Page 1

REV 14MAY02

PN 168324

Heater, Tent

Model UH68ODK, UH68ODH

Manual for UH68G1 with

Hunter Part Number 53100

Outdoor Kit Installed and

UH68ODH, Part Number 168325

Hunter Manufacturing Company

30525 Aurora Rd

Solon, OH, 44139

www.huntermfgco.com

Page 2

Page 3

WARNING!

FUEL WARNING

Gasoline and JP-4 should NOT be used with the UH68OKD/ODH under any

circumstance. Only JP-8 or an approved alternate fuel as detailed in Chapter 1.

Failure to observe fuel requirements could cause damage to the heater assembly

and injury or death to personnel within or around the tent and the heater

assembly. Always place fuel can in well-ventilated area as far away from open

flames and other potential ignition sources as possible. Fuel spills shall be

cleaned up in accordance with local requirements.

Always switch heater to the OFF position and wait until the vent fan is off before

refueling.

EXPLOSION HAZARD

FUEL LEAKS

Do not operate heater if fuel leak is detected.

DEATH OR SERIOUS INJURY

CARBON MONOXIDE

Carbon monoxide is without color or smell, but can kill you. Breathing carbon

monoxide produces symptoms of headache, dizziness, loss of muscular control,

a sleepy feeling, and coma. Brain damage or death can result from heavy

exposure. Carbon monoxide occurs in the exhaust fumes of fuel-burning heaters

and internal combustion engines. Carbon monoxide can become dangerously

concentrated under conditions of no ventilation.

Precautions must be followed to ensure operator’s safety when the Space

Heater, Convective is in operation.

• DO NOT operate Heater in an enclosed area without proper ventilation.

• BE ALERT at all times during operating procedures for carbon monoxide

poisoning. If symptoms are present, IMMEDIATELY evacuate personnel

to fresh air.

• BE AWARE the field protection mask used for nuclear-biologicalchemical attack WILL NOT protect you from carbon monoxide

poisoning.

THE BEST DEFENSE AGAINST CARBON MONOXIDE POISONING IS GOOD

VENTILATION.

Page 4

ELECTRIC SHOCK

Always disconnect power cable from heater before doing any type of service

work or repairs.

SEVERE BURNS

HOT EXHAUST

DO NOT MOVE THE HEATER ASSEMBLY WHILE ANY OF THE ADVISORY

LIGHTS ARE LIT.

Small, portable, shelter heaters of this type are not designed to be moved during

operation or before purge cycles are complete. Serious injury, burns, or death

can occur if the heater assembly is moved while operating, the HEAT LED is on,

or the vent fan is still running.

During operation, some metal components of the heater assembly, such as the

outlet duct, the Pop Up Duct Adapter, combustion exhaust pipe, etc., can cause

severe burn injuries if contact with bare skin occurs.

During heater operation, air leaving the HEATED AIR OUTLET of the heater and

passing through outlet duct may exceed 220°F. Make sure tent personnel are

aware of burn hazards and equipment hazards presented by the heated air.

Combustible material must be kept at least 2 feet away from the sides of the

heater during operation.

Do not attempt service procedures on a burner that has recently been in

operation. Let the burner cool down before performing these procedures to avoid

the possibility of serious burns. Never touch the exhaust stack while heater is

operating. Surface temperatures can exceed 800 degrees F. Allow sufficient time

for heater to cool before removing exhaust stack. The exhaust elbow will remain

hot for several minutes after the heater has shut down.

Page 5

Scope

Type of manual: Operators

Model and Name: UH68ODK and UH68ODH, Forced air tent heater, with ducts.

Purpose of Equipment: Circulates heated air in the Alaska, TEMPER tent, and other soft

walled structures. Maintains temperature via room thermostat in the remote control

panel. Control panel also has diagnostic and operating LED’s.

General

The UH68ODK is Hunter model UH68G1modified for outdoor usage. The outdoor kit

may be field installed or factory installed. The UH68ODK burns all grades of diesel fuel

and JP8 to generate heated air. Fuel is pumped from remote tank to the carburetor,

drawn through the fuel jet by venturi action of the mixer nozzle, ignited, and burned in

the heat exchanger. A fan, capable of delivering up to 2 IWC static pressure, blows the

heated air into the tent. The UH68ODK has the following applications:

• Alaska tent, Temper Tent

• Medium and small soft wall shelters

Features

• Variable room temperature control

• Remote control with 20 foot cable

• Diagnostic LED’s on remote control

• Low voltage opto-isolated controls to eliminate shock hazard.

• “Fan only” ventilation.

UH68ODK Tent Heater

Chapter 1

Introduction

WARNING!

ELECTRICAL SHOCK

Attempting to use an unmodified UH68 series heater outdoors

may result in electrical shock, injury or death

1-1

Page 6

UH68ODK Tent Heater

Specifications

Manufacturer Hunter Manufacturing

Model UH68ODK

Voltage 120 VAC

Cycles 50-60Hz

Power 400 watts

Heat Output 60,000 BTU nominal

Air Flow 650 CFM

@ .5 IWC Back pressure

**Fuel *DF2, DF1, DFA, JP8

Dry Weight 130 Lbs.

* Heater is factory set on for DF2, adjustment to the carburetor is necessary for other fuels.

** Gasoline or MOGAS is not recommended for use on the UH68ODK

Environmental

Temperature Range -65 to 120 F

Elevation 10,000 feet MSL

Authorized Fuels

NOTE: HUNTER MFG DOES NOT RECOMMEND THE USE OF

GASOLINE OR MOGAS, or JP4

Ambient Temperature Specification Military Symbol

Above +20°F (-6,7°C) VV-F-800 DF-2

Above -25°F (-33.3°C) VV-F-800 DF-1

Above -25°F (-33.3°C) MIL-T-83 133 JP-5

Above -60°F(-51.l°C) VV-F-800 DF-A

Above-60°F(-51.1°C) MIL-T-83133 JP-8

1-2

Page 7

UH68 ODK/ODH Tent Heater

Operators Instructions

Chapter 2

Operating Instructions

Operator Controls and Indicators

3

4

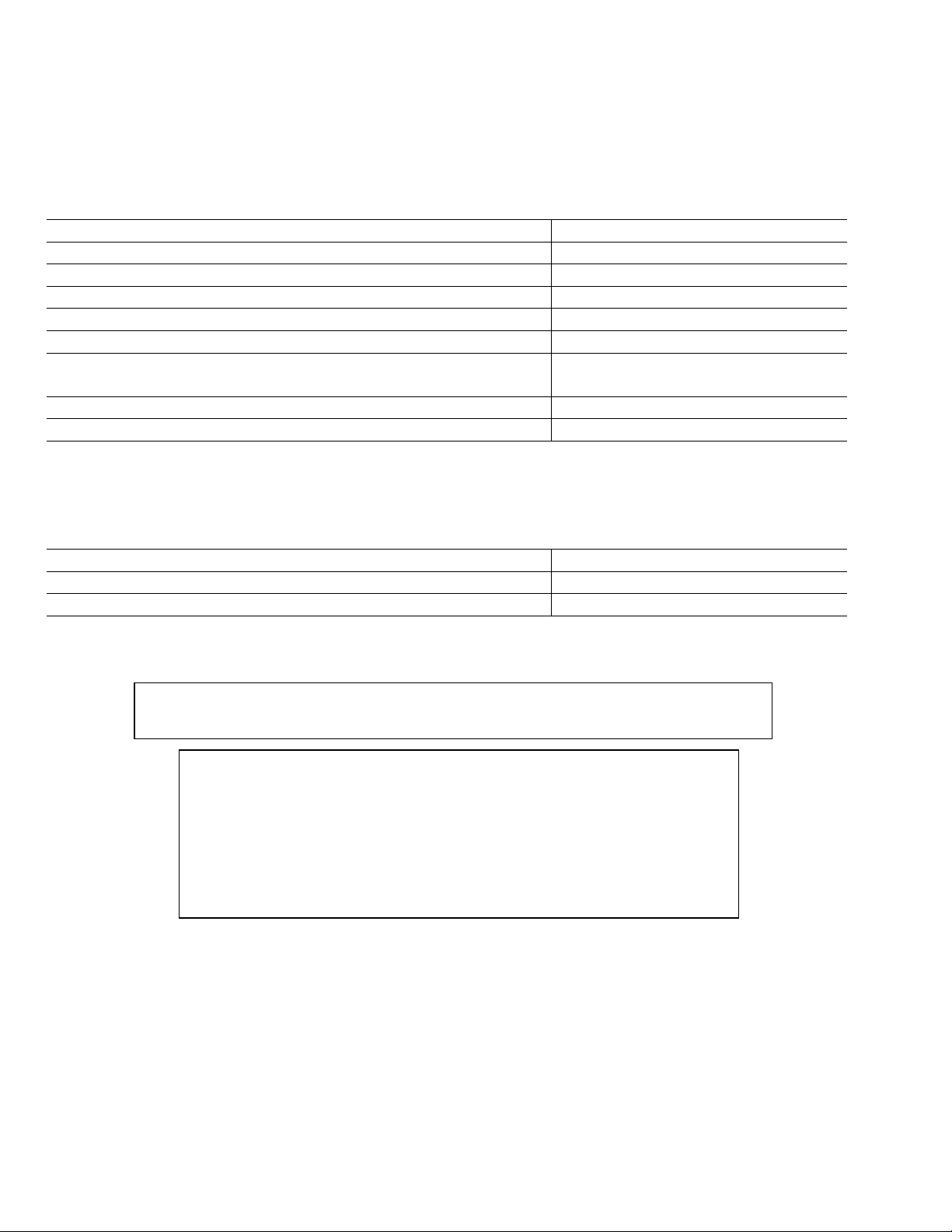

Table 2. Controls and Indicators

Key Control or Indicator Function

1 Main Switch Starts and stops heater. FAN position turns fan only on

2 Room Thermo Set for desired temperature. *

3 Main Power LED (green) Indicates heater is plugged in to AC power

4 Standby LED (green) Indicates main switch is ON but room thermo is not

5 Heat LED (green) Indicates main switch is ON and combustion system is

6 Fault LED (red) Blinks a diagnostic code for corresponding fault. (see

* Heat output is constant. Raising room thermo setting does not heat shelter faster.

5

2

1

6

for ventilation

calling for heat

energized

fault codes table 3)

2-1

Page 8

UH68 ODK/ODH Tent Heater

Table 3. Blink Codes

Number of Blinks Problem

1 Low voltage at AC input (< 100 VAC)

2 Reverse polarity at AC input

3 High voltage (>130 VAC)

4 Not used

5 PC Board over temp

6 Not used

7 Not used

8 Ignition Fault Lockout

Note: Only the Ignition fault lockout will shut down the heater. Any other code will flash the red

led, but still allow the heater to operate normally.

Table 4.

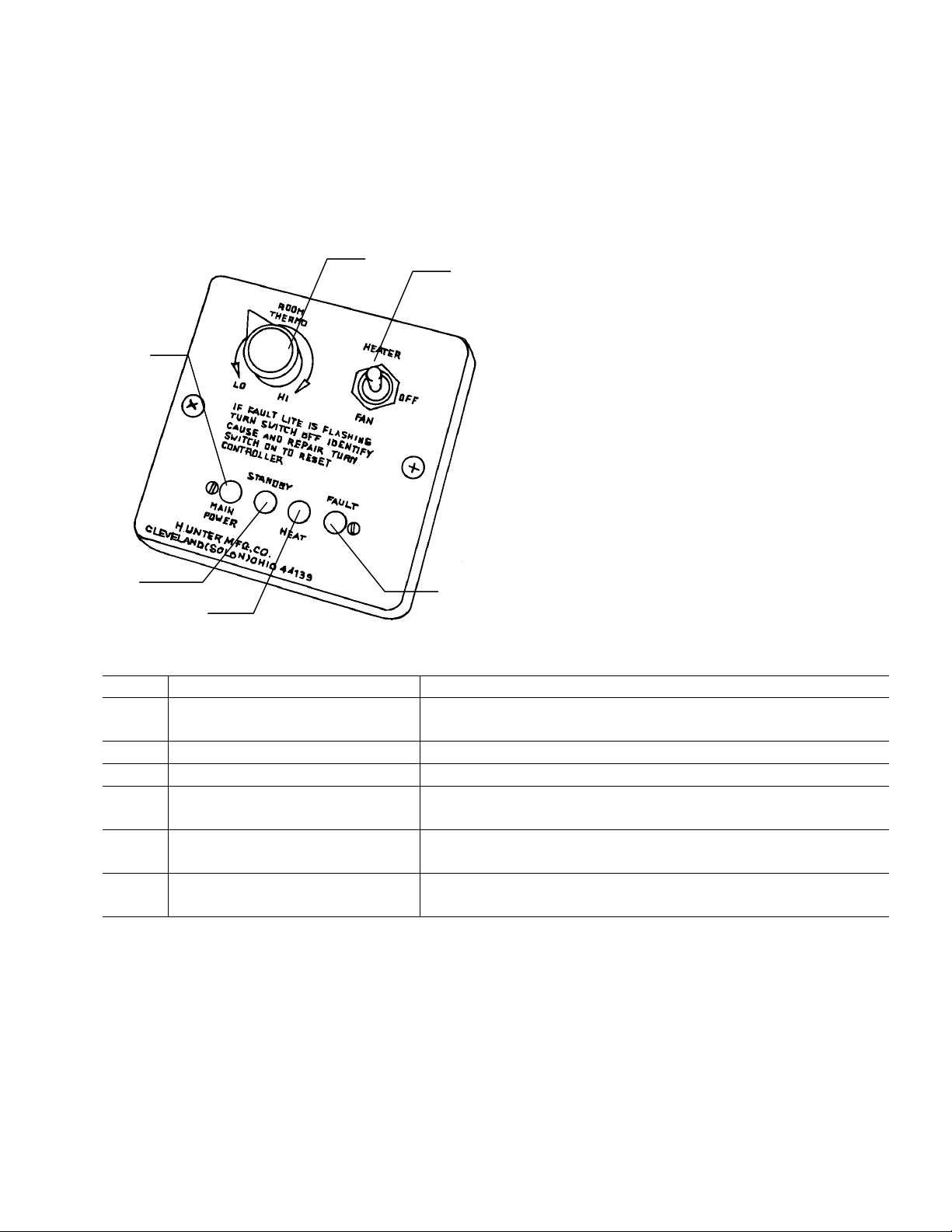

Key Connection / Fitting Function

1 Power Receptacle Connection for power cable

2 Remote Control Receptacle Connection for remote control

3 Fuel Inlet QD fitting for fuel supply

4 Fuel Overflow QD fitting for fuel overflow

4

3

2

1

2-2

Page 9

UH68 ODK/ODH Tent Heater

Operators Instructions

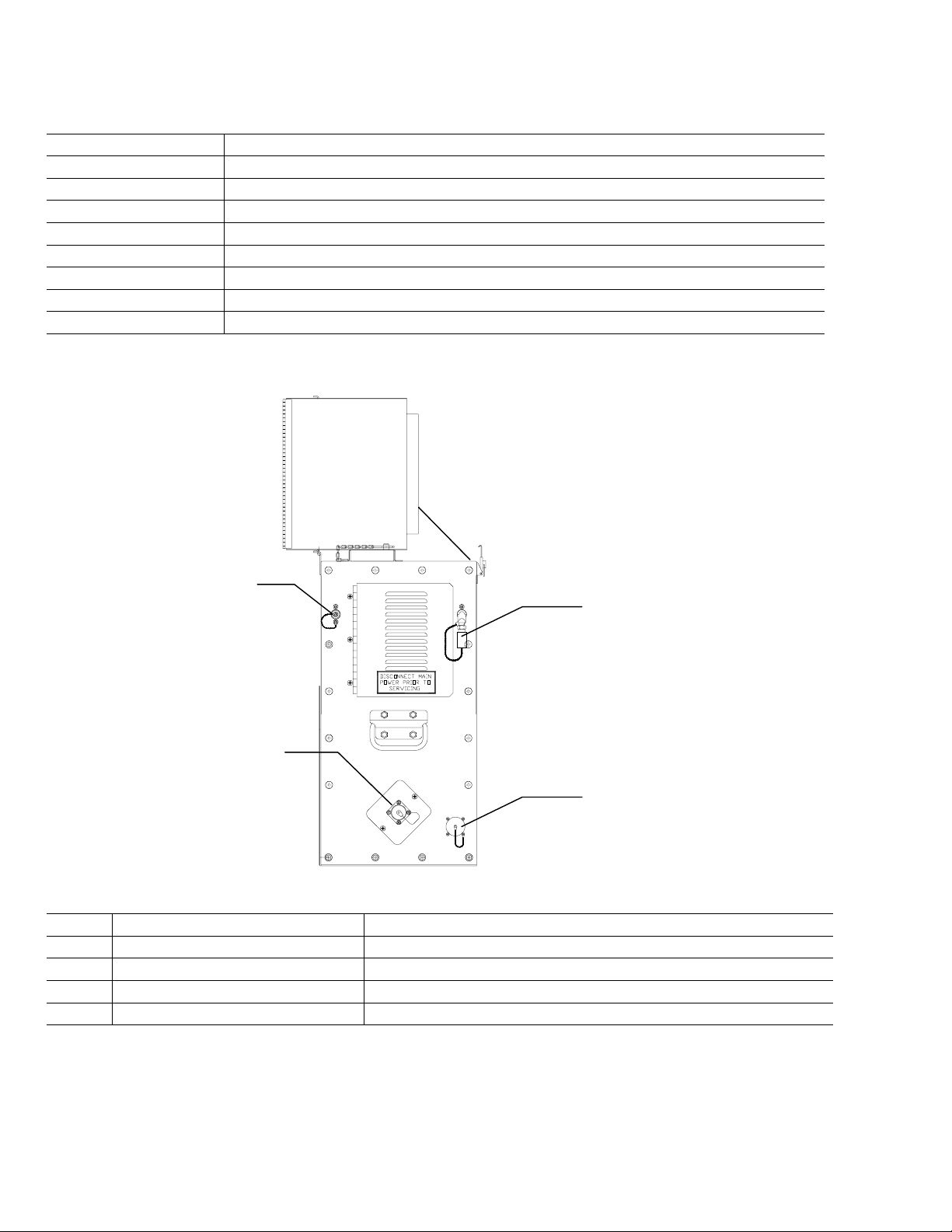

Table 5.

Key Description Function

1 Inlet Adapter Attachment point for return air duct

2 Storage compartment Storage for stack, fuel lines, power cord etc.

3 Exhaust elbow Exhaust stack rests on top

4 Stack support Holds exhaust stack securely

5 Exhaust stack Double wall exhaust stack for extra safety

6 PUDA Pop Up Duct Adapter, attachm ent poin t for su pply duct

4

2

5

3

1

6

2-3

Page 10

UH68 ODK/ODH Tent Heater

Operation Under Usual Conditions

Setup

Alaska Tent TEMPER Tent

Completely setup the Alaska tent, and deploy the duct collars at the end in which you are to

setup the heater. Make sure the generator or power supply is on line.

Before setting up the tent and heater, some thought should be given to the orientation of the

structures as to the prevailing wind direction . Try to orien t the he ater and shelter so the

exhaust is blown down range away from doors and shelter openings.

1. Move the UH68 ODK into position near the duct collars. Set up off ground using skid or

similar.

2. Open PUDA (1) and remove remote control(2) power cord(3) and inlet adapter(4).

3. Attach inlet adapter(4) to heater and attach return duct(5) using band clamp(6). Pa y special

attention to airflow tag(7) on duct. DO NOT PUT RETURN DUCT ON BACKWARDS. This

will restrict incoming airflow.

4. Deploy PUDA(1) by tilting upwards and putting pins(8) in supports(9).

5. Attach supply duct(10) using band clamp(6). Pay special attention to airflow tag(7).

6. Pull ducts into tent and point heated air duct away from inlet duct, towards center of tent.

Pull heater away from tent until ducts are straight but not taught (12).

The UH68ODK weighs 130 Lbs. Attempting to lift

without proper personnel may cause serious injury

CAUTION

TWO PERSON LIFT

2-4

1

3

2

4

Page 11

6 7

UH68 ODK/ODH Tent Heater

Operators Instructions

4

6

5

7

10

4

8

9

Return

Supply

12

2-5

Page 12

UH68 ODK/ODH Tent Heater

7. Uncoil remote control (2) inside tent and feed through the collar with the return duct(5).

Attach remote control (2) to heater. Make main sure switch is in the off position.

8. Attach power cable (3) to heater then plug in to power supply. The green, main power LED,

on the remote panel should illum inate.

9. Check fuel in can(14), fill if necessary with authorized fuel (see section one). Attach Suction

Feed Adapter(15) and open vent(16).

10. Attach fuel supply line(17) to Suction Feed Adapter(15). Make sure drain cock(18) on

supply line(17) is closed. Attach supply line(17) to heater QD fitting(19). Move the fuel

can(14) as far away from the heater as possible without pulling the fuel supply line(17)

taught.

11. Attach overflow line(20)

NOTE!

Open end of overflow hose should discharge to a safe, outside location along a

downslope and below the level of the heater. A piece of commercial petroleum

absorbent material (21), will be placed under the end of the overflow hose to catch any

fuel that may spill.

12. Attach exhaust stack cap(22) to stack(23). Slide exhaust stack(22) through stack holder(24)

on side of PUDA and over exhaust elbow. Push down on stack holder(24) to stabilize stack.

2 3

2-6

Page 13

UH68 ODK/ODH Tent Heater

Operators Instructions

16

19

18

17

15

14

MAX DISTANCE

1417

22

20

23

24

21

2-7

Page 14

UH68 ODK/ODH Tent Heater

Operating Procedures

The UH68 ODK can be operated in either of two modes:

a. Heating mode.

b. Fan only mode.

Heating Mode

1. Set the room thermo (1) to the lowest

detent setting.

2. Move main switch (2) to HEAT. The

green standby LED (3) should

illuminate

3. Rotate the room thermo until the green

HEAT LED (4) illuminates.

After a five second dela y the burner will

come on. You may not hear the burner if

you are inside the tent or there is a lot of

ambient noise. The vent fan will com e on

when the heat exchanger comes up to

temperature. The amount of time will vary

(30 to 120 seconds) depending on the

ambient temperature. Once the v ent fan

comes on the heater will continue to

operate until the call for heat from the room thermo is satisfied or the main switch is

turned off. If the airflow is reduced due to very high back pressure, the burner will cycle

off from time to time.

4. Adjust room thermo (1) as necessary.

Fan Mode

Use this mode when no heat is required.

1. move main switch (2) to FAN position.

The vent motor will start and ambient air will circulate through the shelter

Never operate the UH68 ODK with the pop up duct

adapter closed. Damage to the internal parts may

1

!

!

!!

CAUTION

occur.

3

2

4

2-8

Page 15

UH68 ODK/ODH Tent Heater

Operators Instructions

Shutdown

1. Place main switch in off position.

Vent fan will continue to run until heat exchanger has cooled down. The length of time

will vary depending on ambient temperature.

Operation Under Unusual Conditions

Extreme Cold, Below 10oF

There is a thermostatically controlled fuel heater in the carburetor block. This heats the fuel

when the temperature drops below 40 degrees F. Preheating the fuel aids combustion ignition

during extremely cold conditions. Take these steps to insure reliable operation during extreme

cold:

1. Keep fuel can full to prevent condensation in tank.

2. Clean snow and ice from fuel can filler to prevent moisture from entering fuel can,

causing fuel line freeze up.

3. Rotate the room thermo fully counter clockwise to the lowest detent setting. Turn

main switch to heat. Allow heater to stand for about sixty seconds. This allows the

carb heater to reach operating temperature before heater is started. Operate as

described in HEAT MODE section.

Operation at High Altitudes

The UH68 ODK is designed to operate at elevation up to 10,0 00 fee t without any

modifications. At 10,000 feet heat out put may be reduce about 15 percent. This is a

normal condition which cannot be prevented.

Never disconnect power to the heater while heat exchanger is

hot. Damage to the internal parts may occur.

!

!

!!

CAUTION

2-9

Page 16

UH68 ODK/ODH Tent Heater

Operation Under Rainy Conditions

1. The remote control panel is water-resistant. No

special instructions for setting up in the rain.

2. Do not remove protective covers from the

remote and power receptacles until ready to

connect.

3. To keep rain water from collecting around

heater, place heater on skid (1), bricks or small

logs. Make sure heater is stable.

4. Paint all chipped and scratched surfaces to

prevent rust

Strike Procedure

1. Drain fuel lines

1. While heater is burning, open drain cock (1) on fuel supply line. Let heater run until

you hear combustion stop. (burner)

2. Move main switch to OFF and allow heater to cool.

1

BEFORE PROCEDING MAKE SURE HEATER IS COOLED DOWN AND

DISCONNECTED FROM POWER SUPPLY

3. Close drain cock (1) on supply line. Using a rag or fuel absorbent mat remove supply

line from heater at QD fitting. Make sure to hold rag beneath heater QD fitting to

catch any fuel left in the fitting.

4. Attach heater QD cover (2).

5. Hold supply line (3) above fuel can and open drain cock (1). Raise as high as

possible to let fuel drain into fuel can.

6. Close drain cock (1) and detach supply line from suction feed adapter. Coil up

supply line and connect both ends together (4) to keep out dirt.

7. Disconnect overflow line and coil up. Attach QD cover (2)

2. Disconnect ducts (6) and clamps (5), store separate from the heater.(* see duffle bag

option for storage)

3. Remove stack, fold PUDA fabric (7) and close PUDA leaving doors open.

2-10

Page 17

UH68 ODK/ODH Tent Heater

Operators Instructions

1

1

3

5

6

5

6

7

4

2

2

2-11

Page 18

UH68 ODK/ODH Tent Heater

4. Remove inlet duct collar (8) and stow in PUDA

5. Disconnect Remote Cable (9) coil up and stow in PUDA

6. Disconnect power cable (10), coil up and stow in PUDA. Close PUDA

7. Remove stack (11) and stow in storage compartment (13). Secure with spring hold

down (12).*

8. Store fuel lines in storage compartment (13)

9. Fuel can adapter may be left on the fuel can. Make sure to close the air vent (17).

Heater can now be transported.

*Packing using duffle bag

1. collapse both ducts (14) together.

2. place band clamps (15) over collapsed ducts

3. place stack (11) inside ducts

4. place all inside duffle bag (16)

5. Fuel can adapter may be left on the fuel can. Make sure to close the air vent (17).

2-12

Page 19

11

8

UH68 ODK/ODH Tent Heater

Operators Instructions

12

13

14

11

16

14

14

9

10

11

15

16

17

2-13

Page 20

UH68ODK Tent Heater

Chapter 3

Maintenance Instructions

Lubrication Instructions

Doors, Pop Up Duct Adapter

Lubricate all hinges with MIL-A-907 anti-seize compound.

Preventative Maintenance Checks and Services (PMCS)

Systematic, periodic PMCS are essential to ensure that the heater is ready for operation at all

times.

Description Ref.

Fuel Line system 1.1 BDA

Exhaust Stack 1.2 B

Fuel Supply 1.3 X BD,9Hrs

Electrical Connections 1.4 B

Remote Control Panel 1.5 B

PUDA 1.6 B

Ducts 1.7 B

Sediment Bowl 1.8 1000 Hrs

Carburetor 1.9 500 Hrs

Burner Head 1.9 X

Igniter 1.10 X

Fuel Pump 1.11 X

Heat Exchanger 1.12 X

Overheat Safety System 1.13 B

B – Before Operation A – After operation

D – During Operation Q – Quarterly

Daily Monthly Semi

Para.

Annually

Annually Interval

3-1

Page 21

UH68ODK Tent Heater

PMCS Procedures

1.1 Fuel Line System - check all fuel lines and fittings for leaks. Make sure vent at top Suction

Feed Adapter is clear of ice and snow.

1.2 Exhaust stack - make sure exhaust stack is clear of ice and snow. Check for damage or

anything that might obstruct the flow of exhaust gas.

1.3 Fuel Supply – before filling, check for water or dirt at the bottom of the can. Fill can before

operation. Heater will operate for about 9 hours with full can. Check at regular intervals to

avoid running dry.

1.4 Electrical connections - check cord for nicks or cuts, make sure cord is securely plugged

in to power supply

1.5 Remote Control Panel – check cord for nicks or cuts. Check overall condition of control

box

1.6 Pop Up Duct Adapter – check for cuts in fabric. In the field, repair cuts with duct tape.

Cuts may be sewn shut. If cut is too large to be sewn shut, replace entire fabric interface.

1.7 Ducts - check for cuts in fabric. In the field, repair cuts with duct tape. Cuts may be sewn

shut. If cut is too large to be sewn shut, replace entire duct.

1.8 Sediment Bowl – check for dirt and water. Clean if necessary.

1.9 Carburetor, Burner Head – use the following procedure to service the carb and burner

head:

Look for carbon

deposits in this area.

Check for carbon on

igniter.

Check carb bowl

for water, dirt,

and varnish

3-2

Check mixer for

dirt and carbon

deposits

Page 22

Cleaning, burner head

1. Remove Carb mixer assembly

2. Remove Igniter

3. Clean carbon

deposits in this

area. Use a small

wire brush.

UH68ODK Tent Heater

4. Clean these areas using

compressed air.

CAUTION: Wear

appropriate eye protection

when performing this

operation

5. Finish up with solvent wash

commonly used in parts cleaning

stations or carb cleaner. Let dry

before assembly.

]

3-3

Page 23

UH68ODK Tent Heater

Cleaning, Mixer

1. Remove mixer from carb assembly

Caution: The mixer assembly is made of brass and can be scratched or

dented very easily. Great care must be taken not damage the mixer nozzle.

The performance of your heater depends on this delicate part.

2. Soak mixer in solvent bath for an hour or so to loosen up carbon deposits.

3. With a flashlight look for dirt

or carbon here. Dirt may be

blown out using compressed

air. Do not use a pick or any

hard tools to clean this area

There are two concentric rings

here. The center ring is paperthin. Inspect for dents, scratches

and nicks. This area must be free

of dirt and carbon.

Mixer Assembly

4. Clean this area using a soft

cloth and solvent. Wipe with a

twisting motion.

*

IMPORTANT

If the mixer assembly cannot be cleaned satisfactorily,

replace

it.

3-4

Page 24

Reassembly

*

The mixer assembly must be seated correctly to insure

that your heater has good combustion.

IMPORTANT

Figure 1 shows the mixer assembly properly

seated in the burner head.

( carburetor not shown for clarity)

Figure 1

Figure 2 shows the mixer

incorrectly seated. If left in this

position combustion air will leak

past the mixer and cause poor

combustion and hard starting.

UH68ODK Tent Heater

Figure 2

3-5

Page 25

UH68ODK Tent Heater

g

1.10 Igniter – Check igniter for carbon build up and signs

of wear. As the igniter wears the gap between 1. and 2.

will become wider and oval shaped. Replace when

signs of wear are evident.

1.11 Fuel Pump – the fuel pump has a filter screen

located at the inlet end. To clean remove three screws holding

the cap on, remove the cap being careful not to tear the gasket,

and remove the filter screen. Pay close attention to the

orientation or the filter screen in the pump foe reassembly.

Clean screen and cap with carb cleaner. Cap has a magnet to

trap metal particles. Reassemble and check for leaks.

1.12 Heat Exchanger

DEATH OR SERIOUS INJURY

The heat exchanger must be inspected annually, or more frequently if heater usage is

heavy. A damaged heat exchanger can allow poisonous gases to seep into the heated

enclosure causin

illness or death to occupants.

WARNING!

CARBON MONOXIDE

Inspect heat exchanger in accordance with the procedures in TM 5-4520-253-13

1.13 Overheat Safety System

The overheat safety switch must be cycled before heater is used after storage or

replacement of overheat switch.

Overheat Testing - Start heater and let run for about 10 minutes

without the ducts attached. Using a piece of

paper or similar, block the inlet air about

three-quarters of the way shut. At 70 degrees

F the heater will shutdown in about a minute.

Block inlet air

here for testing

Temperature at shutdown should be between

275 and 300 degrees F. If the overheat safety switch does not

work it MUST be replaced. Replace thermostat in accordance

with procedures in TM 5-4520-253-13, 3-105

Filter located

here

3-6

Page 26

UH68ODK Tent Heater

3-7

Page 27

UH68ODK Tent Heater

Chapter 4

Troubleshooting

General

This section contains information for locating and correcting most operating problems. This

manual can not list all that may occur. When performing trouble shooting procedures, follow

all warnings and safety procedures. At no time does this manual supercede good common

sense.

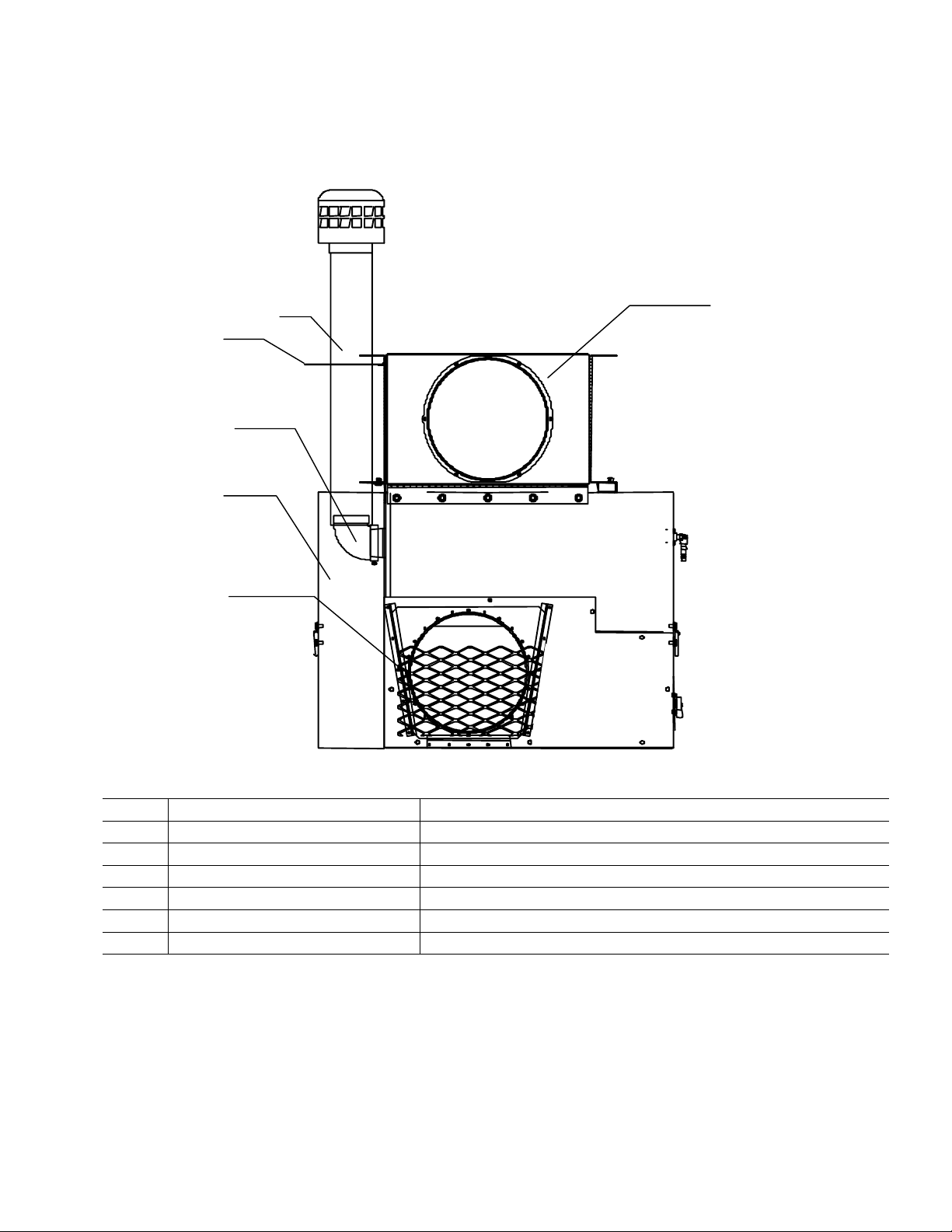

Sequence of Operation

1. Move main switch to HEAT. The green standby LED should illuminate

2. Rotate the room thermo to the nine o'clock position or until the green HEAT LED

illuminates.

3. After a five second delay the burner system will come on. This includes the ignition

transformer, fuel pump, fuel sol en oi d, and combus ti on bl ower.

4. The vent fan will come on when the heat exchanger comes up to temperature and

the flame switch closes. The amount of time will vary (30 to 120 seconds) depending

on the ambient temperature.

5. Once the vent fan comes on the heater will continue to operate until the call for heat

from the room thermo is satisfied or the main switch is turned off. If the airflow is

reduced due to very high back pressure, the burner will cycle off from time to time.

This is normal.

Blink Code Troubleshooting

Blinks Para. Problem / Remedy

1

2

3

4

5

6

7

8

1.1

1.2

1.3

1.4

1.5

1.6

Low voltage at AC input (< 100 VAC)

Check power supply or generator. If using an extension cord, make sure the wire is

heavy enough.

Reverse polarity at AC input

Check power supply or generator. If using an extension cord check connections.

High voltage (>130 VAC)

Check power supply or generator

Not used

PC Board over temp

Not used

Not used

Ignition Fault Lockout

Check fuel supply, refill if necessary.

Check Flame switch.

Check fuel pump

Check fuel flow at carburetor

Check Ignition transformer

Check Overheat thermo

4-1

Page 28

UH68ODK Tent Heater

Note on Blink Codes

Only the ignition fault will stop heater operation. The other flash codes will be displayed

but the heater will continue to operate.

Troubleshooting Procedures

Electrical Schematic

VENT FAN

J6

1

2

CONN-H2

CARB HTR

J5

1

2

CONN-H2

IGNITION

J4

1

2

CONN-H2

COMB BLR

J3

1

2

CONN-H2

BRIDGE

4 A 600V

AC2 AC1

D4

330uF 63WV

J1

1

2

FUEL PUMP

J2

1

2

FUEL SOL.

TR1

J14

1

2

OVERHEAT SW

24 V @ 1.5A

5

6

7

1

48

D3

D1

MOV

MOV

D2

MOV

BR1

+-

TVS

C1

J7

CONN-H3

38

C8

0.01uF

38

C9

0.01uF

38

C10

0.01uF

J8

1

2

3

Cir.Brk1

R8

R6

R3

J9

Cir.Brk2

R1

20KR4500K

R10

180

U8

M2M1

G

R9

1K

R11

180

U7

M2M1

G

R7

1K

R12

180

U9

M2M1

G

R5

1K

TR2

1

4 8

8V @ 300mA

C12

0.1uF

R18

5.6K

1

2

J11

CONN-H2

R21

150

SW-SP-ON-OFF-ON

R19

150

1

2

3

4

CONN-H4

R22

150

R20

150

J15

CONN-H2

N.O. 125F (i.e. it closes at 125F)

U2

1

nc

nc

2

nc

V+

3

nc

V-

4

nc

nc

TMP17

D12

D9

LED

J13

1

2

LED

SW1

D10

LED

LED

S1

FLAME SWITCH

8

7

6

5

D11

U5

6

5

ZCC

4

MOC3031

U4

6

5

ZCC

4

MOC3031

U6

6

5

ZCC

4

MOC3031

5

6

7

R2

500K

R15

1

180

2

3

R14

1

180

2

3

R13

1

180

2

3

D8

1N4001

BR2

AC2AC1

+-

BRIDGE

1.5 A 100V

C5

100uF

R16

5.0

TVS-18V

D6

R17

10K

R23

10K

D7

1N4001

U3

1

2

3

4

PIC12C67X

U1

L4805

MOUSER # 511-L4805CV

C6

0.1uF

V+

GP5/OSC1/CLK

GP4/OSC2/AN3

GP3/MCLR

VI1VO

C7

0.1uF

GP2/T0CLK/AN2/I

4.7VC322uF

GND

2

C11

0.1uF

GP0/AN0

GP1/AN1/Vref

D5

3

C4

100uF

J12

J10

1

1

2

2

3

3

4

4

5

5

6

6

CONN-H6

CONN-H6

8

GND

7

6

5

C2

22uF

D13

1N4004

4-2

Page 29

Troubleshooting Procedures

1.1 Fuel Supply – See PMCS

1.2 Check Flame Switch – the flame switch is a

normally open heat sensitive switch. The UH68G

has two switches. As used in the 68 outdoor kit,

only the normally open switch is active. Normally

switch 1, red and brown wires, is used. The

other switch is normally open and is not used.

1.3 Check Fuel Pump – The fuel pump operates

on 24vdc. Energize the pump and listen for

operation. Remove outlet connector and check

for fuel flow. Pump develops about 4 psi., if fuel

slowly runs from pump, clean filter as defined in PMCS. If

fuel runs out of pump at a good steady rate pump is ok.

1.4 Check Fuel Flow at Carburetor – remove fuel needle (1),

start heater. when combustion blower comes on fuel

should run from the fuel needle hole. If not fuel flow has

been stopped up stream. Check fuel solenoid and float

bowl needle and seat.

1.5 Check Ignition Transformer – CAUTION! The ignition

transformer develops 10,000 volts. Disconect ignition

cable form igniter. Position spring at tip of cable not more

than 1/8 inch from grounded surface. Turn h eater on. I f no

spark is detected, check power to igniton transformer.

1.6 Check Overheat Thermostat – the overheat thermostat (1)

is a normally closed temperature sensitive switch. Disconnect

wires from switch, and check continuity across switch.

UH68ODK Tent Heater

4-3

Loading...

Loading...