Page 1

Installation • Operation • Care

Luminette® Privacy Sheers

PowerView™ Motorization

Page 2

CONTENTS

Questions?

Call Hunter Douglas Consumer Support at

1-888-501-8364.

© 2016 Hunter Douglas. All rights reserved. All trademarks used herein are the property of Hunter Douglas

or their respective owners.

Getting Started:

Product View ............................................................................ 1

Tools and Fasteners Needed ...................................................... 2

Unpack the Components ........................................................... 2

Installation:

Mount the Installation Brackets — Inside/Ceiling Mount .............. 4

Mount the Installation Brackets — Outside Mount ...................... 7

Bracket Locations — Corner and Bay Windows ........................ 11

Install the SofTrak

™

Headrail .................................................... 12

Side-by-Side (Abutted) Installations (Simulated Split Stack) ........ 13

Connect PowerView

™

Components ........................................... 14

Test Headrail Operation .......................................................... 15

Attach the Fabric Panel(s) ........................................................ 16

Operation:

Using the PowerView Remote ................................................. 19

Resetting the Sheer ................................................................. 20

Troubleshooting ...................................................................... 21

Care:

Removing the Fabric/Motor/Headrail ........................................ 23

Cleaning Procedures ............................................................... 25

Additional Product Enhancements ............................................ 27

Declarations .......................................................................... 28

Lifetime Guarantee ..................................................Back Cover

Page 3

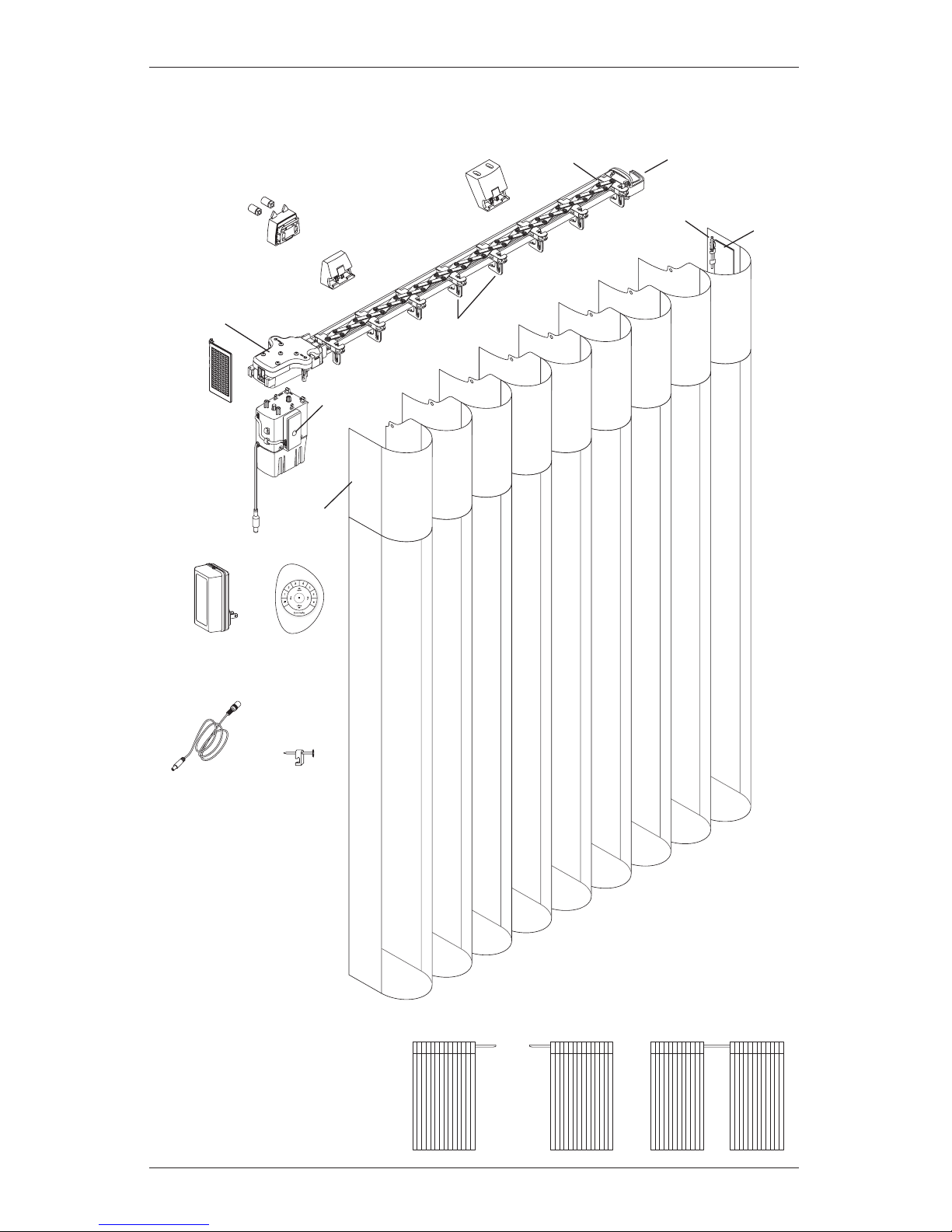

GETTING STARTED

1

Product View

Left Stack Right Stack Split Stack

SofTrak

™

Headrail

Swivel

Plate

Rivet

Swivel

Arm

Left Stack Shown

Inside/Ceiling

Mount Bracket

Installation Bracket

Faceplate

DC Power

Supply

DC Power

Supply Cable

C-Clip

Modular

Motor

Assembly

Manual

Control

Button

PowerView

™

Remote

Drive Assembly

Spacer Block

with Bushings

Pinion

Clips

Swivel

Plate

End

Treatment

Page 4

2

GETTING STARTED

Thank you for purchasing Luminette® Privacy Sheers with PowerView™ Motorization. With proper

installation, operation, and care, your new sheers will provide years of beauty and performance.

Please thoroughly review this instruction booklet and the packing list included with your order

before beginning the installation.

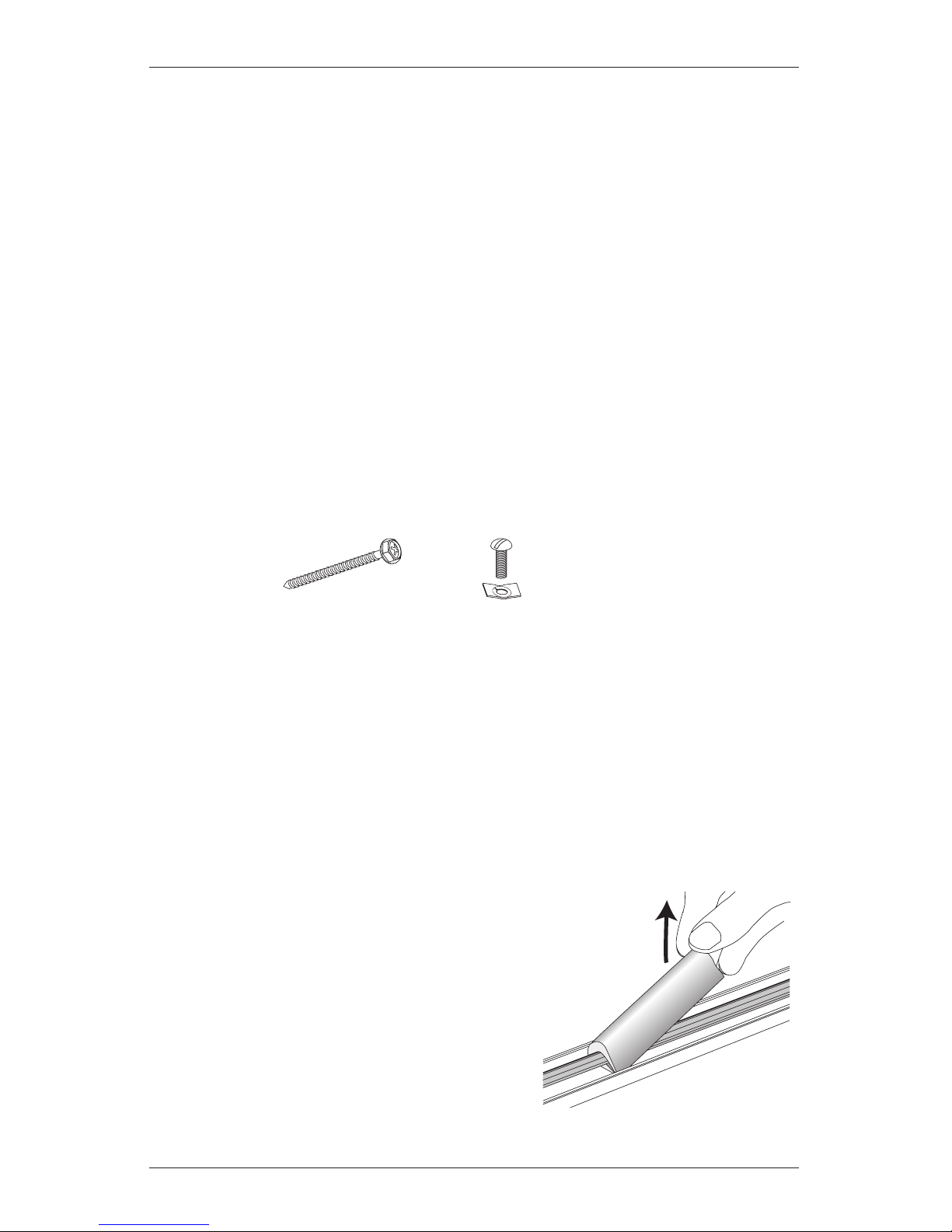

Tools and Fasteners Needed

■ Flat blade and Phillips screwdrivers

■ Measuring tape and pencil

■ Power drill,

3

/32" drill bit,

and

1

/4" hex driver

In addition, you will need fasteners designed to work with your specific mounting surface(s).

■ #6 Hex Head Screws (Provided). Two 1

1

/2" screws are provided per installation bracket.

■ Speed Nuts and Screws (Provided). Extension brackets come with screws and speed nuts.

■ Drywall Anchors (Not Provided). Use drywall anchors when mounting into drywall.

Unpack the Components

■ Make sure you have clean hands or wear disposable gloves when handling Luminette fabric.

To avoid wrinkling the fabric, do not fold it or drape it over furniture.

■ One or more fabric panels may be packaged in a carton.

■ The fabric panels are rolled around a cardboard tube. Do not remove the protective

wrapping until starting the “Attach the Fabric Panel(s)” step on page 16.

■ Remove the SofTrak

™

headrail system and installation hardware from inside the carton.

■ Remove the foam supports from the tilt shaft inside

the headrail. Rotate the supports in either direction

until they can be pulled off.

IMPORTANT: With wider fabrics, the SofTrak

headrail may be shipped separately.

Remove

Foam Supports

■ Level (laser level is recommended)

■ Needlenose pliers

■ Utility knife and scissors

Speed Nut

and Screw

(Two Provided with

Each Extension Bracket)

#6 x 1

1

/2"

Hex Head Screw

(Provided)

Page 5

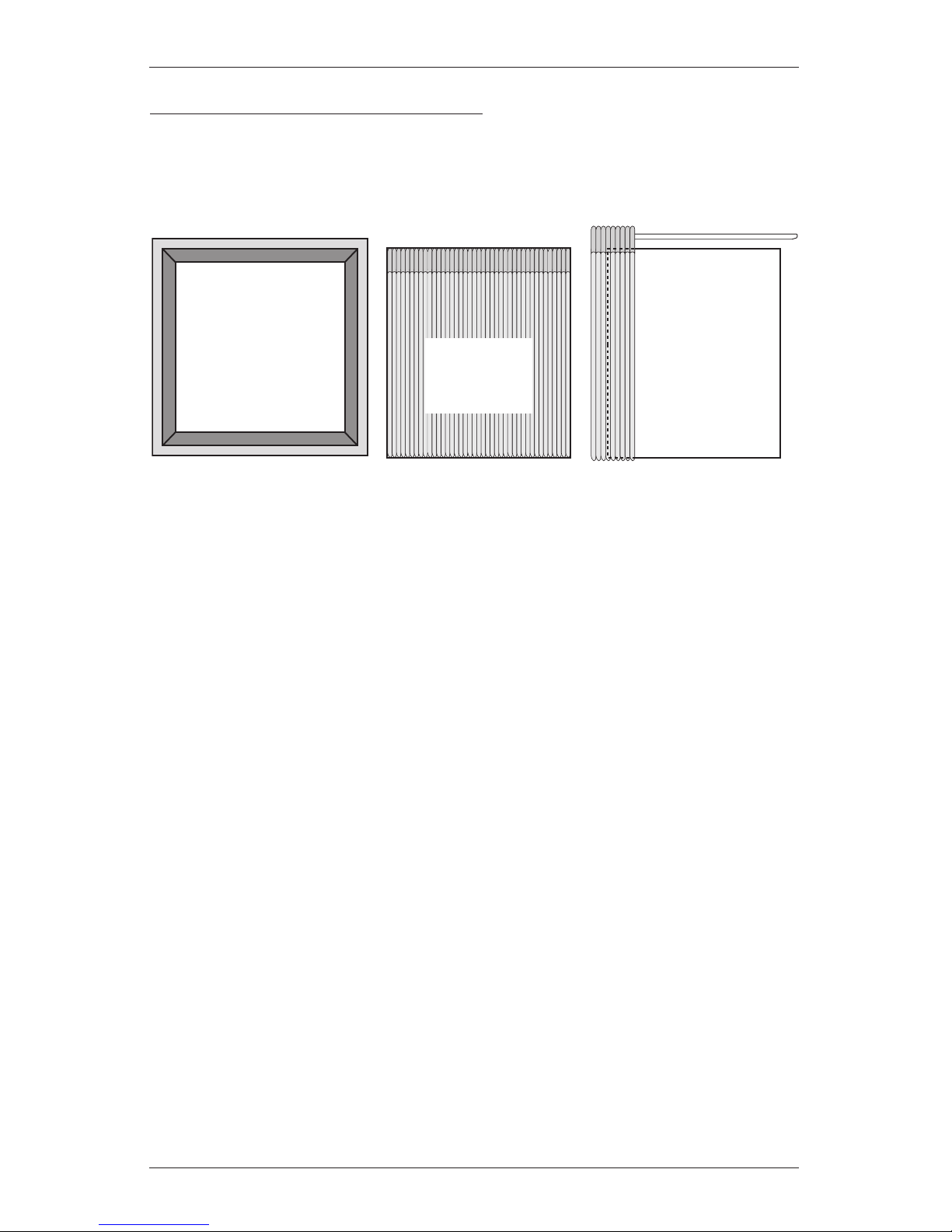

GETTING STARTED

3

Mounting Types and Window Terminology

If the installation brackets are mounted correctly, the rest of the installation process follows

easily. To prepare for this important first step, review the mounting types and basic window

terminology illustrated below.

■ For proper operation, the fabric must clear all obstructions, including window cranks,

handles, and moldings.

➤ Replace protruding window cranks with T-cranks, as needed.

■ Refer to the appropriate page below based on your order:

➤ Inside/Ceiling Mount — Page 4

➤ Outside Mount — Page 7

Collectively, the sill and

jambs are called the

“window casement.”

Molding (or Wall)

Head Jamb

Sill (or Floor)

Jamb Jamb

Inside Mount

Sheer fits

within window

or door opening.

Outside Mount

Sheer mounts

outside window

or door opening.

Page 6

INSTALLATION

4

Mount the Installation Brackets — Inside/Ceiling Mount

If you are mounting on corner or bay windows, refer to “Bracket Locations — Corner and Bay

Windows” on page 11 for specific bracket locations. Return to this page after identifying

the bracket locations.

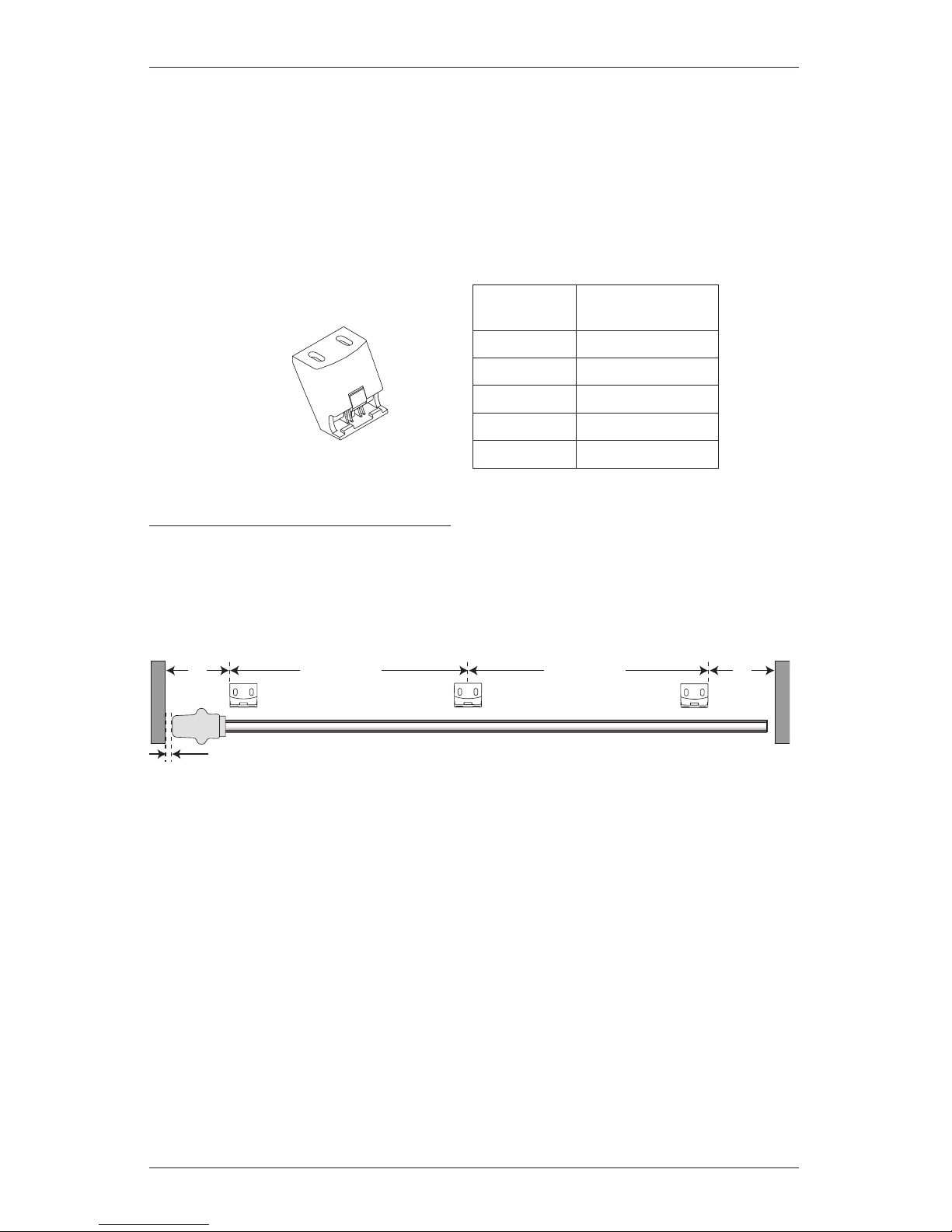

■ Your order will include the appropriate number of inside/ceiling mount installation brackets.

The number of installation brackets required varies with headrail width, as shown below.

Measure and Mark Bracket Locations

■ Mark 5" from each jamb on the mounting surface.

➤ If more than two installation brackets are required (see table above), mark the locations

of additional bracket(s) spaced evenly between the two end brackets.

CAUTION: Installation brackets should be fastened into wood whenever possible. Use drywall

anchors when mounting into drywall. When attaching brackets into drywall, additional brackets

may be required to keep the headrail level after the fabric is attached.

Inside/Ceiling Mount

Installation Bracket

Headrail

Width

Brackets Required

Up to 40" 2

40

1

/8" – 70" 3

70

1

/8" – 96" 4

96

1

/8" – 155" 6

155

1

/8" – 192" 8

Top View

Bracket

Jamb

Jamb

SofTrak

™

Headrail

Space EvenlySpace Evenly5" 5"

5

/8" Gap Required

Motor

Page 7

INSTALLATION

5

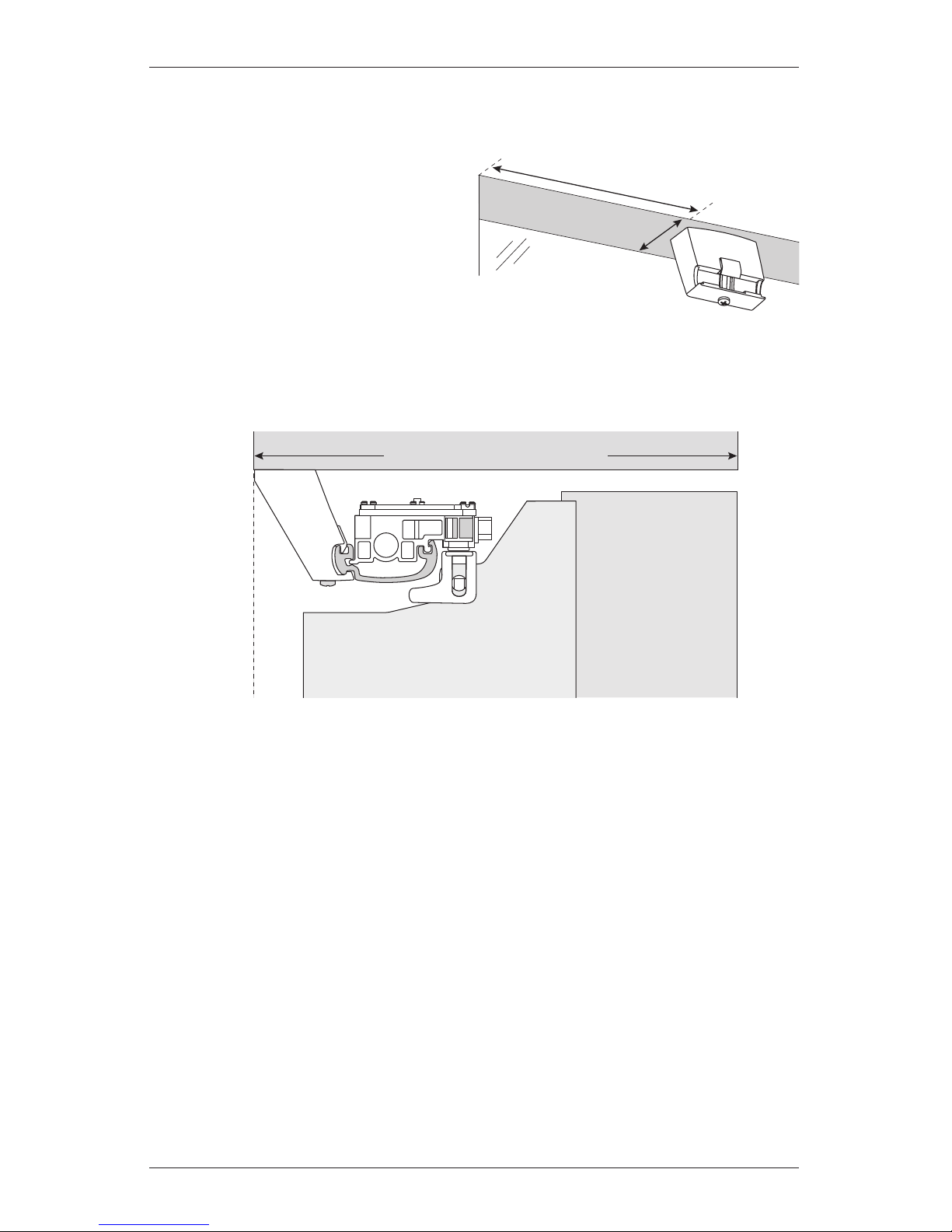

■ Mark where to drill holes for the screws.

IMPORTANT: The front edges of the brackets must align to each other.

➤ Align the outside edge of the end

brackets on your marks, then mark

each of the screw holes. Center

additional brackets on the marks to

mark their screw holes.

➤ The minimum mounting depth required is 1".

➤ To fully recess the fabric in the window casement, the mounting depth required is 6

1

/4".

See the illustration below.

Bracket Headrail

Stacked

Fabric

Vane

6

1

/4" Minimum Fully Recessed Depth

Inside Mount

Fully Recessed Mounting Depth

Window

Side

1" Minimum

5"

Page 8

INSTALLATION

6

Mount the Brackets

■ Drill the screw holes using a 3/32" drill bit.

CAUTION: Use drywall anchors when mounting into

drywall.

■ Attach the installation brackets using the screws provided.

IMPORTANT: For proper operation, the headrail must

be mounted level. Use a laser level to check that the

installation brackets are level and aligned. Shim the

brackets if necessary. The brackets may also need to be

shimmed if the mounting surface is heavily textured.

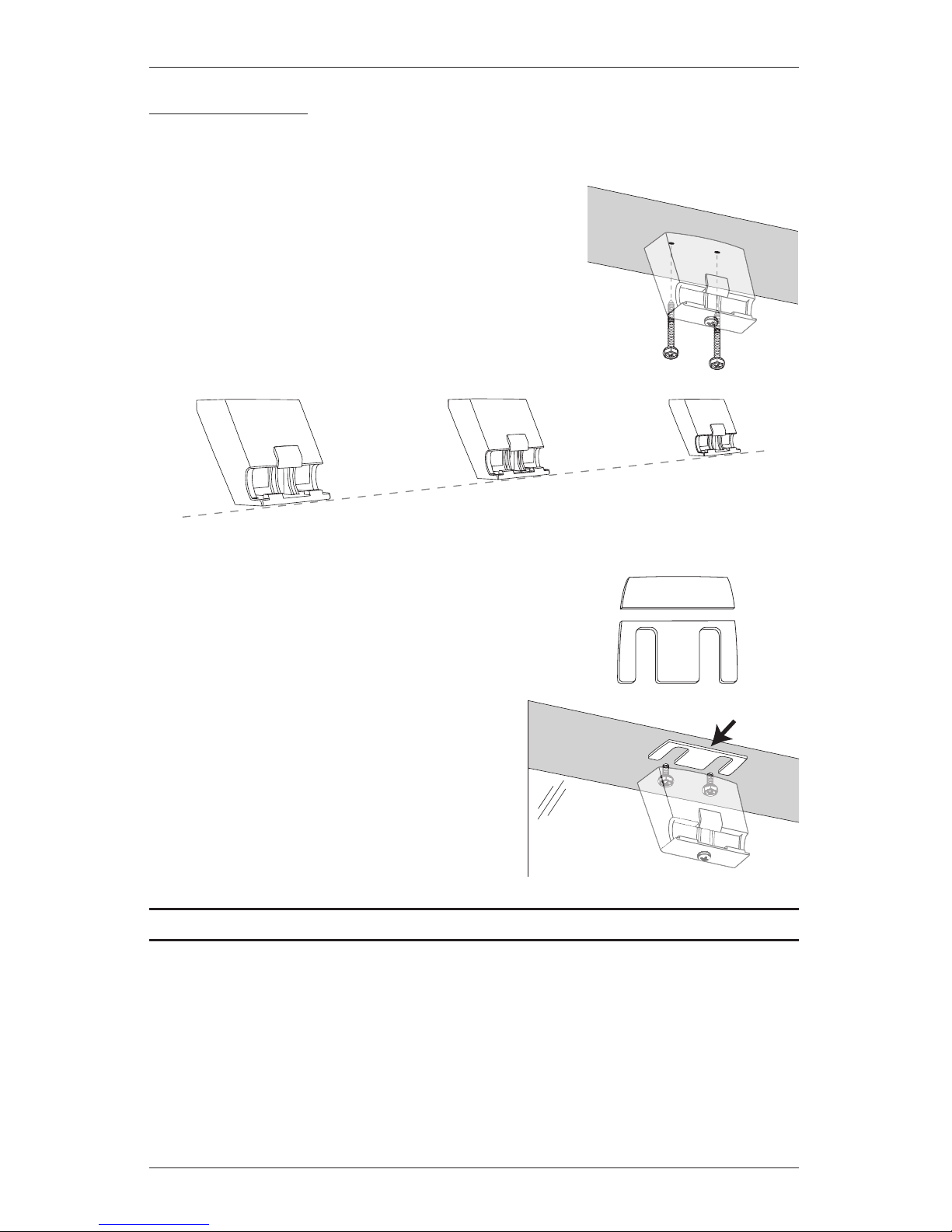

To Shim the Brackets:

■ Snap off the top of the shim for use with inside/ceiling mount

brackets.

■ Use the shims, as needed, between the mounting

surface and the inside/ceiling mount brackets.

Use a laser level as reference.

■ To make further adjustments, you may add

or remove shims by loosening the installation

bracket screws.

Proceed to “Install the SofTrak™ Headrail” on page 12.

Level and

Aligned

Snap Off

Shim

Loosen

screws

to add or

remove shims.

Page 9

INSTALLATION

7

Mount the Installation Brackets — Outside Mount

If you are mounting on corner or bay windows, refer to “Bracket Locations — Corner and Bay

Windows” on page 11 for specific bracket locations. Return to this page after identifying the

bracket locations.

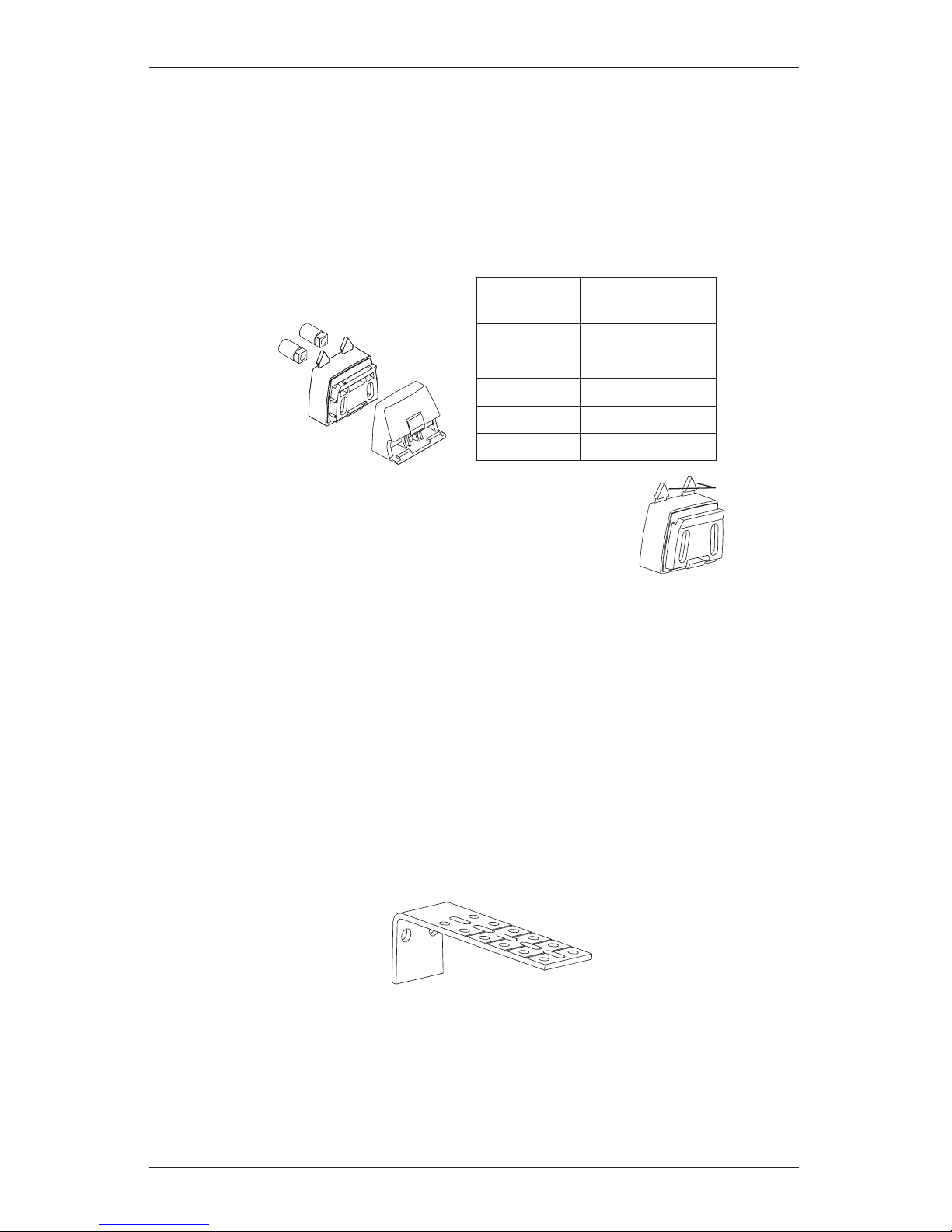

■ Your order will include the appropriate number of installation bracket assemblies. The

number of assemblies required varies with headrail width, as shown below.

IMPORTANT: The spacer blocks have tabs that prevent the

brackets from being mounted too close to the ceiling. If the sheer

will not be mounted at ceiling level, the tabs can be removed.

Adding Clearance

■ Use spacer blocks to add additional clearance. Spacer blocks add clearance in 1/

2

"

increments

.

➤ One spacer block is used with the faceplate for standard installation. Three additional

spacer blocks may be added for an extra 1

1

/2" clearance.

■ Use optional extension brackets to add more clearance.

➤ Extension brackets can provide up to 3

1

/2" clearance.

➤ Indentations are stamped into the extension brackets between each set of holes. Using

the indentations as a guide, you may cut off any unneeded length before mounting the

extension brackets. Each two-hole section is

1

/2" in length.

Headrail

Width

Bracket Assemblies

Required

Up to 40" 2

40

1

/8" – 70" 3

70

1

/8" – 96" 4

96

1

/8" – 155" 6

155

1

/8" – 192" 8

Removable

Tabs

Faceplate

Spacer

Block

Bushings

Outside Mount

Bracket Assembly

Extension

Bracket

Page 10

INSTALLATION

8

Measure and Mark Bracket Locations

■ Position the SofTrak

™

headrail over the window or door opening at the ordered height, found

on the headrail label. Use a pencil to lightly mark each end of the headrail.

➤ Alternatively, measure the width of the headrail and use that width to mark the headrail

end points over the opening.

IMPORTANT: Typically, split stack designs are centered over the opening. However, side

stack designs may be offset to one side if the fabric was intended to stack partially or

completely off the window or door opening. The intended stackback must be taken into

account when marking the headrail end points.

■ Mark 5" from each end of the headrail.

➤ If more than two installation brackets are required (see table on previous page), mark the

locations of additional bracket(s) spaced evenly between the two end brackets.

CAUTION: Installation brackets should be fastened into wood whenever possible. Use drywall

anchors when mounting into drywall. When attaching brackets into drywall, additional brackets

may be required to keep the headrail level after the fabric is attached.

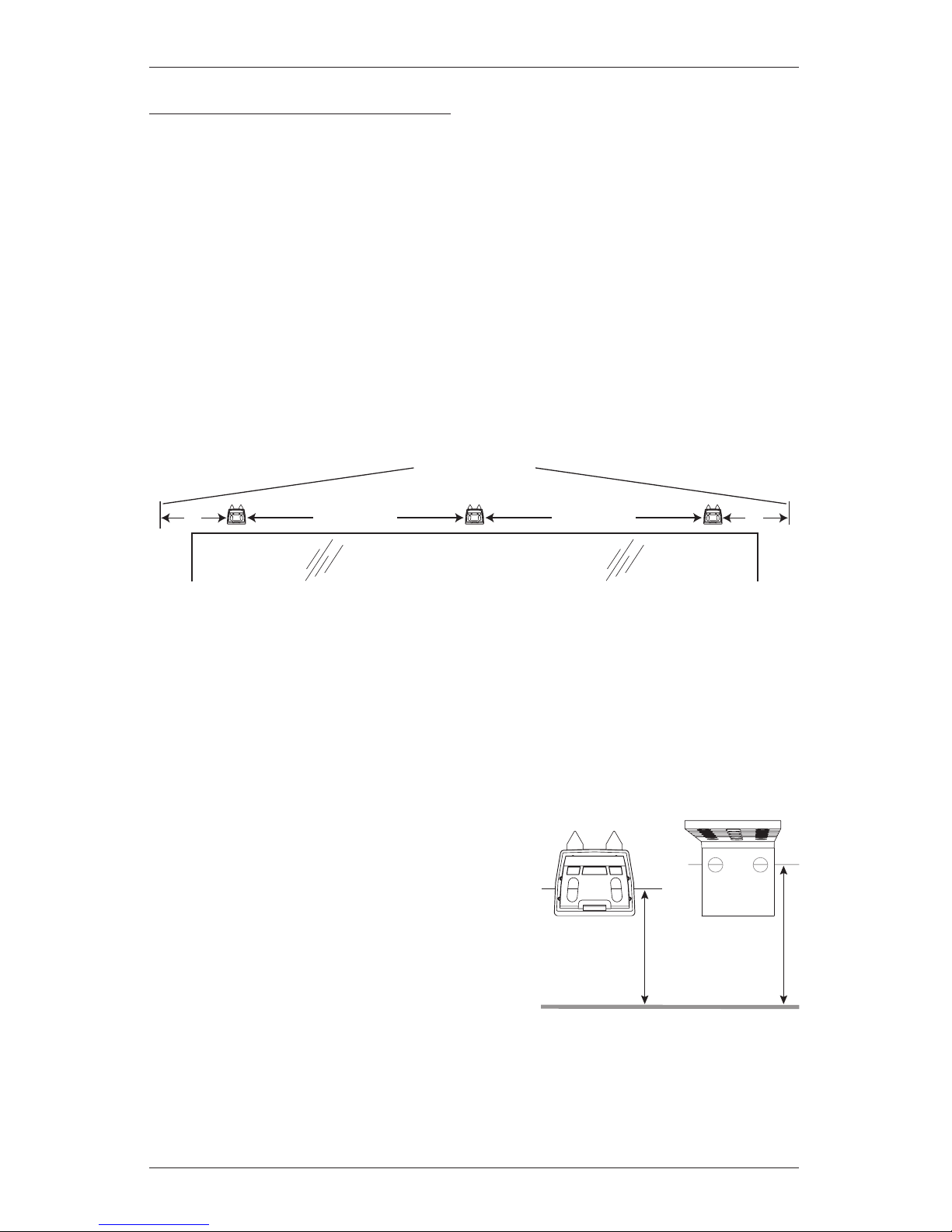

■ Mark the bracket mounting height to allow proper floor clearance for the fabric when

attached to the headrail. This method provides a minimum of

1

/2" floor clearance.

➤ Locate the ordered height on the headrail label.

➤ Spacer Blocks: Measure the ordered height

minus

1

/4" from the floor surface. Mark this

height at each bracket location.

➤ Extension Brackets: Measure the ordered

height plus

1

/4" from the floor surface. Mark

this height at each bracket location.

IMPORTANT: Mount the screws at the

height indicated, or higher for additional

floor clearance. Be sure to clear all floor

obstructions such as carpet, vents, rugs, etc.

Floor Surface

Ordered

Height – 1/4"

Ordered

Height +

1

/4"

Spacer

Block

Extension

Bracket

Headrail End Marks

Window Opening

Space Evenly Space Evenly

5" 5"

Page 11

INSTALLATION

9

■ Mark where to drill holes for the installation screws.

➤ A minimum of 1

1

/8" flat vertical surface is required for spacer block installation and

1

3

/8" flat vertical surface is required for installation with extension brackets.

➤ Align the spacer blocks or extension brackets on your height marks.

➤ Align the outside edge of the end spacer blocks or extension brackets on your bracket

location marks, then mark each of the screw holes. Center any additional brackets on

the bracket location marks to mark their screw holes.

CAUTION: The rear of the spacer blocks or extension brackets must be flush against a flat

mounting surface. Do not mount blocks/brackets oncurved molding.

Mount the Spacer Blocks or Extension Brackets

■ Drill the screw holes using a 3/32" drill bit.

CAUTION: Use drywall anchors when mounting into drywall.

■ Attach the spacer blocks or extension brackets using the

screws provided.

➤ For the spacer block installation, first insert the square end

of the bushings into the slots in the spacer block. Insert the

screws through bushings.

IMPORTANT: With spacer blocks, place the screws in the

middle of the slots to make aligning the brackets easier.

Bushings

Bushings Inserted

5"

Headrail

End Mark

Headrail

End Mark

Screw

Height

Mark

Screw

Height

Mark

5"

Page 12

INSTALLATION

10

➤ For extension bracket installation, you may cut off any unneeded length (before

mounting) at indentations stamped into the brackets between each set of holes. Each

two-hole section is

1

/2" in length.

IMPORTANT: For proper operation, the SofTrak

™

headrail must be mounted level. Use

a laser level to check that the spacer blocks or extension brackets are level and aligned.

Shim the brackets if necessary. The brackets may also need to be shimmed if the mounting

surface is heavily textured.

To Shim the Brackets:

➤ Loosen the installation screws securing

the spacer block or extension bracket.

➤ Insert one or more shims between the

spacer block or extension bracket and

the mounting surface. Tighten the

installation screws.

Finish Bracket Assembly

Spacer Blocks

■ Add any additional spacer blocks required.

IMPORTANT: A maximum of four spacer blocks

can be used.

■ Hook the top of the faceplate to the front spacer

block and snap it into place.

Level and Aligned

Level and Aligned

Loosen

Mounting

Screws

Insert

Shim(s)

1

2

1

2

To Shim

Installation Bracket

To Shim

Extension Bracket

Faceplate

Page 13

INSTALLATION

11

Extension

Bracket

Cover

Extension

Bracket

Extension Bracket

Base Cover

Screws

Speed Nuts

Inside/Ceiling

Mount Bracket

Extension Brackets

■ Slide the base covers onto each extension bracket.

■ If necessary, use scissors to trim the flat bracket cover to length. Slide a cover onto

each bracket.

■ Attach inside/ceiling mount installation brackets using the screws and speed nuts provided.

Proceed to “Install the SofTrak™ Headrail” on page 12.

Bracket Locations — Corner and Bay Windows

■ Mount the spacer blocks or inside/ceiling mount brackets 8" from the corner.

MPORTANT: The ends of the headrails should be located 3"

from the corner.

➤ If additional spacer blocks or extension brackets are used,

the installation brackets must be moved further away from

the corner by the amount of added clearance.

➤ The ends of the headrail must be moved further away from

the corner by the same amount.

■ For bay windows, first center and mount the middle sheer headrail.

➤ Then mount the side sheers so that the abutting ends of the

headrails are the same distance from the bay window angle as

the ends of the middle sheer headrail.

8"

Brackets

5"

8"

5"

Motor

Motor

3"

Page 14

INSTALLATION

12

Install the SofTrak™ Headrail

■ Push up on the locking screws. This raises the

locking tab and makes the headrail easier to install.

■ The grooves on the back of the headrail are designed

to snap into the locking tab on the faceplate and

inside/ceiling mount bracket.

➤ Tilt the front of the headrail (the side with the

pinion clips) up so the top groove fits into the

locking tab on each installation bracket.

■ With the top groove in place on all brackets, tilt

the headrail down so the bottom groove fits into

the bottom tabs on the installation brackets.

■ Position/center the headrail and tighten the locking

screws until snug. Do not overtighten.

Inside Mount and Wall-To-Wall Outside Mount Installations

■ After the SofTrak headrail is installed into the installation brackets, check the clearance at

eachend and make any necessary adjustments.

IMPORTANT: The recommended amount of clearance varies according to the control end

and stack design, as shown below.

Tilt Down

Pinion

Clip

Tighten

Tilt Up

Locking

Tab

SofTrak

™

Headrail

Locking

Screw

Split Stack — Minimum Clearances*

5

/8"

Non-Motor End*

5

/

8

"

Right Stack Design — Minimum Clearances

7

/8"

Non-Motor End

5

/8"

Left Stack Design — Minimum Clearances

5

/8"

Non-Motor End

7

/8"

*Split Stack Design: Motor can be on the right or left, as ordered.

Motor End*

Motor End

Motor End

Page 15

INSTALLATION

13

Side-by-Side (Abutted) Installations (Simulated Split Stack)

A simulated split stack (the fabric opens in the

center) is two side stack systems installed with

the non-control ends side-by-side.

■ Adjust the SofTrak

™

headrails according

to the illustration for proper swivel arm

operation.

IMPORTANT: Be sure to measure the

spacing from end cap to end cap, not from

the swivel arms.

Non-Control

End Cap

Non-Control

End Cap

1

1

/2"

Swivel

Plates

Swivel

Arm

Swivel

Arm

Proper Installation

Simulated Split Stack

Page 16

INSTALLATION

14

Connect PowerView™ Components

Connect the Motor Assembly

■ Remove the orange cover from the drive

assembly, as shown to the right.

■ Align the pins with the holes in the drive

assembly, as shown below. Press the motor

up into the drive assembly until it clicks into

place.

IMPORTANT: If snapping the motor onto

the drive assembly seems difficult, grasp

the lead carrier and pull the carriers slightly

away from the motor, as shown at right.

The motor should now snap in easily.

■ If you remove the motor and need to reinstall it, check the drive assembly and make sure

the tilt gear aligns with the arrows.

➤ If necessary, use a screwdriver to turn the tilt gear until it is aligned.

Aligned Tilt Gear

Page 17

INSTALLATION

15

Connect the DC Power Supply

NOTE: When power is connected to the motor, a green LED inside the manual control button

housing will flash to indicate the sheer is ready.

NOTE: If you ordered an optional large DC power supply, refer to the instructions that came

with the unit.

■ Plug the power cable from the motor into the

extensioncable.

■ Plug the other end of the extension cable into the DC power

supply.

■ Secure the extension cable using the C-clips provided. Hide

the cable behind the fabric, making sure it does not impede

operation.

■ Space the C-clips approximately 15" apart along the

extension cable, as shown.

■ Plug the DC power supply into the power source.

WARNING: Keep cables and small parts

out of the reach of children. They can wrap cables

around their necks and STRANGLE. They can also

put small parts in their mouths and CHOKE.

WARNING: Electric shock and/or afire hazard may

occur if not properlyinstalled.

Test Headrail Operation

■ Use the manual control button on the motor to test the operation of the headrail.

1. Press and hold the manual control button for 6

seconds. The sheer will move slightly.

2. Release the manual control button. The sheer will

move to its fully open position to set the OPEN travel

limit, then move to the fully closed position to set

the CLOSE travel limit. Next, the vanes will rotate

counter-clockwise and then clockwise to set the

rotation limits. The sheer will move slightly one more

time to indicate that the travel limits have been set.

NOTE: There could be up to an 8 second pause between the vanes tilting from counterclockwise to clockwise.

■ Pressing the manual control button while the carriers are traversing or the pinion clips are

rotating will stop the action. The next button press will traverse the carriers or rotate the

pinion clips in the opposite direction.

15"

Maximum

DC

Power

Supply

C-Clip

Extension Cable

Power Cable

Motor

Assembly

Manual

Control

Button

Page 18

INSTALLATION

16

Attach the Fabric Panel(s)

Preparations

■ If necessary, use the manual control button to traverse the fabric carriers to

the fully stacked position.

■ Stand the tube on end on a clean surface with the valance at the top. Position

the tube at the end of the headrail where the fabric stacks.

■ If the tube is too long to stand on end, carefully and safely use a utility knife to

trim the tube to an appropriate length. Do not unroll the fabric until you begin

attaching the vanes to the pinion clips.

CAUTION: Be very careful when trimming the tube to avoid damaging the

fabric in any way.

■ Remove the protective wrapping from the fabric.

Attach the Vanes to the Pinion Clips

■ Unroll the fabric to gain enough slack to attach

the first vane to the pinion clip on the motor

drive assembly.

■ To attach vanes, insert the vane attachment

hole into the clip until it snaps securely in place.

➤ Pull down gently on each vane to ensure

that it is seated properly.

■ Unroll the fabric as you clip the rest of the

vanes into the pinion clips in sequence.

Be careful not to skip any pinion clips

orvanes.

Pinion

Clip

Installed

Vane

Tube

Fabric

Panel

STD R

Vane Attachment

Swivel

Plate

Swivel

Plate

Page 19

INSTALLATION

17

Attach Swivel Plates

■ The end treatments on both ends of the sheer attached with

swivel plates.

➤ Swivel plates are right- and left-specific, marked by

an R or an L. The swivel plates are packaged with the

product’s hardware.

■ Snap the rivet on the swivel plate into the

front clip on the control end cap. Swivel plates

attached on the left will have STD L stamped on

the top. Swivel plates attached on the right will

have STD R on the top.

■ Snap the rivet on the other swivel plate onto the swivel arm (side stack) or into the front clip

on the non-control end cap (split stack). Swivel plates attached on the right will have STD R

stamped on the top. Swivel plates attached on the left will have STD L on the top.

STD R STD L

Swivel Plate

Side Stack

Swivel Arm

Rivet

Swivel Plate

Split Stack

Rivet

Front Clip

Non-Control

End Cap

STD

R

STD

R

Rivet

STD L

Page 20

INSTALLATION

18

Attach the End Treatment(s) to the Swivel Plate(s)

■ Hold the end treatment near the swivel plate at a

height where the end vanes hang straight and the top

of the end treatment is approximately

1

/8" above the

top of the swivel plate.

■ Attach the end treatment by pressing it onto the

swivel plate.

■ If the end treatment is not hanging straight, separate

the swivel plate from the end treatment and reposition

it. Separate the swivel plate by pulling up on the end

treatment while holding the swivel plate in place.

■ Re-attach the end treatment. Repeat the adjustment

as necessary.

Swivel

Plate

Page 21

OPERATION

19

Using the PowerView™ Remote

First, activate the remote by pulling both plastic tabs from the back battery compartment.

IMPORTANT: If you have more than one remote, see “Adding Additional Remote(s) to the

PowerView

™

Shade Network” in the PowerView Motorization Remote Control Guide.

Joining a Sheer to a Group

IMPORTANT: The sheer will not operate using the remote until it has been joined to a group.

1. Press and hold ■ STOP for 4 seconds to put the remote in program mode. The lights on the

remote will flash to indicate it is in program mode.

2. Press the desired group number (1 – 6) on the remote. The backlight for the group number

will flash to show it is selected.

3. Press and hold the manual control button on the motor.

4. While continuing to press the manual button, press ▲ OPEN on the remote. The sheer will

move slightly to indicate it has joined the group. Release the manual control button.

5. Press and hold ■ STOP for 4 seconds to exit program mode. The lights will stop flashing.

Basic Operation

1. To wake up the remote, simply pick it up or press ■ STOP. The last group(s) selected will be

highlighted and active.

2. Press “all” or groups 1 – 6 to select the specific sheer(s) to operate. The group button(s) will

light to show they are selected.

a. Multiple group buttons may be selected at a time.

b. To deselect a group, press the group number again. The backlight for that group button will

go out.

3. Press ▼ CLOSE to traverse the selected sheer(s) closed, covering the opening.

Group 1

Group 2

OPEN

CLOSE

Group 3

Group 4

Group 5

Group 6

Favorite

(Sheer/vane position)

LEFT ARROW

Rotates vanes clockwise

RIGHT ARROW

Rotates vanes counter-clockwise

STOP

(Press and hold for

programming mode)

Page 22

OPERATION

20

4. Press ▲ OPEN to traverse the selected sheer(s) open, uncovering the opening.

5. Press ■ STOP to stop the sheer’s movement anywhere along its travel.

6. Press the right arrow to rotate the vanes counter-clockwise. (If the sheer is not already

drawn closed, pressing this button will close the sheer first and then rotate the vanes.)

7. Press the left arrow to rotate the vanes clockwise. (If the sheer is not already drawn closed,

pressing this button will close the sheer first and then rotate the vanes.)

8. Press ■ STOP to stop vane movement.

9. Press ♥ FAVORITE to send the selected sheer(s) to a preset position. Refer to the PowerView

™

Motorization Remote Control Guide on how to set a favorite position.

Further Operation and Programming Information

PowerView Pebble™ Remote and/or PowerView Surface Remote Operation

For information regarding operation and programming of the PowerView remote, refer to your

PowerView Motorization Remote Control Guide.

PowerView Scene Controller

For information regarding operation and programming of the PowerView Scene Controller, refer

to your PowerView Motorization Scene Controller Guide.

PowerView App Operation

The PowerView Hub is required for PowerView App operation. For information regarding setup

and operation using the PowerView App, refer to the online PowerView App Software Guide at

hunterdouglas.com/powerview/support.

Resetting the Sheer (If Necessary)

Basic Reset

The basic reset is used to set the sheer’s travel limits.

1. Press and hold the manual control button for 6 seconds. The sheer will move slightly.

2. Release the manual control button. The sheer will move to its fully open position to set the

OPEN travel limit, then move to the fully closed position to set the CLOSE travel limit. Next, the

vanes will rotate counter-clockwise and then clockwise to set the rotation limits. The sheer

will move slightly one more time to indicate that the travel limits have been set.

Resetting Shade Programming

This reset erases all programming from memory, including group assignments, preventing any

input device from operating the sheer. Its primary use is during installation to correct group and

network assignments. This reset does not affect travel limits.

1. Press and hold the manual control button for 12 seconds. The sheer will move slightly once

after 6 seconds, then again after 12 seconds. Release the button.

2. Refer to “Joining a Sheer to a Group” on page 19 to program the sheer to a group.

Page 23

OPERATION

21

Troubleshooting

If the sheer is not operating correctly:

■ First review the guide that came with your control device.

■ Refer to the following troubleshooting for specific solutions for your sheer.

If questions remain, please contact Hunter Douglas Consumer Support at

1-888-501-8364.

Problem

The headrail will not fit into the installation brackets.

Solution

Check that the installation brackets are level and aligned. Adjust and/or shim to

level, if necessary.

Check that the SofTrak

™

headrail is completely inserted into the installation

brackets. See “Install the SofTrak Headrail” on page12.

Problem

The sheer does not operate using the manual control button.

Solution

Unplug the power cable from the motor, then plug it back in. A green LED inside

the manual control button housing should flash to indicate the motor has power.

Check that the DC power supply is securely plugged into the wall outlet and that

the outlet has power.

Check that the DC power supply is securely connected to the barrel connector

from the motor. See “Connect the DC Power Supply” on page15.

Problem

The sheer is not responding to the PowerView™ remote.

Solution

IMPORTANT: A sheer will not operate until it is joined to a group.

Check that the correct group number is selected.

Check that the batteries in the remote are correctly inserted andarefresh.

The LEDs that backlight the remote should be bright when ■ STOP is pressed.

Problem

The fabric does not traverse, or does not traverse easily.

Solution

Check that the installation brackets are level, their front edges are aligned, and

there are no obstructions to the movement of the fabric (i.e., the cord is not

caught in thebrackets).

Problem

The fabric end treatment does not hang straight.

Solution

Separate the hook and loop strips. Reposition the end treatment on the swivel

plate. Repeat as necessary until the end treatment hangs straight. See “Attach

the End Treatment to the Swivel Plate” on page 18.

Page 24

OPERATION

22

Problem

The vanes do not rotate or they rotate incorrectly.

Solution

Check that the fabric is fully traversed.

Check that there are no obstructions to the movement of the vanes. Replace

protruding window cranks with T-cranks.

Problem

A vane does not hang correctly.

Solution

Check that the vane is completely inserted into the pinion clip. See “Attach the

Vanes to the Pinion Clips” on page 16.

Problem

A vane is out of alignment.

Solution

Manually turn the pinion clip to align it with the remaining pinion clips.

Problem

The end treatment arm does not swing around the end cap.

Solution

On inside mounts, check that there is clearance between the end of the headrail

and the window casement. See “Install the SofTrak

™

Headrail” on page12.

If the fabric stops before it has fully traversed, reset the system. See “Resetting

the Sheer” on page20.

Problem

The rail makes noise while traversing.

Solution

Check that the installation brackets are level and aligned. Also, check for

obstructions to the movement of the fabric.

From the top of the headrail, pull up

the plastic bead chain to check whether

it is loose. If so, use needlenose pliers

to remove the metal bead, then move

it down a notch and crimp it tightly

closed.

Swivel

Arm

Pull Up

Slack

Metal

Bead

Page 25

CARE

23

Removing the Fabric/ Motor/Headrail

Should you need to remove the fabric, motor, and/or headrail, refer to the following instructions.

Remove the Fabric from the Headrail

IMPORTANT: Make sure you have clean hands or wear disposable gloves when handling

Luminette

®

fabric. Select an area in the home where the fabric can be laid flat. To avoid

wrinkling the fabric, do not fold the fabric or drape it over furniture.

■ Traverse the fabric to the fully stacked position.

■ Detach both end treatments from the ends of the headrail, as shown.

■ Remove the fabric from each pinion clip. Hold the top of the vane near the polytab, and pull

down and to the left.

■ Lay the fabric flat on a clean surface with the vanes facing in the same direction.

■ If the original tube is available, gently roll the fabric onto it, making sure the fabric stays

straight. Do not roll the fabric too tightly.

Remove the Modular Motor

■ Unplug the motor’s power cable from the extension cable to

the DC power supply.

■ There are two methods for removing the motor shown on the

following page. Choose the one that works best for you.

Separate the end treatment

and swivel plate by pulling upward

on the end treatment while

holding the swivel plate in place.

Pinion

Clip

Removing the Fabric Vanes

Polytab

Vane

Page 26

CARE

24

■ Method 1: This method

works best when the fabric

has been removed from the

headrail.

Insert the screwdriver

into the slot on the drive

assembly. Twist about

one-fourth turn to release

the spring-latch, and pull

down gently on the motor

assembly to separate.

■ Method 2: This method

works best when fabric

is still installed on the

headrail.

Insert a hex key into the

side slot on the drive

assembly (either front or

back) to release the springlatch, then pull down gently

on the motor assembly to

separate.

Remove the Headrail

■ With the fabric and motor removed, loosen

and push firmly up on the locking screws of

the mounting brackets until the locking tab

lifts from the headrail.

■ Rotate the headrail down as shown, until

the headrail pops free from the bracket.

Locking Tab

Locking

Screw

Loosen and Push Up

SofTrak

™

Headrail

1

Tilt Down

2

Twist to

Release

Page 27

CARE

25

Cleaning Procedures

The fabric, header, and vane fabric are 100% polyester. They are resilient, anti-static, and dust

resistant. Periodic cleaning is recommended to help keep Luminette

®

Privacy Sheers looking

like new. For all cleaning applications, fabrics should remain hanging to minimize handling,

wrinkling, or puckering.

IMPORTANT: Disposable gloves should be worn when handling fabrics.

CAUTION: Keep all cleaning solutions away from the SofTrak

™

headrail system. Never immerse

the headrail.

Routine Cleaning

■ Use a feather duster for regular light dusting.

■ For more thorough dust removal, a hand-held vacuum with low suction may be used. When

vacuuming, avoid pulling or stretching the fabric.

➤ Start in the upper left corner and work across the fabric using short horizontal strokes

while steadying the fabric with your free hand. Each stroke should be approximately

the width of two to three vanes. Do not use long horizontal or vertical strokes, as these

actions will crease the fabric. Continue to the bottom of the fabric.

CAUTION: Do not use a brush attachment or rigorous vacuuming since either could distort

the fabric.

Electrostatic Cleaning

CAUTION: Do not use electrostatic cleaning devices on any Luminette product.

Spot-Cleaning

To reduce the potential for permanent staining, spots should be treated and cleaned as soon as

possible with a clothing stain pre-treatment solution.

■ Apply the pre-treatment solution to a clean, white cloth.

■ Support the fabric from behind using another clean, dry cloth.

Clean the spot using a gentle

blotting action. Avoid rubbing the fabric since any abrasive action may cause it to distort.

■ Let the area air dry.

■ After the area is dry, remove excess solution by blotting it with distilled or bottled water

applied to another clean cloth.

Deep Cleaning

For deep cleaning, both injection/extraction and ultrasonic cleaning methods are recommended.

CAUTION: Do not dry clean Luminette fabrics.

Page 28

CARE

26

Injection/Extraction Method

Professional injection/extraction cleaning injects a heated cleaning solution into the fabric and

extracts the dirty solution in the same motion. This process is done in the home.

■ Vacuum the fabric following the instructions under “Routine Cleaning” on the previous page,

prior to the injection/extraction cleaning.

■ Have your professional set and maintain their cleaning solution just below steaming.

■ Make sure stains are pre-treated to maximize the benefits of cleaning.

■ When cleaning the vanes from the back, use a 3" upholstery tool and start at the center of

the fabric. Clean one vane at a time from top to bottom working out toward the edge of the

fabric. Repeat for the other half of the fabric.

IMPORTANT: Both sides of each Luminette

®

room-darkening vane need to be cleaned.

This is not necessary on Luminette translucent vanes.

■ When cleaning the face fabric from the front, close the vanes to the right and use a 4"

upholstery tool. Start in the upper left corner, and using short, horizontal strokes (about the

width of three vanes), move across the fabric. Clean from the top to the bottom.

■ Allow the fabric to dry in the fully traversed position with the vanes opened.

■ Steam out any wrinkles.

Ultrasonic Method

Professional ultrasonic cleaning is a process in which the fabric is inserted into a tank of

cleaning solution and then subjected to high frequency vibrations. Dirt is loosened from the

fabric and carried away in the cleaning solution. This process is done outside the home.

■ Ensure the supplier’s ultrasonic tank is long enough to accommodate the full length of the

fabric without folding the fabric or vanes.

■ Ensure the fabrics are rolled onto a tube when being transported to and from the home. This

reduces the chance of wrinkling and damage.

■ Specify water that does not exceed 90° F throughout the process.

CAUTION: If water temperatures exceed 90° F, oxidation will damage the room-darkening

vanes of Luminette room-darkening fabrics.

■ Make sure stains are pre-treated to maximize the benefits of cleaning.

■ Hang fabrics immediately after cleaning with the vanes open and the loops evenly spaced.

Allow the fabric to drip dry completely.

Page 29

CARE

27

Wrinkle and Crease Removal

The steaming methods described below can be used to help minimize hard wrinkles or creases.

Hand Method

■ Rotate vanes to the fully opened position.

■ Apply warm distilled or bottled water to a clean, white cloth.

■ Support the fabric from behind using another clean, dry cloth.

■ Blot the wrinkle or creased area with the wet cloth.

■ Let the area air dry.

Steam Machine Method

■ Rotate vanes to the fully opened position.

■ Steam from the back side of the fabric whenever possible. Set the steamer to its lowest

possible setting, not to exceed 212° F (100° C).

■ The steaming unit should never directly touch the fabric. Hold the wand 2" to 3" away from

the fabric.

■ Use slow, continuous vertical movements. Begin at the top of the fabric and work your

way down.

■ Let the area air dry.

A Note About Textiles

As with all textiles, Luminette® fabrics are subject to some variations.

■ The fabric will change as its position changes.

■ Minor wrinkles, puckers, or other variations can appear and are inherent to this textile

product.

■ Such variations, like those just mentioned, are normal, acceptable quality.

Additional Product Enhancements

■ Luminette face fabric is available by the yard in widths up to 123", for creating such

accessories as top and side treatments, specialty shapes, table rounds, and bed skirts.

■ Add coordinating Silhouette

®

window shadings, Pirouette® window shadings, and Vignette®

Modern Roman Shades where applicable. The Whole House Solution

™

program lists

coordinating colors to make it easy to order these window fashions for installation in the

same room with Luminette fabrics. Contact your dealer for additional information.

Page 30

DECLARATIONS

28

U.S. Radio Frequency FCC Compliance

FCC ID information is located on a label affixed to the modular motor assembly.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

Industry Canada

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type

and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential

radio interference to other users, the antenna type and its gain should be so chosen that the equivalent

isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

Class B Digital Device Notice

This Class B digital apparatus complies with Canadian ICES-003, RSS-Gen and RSS-210.

CAN ICES-3 (B)/NMB-3(B)

European Conformity

We, the undersigned,

Hunter Douglas Window Fashions

One Duette Way, Broomfield, CO 80020, USA

Hunter Douglas Europe B.V.

Piekstraat 2, 3071 EL Rotterdam, The Netherlands

certify and declare under our sole responsibility that assembly PV3 conforms with the essential

requirements of the EMC directive 2004/108/EC and R&TTE directive 1999/5/EC.

A copy of the original declaration of conformity may be found at:

www.hunterdouglas.com/RFcertifications.

Page 31

Page 32

135103641 9/16

The Hunter Douglas® Lifetime Guarantee is an expression of our desire to provide a thoroughly satisfying

experience when selecting, purchasing and living with your window fashion products. If you are not thoroughly

satisfied, simply contact Hunter Douglas at (888) 501-8364 or visit hunterdouglas.com. In support of this policy

of consumer satisfaction, we offer our Lifetime Limited Warranty as described below.

NOTE: In no event shall Hunter Douglas or its licensed fabricators/distributors be liable or responsible for incidental

or consequential damages or for any other indirect damage, loss, cost or expense. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

Different warranty periods and terms apply for commercial products and applications.

Hunter Douglas (or its licensed fabricator/distributor) will repair or replace the

window fashion product or components found to be defective.

COVERED

BY A LIFETIME LIMITED WA RRANTY

• Hunter Douglas window fashion products are

covered for defects in materials, workmanship

or failure to operate for as long as the original

retail purchaser owns the product (unless shorter

periods are provided below).

• All internal mechanisms.

• Components and brackets.

• Fabric delamination.

• Operational cords for a full 7 years from the

date of purchase.

• Repairs and/or replacements will be made with

like or similar parts or products.

• Hunter Douglas motorization components are

covered for 5 years from the date of purchase.

NOT COVERED

BY A LIFETIME LIMITED WA RRANTY

• Any conditions caused by normal wear and tear.

• Abuse, accidents, misuse or alterations to the

product.

• Exposure to the elements (sun damage, wind,

water/moisture) and discoloration or fading

over time.

• Failure to follow our instructions with respect

to measurement, proper installation, cleaning

or maintenance.

• Shipping charges, cost of removal and reinstallation.

TO OBTAIN WARRANTY SERVICE

1. Contact your original dealer (place of purchase) for warranty assistance.

2. Visit hunterdouglas.com for additional warranty information, frequently asked questions and access to service locations.

3. Contact Hunter Douglas at (888) 501-8364 for technical support, certain parts free of charge, for assistance in obtaining

warranty service or for further explanation of our warranty.

Loading...

Loading...