Hunter Stoves Parkray ASPECT 5 COMPACT, Parkray ASPECT 5, Parkray ASPECT 7, Parkray ASPECT 8 COMPACT, Parkray ASPECT 8 User Manual

...Page 1

ASPECT 4 / 4 COMPACT

ASPECT 5 / 5 COMPACT

ASPECT 6

ASPECT 7

ASPECT 8

ASPECT 14

WOOD BURNING STOVE MODELS

HUNTERSTOVES.CO.UK

Page 2

Welcome to the Hunter Stoves family and thank you for

purchasing a Parkray Aspect stove. This stove was designed and

built to be a high-performance heating appliance, and we hope

it will bring you great enjoyment. The natural environment is

important to us, so our stoves are manufactured to provided you

with a clean and efcient burn that will keep you warm through

cold winter nights.

CONTENTS INDEX

STOVE INFORMATION

GENERAL INFORMATION 4/5

MATERIAL CLEARANCES 6

GENERAL GUIDANCE 7 - 10

OPERATING INSTRUCTIONS 11/12

MAINTENANCE AND SERVICING 13 - 14

3

IMPORTANT INFORMATION 15/16

TROUBLESHOOTING 17

WARRANTY INFORMATION 18/19

Page 3

STOVE INFORMATION

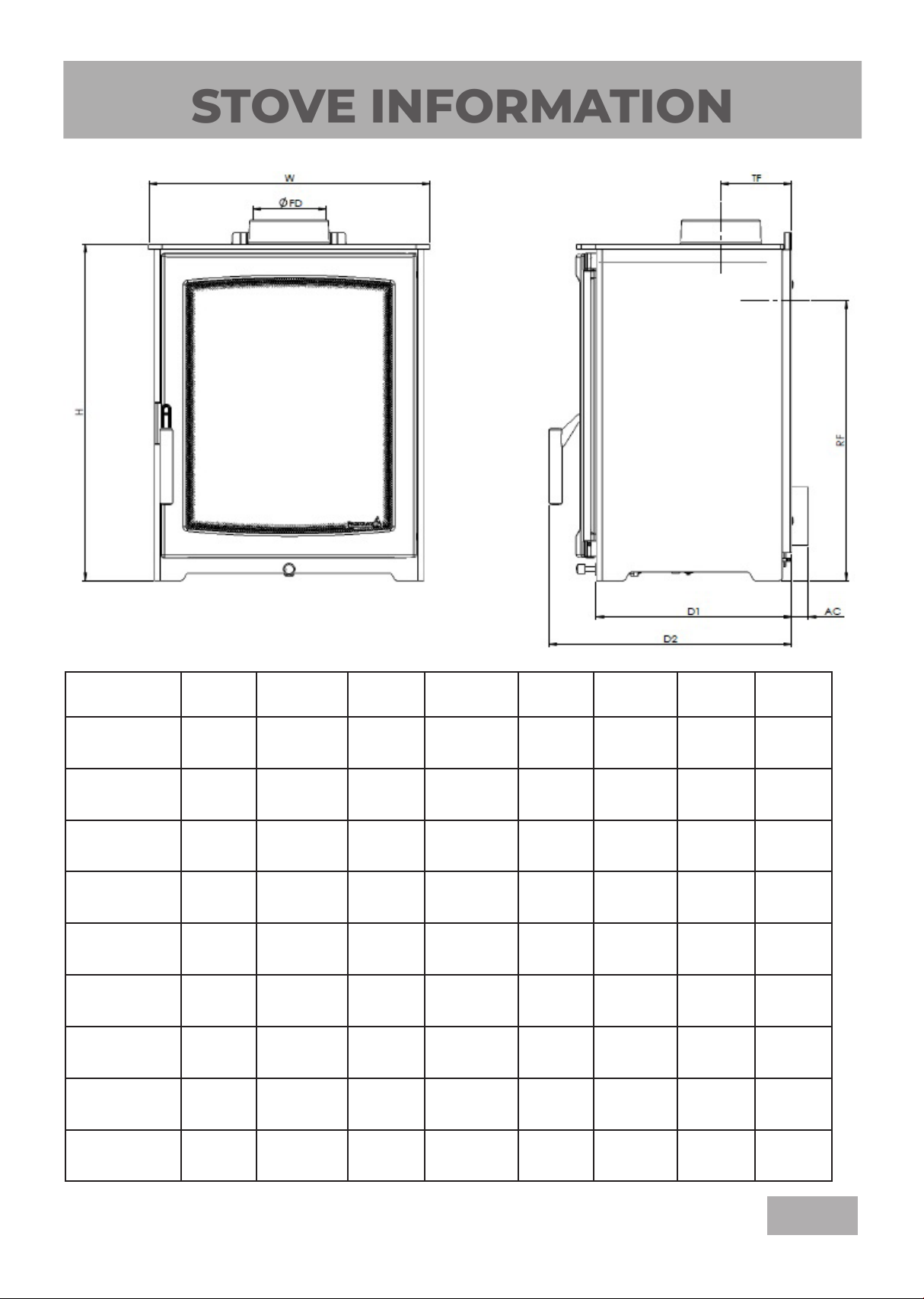

DIMENSIONS H W FD TF RF AC D1 D2

ASPECT 4 515mm 400mm 127mm 110mm 416mm 17.5mm 327mm 410mm

ASPECT 4

COMPACT

ASPECT 5 590mm

ASPECT 5

COMPACT

ASPECT 6 623mm 557mm 127mm 143mm 523mm 2 mm 343mm 422mm

ASPECT 7 550mm 579mm 127mm 110mm 451mm 17.5mm 327mm 410mm

ASPECT 8 623mm 617mm 127mm 128mm. 524mm 7mm 343mm 417mm

ASPECT 8

COMPACT

ASPECT 14 658mm 667mm 127mm

515mm 400mm 127mm 110mm 416mm 17.5mm 277mm 379mm

494mm 127mm 110mm

590mm 494mm 127mm 110mm 491mm 17.5mm 277mm 358mm

648mm 617mm 127mm 153mm

153mm 559mm NA

491mm 17.5mm 327mm 410mm

539mm 13mm 398mm

468mm 555mm

459mm

- 3 -

Page 4

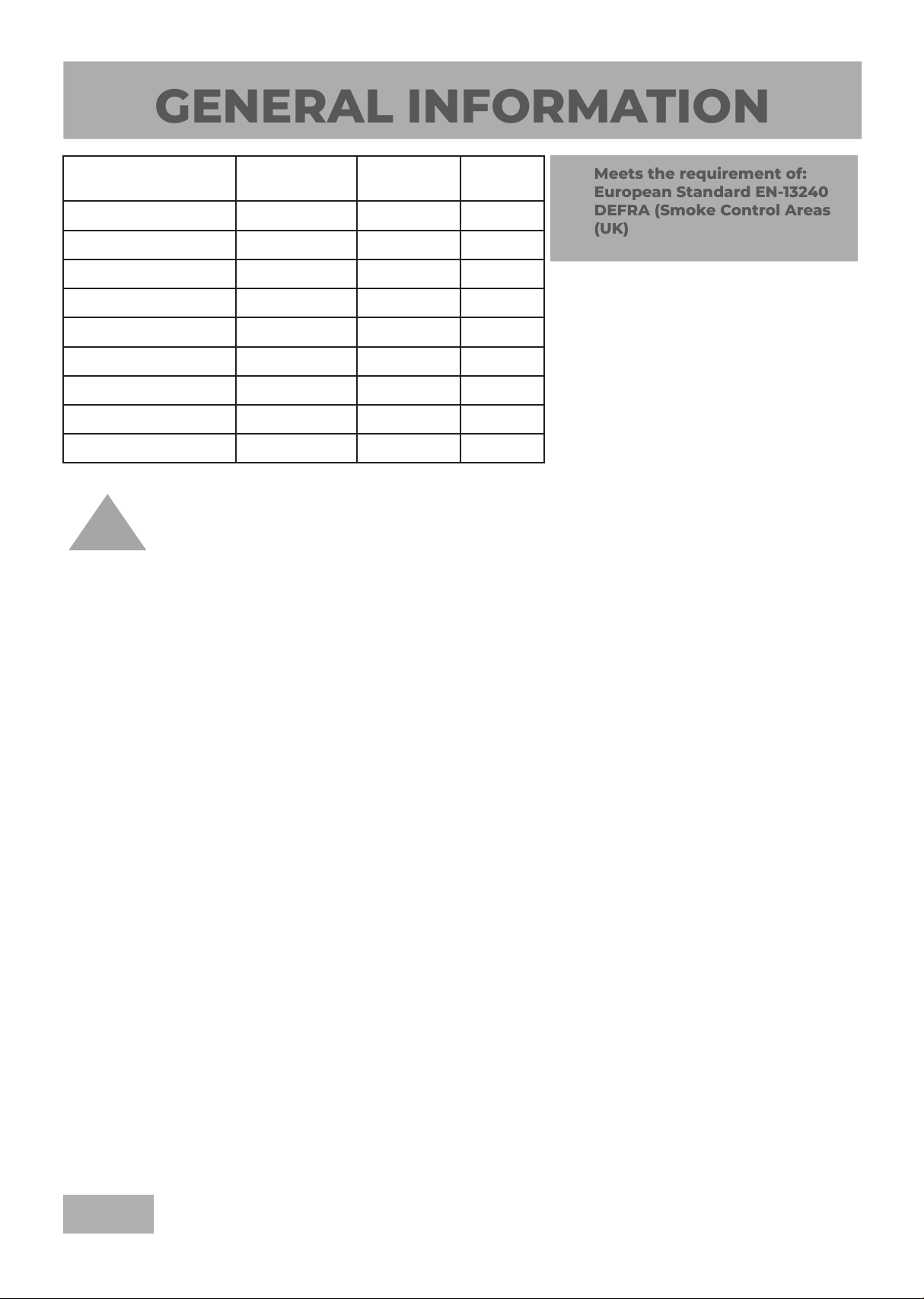

GENERAL INFORMATION

Meets the requirement of:

European Standard EN-13240

DEFRA (Smoke Control Areas

(UK)

Stove Model Nominal

Heat Output

Aspect 4 4.5kW 81.0% 56kg

Efciency Weight

Aspect 4 Compact

Aspect 5

Aspect 5 Compact

Aspect 6

Aspect 7 5.0kW 81.0% 86kg

Aspect 8 7.5kW 76.0% 110kg

Aspect 8 Compact

Aspect 14

!

The appliance will become very hot when used in

accordance with the instructions. The supplied

operating tool or glove may be used to open the door

and operate the air controls. We also recommend use

of a reguard in the presence of childre, the elderley or

the inrm. The reguard should be manufactured in

accordance with BS8423.

4.5kW 81.0%

5.0kW 80.0%

5.0kW 80.0%

5.0kW 80.0%

7.5kw 76.0%

7.8kW 77%

52kg

79kg

72kg

93kg

110kg

130kg

Competent Persons Scheme

Hunter Stoves Group recommend that this stove be

installed by a member of an accredited competent

persons scheme e.g. HETAS.

If the installer is not a member of a competent person’s

scheme, it is a legal requirement, in the UK, to notify

your Local Building Control Ofcer in advance of any

installation work starting.

Legal Requirements

These instructions cover the basic principles to ensure

satisfactory installation of the stove, although details

may need slight modication to suit particular local

site conditions.

In all cases the installation must comply with

current Building Regulations, Local Authority

Byelaws, European and National Standards and

other specications or regulations as they affect the

installation of the stove.

It should be noted that the Building Regulations

requirements may be met by adopting the relevant

recommendations given in British Standards BS

8303, BS 6461 and BS 7566 as an alternative means

to achieve an equivalent level of performance to that

obtained following the guidance given in Approved

Document J.

Hearth

Hearth constructions must comply with the current

building regulations.

Your stove must be installed on a oor with adequate

load-bearing capacity, otherwise suitable measures

should be taken.

If the existing construction does not meet this

pre-requisite, suitable measures (e.g. load distributing

plate) should be put in place.

The hearth should extend at least 225mm from the

front of the appliance(as per Building Regulations) we

recommend 300 mm.

The stove should stand wholly above a solid,

non-combustible hearth, at least 125 mm thick (this

may include the thickness of a solid oor).

Please refer to Building Regulations Approved

Document J for further information.

- 4 -

Page 5

Air Supply

Connection to the Chimney

Aspects 4, 4C, 5, 5C, 6 and 7

The room or space containing this appliance does not

need a permanent, unobstructed air opening unless

the air permeability rating is less than or equal to 5m³/

hour/m².

Aspects 8, 8 Compact, 14

The room or space containing this appliance does

need a permanent, unobstructed air opening.

1375mm² - Aspect 8

1540mm² - Aspect 14.

All

If a draught stabiliser is tted, the air opening should

be at least: -

3825mm² (Aspect 4s),

4250mm² (Aspect 5s, 6 and 7)

3625mm² (Aspect 8)

3880mm² (Aspect 14).

Due consideration should be given to air requirements

for any other appliance in the same room or space.

Any air opening must be kept clear from blockage or

obstruction.

New Build

Attention is needed in new built properties where

the design air permeability is less than 5m3/h.m2.

Approved Document J and Appendix F gives further

information. A window opening is not appropriate.

An existing replace opening can be bricked up or

sealed with a register plate. A short length of ue pipe

of minimum 125mm internal diameter may then be

used to connect the stove to the chimney. This ue

pipe should be made of 316 grade stainless steel or

vitreous enamelled steel, nominal thickness 1.2mm.

Ensure that the pipe end is no closer than 76mm to

the chimney walls. The length of any horizontal run of

ue pipe must not exceed 125mm. It is essential that

all connections between the stove and chimney-ue

are sealed and made airtight. Any bend in the chimney

or connected ue pipe should not exceed 45

bends should not be used.

Ensure any existing chimneys are clear of obstruction

and have been swept prior to installation. If the stove

is being tted into a previous open replace then the

chimney must be swept one month after tting.

Make provision to access the chimney/ue system for

cleaning and the removal of debris. If there is no

existing chimney then either a prefabricated block

chimney in accordance with Building Regulations

Approved Document J, or a twin-walled insulated

stainless-steel ue to BS4543 can be used. These

chimneys must be tted in accordance with the

manufacturer’s instructions and Building Regulations.

New masonry and ue block chimneys must meet

the requirements of Building Regulations Document

J. Any connecting ue pipe systems must also meet

these regulations.

Please check the suitability of the replace and/or

surround for use with this appliance before installing

it. If you have any doubts about the suitability of

your chimney, consult your local Dealer/Stockist or

Installation Engineer.

0

and 90

0

Certicate of Compliance

After completionof the appliance instalation please

ensure the form below (specimen) is completed by your

installer to comply with the requirements of HETAS and

building regulations. The installer must supply these

details, including registration number for any insurance

details that may need changing after installation of the

appliance.

- 5 -

Page 6

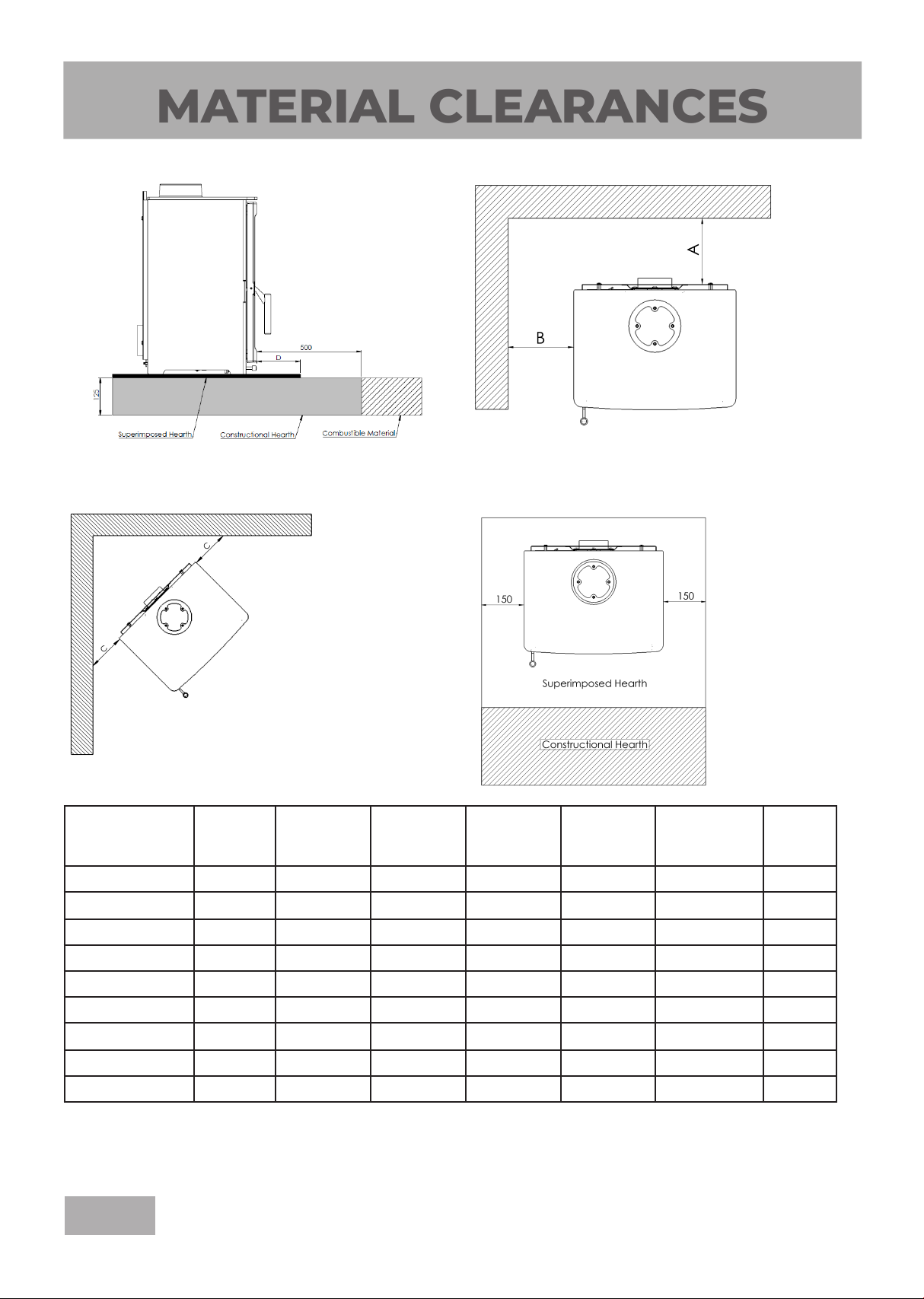

MATERIAL CLEARANCES

Hearth Requirements

Combustible/Non Combustible Distances

Model A (to Twin-

Walled

Flue)

Aspect 4 125mm 500mm 500mm

Aspect 4 Compact 125mm 500mm

Aspect 5 125mm 600mm 600mm 50mm 50mm 500mm 1230mm

Aspect 5 Compact 125mm 600mm 600mm 50mm 50mm 500mm 1230mm

Aspect 6 125mm 600mm 600mm 50mm 50mm 500mm 1230mm

Aspect 7 125mm 500mm 500mm 50mm 50mm 500mm 1230mm

Aspect 8 Compact 100mm 375mm 375mm 50mm 50mm 600mm 1200mm

Aspect 8 100mm 375mm 375mm 50mm 50mm 600mm 1200mm

Aspect 14 100mm 525mm 525mm 50mm 50mm 650mm 1500mm

For clearance distances for the single skin ue pipe please refer to Building Regulations Document J.

B

CombustibleCCombustible

500mm 50mm 50mm

B

Non

Combustible

50mm 50mm 500mm

C

Non

Combustible

Superimposed

Hearth

500mm 1230mm

D

Front

to

Furniture

1230mm

- 6 -

Page 7

Unpacking and Removing Internal

GENERAL GUIDANCE

Components

After unpacking all internal components must be

removed prior to tting the stove. This will make

handling the stove easier; allow access to

xings and the ue outlet; as well as protect the

internal components from damage during the

installation process.

1

1) Box

2) Instructions

3) All bricks

4) Shovel

5) Flue Collar Fixing Box

6) Log Retainer

7) Gauntlet (pair)

2

4

Flue Collar/Blanking Plate Data Plate

If uing from the

rear then reverse

collar and blanking

plate.

3

5

6

7

Direct Air

EXAMPLE

- 7 -

Page 8

Heat Shield

Brick Baffle

Secondary Baffle

Bafes

Heat Shield

shown up.

To take out the secondary bafe rstly remove the brick

bafe. The undo the two screws (as shown) holding the

secondary bafe in. Then remove the secondary bafe.

For top ue installation ensure heatshield plate is in the

correct position (as shown in above drawing).

Smoke Control Stop

Smoke Control Stop

If you are in a Smoke Control Area then the

plate needs to be set fully across to the left.

- 8 -

Page 9

SMOKE CONTROL

AREA EXEMPT

The Clean Air Act 1993 And Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a

smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any

xed boiler if located in a designated smoke control area. It is also an offence to acquire an “unauthorised fuel”

for use within a smoke control area unless it is used in an “exempt” appliance (“exempted” from the controls

which generally apply in the smoke control area).

In England appliances are exempted by publication on a list by the Secretary of State in accordance with

changes made to sections 20 and 21 of the Clean Air Act 1993 by section 15 of the Deregulation Act 2015.

In Scotland appliances are exempted by publication on a list by Scottish Ministers under section 50 of the

Regulatory Reform (Scotland) Act 2014. Similarly, In Northern Ireland appliances are exempted by publication

on a list by the Department of Agriculture, Environment and Rural Affairs under Section 16 of the Environmental

Better regulation Act (Northern Ireland) 2016. In Wales appliances are exempted by regulations made by Welsh

Ministers.

Further information on the requirements of the Clean Air Act can be found here:

https://www.gov.uk/smoke-control-area-rules

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and

supervision of smoke control areas and you can contact them for details of Clean Air Act requirements.

The Aspect wood burning stoves have been recommended as suitable for use in smoke control areas. Suitable

Authorised fuels can also be used in the appliances in Smoke Control Areas (see Authorised fuel list

https://smokecontrol.defra.gov.uk/fuels.php ) (Applies only if a multifuel conversion kit is installed).

Refuelling on to a low re bed

If there is insufcient burning material in the rebed to light a new fuel charge, excessive smoke emission can

occur. Refuelling must be carried out onto a sufcient quantity of glowing embers and ash that the new fuel

charge will ignite in a reasonable period. If there are too few embers in the re bed, add suitable kindling to

prevent excessive smoke.

Fuel overloading

The maximum amount of fuel specied in this manual should not be exceeded, overloading can cause excess

smoke.

Operation with door left open

Operation with the door open can cause excess smoke. The appliance must not be operated with the appliance

door left open except as directed in the instructions.

Dampers left open

Operation with the air controls or appliance dampers open can cause excess smoke. The appliance must not be

operated with air controls, appliance dampers or door left open except as directed in the instructions.

- 9 -

Page 10

Health and Safety Guidance

Special care must be taken when installing the stove such that the requirements of the Health and Safety at Work

Act are met.

Handling

This appliance is very heavy. Adequate facilities must be available for loading, unloading and side handling.

Fire Cement

Some types of re cement are caustic and should not be allowed to come into contact with the skin. In case of

contact, wash immediately with plenty of water.

Asbestos

This stove contains no asbestos. If there is any possibility of disturbing any asbestos in the course of installation,

then please seek specialist guidance and use appropriate protective equipment.

Metal Parts

When installing or servicing this stove, care should be taken to avoid the possibility of personal injury.

Stove Performance

This is a Domestic Appliance nad must only be used in accordance with these instructions.

Important Warning

This stove must not be installed into a chimney that serves any other heating appliance.

Fitting a stove in a room which also contains an extractor fan and/or cooker hood should be avoided where

possible. If this is unavoidable, the suitability of the space for tting this appliance must be decided at the

discretion of a qualied installer, and a ue draught interference test must be performed.

Operating With The Doors Open

The stove is tested as a closed door appliance and as such should not be operated with the doors open (except for

fuel re-loading etc.)

TRIPLEBURN TECHNOLOGY

Our unique cleaner burning technology utilises three streams of air - Primary, Secondary and Tertiary - to

provide optimum air ow to the rebox, aiding combustion and ensuring maximum efciency throughout.

This draws air over the fuel, across the door and behind the fuel. This means a faster light up and a fuller burn

of the fuel.

Airwash Technology allows air to ow over the glass and across the fuel to ensure that the glass is always kept

clean - guaranteering an excelelnt view of of your re as it burns.

THE ENVIRONMENT (FRIENDLY FIRING)

To produce a more enviromentally friendly way of burning your stove avoid turning it down to the point where

you cannot see any visible ames. If the stove is run this way then the gases produced from the wood will

not be burnt off (due to low temperatures in the chamber). This can also cause soot to condense in the ue

system and could lead to a chimney re. The smoke that is left as it exits the chimney will also pollute the

surroundings and cause an unpleasant smell.

Rember - your chimney (however good) will not perform well if the stove is not used correctly.

- 10 -

Page 11

OPERATING INSTRUCTIONS

Stove Body

Safety Advice

The stove paint curing process takes place at room temperature and the surface coating is virtually free f rom fumes

and odours. When being put into operation for the rst time we would recommend that windows and doors are

opened for a short time to provide ventilation.

Air Controls

Air control rod

fully closed

When the air control rod is pushed in fully then both

the Primary and Secondary air intakes are in the closed

position.

Lighting the Stove

1) Ensure all air controls are in the fully open

position.

To operate pull the air control away from the stove.

For the air control to be in the fully open position both

Primary and Secondary pull the air control rod away

from the stove until it stops. This is necessary for

lighting the stove.

Air control rod

fully opened

2)

In the base of the stove, place the larger split

and dry logs (amount dependant upon size of

the rebox). Ensure a gap is left between the

logs as this allows air movement to help the re

breathe when lit.

3) Place approximately six to eight pieces of

kindling (nely chopped wood) on top of the

logs in the opposite direction to the split logs.

4) Put 2 to 4 Eco re lighters on top of the kindling

in the centre.

5) Finally, place 2 to 4 pieces of kindling on top of

the Eco re lighters.

6) Close the door as soon as ames appear.

7) A small amount of soot may appear on the glass

during the lighting. This is perfectly normal and

will go after a period of time.

8) Extra logs should not be added until there is a

bed of glowing embers.

Kindling:

Length - 15cm to 20cm

Diameter - 2cm to 5cm

Approximately 8-12 nely chopped pieces

- 11 -

Page 12

WARNING!

Burning wet or unseasoned wood will create excess smoke emissions, tar deposits in the

stove and chimney and will not produce a satisfactory heat output.

WARNING - DO NOT BURN BITUMINOUS COAL, PETRO-COKE, OTHER PETROLEUM BASED

FUELS OR TREATED WOOD SUCH AS PALLETS AS THIS WILL INVALIDATE THE PRODUCT

WARRANTY. HOUSEHOLD WASTE MUST NOT BE BURNT ON THIS APPLIANCE.

OVER-FIRING

Using an excess amount of wood (than recommended) and/or the air intake is too

much (check instructions on correct use of air controls) can cause the stove to over-

re. This can cause damage to both the stove and the surrounding walls. Therefore, as

recommended use the maximum amount of fuel.

Adding Wood

1. Firstly ensure that the wood you are using has a moisture content of less than 20% (we recommend 12-15%

to ensure an efcient burn).

2. When refuelling open all the air controls fully and the damper (if tted).

3. Open the door slowly by releasing the handle and allowing to stay like this for 10 to 20 seconds. As

opening the door to fast can cause smoke to be drawn into the room as the rebox has not had time

for the pressure to equalise. The smoke will then take the easiest route which is out through the

opening.

4. Fully open the door slowly and carefully place the fuel.

5. It is recommended to use 2 pieces of wood weighing 1.2 to 1.4kg in total. 25cm long. Only refuel when

ames die down.

6. Put the logs diagnoally to each other so that they can catch re easily.

7. Close the door. (All our stoves are tested as closed door appliances and should be used as such.)

8. Keep the air control in the fully open position until the logs catch re.

9. This can then be reduced to aid slower combustion.

Important!

Ensure the wood has a moisture content of less than

20% (we advise 12-15% for a more efcient burn) to

allow the fuel to catch quickly. If the fuel has a higher

moisture content then the you are mostly burning

of this and this will reduce the heat output and take

longer to burn correctly. This can also cause a build up

of soot and tar which could lead to a chimney re. It

will also cause the glass of the stove to blacken.

Refuelling must be carried out with a sufcient

quantity of glowing embers and ash, so that the

new fuel charge will ignite quickly. If there are too

few embers, add some kindling to prevent excessive

smoke. After refuelling leave the air control fully open

for one minute before reducing to the desired setting.

Guide to Wood

Hardwood is a denser fuel than softwood and provides

a higher heat content. Softwood burns at 50% of the

heat content of harwood. Softwoods are more prone to

spitting and popping as they have pockets of moisture

and sap contained within them (this can be reduced

by seasoning and drying correctly).

Woods suitable for closed appliances - Ash, Beech,

Birch, Blackthorn, Elm, Eucalyptus, Hawthorn, Hazel,

Hornbeam, Maple, Oak, Rowan, Sycamore, Wild Cherry,

Willow, Alder, Apple, Pear and Holly. (Oak, beech

and birch burn at the highest rate when seasoned

correctly).

These woods are also suitable but can crackle and spit Cedar, Douglas Fir, Horse Chestnut, Larch, Plane, Sweet

Chestnut and Willow.

- 12 -

Page 13

MAINTENANCE AND SERVICING

Periods Of Prolonged Non-Use

If the stove is to be left unused for a prolonged period, then it should be given a thorough clean to remove ash

and unburned fuel residues. To enable a good ow of air through the appliance to reduce condensation and

subsequent damage, leave the air controls fully open. If the appliance has been unused for a long period, such as

during the spring and summer months, a competent person should check the chimney for potential

obstructions before lighting the stove i.e. get the chimney swept before the start of the heating season?

Bafe Brick

The bafe is located in the upper part of the stove

and this should be removed and cleaned on a regular

basis. This prevents any build-up of soot or y ash that

could lead to blocked ue ways and dangerous fume

emission. If the bafe is removed the chimney/ue way

can be swept through the appliance.

Firebricks

In normal use, these can last for many years. It is

possible however, to crack them if logs are continually

jammed against them or if they are frequently struck

with a poker. Check periodically for seriously cracked

bricks, which can be replaced with new, available from

your dealer or our spares website www.hunterstoves.

co.uk/spares.

1

2

3

2

Glass Panel (see diagram below)

Printed glass should not be cleaned using cleaners

high in alkaline or acidic content. Clean the glass panel

when cool with a propriety glass cleaner by applying

the cleaner to a cloth. Do not apply directly to the

glass as this could cause run of which could soak into

the rope seals around the edge of the glass.

Highly abrasive substances should be avoided as these

can scratch the glass and make subsequent cleaning

more difcult. Wet logs on heated glass, a badly aimed

poker or heavy slamming of the doors could crack the

glass panels, the glass will not fracture from heat.

Should you need to replace a glass panel please ensure

you purchase a new Gasket at the same time. Please

check periodically that the glass clips and screws have

not become loose. They should only be nger tight to

allow for the expansion and contraction of the glass.

Rope

Check the rope (2) around the door. If rope is becoming

detached, use rope glue to reattach it. If the rope is in

poor condition, a replacement rope kit may be ordered

from the Hunter Stoves Group spares range.

4

To remove the bricks -

Bafe brick (1) - Slide over to the LH side of the body and

drop down into the rebox and remove.

Base brick (4) - Lift base brick out of rebox and remove.

(Ensure side bricks are supported).

Side brick (2) - Pull base of the LH side brick in towards

the centre of the rebox and remove. Repeat with RH

side brick.

Rear brick (3) - Bring RH side in towards the centre of the

rebox and remove.

To replace the bricks work in reverse order as above.

Gasket Tape

The glass gasket tape (3) will have to be replaced when a

new piece of glass (4) is tted as the self-adhesive tape is

stuck onto the glass.

Over time you may also nd that the gasket tape

changes colour. This is due to a reduction in the

pigment used in the manufacture of the product and no

cause for concern.

1

2

3

4

- 13 -

Page 14

Stove Body

You can wipe the stove with a damp cloth. Repair any

light damage with Hunter stove paint available through

our spares website www.hunterstoves.co.uk/spares.

Chimney and Flue Ways

It is important that the chimney, ue ways and any

connecting ue pipe are swept regularly. This should

only be carried out by an experienced chimney sweep

with a trusted trade rating.

This means at least once a year for smokeless fuels and

at least twice a year for wood and other fuels. The brick

bafe will need to be removed from the stove in order

to sweep the chimney.

If it is not possible to sweep all parts of the chimney

through the appliance, ensure there is adequate access

to cleaning doors.

If the stove is tted in place of an open re, then the

chimney should be swept one month after installation

to clear any soot falls which may have occurred due to

the difference in combustion between the stove and

the open re.

Annual Service

Hunter Stoves Group recommend that this appliance

be serviced annually, preferably prior to the start of the

heating season, thus avoiding any delay in receiving

replacement components, should you need them. If

you feel unable to undertake this task, Hunter Stoves

recommend that you contact the installation engineer

for advice.

Remove all the internal components: Log retainer,

bricks, ignition air bar & bafe brick. Clean them with a

soft brush carefully and inspect them for damage.

Sweep the chimney/ue system if necessary.

Clean down the internal surfaces of the appliance

using a scraper or wire brush. Inspect these surfaces

for damage/corrosion. If corrosion or damage is found,

we advise that you consult with your installer about

rectication/repair.

Brush out or vacuum the inside of the appliance and re-

t the internal components.

Inspect the glass and glass bretape. Clean the glass

with a non-abrasive cleaner if required. If the glass

bretape is torn or damaged, we recommend that is

replaced to ensure that no products of combustion

enters the room when the appliance is used.

Painted Finish – You can wipe the stove with a damp

cloth. Repair any light damage with Hunter stove paint

spray.

Spares

All spare parts can be purchased through our website www.hunterstoves.co.uk/spares.

- 14 -

Page 15

IMPORTANT INFORMATION

IMPORTANT NOTES

IMPORTANT INFORMATION

WARNING NOTE

Properly installed and operated, this appliance will not emit fumes. Occasional fumes from de-ashing and

refuelling may occur. Persistent fume emission must not be tolerated.

This appliance should not be operated with the door open.

If fume emission persists, then the following immediate action should be taken: -

Open doors and windows to ventilate the room.

Let the re go out or eject and safely dispose of fuel from the appliance.

Check for ue/chimney blockage and clean if required.

Do not attempt to re-light the re until the cause of the fume emission has been identied and

corrected.

If necessary, seek expert advice.

General

Before lighting the stove check with the installer that the installation work and commissioning checks described

above have been carried out correctly and that the chimney has been swept clean, is sound and free from any

obstructions. As part of the stoves’ commissioning and handover, the installer should have shown you how to

operate the stove correctly.

Carbon Monoxide Detector

Hunter Stoves recommend a Carbon Monoxide Detector that conforms to the latest issue of BS EN 50292 be placed

in the same room as the appliance. The installation of such an alarm is not considered a substitute for regular

maintenance or servicing of the appliance and ue system.

Air Controls

See how to use Air Controls on page 10.

Fireguards

Always use a reguard in the presence of children, the elderly or the inrm. The reguard should be

manufactured in accordance with BS8423 – Fireguards for use with solid fuel appliances.

Extractor Fan

Fitting a stove in a room which also contains an extractor fan and/or cooker hood should be avoided where

possible. If this is unavoidable, the suitability of the space for tting this appliance must be decided at the

discretion of a qualied installer, and a ue draught interference test must be performed.

Recommended Fuels

Hunter Stoves Group recommend that only wood logs with a moisture content of less than 20% should be burnt on

this appliance.

Burning wet or unseasoned wood will create excess smoke emissions, tar deposits in the stove and chimney and

will not produce a satisfactory heat output.

WARNING - DO NOT BURN BITUMINOUS COAL, PETRO-COKE, OTHER PETROLEUM BASED FUELS OR

TREATED WOOD SUCH AS PALLETS AS THIS WILL INVALIDATE THE PRODUCT WARRANTY. HOUSEHOLD

WASTE MUST NOT BE BURNT ON THIS APPLIANCE.

- 15 -

Page 16

Aerosols

Do not use an aerosol spray on or near the stove when it is alight.

Operating The Stove

Warning! – This Appliance will be hot when in operation and due care should be taken.

We advise that suitable gloves, or the operating tool is used when operating the air control, and when opening the

door.

Ventilation

It is essential that the stove has an adequate air supply for combustion and ventilation. Requirements can be found

by checking Building Regulations Approved Document J.

Do not obstruct the ventilation required for the safe use of this appliance.

In The Event Of A Chimney Fire

Raise the alarm

Call the Fire Brigade

Close appliance air controls

Move furniture, ornaments etc. away

Place a reguard in front of stove

Check the chimney breast for signs of excessive heat.

If the wall is becoming excessively hot, move furniture away.

Ensure the Fire Brigade can gain access to your roof space in order to check for re spread.

- 16 -

Page 17

TROUBLESHOOTING

PACKAGING

All our packaging both for our stoves and spares

is recyclable. For information detailing where it

can be disposed check with your local council.

Smoke

This can happen for a variety of reasons e.g cold air

trapped in chimney/ue. As cold air is denser, this

causes smoke to be forced back down the chimney.

We recommend trying to heat the chimney before

lighting for example, placing a relighter on top of the

kindling. Ensure wood has a moisture content of less

than 20% as this can cause excess smoke. Also check

the type of wood as softwood produces a lot more

smoke.

Glass

If your glass is blackening this can be due to incorrect

use of air controls (see instructions). Alternatively, poor

quality fuel which has a high moisture content can

also be a cause. When the glass has a white shadow(or

crazing) on the inside then this can be caused due to

over-ring, too much primary air or a vacuum in the

room.

Weather Conditions

Operation Of Fire

There are varying reasons for problems with your

stove however, this could be due to a low or high ue

draught in which case you need to speak to your

installer. Correct use of the air controls (please refer

to instructions). Quality and moisture content of fuel.

Check that chimney is not blocked or that nearby

buildings or trees affect the wind around it.

Appliance Body

Paint Curing

The stove paint curing process takes place at room

temperature and the surface coating is virtually free

from fumes and odours. When being put into operation

for the rst time we would recommend that windows

and doors are opened for a short time to provide

ventilation.

If the surface of the appliance turns grey or the paint

starts to ake or peel then this is caused by over-ring.

Noise

When the appliance body heats up and cools down it

may make some clicking noises. This is due to the large

temperature differences and is not a problem with the

appliance.

Varying weather can have an impact on the way

the stove burns, especially the wind. An anti-down

draught cowl might need to be tted (speak to a

specialist) or a ue damper may also be of help.

Mist and fog may also have an impact on the chimney

draught and you will need to change the settings you

are using on the stove.

Fire Goes Out After A Short Time

Check the ue draught of the stove is not to strong

or to low.

Is the air vent blocked?

Check use of air controls (please refer to these

instructions).

Ensure that the amount of kindling used is enough

to light the added fuel.

Try heating the ue/chimney up rst to ensure air

pressure is not allowing the ue to operate correctly.

If any further help is needed then please refer to the Help section on our website https://www.hunterstoves.co.uk/helpandsupport or contact your dealer.

- 17 -

Page 18

WARRANTY

Hunter Stoves Group Ltd Extended 5 and 10 year Warranty

2 Year Standard Warranty

Any appliance bought through the showroom of an authorised Hunter Stoves Group dealership will automatically

be covered by our standard 2-year conditional guarantee.

However, this standard 2-year warranty can be extended to a 5-year or 10-year conditional warranty dependent on

the model type (5 years - Boiler model and Gas models, 10 year - Room heater).

To qualify for this extended warranty option, you need to:

1.

Register your purchase online at https://www.hunterstoves.co.uk/ProductRegistration

2.

Retain your proof of purchase.

Warranty Conditions

For the Standard 2 year or extended 5/10-year warranty to be valid and to remain in force throughout the warranty

period the following must have been carried out:

1. The appliance must have been installed by an appropriately qualied engineer (from the Competent Person

Scheme/Gas Safe) in accordance with the manufacturer’s instructions and in compliance of any relevant

national or local building regulations. Please visit the following links for details on the Competent Person

Scheme: https://www.gov.uk/guidance/competent-person-scheme-current-schemes-and-how-schemes-areauthorised and Gas Safe register: https://www.gassaferegister.co.uk/

2. The appliance will need to be registered within two months of purchase and the commissioning and

installation documentation completed (these need to be kept by the end user).

3. The appliance must be serviced within 12 months of the installation date for the second year of the standard

warranty to be valid, and within every 12-month anniversary thereafter to maintain the validity and coverage

of any extended warranty. For this purpose, the installation and user instructions, supplied with the appliance,

makes a provision for receipts and annual services to be recorded. This is needed in the event of a claim

during the warranty period.

4. Only genuine Hunter Stoves spare parts or consumables can be used in the servicing and maintenance of

the appliance during any standard or extended warranty period. These can be sourced from your authorised

supplier directly or through our website spares portal. www.hunterstoves.co.uk/spares.

5. Any problems or issues giving rise to any claim under the standard or extended warranty must be submitted

to the authorised Hunter Stoves Group retailer from whom you originally purchased the appliance. Hunter

Stoves Group will then offer appropriate support and help through your original authorised supplier to solve

any issues.

6. The standard or extended warranty option is not transferable. It is solely for the benet of the original

purchaser of the appliance. For this purpose, please retain the proof of purchase.

Warranty Exclusions

For Solid Fuel Stoves:

Glass and rope/ceramic seals

Fire bricks

Bafes/Throat Plates

Log retainers, grate supports and catch bars

Grate parts

Ashpans

Clip-in Boilers

For Gas Stoves:

Gas pilot assemblies

Thermocouples and Oxy pilots

Ceraic log and coal ‘fuel-effects’

Batteries

- 18 -

Page 19

Paint and Surface Coverings

The paint or surface covering of the appliance will be covered (for 2 years after installation) provided the warranty

conditions are met. However, damage due to the following events will not be covered:

1.

2.

3.

Damage to the paint surface caused by the appliance being stored in a damp and cold environment is not

covered under warranty. Please be aware that any moisture within the room where the stove is installed

e.g. through clothes drying, can be a cause of paint issues.

In the course of the initial rings of the appliance the paint or enamel surface may change colour. This is

normal and as such is therefore not covered under warranty.

Damaged caused by over ring, resulting in cracking, bubbling or discolouration to the paint or enamelled

surface nish is not covered under warranty.

Warranty Limitations

1.

2.

3.

4.

5.

6.

Damage to the appliance due to specic local conditions caused by draft or chimney defects.

Damage resulting from installation and use where installation is not in accordance with the

manufacturer’s instructions or local building and/or safety regulations.

Damage or premature wear caused by burning inappropriate fuels such as Bituminous coal, “PetroCoke” or any other Petroleum based coals. Please visit the HETAS website, www.hetas.co.uk, for a full

list of approved fuels which are covered by the warranty. Fuels outside of this list are not covered by the

warranty.

Damage caused by burning material with high creosote content or any other painted/treated timber.

Consequential loss to associated non-Hunter Stoves Group products is not covered under the warranty.

Consequential loss relating to decorations, soft furnishings or other household assets is not covered under

the warranty.

7.

Hunter Stoves Group total liability will only extend to the total purchase price paid for the goods in any warranty

claim. Hunter Stoves Group reserve the right to replace, repair or refund to value of goods purchased.

Cost associated with the removal and re-installation of an appliance subject to a warranty claim.

ANY HUNTERS STOVES GROUP PRODUCT PURCHASED VIA AN INTERNET SUPPLIER, OR THROUGH

AN UNAUTHORISED STOCKIST WILL ONLY BE SUPPORTED BY THE STATUTORY, 12 MONTH

GUARANTEE AND WILL NOT QUALIFY FOR ANY EXTENDED 5 OR 10 YEAR WARRANTY.

The Hunter Stoves Group extended warranty option does not affect your statutory rights.

This revised standard or extended 5 or 10-year warranty option comes into effect on 1st September 2015 and will

apply to all appliances sold from that date.

This standard/extended warranty applies to purchases of Hunter Stoves within the United Kingdom and the

Republic of Ireland. Purchases in all other countries are subject to the warranty conditions specied by the

distributer in those markets.

Hunter Stoves Ltd, 8 Emperor Way, Exeter Business Park, Exeter, Devon, EX1 3QS

www.hunterstoves.co.uk Email: info@hunterstoves.co.uk

- 19 -

Page 20

BRITISH

EXCELLENCE

8 EMPEROR WAY EXETER DEVON EX1 3QS

INFO@HUNTERSTOVES.CO.UK WWW.HUNTERSTOVES.CO.UK

Hunter Stoves reserve the right to change dimensions and procedures described in these instructions

at anytime without special notice.

Loading...

Loading...