Page 1

INSTALLATION MANUAL

Page 2

The Hunter legacy is not only about

quality—it’s about longevity. We invented

the ceiling fan. We build fans that last, fans

that are designed as fans. We design our

fans while considering each person in the

process—from the installer to the owner.

CONTENTS

BEFORE YOU BEGIN

!

SAFETY & PRECAUTIONS 2-3

FAN PLACEMENT 4

MAINTENANCE 5

IN THE BOX 6

TOOLS NEEDED 7

INSTALLATION

STEP 1: MOUNTING 8

STEP 2: MOTOR ASSEMBLY 9

STEP 3: RETENTION SYSTEM 10

STEP 4: CONTROL PANEL 11

STEP 5: TOUCHSCREEN 12

STEP 6: GUY WIRES 13

STEP 7: BLADES 14

TOUCHSCREEN

LEGACY

1886

TOUCHSCREEN TYPES 15-16

HOME SCREEN 17

FAN SCREEN 18

REFERENCE

ELECTRICAL 19

TOUCHSCREEN TEMPLATE 20

CONTROL PANEL 21

TROUBLESHOOTING 22

AUTHENTICITY

In a world full of impersonators, be an

original. We invented the ceiling fan,

and we stand behind our products.

Page 3

!

BEFORE YOU BEGIN

SAFETY & PRECAUTIONS

READ THE ENTIRE MANUAL BEFORE OPERATING THE FAN

Read and understand this manual before installing or operating a fan unit. Installation, adjustment, repair or maintenance must be performed by qualied personnel.

Follow all safety practices and instructions during the installation, operation and servicing of the fan. Failure to apply these safety practices could result in death or serious

injury. If you do not understand the instructions, please call our Technical Department for guidance. Technical Department contact information can be found on page 22.

All fan controls and incoming power should be installed only by qualied technicians familiar with the requirements of the National Electrical Code and local codes.

Failure to follow these guidelines will void the manufacturer’s warranty. All electrical controls are congured at the factory and are ready to use. No user adjustments are

available. Follow the included installation instructions when installing this device to ensure proper operation. Do not make any changes to any part of the fan without rst

consulting Hunter Industrial Fan. Installation is to be in accordance with the National Electrical Code, ANSI/NFPA 70-1999 and local codes.

WARNING! Be aware of electric shock hazard, explosion, or arc ash

The user is responsible for compliance with all international and National Electrical Code requirements with respect to grounding of all equipment. Many of the parts of

this unit operate at line voltage. DO NOT TOUCH. Install all covers before applying power or starting and stopping the unit. To reduce the risk of electric shock or injury,

use this unit only in the manner intended by the manufacturer. If you have questions, call our Technical Department at 1-844-593-FANS (3267).

Before servicing or cleaning the unit, switch power off at the service panel and lock the service disconnecting means to prevent power from being switched on

accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning sign, such as a tag, to the service panel. At all times, leave

the power off at the service panel. To reduce the risk of electric shock or injury, use this unit only in the manner intended by the manufacturer. If you have questions,

call our Technical Department at 1-844-593-FANS (3267).

DAMAGED EQUIPMENT

Do not operate or install any fans or fan accessories that appear to be damaged. Failure to follow this instruction can result in death, serious injury, or equipment damage.

SERVICE

If the fan does not operate properly using the procedures in this manual, remove all power to the unit and contact our Technical Department for further assistance at

1-844-593-FANS (3267). Keep all body parts clear of moving parts at all times. All electrical troubleshooting and repair must be done by a qualied technician and meet

all applicable codes.

2

Page 4

!

BEFORE YOU BEGIN

KEY RETENTION SYSTEM COMPONENTS

Our fans are engineered with key features to prevent pieces of the fan from falling in the unlikely event of a catastrophic failure. Used together, these systems provide

comprehensive protection of people, equipment and property.

Install the retention cable on EVERY fan. The retention cable, if installed per Hunter Industrial Fan specications, will prevent the fan from falling in the unlikely event

that the mounting system should fail.

SAFETY & PRECAUTIONS

CAUTION!

The fan should never be run without a properly installed retention cable, which is supplied with every fan along with all required hardware.

If the retention cable is not installed, the warranty will be voided.

MARK THE FLOOR TO ALERT PERSONNEL

When mounting a fan in an area where materials may be elevated into its path, we recommend marking or painting the oor with a large crosshatched circle to alert

personnel of the overhead location of fans.

WEIGHT CONSIDERATIONS

We recommend that a building structure be capable of holding approximately twice the stated hanging weight of the fan.

The maximum hanging weight for the 24-foot fan is 204 lbs., adding the weight of an additional drop length.

If there is any uncertainty in the strength of the building structure, a professional structural engineer should perform a thorough evaluation of the building prior to

purchasing the fans. Hunter Fan provides guidelines for mounting fans; however, it is the sole responsibility of the building owner and installer to ensure the safety of the

mounting system, that the building structure is sound, and that the installation complies with all federal, state, and local codes.

CHECK FEDERAL, STATE, AND LOCAL CODES

Check all relevant codes to make sure that all product certications, product listings, and building regulations are met.

Code compliance is the responsibility of the installer.

WINDY CONDITIONS

Fans should not be operated in windy conditions. Fans should not be installed in locations where it is frequently windy.

3

Page 5

!

BEFORE YOU BEGIN

FAN PLACEMENT

SPRINKLER SYSTEMS AND FAN PLACEMENT

In any installation where re sprinklers are in place, the fan should

not interfere with their correct operation. Fans should be located

no less than 3 feet below a sprinkler, and placed central to each

sprinkler quadrant. Our industrial control panel can be connected

to a re relay system, which, in an emergency, will stop fans in case

of re.

Prior to installing fans, review all codes applicable to sprinkler

systems and fans to ensure code compliance and refer to NFPA 13

Standard from the National Fire Prevention Association.

Please call our Technical Department for guidance at 1-844-593-FANS

(3267). However, it is your sole responsibility to see that the

installation is completed to code and that it is correct.

OTHER INFORMATION ON PLACEMENT AND SPACING

If possible, avoid mounting fans directly below lights or skylights to

avoid any strobe effect caused by moving airfoils. Note, a large fan,

20 to 24 feet in diameter, performs best at 20 to 30 feet above the

oor, but acceptable performance has been demonstrated as low as

10 feet and as high as 50 feet.

If the building has a mezzanine, fans should be mounted so a

person cannot reach a fan in any way from the upper level/deck.

Make certain that fans are positioned so that the airfoil tips are at

least 3 feet away from any area where a person may be able to

extend outward to reach them.

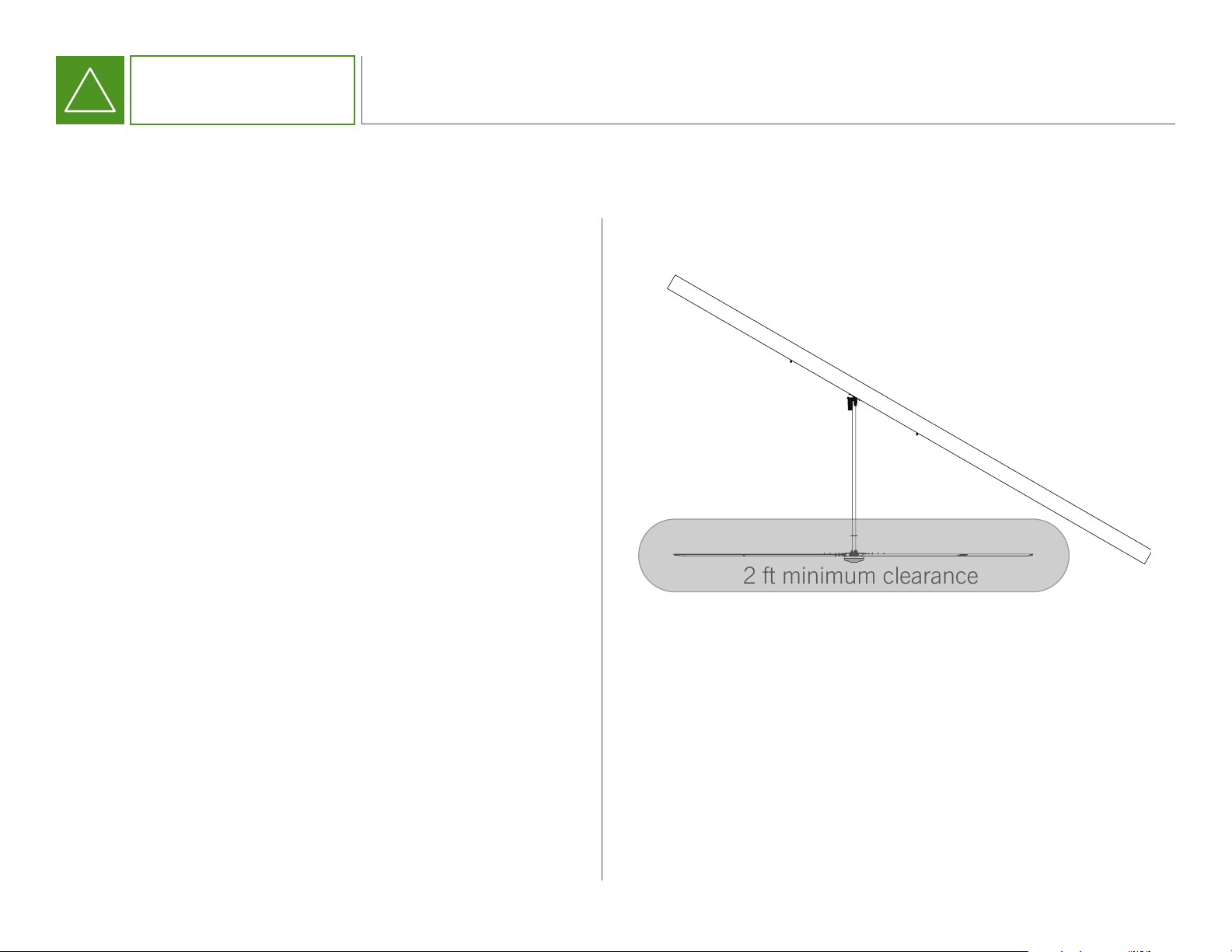

ROOF PITCH

2 ft minimum clearance

Fans should not be located directly beneath any air discharge.

This includes air conditioning units and evaporative coolers. Such

equipment can be used effectively in conjunction with HVLS fans

but the discharge must be located outside of the swept area of

the fan.

4

Page 6

!

BEFORE YOU BEGIN

GUY WIRE CHECK

Checking a fan’s guy wires for tension and inspecting for frayed sections could prevent a problem before it occurs. Fan owners should conrm that the guy wires are not

wrapped around any sharp edges. We recommend attaching guy wires to the building with provided clamps to prevent fraying. Turnbuckles should be checked to ensure

tightness. If they are loose, the guy wire cables need to be re-tensioned.

AIRFOIL CLEANING

Depending on the commercial application of the fan, there can be quite a bit of dust or other particulates that cling to the fan’s airfoils. While this may not affect fan performance, we recommend fan owners keep airfoils clean by having a maintenance person or skilled trade professional–who has experience using a lift–wipe the fan airfoils with

a rag or sponge using hot water or regular cleaning solutions. Please do not use chlorine or any chemicals containing chlorine.

RETENTION SYSTEM CHECK

Each fan is installed with a retention system. The retention cable is attached to the motor and wraps around the building structure. The safety cable is an important part of

the safety system and protects users from if a catastrophic event occurs. It is critical for fan owners to ensure that it is intact and properly secured.

REPLACEMENT PARTS

MAINTENANCE

Please call our Technical Department at (844) 593-3267.

5

Page 7

!

BEFORE YOU BEGIN

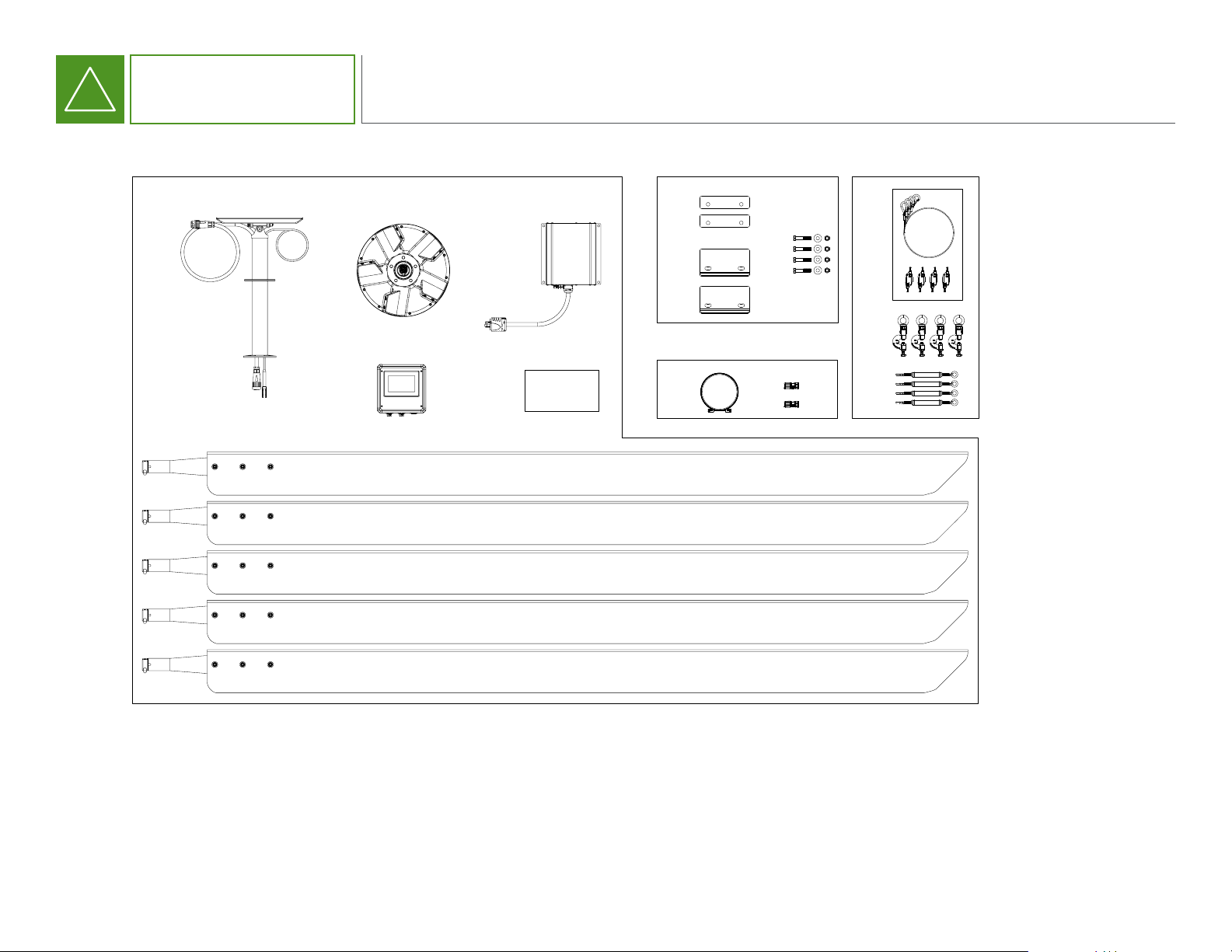

IN THE BOX

FAN COMPONENTS

a)

f)

b)

d) e)

c)

TITAN

MOUNTING HARDWARE KIT

a)

c)

b)

COMMUNICATON KIT

a)

b)

GUY WIRE KIT

a)

b)

c)

FAN COMPONENTS

a) (1) Downrod

b) (1) Motor & (5) Motor Nuts

c) (1) ICP (industrial Control Panel)

d) (1) Touchscreen

e) (1) Installation Manual

f) (5) Blades

MOUNTING HARDWARE KIT

a) (2) Shims

b) (2) Clamps

c) (4) Bolts, Washers, Nuts

GUY WIRE KIT

a) (1) Gripple kit

b) (4) Beam Clamps

c) (4) Turnbuckles

COMMUNICATION KIT

a) (1) 100 ft Terminated Cat5 Cable

b) (2) RJ45 Connectors

6

Page 8

!

BEFORE YOU BEGIN

TOOLS NEEDED

Metric Ratcheting Wrench Set

Metric (Deep & Short) Socket and Ratchet Set

Metric Allen Wrench Set

Metric Allen Socket Set

Tape Measure

Magnetic Level

Torque Wrench

Wire Rope Cutters

Phillips and Flat Head Screwdrivers

#10 to #14 AWG Strippers

Multimeter

Cat5 Termination Tools (optional)

7

Page 9

INSTALLATION

1

MOUNTING

A

Secure bracket and downrod to lift

and raise to I-beam.

B

Assemble the mount with shims

and clamps on bracket. Hook the

clamp on one side of the I-beam and

tighten hardware until the mount is

snug but can still be moved.

C

Assemble the opposing shim

and clamp on to the I-beam and

hand tighten.

D

Center the mount under the I-beam.

Ensure the clamps have maximum

engagement on both sides and

tighten hardware.

A

D

B

BOLTS

WASHERS

CLAMPS

SHIMS

C

NUTS

8

Page 10

INSTALLATION

A

Insert clevis pin into retention rod

and secure with clip provided.

B

Join the two connectors and twist,

making sure they lock together.

C

Lift motor assembly (see tip) while

pushing cables into downrod. Feed

the press studs through downrod

ange. Avoid pinching cable

between motor ange and downrod

ange and secure with nylon lock

nuts. Pull excess wire and cable

through top of downrod.

2

MOTOR ASSEMBLY

A B

C

TIP

Use packaging to

transport motor

onto lift equipment.

Raise lift to install

motor to downrod.

9

Page 11

INSTALLATION

A

Wrap retention cable around

beam or building structure.

B

Secure remaining cable to itself

with cable clamps. Coil excess

cable and secure.

3

RETENTION SYSTEM

A B

10

Page 12

INSTALLATION

4

CONTROL PANEL

A

Position panel with plug connectors

facing down. Mount control panel

with fasteners, one in each corner

of the panel.

B

Connect VFD cable from fan to

control panel. Twist connector to

lock in place. Secure excess cable to

ceiling or beam.

C

Connect the communication

cable to one of the comm terminals

and run down to user touchscreen

location.

A B

C

D

TIP

For detailed

control panel wiring

diagram see

Page 21

NOTE

Twist Lock will act

as a disconnect.

D

Connect electrical plug to panel.

Twist connector to lock into place.

CAUTION: DO NOT CONNECT POWER

UNTIL MECHANICAL INSTALLATION

IS COMPLETE.

11

WARNING!

Before completing the mechanical installation, ensure breaker is off and all Lockout/Tagout procedures are

in place. The electrical receptacle for the panel should be installed prior to panel installation. For a chart of

receptacles, refer to page 19.

If the retention cable is not installed, the warranty will be voided.

Page 13

INSTALLATION

5

TOUCHSCREEN

A

Mount touchscreen enclosure

to wall.

B

Connect communication cable

from control panel to the

COMM 1 port at base of

touchscreen unit.

C

Connect pre-wired 110 plug to

input power receptacle.

D

Attach screen panel to enclosure

using screws in each corner.

A

COMM 1 COMM 2

B

TIP

Use Mounting

Template on

Page 20

D

INPUT

POWER

C

NOTE

For more information on operating the

Touchscreen, refer to Page 15

110 PLUGRJ45

12

Page 14

INSTALLATION

A

Attach guy wire to building structure

with provided beam clamps while

maintaining a 45-degree angle

between the ceiling and the guy wire.

DO NOT WRAP GUY WIRES

AROUND THE BUILDING STRUCTURE.

B

Hook end of turnbuckle to

the guy wire disc located on

the downrod.

6

GUY WIRES

A

C

GUY WIRE DISC

C

Attach guy wire to closed

turnbuckle end with provided

gripple (refer to direction on

gripple package).

D

B

D

Place level against the downrod

and tighten the turnbuckles by

hand in a crisscross pattern.

Periodically check to make sure

fan is level. Tighten set screws.

13

Page 15

INSTALLATION

A

Line up the pin on the post with

the opening on the blade holder.

B

Using our quick connect system,

insert the blade tube into the

blade hub. The blade will click into

place at the correct pre-set angle.

C

Use a torque wrench to tighten

the two set screws to 20 ft. lbs.

7

BLADES

A

(240 lbs.)

D

Repeat steps A-C for each of the

four remaining blades.

B

14

Page 16

TOUCHSCREEN

STARTUP SCREEN

TOUCHSCREEN TYPES

HOME SCREEN

15

Page 17

TOUCHSCREEN

FAN SCREEN

TOUCHSCREEN TYPES

CONFIGURATION

SCREEN

16

Page 18

TOUCHSCREEN

Date and time display

Arrows take you to individual fan screens and display the speed and direction of each fan. Speed is indicated by

the lit green bars, while airow direction is shown by the up or down placement of the arrows.

Powers all fans on and off.

HOME SCREEN

Settings button will take

you to the version screen.

Congure button takes you to

individual fan input screens.

17

Takes you back to

main screen.

Page 19

TOUCHSCREEN

Press to turn individual fan on or off. When button is green,

fan is on. When button is gray, fan is off.

Press to set downward airow direction.

Press to set upward airow direction.

FAN SCREEN

Press “+” to increase fan speed, “-” to reduce.

Use “+” and “-” as toggle to congure multiple fans.

Congure button takes you to

the current fan input screen.

Takes you back to

main screen.

NOTE

For all buttons, “green” indicates

an “ON” status

18

Page 20

REFERENCE

ELECTRICAL

19

Page 21

REFERENCE

TOUCHSCREEN TEMPLATE

5.51 in

(140 mm)

5.51 in

(140 mm)

20

Page 22

REFERENCE

1-844-593-FANS HunterIndustrialFan.com

FOR REFERENCE ONLY

CONTROL PANEL

TO FAN

COMM 1

AC POWER IN

COMM 2

Titan

INPUT

9-40 VDC

E-STOP

+

-

21

NO

NC

Page 23

REFERENCE

TROUBLESHOOTING

FAN WILL NOT START

TOUCHSCREEN IS BLANK

FAULT SCREEN ON UI?

Check to see if all plugs are securely connected.

Verify the touchscreen has power.

Conrm supply power is adequate and functional.

Verify UI has power.

For fault codes, please call our

Technical Department at (844) 593-3267.

22

Page 24

2434 ATRIUM WAY

NASHVILLE, TN 37214

1-844-591-3267

TECHNICAL DEPARTMENT: 1-844-593-FANS (3267)

HUNTERINDUSTRIALFAN.COM

©2016 Hunter Fan Company. All rights reser ved. | REV A.

Loading...

Loading...