Hunter Stoves GTBAV4NR1, GTBCN5NR1S, GTBCN5NM1S, GTBAV4LM1, GTBAV4LR1 Instructions For Installation/operating/maintenance/servicing

...Page 1

1

AVALON 4

CONSORT 5

HAWK 4 MKII

Instructions for

Installation/Operating/Maintenance/Servicing

Please leave this instruction booklet with the user after the installation is complete. Leave the

system ready for operation and instruct the user in the correct use of the appliance and

operation of its controls. Please refer to the appliance data plate for the specific model type.

JIN04KWGAS REV C 27/03/19

Page 2

2

STOVE MODELS

AVALON 4 CONSORT 5

GTBAV4NM1/GTBAV4NR1 GTBCN5NM1S/GTBCN5NR1S

GTBAV4LM1/GTBAV4LR1 GTBCN5LM1SGTBCN5LR1S

GTBCN5NM1B/GTBCN5NR1B

GTBCN5LM1B/GTBCN5LR1B

HAWK 4 MKII

GTBHK4NM1D/GTBHK4NR1D

GTBHK4LM1D/GTBHK4LR1D

GTBHK4NM1T/GTBHK4NR1T

GTBHK4LM1T/GTBHK4LR1T

Page 3

3

Table of Contents

Technical Data

4

Stove Dimensions

5

Installing the Appliance

6

Flue Arrangement

7

Additional Air Venting (GB only)

7

Opening the Stove Door

7

TTB Connection

8

Gas Supply Connections

8/9

Installation of the Fire-Bed

9/11

Fitting the canopy

11

Test for Spillage

11/12

Servicing Instructions

12

Troubleshooting

13/14

User Instructions

15/16

Care, Maintenance and Servicing

16

Instructions for Remote Control Use

17–24

Setting Up Full Function Handset (LCD)

17-19

Advanced Setting Full Function Handset (LCD)

19/20

Restoring Communication with The Fire

20/21

Remote Care and Maintenance

22-24

Installation and Commissioning Checklist

25

Service Records

26

Warranty Information

27/28

Welcome to the Hunter Stoves family and thank you for purchasing a Hunter

4kW Gas stove. This stove was designed and built to be a high-performance

heating appliance, and we hope it will bring you great enjoyment. The

natural environment is important to us, so our stoves are manufactured to

provide you with a clean and efficient burn that will keep you warm through

the cold winter nights.

Page 4

4

Please read these instructions carefully

This appliance is intended for use on a gas installation with a governed meter.

It is important that your stove is correctly installed as Hunter Stoves Limited cannot accept

responsibility for any fault arising through incorrect installation. Any unauthorised changes to

the stove will negate the warranty.

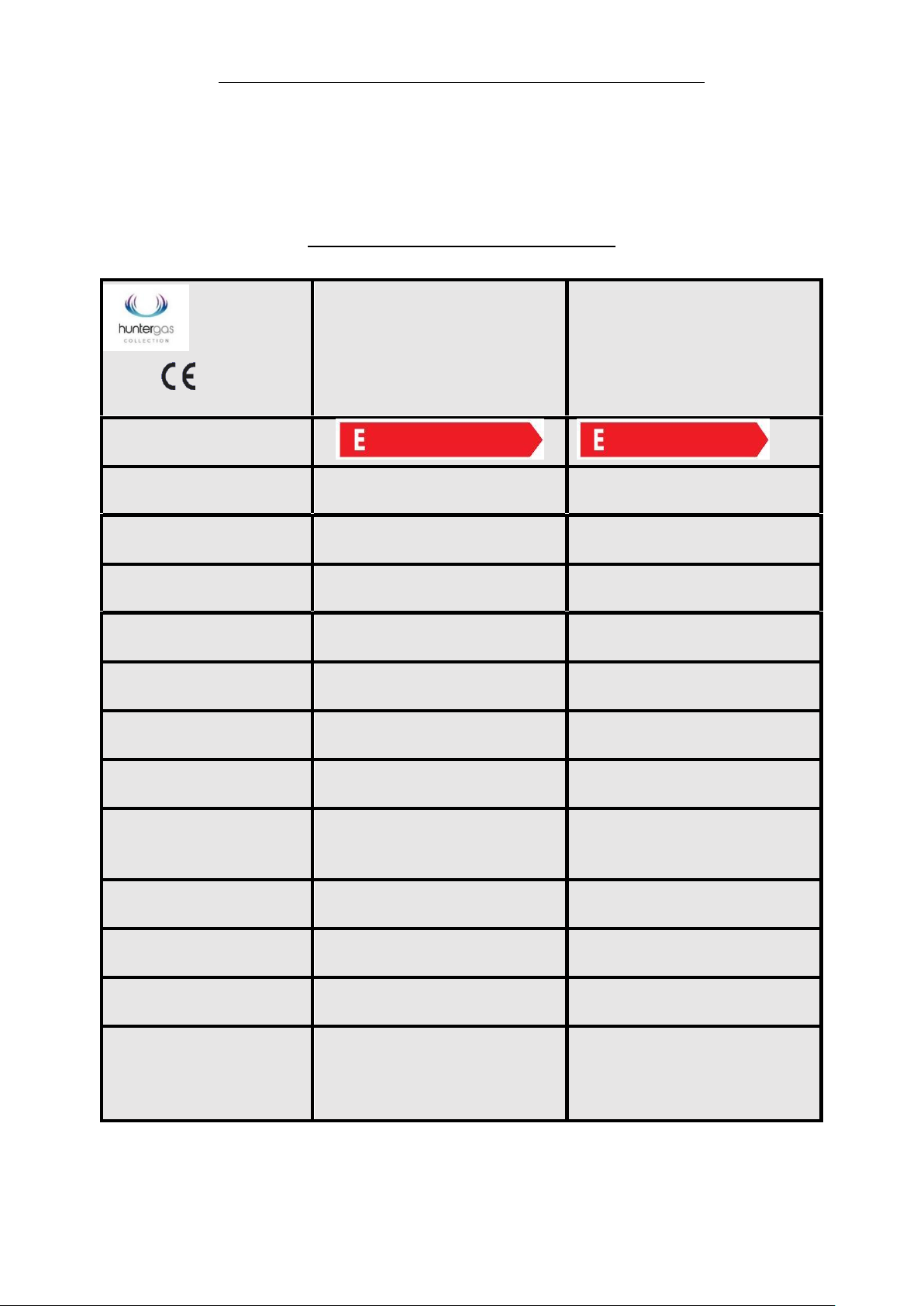

TECHNICAL DATA

0558

NATURAL

GAS

MANUAL/REMOTE

LPG

MANUAL/REMOTE

Energy Efficiency

Class

Nominal Gas

Pressure

20mbar

37mbar

Main Burner Injector

(mm)

0.59 x 7

1.03

Pilot Injector (mm)

0.35

0.27

Burner Aeration

Φ7

Φ9

Supply Gas

Type/Category

G20/I2H

G31/lɜp

Energy Efficiency

71

75

Injector

Type/Marking

380

103

Heat Input (Gross)

Full

Low

4.7kW

3.5kW

4.7kW

3.2kW

Gas Flow Rate (m3/h)

Full 0.447

0.176

NOx Class

4

5

Efficiency Class

2

2

Countries of

Destination

AT, BG, CH, CZ, DK, EE, ES, FI,

GB, GR, HR, IE, IT, LT, LV, NO,

PT, RO, SE, SI ,SK, TR

BE, CH, CZ, ES, FR, GB, GR, IE,

IT, LT, NL, PL, PT, SI, SK

Page 5

5

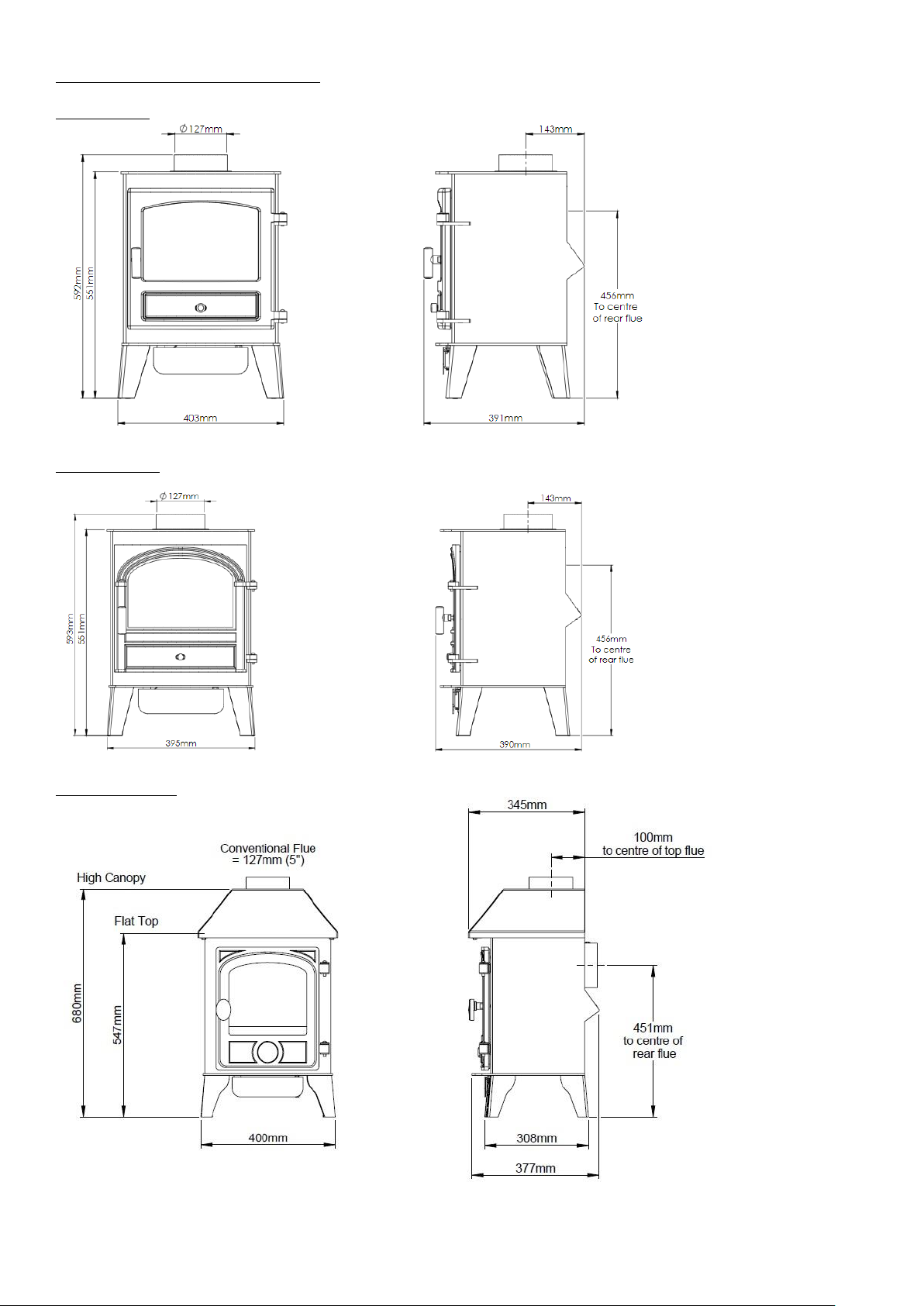

STOVE DIMENSIONS

AVALON 4

CONSORT 5

HAWK 4 MKII

Page 6

6

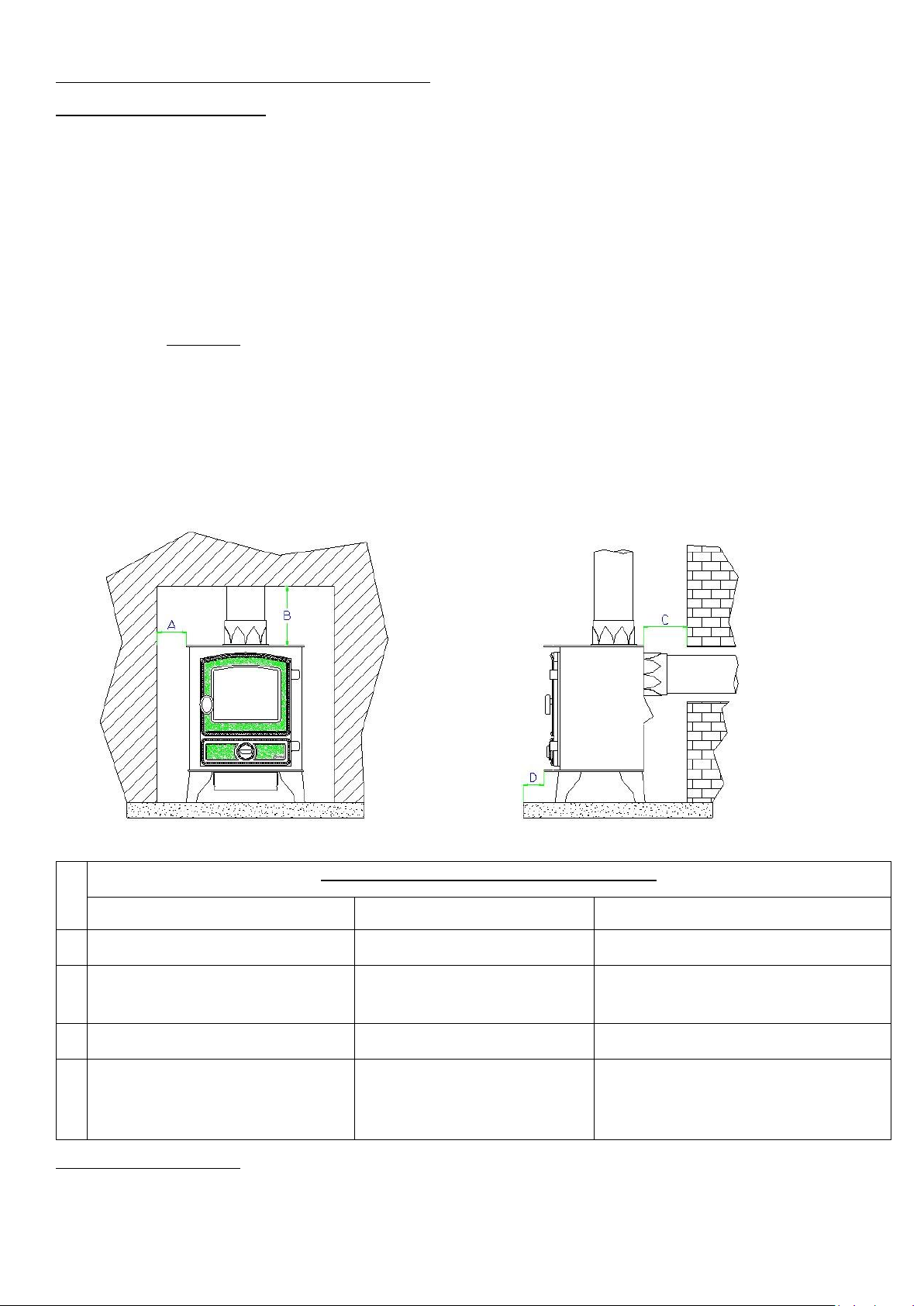

INSTALLING THE APPLIANCE

Pre-installation notes

1. Check the stove data plate to establish the gas type required. Before installation check that the

local distribution conditions, nature of the gas and pressure, and adjustment of the application are

compatible.

2. A GAS SAFE REGISTERED INSTALLER or equally recognised competent person must fit the

appliance. That person is legally responsible for the safe installation of the appliance with due

regard to all relevant local and national building regulations.

3. All outer surfaces of the stove excepting the gas control knobs are defined as working surfaces.

4. Installation site - Any installation area previously used for a solid fuel fire or stove would probably be

deemed suitable for the appliance.

5. The stove must not be installed onto a combustible wall. Any combustible materials must be

removed from behind the appliance.

6. The appliance must be sited on a non-combustible hearth of minimum 12mm thickness.

7. The hearth should be edged or raised to prevent combustible floor finishes (e.g. Carpet) from being

laid too close to the appliance.

8. Opening Clearances: for the relevant clearance distances for installing the appliance in an opening

see figure 2 and table 1.

9. The stove cannot be installed in a basement or bathroom.

IMPORTANT NOTE! Adequate clearance must be given between the appliance and the walls so

that a satisfactory spillage test can be performed as detailed on page 11.

MINIMUM CLEARANCE DISTANCES TO:

DIMENSION DESCRIPTION

COMBUSTIBLE MATERIAL

NON-COMBUSTIBLE MATERIAL

A

Side of stove to wall

150mm

100mm

B

Top of stove to underside of

opening or shelf

250mm

200mm

C

Rear of stove to wall

100mm

100mm

D

Minimum distance for

hearth to extend in front of

stove

50mm

50mm

Figure 1: Opening Clearance

Page 7

7

FLUE ARRANGEMENT

Prior to installation the flue the chimney should be given a precautionary clean to ensure its entire

length is free from blockages. Any flue dampers must be permanently fixed in the open position or

removed altogether. The chimney should be smoke tested to ensure soundness.

The GAS SAFE REGISTERED ENGINEER commissioned to install this appliance is wholly responsible

for deciding the suitability of any flue arrangement to operate in conjunction with this gas appliance.

The chimney or flue system that is to be fitted to the gas stove must comply with the current rules in force.

The 4kW gas stoves are also suitable for other specific class II installation arrangements: pre-cast

flues, ridge-vent flues, and pre-cast chimney block and with the relevant adaption, the appliance will

operate in a closure plate system.

It is suggested to run flue pipe at least 615mm vertically from the unit before there are any changes

in direction of the flue system. Wherever possible horizontal runs of the flue system should be avoided.

The flue must have a minimum of 2.6 meters of vertical height measured from the top of the stove

to the bottom of the terminal outlet.

Please note for rear flue appliances it is recommended that the vertical flue run be established as soon

as is practical from the rear flue exit. (Caution should be taken locating the exit of the flue as explained

in ‘The Building Regulations - Document J’.)

ADDITIONAL AIR VENTING (GB only)

The supply gas heat input into the appliance is nominally less than 7kW. Therefore, under the directives

of the current Health and Safety Executive gas safety and use regulations (Gas Safety [Installation and

Use] Regulations 1998 Approved Code of Practice and guidance) no additional air vents are required in

the room in which the appliance is situated.

OPENING THE STOVE DOOR

NOTE! This appliance must never be used if the glass door panel is broken, removed or if the door

is open.

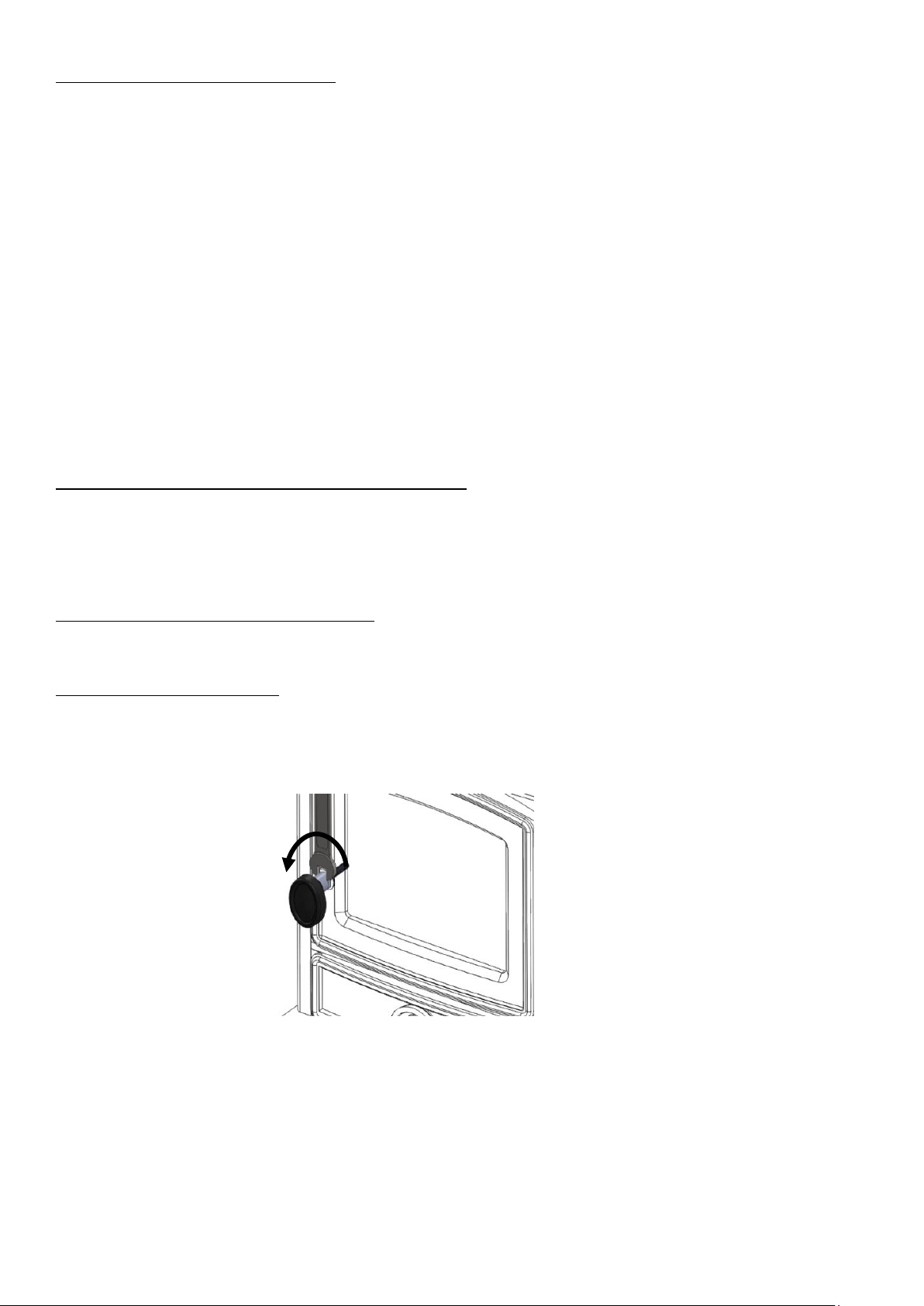

Hawk 4/Consort 5/Avalon 4

Before gaining access to the burner tray, first make sure that the stove is switched off and is cold.

Remove the door handle using a 17mm spanner (diagram 1), turning anticlockwise. Keep turning

until the handle is completely removed. The door glass is held in place by 4 fixing brackets. Ensure

these brackets are tight before operation.

Diagram 1

Page 8

8

TTB INSTALLATION

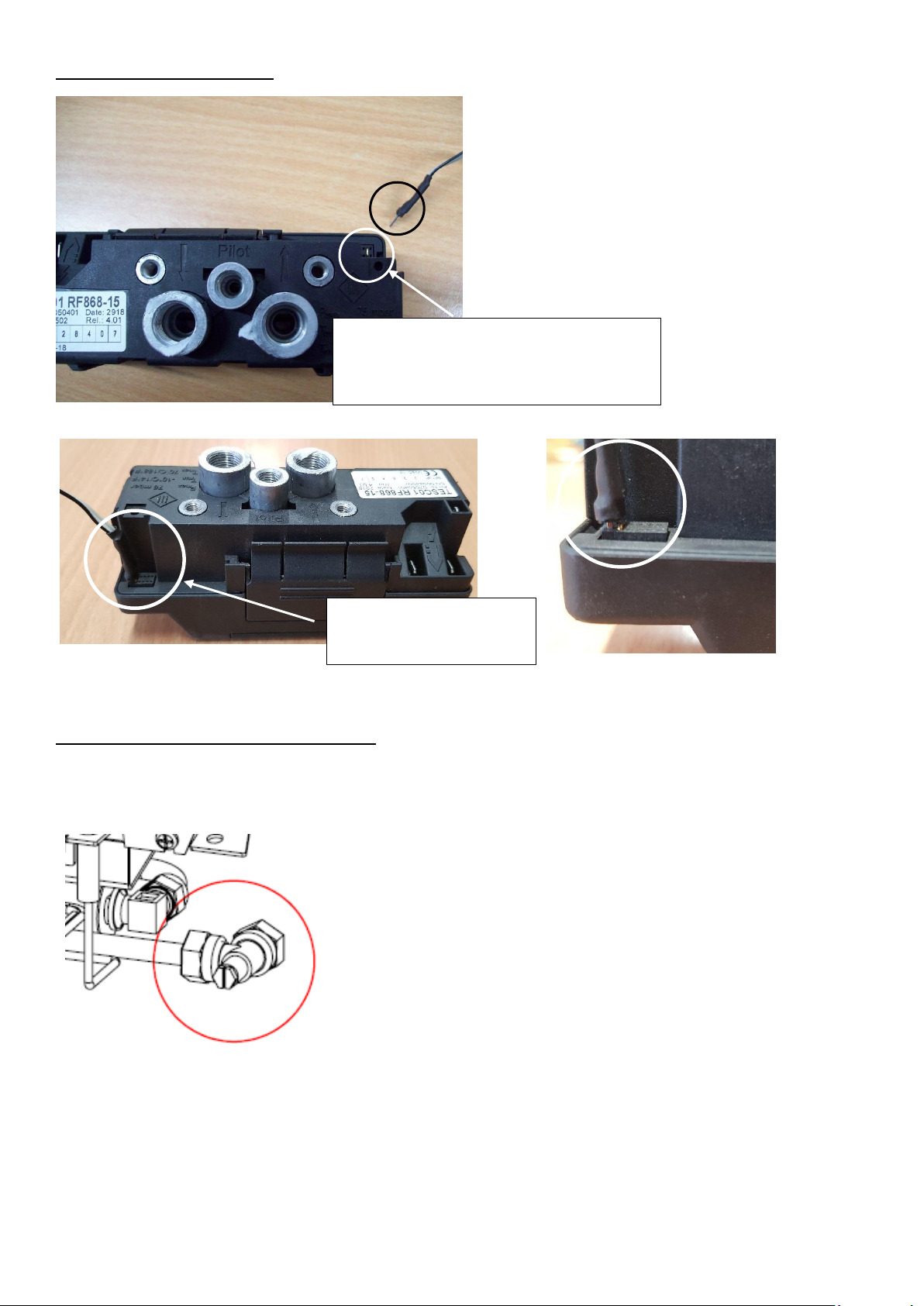

GAS SUPPLY CONNECTIONS

The appliance is supplied with an 8mm Bundy pipe and an 8mm compression elbow to allow easy

connection to the mains gas supply and is connected to the burner by a 14mm spanner. This supply gas

pipe should incorporate a gas service isolation tap situated within 1 metre of the application.

Figure 2: Gas Supply Access

The 8mm Bundy pipe being fitted to the gas

inlet on the valve. The compression joint is

tightened with a 15mm open-ended spanner.

Insert the two TTB Pins into the two

connection holes on the outside next to

the copper bar highlighted by the circle

and arrow.

The circle and arrow

highlight the TTB

engaged into the valve.

Page 9

9

TESTING SUPPLY PRESSURE

Gas pressure at the appliance is measured via the T-piece going to the control valve (circled in figure 5).

Turning the screw approximately half a turn anti-clockwise with a small flat-bladed screwdriver opens

the test point.

ALWAYS CLOSE TEST POINTS AFTER USE!

The gas pressure at the appliance is measured with the appliance running at full rate.

(For information on how to achieve ‘full rate’ read ‘Adjusting Between High and Low Output Settings’ in

the ‘Lighting the Appliance’ section of the User Instructions).

Inlet Gas Pressure should be: 20mbar ± 1.0mbar for Natural Gas

37mbar for LPG

The supply pressure test point (shown in figure 6) is measured at the burner inlet point.

INSTALLATION OF THE FIRE-BED INTO THE STOVE

IMPORTANT NOTE

CERAMIC COALS AND LOGS GET VERY HOT! NEVER ATTEMPT TO HANDLE HOT COALS OR

LOGS WITH BARE HANDS AND NEVER PLACE HOT COALS OR LOGS ON OR NEAR

COMBUSTIBLE SURFACES.

HUNTER STOVES LTD ACCEPTS NO RESPONSIBILITY FOR ANY INJURY HOWEVER CAUSED

WHILST HANDLING HOT COALS, LOGS OR CERAMICS.

FIRE-BED ARRANGEMENT AND INSTALLATION

This appliance can be fitted with log effect ceramics. The fire-bed is constructed of a base ceramic and 6

loose logs.

Figure 3: Supply Pressure Test Point

Inlet Pipe Location

Loose Log Ceramics

Page 10

10

FITTING THE BASE CERAMIC

Log A is then placed around the left-hand front

flame port hole in the matrix. The log should sit

comfortably in place on the matrix as shown in

figure 5.

The second log to be placed is Log B. The single

end is positioned to the right of the second front

flame port hole in the matrix, in the slot provided.

The right-hand fork at the opposite end of the log is

then located in the cut-out on the top edge of the

back of the base ceramic. The left-hand fork should

then rest on the edge of the matrix and the side of

the stove. As shown in figure 6.

Log C sits in a groove to the right of Log B behind

the third flame port hole in the matrix. The top of

the log sits in the cut-out that is located on the

top edge of the back of the base ceramic (Figure 7).

Log D1 sits on the short arm of Log B, with the top

of it sitting in the cut-out on the rear upright at the

back of the base ceramic (Figure 8).

Log D₂ should be positioned behind the

furthermost right-hand flame port hole,

resting against the back upright of the

base ceramic, making sure that it is not

directly above the rear flame port

hole (Figure 8).

Figure 4: Installing Log A

Figure 5: Installing Log B

Figure 6: Installing Log C

Figure 7: Installing Log D1 and D2

Place the Base Ceramic into the fire. Looking from

above the matrix, make sure that the Base Ceramic

does not cover the holes in the tray top.

Page 11

11

Log E is located to the left of the furthermost

right hole in the matrix, the top resting on log

C to the left of it (Figure 9).

FITTING THE CANOPY (OPTIONAL)

There is an optional canopy available for the Hunter Hawk

gas stove.

The canopy can be simply slid into place on the top plate

of the stove body (Shown in figure 10), making sure that

the two welded tabs (located either side of the canopy) fit

under the top plate.

The canopy is then secured in place by tightening the

two fixing screws (one located either side of the canopy)

with a flat-bladed screwdriver, shown in figure 11.

TEST FOR SPILLAGE

A spillage test MUST be carried out before the appliance is left

with the customer. Close all doors and windows in the room

containing the fire before the test is carried out. Complete the Log

picture, close the door and replace the handle and fixing bolt.

Ensure that the fire is burning at full rate for a minimum of 10

minutes.

1. Run a smoke match along the edge of the draught diverter,

both sides of the TTB Bracket (Figure 12).

2. Most of the smoke should be drawn into the draught diverter.

If not, leave the stove running at full rate for a further 10

minutes and then repeat the test.

3. If there is a fan in an adjoining room the spillage test must be

repeated with the fan running and all connecting doors

between the fire and fan open.

4. If there are still problems the chimney/flue or ventilation may

require attention. The stove should not be used until the fault

is rectified.

Figure 8: Installing Log E

Figure 9: Installing The Canopy

Figure 10: Tightening The Canopy

Figure 11: Spillage Test

Page 12

12

SPILLAGE MONITORING SYSTEM

The appliance is fitted with spillage system (TTB), which is located near the draught diverter and

operates to shut the appliance off if the evacuation of combustion products is interrupted (for example

caused by lack of flue pull or flue blockage).

The spillage system MUST NOT be adjusted, modified or put out of action by the installer. The spillage

system MUST NOT be removed or ‘bridged out’ for any reason. If the spillage system is faulty and

requires replacement, only genuine Hunter Stoves parts should be used.

Nuisance shut down may occur if the stove is not installed in accordance with the clearance distances

set out in figure 1 on page 6.

SERVICING INSTRUCTIONS

Any recommendations made here are in addition to the standard servicing procedures used by the

servicing engineer.

Before Testing:

- Do a gas soundness test for the property the appliance is in ensuring there are no leaks before

servicing.

- Check the operation of the appliance before testing.

- Check the spark gap on the pilot is correct. (See Diagram 2)

- After testing advise the customer of any work that needs to be carried out.

A GAS SAFE registered fitter using only original Hunter Stoves parts should carry out servicing.

1. Open the stove door as described on Page 8.

2. Carefully lift-off the logs and remove the base ceramic.

3. Using a soft brush, clean away any lint or light carbon soot deposits out of the gas ports on the

burner top plate.

4. Replace the base ceramic and loose logs as per the fire-bed arrangement instructions (Page 9) using

all re-serviceable logs and any new replacements.

5. Check the gas operating pressure and pipe work for soundness, carry out a spillage test and check

the condition of the flue system.

6. If for any reason the TTB switch is removed or replaced during a service, we recommend wiping the

mating surfaces clean and re-applying a thin smear of 150°C Heat Sink Compound to the face of the

TTB switch.

*Door/glass/rope replacement should only be carried out by a Registered Gas Safe Engineer.

For spare parts please go to our website – www.hunterstoves.co.uk/spares

14mm

Diagram 2

Page 13

13

TROUBLESHOOTING

Page 14

14

Page 15

15

USER INSTRUCTIONS

This manual is designed to ensure your stove is installed correctly and to familiarise you with its

operation. The handset will need to be paired with the valve details can be found on pages 20/21.

Should you have further questions, please do not hesitate to contact your Hunter Stoves Retailer.

IMPORTANT POINTS FOR THE USER

• Read all instructions carefully before attempting to operate this appliance.

• If you have any doubts about the suitability of your chimney for the appliance, please consult your

local Hunter Stoves Gas stockist/dealer. The chimney must be given a precautionary sweep before

connection to the appliance.

• It is required by law that any appliance using gas is installed by a GAS SAFE registered fitter in

conjunction with these instructions and in accordance with current regulations.

• Fires can be dangerous, always use a fireguard in the presence of children, the elderly or the

infirmed.

• All outer surfaces of the appliance are working surfaces except for the gas control knobs and

control cover plate.

• It should be noted that heat given off from this appliance might affect articles placed close to it.

Curtains should not be positioned above the appliance or within 300mm of the sides. Caution

should also be taken if the appliance is to be sighted near to ‘embossed’ type wallpapers.

• Although the appliance is referred to as a stove it is not designed as a ‘cooker’ or a ‘dryer’. It is only

CE approved for use as a room heater with a decorative fuel effect.

• WARNING – Do not use the appliance if the glass door panel is broken, removed or if the door is

open.

• The GAS SAFE REGISTERED ENGINEER commissioned to install this appliance is wholly responsible

for deciding the suitability of any flue arrangement to operate in conjunction with this gas

appliance.

NOTE: During the first few uses the appliance may emit an unpleasant odour. This is the paint curing. It

is non-toxic, but for your comfort you may wish to ventilate the room by opening the doors and

windows.

GAS LEAK

If you think you have a gas leak, or you can smell gas call the 24-hour Gas Emergency Services

immediately on 0800 111 999.

Also do the following:

- Turn of the gas supply at the Meter / emergency control valve.

- Do not turn on/off any electrical switches.

- Ventilate the property; open all windows and doors.

- Do not smoke. Extinguish all sources of ignition.

THE FIREBED

• The stove is supplied with base ceramics and coals/logs, which are to be arranged by the fitter in

strict accordance with the installation instructions. The purchaser must not alter the layout of the

coals/logs or add any extra coals/logs.

• The coals/logs used in this stove to produce a realistic coal/log effect are made from ceramic fibre-

based material. The coals/logs may change colour after use, which is quite normal.

• Replacement base ceramic and coals/logs must be sourced from your approved Hunter Stoves Gas

stockist.

NOTE: It will take approximately 15-20 minutes for the firebed to take on its proper appearance of

glowing coals and yellow flames.

Page 16

16

OPERATING THE APPLIANCE

Please see instructions on page 21 for pairing the handset to the valve. It is strongly recommended

that these instructions are read and thoroughly understood in advance of operating this appliance.

Gas Control Cover Plate

To gain access to the gas control valve, the cover plate must first be opened. The cover plate opens from

the left and swings out, away from the stove to expose the gas controls.

Burner Controls

The gas control valve is situated at the front on the left-hand side of the appliance, behind the gas

control cover plate.

Pilot Assembly

The pilot assembly is positioned at the front of the burner tray on the right-hand side.

IMPORTANT NOTE

The fitted with a spillage system (TTB), which is in close proximity to the draught diverter and operates

to shut the appliance off if the evacuation of combustion products is interrupted (for example caused by

lack of flue pull or flue blockage).

If this occurs, restart the appliance (as detailed in the “Lighting the Appliance” section, page 16).

If the spillage system repeatedly operates to shut the appliance down, a GAS SAFE registered engineer

should be contacted to examine the appliance and installation.

CARE, MAINTENANCE AND SERVICING

Check your chimney and flue arrangement and have the chimney system swept at least once a year.

Painted Appliances

Painted Finish - The stove is finished with a heat resistant paint and this can be cleaned with a dry

microfiber cloth. Do not clean whilst the stove is hot. At no point should any water based, or other

cleaning products be used on the stove. The finish can be renovated with Hunter Stoves paint,

available either through our website www.hunterstoves.co.uk/spares or through your local supplier.

Glass Panel

Clean the glass panel when cool with a propriety glass cleaner by applying the cleaner to a cloth. Do

not apply directly to the glass as this could cause run of which could soak into the rope seals around the

edge of the glass.

Highly abrasive substances should be avoided as these can scratch the glass and make subsequent

cleaning more difficult.

Door/glass/rope replacement should only be carried out by a Registered Gas Safe Engineer.

Servicing

A GAS SAFE registered fitter must carry out an annual service and where necessary replace

unserviceable components with only genuine Hunter Stoves Gas parts.

Service Records can be kept on the following page for your convenience.

Page 17

17

INSTRUCTIONS FOR REMOTE CONTROL USE

SETTING UP THE FULL FUNCTION HANDSET (LCD DISPLAY)

USING THE DISPLAY HANDSET.

IMPORTANT USER INFORMATION – READ THIS BEFORE ATTEMPTING TO OPERATE THE FIRE

For safety reasons, the handset is designed so as to avoid accidental operation. If, during proper use, the

handset fails to communicate with the valve there is a possibility that the pairing has been inadvertently

altered – in this case the handset will need to be reset and re-paired with the valve.

For normal use: -

1) Prior to using the handset for the first time insert new, alkaline, AA batteries into the valve and

handset. Ensure they are mounted firmly and in the correct orientation, and that the battery covers

are replaced fully. Ensure the small isolation switch on the gas control is switched to the ON (I)

position

Hold the handset as shown, wrapping your hand around the handset to make

good contact with both sides. The green unlock light should illuminate, activating

the buttons (if the light is not illuminated, the buttons will not work).

Press and hold the power button, release as soon as PILOT appears on the display

(approx. 1-2 seconds). The fire will commence ignition sequence. If successful, the

fire will automatically go to maximum heat output.

NOTE: Releasing the power button too soon or depressing for too long after the PILOT

appear, will cause the fire not to light because system assumes press to be unintentional.

Power Isolation Switch

Page 18

18

To adjust the flame, hold handset to activate buttons, and use + and – to increase

or decrease flame power accordingly. Tapping the button will increase or decrease

flame stepwise, holding the button will skip through steps. The fire basket display

on the handset will illustrate the level of flame being produced.

To STOP the fire, hold handset to activate buttons, then press the power button.

The fire should shut off immediately (n.b. residual heat will remain). If you wish to

start the fire again you must wait for OFF to be displayed on the handset before

trying to re-start.

NOTE: THE HANDSET IS DESIGNED TO MAKE REMOTE OPERATION OF THE FIRE AS SAFE AS POSSIBLE. IT HAS

BEEN SPECIFICALLY DESIGNED TO MINIMIZE THE RISKS OF ACCIDENTAL OPERATION, WITH THE EXPRESS

INTENTION THAT SUCCESSFUL OPERATION CAN ONLY BE ACHIEVED BY A CONSCIOUS, DELIBERATE ACT. ERGO IT

MAY TAKE SOME TIME TO BECOME FAMILIAR WITH THE INTRICACIES OF HANDSET OPERATION.

TIME, DATE AND TEMPERATURE

1) Hold the handset in one hand ensuring your hand is wrapped around the back and that your hand

comes into contact with both sides of the handset. The green “unlock” light should light, and the

screen will be as shown below.

2) The “H” symbol as shown below indicates that the timer can be set to either 24hr or 12hr mode.

Press the + or – buttons on the handset to move between the two settings.

3) When you have chosen your display, option confirm by pressing the SET button on the handset.

4) Press and release the + and – buttons on the handset until the correct day of the week is shown then

press SET.

5) As shown above the time on the handset can be set by using the + and – buttons to change the hour

and then press SET. Repeat to set the minute (+ and -) then SET to store.

Green unlock symbol

24hr or 12hr display

Day of the week

Hour and Minute display

Set button

Page 19

19

6) The handset will then display the temperature screen as shown below.

7) The control is now ready for use with the burner.

NOTE: If the handset is misplaced, you can “page it” by pressing the + button only on the

control valve on the fire for a period of 5 seconds. The handset will flash and make an audible

sound to help find it. Once you have found the handset wrap your hand around the back so

that your hand is in contact with both sides to stop the sound. The flashing and sound last for

60 seconds. If not found repeat actions.

ADVANCED SETTINGS FOR FULL FUNCTION HANDSET

SNOOZE MODE IN MANUAL OPERATION

1) Snooze mode is a time which can be set turn the fire automatically off after a certain period has

elapsed.

2) Hold the handset in one hand ensuring it is in contact with both sides. The green light of the unlock

symbol should be lit. The snooze time can be set either before or during manual operation of the

fire.

3) Press the mode button to scroll through the functions until the symbols MAN and Zzz are flashing at

the top of the display as shown below. Press and release the SET button and this will put the control

into the manual snooze mode. The default time in snooze mode is 1 hour.

4) Pressing the set button again will show you the snooze time period remaining. The time can be

adjusted by pressing the + or – buttons on the handset. The time period can be set from 1 minute to

4 hours (as shown below). Once done press the SET button.

5) When the countdown time for the snooze period has reached zero the fire will turn off.

Celsius or Fahrenheit

temperature display

Page 20

20

THERMOSTATIC MODE

PLEASE NOTE: Thermostatic mode of this fire will only allow regulation of the room temperature by

the fire when it has been already lit via manual operation of the handset. It will not allow the fire

to light automatically due to low ambient room temperature and should therefore not be relied

upon for frost protection purposes.

1) Unlock the handset as previously described and press and

release the MODE button until the display has the thermometer

symbol flashing at the top of the display. Press the SET button to

enter this mode.

2) Press the SET button again to see the temperature setting that is set (the default is 24 degrees

Celsius). If a different set temperature is required, whilst the display is showing this set temperature,

press the + and – buttons to alter this setting, press the set button to store the required temperature,

or alternatively leave the handset for a few seconds and the temperature will be stored

automatically.

3) If at any time the power button is operated during thermostat mode, the control will cancel any

thermostat operation and return the control to manual mode.

IMPORTANT NOTE: Thermostat mode will not light the fire automatically and will only regulate

between the maximum and minimum burner setting. The fire must be lit manually via the

handset and then you enter thermostat mode as described in this section and set the

temperature. When no longer requiring the thermostat, mode turn off the burner and the

handset will return to manual mode.

RESTORING COMMUNICATION WITH THE FIRE

FULL FUNCTION (LCD) HANDSET

If the handset for whatever reason has lost communication with the Fire Control valve, when the

handset is held, the green light will be permanently lit but will pulse brighter.

In addition, the communication symbol

And other symbols will be missing from the display and it will appear as shown.

To reconnect do the following –

Reset the handset to clear the old pairing and enable it to accept a new pairing: -

1. Hold the handset as described previously to unlock the keypad and keep hold of the handset

2. while doing all the following.

3. Press and hold the SET button and keep held for around 3 seconds until you hear a second beep.

Release the SET button and PROG appears at the top left of the handset. SETUP should also be

flashing at the top right corner of the display.

4. When SETUP is flashing, press and release the SET button to enter the menu. (H24 (or 12), will be

flashing. Press and release the SET button about 9 more times until the display shows CA with a

flashing 0. Press and release the + or – button once to change the CA0 to CA1. Then press and

release the SET button once again. The display will now show 7ESC r4 (or any number next to

the r).

5. The handset is now at factory reset condition and a new pairing can be performed, see next

section.

A video is available on YouTube showing you how to do this please see link below –

https://www.youtube.com/watch?v=-bbeSuk0IWI

Page 21

21

PAIRING THE HANDSET (LCD)

If the handset is in its factory reset condition as above, the display will read 7ESC and r and a number will

show as below.

Picking up and holding the handset will unlock the keypad and the green light will illuminate a solid

green (and the LCD backlight may come on if the room is dark enough).

NOTE: Ensure the small isolation slide switch on the top left of the gas fire control is slid to the

right, (I) position to turn the power on to the valve.

1. Place the handset near the fire, i.e. within a metre (3 feet). No need to hold the handset at this

time.

2. Simultaneously press and hold the – and + buttons on the gas valve control (not the handset)

until the red light on top left of fire control begins to flash rapidly, (it will take about 5 seconds to

start flashing), then immediately release the – and + buttons and quickly pressing just the

POWER button on the gas fire control valve.

Note: Pressing of the power button must be done within 1 second of the red light coming

on. If not done quickly enough, then the above must be repeated until done correctly.

3. When done correctly you will hear an audible sound from the handset and the display will show

the symbol

1. ” and the green light on the handset will be flashing. You now have 60 seconds to

accept the pairing.

To do this pick up and hold the handset and hold it as previously described to activate the

unlocking of the keypad and press and hold the “SET” button for a few seconds.

4. You will hear a few beeps from the handset and the display will change and enter the set-up

menu and set display function.

IMPORTANT NOTE: Even in case you do not complete all of the setup, the pairing is still stored

once accepted by pressing set the first time. The handset will re-enter setup mode at next unlock

(pick up) or by entering set up mode manually. Do not send pairing request again from the valve!

If this is done, then another factory reset of the handset will be required and reset and new pairing

done again.

Page 22

22

CARE AND MAINTENANCE

BATTERIES

• Ensure the batteries are replaced every 12 months will help to prevent damage to the valve and

handset owing to leaking batteries.

• Do not mix battery brands and only use high quality, alkaline batteries (we advise Energizer).

• Keep contacts clean and do not bend them.

• Remove batteries if the fire is not used for lengthy periods (to prevent old batteries from leaking and

damaging the valve).

• Do not operate the fire without the battery covers in place.

• If handset is dropped and damaged, obtain a replacement.

• If you have a display handset and it shows less than a full battery symbol on the display.

• If the red-light indicator on the valve is flashing every 10 seconds.

• If batteries are not replaced the fire will stop working or work intermittently.

• The handset (or valve) may give error codes, which may or may not be correct.

• The batteries may leak and cause permanent, irreversible damage to the electronics which would

mean a replacement must be purchased (not covered by warranty).

REPLACING BATTERIES

The control consists of a handset and gas valve within the gas stove. There are batteries both in the

handset (2 x 1.5v AA Alkaline) and in the valve (3 x 1.5v AA Alkaline). The battery covers can be opened

without tools by using your finger tip and pressing to unhook the clip that retains the cover.

Remove and replace the batteries being careful not to bend the battery contacts. The batteries should

be held firm in place by the valve contacts. It is as important to ensure the contacts on the battery, valve

and handset are completely clean and dry and free from any contamination or surface damage. It is

vital that the batteries are put inside in the correct direction as shown in the above photos. Pay special

attention to the position to the “+” end of the battery.

RED INDICATOR

Issue

Meaning

Permanently lit

Unsuccessful ignition sequence – valve in

lockout (E00)

Flashing rapidly

Valve is busy (will not accept any command)

Flashing once a second

Valve detects an error

Flashing once every 10 seconds

Error detected

Flashing twice every 10 seconds (handset only)

Indication of low battery power in handset

Flashing three times every 10 seconds

(handset only)

Indication of low battery power in both

handset and gas valve

Permanently off

Valve in standby or in a stable operation

On momentarily after power up

Valve doing a self-test

Appears after pressing start

Indicates time to release pressing the start

button

Page 23

23

VALVE ERROR

1. Let the fire cool down (if hot).

2. Check if batteries are good and mounted correctly. Replace with new batteries if in any

doubt

3. Reset the error by first pressing the power button (once the fire has cooled down). Then

press once again to try to start the fire.

IMPORTANT NOTE: The handset will need to be paired with the valve after installation. (If

using a handset with display, the time will be lost after some minutes of no power, but the

pairing will remain. Refer to the instructions on how to set the time to restore the time to the

display. Do not press the buttons on the valve to make a new pairing. If you do then you will

have to reset the handset to accept a new pairing and make a new pairing, see the sections on

restoring handset communication).

If the green indicator is flashing like a heartbeat, it is not in communication with the valve for

some reason (on display handset additionally the communication symbol is missing see photo

below.

Communication can be lost by:

• The slide switch on the valve not in the on (I) position.

• The batteries need replacing in the valve (see section)

• The handset is too far away from the fire (it needs to be some within a few metres)

• If the above is correct, and the handset is still flashing, then the pairing on the valve may have been

accidentally altered and the handset will need to be reset, and a new pairing performed to restore

communication (see section on restoring handset communication.

If this does not resolve the problem, call a service engineer.

FREQUENTLY ASKED QUESTIONS

NOTE: USE THIS GUIDE IN ASSOCIATION WITH YOUR GAS FIRE USER HANDBOOK, ONLY ATTEMPT WORK AS

RECOMMENDED IN THOSE INSTRUCTIONS AND WHERE SUITABLY QUALIFIED

WHAT SHOULD I DO IF MY FIRE DOES NOT LIGHT OR STAY LIT.

Check if gas supply is on.

If the fire is hot, wait for fire to cool down.

If your fire has a remote handset, put the handset to one side and access the gas valve

in the fire (check user instructions for details on how to do this).

Remove battery cover from valve and check batteries are ok, with no leaks visible, or

any other contamination present. If in doubt replace with new, unused batteries.

When replacing batteries, ensure contacts are clean, dry, and free from any contaminants

or surface damage. Be careful not to bend or displace contacts.

THERE ARE VIDEOS AVAILABLE ON YOUTUBE TO WATCH THESE

PROCEDURES. THESE CAN BE FOUND BY SEARCHING TESC GAS CONTROL

Page 24

24

Ensure to mount batteries in correct orientation.

Replace battery cover on valve.

Check ceramic parts (matrix, coals, logs, etc.) are in correct place and in good condition.

Perform any general cleaning of the fire as recommended by manufacturer’s user

instructions, particularly around the pilot assembly.

Replace correctly any part of the fire that was removed to allow access to the valve.

If the red light on the valve is lit, reset by pressing on/off button briefly (light should go out).

Start fire using control buttons on valve.

If fire does not light normally, wait until red light on valve indicates error or lockout.

NOTE: the valve may make several attempts to start the fire, this may take some minutes.

DO NOT interrupt the valve while it completes this process.

If the fire still does not function correctly: -

Double check all of the above, in particular that the batteries are good, mounted

correctly, and all contacts are clean and sturdy.

If the manufacturer’s user instruction manual details cleaning of the pilot, follow these

instructions carefully.

Reset the valve as above.

Attempt to restart the valve several times.

If the fire still does not function correctly you may need assistance from a service engineer. Refer to

manufacturer’s user manual to seek engineer assistance.

If the fire lights, and appears to work correctly, pick up the handset to check correct function: -

Hold the handset firmly, the unlock keypad light should be lit, solid green.

If NO LIGHT present on handset: -

Check the batteries in the handset are good, mounted correctly and firmly, and

there is no contamination or surface damage to the contacts.

Clean and replace batteries as necessary.

NOTE: If the battery contacts are contaminated (e.g. previous battery leakage) the

handset may be permanently and irreversibly damaged, meaning a new handset may

need to be purchased.

IMPORTANT NOTE: THE HANDSET IS WILL NEED TO BE PAIRE WITH THE VALVE IN THE FIRE

AFTER INSTALLATION. PAIRING IS NOT LOST IF BATTERIES ARE REMOVED. THE DISPLAY

HANDSET MAY LOSE RECORD OF THE TIME IF BATTERIES ARE REMOVED BUT PAIRING WITH

THE VALVE WILL REMAIN. REFER TO INSTRUCTIONS RELATING TO SETTING THE TIME TO

RESTORE TIME TO THE DISPLAY.

If the green indicator light is flashing like a heartbeat, the handset is not communicating with the

valve (on the display handset the communication symbol will be missing)

Communication can be lost for various reasons including, but not limited to:-

The slide switch on the valve not in ON (I) position.

The batteries in the valve being low on power, or out of power.

The handset being too far from the fire.

If the above are all in order and the handset is still flashing, pairing with the valve may have been

unintentionally altered. The handset will need to be reset, and a new pairing with the valve

established (see section on restoring handset communication).

If this does not resolve the problem a service engineer will be required.

Page 25

25

INSTALLATION & COMMISSIONING CHECKLIST

PURCHASE INFORMATION

Dealer/Retailer Name

Address

Telephone Number

Email

Date Purchased

INSTALLER INFORMATION

Installer Name

Address

Telephone Number

Email

Gas Safe Registration

Number

APPLIANCE INFORMATION

Date Installed

Appliance Stock Code

Appliance Description

Serial Number

COMMISSIONING CHECK (Complete & Sign)

YES

NO

Does the chimney/flue system meet the appropriate standard?

Has the chimney/flue system been swept and passed the soundness

test?

Has this appliance passed the flue draught test?

Please write down the flue draught reading:

Has this appliance passed the smoke test?

Has this appliance passed the spillage test?

Have you explained how to operate the appliance and explained the

controls?

Signature:

Print Name:

Page 26

26

SERVICE RECORDS

Page 27

27

Hunter Stoves Group Ltd Extended 5 and 10 Year Warranty

2 Year Standard Warranty

Any appliance bought through the showroom of an authorised Hunter Stoves Group dealership will

automatically be covered by our standard 2-year conditional guarantee.

However, this standard 2-year warranty can be extended to a 5 year or 10-year conditional warranty

dependent on the model type (5 years- Boiler models, 10 years- Room heater and Gas models).

To qualify for this extended warranty option, you need to:

1. Register your purchase online at https://www.hunterstoves.co.uk/ProductRegistration

2. Retain your proof of purchase.

Warranty Conditions

For the Standard 2 year or extended 5/10-year warranty to be valid and to remain in force throughout

the warranty period the following must have been carried out:

1. The appliance must have been installed by an appropriately qualified engineer (from the Competent

Person Scheme) in accordance with the manufacturer’s instructions and in compliance of any

relevant national or local building regulations. Please visit the following link for details on the

Competent Person Scheme: https://www.gov.uk/guidance/competent-person-scheme-current-

schemes-and-how-schemes-are-authorised

2. The appliance will need to be registered within two months of purchase and the commissioning and

installation documentation completed (these need to be kept by the end user).

3. The appliance must be serviced within 12 months of the installation date for the second year of the

standard warranty to be valid, and within every 12-month anniversary thereafter to maintain the

validity and coverage of any extended warranty. For this purpose, the installation and user

instructions, supplied with the appliance, makes a provision for receipts and annual services to be

recorded. This is needed in the event of a claim during the warranty period.

4. Only genuine Hunter Stoves spare parts or consumables can be used in the servicing and

maintenance of the appliance during any standard or extended warranty period. These can be

sourced from your authorised supplier directly or through our website spares portal.

www.hunterstoves.co.uk/spares.

5. Any problems or issues giving rise to any claim under the standard or extended warranty must be

submitted to the authorised Hunter Stoves Group retailer from whom you originally purchased the

appliance. Hunter Stoves Group will then offer appropriate support and help through your original

authorised supplier to solve any issues.

6. The standard or extended warranty option is not transferable. It is solely for the benefit of the original

purchaser of the appliance. For this purpose, please retain the proof of purchase.

Warranty Exclusions

No warranty period is extended to naturally-wearing replaceable consumables and spare parts within

the appliance. Such parts include, but are not limited to:

For Solid Fuel Stoves:

Glass and rope/ceramic seals

Fire bricks

Baffles/Throat plates

Log retainers, grate supports & catch bars

Grate parts

Ash-pans

Clip-in Boilers

For Gas Stoves:

Gas pilot assemblies

Thermocouples and Oxy pilots

Ceramic log & coal 'fuel -effects'

Page 28

28

Paint and Surface Coverings

The paint or surface covering of the appliance will be covered (for 2 years after installation) provided the

warranty conditions are met. However, damage due to the following events will not be covered:

1. Damage to the paint surface caused by the appliance being stored in a damp and cold environment

is not covered under warranty. Please be aware that any moisture within the room where the stove

is installed e.g. through clothes drying, can be a cause of paint issues.

2. In the course of the initial firings of the appliance the paint or enamel surface may change colour.

This is normal and as such is therefore not covered under warranty.

3. Damaged caused by over firing, resulting in cracking, bubbling or discolouration to the paint or

enamelled surface finish is not covered under warranty.

Warranty Limitations

1. Damage to the appliance due to specific local conditions caused by draft or chimney defects.

2. Damage resulting from installation and use where installation is not in accordance with the

manufacturer’s instructions or local building and/or safety regulations.

3. Damage or premature wear caused by burning inappropriate fuels such as Bituminous coal, “Petro-

Coke” or any other Petroleum based coals. Please visit the HETAS website, www.hetas.co.uk, for a full

list of approved fuels which are covered by the warranty. Fuels outside of this list are not covered by

the warranty.

4. Damage caused by burning material with high creosote content or any other painted/treated

timber.

5. Consequential loss to associated non-Hunter Stoves Group products is not covered under the

warranty.

6. Consequential loss relating to decorations, soft furnishings or other household assets is not covered

under the warranty.

7. Cost associated with the removal and re-installation of an appliance subject to a warranty claim.

Hunter Stoves Group total liability will only extend to the total purchase price paid for the goods in any

warranty claim. Hunter Stoves Group reserve the right to replace, repair or refund to value of goods

purchased.

ANY HUNTERS STOVES GROUP PRODUCT PURCHASED VIA AN INTERNET SUPPLIER, OR THROUGH

AN UNAUTHORISED STOCKIST WILL ONLY BE SUPPORTED BY THE STATUTORY, 12 MONTH

GUARANTEE AND WILL NOT QUALIFY FOR ANY EXTENDED 5- OR 10-YEAR WARRANTY.

The Hunter Stoves Group extended warranty option does not affect your statutory rights.

This revised standard or extended 5 or 10-year warranty option comes into effect on 1st September 2015

and will apply to all appliances sold from that date.

This standard/extended warranty applies to purchases of Hunter Stoves within the United Kingdom and

the Republic of Ireland. Purchases in all other countries are subject to the warranty conditions specified

by the distributer in those markets.

Hunter Stoves Ltd, 8 Emperor Way, Exeter Business Park, Exeter, Devon, EX1 3QS

www.hunterstoves.co.uk Email : info@hunterstoves.co.uk

FURTHER INFORMATION

For extra guidance on using your stove please contact your supplier/installer.

All genuine Hunter Group spares can be purchased through our website

www.hunterstoves.co.uk/spares or through your authorised dealer.

Loading...

Loading...