Hunter Stoves Di Lusso, Eco R4 Inset, Eco R6 Inset, Eco R6 Slimline Inset, Eco R5 Inset Installation, Operation, Maintenance And Servicing Manual

1

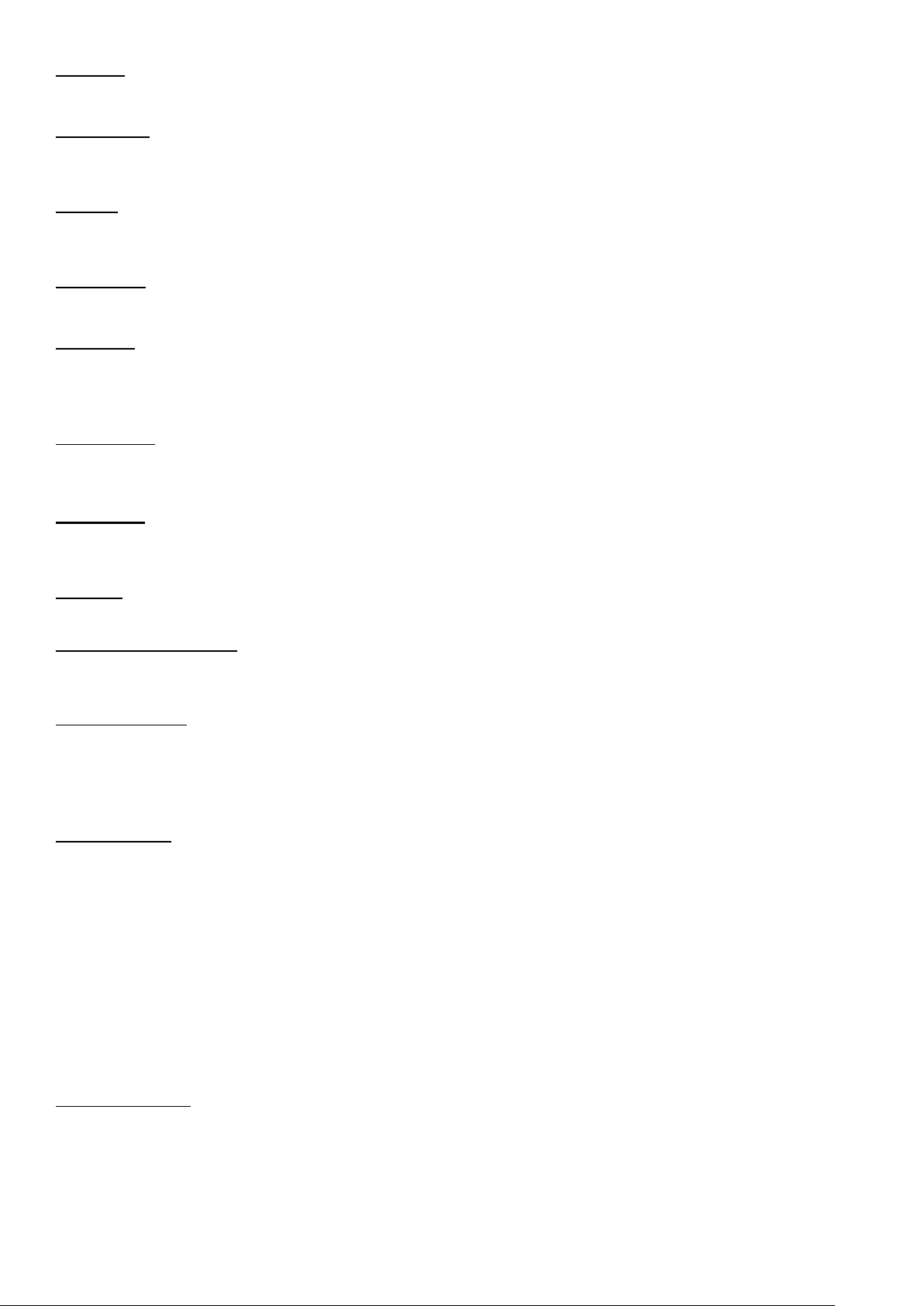

Eco R4 Inset

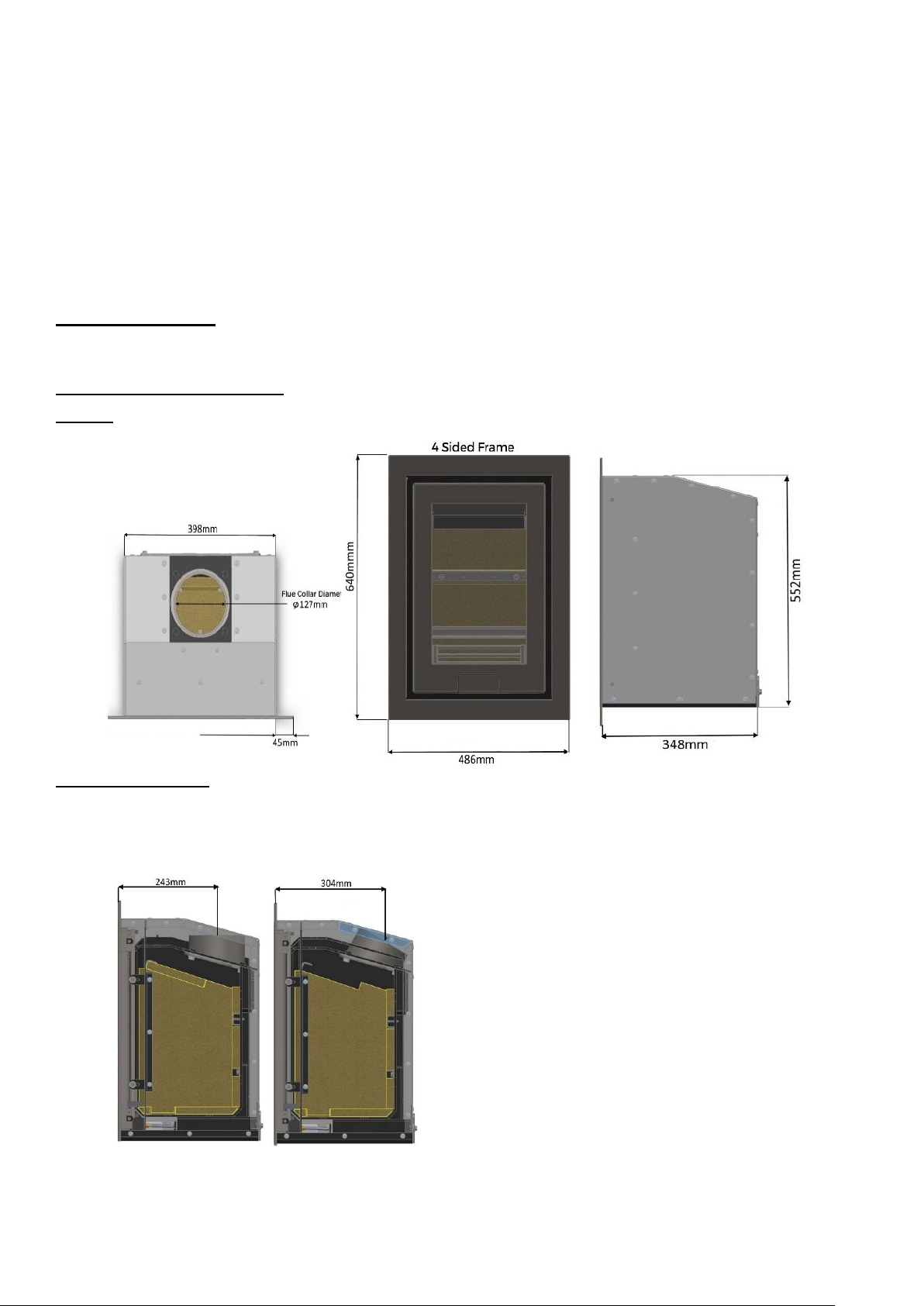

Eco R5 Inset

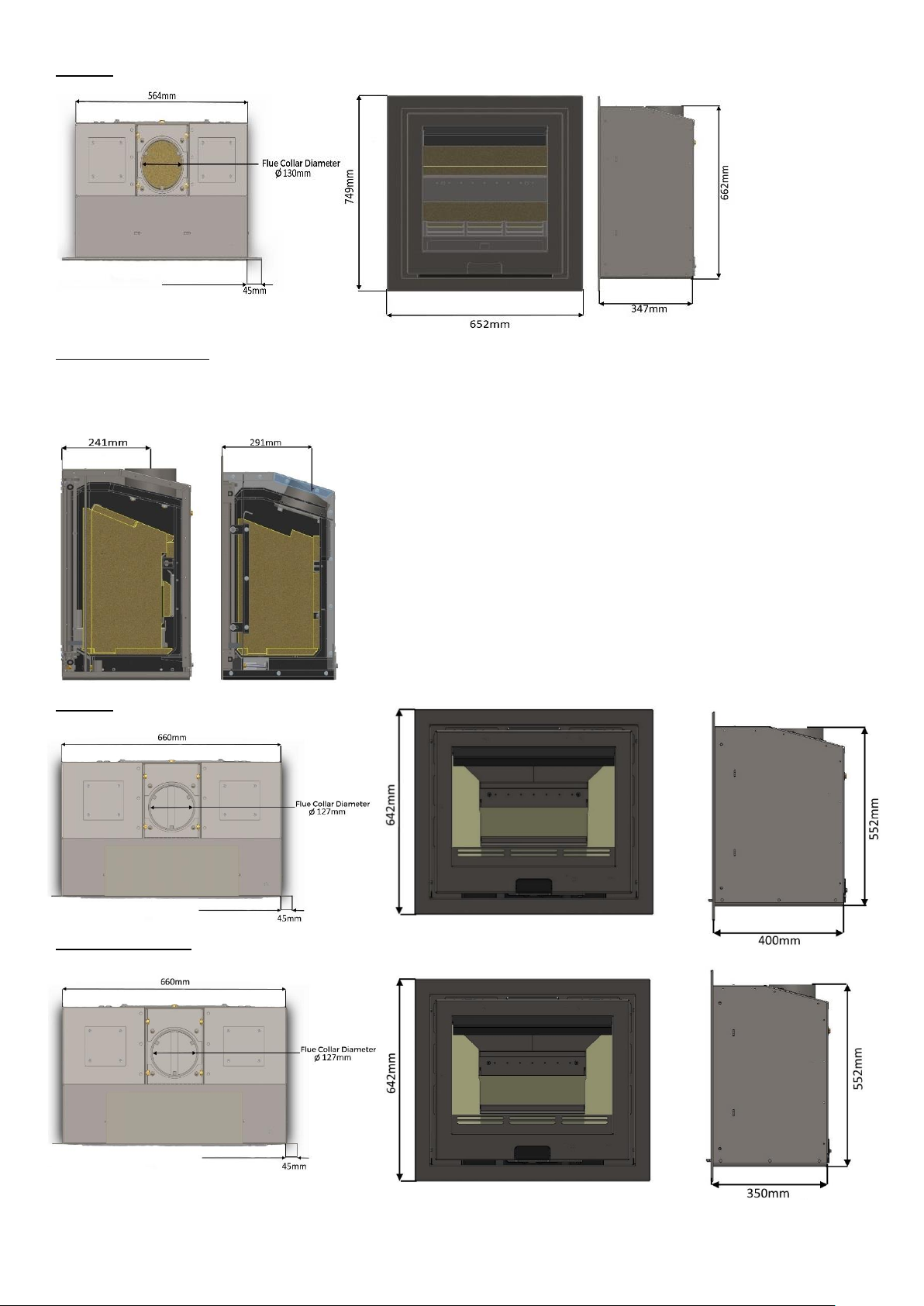

Eco R6 Inset

Eco R6 Slimline Inset

Wood Burning Inset Stove

Instructions for:

Installation/Operating/Maintenance/Servicing Instructions

JINEDLUIN REV B 27/03/2019

2

STOVE MODELS

ECO R4 INSET (FOUR-SIDED FRAME) ECO R4 INSET (THREE-SIDED FRAME)

STOVE - EDDLR04 STOVE – EDDLR04

FRAME – DLR4FP4B50 (BLACK) FRAME – DLR4FP3B50 (BLACK)

FRAME – DLR4FP4P50 (PEWTER) FRAME – DLR4FP3P50 (PEWTER)

ECO R5 INSET (FOUR-SIDED FRAME) ECO R5 INSET (THREE-SIDED FRAME)

STOVE – EDDLR05 STOVE – EDDLR05

FRAME – DLR5FP4B50 (BLACK) FRAME – DLR5FP3B50 (BLACK)

FRAME – DLR5FP4P50 (PEWTER) FRAME – DLR5FP3P50 (PEWTER)

ECO R6/R6 SLIMLINE INSET (FOUR-SIDED FRAME) ECO R6/R6 SLIMLINE INSET (THREE-SIDED FRAME)

STOVE – EDDLR06/EDDLR06S STOVE – EDDLR06/EDDLR06S

FRAME – DLR6FP4B50 (BLACK) FRAME – DLR6FP3B50 (BLACK)

FRAME – DRL6FP4P50 (PEWTER) FRAME – DLR6FP3P50 (PEWTER)

3

CONTENTS INDEX:

STOVE MODELS………………………………………………………………………………………………… 2

TECHNICAL SPECIFICATION……………………………………………………………………………… 4

GENERAL GUIDANCE………………………………………………………………………………………… 5/6

SAFETY……………………………………………………………………………………………………………… 6/7

INSTALLATION

APPLIANCE DIMENSIONS…………………………………………………………………………………… 7 - 9

FLUE REQUIREMENTS……………………………………………………………………………………….. 9/10

DI LUSSO ECO R4 INSTALLATION………………………………………………………………………. 10 - 14

DI LUSSO ECO R5 INSTALLATION………………………………………………………………………. 14 – 17

DI LUSSO ECO R6 INSTALLATION………………………………………………………………………. 17 - 19

FITTING THE STOVE – ALL ……………………………………….………………………………………. 19 - 27

DI LUSSO ECO R4 FLUE CONNECTION……………………………………………………………….. 21/22

DI LUSSO ECO R5 FLUE CONNECTION……………………………………………………………….. 22/23

DI LUSSO ECO R6/R6 SLIMLINE FLUE CONNECTION ……………………………………………. 23/24

DI LUSSO ECO R5/R6/R6 SLIMLINE ENCLOSURE INSTALLATION…………………………… 26 - 27

RE-ASSEMBLING THE STOVE……………………………………………………………………………… 31

OPERATING INSTRUCTIONS………………………………………………………………………………. 31 - 34

MAINTENANCE…………………………………………………………………………………………………. 34/35

TROUBLESHOOTING…………………………………………………………………………………………. 36/37

SPARES…………………………………………………………………………………………………………….. 38- 42

INSTALLATION AND COMMISSIONING CHECK LIST…………………………………………… 43

SERVICE RECORDS……………………………………………………………………………………………. 44

FULL WARRANTY INFORMATION……………………………………………………………………… 45/46

Welcome to the Hunter Stoves family and thank you for purchasing

an Eco Di Lusso Inset stove. This stove was designed and built to be

a high-performance heating appliance, and we hope it will bring

you great enjoyment. The natural environment is important to us,

so our stoves are manufactured to provide you with a clean and

efficient burn that will keep you warm through cold winter nights.

4

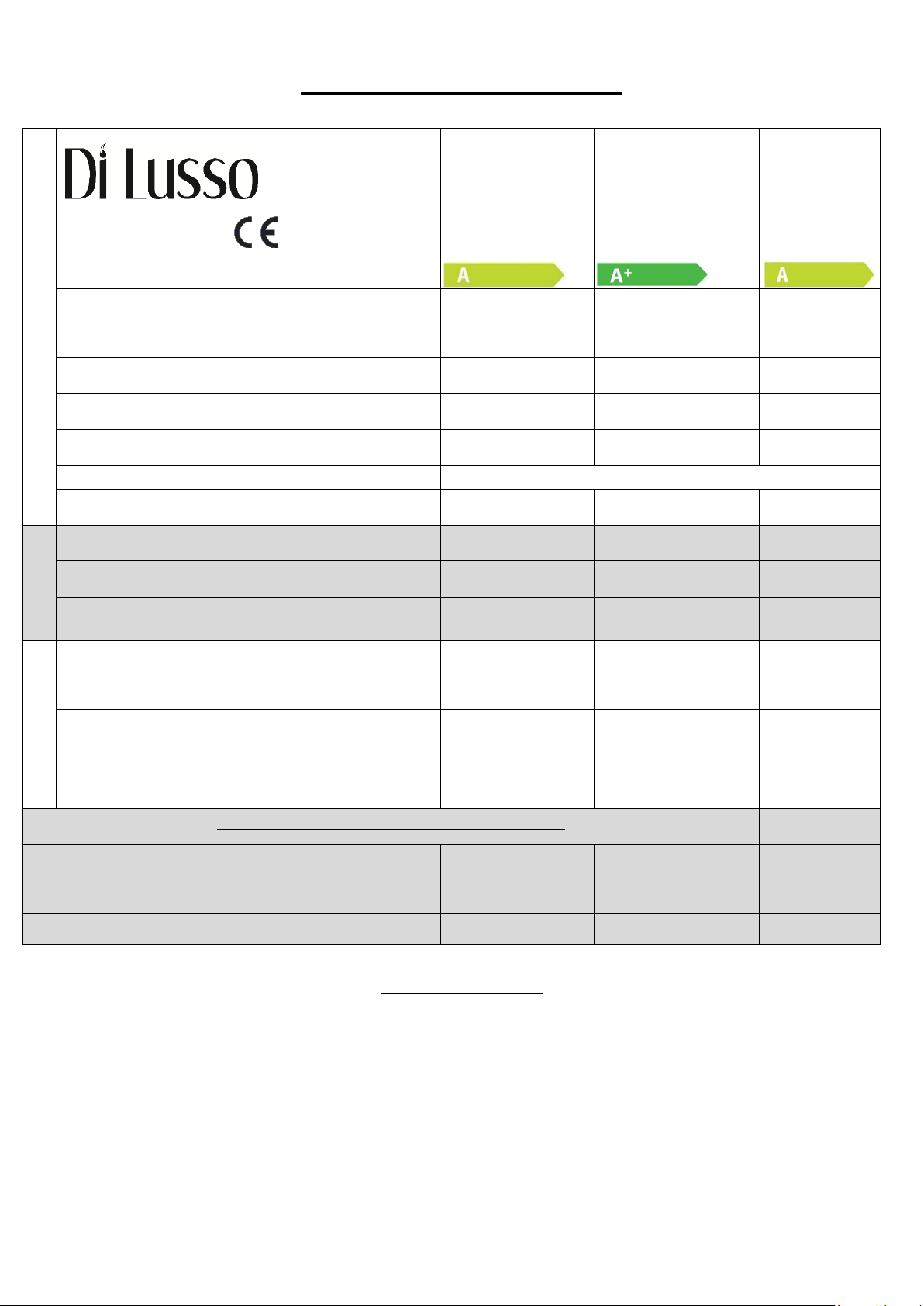

Technical Specification

Eco R4

Eco R5

Eco

R6/R6

Slimline

Energy Efficiency Class

Nominal Heat Output

Wood

4.9kW

6.3kW

6.2kW

Energy Efficiency

EEI

106

107

102

Efficiency

Wood

79%

81%

77%

Mean CO (@13% O₂)

Wood

0.09%

0.12%

0.09%

Appliance Mass

70kg

121kg

116kg

Recommended Fuels

Wood

Seasoned Wood (less than 20% moisture content)

Maximum Log Length

250mm

350mm

330mm

FLUES

Mean Flue Gas Temperature

Wood

226°C

269˚C

299˚C

Flue Gas Mass Flow

Wood

5.5 g/s

4.9 g/s

5.6 g/s

Flue Outlet Size (Top or Rear Option)

127mm

127mm

127mm

VENTILATION

- Where leakage is greater than 5m³/hour/m²

- Ventilation normally required = 550mm² per

kW output over 5kW

NONE

660mm²

715mm²

- Where leakage is less than or equal to

5m³/hour/m²

- Ventilation normally required = 550mm² per

kW output

2695mm²

3410mm²

3465mm²

Minimum Clearance to Combustible Material

At the sides of the stove

250mm (from

outside of frame)

450mm (from

outside of frame)

400mm

(from outside

of frame)

In front of the stove (to furniture etc.)

800mm

1100mm

1200mm

Smoke Control Areas

This appliance is only exempt for use in a smoke control area when fitted with a smoke control area kit (JDLU0401 –

R4) or (JDLU0501 – R5/R6). Find out if you are in a Smoke Control Area by contacting your Local Authority

5

General Guidance

It is important that your stove is correctly installed and operated as Hunter Stoves Group cannot accept responsibility

for any fault arising through incorrect installation, use, maintenance or servicing.

These instructions cover the basic principles to ensure satisfactory installation of the stove, although detail may need

slight modification to suit local site conditions.

The installation must comply with current Building Regulations, National and European Standards, Local Authority

Byelaws and other specifications or regulations as they affect the installation of the appliance.

The Building Regulations requirements may also be met by adopting the relevant recommendations in the current

issues of British Standards BS 8303 and BS EN 15287-1.

Only use approved fuels on this appliance. Information about this can be found on Pages 32.

This is a Domestic Appliance and must only be used in accordance with these instructions. Do not place articles that

are affected by high temperatures on, or near, this appliance. Do not place furniture or other items within 1 metre of

the front of this appliance. See the note on material clearances on pages – R4 – 10 - 12 and R5 – 14 - 16 and R6/R6

Slimline – 17 - 19.

Fitting a stove in a room which also contains an extractor fan and/or cooker hood should be avoided where possible. If

this is unavoidable, the suitability of the space for fitting this appliance must be decided at the discretion of a qualified

installer, and a flue draught interference test must be performed. Do not obstruct the ventilation required for the safe

use of this appliance.

Competent Persons Scheme

Members of the following schemes may self-certify the installation of this stove. If the installer is not a member

of one of these schemes, your local Building Control Department must approve the installation.

Health And Safety Precautions

Special care must be taken when installing the stove such that the requirements of the Health and Safety at Work

Act are met.

Packaging

All packaging supplied with this stove can be re-used or recycled. Please contact your local authority for information

on recycling schemes in your area.

Scheme

Web address

Telephone

APHC (Association of Plumbing and Heating

Contractors (Certification) Limited

www.aphc.co.uk

02476 470 626

Building Engineering Services Competence

Accreditation (BESCA Limited)

www.hvca.org.uk / www.besca.org.uk

0800 652 5533

HETAS Ltd (Heating Equipment Testing and Approval

Scheme)

www.hetas.co.uk

01462 634721

NAPIT Registration Ltd

www.napit.org.uk

0870 444 1392

NICEIC Group Ltd

www.niceic.org.uk

0800 013 0900

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION AND OPERATION. KEEP THESE

INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE AND SERVICING.

THIS APPLIANCE WILL BECOME VERY HOT WHEN USED IN ACCORDANCE WITH THESE INSTRUCTIONS,

HUNTER STOVES RECOMMEND THAT AN APPROVED GUARD IS USED TO PROTECT THE YOUNG, ELDERLY

OR INFIRM FROM HARM.

THE INSTALLER COMMISSIONING SHEET CAN BE FOUND ON THE BACK COVER. PLEASE ENSURE THAT IT IS

COMPLETED PRIOR TO USE.

6

Handling

Adequate facilities must be available for loading, unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should not be allowed to come into contact with the skin. In case of

contact, wash immediately with plenty of water.

Asbetos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of installation then

please seek specialist guidance and use appropriate protective equipment.

Metal Parts

When installing or servicing this stove, care should be taken to avoid the possibility of personal injury.

Air Supply

The room or space containing this appliance should have purpose provided ventilation (where necessary) in

accordance with Building Regulations. Due consideration should be given to air requirements for any other appliance

in the same room or space. Any air opening must be kept clear from blockage or obstruction.

Modification

No unauthorised modification of this appliance should be carried out.

Safety

WARNING – This appliance will be hot when in operation and due care should be taken. The supplied operating tool

or gloves may be used to open the door and operate the air controls.

Aerosols

Do not use an aerosol spray on or near the stove when it is alight.

Fires Can Be Dangerous

Always use a fireguard in the presence of children, the elderly or the infirm. The fireguard should be manufactured in

accordance with BS8423 – Fireguards for use with solid fuel appliances.

Do Not Over-Fire

It is possible to fire the stove beyond its design capacity. This could damage the stove so watch for signs of overfiring. If any part of the stove starts to glow red, the stove is in an over-fire situation and the controls should be

adjusted accordingly. Never leave the stove unattended for lengthy periods without first adjusting the controls to a

safe setting. Careful air supply control should be exercised at all times.

Fume Emission

Properly installed and operated, this appliance will not emit fumes. Occasional fumes from de-ashing and refueling

may occur. Persistent fume emission must not be tolerated.

This appliance should not be operated with the door open.

If fume emission does persist then the following action should be taken immediately –

• Open Doors and windows to ventilate room.

• Let the fire out or eject and safely dispose of fuel from the appliance.

• Check for flue/chimney blockage and clean if required.

• Do not attempt to relight the fire until the cause has been identified and corrected.

• If necessary, seek professional advice.

Adverse Weather

In a small number of installations, occasional local weather conditions (e.g. wind from a particular direction) may

cause downdraught in the flue and the stove to emit fumes. In these circumstances, the stove should not be used. A

professional flue installer will be able to advise on solutions to this problem (e.g. anti-downdraught cowl).

7

IN THE EVENT OF A CHIMNEY FIRE -

• Raise the alarm

• Call the Fire Brigade

• Close appliance air controls

• Move furniture, ornaments etc. away

• Place a fireguard in front of stove

• Check the chimney breast for signs of excessive heat.

If the wall is becoming excessively hot, move furniture away. Ensure the Fire Brigade can gain access to your roof

space in order to check for fire spread.

Installation

(N.B. All dimensions are in Millimetres)

Appliance Dimensions

ECO R4

Flue Outlet Position

The flue outlet angle and position are determined by the orientation of the flue collar. The outlet can be either vertical

or leant backwards by 30°. To change the angle, rotate the flue collar by 180°. The effective centre dimensions in

millimeters are shown below.

8

ECO R5

Flue Outlet Position

The flue outlet angle and position are determined by the orientation of the flue collar. The outlet can be either vertical

or leant backwards by 30°. To change the angle, rotate the flue collar by 180°. The effective

centre dimensions in millimetres are shown below.

ECO R6

ECO R6 SLIMLINE

9

Flue Outlet Position

The flue outlet angle and position are determined by the orientation of the flue collar. The outlet can be either

vertical or leant backwards by 30°. To change the angle, rotate the flue collar by 180°. The effective centre

dimensions in millimeters are shown below.

ECO R6 ECO R6 SLIMLINE

Flue Requirements

The flue serving this appliance must be dry, free from cracks and obstructions and be in accordance with the

designations shown in Table 1.

The diameter of the flue should not be less than 127mm and not more than 200mm. If these requirements are not

met the chimney should be lined by a suitable method. If there is no existing chimney, then either a prefabricated

block chimney in accordance with Building Regulations Approved Document J or a twin-walled insulated stainless-steel

flue to BS EN 1856 can be used. These chimneys must be fitted in accordance with the manufacturer’s instructions

and Building Regulations.

The chimney/flue should have a vertical height of at least 4.5 metres and should terminate in accordance with Table

2.

If the chimney is believed to have previously served an open fire installation, it is possible that the higher flue gas

temperature from the stove may loosen deposits that were previously firmly adhered, with the consequent risk of

flue blockage. It is therefore recommended that the chimney is swept a second time within a month of regular use

after installation.

If you have any doubts about the suitability of your chimney, consult your local dealer/stockist.

Both the chimney and flue pipe must be accessible for cleaning and if ANY part of the chimney cannot be reached

through the stove (with baffle removed), a soot door must be fitted in a suitable position.

Flue Type

Minimum Designation

Masonry or flue block flue with liner

T400 N2 D3 G (BS EN 1443:2003)

Clay Flue Blocks

FB1 N2 (BS EN 1806:2006)

Clay/Ceramic Liners

B1 N2 (BS EN 1457:2009)

Concrete Liners

B2 (BS EN 1857:2003)

Factory Made Metal Chimney

T400 N2 D3 G (BS EN 1856-1:2003)

Table 1 – Minimum Flue Designations

10

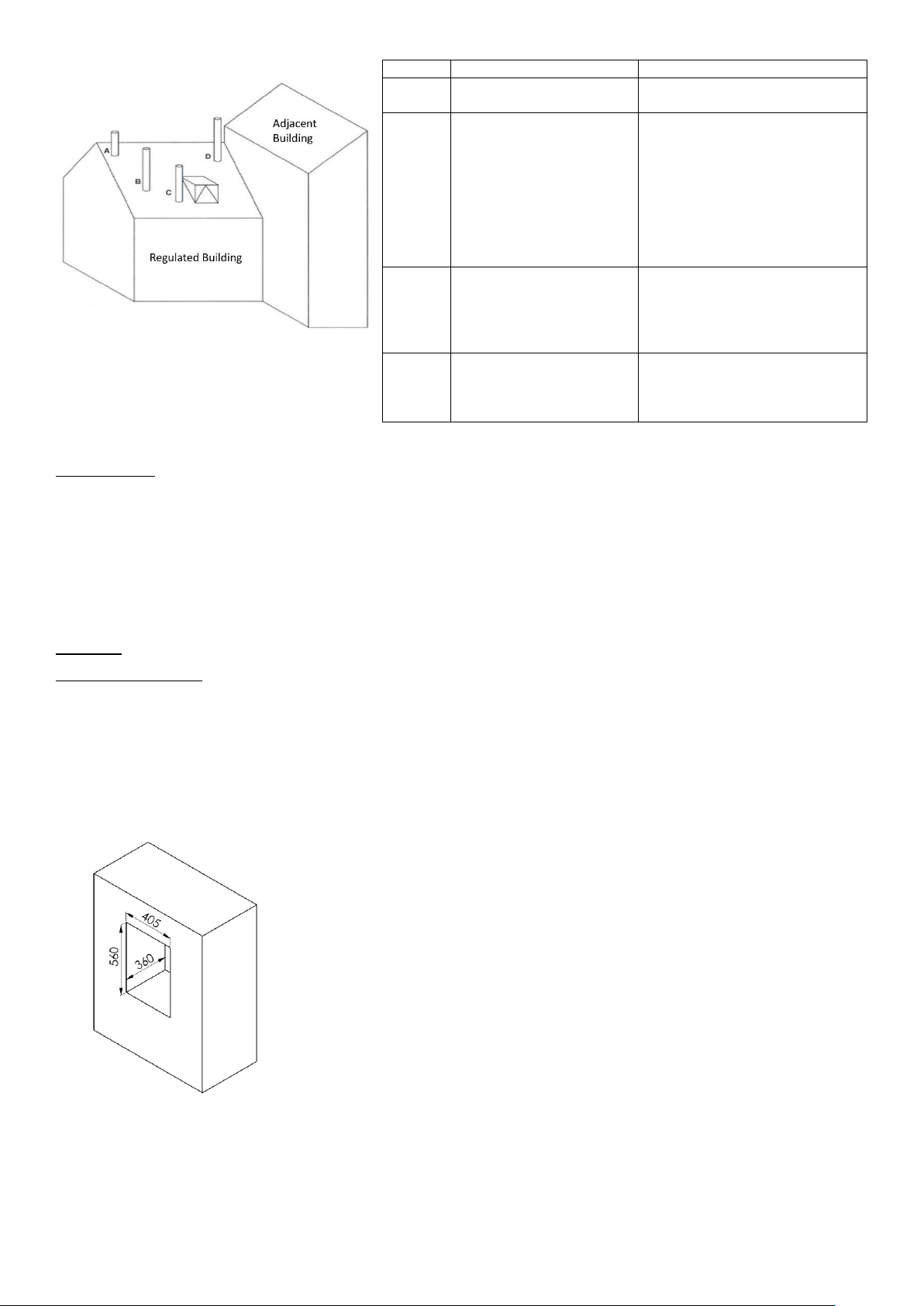

Table 2.

Flue Draught

If the draught exceeds the recommended maximum, a draught stabiliser must be fitted so that the rate of burning

can be controlled and to prevent over firing.

If the reading is less than the recommended minimum, then the performance of the appliance will be compromised.

The flue draught should be checked under fire at high output.

Minimum Draught – 1.2mm Water Gauge

Maximum Draught – 2.5mm Water Gauge

ECO R4

Appliance Opening

This stove must be fitted on a hearth or base with adequate load-bearing capacity.

The opening into which this stove is fitted should be constructed wholly from non-combustible materials. The

dimensions of the opening should be at least those shown in the diagram. Ensure there is a sufficient overlap where

the convection chamber flange meets the face of the opening. If not, either the opening should be made smaller, or

a suitable fire surround should be fitted to reduce the opening dimensions. This appliance will fit into a standard 16”

fireplace opening if the clay fire back is removed.

Any non-combustible walls within 50mm of this appliance should be at least 200mm thick and should extend at

least 300mm above the top of the appliance and at least 1.2 metres above the hearth. Any walls more than 50mm

from the appliance may be reduced to a thickness of 75mm. Ensure the inter-connecting flue pipe also has

adequate clearances to combustible materials.

Terminal

Position

Clearances to Flue Outlet

A

At or within 600mm of the

ridge

At least 600m above the ridge

B

Elsewhere on a roof (whether

pitched or flat)

At least 2300mm horizontally from

the nearest point on the weather

surface and:

a) At least 1000mm above the

highest point of intersection of

the chimney and the weather

surface or

b) At least as high as the ridge

C

Below (on a pitched roof) or

within 2300mm horizontally

to an openable roof light,

dormer window or other

opening.

At least 1000mm above the top of

the opening.

D

Within 2300mm of an

adjoining or adjacent

building, whether or not

beyond the boundary.

At least 600mm above any part of

the adjacent building within

2300mm

11

The wall above the stove will become hot and should therefore be finished in a heat resistant plaster.

IMPORTANT Do not hang pictures, electrical equipment or ornaments above the stove, as these could be damaged

and could potentially create a fire hazard.

Please check the suitability of any fireplace/surround for closed solid fuel appliances before installation. Di Lusso

cannot be held responsible for any fault arising through incorrect use or installation. Fire surround back panels

suitable for solid fuel are usually in three sections and slabbed. Many fire surrounds are suitable only for use with

gas and electric fires and therefore not suitable for solid fuel.

Direct Air Adaptor

If fitting the direct air adaptor kit, the opening depth may need to be increased. Read the instructions supplied with

the kit before proceeding.

Hearth Requirements

A constructional hearth with a minimum thickness of 225mm should be provided. The constructional hearth should

be made of solid non-combustible material and can include any solid non-combustible floor. The boundary of the

hearth must be clearly marked. This can be done by adding a super-imposed hearth on top of the constructional

hearth – e.g. a slate slab on top of a solid concrete floor.

Appliances installed with the base plate lower than 300mm above the hearth should have a constructional hearth

extending to at least 300mm in front of the stove (as per Building Regulations) however we would recommend

400mm and 150mm at the sides.

12

Appliances installed on a surface more than 300mm above the hearth require a constructional hearth with a depth

of 225mm in front of the stove. The base on which the appliance is mounted should be an extension of the

constructional hearth – i.e. all material between the stove base and the constructional hearth must be solid-

noncombustible material.

Clearances To Combustible Materials

There should be no combustible materials for a distance of 250mm either side of the stove or 680mm above. No

combustible furniture should be placed any closer than 800mm from the front of the stove.

Allow sufficient clearance between the stove and pictures, electrical equipment or ornaments etc., as these could

be damaged and could potentially create a fire hazard.

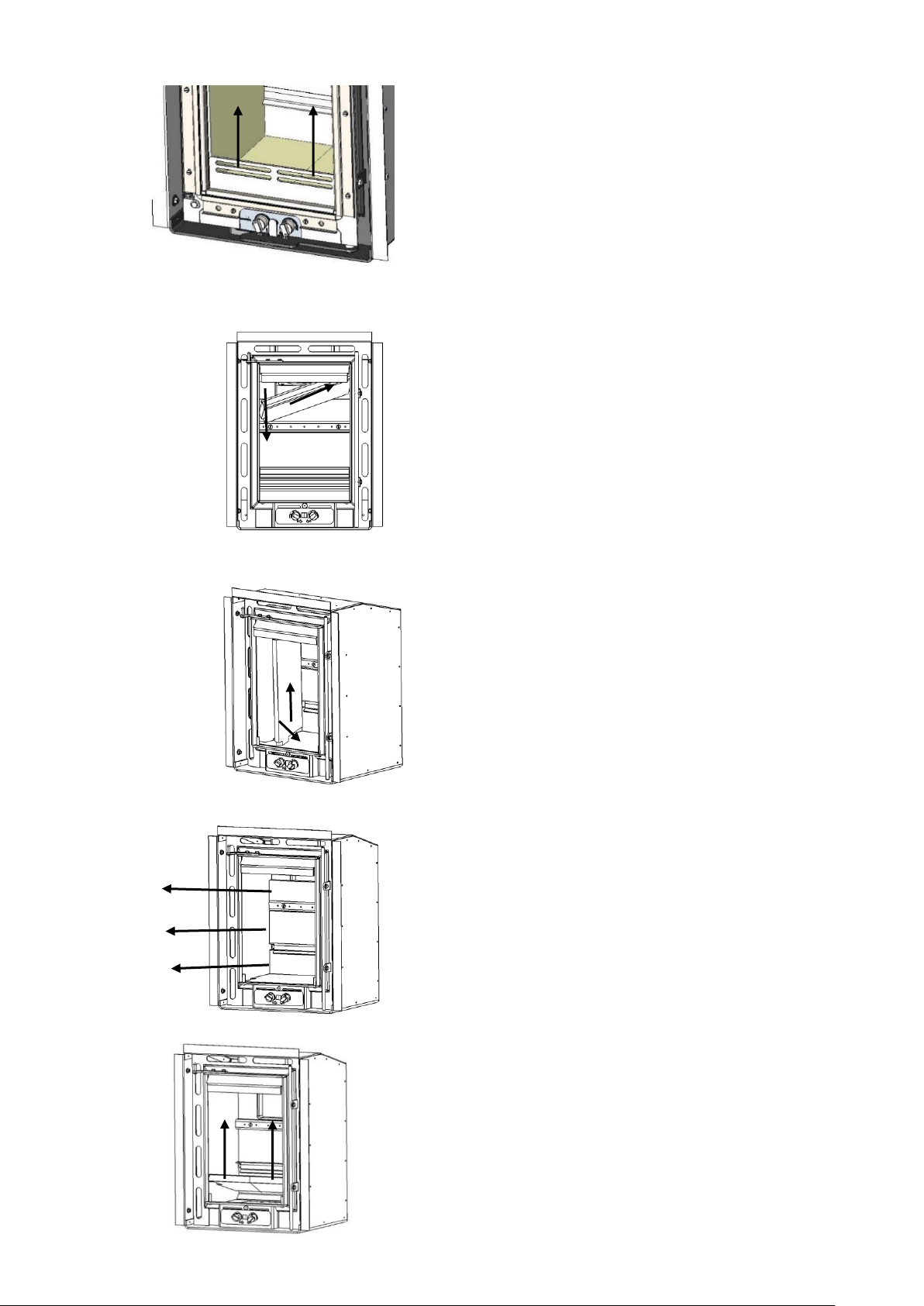

Removing Internal Components (All)

All internal components must be removed prior to fitting the stove. This will make handling the stove easier; allow

access to fixings and the flue outlet; as well as protect the internal components from damage during the

installation process.

1. To open the stove door, pull the door lever towards you to release from the magnet. Swing the handle out to the

right until the mechanism engages and the door catch is released.

N.B. When closing the door keep the door handle out to the right

until the door is closed.

13

2. Remove the log retainer by lifting it clear of the two support pins.

3. Remove the baffle brick (Eco R4/Eco R5 by lifting it up, sliding it to the right and then lowering the left-hand

edge into the firebox. For the Eco R6/R6 Slimline slide both baffle plates to the centre with left hand baffle

on top of right-hand baffle and lift out of stove together.

4. Remove the two side bricks by lifting them up to release them from the slots in the base brick. Swing the

bricks into the centre and remove them from the stove.

5. Remove the three rear brick sections (Eco R4) and two rear bricks (Eco R5/Eco R6) noting their positions and

orientation.

6. Lift up and remove the two base bricks.

14

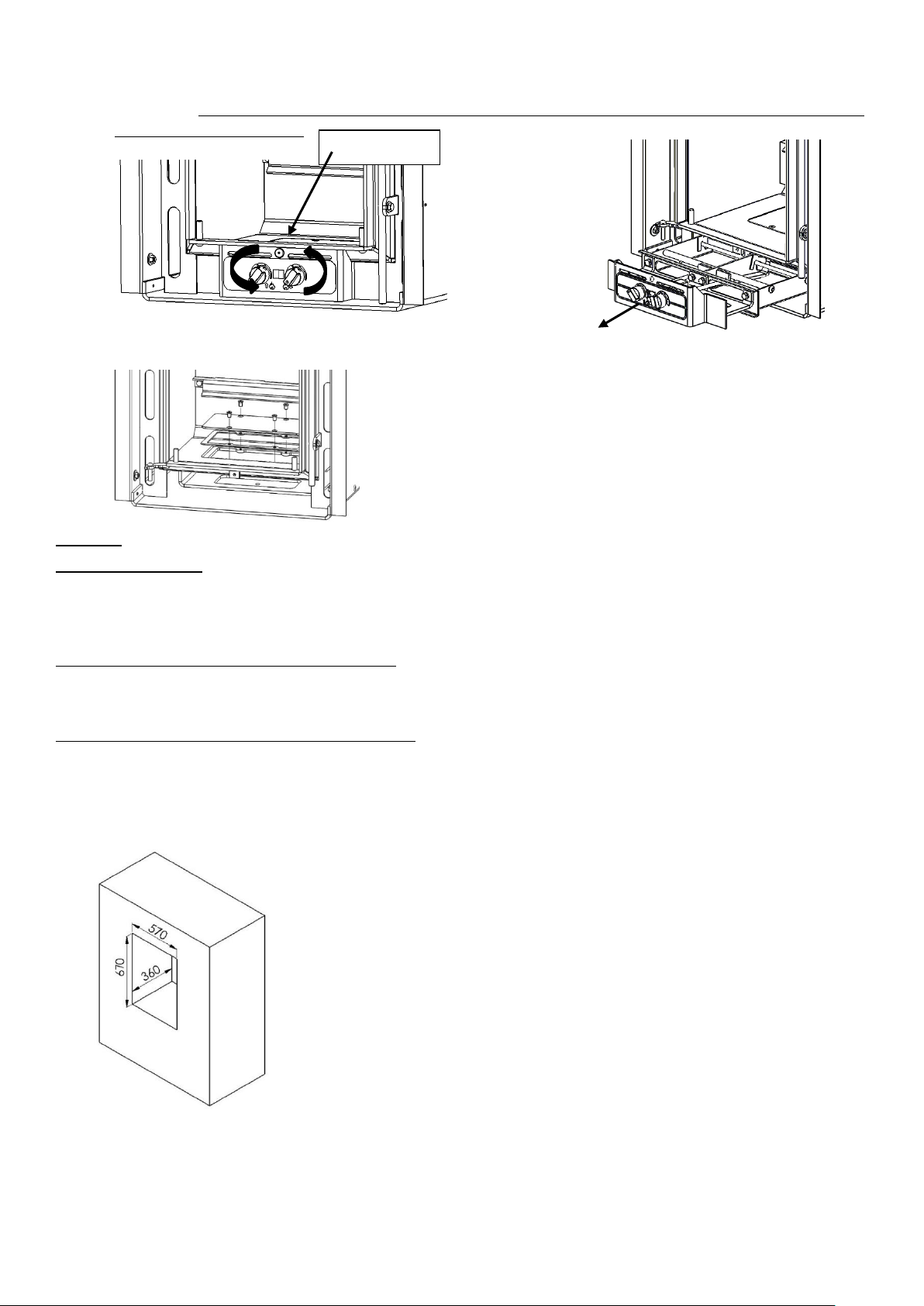

7. Remove the Air Valve Cassette by removing the socket screw holding it in place, turning both air controls to

the fully open position (clockwise) and then gently pulling on the fascia to slide the cassette out from under

the firebox. N.B. DO NOT Remove the Air Valve Cassette with the controls in the closed position as this will

damage the valve gaskets.

8. Undo the four countersunk screws and remove the base fixing access plate and gasket.

ECO R5

Appliance Opening

Important! This appliance may be installed either into a solid non-combustible opening or into an enclosure

fabricated from non-combustible sheet material as per the specifications in these instructions. For installation

instructions covering the approved enclosure design please proceed to 26.

Direct Air Adaptor And Convection Duct Kits

If fitting either the Direct Air Adaptor Kit or Convection Duct Kit the dimensions of the opening may need to be

altered. Read the instructions supplied with the kit before proceeding.

Installation Into A Solid Non-Combustible Wall

This stove must be fitted on a hearth or base with adequate load bearing capacity. The opening into which this stove

is fitted should be constructed wholly from non-combustible materials. The dimensions of the opening should be at

least those shown in the diagram. Ensure there is a sufficient overlap where the convection chamber flange meets

the face of the opening. If not, either the opening should be made smaller, or a suitable fire surround should be

fitted to reduce the opening dimensions.

Any non-combustible walls within 50mm of this appliance should be at least 200mm thick and should extend at

least 300mm above the top of the appliance and at least 1.2 metres above the hearth. Any walls more than 50mm

from the appliance may be reduced to a thickness of 75mm. Ensure the inter-connecting flue pipe also has

adequate clearances to combustible materials.

Socket screw

Loading...

Loading...