Hunter Stoves Telford Inset 20DB CVWSTI08DBFM, Telford Inset 20DB, Telford Inset 20DB CVWTI08DBFM Instructions For Installation/operating/maintenance/servicing

Page 1

Telford Inset 20DB

Multifuel Boiler Stove

Model: CVWSTI08DBFM/CVWTI08DBFM

Instructions for:

Installation/Operating/Maintenance/Servicing

JINTDBW09 Rev B 05/03/15

Page 2

CONTENTS INDEX:

TECHNICAL SPECIFICATION……………………………………………………………………………………………… 3

IMPORTANT INFORMATION……………………………………………………………………………………………. 4

REMOVING INTERNAL COMPONENTS……………………………………………………………………………… 6

APPLIANCE DIMENSIONS ……………………………………………………………………………………………… 7

PRE INSTALLATION REQUIREMENTS…………………………………………………………………………………. 8

INSTALLATION INSTRUCTIONS………………………………………………………………………………………… 11

INSTALLATION OF HEATING & HOT WATER……………………………………………………………………………. 13

COMMISSIONING AND HANDOVER………………………………………………………………………………….. 15

OPERATING INSTRUCTIONS……………………………………………………………………………………………… 16

MAINTENANCE & SERVICING…………………………………..……………………………………………………….. 19

SPARES INFORMATION……………………………………………………………………………………………………… 21

COMMISSIONING & INSTALLATION CHECK LIST……………..……………….……………………………….. 24

SERVICE RECORDS…………………………………………………………………………………………………………….. 25

Hunter Stoves,

Emperor Way,

Exeter Business Park,

Exeter,

Devon. EX1 3QS

Email info@hunterstoves.co.uuk

Website http://www.hunterstoves.co.uk

WARRANTY

Hunter Stoves appliances come with a standard 2 year warranty; however this excludes naturally

wearing “consumable” components and the use of un-authorised fuels.

Consumables are deemed to be; Glass, Seals, Gaskets, Grate Components, Log Retainers, Baffles,

Thermostat and the surface finish of the appliance.

The Warranty will only be valid if the appliance is installed by an appropriately qualified engineer in

accordance with the manufacturer’s instructions and to the appropriate Building Regulations and/or

Local By-Laws and serviced within 12 months of installation.

Hunter Stoves will also support an extended 5 year warranty on external Cast Iron components such

as Doors, Flue Collars and Covers.

If this appliance is purchased through an un-authorised stockist or an internet trader Hunter Stoves

are only obliged to support the statutory requirements.

This appliance must be regularly serviced and maintained, using only Hunter Stoves approved

components for the Warranty to be valid

JINTDBW09 Rev B 05/03/15

2

Page 3

INSET TELFORD 20DB

Unit 8 Emperor Way, Exeter Business

Park, Exeter, Devon, EX1 3QS

BS/EN 13229

UKAS# 0692

Stove Mass: 127.67kg

NOMINAL OUTPUT: 15.8KW

NOMINAL OUTPUT TO WATER: 10.7KW

NOMINAL OUTPUT TO SPACE: 5.1KW

CO Emission at 13% O2: 0.33%

Mean Flue Gas Temperature: 385°C

EFFICIENCY: 69.9%

Flue Gas Mass Flow: 14.1g/s

Maximum operating water temperature in °C: 100°C

Maximum operating pressure in bar: 1.2 Bar

Minimum clearance to combustible material

Top of Fire Surround:

150mm

Side of Fire Surround:

75mm

Side Wall:

200mm

This appliance is suitable for intermittent burning

This appliance is not suitable for use in a shared flue

Read and follow the operating instructions

Use only recommended fuels

15

Inset Telford 20DB

Technical Specification

JINTDBW09 Rev B 05/03/15

3

Page 4

IMPORTANT INFORMATION

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION AND OPERATION.

KEEP THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE AND SERVICING.

THIS APPLIANCE WILL BECOME HOT WHEN USED IN ACCORDANCE WITH THESE INSTRUCTIONS.

HUNTER STOVES RECOMMEND THAT AN APPROVED GUARD IS USED TO PROTECT THE YOUNG,

ELDERLY OR INFIRM FROM HARM.

THE INSTALLER COMMISSIONING SHEET CAN BE FOUND ON THE BACK COVER.

PLEASE ENSURE THAT IT IS COMPLETED PRIOR TO USE.

GENERAL GUIDANCE

It is important that your stove is correctly

installed and operated as Hunter Stoves cannot

accept responsibility for any fault arising through

incorrect installation, use, maintenance or

servicing.

These instructions cover the basic principles to

ensure satisfactory installation of the stove,

although detail may need slight modification to

suit particular local site conditions.

The installation must comply with current Building

Regulations, National and European Standards,

Local Authority Byelaws and other specifications

or regulations as they affect the installation of the

appliance.

The Building Regulations requirements may also

be met by adopting the relevant

recommendations in the current issues of British

Standards BS 8303 and BS EN 15287-1.

Only use approved fuels on this appliance.

Information about this can be found on Page 18.

This is a Domestic Appliance and must only be

used in accordance with these instructions.

Do not place articles that are affected by high

temperatures on, or near, this appliance. Do not

place furniture or other items within 700mm of

the front of this appliance. See the note on

material clearances on page 10.

JINTDBW09 Rev B 05/03/15

Extractor Fans and/or Cooker Hoods must not be

installed in the same space or room as this can

cause the appliance to emit fumes into the room.

Do not obstruct the ventilation required for the

safe use of this appliance.

COMPETENT PERSONS SCHEME

Hunter Stoves recommend that this stove is

installed by a member of an accredited

competent persons scheme e.g. HETAS.

If the installer is not a member of a competent

person’s scheme, it is a legal requirement, in the

UK, to notify your Local Building Control Officer in

advance of any installation work starting.

HEALTH AND SAFETY PRECAUTIONS

Special care must be taken when installing the

stove such that the requirements of the Health

and Safety at Work Act are met.

HANDLING

This appliance is very heavy. Adequate facilities

must be available for loading, unloading and site

handling

FIRE CEMENT

Some types of fire cement are caustic and should

not be allowed to come into contact with the skin.

In case of contact, wash immediately with plenty

of water.

4

Page 5

ASBESTOS

This stove contains no asbestos. If there is a

possibility of disturbing any asbestos in the course

of installation then please seek specialist guidance

and use appropriate protective equipment.

METAL PARTS

When installing or servicing this stove, care should

be taken to avoid the possibility of personal injury.

MODIFICATION

No unauthorized modification of this appliance

should be carried out.

SAFETY

WARNING!

This appliance will be hot when in operation and

due care should be taken. The supplied gloves

may be used to open the door and operate the air

controls.

AEROSOLS

Do not use an aerosol spray on or near the stove

when it is alight.

FIREGUARDS

Always use a fireguard in the presence of children,

the elderly or the infirm. The fireguard should be

manufactured in accordance with BS8423 –

Fireguards for use with solid fuel appliances.

DO NOT OVER-FIRE

It is possible to fire the stove beyond its design

capacity. This could damage the stove so watch

for signs of over-firing. If any part of the stove

starts to glow red, the stove is in an over-fire

situation and the controls should be adjusted

accordingly. Never leave the stove unattended for

long periods without first adjusting the controls to

a safe setting. Careful air supply control should be

exercised at all times.

FUME EMISSION

Properly installed and operated, this appliance

will not emit fumes. Occasional fumes from deashing and refueling may occur. Persistent fume

emission must not be tolerated.

This appliance should not be operated with the

door open.

If fume emission does persist then the following

action should be taken immediately;

Open Doors and windows to ventilate room.

Let the fire out, or eject and safely dispose of

fuel from the appliance.

Check for flue/chimney blockage and clean if

required.

Do not attempt to relight the fire until the

cause has been identified and corrected.

If necessary seek professional advice.

ADVERSE WEATHER

In a small number of installations, occasional local

weather conditions (e.g. wind from a particular

direction) may cause downdraught in the flue and

the stove to emit fumes. In these circumstances

the stove should not be used. A professional flue

installer will be able to advise on solutions to this

problem (e.g. anti-downdraught cowl).

CARBON MONOXIDE DETECTOR

Hunter Stoves recommend a Carbon Monoxide

Detector that conforms to the latest issue of BS

EN 50292 is placed in the same room as the

appliance. The installation of such an alarm is not

considered as a substitute for regular

maintenance or servicing or the appliance and

Flue system.

IN THE EVENT OF A CHIMNEY FIRE:

Raise the alarm

Call the Fire Brigade

Close appliance air controls

Move furniture, ornaments etc. away

Place a fireguard in front of stove

Check the chimney breast for signs of excessive

heat.

If the wall is becoming excessively hot, move

furniture away.

Ensure the Fire Brigade can gain access to your

roof space in order to check for fire spread.

JINTDBW09 Rev B 05/03/15

5

Page 6

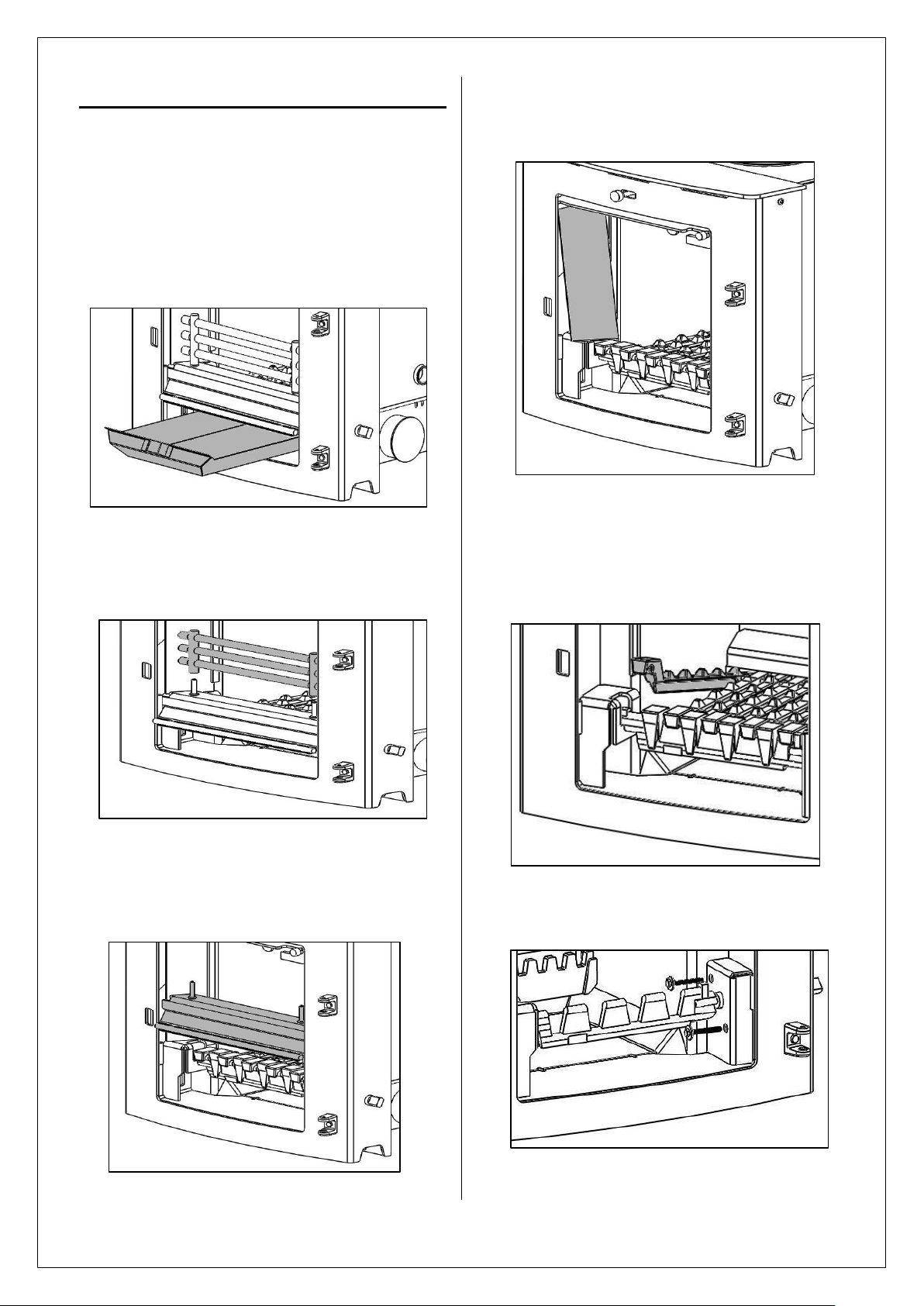

Removing Internal Components

All internal components must be removed prior

to fitting the stove. This will make handling the

stove easier; allow access to fixings and the flue

outlet; as well as protect the internal

components from damage during the installation

process.

1. Open the door(s) and remove the ashpan.

2. Remove the fuel retainer by lifting

upwards of its supports and remove from

firebox.

4. Remove the bricks by sliding forward so

they are clear of their supports and tilting

the bottom edge into the fire box.

5. Remove the grate bars by lifting the front

up off the cam bar and sliding forward off

the rear grate support and lifting out of

the firebox. Repeat with remaining grate

bars.

3. Remove the fuel retainer support (front

plate) by lifting the fuel retainer support

clear from its locating slots. Then remove.

JINTDBW09 Rev B 05/03/15

6. Remove cam bar by removing the two M6

x 50mm screws form the cam bar cover.

6

Page 7

7. Remove the cam bar and cam bar cover

by lifting the cam bar from the left hand

side until clear of the support. Slide the

cam bar to the left and remove.

8.

Remove the rear grate bar support by

lifting the grate bar support clear of the

locating slots and remove.

RE-ASSEMBLING THE STOVE

Refit all the internal parts by following the

‘removing internal components’ instructions in

reverse orders.

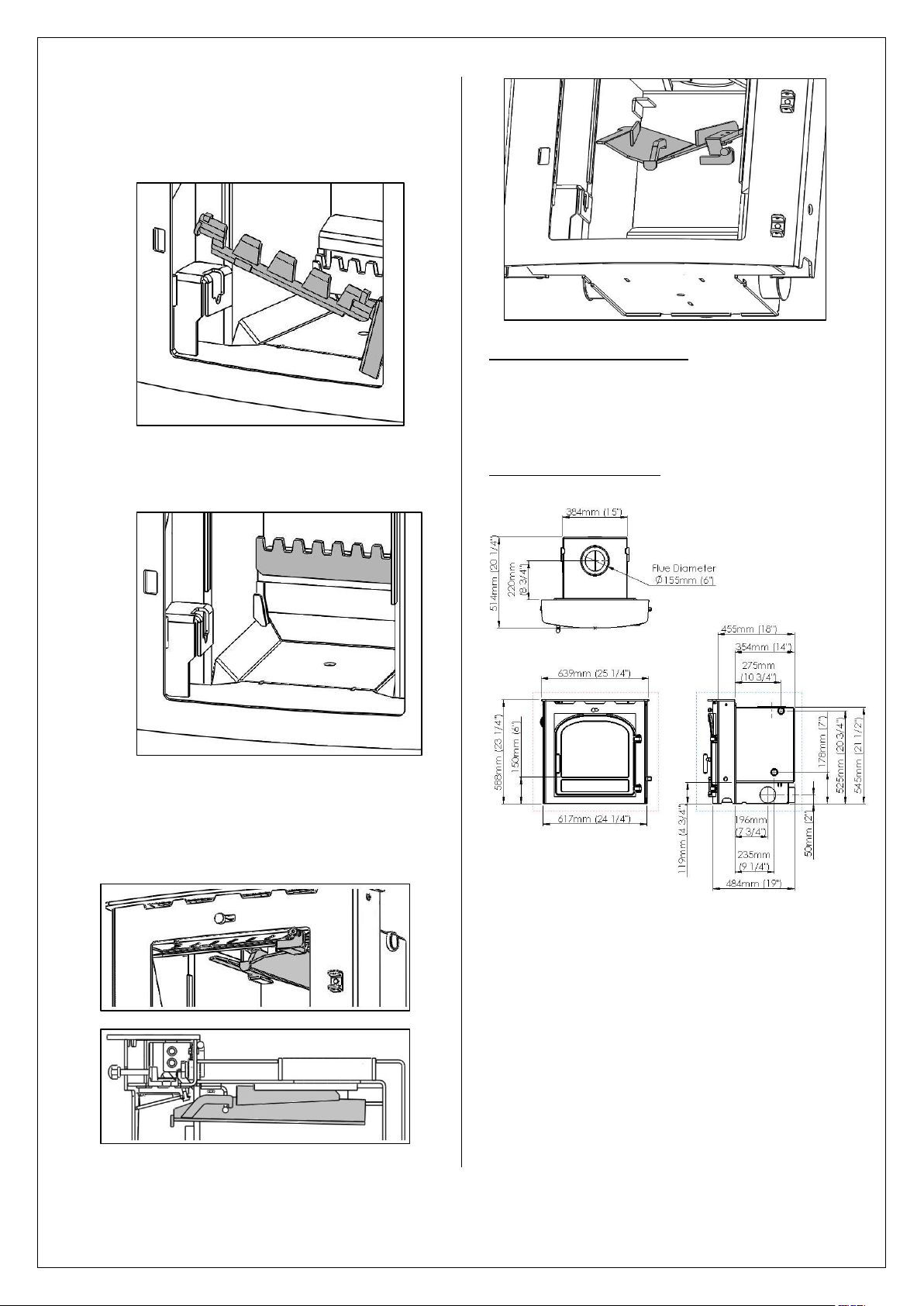

APPLIANCE DIMENSIONS

9. Remove the baffle by sliding it forward

until it reaches its stop. Then lift and slide

forward until clear of its supports and

lower into the firebox.

JINTDBW09 Rev B 05/03/15

7

Page 8

Pre Installation Requirements

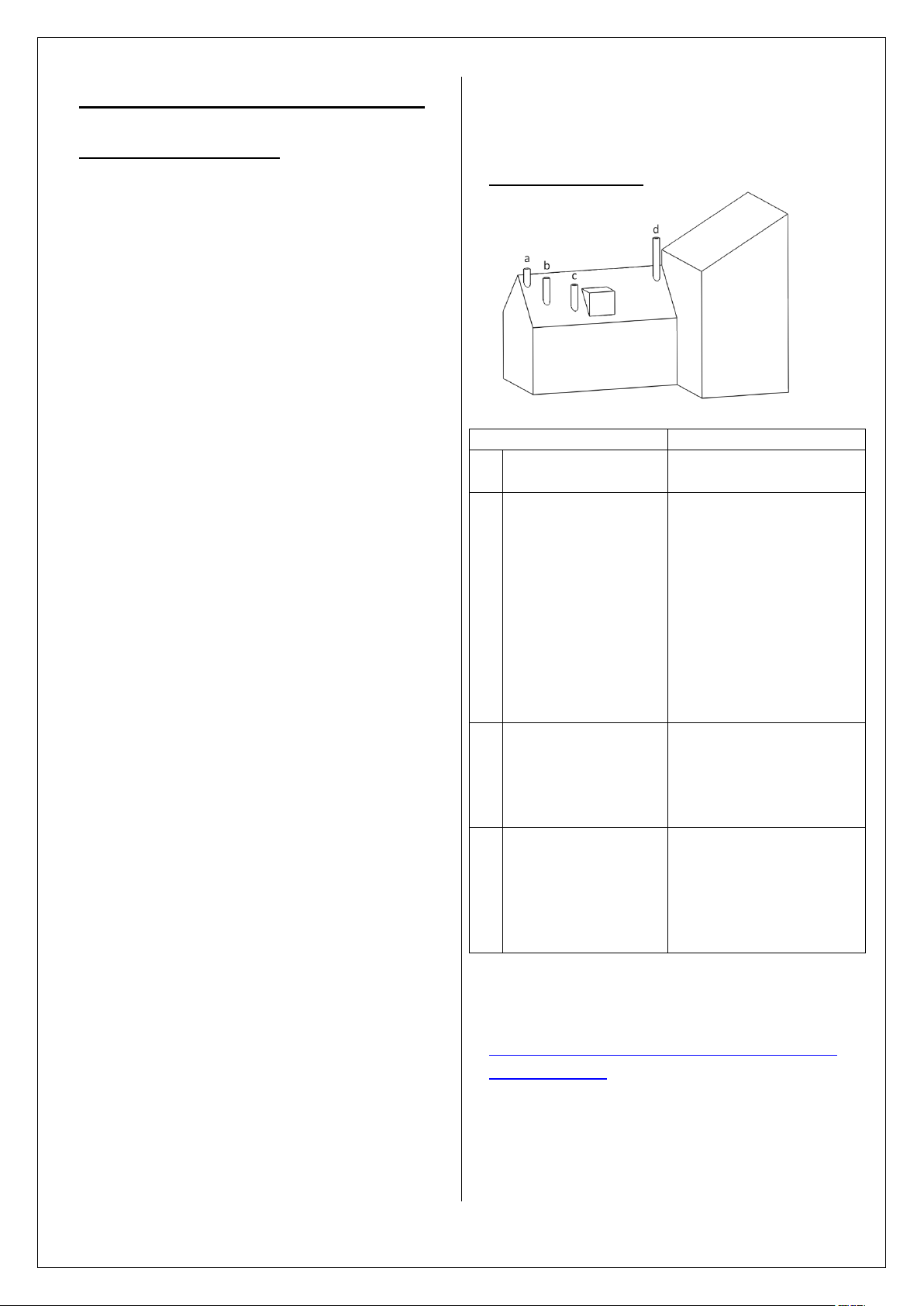

Position on Roof

Clearances to flue exit

A

At or within

600mm of the ridge

At least 600mm

above the ridge

B

Elsewhere on a roof

(Pitched or Flat)

At least 2.3 M

horizontally from the

nearest point on the

weather surface and:

a) At least 1.0 M above

the highest point of

intersection between the

chimney and weather

surface; or

b)at least as high as the

ridge

C

Below (on a pitched

roof) or within 2.3 M

horizontally to an

opening window or

dormer

At least 1.0 M above the

top of the opening

D

Within 2.3 M of an

adjoining or

adjacent building,

whether or not

beyond the

boundary

At least 600mm above

any part of the adjacent

building within 2.3 M

PLEASE CHECK THE FOLLOWING:

Any existing chimney/flue system must be

confirmed as suitable for this appliance as defined

in Building Regulations Document J. It must be

swept and inspected, by a competent person (see

notes), to confirm that is structurally sound and

free from cracks and obstructions. The diameter

of the Flue should not be less than Ø150mm and

not more than Ø200mm. Do not connect to

systems that have large voids or spaces. If any of

these requirements are not met, the chimney

should be lined by a suitable method.

If the chimney is suspected of previously serving

an open fire it must be swept again, within a

month of regular use, to clear any soot that may

have been dislodged due to the variation in

combustion levels and higher flue gas

temperature levels. The chimney/flue system exit

must comply with Building Regulations Document

J. The minimum height of the chimney/flue system

must be 4.5 metres and should terminate in

accordance with Table 1.

Make provision to access the chimney/flue system

for cleaning and the removal of debris. If there is

no existing chimney then either a prefabricated

block chimney in accordance with Building

Regulations Approved Document J, or a twinwalled insulated stainless steel flue to BS4543 can

be used. These chimneys must be fitted in

accordance with the manufacturer’s instructions

and Building Regulations. New masonry and flue

block chimneys must meet the requirements of

Building Regulations Document J. Any connecting

flue pipe systems must also meet these

regulations.

Please check the suitability of the fireplace and/or

surround for use with this appliance before

installing it. Many Fire Surrounds are only suitable

for use with gas and electric fires and therefore

may not suitable for this Solid Fuel Appliance.

Please check your Fire Surround. Fire Surround

Back Panels suitable for solid fuel are usually in

three sections and slabbed.

If you have any doubts about the

suitability of your chimney, consult your

local dealer/stockist.

Both the chimney and flue pipe must be

accessible for cleaning and if ANY part of

JINTDBW09 Rev B 05/03/15

the chimney cannot be reached through the

stove (with baffle removed), a soot door

must be fitted in a suitable position.

FLUE OUTLET POSITIONS

Table 1. – Flue Terminal Positions

A full copy of Document J can be found here:

http://www.planningportal.gov.uk/uploads/br/BR

_PDF_ADJ_2010.

8

Page 9

LEGAL REQUIREMENTS

Scheme

Web address

Telephone

APHC (Association

of Plumbing and

Heating

Contractors

(Certification)

Limited

www.aphc.co.uk

0121 711 5030

Building

Engineering

Services

Competence

Accreditation

(BESCA Limited)

www.hvca.org.uk /

www.besca.org.uk

0800 652 5533

HETAS Ltd

(Heating

Equipment Testing

and Approval

Scheme)

www.hetas.co.uk

01684 278170

NAPIT Registration

Ltd

www.napit.org.uk

01623 811483

NICEIC Group Ltd

www.niceic.com

0870 013 0389

Hunter Stoves requests that before installation

and/or use of this appliance that you read these

instructions carefully to ensure that all the

relevant requirements are fully understood.

These instructions cover the basic principles to

ensure satisfactory installation of the stove,

although detail may need slight modification to

suit particular local site conditions. In all cases

the installation must comply with current Building

Regulations, Local Authority Byelaws, European

and National Standards and other specifications

or regulations as they affect the installation of the

stove.

It should be noted that the Building Regulations

requirements may be met by adopting the

relevant recommendations given in British

Standards BS 8303, BS 6461 and BS 7566 as an

alternative means to achieve an equivalent level

of performance to that obtained following the

guidance given in Approved Document J.

Your local Building Control Officer can advise you

regarding the interpretation of the Regulations

should there be any questions.

This appliance must be installed by a Registered

Installer (see Competent Persons Scheme) or

approved by your local Building Control Officer.

All works undertaken must be carried out with

due care and attention to meet the requirements

of the Health & Safety code of practice and any

other legislation that may have been introduced

since the publication of these instructions.

COMPETENT PERSONS SCHEME

Members of the following schemes may selfcertify the installation of this stove. If the installer

is not a member of one of these schemes, your

local Building Control Department must approve

the installation.

AIR SUPPLY

The room or space containing this appliance

should have purpose provided ventilation (where

necessary) in accordance with Building

Regulations.

Due consideration should be given to air

requirements for any other appliance in the same

room or space.

Any air opening must be kept clear from blockage

or obstruction.

This stove must be fitted on a hearth or base with

adequate load-bearing capacity.

APPLIANCE OPENING

The opening into which this stove is fitted should

be constructed wholly from non-combustible

materials. The dimensions of the opening should

be at least those shown in the diagrams on page

10.

JINTDBW09 Rev B 05/03/15

9

Page 10

This appliance will fit into a standard 16” fireplace

opening if the clay fire back is removed.

Any non-combustible walls within 50mm of this

appliance should be at least 200mm thick and

should extend at least 30mm above the top of

the appliance and at least 1.2 metres above the

hearth. Any walls more than 50mm from the

appliance may be reduced to a thickness of

75mm. Ensure the inter-connecting flue pipe also

has adequate clearances to combustible

materials

The walls surrounding the stove will become hot

and should therefore be finished in a heat

resistant plaster.

Do not hang pictures, plasma screen televisions

or ornaments above the stove, as these could be

damaged and could potentially create a fire

hazard.

HEARTH REQUIREMENTS

A constructional hearth with a minimum thickness

of 125mm should be provided. This constructional

hearth should extend to at least 300mm in front

of the stove and 150mm at the sides

The constructional hearth should be made of solid

non-combustible material and can include any

solid non-combustible floor. The boundary of the

hearth must be clearly marked. This can be done

by adding a super-imposed hearth on top of the

constructional hearth – e.g. a slate slab on top of a

solid concrete floor.

FLUE DRAUGHT

If the draught exceeds the recommended

maximum, a draught stabiliser must be fitted so

that the rate of burning can be controlled and to

prevent over firing.

If the reading is less than the recommended

minimum then the performance of the appliance

will be compromised.

The flue draught should be checked under fire at

high output.

Minimum Draught – 1.2mm Water Gauge

Maximum Draught – 2.5mm Water Gauge

CLEARANCES TO COMBUSTIBLE MATERIALS

Excluding some fire surround installations (see

below) there should be no combustible material

within 200mm of either side of the stove or

275mm above.

No combustible furniture should be placed any

closer than 700mm from the front of the stove.

JINTDBW09 Rev B 05/03/15

10

Page 11

FIRE SURROUNDS

Rope Seal

Please check the suitability of any

fireplace/surround for closed solid fuel

appliances before installation.

Hunter Stoves cannot be held responsible for any

fault arising through incorrect use or installation.

Fire surround back panels suitable for solid fuel

are usually in three sections and slabbed. Many

fire surrounds are suitable only for use with gas

and electric fires and therefore not suitable for

solid fuel.

A combustible fire surround with a depth of up to

100mm requires a minimum clearance of 75mm

from the side of the stove. For combustible fire

surrounds with a depth in excess of 100mm this

clearance must be increased to 200mm.

Installing the Stove

1. Check positions of pipe connections.

2. Make suitable access holes so you can access

the tappings and infill with vermiculite

concrete.

3. Apply fire cement around the rope seal. This

will help seal the stove when in position.

4. Move the stove into position inside the

fireplace opening, being careful not to

damage the hearth or paintwork on the stove

and making sure that the rope seal is

compressed forming a tight seal between the

stove and fireplace.

5. Drill hole into hearth through base using a

10mm drill bit.

6. Position anchor bolt provided through base

plate and fix stove in place.

7. Connect the boiler – see ‘Installation of boiler

models’.

8. Fill the boiler and check for leaks.

9. Connect the flue – see ‘Flue connection’.

10. Infill around the stove with vermiculite

concrete.

11. Fill in the access for the boiler pipe

connections.

12. Fill in the top access.

11

JINTDBW09 Rev B 05/03/15

Page 12

FLUE CONNECTION

N.B. An adjustable flue bend may be required for

some installations.

If connecting to a stainless liner, a proprietary

single wall flue adaptor will be required. It is

recommended that a short length of flue pipe is

connected before the liner.

Alternatively a connection can be made using a

register plate although it will be necessary to allow

access for fitting the flue pipe to the register plate,

infilling with vermiculite concrete and sealing all

joints.

If connecting to an existing masonry chimney it is

recommended that a flue forming pipe (short

length of flue pipe) is used and the void between

the flue forming pipe and the chimney is filled with

vermiculite concrete.

A suitable access hole will need to be made in the

chimney breast to allow the back filling to be

carried out and then filled and sealed once the

installation is complete.

JINTDBW09 Rev B 05/03/15

12

Page 13

INSTALLATION OF HEATING & HOT WATER SYSTEM

We strongly recommend that a knowledgeable,

experienced and qualified plumbing and heating

engineer is responsible for the design and

installation of the heating and hot water system.

Hunter Stoves Ltd cannot accept responsibility for

any consequential loss, however caused, due to

under or over specification of the appliance in any

installation.

Do Not – Under any circumstances connect the

stove to a sealed (pressurised)

heating system or unvented hot water

cylinder.

Do Not – Link the stove into a heating or hot

water system with an existing boiler

without the use of suitable equipment

such as a neutralizer. When fitting this

type of system the neutralizer

manufacturer’s instructions must be

followed.

Do – Fit an open cold feed and expansion

cistern with separate cold feed and

vent pipes. The cold feed and vent

pipes must be unvalued. The open vent

pipe should have a diameter of 22mm

and rise continuously from the boiler.

It is common practice to form the vent

pipe from an extension of the primary

flow (see diagram).

If a common flow and return is used, these should

also be taken from diagonally opposite sides of

the boiler, and plugs inserted into the sockets not

used.

Systems using a common flow and return to the

boiler should incorporate an injector tee on the

primary return connection from the central

heating pump (see diagram).

A HIGH LIMIT thermostat should be fitted to the

gravity flow pipe close to the boiler and set at

90°C. This should override any pump control,

switching the pump on and dissipating any excess

heat around the radiator circuit.

To prevent boiler corrosion due to condensation it

is necessary to maintain the return water

temperature above 45°C. This can be achieved by

the use of a LOW LIMIT thermostat on the return

pipe from the hot water cylinder, close to the

boiler. The thermostat should make on

temperature rise, preventing the circulating pump

from operating until the gravity circuit is up to

temperature.

Do – Connect the stove to a double feed,

indirect hot water cylinder via 28mm

copper flow and return pipe work,

rising continuously from the boiler to

the cylinder. The cylinder and heat leak

radiator must be sited higher than the

stove.

Semi pumped systems should be used on heating

and hot water systems with gravity circulation to

the hot water cylinder and one unvalved 2 KW

radiator to act as a heat leak when the central

heating is switched off.

All four tappings on wraparound boilers should be

used for systems incorporating separate gravity

and pumped heating loops. Each flow and return

should be taken from diagonally opposite sides of

the boiler.

JINTDBW09 Rev B 05/03/15

13

Page 14

Room Thermostat

High Limit

Thermostat

90°C

Circulating Pump

Low Limit Thermostat (45°C)

Time Switch

Drain Cock

Room Thermostat

High Limit

Thermostat

90°C

Circulating Pump

Low Limit Thermostat (45°C)

Time Switch

Drain Cock

Injector Tee

Four Tapping System

Two Tapping System

Wiring Diagram for general guidance only

All electrical work must be carried out by a

competent electrician in accordance with the

rules in force and the instructions provided by

the circulating pump and heating controls

manufacturer

Central Heating Control

JINTDBW09 Rev B 05/03/15

14

Page 15

Commissioning and Handover

APPLIANCE CHECK

Please check that all components are correctly

assembled and working correctly.

Ensure the Air Controls are working correctly.

Hunter Stoves recommend that you carry out a

smoke draw test to check the soundness of the

chimney/flue system and seals:

Place a Smoke Pellet in the centre of the Grate,

ensure that all of the Air Controls are fully open

and close the Door.

The smoke should now be drawn up the chimney

and you should be able to see it exit from the

chimney/flue terminal.

We recommend that you do this test with all of

the windows and doors, to the room where the

appliance is fitted, closed.

If there any adjoining room(s) that have an

Extractor Fan fitted, open the adjoining door to

ensure that the chimney/flue system is not

compromised when the fan is operating.

If there is a ceiling fan fitted in the room please

operate it and ensure that it does not affect the

operation of the chimney/flue system.

If any of these tests fail, please re-check the

suitability of the chimney/flue system together

with the ventilation.

A small fire can now be lit and allow the appliance

to heat up slowly ensuring that no products of

combustion enter into the room.

When the appliance has reached working

temperature open the door, move the Baffle to

the re-fuelling position (see instructions on page

17), and carry out a spillage test using a smoke

match around the door opening.

If there is excessive spillage please allow the

appliance to cool and then re-check the

chimney/flue system and ventilation.

Do not run the stove at full output for at least 24

hours.

On completion of the commissioning:

Upon completion, allow a suitable period of time

for any fire cement and mortar to dry out. Do not

run the stove at full output for at least 24 hours.

Please instruct the user on the safe operation of

this appliance, how the controls work and basic

maintenance requirements.

Ensure that the operating instructions and

appliance tools are left with the customer and the

check lists have been filled out correctly.

Please advise the customer on the correct use of

the appliance with the fuels likely to be used on

the stove and warn them to use only the

recommended fuels for the stove.

Advise the user on what to do should smoke or

fumes be emitted from the stove.

The user should be warned to use a fireguard to

BS 6539 in the presence of children, aged and/or

infirm persons.

Hunter Stoves also recommend that a CO alarm is

fitted into the room where the appliance is

located.

JINTDBW09 Rev B 05/03/15

15

Page 16

Operating Instructions

SHUT

OPEN

Read the ‘General Guidance’ Section at the start

of these instructions before operating your stove

for the first time.

Allow sufficient clearance between the stove and

pictures, plasma screen televisions or ornaments

etc, as these could be damaged and could

potentially create a fire hazard (For more

information read the ‘Material Clearance’ section

of these installation instructions).

WARNING – This appliance will be hot when in

operation and due care should be taken. The

supplied operating tool or gloves may be used to

open the door and operate the air controls.

USING THE APPLIANCE FOR THE FIRST TIME

We recommend that the appliance is left for 24

hours after installation to allow the fire cement,

fixing glues, etc. to cure.

We also recommend that you have two or three

small fires before you operate your stove to its

maximum heat output. This is to allow the paint to

cure in steadily and to give a long service life of the

paint finish.

During this curing in process you may notice an

unpleasant smell. It is non-toxic, but for your

comfort we would suggest that during this period

you leave all doors and windows open.

AEROSOLS

Do not use an aerosol spray on or near the stove

when it is alight.

AIR CONTROLS

This stove has been designed to burn cleaner and

more efficiently than a conventional stove. If used

correctly this stove will burn far more efficiently

than normal, with the obvious notable feature of

CLEAN GLASS.

For this product to work properly it must be used

correctly. It is essential that the stove has an

adequate air supply for combustion and

ventilation. The primary and secondary air inlets

must be kept clear from obstruction and blockage.

JINTDBW09 Rev B 05/03/15

THERMOSTAT (PRIMARY AIR)

The thermostat is controlled by the knob on the

side of the stove with settings from 0 - 10. The

thermostat generally operates between 50° to 90°.

Experiment with the settings to find the desired

temperature.

SECONDARY AIR

Secondary air is controlled via the slider above the

door(s), it is this “Airwash” that keeps a clean and

uninterrupted view of the fire.

BAFFLE OPERATION

Your Hunter Stove if fitted with a sliding baffle.

The baffle needs to be slid into its open position

when lighting and re-fuelling your stove. This will

prevent spillage while the stove door is open.

To slide the baffle forward you will need to use the

tool provided. Hook the tool onto the tab at the

front of the baffle and pull forward until it hits the

stop. This will create a 30mm gap at the back of

firebox.

16

Page 17

LIGHTING

Baffle in Closed

Position. Hook

Tool on Tab.

Baffle in Open

Position. Slide

Forward until Stop.

Baffle Arm.

Slide the baffle into its open position (see Baffle

Operation below) and open secondary air control

fully and light one or two firelighters placed

centrally on the grate, allowing the flames to

become established before placing several pieces

of small dry kindling in a criss-cross fashion above

the firelighters, taking care not to smother the fire.

Close the stove door. Once the kindling is well

alight open the door and build the fire by gradually

adding fuel, closing the door afterwards.

Once the fire is established gradually close the

secondary air control until around 20% open

(slide control to your left) and add more fuel as

necessary.

When the stove is up to operating temperature

the operating tool or gloves should be used to

operate the air controls.

The baffle will automatically slide back into its

closed position when the door is closed. This is

achieved by the door pushing onto the baffle arm.

LOCOMOTIVE GRATE

Your Hunter Stove is fitted with a locomotive type

grate. So that de-ashing can be carried out cleanly

and easily, it is riddled from the outside of the

stove with the doors closed.

GRATE OPERATION & BURNING SOLID MINERAL FUELS

It is important that the riddling tool is used to

remove the ash to ensure airflow through the fire

bed and allow the fire to burn over the entire area

of the grate. The ashpan should be emptied at

least daily and ash should never be allowed to

build up over a period of time as this will result in

damage to the fire bars. The flat end of the

riddling tool can be used to carry the ashpan.

LOADING THE APPLIANCE (SOLID MINERAL FUEL)

Solid mineral fuel should not be stacked higher

than the top of the fuel retainer as this may result

in damage to the stove.

With a full load of fuel, the stove will need to be

refuelled approximately once every 4 hours.

AIR CONTROLS (SOLID MINERAL FUEL)

Solid mineral fuel burns most efficiently with the

secondary air control around the 20% open position.

Always de-ash before refuelling and do not let the

ash level reach the underside of the grate bars.

Solid mineral fuel produces ash, which if allowed

to build-up will stifle the airflow through the

Primary air inlets and grate. This will eventually

cause the fire to die.

With some solid mineral fuels a residue of burnt

fuel or clinker will accumulate on the grate, allow

the fire to go out periodically to remove this.

IMPORTANT!

We cannot stress firmly enough how important it

is to empty the ashpan regularly. Air passing

through the fire bed cools the grate bars.

Distortion or burning out the grate bars is nearly

always caused by ash being allowed to build up to

the underside of the grate.

JINTDBW09 Rev B 05/03/15

17

Page 18

EXTENDED BURNING (SOLID MINERAL FUEL)

The stove can be banked up for extended burning.

When burning solid fuel, empty the ashpan. Open

air controls and let the fire burn brightly for a

short period. Refuel and close both air controls,

the exact setting required will depend on the fuel

used and the chimney draw so some practice may

be necessary. To revive the fire, open the air

controls until the fire is burning brightly de-ash if

necessary and refuel. Set air controls as required.

Never leave the stove unattended until you are

certain that the flames are fully established.

Should the fire fail to light correctly open the door

and use a poker to spread the fuel across the

bottom of the firebox. Close the door and allow

the fuel and stove to cool before attempting to

relight the fire.

REDUCED COMBUSTION

In order to shut down the stove, reduce the

thermostat control to ‘0’ and close the secondary

air by sliding control to the left. If the controls are

left in this position, the fire will be starved of air

and will die down. If you want to revive the fire it

is recommended that the thermostat control is

opened first, and then the secondary air control.

Warning! - The stove will remain hot for a

considerable time after the fire has been

extinguished.

REFUELLING

When the fuel has burnt down to the fire bed, add

new fuel. The air controls should not need

adjusting while refuelling.

When refuelling it is important to slide the baffle

into its open position to reduce any spillage. (see

Baffle Operation) The baffle will be hot when

refuelling so due care should be taken.

RECOMMENDED FUELS

Hunter Stoves recommend that approved

smokeless fuels are burnt in this appliance.

Only authorised smokeless fuels may be used in

smoke control areas.

Warning! - Petroleum coke fuels (e.g coal) or

household waste must not be burnt on this

appliance. This appliance must not be used as an

incinerator.

Burning wet or unseasoned wood will create tar

deposits in the stove and chimney and will not

produce a satisfactory heat output.

Should any difficulties arise over fuel quality or

suitability, consult your local approved coal

merchant or:

HETAS Ltd – Telephone 01242 673257 –

www.hetas.co.uk

Solid Fuel Association – Telephone 0800 600 000

– www.solidfuel.co.uk

JINTDBW09 Rev B 05/03/15

18

Page 19

MAINTENANCE & SERVICING

WARNING!

NO unauthorised modification of this appliance

should be carried out.

IMPORTANT!

In order to ensure continued compliance with

current Building Regulations and Local Authority

Byelaws, this appliance requires regular

maintenance by a competent person. N.B. Refer to

the ‘Removing Internal Components’ section of the

installation instructions for details on how to

remove each component.

PERIODS OF PROLONGED NON-USE

If the stove is to be left unused for a prolonged

period, then it should be given a thorough clean to

remove ash and unburned fuel residues. To enable

a good flow of air through the appliance to reduce

condensation and subsequent damage, leave the

air controls fully open. If the appliance has been

unused for a long period, such as during the spring

and summer months, a competent person should

check the chimney for potential obstructions

before lighting the stove i.e. get the chimney

swept before the start of the heating season.

BAFFLE

This should be removed and cleaned at least once

a month to prevent any build-up of soot or fly ash

that could lead to blocked flue ways and

dangerous fume emission. If the baffle is removed

the chimney/flue way can be swept through the

appliance.

STOVE BODY

The stove is finished with a heat resistant paint

and this can be cleaned with a soft brush. Do not

clean whilst the stove is hot; wait until it has

cooled down. The finish can be renovated with a

propriety high temperature stove paint.

GLASS PANEL(S)

Clean the glass panel when cool with a propriety

glass cleaner. Highly abrasive substances should

be avoided as these can scratch the glass and

make subsequent cleaning more difficult. Wet

logs on heated glass, a badly aimed poker or

heavy slamming of the doors could crack the glass

panels. The glass will not fracture from heat.

Should you need to replace a glass panel please

ensure you purchase a new Gasket at the same

time. Please check periodically that the glass clips

and screws have not become loose.

GASKETS

All gasket used on this appliance are produced

from a heat resistant material called Manniglas.

Over time you may find that the gasket changes

colour. This is due to a reduction in the pigment

used in the manufacture of the product, and is no

cause for concern

FIREBRICKS

In normal use, these can last for many years. It is

possible however, to crack them if logs are

continually jammed against them or if they are

frequently struck with a poker. Check periodically

for seriously cracked bricks, which can be replaced

with new; available from your dealer or our spares

website www.hunterstoves.co.uk.

DOOR CATCH

Should the door catch require adjustment, please

use the follow procedure: Open the Door. Slacken

the M6 grub screw, on the underside of the

Handle Boss. Turn the inside catch shaft one turn

clockwise, this will achieve a tighter lock when the

door is closed. Re-tighten the M6 grub screw.

Close and test the operation of the Handle

mechanism.

ROPE

Check the 12mm rope around the door. If rope is

becoming detached, use Hunter Stoves rope glue

to reattach it. If the rope is in a poor condition, a

replacement rope kit may be ordered from the

Hunter Stoves spares range.

CHIMNEY & FLUE WAYS

It is important that the chimney, flue ways and

any connecting flue pipe are swept regularly. This

means at least once a year for smokeless fuels and

at least twice a year for wood and other fuels.

The baffle will need to be removed from its

supports in order to sweep the chimney. Only

wire-centred sweeps’ brushes fitted with a guide

wheel should be used. If it is not possible to sweep

all parts of the chimney through the appliance,

ensure there is adequate access to cleaning doors.

If the stove is fitted in place of an open fire, then

the chimney should be swept one month after

installation to clear any soot falls which may have

occurred due to the difference in combustion

between the stove and the open fire.

JINTDBW09 Rev B 05/03/15

19

Page 20

ANNUAL SERVICE

Hunter Stoves recommend that this appliance is

serviced annually, preferably prior to the start of

the heating season, thus avoiding any delay in

receiving replacement components, should you

need them. If you are unable to undertake this

task, Hunter Stoves recommend that you contact

the installation engineer for advice.

Remove all the internal components:

Riddling Bars, Cam Bar, Catch Bar, Ashpan, Side

Plates and Baffle. Clean them with a wire brush

and inspect them for damage.

Sweep the chimney/flue system if necessary.

Clean down the internal surfaces of the appliance

using a scraper or wire brush.

Inspect these surfaces for damage.

If damage is found we advise that you consult with

your installer about rectification/repair.

Brush out or vacuum the inside of the appliance

and re-fit the internal components.

Inspect the Glass and Gasket. Clean the Glass with

a non-abrasive cleaner if required. If the Gasket is

torn or damaged we recommend that is replaced.

Brush down the outer surface and touch up the

paint if necessary.

Burn the appliance at a low rate, after

maintenance, to allow any new seals, paint or glue

to cure properly. The appliance may emit

unpleasant odours during this process, please

ensure the room is well ventilated.

TROUBLESHOOTING:

Incorrect Flue Draught in your chimney/flue

system will cause poor performance of your

appliance. Excessive Flue Draught can cause low

heat output/ Poor burning control, excessive fuel

consumption and even noise from the Air

Controls. Low Flue Draught can cause difficulty in

lighting and running the appliance, poor heat

output and smoke entering the room when the

Appliance Door is opened.

Poor quality Solid Mineral Fuel and/or damp wood

will also affect the performance of your appliance.

Please be aware of the possible warning signs that

your appliance is not functioning correctly.

Poor combustion, staining or sooting around the

appliance, condensation or dampness on walls or

windows in the room where the appliance is

fitted, a strange smell when the appliance is lit or

water leaking from the appliance.

Please consult with your installer if you are

concerned in any way about the performance of

this appliance.

TROUBLESHOOTING EXAMPLES:

FIRE WILL NOT BURN

Check that:

1. The air inlet is not obstructed in any way.

2. Chimneys and flue ways are clear.

3. A suitable fuel is being used.

4. There is an adequate air supply into the

room.

5. An extractor fan is not fitted in the same

room as the stove.

6. Flue draught is above minimum level (see

installation instructions).

FIRE BLAZING OUT OF CONTROL

Check that:

1. The doors are tightly closed.

2. The air controls are all in the closed

position.

3. A suitable fuel is being used.

4. The glass retaining clips are not loose.

5. The door rope seals are in good condition

Flue draught is below maximum level (see

installation instructions).

JINTDBW09 Rev B 05/03/15

20

Page 21

Spares Information

SINGLE DOOR

HCE09008

DOOR HANDLE

ASSEMBLY

TDI05ARRT011MB

DOOR GLASS

HCE09102

ROPE SEALING KIT

SCPCB900SDRSKREVC

GLASS GASKET

HCE09101

GLASS CLIP

HHR08046

SCREW

FSJM05008SS

SINGLE DOOR

JINTDBW09 Rev B 05/03/15

21

Page 22

LEFT HAND DOOR

TDI05008

DOOR GLASS

HCE09031

ROPE SEALING

SCPCB900DRSK

GLASS GASKET

HCE09030

GLASS CLIP

HHR08046

SCREW

FSJM05008SS

RIGHT HAND DOOR

HCE09009

DOOR HANDLE

ASSEMBLY

TDW09ARRT011MB

GLASS CLIP

HHR08046

SCREW

FSJM05008SS

GLASS GASKET

HCE09030

ROPE SEALING KIT

SCPCB900DRSK

DOOR HANDLE

AVA08020MB

DOUBLE DOORS

JINTDBW09 Rev B 05/03/15

22

Page 23

Body Assembly Spares

REAR GRATE

SUPPORT

HDW09012

GRATE BARS

UPPER: P112032

LOWER: P112033

OPERATING TOOL

HFR07040

FUEL RETAINER

HCW09ARRT025

HINGE PIN

FRRE08-1.75

HINGE

HH06050

BRICK

LEFT: HCW09051A

RIGHT: HCW09051B

SLIDER KNOB

HCE05040M

BAFFLE

HCW09ARRT011

CAM BAR

HCW09ARRT020

ASHPAN

HDW09ARRT007

BAFFLE SUPPORT

HCW09ARRT013

CATCH BAR

HDW09ARRT008

JINTDBW09 Rev B 05/03/15

23

Page 24

COMMISSIONING & INSTALLATION CHECKLIST

PURCHASE INFORMATION

Dealer/Retailer Name

Address

Telephone Number

Email

Date Purchased

INSTALLER INFORMATION

Installer Name

Address

Telephone Number

Email

APPLIANCE INFORMATION

Date Installed

Appliance Stock Code

Appliance Description

Serial Number

COMMISSIONING CHECK (Complete & Sign)

YES

NO

Does the chimney/flue system meet the appropriate standard?

Has the chimney/flue system been swept and passed the soundness test?

Has this appliance passed the smoke test?

Has this appliance passed the spillage test?

Have you explained how to operate the appliance and explained the controls?

Signature:

Print Name:

24

JINTDBW09 Rev B 05/03/15

Page 25

SERVICE RECORDS

1st Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

3rd Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

5th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

7th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

9th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

2nd Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

4th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

6th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

8th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

10th Service

Date of Service

Date of next Service

Servicing Company/

Engineer

Signature

JINTDBW09 Rev B 05/03/15

25

Loading...

Loading...