Hunter Stoves Telford Inset 20DB CVWSTI08DBFM, Telford Inset 20DB, Telford Inset 20DB CVWTI08DBFM Instructions For Installation/operating/maintenance/servicing

Telford Inset 20DB

Multifuel Boiler Stove

Model: CVWSTI08DBFM/CVWTI08DBFM

Instructions for:

Installation/Operating/Maintenance/Servicing

JINTDBW09 Rev B 05/03/15

CONTENTS INDEX:

TECHNICAL SPECIFICATION……………………………………………………………………………………………… 3

IMPORTANT INFORMATION……………………………………………………………………………………………. 4

REMOVING INTERNAL COMPONENTS……………………………………………………………………………… 6

APPLIANCE DIMENSIONS ……………………………………………………………………………………………… 7

PRE INSTALLATION REQUIREMENTS…………………………………………………………………………………. 8

INSTALLATION INSTRUCTIONS………………………………………………………………………………………… 11

INSTALLATION OF HEATING & HOT WATER……………………………………………………………………………. 13

COMMISSIONING AND HANDOVER………………………………………………………………………………….. 15

OPERATING INSTRUCTIONS……………………………………………………………………………………………… 16

MAINTENANCE & SERVICING…………………………………..……………………………………………………….. 19

SPARES INFORMATION……………………………………………………………………………………………………… 21

COMMISSIONING & INSTALLATION CHECK LIST……………..……………….……………………………….. 24

SERVICE RECORDS…………………………………………………………………………………………………………….. 25

Hunter Stoves,

Emperor Way,

Exeter Business Park,

Exeter,

Devon. EX1 3QS

Email info@hunterstoves.co.uuk

Website http://www.hunterstoves.co.uk

WARRANTY

Hunter Stoves appliances come with a standard 2 year warranty; however this excludes naturally

wearing “consumable” components and the use of un-authorised fuels.

Consumables are deemed to be; Glass, Seals, Gaskets, Grate Components, Log Retainers, Baffles,

Thermostat and the surface finish of the appliance.

The Warranty will only be valid if the appliance is installed by an appropriately qualified engineer in

accordance with the manufacturer’s instructions and to the appropriate Building Regulations and/or

Local By-Laws and serviced within 12 months of installation.

Hunter Stoves will also support an extended 5 year warranty on external Cast Iron components such

as Doors, Flue Collars and Covers.

If this appliance is purchased through an un-authorised stockist or an internet trader Hunter Stoves

are only obliged to support the statutory requirements.

This appliance must be regularly serviced and maintained, using only Hunter Stoves approved

components for the Warranty to be valid

JINTDBW09 Rev B 05/03/15

2

INSET TELFORD 20DB

Unit 8 Emperor Way, Exeter Business

Park, Exeter, Devon, EX1 3QS

BS/EN 13229

UKAS# 0692

Stove Mass: 127.67kg

NOMINAL OUTPUT: 15.8KW

NOMINAL OUTPUT TO WATER: 10.7KW

NOMINAL OUTPUT TO SPACE: 5.1KW

CO Emission at 13% O2: 0.33%

Mean Flue Gas Temperature: 385°C

EFFICIENCY: 69.9%

Flue Gas Mass Flow: 14.1g/s

Maximum operating water temperature in °C: 100°C

Maximum operating pressure in bar: 1.2 Bar

Minimum clearance to combustible material

Top of Fire Surround:

150mm

Side of Fire Surround:

75mm

Side Wall:

200mm

This appliance is suitable for intermittent burning

This appliance is not suitable for use in a shared flue

Read and follow the operating instructions

Use only recommended fuels

15

Inset Telford 20DB

Technical Specification

JINTDBW09 Rev B 05/03/15

3

IMPORTANT INFORMATION

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION AND OPERATION.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE AND SERVICING.

THIS APPLIANCE WILL BECOME HOT WHEN USED IN ACCORDANCE WITH THESE INSTRUCTIONS.

HUNTER STOVES RECOMMEND THAT AN APPROVED GUARD IS USED TO PROTECT THE YOUNG,

ELDERLY OR INFIRM FROM HARM.

THE INSTALLER COMMISSIONING SHEET CAN BE FOUND ON THE BACK COVER.

PLEASE ENSURE THAT IT IS COMPLETED PRIOR TO USE.

GENERAL GUIDANCE

It is important that your stove is correctly

installed and operated as Hunter Stoves cannot

accept responsibility for any fault arising through

incorrect installation, use, maintenance or

servicing.

These instructions cover the basic principles to

ensure satisfactory installation of the stove,

although detail may need slight modification to

suit particular local site conditions.

The installation must comply with current Building

Regulations, National and European Standards,

Local Authority Byelaws and other specifications

or regulations as they affect the installation of the

appliance.

The Building Regulations requirements may also

be met by adopting the relevant

recommendations in the current issues of British

Standards BS 8303 and BS EN 15287-1.

Only use approved fuels on this appliance.

Information about this can be found on Page 18.

This is a Domestic Appliance and must only be

used in accordance with these instructions.

Do not place articles that are affected by high

temperatures on, or near, this appliance. Do not

place furniture or other items within 700mm of

the front of this appliance. See the note on

material clearances on page 10.

JINTDBW09 Rev B 05/03/15

Extractor Fans and/or Cooker Hoods must not be

installed in the same space or room as this can

cause the appliance to emit fumes into the room.

Do not obstruct the ventilation required for the

safe use of this appliance.

COMPETENT PERSONS SCHEME

Hunter Stoves recommend that this stove is

installed by a member of an accredited

competent persons scheme e.g. HETAS.

If the installer is not a member of a competent

person’s scheme, it is a legal requirement, in the

UK, to notify your Local Building Control Officer in

advance of any installation work starting.

HEALTH AND SAFETY PRECAUTIONS

Special care must be taken when installing the

stove such that the requirements of the Health

and Safety at Work Act are met.

HANDLING

This appliance is very heavy. Adequate facilities

must be available for loading, unloading and site

handling

FIRE CEMENT

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin.

In case of contact, wash immediately with plenty

of water.

4

ASBESTOS

This stove contains no asbestos. If there is a

possibility of disturbing any asbestos in the course

of installation then please seek specialist guidance

and use appropriate protective equipment.

METAL PARTS

When installing or servicing this stove, care should

be taken to avoid the possibility of personal injury.

MODIFICATION

No unauthorized modification of this appliance

should be carried out.

SAFETY

WARNING!

This appliance will be hot when in operation and

due care should be taken. The supplied gloves

may be used to open the door and operate the air

controls.

AEROSOLS

Do not use an aerosol spray on or near the stove

when it is alight.

FIREGUARDS

Always use a fireguard in the presence of children,

the elderly or the infirm. The fireguard should be

manufactured in accordance with BS8423 –

Fireguards for use with solid fuel appliances.

DO NOT OVER-FIRE

It is possible to fire the stove beyond its design

capacity. This could damage the stove so watch

for signs of over-firing. If any part of the stove

starts to glow red, the stove is in an over-fire

situation and the controls should be adjusted

accordingly. Never leave the stove unattended for

long periods without first adjusting the controls to

a safe setting. Careful air supply control should be

exercised at all times.

FUME EMISSION

Properly installed and operated, this appliance

will not emit fumes. Occasional fumes from deashing and refueling may occur. Persistent fume

emission must not be tolerated.

This appliance should not be operated with the

door open.

If fume emission does persist then the following

action should be taken immediately;

Open Doors and windows to ventilate room.

Let the fire out, or eject and safely dispose of

fuel from the appliance.

Check for flue/chimney blockage and clean if

required.

Do not attempt to relight the fire until the

cause has been identified and corrected.

If necessary seek professional advice.

ADVERSE WEATHER

In a small number of installations, occasional local

weather conditions (e.g. wind from a particular

direction) may cause downdraught in the flue and

the stove to emit fumes. In these circumstances

the stove should not be used. A professional flue

installer will be able to advise on solutions to this

problem (e.g. anti-downdraught cowl).

CARBON MONOXIDE DETECTOR

Hunter Stoves recommend a Carbon Monoxide

Detector that conforms to the latest issue of BS

EN 50292 is placed in the same room as the

appliance. The installation of such an alarm is not

considered as a substitute for regular

maintenance or servicing or the appliance and

Flue system.

IN THE EVENT OF A CHIMNEY FIRE:

Raise the alarm

Call the Fire Brigade

Close appliance air controls

Move furniture, ornaments etc. away

Place a fireguard in front of stove

Check the chimney breast for signs of excessive

heat.

If the wall is becoming excessively hot, move

furniture away.

Ensure the Fire Brigade can gain access to your

roof space in order to check for fire spread.

JINTDBW09 Rev B 05/03/15

5

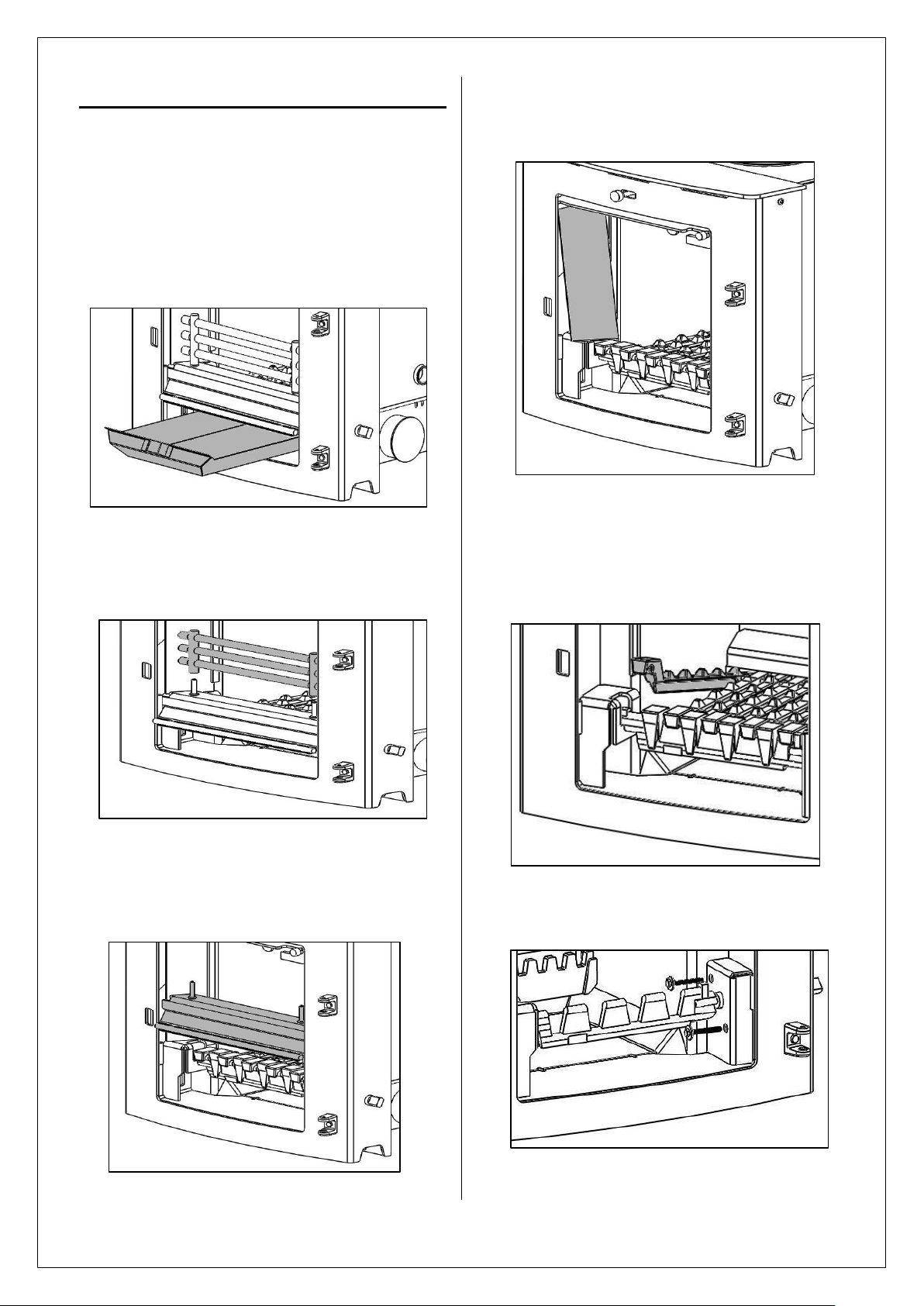

Removing Internal Components

All internal components must be removed prior

to fitting the stove. This will make handling the

stove easier; allow access to fixings and the flue

outlet; as well as protect the internal

components from damage during the installation

process.

1. Open the door(s) and remove the ashpan.

2. Remove the fuel retainer by lifting

upwards of its supports and remove from

firebox.

4. Remove the bricks by sliding forward so

they are clear of their supports and tilting

the bottom edge into the fire box.

5. Remove the grate bars by lifting the front

up off the cam bar and sliding forward off

the rear grate support and lifting out of

the firebox. Repeat with remaining grate

bars.

3. Remove the fuel retainer support (front

plate) by lifting the fuel retainer support

clear from its locating slots. Then remove.

JINTDBW09 Rev B 05/03/15

6. Remove cam bar by removing the two M6

x 50mm screws form the cam bar cover.

6

7. Remove the cam bar and cam bar cover

by lifting the cam bar from the left hand

side until clear of the support. Slide the

cam bar to the left and remove.

8.

Remove the rear grate bar support by

lifting the grate bar support clear of the

locating slots and remove.

RE-ASSEMBLING THE STOVE

Refit all the internal parts by following the

‘removing internal components’ instructions in

reverse orders.

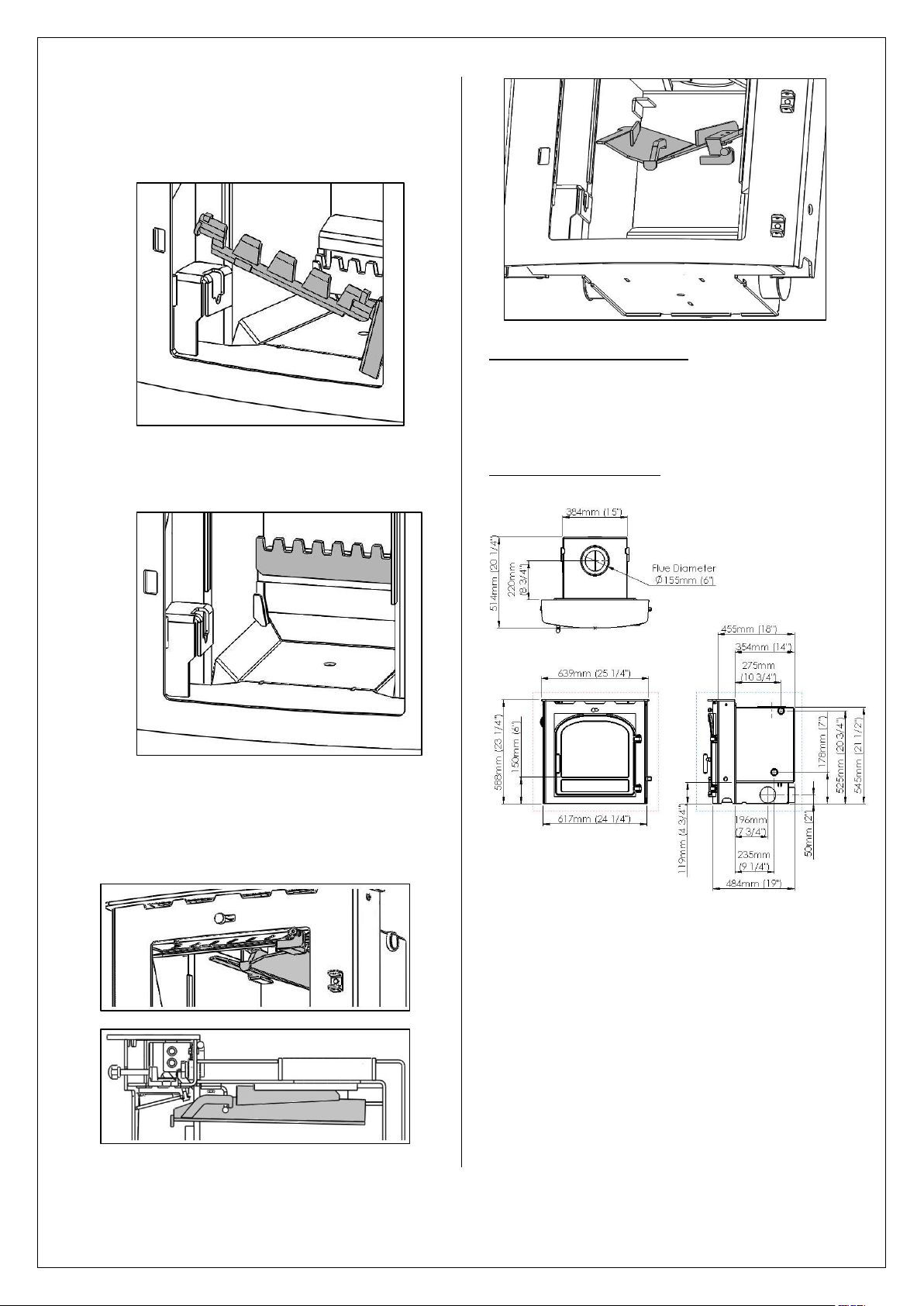

APPLIANCE DIMENSIONS

9. Remove the baffle by sliding it forward

until it reaches its stop. Then lift and slide

forward until clear of its supports and

lower into the firebox.

JINTDBW09 Rev B 05/03/15

7

Pre Installation Requirements

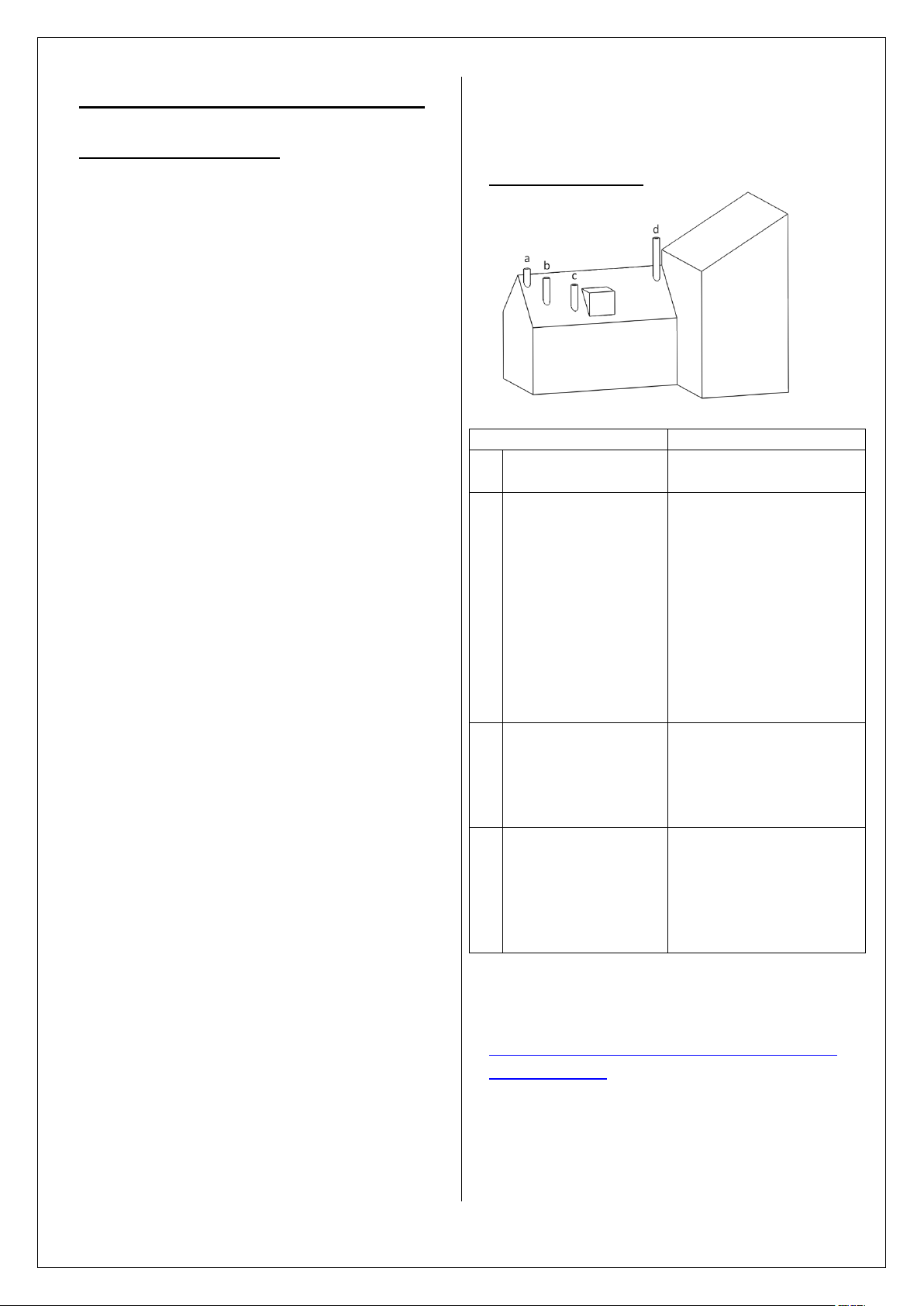

Position on Roof

Clearances to flue exit

A

At or within

600mm of the ridge

At least 600mm

above the ridge

B

Elsewhere on a roof

(Pitched or Flat)

At least 2.3 M

horizontally from the

nearest point on the

weather surface and:

a) At least 1.0 M above

the highest point of

intersection between the

chimney and weather

surface; or

b)at least as high as the

ridge

C

Below (on a pitched

roof) or within 2.3 M

horizontally to an

opening window or

dormer

At least 1.0 M above the

top of the opening

D

Within 2.3 M of an

adjoining or

adjacent building,

whether or not

beyond the

boundary

At least 600mm above

any part of the adjacent

building within 2.3 M

PLEASE CHECK THE FOLLOWING:

Any existing chimney/flue system must be

confirmed as suitable for this appliance as defined

in Building Regulations Document J. It must be

swept and inspected, by a competent person (see

notes), to confirm that is structurally sound and

free from cracks and obstructions. The diameter

of the Flue should not be less than Ø150mm and

not more than Ø200mm. Do not connect to

systems that have large voids or spaces. If any of

these requirements are not met, the chimney

should be lined by a suitable method.

If the chimney is suspected of previously serving

an open fire it must be swept again, within a

month of regular use, to clear any soot that may

have been dislodged due to the variation in

combustion levels and higher flue gas

temperature levels. The chimney/flue system exit

must comply with Building Regulations Document

J. The minimum height of the chimney/flue system

must be 4.5 metres and should terminate in

accordance with Table 1.

Make provision to access the chimney/flue system

for cleaning and the removal of debris. If there is

no existing chimney then either a prefabricated

block chimney in accordance with Building

Regulations Approved Document J, or a twinwalled insulated stainless steel flue to BS4543 can

be used. These chimneys must be fitted in

accordance with the manufacturer’s instructions

and Building Regulations. New masonry and flue

block chimneys must meet the requirements of

Building Regulations Document J. Any connecting

flue pipe systems must also meet these

regulations.

Please check the suitability of the fireplace and/or

surround for use with this appliance before

installing it. Many Fire Surrounds are only suitable

for use with gas and electric fires and therefore

may not suitable for this Solid Fuel Appliance.

Please check your Fire Surround. Fire Surround

Back Panels suitable for solid fuel are usually in

three sections and slabbed.

If you have any doubts about the

suitability of your chimney, consult your

local dealer/stockist.

Both the chimney and flue pipe must be

accessible for cleaning and if ANY part of

JINTDBW09 Rev B 05/03/15

the chimney cannot be reached through the

stove (with baffle removed), a soot door

must be fitted in a suitable position.

FLUE OUTLET POSITIONS

Table 1. – Flue Terminal Positions

A full copy of Document J can be found here:

http://www.planningportal.gov.uk/uploads/br/BR

_PDF_ADJ_2010.

8

Loading...

Loading...