Page 1

Installation and Operation Manual

For Hunter Ceiling Fans

®

41462-01 10/14/2005

41462-01 10/14/2005

1

Page 2

®

41462-01 10/14/2005

2

Page 3

®

CONGRACONGRA

CONGRA

CONGRACONGRA

Your new Hunter ceiling fan is an

addition to your home or office that

will provide comfort and performance for many years. This manual

gives you complete instructions for

installing and operating your fan.

We are proud of our work. We appreciate the opportunity to supply

you with the best ceiling fan available anywhere in the world.

Before installing your fan, record the

following information for your

records and warranty assistance.

Please refer to the carton and the

Hunter nameplate (located on top

outside fan motor housing) for the

proper information.

41462-01 10/14/2005

TULATULA

TULA

TULATULA

TIONS!TIONS!

TIONS!

TIONS!TIONS!

Model Name ___________________

Catalog No. ___________________

Serial No.______________________

Date Purchased _________________

Where Purchased _______________

Attach Your Receipt

or a Copy of

Your Receipt Here

© 2005 Hunter Fan Co.

10/14/2005

3

Page 4

®

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

Important Information .......................................................................................................................... 5

Step 1 - Getting Ready .......................................................................................................................... 6

Step 2 - Installing The Ceiling Plate ........................................................................................................ 8

Step 3 - Assembling The Fan ................................................................................................................ 10

Step 4 - Hanging The Fan .................................................................................................................... 11

Step 5 - Wiring The Fan ....................................................................................................................... 12

Step 6 - Attaching The Canopy ............................................................................................................ 14

Step 7 - Assembling Fan Blades ............................................................................................................ 15

Step 8 - Attaching The Switch Housing ................................................................................................ 16

Step 9 - Remote Control ...................................................................................................................... 18

Operating Your Hunter Fan ................................................................................................................. 22

Cleaning And Maintenance ................................................................................................................. 23

Troubleshooting .................................................................................................................................. 24

41462-01 10/14/2005

4

Page 5

®

IMPORIMPOR

IMPOR

IMPORIMPOR

• Read entire booklet carefully before beginning installation and save these

instructions.

• To reduce the risk of personal injury, attach the fan

directly to the support

structure of the building according to these instructions, and use only the

hardware supplied.

• Do not hang fan on ceilings

that have a height less than

9 feet.

• To avoid possible electrical

shock, before installing

your fan, disconnect the

power by turning off the

circuit breakers to the out-

TT

ANT INFORMAANT INFORMA

T

ANT INFORMA

TT

ANT INFORMAANT INFORMA

CAUTIONSCAUTIONS

CAUTIONS

CAUTIONSCAUTIONS

WARNINGSWARNINGS

WARNINGS

WARNINGSWARNINGS

TIONTION

TION

TIONTION

let box and associated wall

switch location. If you cannot lock the circuit breakers

in the off position, securely

fasten a prominent warning

device, such as a tag, to the

service panel.

• All wiring must be in accordance with national and local electrical codes and

ANSI/NFPA 70. If you are

unfamiliar with wiring, you

should use a qualified electrician.

• To reduce the risk of personal injury, do not bend

the blade attachment system when installing, balancing, or cleaning the fan.

Never insert foreign objects

between rotating fan

blades.

• To reduce the risk of fire,

electrical shock, or motor

damage, do not use a solidstate speed control with this

fan. Use only Hunter speed

controls.

DO YOU NEED HELP?DO YOU NEED HELP?

DO YOU NEED HELP?

DO YOU NEED HELP?DO YOU NEED HELP?

To install a ceiling fan, be sure you

can do the following:

• Locate ceiling joist or other suitable support in ceiling.

• Drill holes for and install wood

screws.

• Identify and connect electrical

wires.

• Lift 40 pounds.

If you need help installing the fan,

your Hunter fan dealer can direct you

to a licensed installer or electrician.

41462-01 10/14/2005

5

Page 6

®

STEP 1 - GETTING READYSTEP 1 - GETTING READY

STEP 1 - GETTING READY

STEP 1 - GETTING READYSTEP 1 - GETTING READY

GAGA

THERING THE TOOLSTHERING THE TOOLS

GA

THERING THE TOOLS

GAGA

THERING THE TOOLSTHERING THE TOOLS

You will need the following tools for

installing the fan:

• Electric drill with 9/64" bit

• Standard screwdriver

• Phillips-head screwdriver

• Wrench or pliers

PREPPREP

ARING THE FAN SITEARING THE FAN SITE

PREP

ARING THE FAN SITE

PREPPREP

ARING THE FAN SITEARING THE FAN SITE

Ceiling height must be a minimum

of 9 feet.

The location of a ceiling fan and

how the fan is attached to the building structure are essential for reliable operation, maximum efficiency, and energy savings. For this

reason, we have included a separate booklet — “Guide to Choosing and Preparing a Ceiling Fan

Site” — to help you select the best

location for your fan. The booklet

also provides information to ensure

your fan support and electric outlet box meet UL-approved safety

codes for ceiling fans.

The instructions in this installation

manual assume that you have used

“Guide to Choosing and Preparing

a Ceiling Fan Site” to pick the fan

location and make certain the proper

fan support and outlet box are installed.

CHECKING YOUR FAN PARCHECKING YOUR FAN PAR

CHECKING YOUR FAN PAR

CHECKING YOUR FAN PARCHECKING YOUR FAN PAR

Carefully unpack your fan to avoid

damage to the fan parts. Check for

any shipping damage to the motor

or fan blades. If one of the fan blades

was damaged in shipment, return all

the blades for replacement.

TSTS

TS

TSTS

Hint: If you are installing more than

one fan, keep the fan blades

in sets, as they were shipped.

If any parts are missing or damaged,

contact your Hunter dealer or call

Hunter Parts Department at

901-248-2222.

41462-01 10/14/2005

6

Page 7

®

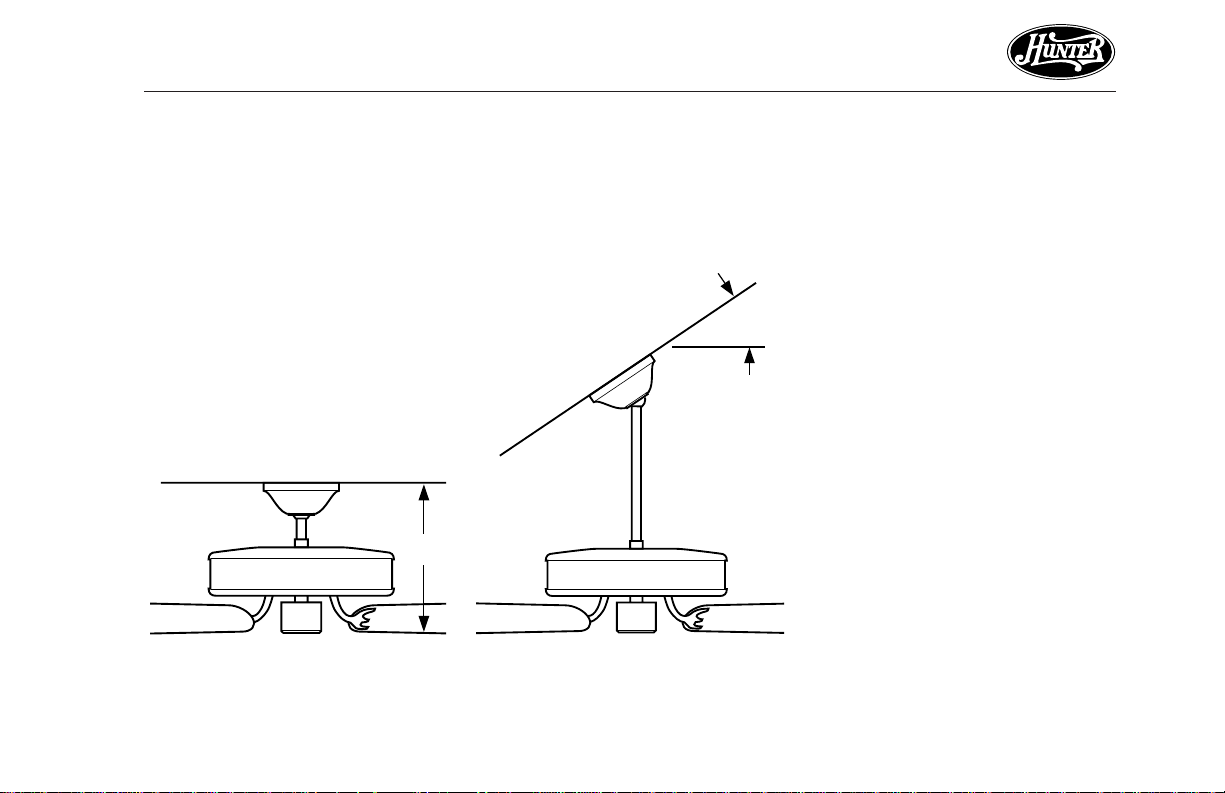

Standard MountingStandard Mounting

Standard Mounting (Figure 1a)

Standard MountingStandard Mounting

hangs from the ceiling by a connector pipe (included), for ceilings 9

feet or higher. For ceilings higher

than nine feet, you can purchase

Hunter extension rods. All Hunter

fans use sturdy 3/4" diameter pipe

to assure stability and wobble-free

performance.

15.65"

12"

Figure 1a - Standard MountingFigure 1a - Standard Mounting

Figure 1a - Standard Mounting

Figure 1a - Standard MountingFigure 1a - Standard Mounting

Angle MountingAngle Mounting

Angle Mounting

Angle MountingAngle Mounting

(Figure 1b)

hangs from a vaulted or angled ceiling.

29° Max

34° Max

Pitch

8

12

Figure 1b - Angle MountingFigure 1b - Angle Mounting

Figure 1b - Angle Mounting

Figure 1b - Angle MountingFigure 1b - Angle Mounting

41462-01 10/14/2005

7

Page 8

®

STEP 2 - INSTSTEP 2 - INST

STEP 2 - INST

STEP 2 - INSTSTEP 2 - INST

WW

ARNINGARNING

W

ARNING

WW

ARNINGARNING

• To avoid possible electrical

shock, before wiring fan,

disconnect power by turning off the circuit breakers

both to the outlet box and

to its associated wall switch

location. If you cannot lock

the circuit breakers in the

off position, securely fasten

a prominent warning device, such as a tag, to the

service panel.

ALLING THE CEILING PLAALLING THE CEILING PLA

ALLING THE CEILING PLA

ALLING THE CEILING PLAALLING THE CEILING PLA

1. Drill two pilot holes into the wood

support structure through the

outermost holes on the outlet

box. The pilot holes should be

9/64" in diameter by 2 3/4" in

depth.

2. Thread the lead wires from the

outlet box through the hole in the

middle of the ceiling plate.

3. Position the three isolators between the ceiling plate and ceiling by inserting the raised areas

on each isolator into the holes in

the ceiling plate. Refer to Figure

2a.

4. Align the slotted holes in the ceiling plate with the pilot holes in

the wood support structure.

Note: The isolation pads should

be flush against the ceiling.

TETE

TE

TETE

Ceiling

Plate

FigurFigur

e 2a - Adding Isolators toe 2a - Adding Isolators to

Figur

e 2a - Adding Isolators to

FigurFigur

e 2a - Adding Isolators toe 2a - Adding Isolators to

Ceiling PlateCeiling Plate

Ceiling Plate

Ceiling PlateCeiling Plate

Isolators

41462-01 10/14/2005

8

Page 9

®

For Angle Mounting OnlyFor Angle Mounting Only

For Angle Mounting Only: Be

For Angle Mounting OnlyFor Angle Mounting Only

sure to orient the ceiling plate so

that the arrows on the plate point

up towards the ceiling peak as

shown in Figure 2b.

FigurFigur

e 2b - Corre 2b - Corr

Figur

e 2b - Corr

FigurFigur

e 2b - Corre 2b - Corr

Plate for Angle MountingPlate for Angle Mounting

Plate for Angle Mounting

Plate for Angle MountingPlate for Angle Mounting

41462-01 10/14/2005

ect Position of Ceilingect Position of Ceiling

ect Position of Ceiling

ect Position of Ceilingect Position of Ceiling

5. Place a flat washer on each of the

two 3" screws and pass the screws

through the slotted holes in the

ceiling plate as shown in Figure

2c.

6. Tighten the screws into the 9/64"

pilot holes; do not use lubricants

on the screws. Do not overtighten.

Ceiling Joist

2 x 4 Brace

Ceiling

Plate

Flat

Washer

FigurFigur

e 2c - Attaching Ceiling Plate toe 2c - Attaching Ceiling Plate to

Figur

e 2c - Attaching Ceiling Plate to

FigurFigur

e 2c - Attaching Ceiling Plate toe 2c - Attaching Ceiling Plate to

2 x 4 Brace2 x 4 Brace

2 x 4 Brace

2 x 4 Brace2 x 4 Brace

Outlet Box

3" Wood

Screw

Ceiling

9

Page 10

®

STEP 3 - ASSEMBLING THE FANSTEP 3 - ASSEMBLING THE FAN

STEP 3 - ASSEMBLING THE FAN

STEP 3 - ASSEMBLING THE FANSTEP 3 - ASSEMBLING THE FAN

1. Insert the pipe through the hanger

bracket and canopy as shown in

Figure 3a. Feed wires from the fan

Pipe

through the pipe.

2. Screw pipe into fan assembly un-

Hanger

Bracket

til tight. IMPORTANT! Tighten

allen head pipe set screw as shown

in Figure 3 with the included allen

Canopy

wrench.

Allen

Head

Pipe Set

Screw

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

The pipe has a special coating

on the threads. Do not remove

this coating; the coating prevents the pipe from unscrewing. Once assembled, do not remove the pipe.

Figure 3 - Inserting Pipe throughFigure 3 - Inserting Pipe through

Figure 3 - Inserting Pipe through

Figure 3 - Inserting Pipe throughFigure 3 - Inserting Pipe through

Hanger Bracket and CanopyHanger Bracket and Canopy

Hanger Bracket and Canopy

Hanger Bracket and CanopyHanger Bracket and Canopy

10

41462-01 10/14/2005

Page 11

STEP 4 - HANGING THE FANSTEP 4 - HANGING THE FAN

STEP 4 - HANGING THE FAN

STEP 4 - HANGING THE FANSTEP 4 - HANGING THE FAN

1. Disconnect the power by turning off the circuit breakers to the

outlet box and associated wall

switch location.

2. Confirm that the three isolators

NoteNote

Note: To remove the hanger

NoteNote

bracket, while pressing the two

small releases on the ceiling

plate, twist the hanger bracket

counterclockwise.

are pre-installed on the hanger

bracket. Refer to Figure 4a for

Hanger Bracket

location of the isolators.

Do not install the hanger bracket

without the isolators installed.

NoteNote

Note: If the isolators are not

NoteNote

pre-installed, place the three isolators on the hanger bracket as

shown in Figure 4a.

3. Holding the hanger bracket with

one hand and supporting the

weight of the fan with the other

hand, raise the hanger bracket up

Isolators

Figure 4a - Adding Isolators to theFigure 4a - Adding Isolators to the

Figure 4a - Adding Isolators to the

Figure 4a - Adding Isolators to theFigure 4a - Adding Isolators to the

Hanger BracketHanger Bracket

Hanger Bracket

Hanger BracketHanger Bracket

flush to the ceiling plate as shown

in Figure 4b. Twist hanger bracket

clockwise and lock in place.

Ceiling Plate

Hanger Bracket

Figure 4b - Hanging the FanFigure 4b - Hanging the Fan

Figure 4b - Hanging the Fan

Figure 4b - Hanging the FanFigure 4b - Hanging the Fan

®

41462-01 10/14/2005

11

Page 12

®

STEP 5 - WIRING THE FANSTEP 5 - WIRING THE FAN

STEP 5 - WIRING THE FAN

STEP 5 - WIRING THE FANSTEP 5 - WIRING THE FAN

12

WW

ARNINGARNING

W

ARNING

WW

ARNINGARNING

• To avoid possible electrical

shock, before wiring fan,

disconnect power by turning off the circuit breakers

both to the outlet box and

to its associated wall switch

location. If you cannot lock

the circuit breakers in the

off position, securely fasten

a prominent warning device, such as a tag, to the

service panel.

• All wiring must be in accordance with national and local electrical codes and

ANSI/NFPA 70. If you are

unfamiliar with wiring, you

should use a qualified electrician.

WW

ARNINGARNING

W

ARNING

WW

ARNINGARNING

To reduce the risk of fire, electrical shock, or motor damage,

do not lift or carry the fan by

the lead wires.

CONNECTING FAN TO ELECTRI-CONNECTING FAN TO ELECTRI-

CONNECTING FAN TO ELECTRI-

CONNECTING FAN TO ELECTRI-CONNECTING FAN TO ELECTRICAL SOURCECAL SOURCE

CAL SOURCE

CAL SOURCECAL SOURCE

1. Connect the wires as shown in

Figure 5. To connect the wires,

twist the bare metal leads together. Place a wire nut over the

intertwined length of wire and

twist clockwise until tight as

shown.

2. Separate the connected wires by

placing the green and white wires

on one side of the outlet box and

the black wires on the other side

of the outlet box.

3. Turn the connectors upward. Push

the wires gently into the outlet

box.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Be sure no bare wire or wire

strands are visible after making connections.

41462-01 10/14/2005

Page 13

Power

Wires

In

Ceiling

Bare or Green

2 x 4 Brace

Black

White

Outlet

Box

®

41462-01 10/14/2005

Green

Approved

Connectors

Green Ground

Wire from Hanger

Pipe (not present

with flush mounting

option)

Black

White

Ceiling

Plate

Figure 5 - Wiring DiagramFigure 5 - Wiring Diagram

Figure 5 - Wiring Diagram

Figure 5 - Wiring DiagramFigure 5 - Wiring Diagram

13

Page 14

®

STEP 6 - ATTSTEP 6 - ATT

STEP 6 - ATT

STEP 6 - ATTSTEP 6 - ATT

Refer to Figure 6.

1. Raise the canopy and align the

holes in the canopy with the holes

in the ceiling plate.

2. Install and tighten the three

canopy screws.

Figure 6 - Attaching Canopy to CeilingFigure 6 - Attaching Canopy to Ceiling

Figure 6 - Attaching Canopy to Ceiling

Figure 6 - Attaching Canopy to CeilingFigure 6 - Attaching Canopy to Ceiling

PlatePlate

Plate

PlatePlate

ACHING THE CANOPYACHING THE CANOPY

ACHING THE CANOPY

ACHING THE CANOPYACHING THE CANOPY

14

41462-01 10/14/2005

Page 15

STEP 7 - ASSEMBLING FAN BLADESSTEP 7 - ASSEMBLING FAN BLADES

STEP 7 - ASSEMBLING FAN BLADES

STEP 7 - ASSEMBLING FAN BLADESSTEP 7 - ASSEMBLING FAN BLADES

1. Attach each blade to the blade

iron using three barrel nuts and

Blade

Decorative

Screw

three decorative screws as shown

in Figure 7a, 7b and 7c.

Decorative

Screw

Barrel Nut

Blade

Iron

WARNINGWARNING

WARNING

WARNINGWARNING

Failure to securely tighten the

1/4"-20 Screws into the Motor

could cause the Blade Assembly to fall.

®

FigurFigur

e 7a - Attaching Blades to Bladee 7a - Attaching Blades to Blade

Figur

e 7a - Attaching Blades to Blade

FigurFigur

e 7a - Attaching Blades to Bladee 7a - Attaching Blades to Blade

IrIr

onon

Ir

on

IrIr

onon

41462-01 10/14/2005

Blade

Iron

Barrel Nut

FigurFigur

e 7be 7b

Figur

e 7b

FigurFigur

e 7be 7b

2. Remove the blade mounting

screws and rubber shipping

bumpers from the motor.

3. Align the holes in the blade

bracket and the cover plate with

the five holes in the bottom of

the motor and partially install

the five 1/4"-20 Screws. Refer

to Figure 7c.

4. Once all five screws are partially

installed, tighten them securely.

FigurFigur

e 7c - Attaching Blade Ire 7c - Attaching Blade Ir

Figur

e 7c - Attaching Blade Ir

FigurFigur

e 7c - Attaching Blade Ire 7c - Attaching Blade Ir

Assembly to MotorAssembly to Motor

Assembly to Motor

Assembly to MotorAssembly to Motor

Blade

Bracket

onon

on

onon

Cover

Plate

Blade

Bracket

Assembly

Screws

15

Page 16

®

STEP 8 - ATTSTEP 8 - ATT

STEP 8 - ATT

STEP 8 - ATTSTEP 8 - ATT

ACHING THE SWITCH HOUSINGACHING THE SWITCH HOUSING

ACHING THE SWITCH HOUSING

ACHING THE SWITCH HOUSINGACHING THE SWITCH HOUSING

The switch housing is made up of

two sections: the upper switch housing, and the lower switch housing.

AA

TTTT

ACHING THE UPPER SWITCHACHING THE UPPER SWITCH

A

TT

ACHING THE UPPER SWITCH

AA

TTTT

ACHING THE UPPER SWITCHACHING THE UPPER SWITCH

HOUSINGHOUSING

HOUSING

HOUSINGHOUSING

1. Partially install two #6-32 x 3/8"

housing assembly screws into the

switch housing mounting plate as

shown in Figure 8a.

Switch

Housing

Mounting

Plate

Upper

Switch

Housing

FigurFigur

e 8a - Attaching Upper Switche 8a - Attaching Upper Switch

Figur

e 8a - Attaching Upper Switch

FigurFigur

e 8a - Attaching Upper Switche 8a - Attaching Upper Switch

Housing to Switch Housing Mount-Housing to Switch Housing Mount-

Housing to Switch Housing Mount-

Housing to Switch Housing Mount-Housing to Switch Housing Mounting Plateing Plate

ing Plate

ing Plateing Plate

Housing

Assembly

Screw

Wires for

Optional

Light Kit

2. Feed the two optional accessory

light kit wires with the attached

wire nuts through the center

opening of the upper switch

housing. See Figure 8a.

3. Align the keyhole slots in the upper switch housing with the housing assembly screws installed in

sub-step 1.

4. Turn the upper switch housing

counterclockwise until the housing assembly screws are firmly

situated in the narrow end of the

keyhole slots as shown in Figure

8b. Install the one remaining #632 x 3/8" housing assembly screw

into the third hole in the upper

switch housing. Tighten all three

screws firmly.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Make sure the upper switch

housing is securely attached to

the switch housing mounting

plate. Failure to properly attach and tighten all three housing assembly screws could result in the switch housing and

light fixture falling.

FigurFigur

e 8b - Mounting the Uppere 8b - Mounting the Upper

Figur

e 8b - Mounting the Upper

FigurFigur

e 8b - Mounting the Uppere 8b - Mounting the Upper

Switch HousingSwitch Housing

Switch Housing

Switch HousingSwitch Housing

16

41462-01 10/14/2005

Page 17

AA

TTTT

ACHING THE LOWERACHING THE LOWER

A

TT

ACHING THE LOWER

AA

TTTT

ACHING THE LOWERACHING THE LOWER

SWITCH HOUSINGSWITCH HOUSING

SWITCH HOUSING

SWITCH HOUSINGSWITCH HOUSING

1. Place the lower switch housing

assembly over the upper switch

housing. Make sure that the two

wires for the optional light kit

with wire nuts firmly attached,

are completely inside the lower

switch housing.

2. Align the side screw holes in the

upper and lower switch housings. Attach the lower switch

housing to the upper switch

housing with three #6-32 x 3/8"

housing assembly screws. See

Figure 8c.

2 Wires for

Optional

Light Kit

Housing

Assembly

Screw

FigurFigur

e 8c - Lower Switch Housinge 8c - Lower Switch Housing

Figur

e 8c - Lower Switch Housing

FigurFigur

e 8c - Lower Switch Housinge 8c - Lower Switch Housing

InstallationInstallation

Installation

InstallationInstallation

Upper

Switch

Housing

Lower

Switch

Housing

INSTINST

INST

INSTINST

KITSKITS

KITS

KITSKITS

ALLING ALLING

ALLING

ALLING ALLING

ACCESSORACCESSOR

ACCESSOR

ACCESSORACCESSOR

Y LIGHTY LIGHT

Y LIGHT

Y LIGHTY LIGHT

To install an optional light kit, replace

the lower switch housing with the

light kit compatible switch housing.

Follow the instructions included with

the light kit for wiring, mounting and

assembly. After completing installation refer to the fan instructions for

switch housing reassembly.

The following Hunter Low Profile

type light kit models

patible with this fan.

ARE NOTARE NOT

ARE NOT com-

ARE NOTARE NOT

DO NOTDO NOT

DO NOT use

DO NOTDO NOT

the following models.

22498

22898

22909

26122

26126

26130

26131

26132

26133

26134

26135

26136

27140

27141

27142

27196

28048

29130

®

41462-01 10/14/2005

17

Page 18

®

STEP 9 - REMOTE CONTROLSTEP 9 - REMOTE CONTROL

STEP 9 - REMOTE CONTROL

STEP 9 - REMOTE CONTROLSTEP 9 - REMOTE CONTROL

REMOTE CRADLE INSTREMOTE CRADLE INST

REMOTE CRADLE INST

REMOTE CRADLE INSTREMOTE CRADLE INST

STST

ANDARD LIGHT SWITCHANDARD LIGHT SWITCH

ST

ANDARD LIGHT SWITCH

STST

ANDARD LIGHT SWITCHANDARD LIGHT SWITCH

1. Remove the two screws holding

the switch cover plate. Do not remove the cover plate.

2. Orient the control cradle as

shown in Figure 9a, and line up

the two inner mounting holes

with those on the switch, insert

screws, don't over tighten.

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

ROCKER LIGHT SWITCHROCKER LIGHT SWITCH

ROCKER LIGHT SWITCH

ROCKER LIGHT SWITCHROCKER LIGHT SWITCH

1. Break off the two tabs by pushing outward. See Figure 9b.

2. Remove the two screws holding

the switch cover plate. Do not remove the cover plate.

3. Orient the remote cradle as

shown in Figure 9b. Line up the

two outer mounting holes with

those on the switch , insert

screws, don't over tighten.

Remove tabs

WALL INSTWALL INST

WALL INST

WALL INSTWALL INST

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

1. Locate a 2x4 wall stud in a convenient location.

2. Orient the remote cradle as shown

in Figure 9c, over the 2x4 stud.

3. Use the 1” wood screws in either

the inner or outer mounting holes.

Note:Note:

Note: Wall anchors and 6-32 x 1”

Note:Note:

screws may be used in situations

where mounting to a stud is not possible. Use the inner mounting holes.

18

FigurFigur

Figur

FigurFigur

e 9ae 9a

e 9a

e 9ae 9a

FigurFigur

Figur

FigurFigur

e 9be 9b

e 9b

e 9be 9b

FigurFigur

Figur

FigurFigur

e 9ce 9c

e 9c

e 9ce 9c

41462-01 10/14/2005

Page 19

BABA

TTERTTER

BA

BABA

TTER

TTERTTER

Y INSTY INST

Y INST

Y INSTY INST

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

1. Slide the cover off the back of the

remote as shown in Figure 9d,

pressing in and sliding the cover

down to release.

2. Install the included 12 volt alkaline battery (Type 23A, MN-21 or

equivalent) inside the remote,

matching polarity on the Battery

as indicated by the + and - symbols in the Battery Compartment.

See Figure 9d. Replace the cover.

DIP SWITCH SETTINGDIP SWITCH SETTING

DIP SWITCH SETTING

DIP SWITCH SETTINGDIP SWITCH SETTING

Note:Note:

Note: You will only have to change

Note:Note:

the DIP switch settings in the remote

if you are using more than one remote controlled fan in the same area

and want to control them separately.

1. At the circuit breaker or fuse box,

turn the power off for the fan you

want to change.

FigurFigur

e 9de 9d

Figur

e 9d

FigurFigur

e 9de 9d

2. Slide the cover off the back of

the remote and remove the battery. The battery must be removed when changing dip switch

settings. Refer to BATTERY INSTALLATION and Figure 9d.

3. Change the DIP switch settings,

assuring that they are different

from the previously installed fan.

Refer to Figure 9e.

4. Replace the battery and cover.

5. At the circuit breaker or fuse box,

turn the power back on for the fan

whose settings you are changing.

6. Within 20 seconds of restoring

power, push the Hi, Med, and Lo

buttons (in that order). Refer to

Figure 9f.

Note:Note:

Note: You may want to label your

Note:Note:

controls to assure you do not mix

them up.

DIP Switch

FigurFigur

Figur

FigurFigur

Set to

01110

e 9ee 9e

e 9e

e 9ee 9e

DIP Switch

Set to

01001

®

41462-01 10/14/2005

19

Page 20

®

Do not turn the power off at the

circuit breaker, then back on, for the

previously installed fan(s), as you

may inadvertently change the DIP

switch code settings for it as well.

Note: Note:

Note: The DIP SWITCH SETTING

Note: Note:

sub steps must be repeated as described above for the proper setting of the DIP switch code in the

receiver and remote.

POWER FAILUREPOWER FAILURE

POWER FAILURE

POWER FAILUREPOWER FAILURE

The receiver has a memory function

that retains the last DIP switch code

setting. The setting will not change

in the event of power failure or if

power to the fan is inadvertently shut

off.

FAN CONTROLFAN CONTROL

FAN CONTROL

FAN CONTROLFAN CONTROL

Refer to Figure 9f for identification of

control buttons.

To start the fan press the selected

speed button to run the fan at the

desired speed.

To turn off the fan. Press the FAN OFF

button.

Light

Fan Medium

Fan High

Fan Low

Fan Off

Figure 9f - Control ButtonsFigure 9f - Control Buttons

Figure 9f - Control Buttons

Figure 9f - Control ButtonsFigure 9f - Control Buttons

Reverse

AIRFLOW DIRECTIONAIRFLOW DIRECTION

AIRFLOW DIRECTION

AIRFLOW DIRECTIONAIRFLOW DIRECTION

To reverse the airflow press the RE-

VERSE button. Reverse operates at

any speed whether fan is on or off.

The fan returns to its set speed after

reversing.

If the fan is not functioning af-If the fan is not functioning af-

If the fan is not functioning af-

If the fan is not functioning af-If the fan is not functioning after installation:ter installation:

ter installation:

ter installation:ter installation:

1. Check to make sure that battery

is installed correctly in the control.

2. Turn the power off to the fan

(from the circuit breaker) for at

least 5 seconds.

3. Turn the power back on (at the

circuit breaker) and push the Hi,

Med, and Low buttons–in that

order–within 20 seconds.

4. The fan should now function

properly.

20

41462-01 10/14/2005

Page 21

LIGHT CONTROLLIGHT CONTROL

LIGHT CONTROL

LIGHT CONTROLLIGHT CONTROL

Turn the light on or off indepen-

dently from the fan by pressing the

LIGHT button. When the light is on,

press the LIGHT button 1 time for

a gradual off (light dims from full

brightness to completely off) or

press the LIGHT button 2 times for

an instant off.

Press the button for longer than 1

second, it becomes a dimmer. The

light varies from ‘bright’ to ‘dim’

over approximately 8 seconds. This

sequence will reverse the light

when it reaches the brightest or

dimmest level if you continue to

hold the LIGHT button. Release the

button when the desired level is

reached.

AUTO RESUMEAUTO RESUME

AUTO RESUME

AUTO RESUMEAUTO RESUME

Quick (pressing less than 1 second)

on/off operation of the LIGHT button maintains the desired brightness level set previously.

41462-01 10/14/2005

FCC INFORMA FCC INFORMA

FCC INFORMA

FCC INFORMA FCC INFORMA

1 . This device complies with Part 15 of

the FCC Rules. Operation is subject

to the following two conditions: (1)

This device may not cause harmful

interference, and (2) this device

must accept any interference received, including interference that

may cause undesired operation.

2. This equipment has been tested

and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide

reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment

TIONTION

TION

TIONTION

off and on, the user is encouraged

to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving

antenna.

• Increase the separation between

the equipment and receiver.

• Connect the equipment into an

outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Note:Note:

Note: Any changes or modifica-

Note:Note:

tions to the transmitter or receiver

not expressly approved by Hunter

Fan Company may void one’s authority to operate this remote control.

3. For use only with electrically reversible ceiling fans rated at 1.0

amp or less, and fan incandescent

light kits rated at 300 watts or less.

4. Not for use with shaded-pole or

nonreversible motors. Not recommended for use with the Hunter

Original ®.

®

21

Page 22

®

OPERAOPERA

OPERA

OPERAOPERA

1. Turn on electrical power to the

fan.

2. Refer to the STEP 9 - REMOTE

CONTROL, for operation.

3. Ceiling fans work best by blowing air downward (counterclockwise blade rotation) in warm

weather to cool the room with a

direct breeze. In winter, having

the fan draw air upward (clockwise blade rotation) will distribute the warmer air trapped at the

ceiling around the room without

causing a draft.

4. If your fan wobbles when operating, use the enclosed balancing

kit and instructions to balance the

fan.

TING YOUR HUNTER FANTING YOUR HUNTER FAN

TING YOUR HUNTER FAN

TING YOUR HUNTER FANTING YOUR HUNTER FAN

FigurFigur

e 10a - Air Flow Pattere 10a - Air Flow Patter

Figur

e 10a - Air Flow Patter

FigurFigur

e 10a - Air Flow Pattere 10a - Air Flow Patter

nsns

ns

nsns

22

41462-01 10/14/2005

Page 23

CLEANING AND MAINTENANCECLEANING AND MAINTENANCE

CLEANING AND MAINTENANCE

CLEANING AND MAINTENANCECLEANING AND MAINTENANCE

Caring for finishes: For cleaning, a

soft brush or lint-free cloth should

be used to prevent scratching the finish. A vacuum cleaner brush nozzle

can remove heavier dust. Surface

smudges or an accumulation of dirt

and dust can easily be removed by

using a mild detergent and a slightly

dampened cloth. An artistic agent

may be used, but never use abrasive

cleaning agents as they will damage

the finish.

Caring for blades: Wood finish

blades should be cleaned with a furniture polishing cloth. Occasionally,

a light coat of furniture polish may

be applied for added protection and

beauty. Painted and high-gloss

blades may be cleaned in the same

manner as the fan finish.

MANUFMANUF

MANUF

MANUFMANUF

PHONE NUMBERPHONE NUMBER

PHONE NUMBER

PHONE NUMBERPHONE NUMBER

If you need parts or service assistance, please call 901-248-2222 or

visit us at our WEB site at:

http://www.hunterfan.com

ACTURER'SACTURER'S

ACTURER'S

ACTURER'SACTURER'S

®

41462-01 10/14/2005

23

Page 24

®

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTINGTROUBLESHOOTING

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

Nothing happens; fan does not move. 1. Power turned off, fuse blown, or

Note:Note:

Note: Replace with battery type

Note:Note:

23A, MN-21 or equivalent. See STEP

9 - REMOTE CONTROL.

PROBABLE CAUSEPROBABLE CAUSE

PROBABLE CAUSE

PROBABLE CAUSEPROBABLE CAUSE

circuit breaker tripped.

2. Loose wire connections or wrong

connections.

3. Remote battery weak or not installed properly.

4. Shipping bumpers still in place.

5. Dip Switches not set.

6. Fan remote receiver defective.

SOLUTIONSOLUTION

SOLUTION

SOLUTIONSOLUTION

1. Turn power on, replace fuse, or reset breaker.

2a.Loosen canopy, check all con-

nections according to STEP 5 WIRING THE FAN (turn power

off before checking).

2b.Check the plug connection in the

switch housing according to STEP

8 - ATTACHING THE SWITCH

HOUSING.

3. Install fresh Alkaline battery. See

STEP 9 - REMOTE CONTROL.

4. Remove shipping bumpers.

5. See STEP 9 - REMOTE CONTROL.

6. Replace receiver.

24

41462-01 10/14/2005

Page 25

®

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

PROBABLE CAUSEPROBABLE CAUSE

PROBABLE CAUSE

PROBABLE CAUSEPROBABLE CAUSE

Noisy op eration. 1. Blade iron screwed loosely to motor.

2. Blade screwed loosely to blade

iron.

3. Blade cracked.

4. Using non-approved speed control.

5. Optional Light Kit is not properly

installed.

6. Switch housing is loose.

Excessive wobbling.

Note:Note:

Note: When switching from medium

Note:Note:

to low speed, you may notice some fan

wobble. When the fan stabilizes at low

1. Unbalanced blades.

2. Loose blades or blade iron.

3. Fan not secure on hanger assembly.

speed, wobble will disappear.

4. Fan hanger ball not seated in

canopy tabs.

SOLUTIONSOLUTION

SOLUTION

SOLUTIONSOLUTION

1. Tighten screws until snug.

2. Tighten screws until snug.

3. Replace all blades.

4. Change to approved speed control.

5. Refer to the Optional Light Kit installation instructions.

6. Check and tighten screws to the

switch housing mounting plate

and to the upper and lower switch

housing.

1. Use balancing kit included with fan.

2. Tighten all screws.

3. Turn power off, support fan very

carefully, loosen canopy and hang

correctly.

4. Turn power off, support the fan

very carefully, and check that the

hanger ball is properly seated.

41462-01 10/14/2005

25

Page 26

®

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

PROBABLE CAUSEPROBABLE CAUSE

PROBABLE CAUSE

PROBABLE CAUSEPROBABLE CAUSE

SOLUTIONSOLUTION

SOLUTION

SOLUTIONSOLUTION

Not using alkaline batteries.Remote battery life seems short. Replace with alkaline battery.

Remote operates only at close range.

Battery too weak.

Replace with new alkaline battery,

type 23A, MN-21 or equivalent.

Inconsistent Remote operation.

1. RF interference.

1. Turn OFF wall switch for 5 seconds, then turn back ON.

2. Continuing RF interference.

2. Change DIP switch settings to a

different code. Follow complete

DIP switch change steps found in

STEP 9 - REMOTE CONTROL, sub

step DIP SWITCH SETTING.

If you have tried these troubleshooting solutions and still have trouble, call 901-248-2222 or visit our

Web site at http://www.hunterfan.com.

26

41462-01 10/14/2005

Loading...

Loading...