Hunter Stoves Telford Inset 5 MKII Instructions For Installation/operation/maintenance/servicing

Telford Inset 5 MKII

Models: CVSTI05FM/CVTI05FM

Instructions for:

Installation/Operation/Maintenance/Servicing

JINTDI05 Rev E 20/04/15

CONTENTS INDEX:

TECHINCAL SPECIFICATION………………………………………………………………………………………………. 3

IMPORTANT INFORMATION…………………………………………………………………………………………….. 4

FLUE ADAPTOR INSTRUCTIONS............................................................................................ 6

DIRECT AIR ADAPTOR INSTRUCTIONS.................................................................................. 7

PRE INSTALLATION REQUIRMENTS…………………………………………………………………………………… 9

REMOVING INTERNAL COMPONENTS.................................................................................. 12

INSTALLATION INSTRUCTIONS………………………………………………………………………………………….. 14

COMMISSIONING AND HANDOVER………………………………………………………………………………….. 15

USER INSTRUCTIONS………………………………………………………………………………………………………… 16

MAINTENANCE & SERVICING…………………………………..……………………………………………………….. 19

SPARES INFORMATION…………………………………………………………………………………………………….. 21

COMMISSIONING & INSTALLATION CHECK LIST……………..……………….……………………………….. 24

SERVICE RECORDS…………………………………………………………………………………………………………….. 25

Hunter Stoves,

Emperor Way,

Exeter Business Park,

Exeter,

Devon. EX1 3QS

Email - info@hunterstoves.co.uk

Website - www.hunterstoves.co.uk

WARRANTY

Hunter Stoves appliances come with a standard 2 year warranty, however this excludes naturally wearing

“consumable” components and the use of un-authorised fuels.

Consumables are deemed to be;

Glass, Seals, Gaskets, Grate Components, Log Retainers, Baffles and the surface finish of the appliance.

The Warranty will only be valid if the appliance is installed by an appropriately qualified engineer in

accordance with the manufacturer’s instructions and to the appropriate Building Regulations and/or Local ByLaws and serviced within 12 months of installation.

Hunter Stoves will also support an extended 5 year warranty on external Cast Iron components such as Doors,

Flue Collars and Covers.

If this appliance is purchased through an un-authorised stockist or an internet trader Hunter Stoves are only

obliged to support the statutory requirements.

This appliance must be regularly serviced and maintained, using only Hunter Stoves approved components for

the Warranty to be valid.

JINTDI05 Rev E 20/04/54

2

TELFORD INSET 5 MKII

Hunter Stoves, Emperor Way,

Exeter Business Park, Exeter,

Devon. EX1 3QS

BS/EN 13229

UKAS# 0692

Stove Mass: 100 kg

NOMINAL OUTPUT: 4.9 KW

CO Emission at 13% O2: 0.19%

Mean Flue Gas Temperature: 292°C

EFFICIENCY: 77.1%

Flue Gas Mass Flow: 4.3 g/s

Minimum clearance to combustible material

Top of Fire Surround:

200mm

Side of Fire Surround:

150mm

Side Wall:

300mm

This appliance is suitable for intermittent burning

This appliance is not suitable for use in a shared flue

Read and follow the operating instructions

Use only recommended fuels

15

Telford Inset 5 MKII

TECHNICAL SPECIFICATION

JINTDI05 Rev E 20/04/54

3

IMPORTANT INFORMATION

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION AND OPERATION.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERANCE AND SERVICING.

THIS APPLIANCE WILL BECOME HOT WHEN USED IN ACCORDANCE WITH THESE INSTRUCTIONS,

HUNTER STOVES RECOMMEND THAT AN APPROVED GUARD IS USED TO PROTECT THE YOUNG,

ELDERLY OR INFIRM FROM HARM.

THE INSTALLER COMMISSIONING SHEET CAN BE FOUND ON THE BACK COVER.

PLEASE ENSURE THAT IT IS COMPLETED PRIOR TO USE.

GENERAL GUIDANCE

It is important that your stove is correctly

installed and operated as Hunter Stoves cannot

accept responsibility for any fault arising through

incorrect installation, use, maintenance or

servicing.

These instructions cover the basic principles to

ensure satisfactory installation of the stove,

although detail may need slight modification to

suit particular local site conditions.

The installation must comply with current Building

Regulations, National and European Standards,

Local Authority Byelaws and other specifications

or regulations as they affect the installation of the

appliance.

The Building Regulations requirements may also

be met by adopting the relevant

recommendations in the current issues of British

Standards BS 8303 and BS EN 15287-1.

Only use approved fuels on this appliance.

Information about this can be found on Page 18.

This is a Domestic Appliance and must only be

used in accordance with these instructions.

Do not place articles that are affected by high

temperatures on, or near, this appliance. Do not

place furniture or other items within 900mm of

the front of this appliance. See the note on

material clearances on page 11.

Extractor Fans and/or Cooker Hoods must not be

installed in the same space or room as this can

cause the appliance to emit fumes into the room.

Do not obstruct the ventilation required for the

safe use of this appliance.

COMPETENT PERSONS SCHEME

Hunter Stoves recommend that this stove is

installed by a member of an accredited

competent persons scheme e.g. HETAS.

If the installer is not a member of a competent

person’s scheme, it is a legal requirement, in the

UK, to notify your Local Building Control Officer in

advance of any installation work starting.

HEALTH AND SAFETY PRECAUTIONS

Special care must be taken when installing the

stove such that the requirements of the Health

and Safety at Work Act are met.

HANDLING

This appliance is very heavy. Adequate facilities

must be available for loading, unloading and site

handling.

FIRE CEMENT

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin.

In case of contact, wash immediately with plenty

of water.

JINTDI05 Rev E 20/04/54

4

ASBESTOS

This Stove contains no asbestos. If there is a

possibility of disturbing any asbestos in the course

of installation then please seek specialist guidance

and use appropriate protective equipment.

METAL PARTS

When installing or servicing this stove, care should

be taken to avoid the possibility of personal injury.

MODIFICATION

No unauthorized modification of this appliance

should be carried out.

SAFETY

WARNING!

This appliance will be hot when in operation and

due care should be taken. The supplied gloves

may be used to open the door and operate the air

controls.

AEROSOLS

Do not use an aerosol spray on or near the stove

when it is alight.

FIREGUARDS

Always use a fireguard in the presence of children,

the elderly or the infirm. The fireguard should be

manufactured in accordance with BS8423 –

Fireguards for use with solid fuel appliances.

DO NOT OVER-FIRE

It is possible to fire the stove beyond its design

capacity. This could damage the stove so watch

for signs of over-firing. If any part of the stove

starts to glow red, the stove is in an over-fire

situation and the controls should be adjusted

accordingly. Never leave the stove unattended for

long periods without first adjusting the controls to

a safe setting. Careful air supply control should be

exercised at all times.

FUME EMISSION

Properly installed and operated, this appliance

will not emit fumes. Occasional fumes from deashing and refueling may occur. Persistent fume

emission must not be tolerated.

This appliance should not be operated with the

door open.

If fume emission does persist then the following

action should be taken immediately;

Open Doors and windows to ventilate room.

Let the fire out, or eject and safely dispose of

fuel from the appliance.

Check for flue/chimney blockage and clean if

required.

Do not attempt to relight the fire until the

cause has been identified and corrected.

If necessary seek professional advice.

ADVERSE WEATHER

In a small number of installations, occasional local

weather conditions (e.g. wind from a particular

direction) may cause downdraught in the flue and

the stove to emit fumes. In these circumstances

the stove should not be used. A professional flue

installer will be able to give advice on solutions to

this problem (e.g. anti-downdraught cowl).

CARBON MONOXIDE DETECTOR

Hunter Stoves recommend a Carbon Monoxide

Detector that conforms to the latest issue of BS

EN 50292 is placed in the same room as the

appliance. The installation of such an alarm is not

considered as a substitute for regular

maintenance or servicing or the appliance and

Flue system.

IN THE EVENT OF A CHIMNEY FIRE:

Raise the alarm

Call the Fire Brigade

Close appliance air controls

Move furniture, ornaments etc. away

Place a fireguard in front of stove

Check the chimney breast for signs of excessive

heat.

If the wall is becoming excessively hot, move

furniture away.

Ensure the Fire Brigade can gain access to your

roof space in order to check for fire spread.

JINTDI05 Rev E 20/04/54

5

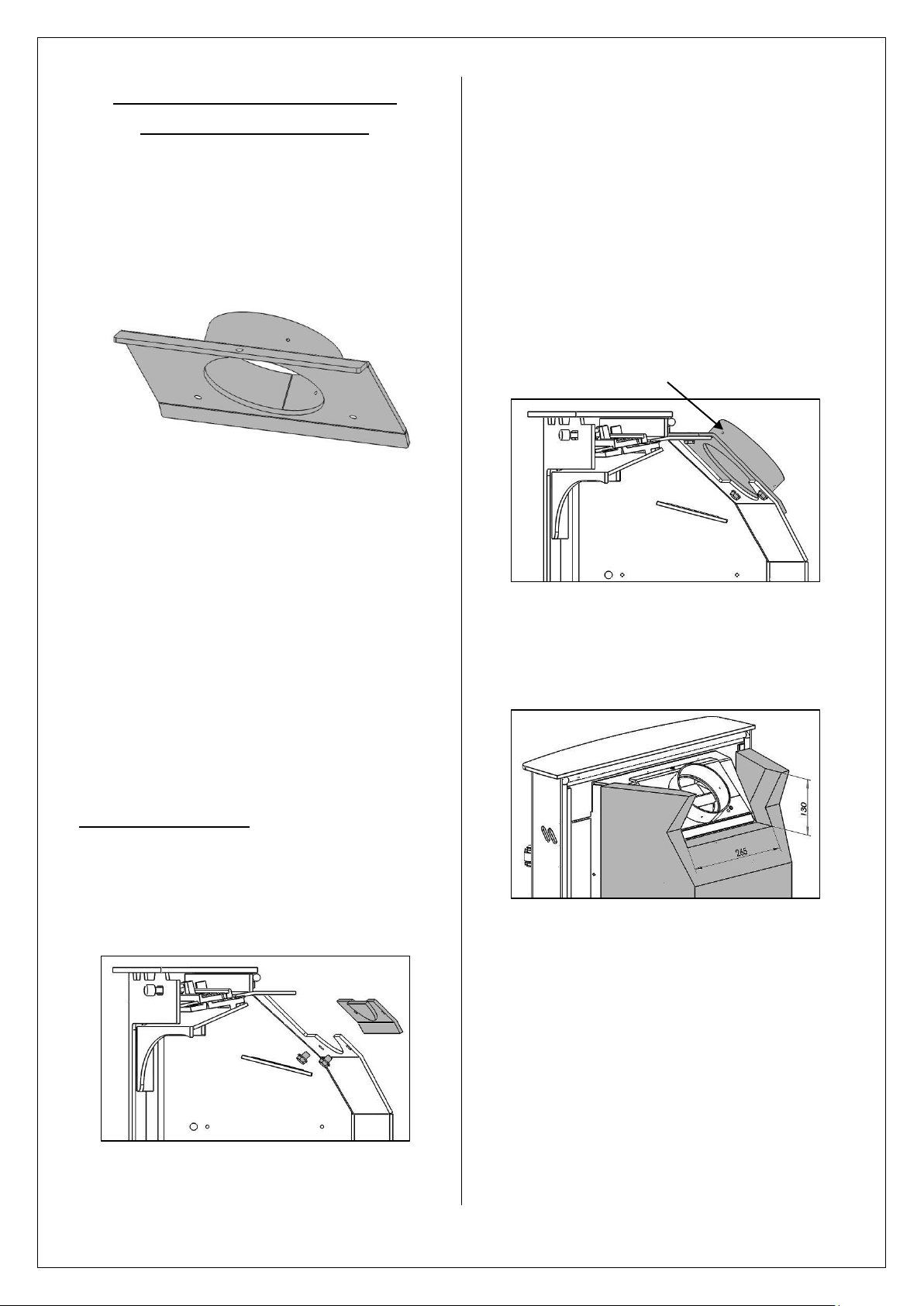

INSTRUCTIONS FOR FITTING THE

Self Tapping Screw Holes.

OPTIONAL FLUE ADAPTOR

This product is designed to fit into a standard 16

inch fireback.

An optional Flue Adaptor (Part No: HCN05074) for

Ø125mm flexible liners is supplied with this

Appliance.

N.B.The flue adaptor is designed to allow

connection of a 125mm flexible flue liner or

125mm single skin flue pipe to the flue outlet

of the Inset 5 MKII room heater. Some

modification of the fireplace opening will be

necessary to allow sufficient room to

accommodate the adaptor. The adaptor has a

125mm (5”) flue socket designed to accept

flue liner adaptors and flue pipe. Flexible flue

liners should not be directly connected to the

Inset 5 MKII Flue adaptor as this may result in

deformation of the liner.

TO FIT THE FLUE ADAPTOR

Remove all the stove interior parts and door(s) as

detailed on (page 12).

Unscrew the two M8 screws from the inside of the

stove and remove the Flue Infill plate.

Replace the Flue Infill Plate with the Flue Adaptor.

Apply fire cement to the mating surfaces of the

adaptor and stove flue outlet.

Screw the Flue adaptor in place with the three M8

screws and washers from the inside of the stove.

If connecting to a flexible flue liner, use a flexible

flue liner to single skin flue adaptor to connect to

the Inset 5 MKII adaptor. Use self tapping screws

through the holes provided to fix the flue in place.

The upper section of the fireback will need to be

removed to fit the stove with the optional flue

adaptor fitted.

JINTDI05 Rev E 20/04/54

6

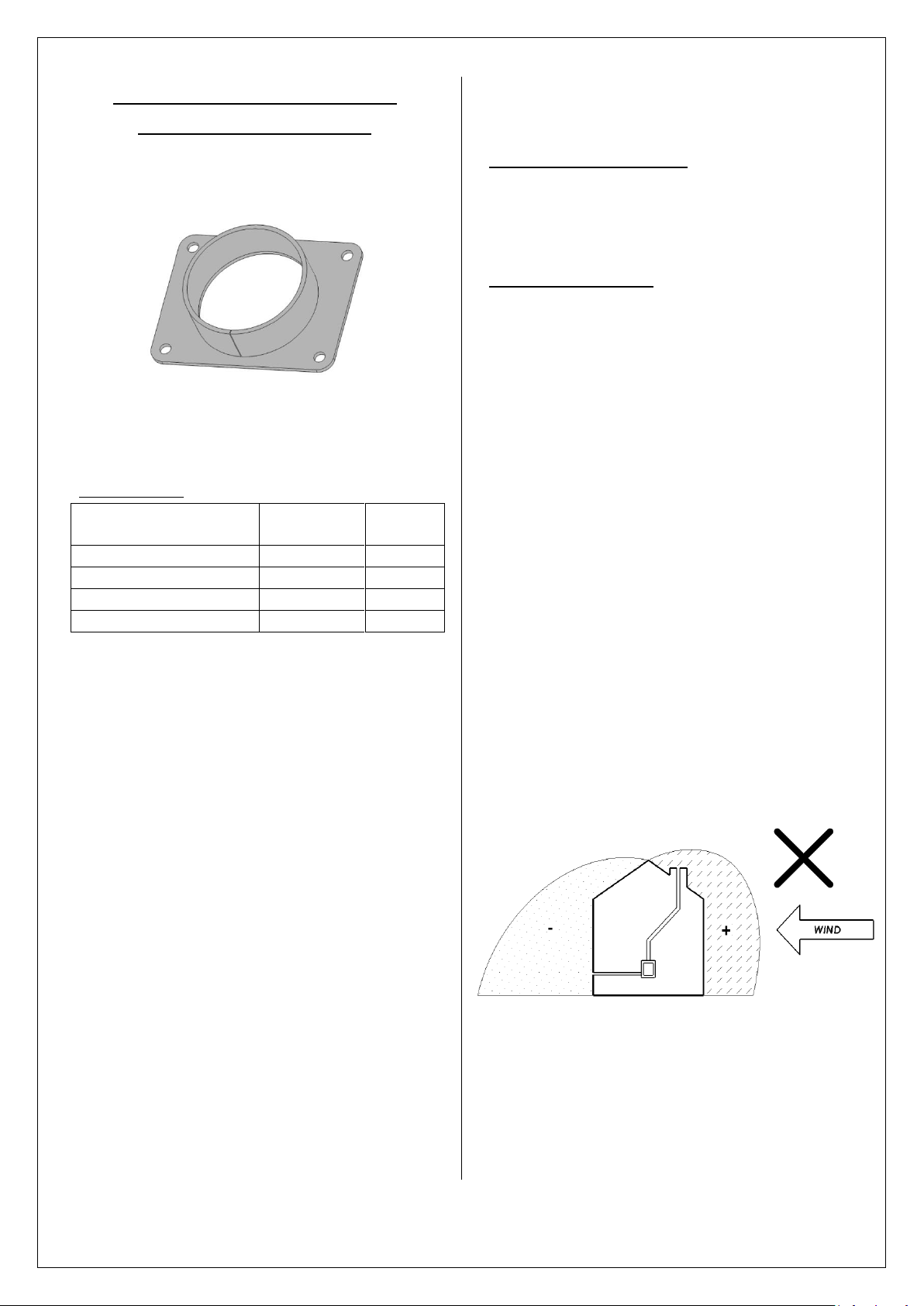

INSTRUCTIONS FOR FITTING THE

Description

Part

Number

Quantity

Adaptor Coupling

DACM80

1

Aluminium Duct

DAPM80

1

Bull Nose Vent & Flange

DAVM80 1 Duct Clip

FHC1060135

1

OPTIONAL DIRECT AIR KIT

An optional Direct Air Adaptor (Part No: HCN05079)

is supplied with this appliance.

If the Direct Air Adaptor is to be fitted a Direct Air

kit will need to be purchased.

Direct Air Kit Code: (HCE16ARRT007)

Contents of kit

These instructions cover the installation of the

Direct Air Adaptor kit to the Hunter Inset 5 MKII

stoves.

This Direct Air Adaptor allows the combustion air

for the stove to be ducted directly from outside.

N.B. This does not constitute a “room sealed

installation” as some air is allowed to pass

through the stoves inlet duct. This provides relief

from draught fluctuations and will help to clear the

air in the room should flue gas spillage occur.

It is important that your stove is correctly installed

as Hunter cannot accept responsibility for any fault

arising from incorrect use or installation.

The installation must comply with current Building

Regulations, national and European standards,

Local Authority Byelaws and other specifications or

regulations as they affect the installation of the

stove.

The Building Regulations requirements may also

be met by adopting the relevant recommendations

in the current issues of British Standards BS 8303

and BS EN 15287-1.

Competent Persons Scheme

Hunter recommend that this Direct Air Adaptor is

installed by a member of an accredited competent

persons scheme e.g. Hetas.

Siting of the Inlet Grille

Due consideration should be given to the siting of

the inlet grill to ensure that strong winds on either

the flue terminal, inlet grill or the building itself

will not cause the flow of flue gasses or

combustion air to be stalled or reversed.

If in doubt the inlet duct should be divided by a tee

piece and two inlet grills fitted on opposite sides of

the building. Alternatively the duct may be

connected to a space or chamber under the floor

on which the stove is installed which is ventilated

from all sides of the building.

Take note of prevailing winds in the area as well as

any tall buildings or trees that may be present and

could potentially create pressure zones around the

chimney terminal.

Do not fit the inlet vent on the downwind side of

the building unless the flue terminal is also on the

same side. Otherwise downdraft may occur in

windy conditions.

Care must also be taken when siting the inlet grille

to ensure that it will not become susceptible to

blockage.

JINTDI05 Rev E 20/04/54

7

Clearances to Combustible materials

In extreme circumstances it may be possible for

the flow of flue gasses in the stove to become

reversed. In this condition the duct will become

heated by the hot flue gas and consideration must

therefore be given to preventing the risk of fire.

The duct must be insulated wherever there is any

combustible material within a distance of 300mm

from the surface of the duct. It is also advisable to

insulate the duct wherever possible to reduce the

risk of condensation.

Where necessary the duct should be insulated

with 30mm thick Rockwool Rocklap H&V Pipe

Sections, having a nominal density not less than

120kg/m³, with a factory applied facing of

reinforced aluminium foil incorporating integral

lap for fixing. Fixing to be in accordance with

manufacturer’s instructions.

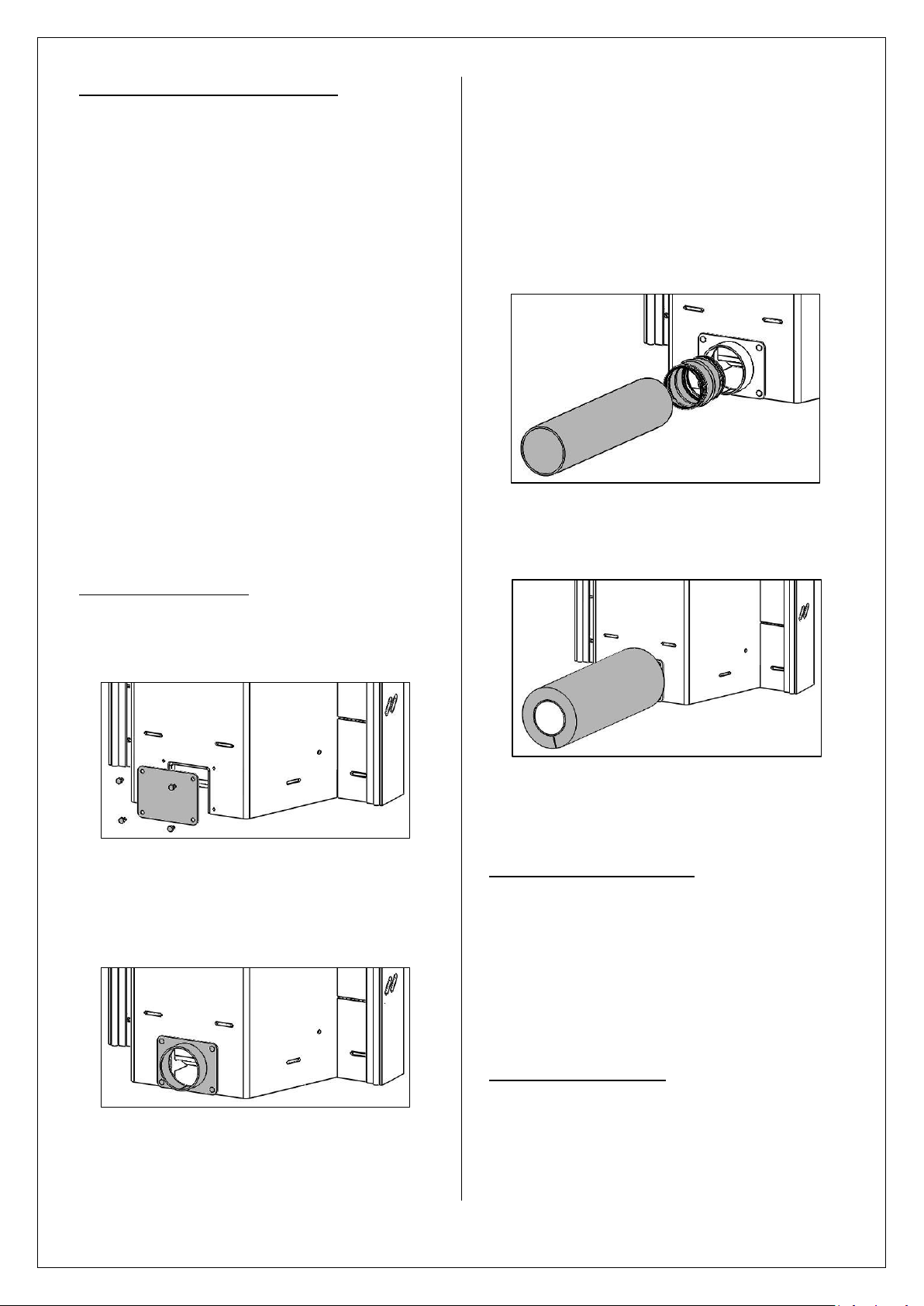

Connection to the stove

Fit the Direct Air Adaptor to the rear of the stove.

Unscrew the four M6 screws and remove the

Direct Air cover plate.

ducting and any insulation is suitably sized and

positioned. Carry out any necessary remedial

work.

Measure and cut the duct as necessary, allowing

an extra 50mm to make the connection to the inlet

grille. Connect the duct to the adaptor using the

Direct Air Coupling.

Where necessary fit the insulation to the duct,

sealing all joints with foil tape.

Replace the Direct Air Cover Plate with the Direct

Air adaptor.

Screw the Direct Air adaptor in place with the four

M6 screws and washers.

Measure the fireplace opening and check that

there is sufficient room for the Direct Air Adaptor

and that the position of any hole for the flexible

Pass the duct through the prepared hole and

manoeuvre the stove into position.

Connection to the Inlet Grille

Offer the Inlet grille into position on the outside

wall and where necessary mark and drill the fixing

holes.

Connect the Inlet grille to the duct using the clamp

provided. Apply a bead of sealant to the back face

of the inlet grille and fix the grille to the wall.

Commissioning

Carry out the commissioning procedure as

described in these instructions.

JINTDI05 Rev E 20/04/54

8

Loading...

Loading...