Page 1

TRAK

INSTALLATION

MANUAL

Page 2

CONTENTS

The Hunter legacy is not only

about quality—it’s about longevity.

We invented the modern ceiling

fan. We build fans that last, fans

that are designed as fans. We

design our fans while considering

each person in the process—from

the installer to the owner.

BEFORE YOU BEGIN

!

SAFETY & PRECAUTIONS 3

FAN PLACEMENT 6

PRE-INSTALLATION 9

TOOLS NEEDED 10

IN THE BOX 11

INSTALLATION

STEP 1: PREPARATION 12

STEP 2: CEILING BRACKET 13

STEP 3: DOWNROD 14

STEP 4: MOTOR ASSEMBLY 15

STEP 5: RETENTION SYSTEM 16

STEP 6: WIRING 17

STEP 7: MOUNTING 18

STEP 8: BLADES 19

STEP 9: REMOTE CONTROL 20

REFERENCE

LEGACY

1886

MAINTENANCE 21

TROUBLE SHOOTING 22

AUTHENTICITY

In a world full of impersonators,

be an original. We invented the

modern ceiling fan, and we stand

behind our products.

2

Page 3

!

BEFORE YOU BEGIN

SAFETY & PRECAUTIONS

Important Safety Information

To prevent SERIOUS INJURY, DEATH and PROPERTY DAMAGE, you should read, understand and follow the warnings and instructions in this

manual before installing or operating the fan.

READ AND SAVE THESE INSTRUCTIONS. This manual must always be kept with the fan and should remain with the fan if

it is transferred or sold. Always give manual to fan owner following installation.

FIRE, ELECTRIC SHOCK and CRUSH HAZARDS.

To prevent SERIOUS INJURY or DEATH:

• To reduce the risk of re, electrical shock, or personal injury, mount fan directly from building structure and/or an

outlet box marked acceptable for fan support of 70 lbs (31.8 kg) and use the mounting screws provided with the

outlet box.

• To avoid possible electrical shock, before installing or servicing your fan, disconnect the power by turning off the

circuit breakers to the outlet box and associated wall switch location. If you cannot lock the circuit breakers in the

off position, securely fasten a prominent warning device, such as a tag, to the service panel.

• To reduce the risk of electric shock, this fan must be installed with an isolating wall control/switch.

• To reduce the risk of personal injury, do not insert foreign objects in between rotating fan blades.

• Chemical burn hazard. Keep batteries away from children. This remote contains a lithium button cell battery. If a new

or used lithium button/coin cell battery is swallowed or enters the body, it can cause severe internal burns and can

lead to death in as little as 2 hours. Always completely secure the battery compartment. If the battery compartment

does not close securely, stop using the product, remove the batteries, and keep it away from children. If you think

batteries might have been swallowed or placed inside any part of the body, seek immediate medical attention.

Dispose of cells properly and keep away from children. Even used cells may cause injury.

Installation, Adjustment, Repair or Maintenance Must Be Performed By Qualied Personnel.

Follow all safety practices and instructions during the installation, operation and servicing of the fan. Failure to apply these safety practices

could result in death or serious injury. If you do not understand the instructions, please call our Technical Department at 1-844-593-FANS

(3267) for guidance.

Always Check Federal, State and Local Codes Before Installing Fan.

Code compliance is the responsibility of the installer. Check all relevant codes to make sure that all product certications, product listings

and building regulations are met.

5007479

3

Page 4

!

BEFORE YOU BEGIN

SAFETY & PRECAUTIONS

Electric Shock Hazard

To prevent serious injury or death:

• BEFORE installing or servicing your fan, ALWAYS disconnect the power by turning off the circuit breaker or breakers, to the

fan locations and conrm Lockout/Tagout procedures are in place. If you cannot lock the circuit breakers in the off position,

securely fasten a prominent warning device, such as a tag, to the electrical panel.

• All wiring must be in accordance with national and local electrical codes, including ANSI/NFPA 70. If you are unfamiliar with

wiring or are in doubt, consult a qualied electrician.

• Do not use extension cord with fan.

• Do not remove covers while power is on.

• Do not use improper voltage source.

All fan controls and incoming power should be installed only by qualied technicians familiar with the requirements of the National Electrical Code

and local codes. Failure to follow these guidelines will void the manufacturer’s warranty.

All electrical controls are congured at the factory and are ready to use. No user adjustments are available. Follow the included installation

instructions when installing this device to ensure proper operation. Do not make any changes to any part of the fan without rst consulting Hunter

Industrial Fan. Installation is to be in accordance with ANSI/NFPA 70: National Electrical Code and local codes.

The user is responsible for compliance with all international and National Electrical Code requirements with respect to grounding of all equipment.

Many of the parts of this unit operate at line voltage.

Before installing, servicing or cleaning the unit, switch power off at the service panel, lock the service disconnecting means and conrm Lockout/

Tagout procedures are in place to prevent power from being switched on accidentally. When the service disconnect means cannot be locked,

securely fasten a prominent warning sign, such as a tag, to the service panel.

To reduce the risk of electric shock, serious injury and death, only use this unit as intended by the manufacturer. If you have any questions, call

our Technical Department at 1-844-593-FANS (3267).

4

Page 5

!

BEFORE YOU BEGIN

SAFETY & PRECAUTIONS

CRUSH HAZARD

To prevent serious injury or death, ALWAYS attach the Retention Cable to the fan motor and secure to the building structure on

EVERY fan.

The Retention Cable limits the distance the fan could fall in the unlikely event of mounting system failure. Failure to install and to secure the

Retention Cable will void your warranty.

Weight and Torque Considerations

Always mount fan directly to building structure that can withstand approximately double (2x) the maximum hanging weight of the fan.

The hanging weight of a 8’ fan with a standard 11” downrod is 50 lbs. The maximum hanging weight of a 8’ fan with a 59” downrod is 55

lbs and a maximum torque of 7 ft-lbs.

Hunter Fan provides guidelines for mounting fans; however, it is the sole responsibility of the building owner and installer to ensure the

safety of the mounting system and Retention Cable, the building structure is sound, and the installation complies with all federal, state and

local codes.

Always Use Personal Protective Equipment

You should always wear Personal Protective Equipment, such as a Hard Hat, Safety Glasses and a Fall Harness when installing fans.

Damaged Equipment

Never operate or install any fans or fan accessories that appear to be damaged. Failure to follow this instruction can result in death, serious

injury or equipment damage.

To reduce the risk of personal injury, do not bend the blades or blade holders when installing or cleaning the fan.

Do not insert foreign objects in between rotating fan blades.

Service

If the fan does not operate properly using the procedures in this manual, remove all power to the unit and contact our Technical Department

for further assistance at 1-844-593-FANS (3267).

5

Page 6

!

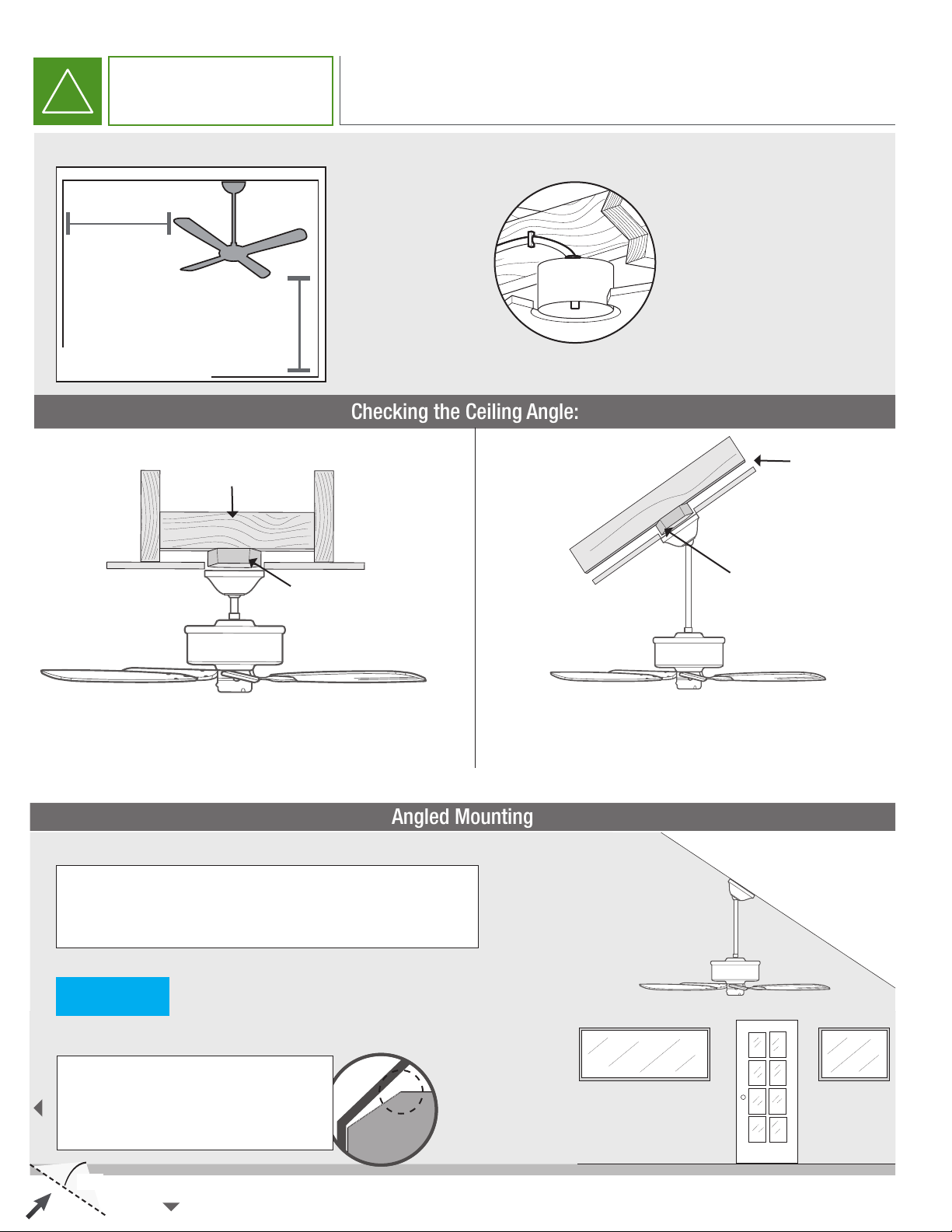

Checking the Ceiling Angle:

Angled Mounting

BEFORE YOU BEGIN

CHOOSE THE RIGHT LOCATION

Check the room dimensions: Check the outlet box:

30 inches

from blade tip to

nearest wall or

obstruction

10 feet

from bottom edge

of blade to the

oor

Standard Mounting

Support Structure

Ceiling Outlet

Box (required)

You must be able to

secure the fan to building

structure or fan-rated

outlet box and clearly

marked acceptable for

fan support of 70 lbs

(31.8 kg) or less.

Support

Structure

Angled Mounting

Ceiling Outlet

Box (required)

If you have a at ceiling:

Hang your fan by a standard downrod. For tall ceilings

you may need a longer downrod.

A little more information on Angled Mounting:

For optimum performance and appearance, a longer downrod should be

used with your Hunter ceiling fan when installing on high or angled ceiling.

Fan can not be mounted on to a

NOTICE

Hunter Pro Tip:

WALL

Determining angle of ceiling:

Fold on the dotted line. Place long edge againts the

wall. Slide towards the ceiling. If the guide touches

the wall but not the ceiling, your ceiling is greater

than 34°.

ceiling with an angle greater than 34°

If you have an angled or vaulted ceiling:

1. You will need a longer downrod.

6

34°

CEILING

Page 7

!

BEFORE YOU BEGIN

FAN PLACEMENT

FAN PLACEMENT

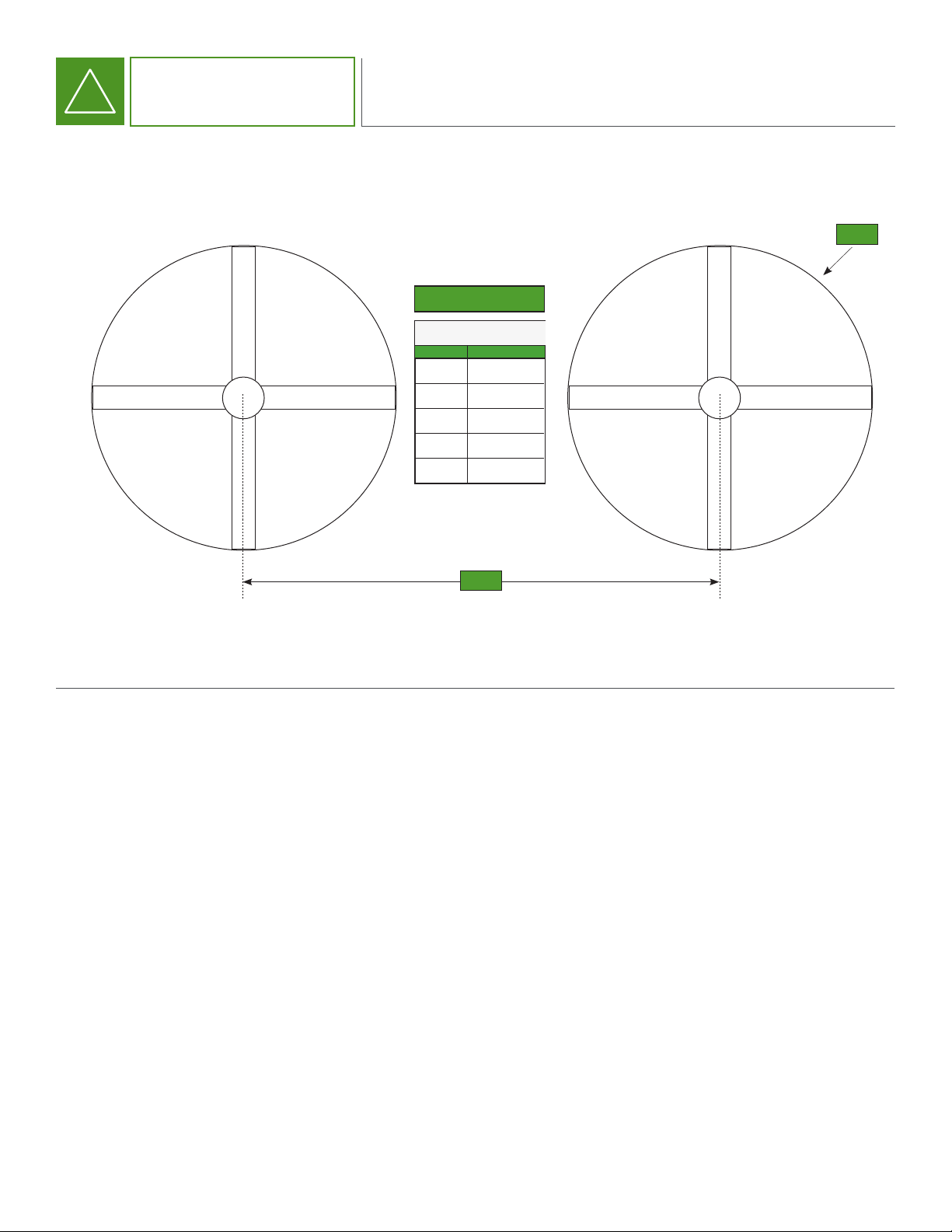

FAN SPACING CHART

TRAK

A B

MIN - MAXDIA

8ft (96”)

7ft (84”)

6ft (72”)

5ft (60”)

20ft - 32ft

18ft - 28ft

16ft - 24ft

14ft - 20ft

B

A

7

Page 8

!

BEFORE YOU BEGIN

FAN PLACEMENT

ALWAYS mount fan so the bottom edge of blade to the oor is at least 10 feet.

Always mount fans away from the following:

Sprinkler Systems

Prior to installing fans, review all codes applicable to sprinkler systems and fans to ensure code compliance and refer to NFPA 13: Fire

Sprinkler System Installation. In any installation where re sprinklers are present, the fan should not interfere with their operation.

o Fans should be located at least 3 feet below a sprinkler deector.

o Fans should be centered between 4 adjacent sprinklers.

It is your responsibility that the installation complies with the applicable codes. For assistance, please call our Technical Department at 1-844593-FANS (3267).

Walkways and Mezzanines

If the building has elevated walkways or mezzanines, mount the fans so that a person cannot reach the rotating blades in any way. Position

fans so that the tips of the blades are at least 5 feet away from any area where a person may be able to extend outward to reach them.

Lights and Skylights

If possible, avoid mounting fans directly below lights or skylights to avoid any strobe effect caused by moving blades.

There should be a minimum of 2 feet between the blades and any light xture.

Air Discharge Locations

Fans should not be located directly beneath or in line with any air discharge. This includes air conditioning units and evaporative coolers.Such

equipment can be used effectively in conjunction with ceiling fans however the discharge of the unit must be located outside the swept area

of the fan and at a distance of at least two times the diameter.

8

Page 9

!

BEFORE YOU BEGIN

Must be able to

secure the fan to

building structure or

fan-rated outlet box

PRE-INSTALLATION CHECKLIST

The location of the fan will alow for a minumum of 2 feet of blade clearance from

any obstruction and at least 10 feet of clearance above the oor.

If installing multiple fans, reference the fan placement chart for optimal spacing.

The control panel voltage markings (either 100-120VAC or 220-240VAC) should match

your building supply power.

If you are unfamiliar

with wiring, use a

qualied electrician.

30 inches

from blade tip to

nearest wall or

Know your wiring

obstruction

Assess location

10 feet

from bottom

edge of blade

to the oor

Maximum ceiling

angle is 34°.

Assess ceiling angle

Standard Downrod

1

for ceilings 12-14 feet high

Longer Downrod

2

for ceilings 14 feet or higher

Select a downrod length

9

Page 10

!

BEFORE YOU BEGIN

TOOLS NEEDED

Included

1/2”/ M4 Wrench

Ladder

Screwdrivers

x2

Right Angled Screwdriver

Allen Wrench

10

Blade Installation Tool

Page 11

!

BEFORE YOU BEGIN

IN THE BOX

FAN COMPONENTS

G

I

x12

H

x4

E

x2

J

x2

F

K

1 2

E (1) Downrod

F (1) Motor

G (4) Blades

H (1) Ceiling Bracket

I (1) Canopy

J (1) Motor Housing Cover

M

L

K (K1)Data Cable Connector;

(K2) Power Cable Connector

L (1) Remote Control Assembly

M Hanger Bracket Guide

N (1) Installation Manual (not shown)

11

Page 12

INSTALLATION

1

PREPARATION

A

If you have a building

management system you will

need to set the dip switches for

your fan IP address. Use the chart

to set your switches. On is 1. 0 is

the dip switch in the off position.

IP Bit 1 Bit 2 Bit 3 Bit 4 Bit 5

192.168.1.61 0 0 0 0 0

192.168.1.62 0 0 0 0 1

192.168.1.63 0 0 0 1 0

192.168.1.64 0 0 0 1 1

192.168.1.65 0 0 1 0 0

192.168.1.66 0 0 1 0 1

192.168.1.67 0 0 1 1 0

192.168.1.68 0 0 1 1 1

192.168.1.69 0 1 0 0 0

192.168.1.70 0 1 0 0 1

192.168.1.71 0 1 0 1 0

192.168.1.72 0 1 0 1 1

192.168.1.73 0 1 1 0 0

192.168.1.74 0 1 1 0 1

192.168.1.75 0 1 1 1 0

192.168.1.76 0 1 1 1 1

192.168.1.77 1 0 0 0 0

192.168.1.78 1 0 0 0 1

192.168.1.79 1 0 0 1 0

192.168.1.80 1 0 0 1 1

192.168.1.81 1 0 1 0 0

192.168.1.82 1 0 1 0 1

192.168.1.83 1 0 1 1 0

192.168.1.84 1 0 1 1 1

192.168.1.85 1 1 0 0 0

192.168.1.86 1 1 0 0 1

192.168.1.87 1 1 0 1 0

192.168.1.88 1 1 0 1 1

192.168.1.89 1 1 1 0 0

192.168.1.90 1 1 1 0 1

192.168.1.91 1 1 1 1 0

192.168.1.92 1 1 1 1 1

A

F

12

Page 13

INSTALLATION

WARNING

2

CEILING BRACKET

CRUSH HAZARD

To prevent SERIOUS INJURY or DEATH, ALWAYS mount fan directly from building structure or outlet box marked acceptable for fan support

of 70 lbs (31.8 kg).

• CAUTION: Do not install the fan from a single structure such as a purlin, truss, I-beam or bar joist.

• For any questions or concerns regarding the building structure, consult a structural engineer.

A

Remove the four screws

from the restraining bracket

and set aside. Remove the

restraining bracket from

the hanging bracket (H) and

set aside.

Remove any existing bracket prior to installation. Only use the provided Hunter ceiling bracket that came in your fan’s box.

To avoid possible electrical shock, before

installing your fan, disconnect the power by

turning off the circuit breakers to the outlet

box associated with the wall switch location.

Turn Power

A

OFF

Do this rst!

HH

Machine Screws

Use machine screws

(provided with outlet box)

H

and washers when securing

to existing ceiling fan-rated

outlet box. Make sure it is

securely installed and is

acceptable for fan support of

31.8 kg (70 lbs) or less.

MOUNTING TIP

ANGLED

For angled ceilings,

point opening

toward peak.

If you are unable to do this,

call Technical Department at

1-844-593-FANS(3267) for guidance.

13

Page 14

INSTALLATION

WARNING

3

DOWNROD

A

Place the preassembled

downrod (E) through the

canopy(I) and upper motor

housing (J).

A

I

B

Place the bottom of the downrod

into the bracket of the fan while

aligning the holes. Make sure power

cable and communication cable are

facing the power and data ports to

ensure a connection.Place a bolt

through each hole and secure each

bolt with a nut.

E

J

Large End

x2

C

Connect the communication

cable from the downrod to the

fan. Connect the power cable

from the downrod to the fan.

(*240V will have a different

power cable port)

B

I

J

E

D

Attached the secondary hanging

cable to the fan by threading the

cable eye through the upper slot

of the motor shaft. Attach the

D-shackle to the wire as shown and

secure by screwing the pin through

unthreaded wall of shackle and the

cable eye into the threaded wall of

shackle until it is tight.

C

Power Cable

Communication Cable

A

F

D

J

E

Motor Shaft

Upper Slot

F

F

*For 240 V models the power cable

will need to attach to module (A)

14

FAN FALL HAZARD

To prevent SERIOUS INJURY or DEATH, make

sure bolts are securely tightened and shackle

is secure.

Page 15

INSTALLATION

4

CRUSH HAZARD. To prevent serious injury or death, ALWAYS attach the

Retention Cable to the fan motor and secure to the building structure

on EVERY fan.

MOTOR ASSEMBLY

A

Lower the upper motor

housing (J) and twist

clockwise to secure.

Ensure the fan is sealed

by eliminating any gap

between the housing

and fan.

A

F

B

Place hanger guide (M) through the

back of the hanger bracket (H) until

the back of the guide and bracket

are ush. It should snap into place

when correctly installed.

E

J

C

Lift motor assembly and insert hanger

ball into hanger bracket (H), guiding the

hanger ball tabs along the hanger guide

rails until the hanger ball is secure. The

hanger groove should be in between both

hanger ball tabs. REMOVE HANGER

GUIDE FROM BRACKET by squeezing

ends together and sliding away from

bracket.

B

H

D

To secure the motor assembly

take the restraining bracket and

place over the ceiling bracket and

align the holes. Insert and secure a

screw into each hole.

M

C

Hanger

Ball Tabs

Hanger Guide Rails

D

H

H

Hanger Groove

E

H

E

E

15

Page 16

INSTALLATION

5

CRUSH HAZARD. To prevent serious injury or death, ALWAYS attach the

Retention Cable to the fan motor and secure to the building structure

on EVERY fan.

RETENTION SYSTEM

A

Wrap retention cable around

building structure that can

withstand double the installed

fan weight. Use mounting slot in

the canopy to allow the retention

cable to pass out of the canopy

and through the gasket.

B

Secure remaining cable to itself

with cable clamps.

NOTICE

the downrod opening.

A A

Leave approximatlely 3” of slack in

the wire and the cable, at the top of

Dead End

Secure rst clamp on the

loose end of the cable.

Live End

Secure the second clamp to the

cable approximately 6” from

the rst clamp.

H

H

Small End

I

NOTICE

Retention Cable. If done incorrectly, the U-bolt could crush the wire when tightened and can reduce the strength of the wire.

When attaching cable clamps, remember: “Never saddle a dead horse.”

Place the u-bolt on the “dead” end of the Retention Cable and the saddle on the “live” portion of the

I

16

Page 17

INSTALLATION

6

WIRING

Electric Shock Hazard

Electric Shock Hazard.

To prevent serious injury or death:

• BEFORE installing or servicing your fan, ALWAYS disconnect the power by turning off the circuit

breaker or breakers to the fan locations and conrm Lockout/Tagout procedures are in place.

• If you cannot lock the circuit breakers in the off position, securely fasten a prominent warning

device, such as a tag, to the electrical panel.

• All wiring must be in accordance with national and local electrical codes, including ANSI/NFPA

70. If you are unfamiliar with wiring or in doubt, consult a qualied electrician.

A

Fully unscrew data connector and remove the gasket from either

end. Slide data connector end over data cable. Slip gasket onto

data cable text side out and insert gasket into data connector end.

Push gasket until it is ush with data connector end. Slip data

connector housing over data cable. Plug data cable into center

connector and thread data connector housing onto data connector

center by twisting clockwise until tight. Thread data connector end

onto data connector housing by twisting clockwise until tight and

gasket seals the cable. Repeat for the other end.

Data Connector

Housing

A

Data Connector

End

K1

Gasket

B

Fully unscrew power connector. Place power cable and canopy ground wire through power connector

end. Next, slide male power connector housing over wires. Using a small phillips head screw driver,

back off screws on one half of wire terminal. The ridged side of the power cable is the neutral and goes

into the hole marked (N). The center wire from the power cable is ground. Twist together with ground

wire from canopy and insert into hole with ground symbol ( ). The outer wire without ridges is the

Live (L) and goes into the hole marked (L). Tighten down all terminal screws securely to make wire

connections. Repeat for wires from ceiling with female power connector housing and the other power

connector end. To secure the power connector, tighten male to female and then the connector ends by

twisting clockwise. (all sections of the power connector)

Data Connector

Center

Data Cable

Data Connector

Housing

Data Cable Sealed

Data Connector

End

Gasket

B

Canopy

Ground Wire

K2

Power Connector

End

Ridged

Side

Downrod Wiring Ceiling Wiring

Male Power

Connector Housing

N

L

Power Connector

Center Wiring Engaged

Power

Connector Center

Female Power

Connector Housing

N

L

Power Cable Sealed

Power Connector

End

K

17

Page 18

INSTALLATION

7

A

Position data connector, power connector, and excess wiring inside

the ceiling bracket. Lift the canopy and align the single ridge on the

canopy with the single ridge on the ceiling gasket. Twist clockwise

to secure. The singe ridge of the canopy will align with the two

ridges of the ceiling gasket.

A

MOUNTING

H

I

H

I

J

E

18

Page 19

INSTALLATION

8

BLADES

A

Match blade with colored circle to blade iron with the

same colored circle. Slide blade over blade iron and

align the blade screw holes with the blade iron holes.

Place blade installation tool into hole closest to the

fan to help align screw holes.

A

G

F

B

Insert a screw into the remaining two

screw holes. Tighten both screws

G

C

Remove installation tool and insert a

screw into the remaining screw hole

and tighten. Repeat for each blade.

F

B

C

Repeat x4

F

G

NOTICE

personal injury, do not bend the blades or blade holders when installing the fan.

ALWAYS conrm the colors on each fan blade holder matches the colors on the blade. This will ensure

that the fan is properly balanced to prevent possible damage due to wobble. To reduce the risk of

19

Page 20

INSTALLATION

9

REMOTE CONTROL

A

To access the battery compartment, remove the

small Phillips head screw that secures the battery

door to the transmitter assembly. The battery should

be installed with the positive (+) side up. Replace

with a CR2032 battery when necessary.

The remote transmitter is already paired to the

receiver and ready to use.

Note: If you would like to operate multiple fans or

multiple remotes, or if your remote is not working,

please see the Troubleshooting section at the end of

this manual.

A

Battery

Door

Press = Fan Off

Single Press = Set Fan to Speed 1

Press Twice= Set Fan to Speed 2

Single Press = Set Fan to Speed 3

Press Twice = Set Fan to Speed 4

Single Press = Set Fan to Speed 5

Press Twice = Set Fan to Speed 6

Single Press = Set Fan to Speed 7

Press Twice = Set Fan to Speed 8

Single Press = Incremental Light Output 10%

Long Press = Light On Output 100%

Single Press = Decremental Light Output 10%

Long Press = Light Off

Slide Up = Updraft

Slide Down = Downdraft

Phillips

Head

Screw

B

Your remote comes with three mounting options.

B.1

Option one is a wall

plate that has two posts

on which to mount your

remote transmitter

when not in use.

B.2

Option two and three use an extended wall plate

that replaces your pre-existing light switch plate.

Option two combines the extended wall plate with

an additional plate that has two posts on which to

mount your remote transmitter when not in use.

Install the extended wall plate. Then install the

x2 x2

secondary plate to the extended wall plate.

NOTICE

Toggle dimming mode by holding OFF ( ) and quickly press

Light Down ( ) two times

B.3

Option three adds two cradle arms overtop

of the remote transmitter onto the extended

x2

wall plate. This locks the remote transmitter

into place so that it can only be removed by

removing the two cradle arms.

x4

x2

20

Page 21

REFERENCE

MAINTENANCE

Electric Shock Hazard

Electric Shock Hazard

To prevent serious injury or death:

• BEFORE performing maintenance or service, ALWAYS disconnect the power by turning off the circuit

breaker or breakers to the fan locations and conrm Lockout/Tagout procedures are in place.

• If you cannot lock the circuit breakers in the off position, securely fasten a prominent warning device,

such as a tag, to the electrical panel.

• Do not remove covers while power is on.

Blade Cleaning

Depending on the commercial application, dust or other particulates can build up on the fan blades over time. At

least every 12 months, a maintenance person or skilled trade professional should clean the blades using a rag or

sponge and hot water or regular cleaning solutions.

DO NOT use chlorine or any chemicals containing chlorine as they may cause damaged to the blades.

Retention System Check

Each fan is installed with a retention system. Every 12 months, check that the Retention Cable is properly attached

to the building structure. Inspect the visible portions of the Retention Cable for damage, including fraying.

The Retention Cable is an important part of the safety system and protects users in the

unlikely event of a catastrophic situation. It is critical for fan owners to ensure that it is intact and properly secured.

Replacement Parts

Please call 1-844-593-FANS (3267) for replacement parts.

Service

If the fan does not operate properly using the procedures in this manual, follow Lockout/Tagout procedures for your

facility and lockout all power to the unit and contact our Technical Department for further assistance at 1-844-593FANS (3267).

21

Page 22

REFERENCE

TROUBLESHOOTING

Symptom

FAN WILL NOT START

MOTOR IS PULLING

EXESSIVELY HIGH AMPS

FAN IS “SWINGING” AS IT

RUNS

A FAN BLADE APPEARS TO

BE ‘SAGGING’

Possible solution

• Verify that the fan’s circuit breaker has power and that it is on.

• Check for secured plug connections. Each connection should be checked to

ensure they are fully engaged.

• Inspect for loose wiring connections. Each termination should be checked

to be sure they are rmly tightened.

• Make sure the motor voltage is a match for the supply voltage.

• Check for correct fan blade installation. Be sure that all blades have been

properly installed according to color and are tightened.

• Ensure all downrod hardware has been tightened.

• Check for improper incoming air discharge. Make sure that no discharge is

blowing directly on the fan.

• Make sure that the ‘sagging’ blade has been properly tightened.

TO PAIR A REMOTE TO

A FAN(S):

TO UNPAIR A REMOTE

FROM A FAN(S):

TO TOGGLE DIMMING MODE:

• Turn OFF Power to Fan for at least 5sec, and then restore Power. Hold down

both the “Fan OFF” and “ ” button at the same time. The remote LED will

ash after several seconds. Fan will emit audible “BEEP” to conrm the

operation.

1. Power Cycle the Fan

2. Long hold on both button and DOWN. You will see LED is on.

3. Wait until the LED is off

4. While still pressing button , release button DOWN.

5. Keep pressing button and have a short press on the button DOWN.

6. You will see LED blinks 5 times for command sent conrmation. Release

button .

1. Long hold on both button OFF and DOWN. You will see LED is on.

2. Wait until the LED is off

3. While still pressing Power button, release button DOWN.

4. Keep pressing button OFF and have a short press on the button DOWN.

5. You will see LED blink once for command sent conrmation. Release the

power button.

For situations beyond the scope of this Guide,

please call our Technical Service Department at

22

1-844-593-3267 (FANS).

180 Threet Industrial Road

Suite 120, Smyrna, TN 37167

HUNTERFAN.COM

©2020 Hunter Fan Company. All rights reserved.

MI001-01 020620

Loading...

Loading...