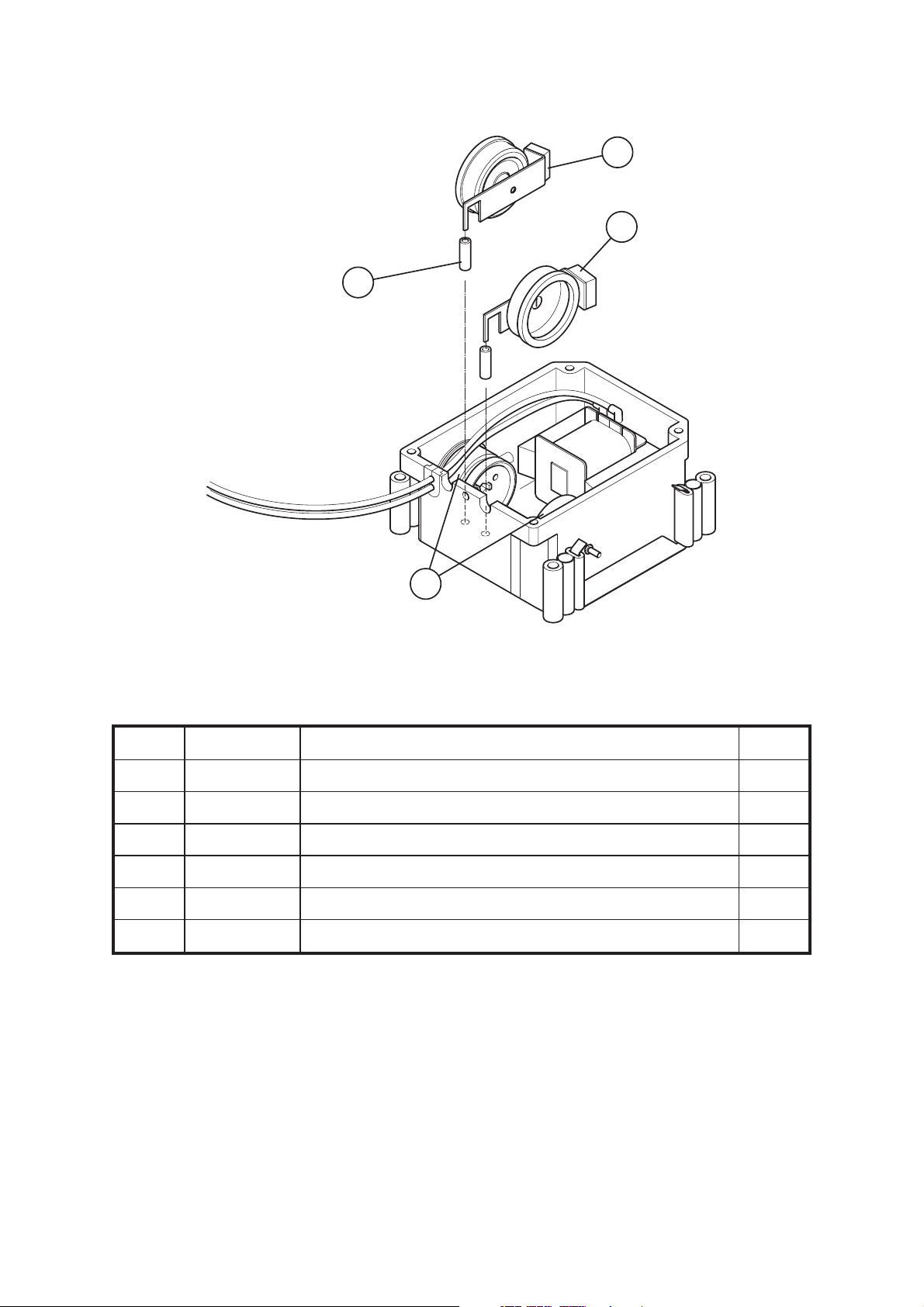

Pump Repair Mini Pump Service Manual

30

10

20

40

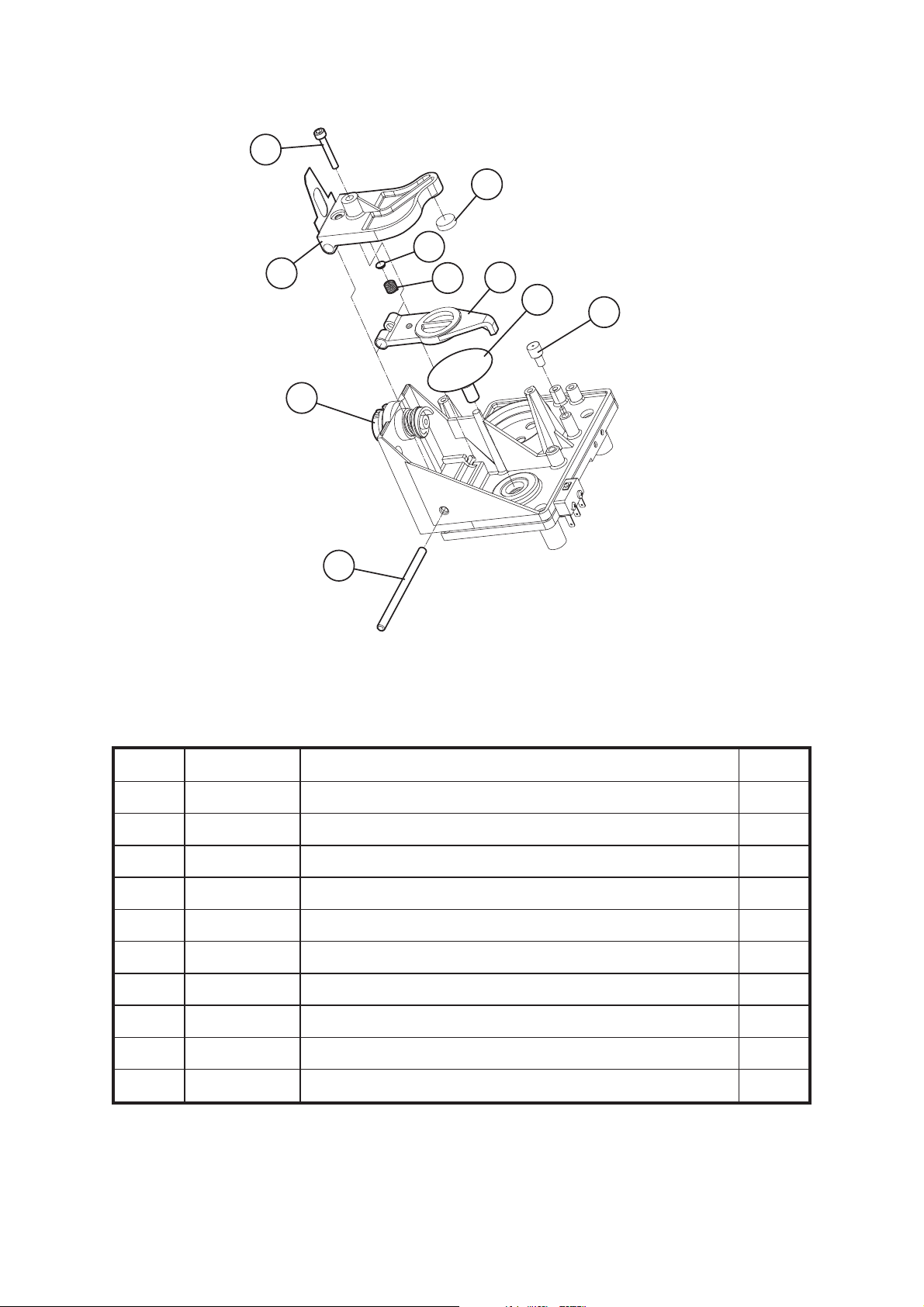

Figure 11 - Bellows Armature Assembly and Pivots

Table 15- Bellows Armature Assembly Part List

Item Part Number Description Qty

10 502054 Bellows Armature Assembly Left-Hand 230V 50Hz 1

BP215 Bellows Armature Assembly Left-Hand 110V 60Hz 1

20 502053 Bellows Armature Assembly Right-Hand 230V 50Hz 1

BP214 Bellows Armature Assembly Right-Hand 110V 60Hz 1

30 BP043 Armature Pivot 2

40 BP554 Valve Body 2

Chap 3 Issue 2

Page 20 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

23 Replacing the Bellows Armature Assemblies and Pivots

23.1 Remove/disassemble the compressor/AV bracket assembly and remove the silencer bag

(Refer to Page 19, Section 22.1, 22.2,22.3 and 22.4).

23.2 Using long nosed pliers, extract the armature blade, part of bellows armature assembly (Fig 11,

Item 10 or 20) from the armature pivot (Fig 11, Item 30)

23.3 Unclip the bellows, part of bellows armature assembly from the valve body (Fig 11, Item 40)

and lift the bellows armature assembly clear of the compressor.

23.4 Repeat 23.2 and 23.3 as required to remove the other bellows armature assembly.

23.5 Discard the old bellows armature assembly and fit a replacement of the same type by reversing

the actions carried out in Section 23.3 and 23.2.

23.6 Fit a new silencer bag and gasket, then replace the compressor lid (Refer to Page 19 and

reverse the operations carried out in Section 22.4, 22.3 and 22.2).

23.7 Refit the compressor/AV bracket assembly to the pump case (Refer to Page 13, Section 15.2,

15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style AV

mounts)).

23.8 Test the assembly. Note, in order to achieve flow/pressure performance, the new bellows may

have to be heated with a hot air gun whilst operating. This anneals the bellows permanently

and alters the pressure/flow characteristics.

Caution: The bellows will be damaged if overheated.

24 Replacing the Compressor Armature Pivots

24.1 Remove/disassemble the compressor/AV bracket assembly and remove the silencer bag

(Refer to Page 19, Section 22.1, 22.2, 22.3 and 22.4).

24.2 Extract the armature blade from the pivot (Refer to Section 23.2).

24.3 Use a sharp, pointed tool and carefully extract the pivot (Fig 11, Item 30) from the hole in the

compressor casing.

24.4 Discard old armature pivots and replace with same type. Carefully insert the new pivot into the

compressor casing using a small screwdriver to ensure the slot in the pivot is aligned to accept

the armature blade.

24.5 Fit the armature blade to the pivot reversing the actions carried out in Section 23.2.

24.6 Fit a new silencer bag and gasket, then replace the compressor lid (Refer to Page 19 and

reverse the operations carried out in Section 22.4, 22.3 and 22.2).

24.7 Refit the compressor/AV bracket assembly to the pump case (Refer to Page 13, Section 15.2,

15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style AV

mounts)).

Issue 2 Chap 3

Nov 2001 SER0004 Page 21

Pump Repair Mini Pump Service Manual

30

70

60

20

60

70

50

40

Figure 12 - Compressor Valve Bodies

Table 16 - Compressor Valve Bodies Part List

Item Part Number Description Qty

10 BP554 Valve Body Assy, Blue

2

(Each valve body contains items 20 to 70)

20 BP351 Valve Body 1

30 FAS027 Screw, Hex Head 4BA x 3/4 1

40 FAS013 4BA Full Nut 1

50 BP039 Valve Body Washer 2

60 BP037 Valve Flap 2

70 BP038 Valve Flap Securing Pad 2

Chap 3 Issue 2

Page 22 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

25 Replacing the Compressor Valve Bodies

25.1 Remove/disassemble the compressor/AV bracket assembly and remove the silencer bag

(Refer to Page 19, Section 22.1, 22.2, 22.3 and 22.4).

25.2 Unclip the bellows, part of bellows armature assembly from the valve body (Refer to Page 20,

Fig 11, Items 10 or 20 and 40).

25.3 Unscrew and remove the securing nut (Fig12, Item 40) on the side of the compressor housing.

25.4 Remove the valve body (Fig 12, Item 20) and Valve body washers (Fig 12, Item 50).

25.5 Remove the valve flap securing pads and the valve flaps (Fig 12, Items 70 and 60)

25.6 Discard the old valve body and replace with the same type.

25.7 Repeat Sections 25.3 to 25.6 as necessary to replace the other valve body.

25.8 When replacing the valve flaps and valve flap securing pads, make sure that the valve flap sits

flat over the hole in the valve body and the valve securing pad is pushed fully on to the lug.

25.9 Position the replacement valve body and secure with screw (Fig 12, Item 20) and nut. Fit the

bellows to the valve body.

25.10 Fit a new silencer bag and gasket, then replace the compressor lid (Refer to Page 19 and

reverse the operations carried out in Section 22.4, 22.3 and 22.2).

25.11 Refit the compressor/AV bracket assembly to the pump case (Refer to Page 13, Section 15.2,

15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style AV

mounts)).

Issue 2 Chap 3

Nov 2001 SER0004 Page 23

Pump Repair Mini Pump Service Manual

10

50

20

30

40

60

Figure 13 - ‘E’ Stack and Coil Assembly

Table 17 - ‘E’ STACK and Coil Assembly Part List

Item Part Number Description Qty

10 BP028 ‘E’ Stack 1

20 FAS048 Pan Head Screw M3 x 25 mm Pozi 2

30 FAS002 Washer - 6BA Anti-Vib. 2

40 502050 Coil Assembly 230V 50Hz (black/white leads) 1

502062 Coil Assembly 110V 60Hz (grey leads) 1

BP275 Coil Assembly 100V 50/60Hz (blue leads) 1

50 165303 Grommet 1

60 502304 Compressor Case 1

Chap 3 Issue 2

Page 24 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

26 Replacing the ‘E’ Stack Assembly

Note : After doing work in either Section 26 or 27 the pressure/flow characteristics can be altered by

moving the coil assembly/’E’ stack nearer or further from the armature magnets. This can be

done by adjusting screws (Fig 13, Item 20). Ensure the screws are tightened afterwards.

26.1 Remove/disassemble the compressor/AV bracket assembly and remove the silencer bag

(Refer to Page 19, Section 22.1, 22.2, 22.3 and 22.4).

26.2 Unscrew and remove the two screws and anti-vibration washers (Fig 13, Items 20 and 30)

which secure the ‘E’ stack/coil assembly (Fig 13, Items 10 and 40).

26.3 Withdraw the ‘E’ stack/coil assembly from the compressor case as far as the electrical wires will

allow.

26.4 Carefully remove the ‘E’ stack from the coil assembly.

26.5 Replace the ‘E’ stack by reversing the operations carried out in Section 26.4, 26.3 and 26.2.

26.6 Fit a new silencer bag and gasket, then replace the compressor lid (Refer to Page 19 and

reverse the operations carried out in Section 22.4, 22.3 and 22.2).

26.7 Refit the compressor/AV bracket assembly to the pump case (Refer to Page 13, Section 15.2,

15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style AV

mounts)).

27 Replacing the Coil Assembly

27.1 Remove/disassemble the compressor/AV bracket assembly and remove the silencer bag

(Refer to Page 19, Section 22.1, 22.2, 22.3 and 22.4).

27.2 Remove the ‘E’ stack/coil assembly as described in Section 26.2 and 26.3.

27.3 Disconnect the compressor electrical wires from the terminal block. Carefully cut the cable ties

from the pneumatic tubing/cable loom as required.

27.4 Feed the compressor electrical wires through the compressor case cable grommet (Fig 13,

Item 50).

27.5 Remove the ‘E’ stack/coil assembly from the compressor case (Fig 13, Item 60) and carefully

separate the coil from the ‘E’ stack.

27.6 Replace the coil assembly by reversing the operations carried out in Section 27.5, 27.4, 27.3

and 27.2; fit new cable ties where required.

27.7 Fit a new silencer bag and gasket, then replace the compressor lid (Refer to Page 19 and

reverse the operations carried out in Section 22.4, 22.3 and 22.2).

27.8 Refit the compressor/AV bracket assembly to the pump case (Refer to Page 13, Section 15.2,

15.3 and 15.4 (new style AV mounts) or Page 15, Section 17.3, 17.4 and 17.5 (old style AV

mounts)).

28 Replacing the Compressor Assembly

28.1 Disconnect the compressor electrical wires as described in Section 27.3.

Issue 2 Chap 3

Nov 2001 SER0004 Page 25

Pump Repair Mini Pump Service Manual

28.2 Remove the compressor air inlet filter and clip from the ‘F’ tube connector, then disconnect the

‘F’ tube connector from the silencer bag outlet tubes (Refer to Page 11, Section 12.1, 12.2,

12.3 and 12.4).

28.3 Remove the compressor/AV bracket assembly from the pump case (Refer to Page 13, Section

14.1, 14.2 and 14.3 (new style AV mounts) or Page 15, Section 16.1, 16.2 and 16.3 (old style

AV mounts)).

28.4 Remove the compressor mounting bracket (Refer to Page 17, Section 18).

28.5 Fit a replacement compressor assembly by reversing the actions detailed above.

40 80

70

10

20

30

60

Figure 14 - Pressure Control Module

50

Chap 3 Issue 2

Page 26 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

Table 18 - Pressure Control Module Part List

Item Part Number Description Qty

10 500347 Terminal Block 5 way 1

20 BP196 Cable Tie 2

30 500362 Tube Sil ID 3/16” 135 mm ± 5 mm LG 1

40 FAS145 Screw 3 Dia.x8mmPozi Pan Head PT 1

50 FAS223 Screw 3 Dia. x 10 mm Pozi Pan Head PT 3

60 500315 Panel Side Colder 1

70 500328 Panel Side Push On 1

80 151309 Fixing Cap 1

29 Replacing the Pressure Control Module

29.1 Remove the pressure control knob as described in Page 3, Section 2.

29.2 Remove the rear case assembly as described in Page 5, Section 6.

29.3 Remove the compressor wires (Fig 14, Item 10) from the terminal block (terminals 3 and 4).

This also releases two switch wires.

29.4 Carefully cut the cables ties from the wiring loom as required (Fig 14, Item 20).

29.5 Remove the tube (Fig 14, Item 30) between the pressure control module and the ‘F’ connector.

29.6 Remove the module securing screw (Fig 14, Item 40) and the fixing cap (Fig 14, Item 80).

29.7 Carefully lift the module with the side panel attached from the pump case.

29.8 Disconnect the fuse wire from the terminal block (terminal 6) and disconnect the adjacent

switch wire (terminal 5) (Fig 14, Item 10).

29.9 Disconnect the mains/power lead wires from the terminal block (terminals L and N) (Fig 14,

Item 10).

29.10 Remove three screws (Fig 14, Item 50) and detach (pull off the pressure control module from

the side panel assembly (Fig 14, Item 70).

29.11 Replacement is the reversal of the above procedures. Refer to the wiring diagram (Chap. 4,

Fig 23 (electronic) or 24 (mechanical)) when reconnecting the wires to the terminal block.

Issue 2 Chap 3

Nov 2001 SER0004 Page 27

Pump Repair Mini Pump Service Manual

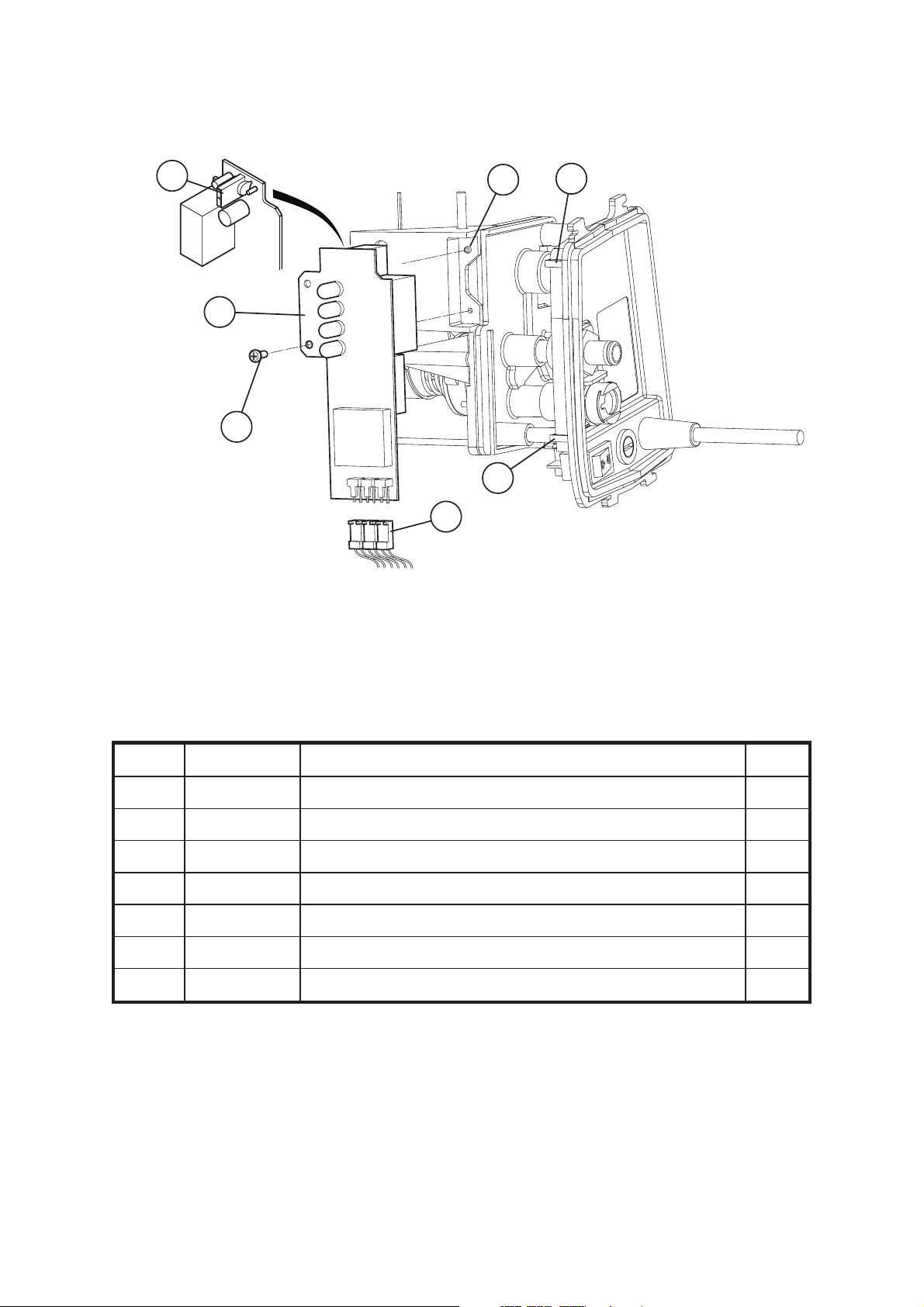

60

20

10

30

40

50

40

Figure 15 - Removing the Alarm Monitoring PCB

Table 19 - Removing the Alarm Monitoring PCB Part List

Item Part Number Description Qty

10 FAS083 Screw No. 6 x 5/16” Pozi Pan Head PT 1

20 500346 PCB Alarm Monitoring 230 V 1

500345 PCB Alarm Monitoring 100/120 V 1

30 N/A Signal Connectors REF

40 N/A Side Panel Slotted Mounts REF

50 N/A Lug REF

60 N/A PCB Power Wires Socket REF

Chap 3 Issue 2

Page 28 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

30 Replacing the Alarm Monitoring PCB

CAUTION : Electrostatic discharge can seriously damage the alarm monitoring PCB. Prior to

replacing or handling, adequate earth/grounding precautions must be taken.

Notes:1Itisnotnecessary to remove the side panel in order to replace the alarm monitoring PCB.

2 The alarm monitoring PCB is only applicable to electronic versions of the mini pump.

30.1 Remove the pressure control module as described in Page 27, Section 29.1 to 29.7.

30.2 Disconnect PCB power wires (Fig 15, Item 60) from PCB.

30.3 Disconnect the three signal connectors from the PCB (Fig 15, Item 30).

30.4 Remove the PCB securing screw (Fig 15, Item 10) and withdraw the PCB (Fig 15, Item 20).

30.5 Replacement is the reverse procedure to removal. Ensure that the PCB is seated in the two

slotted mounts of the side panel (Fig 15, Item 40) and the lug (Fig 15, Item 50) on the pressure

control module.

Issue 2 Chap 3

Nov 2001 SER0004 Page 29

Pump Repair Mini Pump Service Manual

10

20

30

Figure 16 - Replacing the Power Failure Alarm Battery

Table 20 - Battery (Power Failure Alarm) Part List

Item Part Number Description Qty

10 151457 Battery 1

20 N/A Cable Tie 1

30 N/A Battery Plug to PCB 1

Chap 3 Issue 2

Page 30 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

31 Changing the Battery

Caution : Electrostatic discharge can seriously damage the alarm monitoring PCB. Prior to

replacing or handling, adequate earth/grounding precautions must be taken.

Notes:1Itisnotnecessary to remove the side panel in order to change the battery.

2 The battery (power failure alarm) is only applicable to electronic versions of the mini pump.

31.1 Remove the PCB (Refer to Page 29, Section 30,).

31.2 Remove the battery plug (Fig 16, Item 30) from the PCB.

31.3 Cut and remove the cable tie (Fig 16, Item 20) and remove the battery (Fig 16, Item 10).

31.4 Replacement is the reverse procedure to removal.

Note : The cable tie must be renewed/replaced when changing the battery.

Issue 2 Chap 3

Nov 2001 SER0004 Page 31

Pump Repair Mini Pump Service Manual

30

10

30

ENS

THISSIE

RE

20

Figure 17 - Replacing the Neon Indicator Light

Table 21 - Neon Indicator Part List

Item Part Number Description Qty

10 FAS083 Screw No. 6 x 5/16” Pozi Pan Head PT 1

20 500324 Plate Neon Mounting 1

30 500373 Neon Assembly Red 230 V 1

500371 Neon Assembly Red 110 V

Chap 3 Issue 2

Page 32 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

32 Replacing the Neon Indicator Light

Note : The neon indicator light is only applicable to the mechanical versions of the pump. The

electronic version of the pump has two red indicators, a green indicator and a yellow indicator.

These are wired directly into the PCB and are replaced only by exchanging the complete PCB.

32.1 Disconnect the indicator lead from the terminal block (terminal 2) (Fig 14, Item 10).

32.2 Disconnect the indicator lead from the Micro switch (Fig 18, Item 10).

32.3 Release the screw (Fig 17, Item 20) attaching the neon mounting plate (Fig 17, Item 10) and

remove the neon (Fig 17, Item 30) and mounting plate assembly.

32.4 Note the orientation of the components, unclip the neon (Fig 17, Item 30) from the lens and

push the lens out of the mounting plate.

32.5 Replacement is the reverse procedure of the above. Ensure the correct orientation of

components. Connect the wires to the terminal block and the Micro switch in accordance with

the wiring diagram for the mechanical version of the pump unit (Chap. 4, Fig 25).

Issue 2 Chap 3

Nov 2001 SER0004 Page 33

Pump Repair Mini Pump Service Manual

10

20

30

L

40

6

N

5

1

4

2

3

L

N

1

2

6

5

4

3

Figure 18 - Replacing the Micro switch and Terminal Block

Table 22 - Micro switch and Terminal Block Part List

Item Part Number Description Qty

10 500338 Micro switch Sub Min 230 V/0.1A 1

20 FAS224 Screw 2.2 Dia. x 14 mm Pozi Pan Head PT 2

30 500347 Terminal Block 5 Way 1

40 FAS225 Screw 3 Dia. x 16 mm Pozi Pan Head PT 2

Chap 3 Issue 2

Page 34 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

33 Replacing the Microswitch

Note : It is not necessary to remove the pressure control module from the pump case.

33.1 Pull off connectors from the Micro switch terminals 1 and 3 (Fig 18, Item 10).

33.2 Release two screws (Fig 18, Item 20) and remove the Micro switch from the pressure control

module.

33.3 Replacement is the reverse of the above procedure.

34 Replacing the Terminal Block

Note : It is not necessary to remove the pressure control module from the pump case.

34.1 Disconnect all wires from the terminal block (Fig 18, Item 30).

34.2 Release two securing screws (Fig 18, Item 40) and remove the terminal block from the

pressure control module.

34.3 Replacement is the reversal of the above procedure. Refer to the wiring diagram (Chap. 4,

Fig 24) when reconnecting the wires for the electronic version of the pump and wiring diagram

(Chap. 4, Fig 25) when reconnecting the wires for the mechanical version of the pump.

Issue 2 Chap 3

Nov 2001 SER0004 Page 35

Pump Repair Mini Pump Service Manual

90

70

60

20

50

10

30

40

80

(Aura Pumps Only)

100

Figure 19 - Pressure Control Flaps, Air Bag, Control Knob Cam and Arbour

Table 23 - Pressure Control Flaps, Air Bag, Control Knob Cam and Arbour Part List

Item Part Number Description Qty

10 500304 Knob Control Arbour 1

20 500312 Upper Pressure Control Flap 1

30 500318 Pivot Pin, Pressure Control 1

40 500303 Lower Pressure Control Flap 1

50 500341 Spring 0,024” Diameter 1

60 151339 Pressure Control Disc 1

70 PRE022 Rubber Valve Disc 1

80 500103 Bag Pressure with Restrictor Assembly 1

90 500355 Screw M3 x16 mm Socket Cap Hd Black 1

100 403306 Restrictor (Aura Pumps Only) 1

Chap 3 Issue 2

Page 36 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

35 Replacing the Pressure Control Flaps and Air Bag

35.1 Turn the control knob arbour fully counter-clockwise (Fig 19, Item 10). Hold the upper pressure

control flap (Fig 19, Item 20) in position and withdraw the pivot pin (Fig 19, Item 30). Carefully

remove the upper flap and the lower flap (Fig.19, Item 40) together with the low pressure

operating spring and brass disc (Fig 19, Items 50 and 60).

35.2 Remove and discard the pressure control disc (Fig 19, Item 70) from the upper flap. Replace

with new item.

35.3 Remove and discard the air bag assembly (Fig 19, Item 80). Replace with a new item. Ensure

the air bag is secure by pushing in the centre and rotate it slightly to ensure it is seated.

35.4 Ensure that the low pressure adjustment screw (Fig 19, Item 90) is fully disengaged. Carefully

locate the brass disc (Fig 19, Item 60), boss uppermost in the rebate in the upper flap. Locate

the spring (Fig 19, Item 50) on the disc and position the lower flap (Fig 19, Item 40) against the

spring.

35.5 Refitting is the reverse of the above procedure. When refitting, hold the group of components

together and position them on the pressure control module. Insert the pivot pin (Fig 19, Item

30) to retain the flaps.

Issue 2 Chap 3

Nov 2001 SER0004 Page 37

Pump Repair Mini Pump Service Manual

10

A

B

60

A

NEW

NEW

50

OLD

OLD

B

30

40

20

Figure 20 - Control Knob Cam and Arbour

Table 24 - Control Knob Cam and Arbour Part List

Item Part Number Description Qty

10 FAS225 Control Adjustment Screw, 3 Dia x 16 mm Pozi Pan Head PT 1

20 500305 Knob Control Cam 1

30 500411 Cup Arbour Drive Spring 1

40 500339 Spring Comp 1.07 Diameter 1

50 500349 Pressure Assembly Module 1

60 500304 Knob Control Arbour 1

Chap 3 Issue 2

Page 38 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

36 Replacing the Pressure Control Assembly

Note:Itisnot necessary to remove the side panel assembly from the pressure control module.

36.1 Remove the pressure control module from the pump case as described in Section 29.

36.2 Remove the pressure control flaps as described in Section 35.

36.3 Release the control adjustment screw on the control knob arbour (Fig 20, Item 10).

36.4 Carefully remove the arbour, cam, spring cup and spring (Fig 20, Items 20, 30 and 40).

36.5 Renew/replace components with the same type.

Note : Early versions may have a nylon washer in lieu of the spring cup. Discard the washer and

replace with the cup.

36.6 Replacement is the reverse of the above procedure. Refit the pressure control flaps as

described in Section 35.

Note : The new control knob arbour will NOT fit the old pressure assembly module because of the

moulded wall on the old pressure assembly module. The old control knob abour will fit both.

Issue 2 Chap 3

Nov 2001 SER0004 Page 39

Pump Repair Mini Pump Service Manual

10

20

110

100

90

70

80

50

30

40

60

Figure 21 - Synchronous Motor (Gearbox), Rotor/Stator Assembly

Table 25 - Synchronous Motor (Gearbox), Rotor/Stator Assembly Part List

Item Part Number Description Qty

10 FAS223 Screw 3 Dia x 10 mm Pozi Pan Head 2

20 500097 Gearbox 240V and Ferrule Assembly 1

500098 Gearbox 120V and Ferrule Assembly 1

500099 Gearbox 100V and Ferrule Assembly 1

151409 Motor Gearbox 100V, 50 Hz, 1/10 RPM 1

30 500308 Rotor Module 1

40 500307 Stator Module 1

50 500332 Felt Rotor Silencer 1

Chap 3 Issue 2

Page 40 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

Table 25 - Synchronous Motor (Gearbox), Rotor/Stator Assembly Part List (continued)

Item Part Number Description Qty

60 500319 Stator Gasket 1

500418 Stator Gasket (Restricted) 1

70 500356 Rotor Drive Cup 1

80 500322 Pin Rotor Drive 1

90 500354 Washer Starlock O/D 21 mm 1

100 500358 Spring Comp 1.6 Diameter FL 22.36 1

110 TIM017 Oil Seal Cap 1

37 Replacing the Synchronous Motor (Gearbox), Rotor Stator Assembly

Note:Itisnot necessary to remove the side panel assembly from the pressure control module.

37.1 Remove the pressure control module from the pump case as described in Section 29.

37.2 Remove any relevant cable ties.

37.3 Identify the synchronous motor electrical lead from the terminal block (terminals 1 and 2) (Fig

18, Item 30). remove the relevant cable ties and release the synchronous motor electrical lead.

37.4 Remove the two screws securing the gearbox motor (Fig 21, Item 10).

37.5 Carefully remove the synchronous motor, rotor and stator (Fig 21, Items 20, 30 and 40) from

the pressure control module. Remove the felt rotor silencer (Fig 21, Item 50) from the rotor.

Remove the stator gasket (Fig 21, Item 60) from the pressure assembly module.

37.6 Depress the motor drive cup (Fig 21, Item 70) toward the motor and remove the drive shaft pin

(Fig 21, Item 80).

37.7 Carefully remove the rotor drive cup, star washer (Fig 21, Item 90), spring (Fig 21, Item 100)

and oil seal cap (Fig 21, Item 110) from the motor.

37.8 Replace any faulty parts with same type.

37.9 Discard the stator gasket and replace with a new one before reassembly.

37.10 Replacement is the reverse of the above procedure. Ensure that the stator is correctly located

in the key and cables are secured with relevant cable ties.

Issue 2 Chap 3

Nov 2001 SER0004 Page 41

Pump Repair Mini Pump Service Manual

BROWN

BROWN

1A

2A

4B

3B

ORANGE

10

50

40

20

30

Figure 22 - Replacement of the Side Panel On/Off Switch

Table 26 - Side Panel On/Off Switch, Mains/Power Lead and Fuses Part List

Item Part Number Description Qty

10 500351 Switch Mains/Power Rocker 230 V Black (All electronic pumps) 1

500343 Switch Mains/Power Rocker 230 V Green (Illuminated) 1

500359 Switch Mains/Power Rocker 110 V Green (Illuminated) 1

20 198315 Grommet 1

30 BP532 Cordset Standard Moulded UK (Cable) 1

CAS041 Mains/Power Cable - European “Shuko” Socket 1

BP087 Mains/Power Cable - USA 2 pin 1

CAS020 Mains/Power Cable - Japan 2 pin 1

BP171 Mains/Power Cable - Australia 1

40 500344 Fuse Holder 1

50 CAS011 Fuselink 20x5mm500mAQB 1

Chap 3 Issue 2

Page 42 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

38 Replacing the Side Panel Mains/Power On/Off Switch

38.1 Remove the pressure control module and remove the side panel as described in Section 29.

38.2 Pull off the electrical connections from the On/Off switch (Fig 22, Item 10).

38.3 Squeeze together the retaining flanges located on either side of the switch body and push the

switch through the side panel.

38.4 Replace the switch with same type. Ensure correct orientation of the switch (symbol nearest

the fuse). Ensure that the retaining flanges snap into position. Refer to the wiring diagram

(Chap. 4, Fig 23) when reconnecting the electrical wires for the electronic version of the pump

and (Chap. 4, Fig 24 ) when connecting the electrical wires for the mechanical version of the

pump.

39 Replacing the Side Panel Mains/Power Lead

39.1 Remove the pressure control module, and remove the side panel as described in Section 29.

39.2 Carefully withdraw the mains/power lead (Fig 22, Item 30) through the mains lead/power cord

grommet.

39.3 Carefully withdraw the mains/power lead grommet (Fig 22, Item 20) through the side panel.

39.4 Replace the lead with the same part number. Replacement is the reverse of the above

procedure. Ensure adequate cable length so that wires are not strained.

WARNING:

WHEN AN UNSERVICEABLE MAINS/POWER LEAD FITTED WITH A

NON-REWIREABLE PLUG IS REMOVED FROM THIS EQUIPMENT, THE

LEAD/CORD AND THE PLUG MUST BE DESTROYED AND DISPOSED OF

SAFELY. TO AVOID THE DANGER OF ELECTRIC SHOCK THE PLUG

MUST NEVER BE INSERTED IN ANY POWER OUTLET.

40 Replacing the Fuses

Note : The side panel assembly is supplied complete with fuse holder fitted. The fuse holder is not a

replaceable item.

40.1 To replace the pump fuse undo the fuse holder (Fig 22, Item 40) and remove the fuse (Fig 22,

Item 50). Replace with fuse of same type.

40.2 To replace the mains/power lead plug fuse in moulded plugs use a small bladed electrical

screwdriver and carefully lever off the fuse cover on the pin side of the plug. Replace with fuse

of same type.

Issue 2 Chap 3

Nov 2001 SER0004 Page 43

Pump Repair Mini Pump Service Manual

20

30

10

20Part

40

10Part

Figure 23 - Snap-lock Connectors

Table 27- Snap-lock Connectors

Item Part Number Description Qty

10 500350 Connector Panel, Female 1/4” Flow 1

20 504316 Connector Panel, Male 1/4” Flow 1

30 500361 Tube Sil Blue ID 6 OD 10 24 LG ± 1 1

40 500360 Tube Sil Blue ID 6 OD 10 15 LG ± 1 1

Chap 3 Issue 2

Page 44 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

41 Replacing the Snap-lock Connectors

Note : Older versions have a pump connectors moulded within the side panel and are not

replaceable.

41.1 Remove pressure control module with side panel (Refer to Section 29.1 to 29.7)

41.2 Refer to Fig 15, disconnect the three signal connectors (Fig 15, Item 30 ) and the power wires

from the PCB.

41.3 Remove screw (Fig 15, Item 10) and remove the PCB.

41.4 Undo locknut and withdraw connector through side panel with tube.

41.5 Remove tube from connector.

41.6 Replace with the same type. Replacement is the reverse of the above procedure. Ensure that

the snap lock release clip on the female (lower) connector is pointing toward the rear of the

case. Make sure the locknut is on the pressure module before the connector and tube is

inserted.

Issue 2 Chap 3

Nov 2001 SER0004 Page 45

Pump Repair Mini Pump Service Manual

42 Removing the Front Case

42.1 Remove the pressure control knob (Page 3, Section 2).

42.2 Disassemble the rear case (Page 5, Section 6).

42.3 Remove the screw and the fixing cap (Refer to Fig 14, Items 40 and 80) from the pressure

control module.

42.4 Remove the pressure control module, together with the side panel, and the compressor from

the front case (Fig 2, Item 40).

43 Installing the Front Case

43.1 For Aura, AlphaXcell, AlphaTrancell ALT01-09, fit the pin (Fig 2, Item 30) to the new front case.

Note : For Alpharelief, Alphabed, Alphacare and AlphaTrancell ALT10 pumps, the pin is not needed.

This allows 270° movement of the Pressure Control Knob.

43.2 Fit a front label to the front case (Refer to Table 28 for the correct label set).

43.3 Install the pressure control module, together with the side panel, and the compressor in the

front case.

43.4 Install the fixing cap and the screw (Refer to Fig 14, Items 80 and 40) to the pressure control

module.

43.5 Assemble the rear case (Page 5, Section 7).

43.6 Install the pressure control knob (Page 3, Section 3).

43.7 Fit rubber feet to the base of the front case (Fig 4, Item 50).

Chap 3 Issue 2

Page 46 SER0004 Nov 2001

Mini Pump Service Manual Pump Repair

44 Pump Label Sets

The following table gives the part numbers for the pump label sets:

Table 28 - Pump Label Sets

Part Number Description Qty

AlphaXcell

Series

500386 Label set UK - AlphaXcell (ALX01) 1

500387 Label set Germany - AlphaXcell (ALX02) 1

500388 Label set USA - AlphaXcell (ALX03) 1

500389 Label set Euro - AlphaXcell (ALX04) 1

500390 Label set France - AlphaXcell (ALX05) 1

500391 Label set Japan - AlphaXcell (ALX06) 1

500392 Label set Italy - AlphaXcell (ALX017) 1

500393 Label set Australia - AlphaXcell (ALX08) 1

500394 Label set Rest of the World - AlphaXcell (ALX09) 1

500395 Label set Holland - AlphaXcell (ALX10) 1

500472 Label set Rest of the World - AlphaXcell (ALX11) 1

AlphaBed

Series

500397 Label set UK - AlphaBed (ALB01) 1

500398 Label set Euro - AlphaBed (ALB04) 1

500441 Label set Poland - AlphaBed (ALB04 - PL) 1

500399 Label set Australia - AlphaBed (ALB08) 1

500400 Label set Rest of the World - AlphaBed (ALB09) 1

Alpha Trancell

Series

500412 Label set UK - Alpha Trancell (ALT01) 1

500396 Label set Germany - AlphaTrancell (ALT02) 1

500414 Label set Holland - Alpha Trancell (ALT10) 1

500440 Label set Poland - Alpha Trancell (ALT01-PL) 1

Issue 2 Chap 3

Nov 2001 SER0004 Page 47

Pump Repair Mini Pump Service Manual

Table 28 - Pump Label Sets (continued)

Part Number Description Qty

Alpha Relief

Series

500475 Label set UK - Alpha Relief (ALR01) 1

500478 Label set Germany - Alpha Relief (ALR02) 1

500470 Label set USA - Alpha Relief (ALR03) 1

500476 Label set Euro - Alpha Relief (ALR04) 1

AlphaCare

Series

500401 Label set USA - AlphaCare (ALC03) 1

500402 Label set Euro - AlphaCare (ALC04) 1

500473 Label set Japan - AlphaCare (ALC06) 1

Aura Series

500474 Label set UK - Aura (ALS01) 1

500479 Label set USA - Aura (ALS03) 1

500477 Label set Euro - Aura (ALS04) 1

Chap 3 Issue 2

Page 48 SER0004 Nov 2001

Mini Pump Service Manual Troubleshooting

CHAPTER 4

TROUBLESHOOTING

1 General

This section details some problems which may occur after a long period of use and the appropriate

procedures to correct them.

The Alpha Relief, Aura and AlphaXcell (electronic) pump units are fitted with a visual and audible

alarm for LOW PRESSURE and POWERFAIL alarm conditions. The alarm for the AlphaBed, Care

and Trancell (mechanical) pump units are limited to a visual red LOW PRESSURE (!) lamp indicator.

The alarm automatically resets when the operating pressure is regained. See Table 4 for details of

the each product’s visual indicators.

Table 29 gives a quick reference to common problems, possible causes and actions. Refer to the

table first when carrying out troubleshooting on a pump.

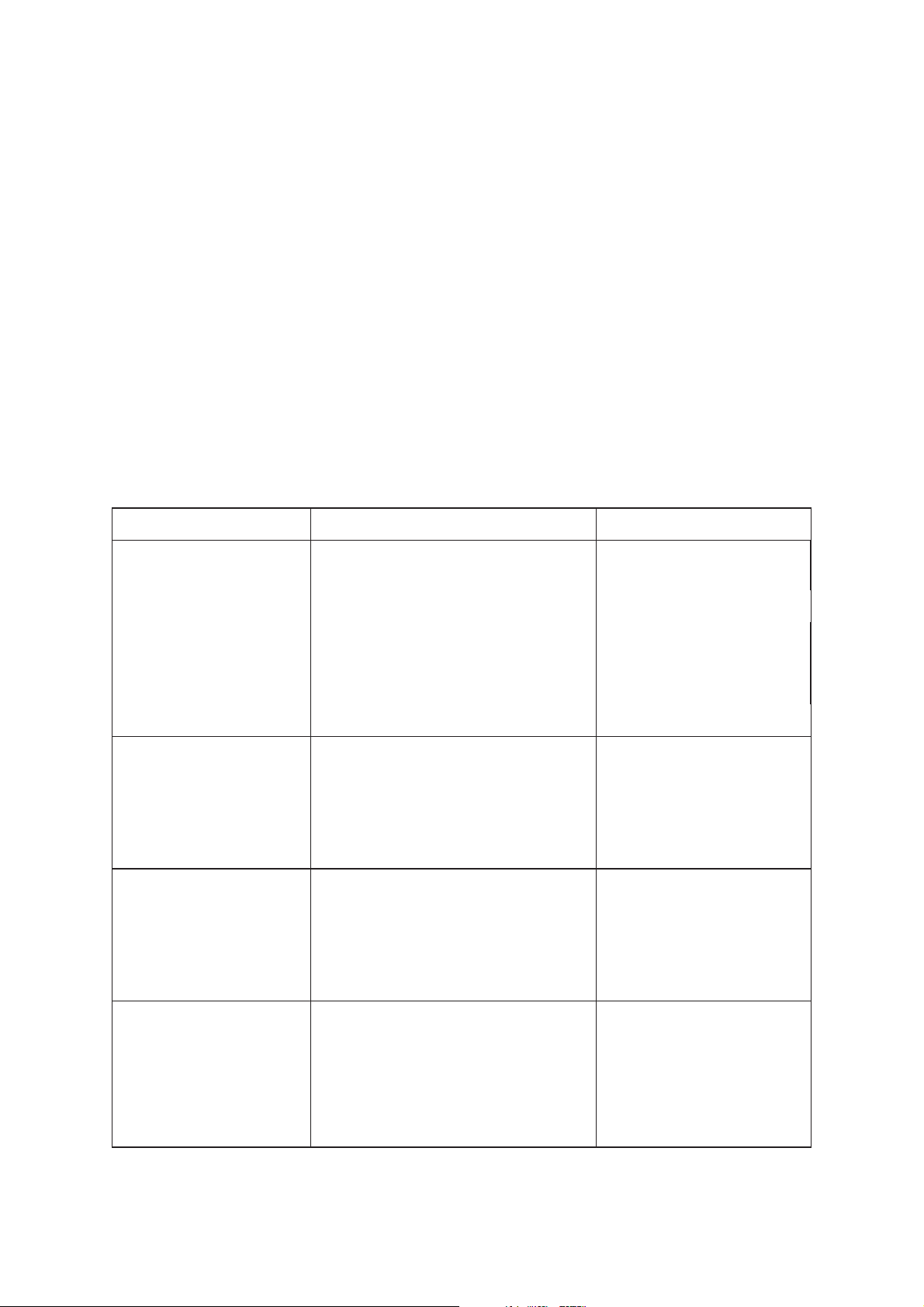

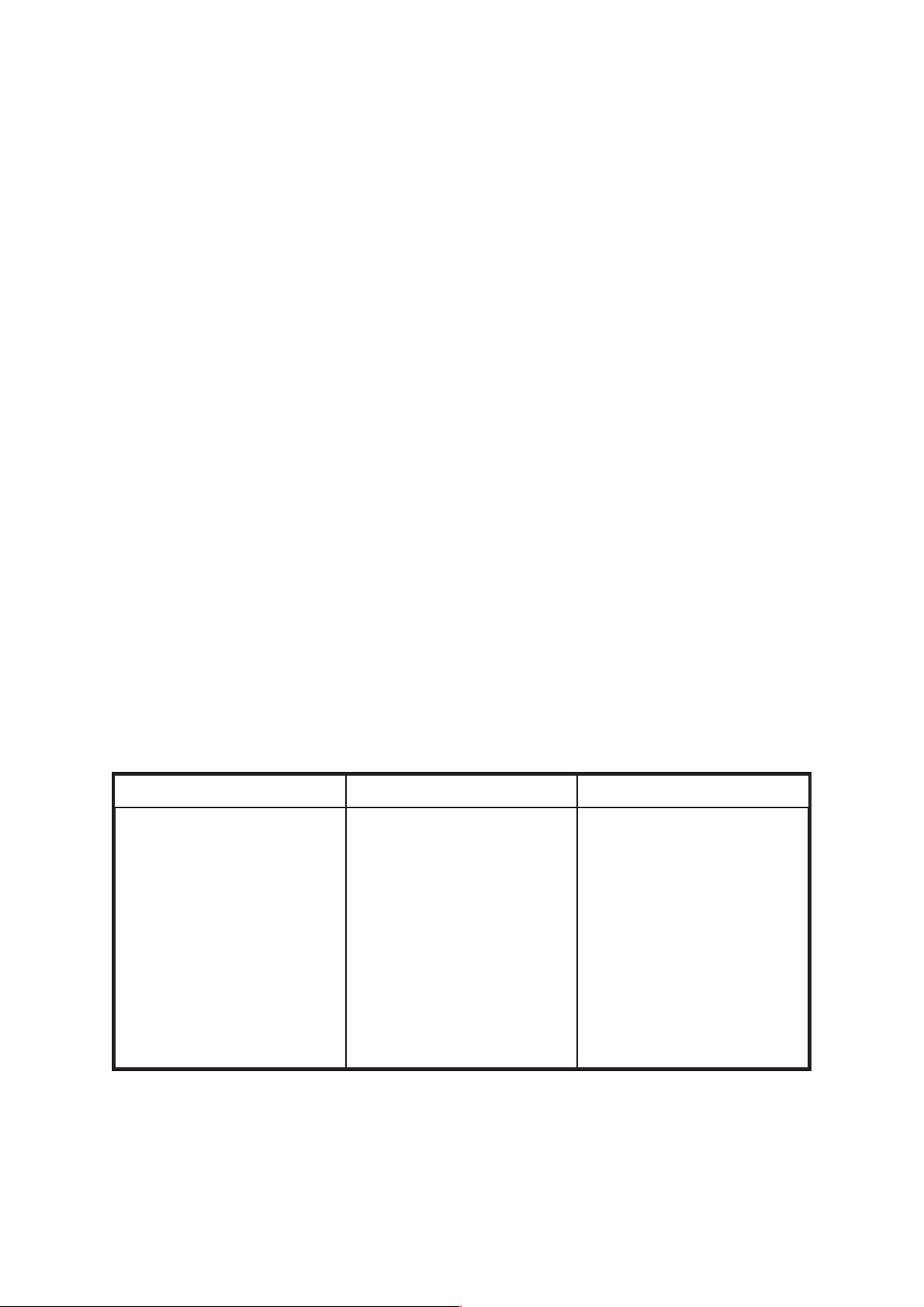

Table 29 - Troubleshooting

Problem Possible Cause Action

Mattress/Seat not

Inflating.

Applicable to all pumps.

Low pressure alarm.

Applicable to all pumps.

Wait indicator does not go

out not allowing the

system to pressurize.

Applicable to:

ALR 01-10

ALX 01-10

1. CPR not inserted (mattress only). Check CPR (See Mattress

Service Manual SER0005).

2. Tubes kinked. Check.

3. Pump not switched on. Check.

4. No pump output. Check. See ‘Pump not

operating’ below.