Page 1

ALPHA AWNING

SERIES

INSTALLATION AND MEASURING GUIDELINES

(INCLUDES THE SRS V2)

11/2019

Page 2

ALPHA AWNING SERIES INSTALLATION MANUALALPHA AWNING SERIES INSTALLATION MANUAL

Hunter Douglas Limited

Australia

PRODUCT MANUAL

INFORMATION

MEASURING AND INSTALLATION MANUAL ONLY.

PLEASE REFER TO YOUR ONLINE PORTAL FOR THE

UPDATED VERSION.

This Product Manual is only a guide to the measurement and installation.

Hunter Douglas Limited does not warrant the accuracy contained in this manual.

The information contained in this Product Manual is based on the measurement and installation

data known to us at the time of issue of the Product Manual and is therefore subject to changes

or amendments at any time without notice, and the right to change or amend is hereby expressly

reserved by Hunter Douglas Limited.

IMPORTANT

This Product Manual at all times remains the property of Hunter Douglas Limited.

Its contents are strictly confidential and may not be reprinted, copied, reproduced or multiplied in any

form. This Product Manual must be maintained in its original form and must be returned to Hunter

Douglas Limited upon first request. Hunter Douglas Limited is not responsible to you or anyone else

for any loss suffered in connection with the use of this product manual or any of the content.

© Copyright 2019 Hunter Douglas Limited [ABN 98 009 675 709] •18.016.085 •11/19

® Registered Trade Marks of Hunter Douglas Limited Somfy is a registered trade mark of SOMFY Pty Limited

DISCLAIMER ISSUED: NOVEMBER 2019

SAFETY & WARNING ADVICE

Page 2

Page 3

ALPHA AWNING SERIES INSTALLATION MANUAL

Safety and Warning Advice + General Advice .... 2

Fixings .......................................................... 3

Characteristics of Awning Fabrics ................... 4

Options and Limitations .................................. 5

Component Dimensions ................................. 6

INSTALLATION

Open Roller Installation ................................ 7

• Flow Chart .......................................................... 7

• Installation Instructions ........................................ 8

Headbox Installation ................................... 9

• Flow Chart ......................................................... 9

• Installation Instructions ..................................... 10

Installing the Roller Tube ........................... 12

• Flow Chart ....................................................... 12

• Installation Instructions ..................................... 13

ALPHA SRS V2 (Side Retention System)

Awning ....................................................... 22

• Exploded view diagram .................................... 22

• Flow Chart ....................................................... 23

• Installation Instructions

ALPHA Deep Channel Awning ................. 30

• Exploded view diagram .................................... 30

• Flow Chart ....................................................... 31

• Installation Instructions

ALPHA Pivot Arm Awning ......................... 34

• Exploded view diagram .................................... 34

• Flow Chart ....................................................... 35

• Installation Instructions

Pretensioning the Spring for Literise/Light Lift

Pretensioning the Spring for Literise/Light Lift .....38

Pretension Chart

..................................... 24

..................................... 32

..................................... 36

.......................................... 39

ALPHA Straight Drop Awning ................... 15

• Exploded view diagram .................................... 15

• Flow Chart ....................................................... 16

• Installation Instructions

ALPHA Cable Guide Awning .................... 18

• Exploded view diagram .................................... 18

• Flow Chart ....................................................... 19

• Installation Instructions

..................................... 17

..................................... 20

ALPHA Linking Option .............................. 40

• Exploded view diagram .................................... 40

• Flow Chart ....................................................... 41

• Installation Instructions

..................................... 42

USER INFORMATION

Operating Instructions .................................. 46

MEASURING INSTRUCTIONS

On Face Architrave ....................................... 46

Reveal and Top Fix (Side Fix) ........................ 48

Contents

Page 1

Page 4

ALPHA AWNING SERIES INSTALLATION MANUAL

SAFETY AND WARNING ADVICE

A minimum of 2 people are necessary for proper installation.

PLEASE NOTE:

Installation fixings will NOT be supplied with any of the ALPHA Awning Series.

Please refer to fixing section. Each installation should be assessed on a case by case scenario.

WARNING! – The brackets must be fixed solidly to a substantial surface. Hollow bricks or foam

products are not suitable. Brick veneer surfaces require at least 2 courses of brickwork above the

bracket and 2 courses below.

GENERAL ADVICE

The electrical data is shown on the label of electric operating awnings.

Tools: The following tools are required for installation:

• Level

• Battery Drill

• Screwdrivers

• Hammer Drill

• Drill Bits

• Spanner - 7mm (size of open end spanner for top aligner)

• Allen Key

Page 2

Page 5

ALPHA AWNING SERIES INSTALLATION MANUAL

FIXINGS

Due to possible differences in specification, application and interpretation of results, users must

make their own evaluation of the product to determine the suitability of fixings and their intended

use.

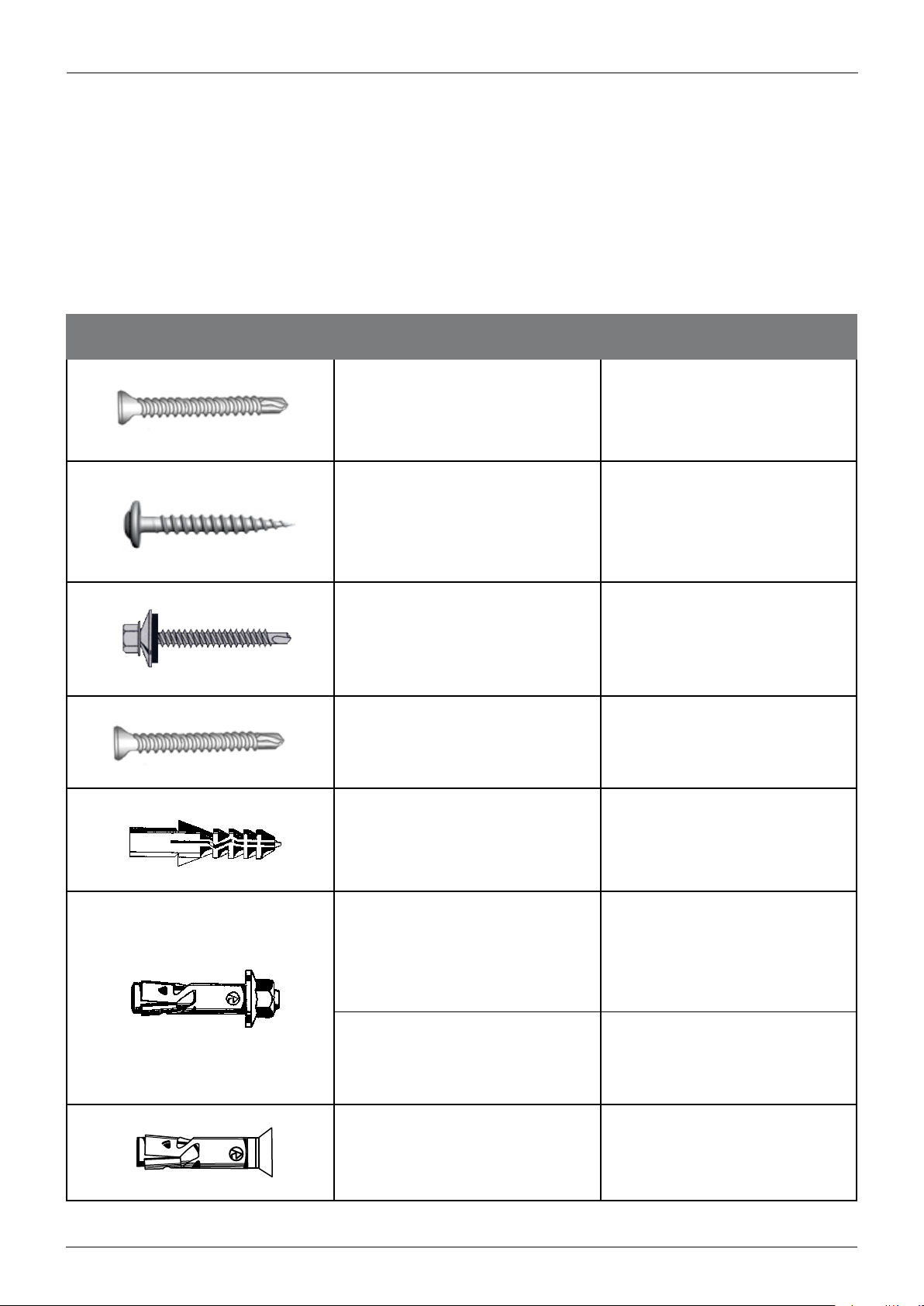

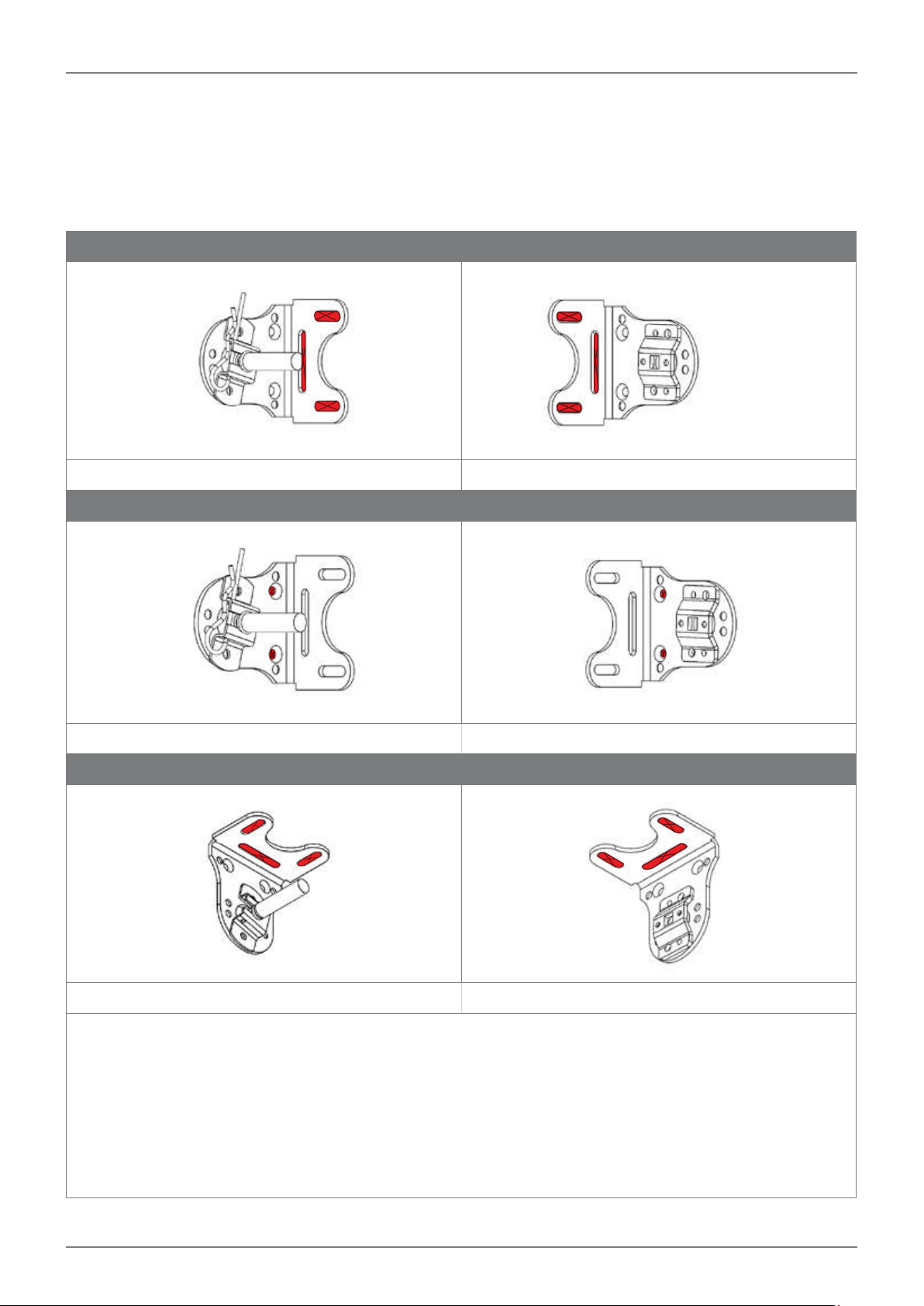

ITEM TITLE DESCRIPTION

Counter Sunk (Zenith)

10g x 50mm

Available in Metal or Timber thread

Stainless

Waffer/Button Head (Buildex)

8g x 50mm

Available in Metal or Timber thread

Used to side fix channels.

Used to face fix channels.

Roofing & Cadding

Hex Head (Buildex)

12g x 50mm

Available in Metal or Timber thread

Counter Sunk (Zenith)

10g x 50mm

Available in Metal or Timber thread

Stainless

Ramplug/Green Plug (Ramset)

50mm Length

Dyna Bolt (Ramset)

6m x 30mm

Dyna Bolt (Ramset)

8mm x 50mm

Used to fix universal brackets.

Used to fix wire guide bottom

bracket.

Used to fit to brick or concrete

Used to face fix channels.

Used to fix universal brackets.

Counter Sunk (Ramset)

4.5mm x 30mm

Stainless

Page 3

Used to fix wire guide bottom

bracket.

Page 6

ALPHA AWNING SERIES INSTALLATION MANUAL

CHARACTERISTICS OF AWNING FABRICS

Some slight fabric curling may occur on fabric edge on large applications, whilst the following

characteristics are considered normal occurrences.

• Creasing (Figs. 1, 2)

• Puckering (Figs. 3, 4 & 5)

• Tension Induced Stretching (Figs. 6)

WARRANTY

Conditions apply. See www.hunterdouglas.com.au for Warranty document.

Page 4

Page 7

ALPHA AWNING SERIES INSTALLATION MANUAL

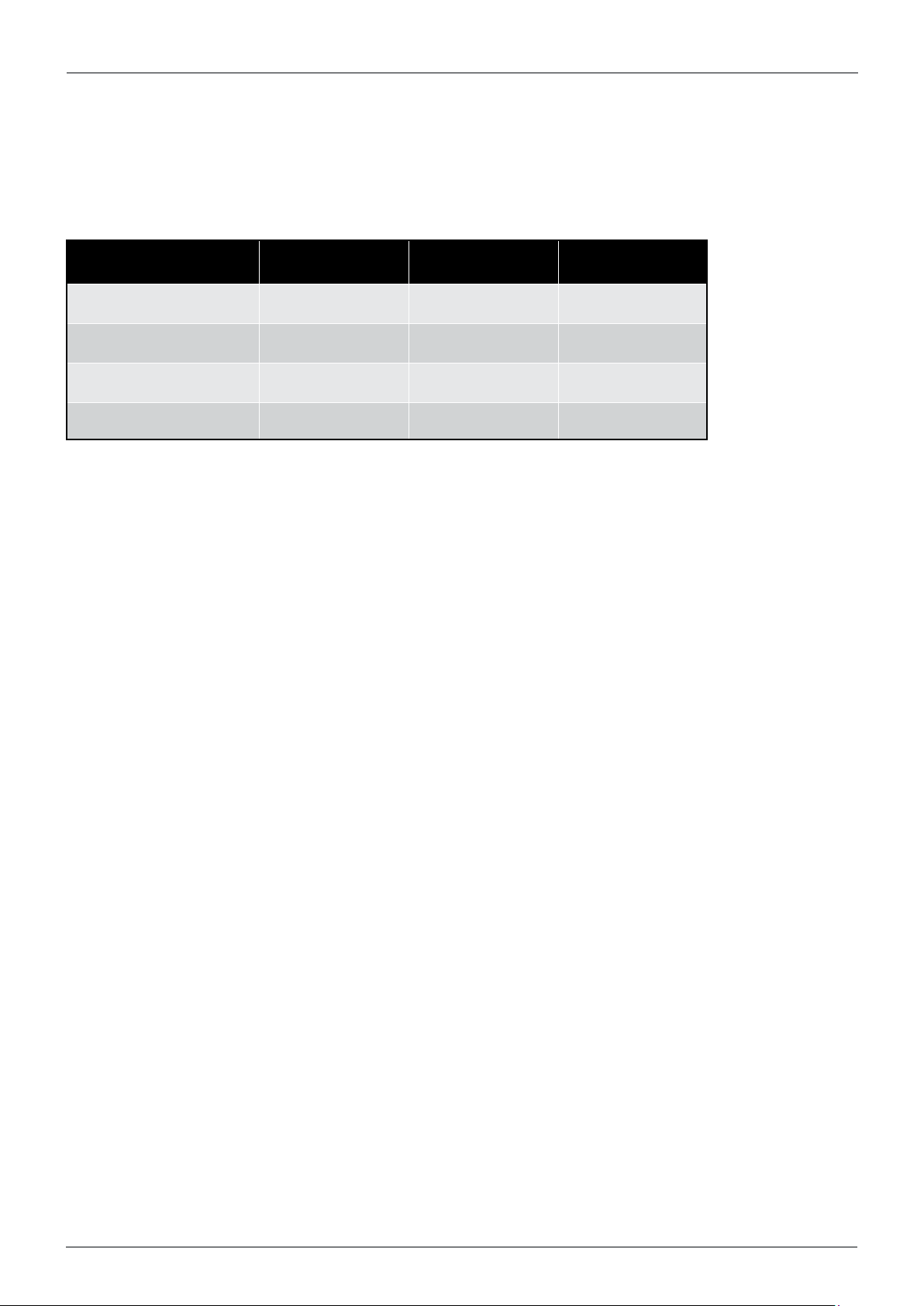

OPTIONS AND LIMITATIONS

CRANK GEAR MOTORISED INTERNAL CORD

OVERALL MAX WIDTH 5000mm 5000mm 3500mm

OVERALL MAX DROP 4000mm 4000mm 2900mm

OVERALL MIN DROP 300mm 300mm 300mm

MAX AREA 16 Sqm 16 Sqm 10 Sqm

MEASURING INSTRUCTIONS

Accurate measuring of the ALPHA Awning Series is vital for successful fitting and consequential

use. The product can be fitted on Face, Side or Ceiling fixing applications and can be operated by

crank, cord or motorised.

2mm deduction for Reveal Installs

Face Fit Supplied Overall Size

+/- 2mm Manufacturing Tolerance

Page 5

Page 8

ALPHA AWNING SERIES INSTALLATION MANUAL

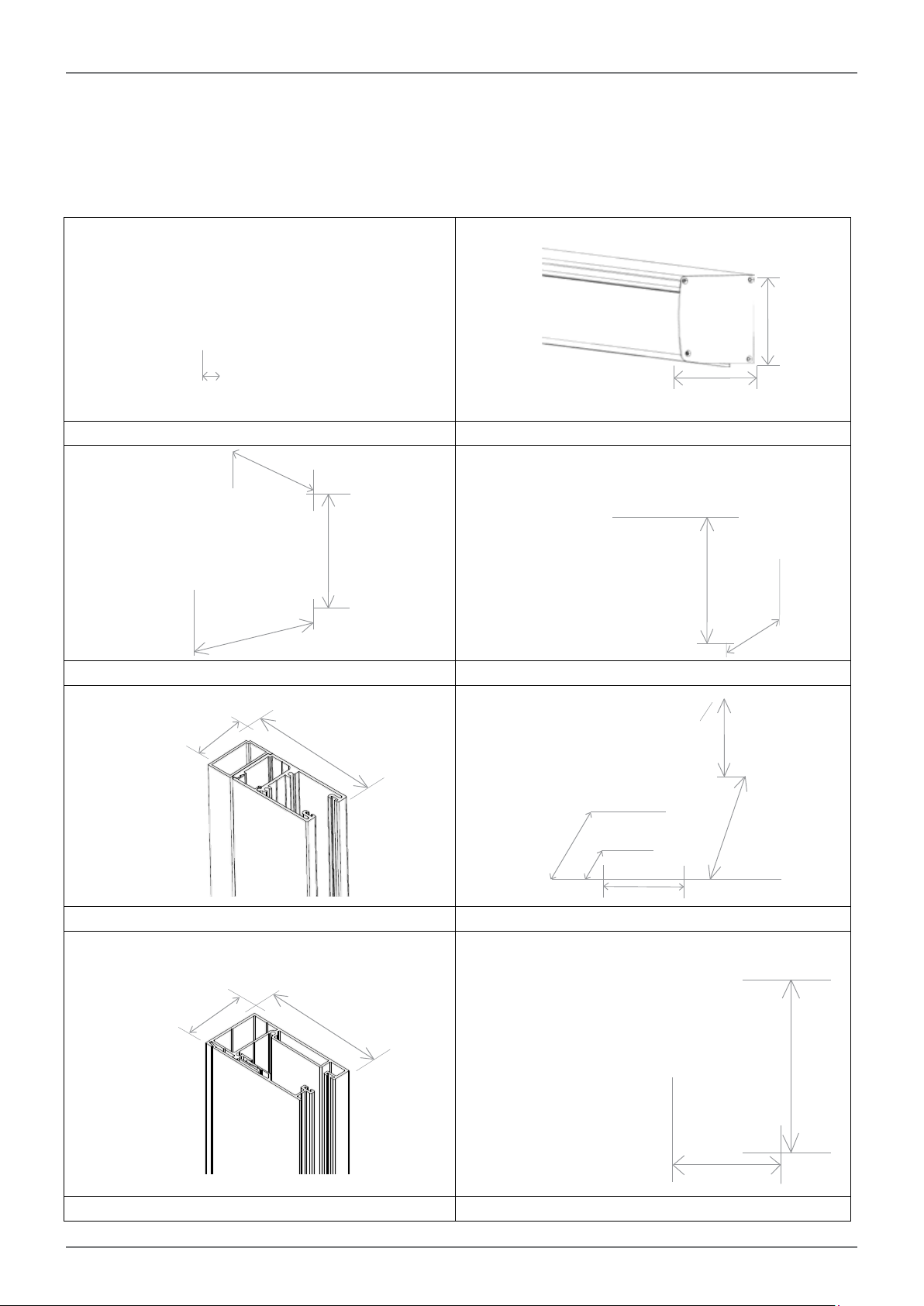

COMPONENT DIMENSIONS

125mm

14.7mm

130mm

CABLE GUIDE HEADBOX

68mm

100mm

50mm

100mm

UNIVERSAL INSTALLATION BRACKET BOTTOM RAIL

33.5mm

81mm

37mm

16mm

30mm

30mm

52mm

Page 6

23mm

DEEP CHANNEL BOTTOM CABLE BRACKET

37.5mm

73mm

ALPHA SRS V2 PIVOT ARM FRONT RAIL

50mm

33mm

Page 9

ALPHA AWNING SERIES INSTALLATION MANUAL

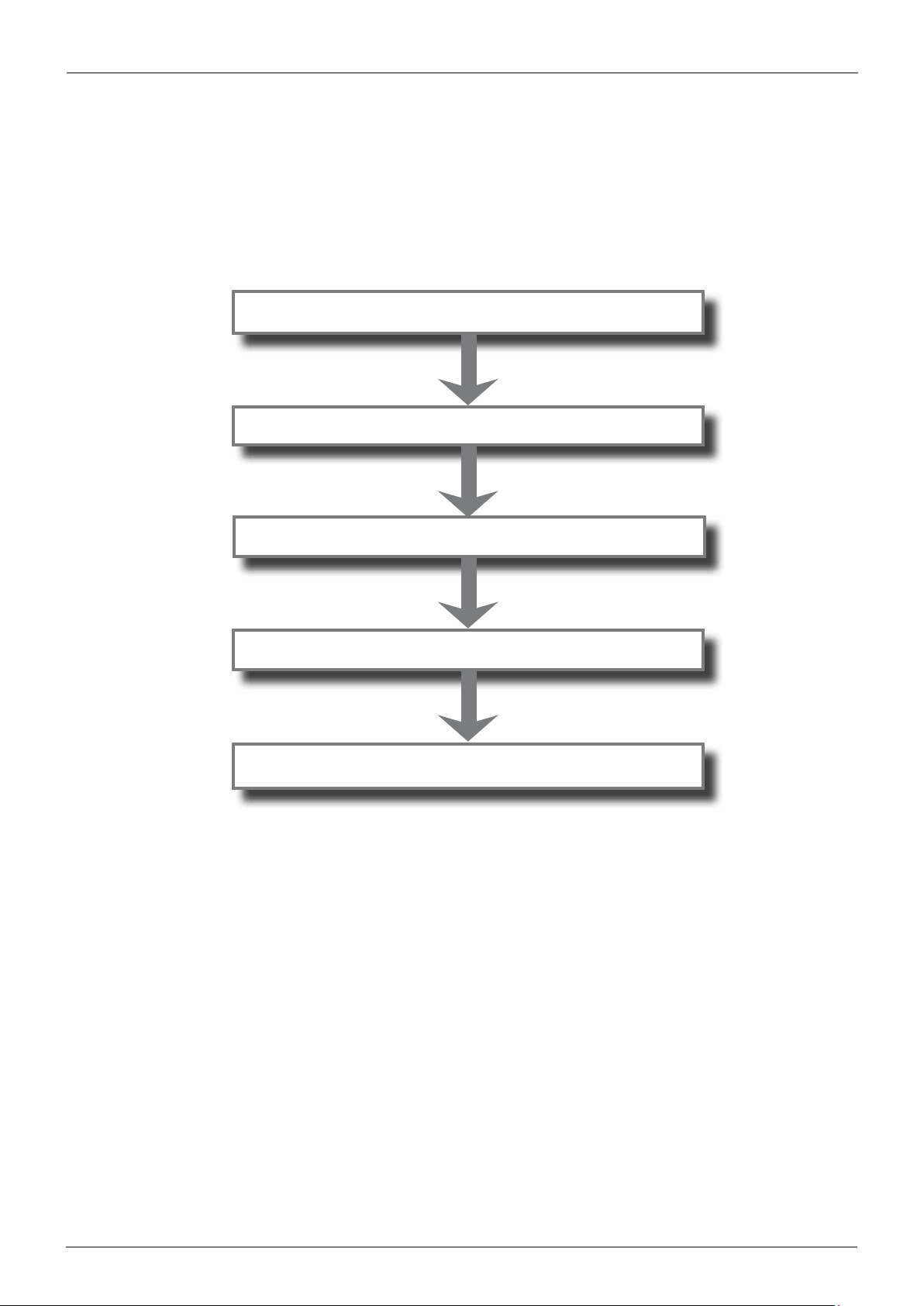

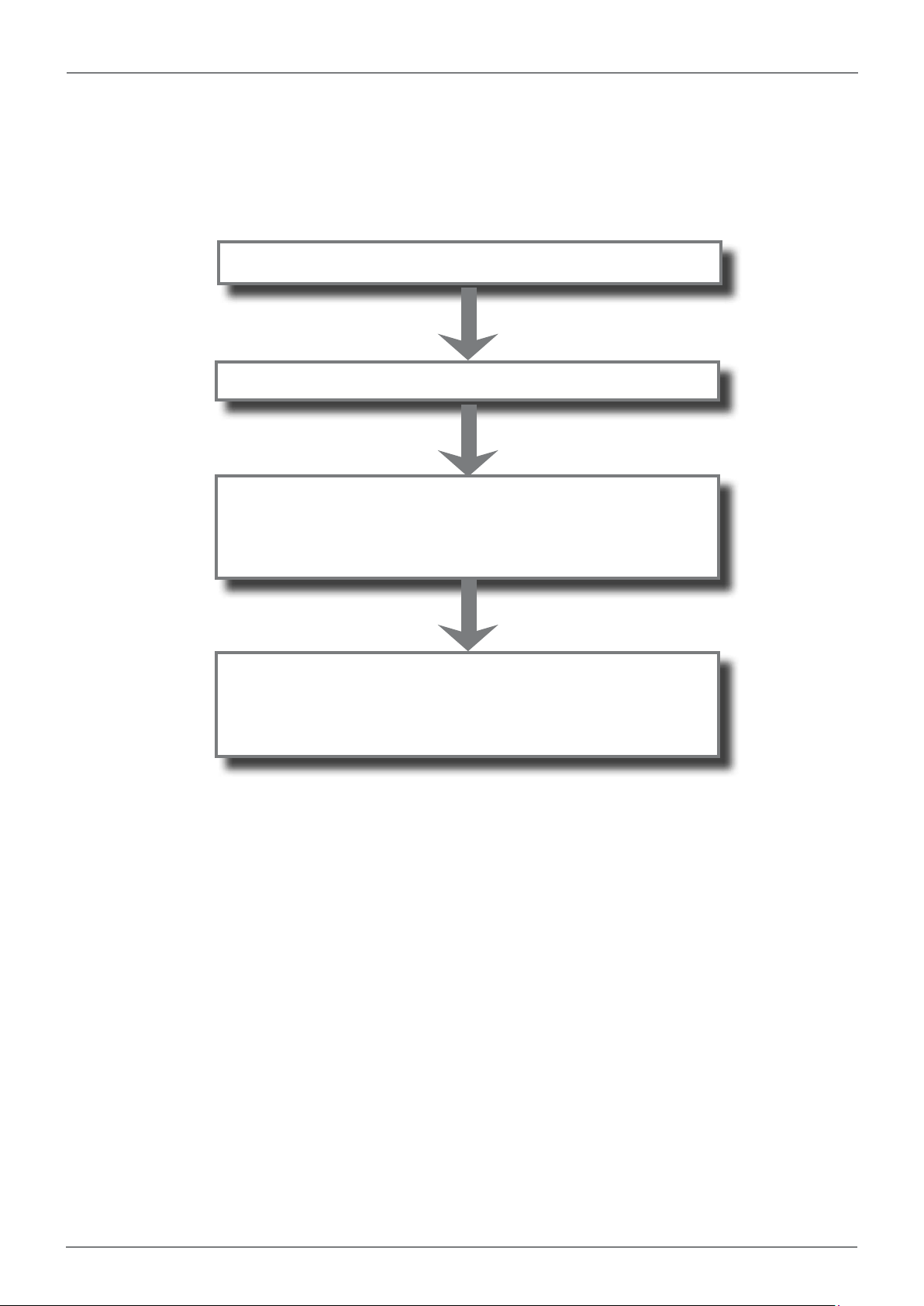

OPEN ROLLER INSTALLATION

STEP 1 - MARK FIXING HOLES FOR THE FIRST BRACKET

STEP 2 - DRILL FIXING HOLES

STEP 3 - INSTALL THE FIRST BRACKET

STEP 4 - MEASURE OVERALL WIDTH

STEP 5 - REPEAT STEPS 1,2 & 3 FOR

THE SECOND BRACKET

Page 7

Page 10

ALPHA AWNING SERIES INSTALLATION MANUAL

OPEN ROLLER INSTALLATION

STEP 1/2/3 - FACE FIT INSTALL

IDLE END DRIVE END

REVEAL FIT INSTALL

IDLE END DRIVE END

CEILING FIT INSTALL

IDLE END DRIVE END

Brackets will come pre-assembled with idle and drive end components attached. The orientation of these components

on the brackets will be determined by the fixing orientation specified on the order form. Example: Face/Reveal, Ceiling.

- Mark the fixing holes for the first bracket.

- Drill holes to suit the method of fixing determined by the substrate being fixed to.

- Screw the first bracket in place. Ensure the bracket is installed straight using a spirit level. If required, pack out

the bracket.

- Repeat process for the second bracket.

- Ensure both brackets are installed level and the distance apart is enough for the roller tube to be inserted. The

distance between the brackets should be the ordered overall measurement from outside of bracket to outside of

bracket.

Page 8

Page 11

ALPHA AWNING SERIES INSTALLATION MANUAL

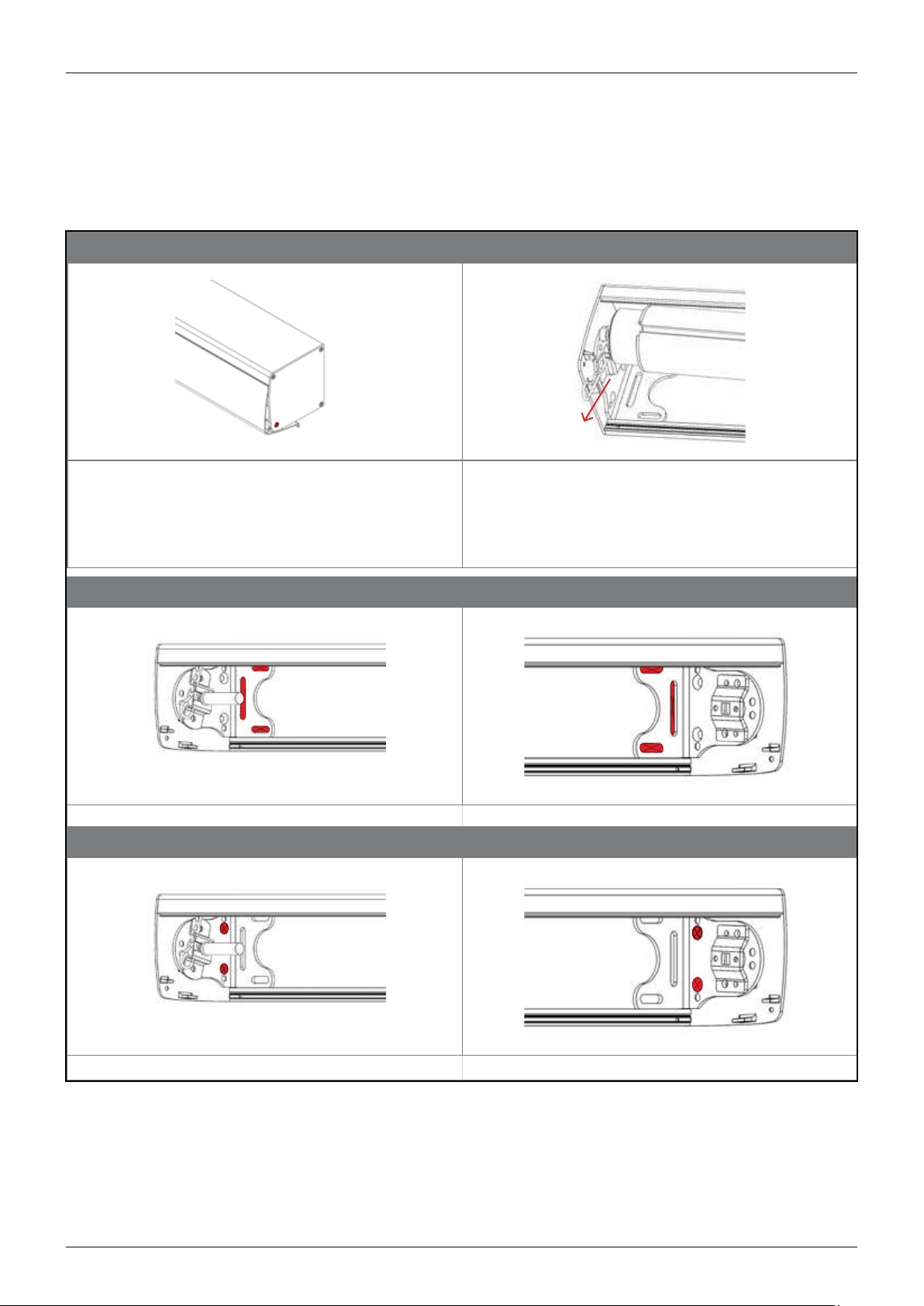

HEADBOX INSTALLATION

STEP 1 - OPEN THE HEADBOX

STEP 2 - REMOVE ROLLER TUBE

STEP 3 - MARK & PRE DRILL HEADBOX BACK PANEL

- MARK FIXING HOLES ON INSTALLATION SURFACE

- DRILL FIXING HOLES ON INSTALLATION SURFACE

- INSTALL HEADBOX THROUGH BRACKETS

ACCESSORIES

INSTALLATION SPREADER PLATE

PLEASE REFER TO RELEVANT SECTION FOR INSTRUCTIONS

Page 9

Page 12

ALPHA AWNING SERIES INSTALLATION MANUAL

HEADBOX INSTALL

STEP 1 - OPEN THE HEADBOX STEP 2 - REMOVE ROLLER TUBE

Open the headbox front cover by unscrewing the bottom

screw on the headbox end cap. Repeat on opposite side.

NOTE: For reveal fit the screw is no longer required.

STEPS 3 - FACE FIT

IDLE END DRIVE END

STEPS 3 - REVEAL FIT INSTALL

Pull out the idle end locking pin and remove the roller

tube idle end first.

Page 10

IDLE END DRIVE END

Page 13

ALPHA AWNING SERIES INSTALLATION MANUAL

STEPS 3 - CEILING FIT INSTALL

IDLE END DRIVE END

Mark and drill the head box back plate where the fixings will go.

NOTE: Always secure the headbox back panel through the installation brackets or spreader plate!

• After determining the exact position of the headbox you can fasten the brackets and headbox on the installation

surface.

• Mark the fixing holes for the first bracket.

• Drill holes to suit the method of fixing determined by the substrate being fixed to.

• Secure installation screw in bracket to hold one side of head box.

• Repeat the process for the opposite bracket and ensure that the head box is straight using a spirit level.

NOTE: If required pack out the headbox.

• Once satisfied the headbox is level, secure remaining fixing points.

NOTE: For awnings over 3500mm wide, add an additional fixing point through the centre of the headbox back panel.

E.g 3500mm wide secure at 1750mm.

ACCESSORIES REVEAL FIT - HEADBOX COVER INSTALL

D4.5mm

6.0mm

D4.5mm

45mm

6.0mm

SPREADER PLATE OPEN HEADBOX CLOSED HEADBOX

If there is no substantial fixing point at the ends

of the headbox, a Spreader Plate can be added.

This allows 250mm of flexibility for installation

points at each end of the awning. If a spreader

plate is ordered, this will come preassembled to

A 4.5mm hole needs to be drilled in the headbox cover in

REVEAL applications. Location of hole, refer to diagram above.

the bracket inside the headbox determined by the

installation type specified. Secure through Fixing

points highlighted in the image.

Page 11

Page 14

ALPHA AWNING SERIES INSTALLATION MANUAL

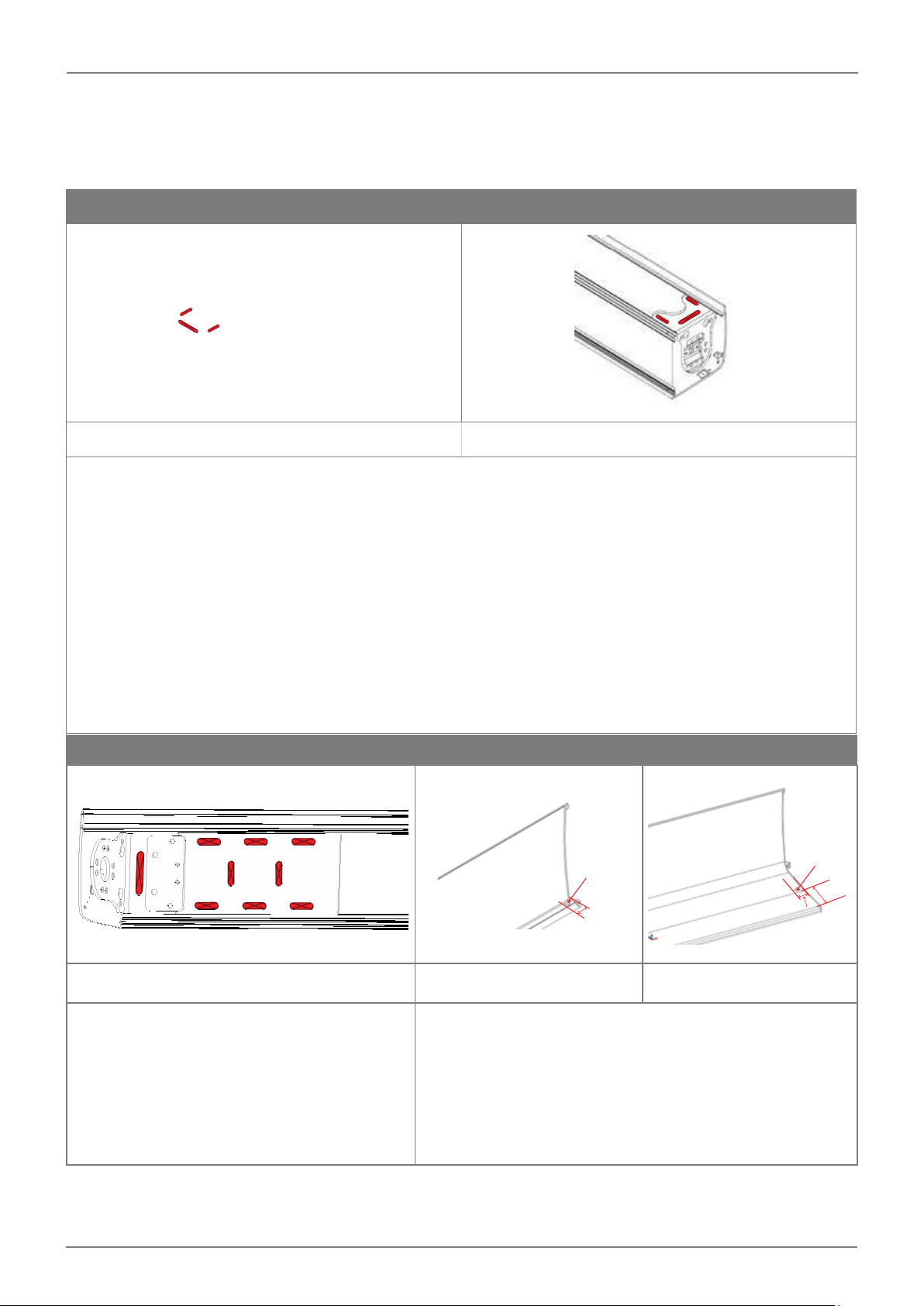

INSTALLING THE ROLLER TUBE

STEP 1 - INSTALL THE DRIVE END

STEP 2 - INSTALL THE IDLE END

OPTIONAL: STEP 3 - ATTACH THE HEADBOX FRONT COVER

OPTIONAL: INTERNAL TAPE WINCH INSTALLATION

INSTRUCTIONS

Page 12

Page 15

ALPHA AWNING SERIES INSTALLATION MANUAL

INSTALLING THE ROLLER TUBE

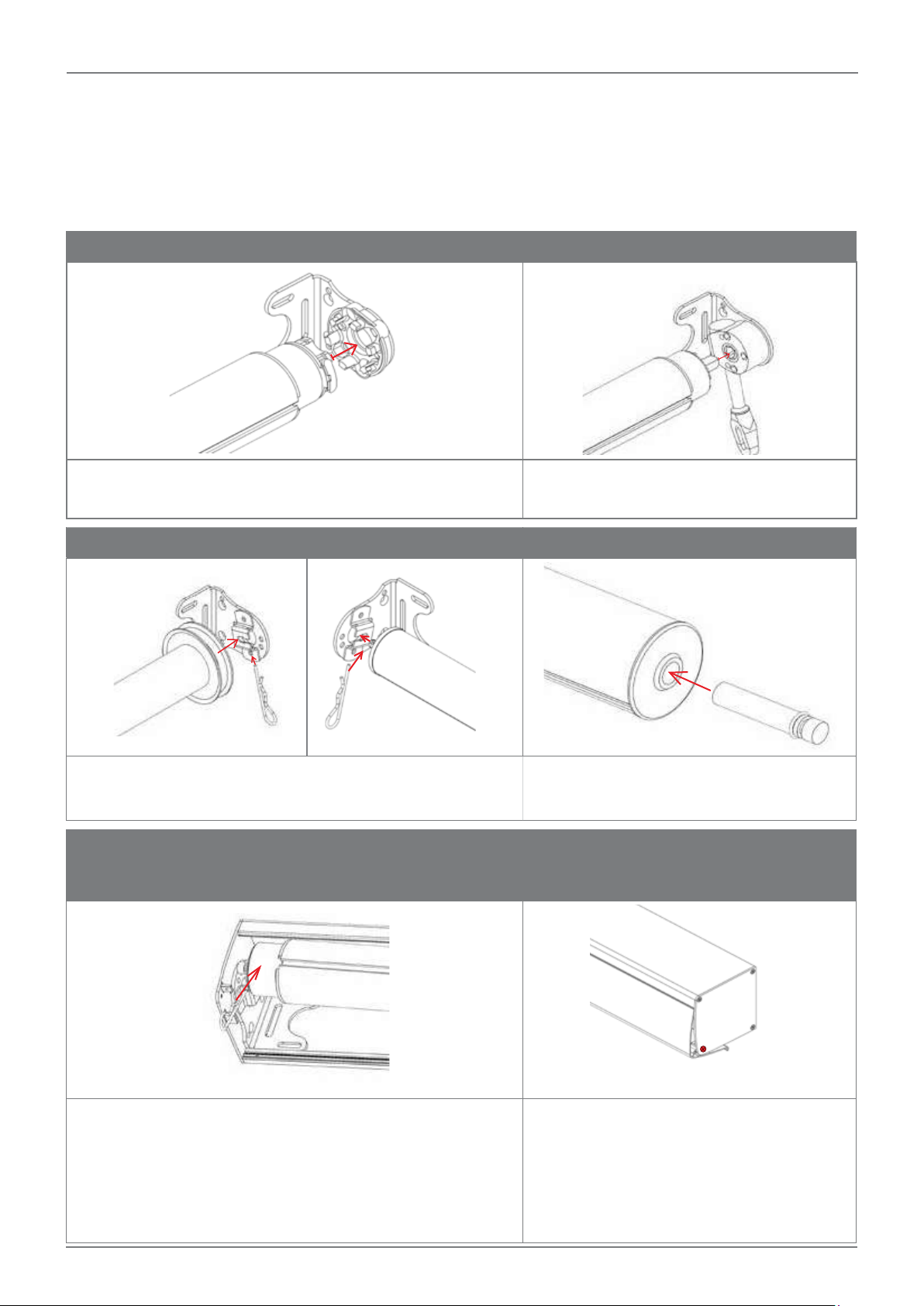

STEP 1 i - MOTORISED STEP 1 ii - CRANK

Motorised – Insert motor into motor bracket then secure using

motor clip

STEP 1 iii - INTERNAL TAPE WINCH

Internal Tape Winch – Insert pin into spring plate and use locking

pin to secure.

STEP 2 B - INSTALL THE ROLLER

Crank – insert crank pin into crank gear

STEP 2 A - INSERT PIVOT PIN

Insert Pivot Pin into idle end on tube.

OPTIONAL: STEP 3 - ATTACH THE

HEADBOX FRONT COVER

Lift Roller over the installation bracket and down so pivot pin sits

inside the pivot plate. Insert idle locking pin to secure roller.

*Operate the awning a couple of times to ensure tracking and correct operation of the awning.

Page 13

Once satisfied, reattach the headbox front

cover.

Page 16

ALPHA SERIES INSTALLATION MANUAL

ALPHA AWNING SERIES INSTALLATION MANUAL

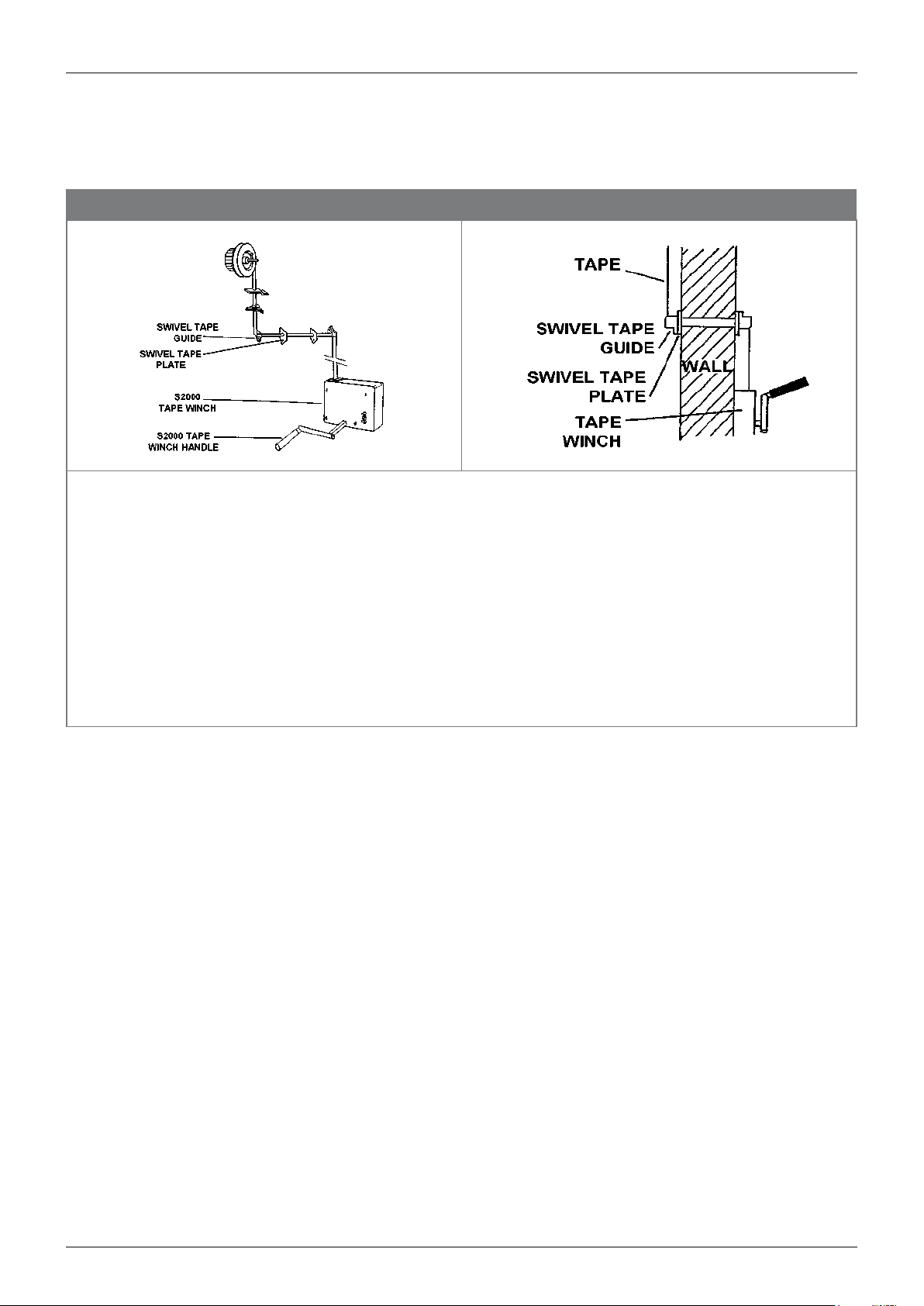

INTERNAL TAPE WINCH INSTALL INSTRUCTIONS

Fitting Internal Tape Winch

- Unscrew the cover of the internal tape winch and note the direction in which the tape runs off the spool.

- Remove the tape supplied with the winch.

- Thread the tape from the awning tape spool through the two swivel tape guides. Attach swivel tape guides to the

internal and external walls. Lower the awning.

- Thread the end of the tape through the slot on the tape winch spool. Cut the tape so that only 1 - 2 windings will

remain on the spool. Tie a secure knot in the end. Wind the excess tape on to the spool. Replace the spool in the

winch ensuring that the tape winds off in the correct direction. Screw cover back on to winch.

- Drill four (4) holes in the wall for the winch and fit rawl plugs supplied or use the fastener appropriate for the

installation. At least two of the screws should be set into an architrave or stud. All four screws must be used. If

necessary add packing behind the winch if attaching to an uneven surface.

- Test the awning to see if it functions properly.

Page 14

Page 17

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA STRAIGHT DROP

2

5

6

3

1

7

8

19

9

4

17

16

12

13

14

15

18

11

10

No Part Description

1 46.608.XXX HEADBOX END CAP LH & RH

2 46.005.XXX HEADBOX BACK PLATE

46.012.XXX*

3

46.013.XXX*

4 46.019.XXX 100MM UNIVERSAL BRACKET

5 46.002.XXX PIVOT PIN & PLATE

46.506.000

6

44.210.000

46.507.000

42.180.049

46.522.500

7

46.522.700

46.521.500

46.521.700

42.603.855

44.209.000

8

46.504.000

46.505.000 6.

*000 - MILL, 100 -SILVER PEARL, 134-MOMBASA, 734-YALUMBA, 737-CHARDONNAY, 810-THUNDERCLOUD, 850-WHITE SATIN

Page 15

R HEADBOX FRONT COVER (CLOSED)

R HEADBOX FRONT COVER (OPEN)

60MM IDLE END

70MM IDLER WITH HOLE

78MM IDLE END

60MM TUBE

70MM TUBE 5MT

70MM TUBE 7MT

78MM TUBE 5MT

78MM TUBE 7MT

60MM DRIVE END - SMALL

70MM DRIVE END

78MM CRANK DRIVE END

60MM DRIVE END - 13MM SHAFT

No Part Description

9 46.502.XXX 9:1 GEAR

10 46.524.000 PLAIN BOTTOM RAIL END CAP

11 46.517.000 R BOTTOM RAIL LOCKING PIN

12 46.500.000 HOLD DOWN CLIP

13 42.236.000 BUCKLE FOR HOLD DOWN STRAP

14 42.230.000 RUA STRAP

15 42.204.000 BREECHING STAPLE

16 46.011.XXX R BOTTOM RAIL

17

18

19

82.29X.XXX

44.XXX.XXX

44.132.000

42.421.855

42.198.000

42.421.855

CANVAS FABRIC

EXTERNAL SCREEN FABRIC

4.2MM ES SOLID SPLINE

6MM SPLINE

3.5MM HARD SPLINE

6MM SPLINE

Page 18

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA STRAIGHT DROP AWNING INSTALLATION

STEP 1

i - OPEN ROLLER INSTALL (pg7)

ii - HEADBOX INSTALL (pg9)

STEP 2

INSTALL ROLLER TUBE (pg12)

STEP 3

i - INSTALL HOLD DOWN STRAPS (pg17)

ii - INSTALL LOCKING BOLTS (pg17)

Page 16

Page 19

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA STRAIGHT DROP AWNING INSTALLATION

STEP 1 - INSTALL HEADBOX OR OPEN ROLLER

Refer to the following sections for instructions

i - open roller install (pg7)

ii - headbox install (pg9)

STEP 3 - INSTALL HOLD DOWN STRAPS

In order to protect the hold down clips they will be supplied uninstalled from the bottom rail.

- Remove Bottom Rail end cap

- Insert ALL Hold down clips with strap, buckle and dog clip attached.

- Lower awning to desired fixing height.

- Slide hold down clips and straps to desired hold down locations.

- Reattach bottom rail end cap.

- Fix breeching staple to floor or wall surface under hold down straps.

- Use dog clip to attach hold down to breeching staple.

STEP 2 - INSTALL THE ROLLER TUBE

refer to installing the roller section (pg12)

STEP 3 ii - INSTALL LOCKING BOLTS TO

REVEAL POST

The locking bolts will be supplied pre-installed in the

bottom rail

Secure to Reveal post

- Lower awning to desired fixing height.

- Slide locking bolts out to desired fixing location

- Line up locking bolts with the posts and ensure the

bottom rail is level.

- Mark fixing holes on post and drill using a 12mm drill

bit.

- Slide locking bolts into the hole and apply tension to

ensure a level installation.

- Holes can be drilled at a variety of different stopping

locations along the post dependent on consumer

requirements

STEP 3 iii - INSTALL LOCKING BOLTS USING

BREECHING STAPLE

The locking bolts will be supplied pre-installed in the

bottom rail

Secure using Breeching Staple

- Lower awning to desired fixing height.

- Slide locking bolts out to desired fixing location

- Place breeching staple to floor or wall surface to

ensure the locking bolt can be secured under the

breeching staple.

- Ensure the bottom rail is level. If not, pack out

breeching staple to ensure bottom rail will be perfectly

horizontal when secured.

- Fix breeching staple to floor or wall surface.

- Slide locking bolts into the hole and apply tension to

ensure a level installation.

Page 17

Page 20

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA CABLE GUIDE AWNING

2

1

5

6

No Part Description

1 46.608.XXX HEADBOX END CAP LH & RH

2 46.005.XXX HEADBOX BACK PLATE

46.012.XXX*

3

46.013.XXX*

4 46.019.XXX 100MM UNIVERSAL BRACKET

5 46.002.XXX PIVOT PIN & PLATE

6

46.506.000

44.210.000

46.507.000

42.180.049

7

46.522.500

46.522.700

46.521.500

46.521.700

8

42.603.855

44.209.000

46.504.000

46.505.000

R HEADBOX FRONT COVER (CLOSED)

R HEADBOX FRONT COVER (OPEN)

60MM IDLE END

70MM IDLE END

78MM IDLE END

60MM TUBE

70MM TUBE 5MT

70MM TUBE 7MT

78MM TUBE 5MT

78MM TUBE 7MT

60MM DRIVE END - SMALL

70MM DRIVE END

78MM CRANK DRIVE END

60MM DRIVE END - 13MM SHAFT

3

7

8

16

9

12

4

14

11

15

13

10

18

No Part Description

9 46.502.XXX 9:1 GEAR

10 46.524.000 PLAIN BOTTOM RAIL END CAP

11 46.108.063 CG CABLE GUIDE SET

12 46.530.063 EXTENSION PLATE

13 46.011.XXX R BOTTOM RAIL

82.29X.XXX

14

44.XXX.XXX

44.132.000

15

42.421.855

42.198.000

16

42.421.855

17 46.520.000 HEADBOX REVEAL CLIP

18 46.517.000 R BOTTOM RAIL LOCKING PIN

CANVAS FABRIC

EXTERNAL SCREEN FABRIC

4.2MM ES SOLID SPLINE

6MM SPLINE

3.5MM HARD SPLINE

6MM SPLINE

Page 18

*000 - MILL, 100 -SILVER PEARL, 134-MOMBASA, 734-YALUMBA, 737-CHARDONNAY, 810-THUNDERCLOUD, 850-WHITE SATIN

Page 21

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA CABLE GUIDE AWNING INSTALLATION

STEP 1

i - OPEN ROLLER INSTALL (pg7)

ii - HEADBOX INSTALL (pg9)

STEP 2 - INSTALL THE BOTTOM CABLE BRACKET

STEP 3 - INSTALL THE CABLE & FLOATING END CAP

STEP 4 - APPLY TENSION TO THE WIRE

STEP 5 - INSTALL THE ROLLER TUBE (pg12)

STEP 6 - CONNECT FLOATING END CAP TO BOTTOM RAIL

ACCESSORIES

NOTE: OPTIONAL EXTRAS INCLUDE:

HOLD DOWN CLIPS (pg21)

SLIDING BOLT (pg21)

PLEASE REFER TO RELEVANT SECTION FOR INSTRUCTIONS

Page 19

Page 22

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA CABLE GUIDE AWNING INSTALLATION

STEP 1 - INSTALL HEADBOX OR OPEN ROLLER

Reveal” Install

through this location

Top Cable Bracket

Refer to the following sections for instructions

i - open roller install (pg7)

ii - headbox install (pg9)

NOTE: cable guide installation bracket will come with top

cable bracket pre attached

STEP 2 B - INSTALL THE BOTTOM CABLE

BRACKET

STEP 2 A - PREPARE THE BOTTOM CABLE

BRACKET

Eclip

Barrel

Bottom Cable Bracket

Tension Pin

Use a string line or sprit level from the edge of the blind

bracket or side of the headbox to determine the correct

location of the wire guide bottom bracket.

NOTE: The bottom bracket is universal and can be used

for wall, floor or reveal mounting.

- Remove the Eclip from the barrel using screw driver or

pointy nose plyers.

- unscrew the bottom tension pin from the bottom of the

wire.

- remove the barrel from the bracket.

STEP 2 C - SECURE THE BARREL

Barrel Lip

Once bracket is fixed to ground/wall, slide in barrel, ensure

Place the bottom cable bracket on the location mark and

fix into place with the appropriate fixings.

the “lip” of barrel is facing towards the awning fabric.

Insert the Eclip around the “lip” of the barrel to ensure

the barrel is secure.

STEP 3 A - ATTACH WIRE TO BOTTOM BRACKET STEP 3 B - ATTACH FLOATING END CAP TO WIRE

Lock Nut

Insert the Tension pin through the barrel and screw to the

bottom of the wire, turn 3 - 4 times to secure.

Page 20

Unwind the wire and feed floating end cap onto the wire.

Page 23

ALPHA AWNING SERIES INSTALLATION MANUAL

STEP 4 A - ATTACH WIRE TO TOP CABLE BRACKET STEP 4 B - APPLY TENSION TO THE WIRE

Feed wire through the top cable brackets. Pull the wire

tight. Lock off with a 4mm Allen key. Ensure the grub

screw is secured tightly.

STEP 5 - INSTALL THE ROLLER TUBE

Refer to installing the roller tube section. (pg12)

ACCESSORIES

Return to the bottom bracket and use 2 pairs of pliers to

tighten the tension pin by holding the wire with one pair

of pliers and turn the pin with the other pair. Repeat on

opposite side.

STEP 6 - CONNECT FLOATING END CAP TO

BOTTOM RAIL

- Once the awning is installed lower the awning to a

position where it can be reached from the ground. Tilt

the awning and insert the floating end cap into bottom

rail. Repeat for other side.

OPTIONAL: HOLD DOWN STRAPS OPTIONAL: LOCKING BOLTS

In order to protect the hold down clips they will be

supplied uninstalled from the bottom rail.

- Remove Bottom Rail end cap

- Insert ALL Hold down clips with strap, buckle and dog

clip attached.

- Lower awning to desired fixing height.

- Slide hold down clips and straps to desired hold down

locations.

- Fix breeching staple to floor or wall surface under hold

down straps. Use dog clip to attach hold down to

breeching staple

Page 21

The locking bolts will be supplied pre-installed to the

bottom rail

- Lower awning to the bottom cable guide brackets.

- Slide locking bolts into the bottom cable guide bracket

and apply tension to ensure a level installation. If not

level, pack out bottom cable guide bracket to ensure

bottom rail will be perfectly horizontal when under

tension.

Page 24

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA SRS V2 (SIDE RETENTION SYSTEM) AWNING

22

23

24

2

1

4

10

9

3

7

15

20

18

8

6

5

26

14

16

21

17

19

11

13

No Part Description

1 46.608.XXX* HEADBOX END CAP LH & RH

2 46.005.XXX* HEADBOX BACK PLATE

46.012.XXX*

3

46.013.XXX*

46.019.000

4

46.019.063

46.002.000

5

46.002.063

6 46.506.000 60MM IDLE END

46.612.500

7

46.612.700

8 46.306.000 ZS TUBE REDUCER

42.603.855

9

46.505.000

46.502.100

10

46.502.122

46.502.837

11 46.606.XXX DC ZS CHANNEL V2

12 46.610.000 ZS FLOATING CHANNEL V2

13 46.607.XXX DC ZS CHANNEL COVER V2

R HEADBOX FRONT COVER (CLOSED)

R HEADBOX FRONT COVER (OPEN)

100MM UNIVERSAL BRACKET Z

100MM UNIVERSAL BRACKET SS

PIVOT PIN & PLATE Z

PIVOT PIN & PLATE SS

78MM TUBE 5MT

78MM TUBE 7MT

60MM DRIVE END - SMALL

60MM DRIVE END - 13MM SHAFT

9:1 GEAR SILVER

9:1 GEAR WHITE (CRANK OPERATION ONLY)

9:1 GEAR BLACK

12

No Part Description

14 46.599.000 ZIP

15 46.609.000 DC ZS CHANNEL END CAP SET V2

16 46.611.000 ZS BOTTOM RAIL END CAP R V2

17 46.011.XXX* R BOTTOM RAIL

82.29X.XXX

18

44.XXX.XXX

44.132.000

19

42.421.855

42.198.000

20

42.421.855

21 46.517.000 R BOTTOM RAIL LOCKING PIN

22 45.615.063 SCREW 8G X 25 MUSH SS

42.064.000

42.065.000

42.066.000

23

42.067.000

24 42.068.000 SPRING ASSY ADAPTORS

CANVAS FABRIC

EXTERNAL SCREEN FABRIC

4.2MM ES SOLID SPLINE

6MM SPLINE

3.5MM HARD SPLINE

6MM SPLINE

RUA 60 SPRING ASSY 750MM BARE

RUA 60 SPRING ASSY 750MM LIGHT BARE

RUA 60 SPRING ASSY 1200MM BARE

RUA 60 SPRING ASSY 1800MM BARE

(SPRING OPERATION ONLY)

Page 22

*000 - MILL, 100 -SILVER PEARL, 134-MOMBASA, 734-YALUMBA, 737-CHARDONNAY, 810-THUNDERCLOUD, 850-WHITE SATIN

Page 25

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA SRS V2 (SIDE RETENTION SYSTEM)

AWNING INSTALLATION

STEP 1

i - OPEN ROLLER INSTALL (pg7)

ii - HEADBOX INSTALL (pg9)

STEP 2 - OPEN THE CHANNEL FRONT COVER

STEP 3 - REMOVAL OF FLOATING GUIDE (p25)

STEP 4 - POSITION THE SIDE CHANNEL (pg25)

STEP 5 - INSTALL THE SIDE CHANNEL (pg26)

STEP 6 - INSTALL THE ROLLER TUBE (pg12)

STEP 7 - FEEDING FABRIC INTO SIDE CHANNEL

STEP 8 - POSITIONING THE FABRIC AND FLOATING GUIDES

STEP 9 - ATTACHING THE FRONT COVER

ACCESSORIES

NOTE: OPTIONAL EXTRAS INCLUDE:

HOLD DOWN STRAPS (pg29)

LOCKING BOLT (pg29)

PLEASE REFER TO RELEVANT SECTION FOR INSTRUCTIONS

Page 23

Page 26

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA SRS (SIDE RETENTION SYSTEM) V2

AWNING INSTALLATION

STEP 1 - INSTALL HEADBOX OR OPEN ROLLER

Refer to the following sections for instructions

i - open roller install (pg7)

ii - headbox install (pg9)

STEP 2 - OPEN THE CHANNEL FRONT COVER

The installation channel will be supplied fully assembled (Back Channel,

Floating Channel, Front channel with Top and Bottom channel caps

attached.

a) Check if front cover fixing screws

at top of bottom end caps are

used, if so remove screws.

Note: An installed awning will have

these in place.

b) Slide front cover towards middle

of blind about 12mm where it will

stop. This operation can be performed on either end of channel.

b) Front cover can then be

removed by lifting towards user.

Page 24

Page 27

ALPHA AWNING SERIES INSTALLATION MANUAL

STEP 3 - REMOVAL OF FLOATING GUIDE

1

2

a) Lift black floating guide towards

top of channel about 2mm and

tilt bottom guide towards middle

of awning.

STEP 4 - POSITION THE SIDE CHANNEL

b) Pull floating guide towards user and lower guide so bottom end comes

out first.

Note: If this cannot be removed loosen bolt on top end cap.

A

B

A. Install the headbox back plate,

level the headbox before fixing

with the specified screws

through the Universal Mounting

Brackets.

C

B. Install the DC ZC CHANNEL

V2, for on face install use a

spirit level to ensure the side

channel is vertical and squared

on the head box, for reveal

mount directly to the substrate

(for reveals up to 20mm out of

square).

C. Install the fabric roll onto the

head box and secure with the

supplied safety pin.

D. Lower the bottom rail at least

100mm or 1/2 of the drop

(power up the motors and use

D

** The factory will cut the zip with a 30mm to 40mm tail, which should not be cut off on install. This will ensure an easier feed on of the

guide and ensure the zip will not exit the top of the ZS guide if the awning is “over-raised”. The tail will collapse into to bottom of the

side channel when the awning is down.

Page 25

the remote if motorised)

Page 28

ALPHA AWNING SERIES INSTALLATION MANUAL

STEP 4 - POSITION THE SIDE CHANNEL CONT..

F - Locating Nut

E

E. Insert the zipper into the ZS

FLOATING GUIDE CHANNEL

V2 and slide the guide up. Once

the zip is located into the guide

insert the guide onto the top end

cap locator post with the screw.

Then place the guide into the

side channel with the bottom

sitting on the vertical fins of the

bottom end cap. Complete

this process on the other side

channel.

F. Fully lower and raise the awning

2-3 times to align the floating

guide channels.

1. Then with the awning in the

down position check the skin

is centred on the awning

and the positioning of the

guides in the side channel

looks balanced, adjust the

skin position as required to

achieve this.

2. Tighten up the top end cap

locating nut. (7mm spanner is

required).

STEP 5 - SECURING THE FLOATING GUIDE ONTO SIDE CHANNEL

Note: It is important to set the torque of the power screw driver to a lower setting then change the adjust the torque a bit higher if needed.

a. Lower the awning skin down to the bottom of the side channel.

b. Choose one of the side channels to fasten first i.e. either left or right.

c. Starting at the bottom of the channel move to the closest cut out in the side channel. Drill a 2.5mm pilot hole

in both the Grey floating guide and the first layer of the side channel ( you will feel the movement with the drill

once the bit passes through the first layer of side channel) and fasten with the supplied fixing screw. Continue

this procedure moving up the side channel at each cut out.

Note: Drill the pilot hole with medium pressure, this will ensure you do not drill through the back of the side guide.

Page 26

Page 29

ALPHA AWNING SERIES INSTALLATION MANUAL

STEP 6 - ONCE THE FIRST CHANNEL IS FIXED INTO POSITION MOVE TO THE CHANNEL ON THE

OTHER SIDE.

Raise the blind and align

the bottom rail onto the

2.5mm Pilot

drill and screw

to secure then

repeat on the

next top cut out.

next cut out. Apply light

tension and 2.5mm pilot

drill & screw to the side

channel.

NB. Do not raise the

blind while screw fixing

the floating guide on

this side.

1. Again, start at the bottom cut out

and drill the 2.5mm pilot hole and

fix off the guide with the supplied

fastener.

2. Then unlike the other side move the bottom rail up to the next cut out

and drill and secure the guide as above, ensuring only small tensioning

pressure is applied to the channel / guide. Repeat this until the guide is

secure at each cut out.

Page 27

Page 30

ALPHA AWNING SERIES INSTALLATION MANUAL

STEP 7 - TEST AND ADJUSTMENT

a. Run the awning up and down a

few times to assess it is running

smoothly and does not catch.

STEP 8 - ATTACHING THE FRONT COVER SIDE CHANNEL

a. Raise the skin so the bottom rail is

within 100mm of top end cap.

b. Where there is any tightness /

catch points adjust the positioning

of the fasteners at the nearest /

relevant cut outs to either move

the floating channel in or out.

Here it is best to redrill a new pilot

hole in the floating guide above or

below the original one.

b. Align the front cover on back plate

so the leading face is flush with

side channel outer surface then

slide into position.

c. Check and adjust the top endcap

locating nut to ensure the skin is

rolling square.

c. Fasten the front cover into position

by fixing screws with a screw

driver through front cover of the

top and bottom end caps.

STEP 9 - ATTACHING THE FRONT COVER

a) Raise skin so bottom rail is within 100mm of top end cap.

b) Align front cover on back plate so face is flush with side

channel outer surface then slide into position.

Fixing screws (12mm)

Fixing screw (12mm)

c) Fasten the front cover into position by fixing the

screws with a screwdriver through the front cover

at the top of the bottom end caps.

Page 28

Page 31

ALPHA AWNING SERIES INSTALLATION MANUAL

STEP 9 - ATTACHING THE FRONT COVER CONT..

Drill and screw both sides with the

screws supplied when installing in

the reveal.

ACCESSORIES

OPTIONAL: HOLD DOWN STRAPS OPTIONAL: LOCKING BOLTS

These instructions relate to fixing hold down straps to

other guiding options.

In order to protect the hold down clips, they will be supplied uninstalled from the bottom rail.

- Remove Bottom Rail end cap

- Insert ALL Hold down clips with strap, buckle and dog

clip attached.

- Lower awning to desired fixing height.

- Slide hold down clips and straps to desired hold down

locations.

- Fix breeching staple to floor or wall surface under hold

down straps.

- Use dog clip to attach hold down to breeching staple.

The locking bolts will be supplied pre-installed to the

bottom rail. Note - Channels need to be installed at the

same height to ensure the bottom rail will be level when

locked in place.

- Lower awning to the bottom of the channels.

- Drill 12mm hole in the side of the channel backplate.

Ensure the hole is between the wedges on the bottom

channel end cap and perfectly in line.

- Slide locking bolts into the channel back plate hole to

secure and apply tension to ensure a level installation.

Page 29

Page 32

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA DEEP CHANNEL AWNING

2

5

6

3

1

7

8

19

9

4

No Part Description

1 46.608.XXX HEADBOX BOX END CAP LH & RH

2 46.005.XXX HEADBOX BACK PLATE

3

4 46.019.XXX 100MM UNIVERSAL BRACKET

5 46.002.XXX PIVOT PIN & PLATE

6

7

8

46.012.XXX*

46.013.XXX*

46.506.000

44.210.000

46.507.000

42.180.049

46.522.500

46.522.700

46.521.500

46.521.700

42.603.855

44.209.000

46.504.000 6.

R HEADBOX FRONT COVER (CLOSED)

R HEADBOX FRONT COVER (OPEN)

60MM IDLE END

70MM IDLER WITH HOLE

78MM IDLE END

60MM TUBE

70MM TUBE 5MT

70MM TUBE 7MT

78MM TUBE 5MT

78MM TUBE 7MT

60MM DRIVE END - SMALL

70MM DRIVE END

78MM CRANK DRIVE END

17

15

12

16

21

13

18

12

No Part Description

9 46.502.XXX 9:1 GEAR

10 46.020.XXX DEEP CHANNEL SPACER

11 46.600.XXX DC ZS CHANNEL

12 46.601.XXX DC ZS CHANNEL COVER

13 46.205.000 DC BOTTOM RAIL END CAP

14 46.016.000 DC ZS CHANNEL END CAP SET

15 46.203.000 PILE BRUSH

16 46.011.XXX R BOTTOM RAIL

17

18

19

21 46.517.000 R BOTTOM RAIL LOCKING PIN

82.29X.XXX

44.XXX.XXX

44.132.000

42.421.855

42.198.000

42.421.855

CANVAS FABRIC

EXTERNAL SCREEN FABRIC

4.2MM ES SOLID SPLINE

6MM SPLINE

3.5MM HARD SPLINE

6MM SPLINE

14

11

10

11

14

Page 30

*000 - MILL, 100 -SILVER PEARL, 134-MOMBASA, 734-YALUMBA, 737-CHARDONNAY, 810-THUNDERCLOUD, 850-WHITE SATIN *ONLY FOR CRANK OPERATION

Page 33

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA DEEP CHANNEL AWNING INSTALLATION

STEP 1

i - OPEN ROLLER INSTALL (pg7)

ii - HEADBOX INSTALL (pg9)

STEP 2 - OPEN THE CHANNEL FRONT COVER

STEP 3 - INSTALL THE BACK CHANNEL

STEP 4 - INSTALL THE ROLLER TUBE (pg12)

STEP 5 - FEED FABRIC INTO THE BACK CHANNEL

STEP 6 - ATTACH CHANNEL FRONT COVER

ACCESSORIES

NOTE: OPTIONAL EXTRAS INCLUDE:

HOLD DOWN STRAPS (pg33)

SLIDING BOLT (pg33)

PLEASE REFER TO RELEVANT SECTION FOR INSTRUCTIONS

Page 31

Page 34

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA DEEP CHANNEL AWNING INSTALLATION

STEP 1 - INSTALL HEADBOX OR OPEN ROLLER

Refer to the following sections for instructions

i - open roller install (pg7)

ii - headbox install (pg9)

STEP 3 - INSTALL THE BACK CHANNEL

STEP 2 - OPEN THE CHANNEL FRONT COVER

The installation channel will be supplied fully assembled

(Back Channel, Brush, Front channel with Top and Bottom channel caps attached).

- Disconnect the front Channel by leveraging pressure

on the Inside edge. If needed use a screw driver in the

shadow detail to assist with the disconnect.

STEP 4 - INSTALL THE ROLLER TUBE

Use the bolt attached to the top channel cap to locate

the bottom hole of the installation bracket. (Face fit installs

only) This will ensure the channel is correctly lined up.

- Secure the back channel to the fixing surface every

700mm. Use a spirit level to ensure the channel is level.

STEP 5 - FEED FABRIC INTO THE BACK CHANNEL

Lower the awning approximately 100mm from top.

- Feed the fabric through the top channel cap.

Refer to installing the roller tube section (pg12)

STEP 6 - ATTACH CHANNEL FRONT COVER

Fully lower and raise the awning to ensure the installation

is square.

- Once satisfied, snap on the front cover using the hook

detail and leveraging pressure on the outside edge of

the front cover.

Page 32

Page 35

ALPHA AWNING SERIES INSTALLATION MANUAL

ACCESSORIES

OPTIONAL: HOLD DOWN STRAPS

These instructions relate to fixing hold down straps to

other guiding options.

In order to protect the hold down clips, they will be

supplied uninstalled from the bottom rail.

- Remove Bottom Rail end cap

- Insert ALL hold down clips with strap, buckle and dog

clip attached.

- Lower awning to desired fixing height.

- Slide hold down clips and straps to desired hold down

locations.

- Fix breaching staple to floor or wall surface under hold

down straps.

- Use dog clip to attach hold down to breaching staple.

OPTIONAL: LOCKING BOLTS

The locking bolts will be supplied pre-installed to the

bottom rail.

- Lower awning to desired fixing height.

- Slide locking bolts out to desired fixing location

- Line up locking bolts with the channels and ensure the

bottom rail is level.

- Mark fixing holes on channel and drill using a 12mm

drill piece

- Slide locking bolts into the hole and apply tension to

ensure a level installation.

- Holes can be drilled at a variety of different stopping

locations along the channel dependent on consumer

requirements

Page 33

Page 36

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA PIVOT ARM AWNING

2

5

6

14

15

3

18

13

12

11

1

7

8

19

9

4

17

16

10

No Part Description

1 46.608.XXX HEADBOX END CAP LH & RH

2 46.005.XXX HEADBOX BACK PLATE

46.012.XXX*

3

46.013.XXX*

4 46.019.XXX 100MM UNIVERSAL BRACKET

5 46.002.XXX PIVOT PIN & PLATE

46.506.000

6

44.210.000

46.507.000

42.180.049

46.522.500

7

46.522.700

46.521.500

46.521.700

42.603.855

44.209.000

8

46.504.000 6.

46.505.000

Page 34

*000 - MILL, 100 -SILVER PEARL, 134-MOMBASA, 734-YALUMBA, 737-CHARDONNAY, 810-THUNDERCLOUD, 850-WHITE SATIN *ONLY FOR CRANK OPERATION

R HEADBOX FRONT COVER (CLOSED)

R HEADBOX FRONT COVER (OPEN)

60MM IDLE END

70MM IDLER WITH HOLE

78MM IDLE END

60MM TUBE

70MM TUBE 5MT

70MM TUBE 7MT

78MM TUBE 5MT

78MM TUBE 7MT

60MM DRIVE END - SMALL

70MM DRIVE END

78MM CRANK DRIVE END

60MM DRIVE END - 13MM SHAFT

No Part Description

9 46.502.XXX 9:1 GEAR

10 46.423.100 PA ARM BRACKET WITH SPRING

11 46.421.000 PA ARM PROFILE

12 46.422.030 PA FRONT RAIL CONNECTOR

13 46.420.000 PA FRNT RAIL END CAP

46.419.XXX R PA FRONT RAIL

82.29X.XXX

15

44.XXX.XXX

16 46.414.000 PA SLIDE RAIL 32X25MM 6M

17 46.416.100 PA ANGLE BRACKET (SIDE FIX)

44.132.000

18

42.421.855

42.198.000

19

42.421.855

CANVAS FABRIC

EXTERNAL SCREEN FABRIC

4.2MM ES SOLID SPLINE

6MM SPLINE

3.5MM HARD SPLINE

6MM SPLINE

Page 37

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA PIVOT ARM AWNING INSTALLATION

STEP 1

i - OPEN ROLLER INSTALL (pg7)

ii - HEADBOX INSTALL (pg9)

STEP 2 - INSTALL THE ROLLER TUBE (pg12)

STEP 3 - ATTACH PIVOT ARMS TO FRONT RAIL

STEP 4 - INSTALL PIVOT ARMS

ACCESSORIES

NOTE: OPTIONAL EXTRAS INCLUDE:

REVEAL FIT BRACKET

SLIDING ARM SET (pg37)

PLEASE REFER TO RELEVANT SECTION FOR INSTRUCTIONS

Page 35

Page 38

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA PIVOT ARM AWNING INSTALLATION

STEP 1 - INSTALL HEADBOX OR OPEN ROLLER STEP 2 - INSTALL THE ROLLER TUBE

Refer to the following sections for instructions

i - open roller install (pg7)

ii - headbox install (pg9)

STEP 3 - ATTACH PIVOT ARMS TO FRONT RAIL STEP 4 - INSTALL PIVOT ARMS

Refer to installing the roller section (pg12)

Attach pivot arms to front rail

NOTE: Arms should be positioned within 300mm of the

ends of the bottom rail and should be of equal distance.

ACCESSORIES

Lower front rail 20mm below headbox or brackets and

ensure the tube and front rail are parallel.

- Mark fixing location of pivot arm installation foot.

- Install pivot arms using screws.

NOTE: For ALPHA Pivot Awning Reveal installations an

angle bracket will be provided to mount the pivot arm

foot to. The location of the angle bracket can be determined using the above process.

OPTIONAL: STEP 3 A - SLIDING ARM SET OPTIONAL: STEP 3 B - SLIDING ARM SET

Place slide rail under top bracket and align vertically.

- Secure slide rail to wall surface using screws.

Page 36

Attach Pivot Arm to slide rail set.

- Insert slide rail set and Pivot Arm into the slide rail.

- Lift spring bolts on sliding set to move the pivot arms.

Page 39

ALPHA AWNING SERIES INSTALLATION MANUAL

OPTIONAL: STEP 3 C - SLIDING ARM SET

Raise front rail over Pivot Arm front rail connector and

onto fabric.

- Align Front rail 20mm below the top bracket – this is

the resting location for the Pivot Arms.

- Ensure the front rail and roller tube are parallel at all

times.

Page 37

Page 40

AUTOMATIC ROLL UP AWNINGS

Assembly 4

Page

25

ALPHA AWNING SERIES INSTALLATION MANUAL

PRETENSIONING THE SPRING FOR LITERISE/LIGHT LIFT

For LiteRise/Light Lift only. To be done prior to installation of Roller Tube if required.

Note: Spring must be installed for left hand control.

STEP 1 - SELECT THE CORRECT SPRING SIZE

a) Plot the width and drop of the awning on the Spring

Tension Chart. Go up to the nearest incremental size. The

chart will indicate the number of spring turns and spring

type required to operate the blind correctly. Refer to

Diagram on Page 39.

STEP 3 - PRETENSION THE SPRING

STEP 2 - PRETENSION THE SPRING

Spring Adjustment Lug

DO NOT EXCEED RECOMMENDED

NUMBER OF PRE-TENSION TURNS.

b) The spring should already be pretensioned at the

factory. If there is need to tension, turn the spring

adjustment lug clockwise. It is important to position the

tube so that the pawl is at the top in order for the spring

to be tensioned properly.

STEP 4 - PRETENSION THE SPRING

Lock Position

Pawl

Ensure the pawl is locked off prior to installation of spring assembly onto the bracket.

Page 38

Page 41

Drop (m)

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

3

ALPHA AWNING SERIES INSTALLATION MANUAL

SPRING TENSION CHART

Width (m)

1.2 1.4 1.6 1.8

1

7 10 14 18

7 10 14 18 8 9 10 11 12 12 13 14 15 16 16 17 18 15 16 17

7 10 14 18 8 9 10 11 12 12 13 14 15 16 16 17 14 15 16 17

7 10 14

7 10 14

7 10 14 7 8 9 10 11 12 12 13 14 15 13 14 14 14 15 16 17

7 10 14 7 8 9 10 11 12 12 13 14 15 13 14 14 14 15 16 17

7 10 14 7 8 9 10 11 12 12 13 13 13 13 14 14 14 15 16

7 10 14 7 8 9 10 11 12 12 13 13 13 13 14 14 14 15

7 10 14 7 8 9 10 11 12 12 12 13 13 13 14 14 14

7 10 14 7 8 9 10 11 12 12 12 13 13 13 14 14

2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6 4.8 5

8 9 10 11 12 12 13 14 15 16 16 17 18 19 16 17

18 8 9 10 11 12 12 13 14 15 16 16 14 14 15 16 17

7 8 9 10 11 12 12 13 14 15 16 14 14 14 15 16 17

KEY

42.065.000 750mm Spring Assembly (Light)

42.064.000 750mm Spring Assembly

42.066.000 1200mm Spring Assembly

42.067.000 1800mm Spring Assembly

Outside of limitations

Page 39

Page 42

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA LINKED OPTION

1

3

4

2

5

1

4

3

2

No Part Description

1 46.558.000 GRUB SCREW

2

46.556.000

46.557.000

78MM TUBE END SQR CONNECTOR

70MM TUBE END SQR CONNECTOR

Page 40

3 46.561.000 16MM SHAFT COLLAR

4 46.560.000 BRACKET BUSHING

5 46.559.030 SQR SHAFT LINK CONNECTOR

Page 43

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA LINKED OPTION

STEP 1

i - HEADBOX INSTALL (pg40)

STEP 2 - INSTALL THE ROLLER TUBE (pg42)

Page 41

Page 44

ALPHA AWNING SERIES INSTALLATION MANUAL

ALPHA LINKED OPTION HEADBOX INSTALL

STEP 1 - OPEN THE HEADBOX STEP 2 - REMOVE ROLLER TUBE

Open the headbox front cover by unscrewing the bottom

screw on the headbox end cap. Repeat on opposite side.

NOTE: For reveal fit the screw is no longer required.

STEPS 3 - FACE FIT

IDLE END DRIVE END

STEPS 3 - REVEAL FIT INSTALL

Pull out the idle end locking pin and remove the roller

tube idle end first.

Page 42

IDLE END DRIVE END

Page 45

ALPHA AWNING SERIES INSTALLATION MANUAL

STEPS 3 - CEILING FIT INSTALL

SEPARATE HEADBOX

Mark and drill the head box back plate where the fixings will go.

NOTE: Always secure the headbox back panel through the installation brackets or spreader plate!

• After determining the exact position of the headbox you can fasten the brackets and headbox on the installation

surface.

• Mark the fixing holes for the first bracket.

• Drill holes to suit the method of fixing determined by the substrate being fixed to.

• Secure installation screw-in bracket to hold one side of head box.

• Repeat the process for the opposite bracket and ensure that the head box is straight using a spirit level.

• Repeat the above process for the remaining blinds and ensure the holes in the end plates match up.

NOTE: If required pack out the headbox.

• Once satisfied the headbox is level, secure remaining fixing points.

NOTE: For awnings over 3500mm wide, add an additional fixing point through the centre of the headbox back panel.

E.g 3500mm wide secure at 1750mm.

ACCESSORIES

SPREADER PLATE

If there is no substantial fixing point at the ends of the headbox, a Spreader Plate can be added. This allows

250mm of flexibility for installation points at each end of the awning. If a spreader plate is ordered, this will come

preassembled to the bracket inside the headbox determined by the installation type specified. Secure through Fixing

points highlighted in the image.

Page 43

Page 46

ALPHA AWNING SERIES INSTALLATION MANUAL

ALL IN ONE HEADBOX

Mark and drill the head box back plate where the fixings will go.

NOTE: Always secure the headbox back panel through the installation brackets or spreader plate!

• After determining the exact position of the headbox you can fasten the brackets and headbox on the installation

surface.

• Mark the fixing holes for the first bracket.

• Drill holes to suit the method of fixing determined by the substrate being fixed to.

• Secure installation screw-in bracket to hold one side of head box.

• Secure the idle end and subsequent brackets, ensuring the outside of bracket to outside of bracket measurements

are as measured. Ensure you have inserted the 2 bushings into the centre holes of the brackets from the outside in

before securing any subsequent brackets.

INSTALLING THE ROLLER TUBE

Collar

A

Square Drive Shaft

Bushing

Insert the square drive shaft through the bushings. Insert a collar on either side of the square drive shaft.

B

Insert the drive end of the first blind into the crank gear. Raise and position the idle end of this blind in line with the

square drive shaft.

Page 44

Page 47

ALPHA AWNING SERIES INSTALLATION MANUAL

INSTALLING THE ROLLER TUBE - CONTINUED

C

*

Insert the square drive shaft into the idle end of the drive blind so only 40mm (*) is protruding into the drive end of the

second blind. Use an Allen key to secure the collar against the idle end of the drive blind.

D

Repeat step B above ensuring the bottom rails are as close to level as possible. For final blind insert idle pin into the

standard tube idle end and position into idle end bracket. Use an Allen key to secure the collar against the drive end

of the idle blind

Un-wind the fabric on all blinds and use an Allen key through the 6mm drilled hole in the roller tube to lock the grub

screw on the square shaft in location. This will ensure the bottom rails roll up evenly.

Install all other components as per the normal installation process for that style of ALPHA awning.

Page 45

Page 48

ALPHA AWNING SERIES INSTALLATION MANUAL

OPERATING INSTRUCTIONS

Manual Operation of the awnings with Crank

To extend the awning:

• Insert end of crank handle into the drive gear winding mechanism.

• Rotate crank clockwise until awning is fully extended. (Do not keep winding once resistance is felt).

It is then recommended that you turn the crank anti clockwise slightly to reduce tension.

To retract the awning:

• Insert end of crank handle into gear winding mechanism.

• Rotate anti-clockwise until awning is fully retracted.

(Do not keep winding once resistance is felt.)

Warning!

Watch the screen fabric carefully when retracting the awning to ensure there are no obstructions or creasing of the

fabric. Should any resistance be felt or visible signs of the fabric not rolling up straight, stop immediately and turn

crank in opposite direction until fabric is clear and runs smoothly, then start retracting again slowly.

To extend the awning:

• Press the appropriate button on the remote control.

• The awning will extend until it reaches the preset fully extended position.

• The motor will stop automatically.

To retract the awning:

• Press the appropriate button on the remote control.

• The awning will retract until it reaches the preset fully retracted position.

• The motor will stop automatically.

Warning!

For automatic operating awnings or accessories, please ensure these are switched off during periods of absence

(e.g. holidays ) or when the awning will be left unattended.

Sun and/or winds Remote Options

• If the awning is equipped with sun and wind or wind only sensors, the awning will automatically extend or retract

according to how the criteria has been set by the installation technician.

• The automatic retraction options are not fail safe and should not be relied upon to react quickly, especially with

sporadic strong wind gusts.

• Never leave the awning unattended as manual intervention may be required.

Warning!

Alterations to the preset limits for extension and retraction of the awning must be made by qualified personnel only.

Do not attempt this yourself.

Page 46

Page 49

ALPHA AWNING SERIES INSTALLATION MANUAL

FULL BRICK ON FACE/ BRICK VENEER

Minimum Requirements

Opening Size

+ 165 Channel

+ 150 SRS V2

+ 300 Cable

Deep Channel Dimensions 81 x 33.5mm

Side Retention System Dimensions 73 x 37.5mm

Drop as

Measured

Face Fix Factory

will deduct NIL mm

Page 47

Page 50

ALPHA AWNING SERIES INSTALLATION MANUAL

ON FACE ARCHITRAVE

Above Architrave

Overall

Measure

Minus NIL MM

Face Fix Factory

will deduct NIL mm

Drop as

Measured

No Still With Still

Drop

Drop

Bottom Rail

Headbox Size

With

timber packing

(+125mm)

+60mm

to lift

bottom

rail

above

opening

Drop plus

(+125mm)

REVEAL AND TOP FIX (SIDE FIX)

To Fully Recess

*130mm

Width

Measure Shortest

Smallest

Opening Size

Minus NIL MM

Factory

will Deduct 2mm

Headbox Dimensions are

Projection= 130mm

Drop =

125mm

Drop

130mm

125mm

Measure Drop

Straight Still Angled Still

Bracket Dimensions are

Drop = 100mm

Projection= 100mm

Width= 68mm

To Fully Recess

*130mm

Measure

Drop

*NB: Manufacturing

tolerance is + or -2mm

Allow Minimum of 100mm

on Drop if Using HOLD Down

Straps

68mm

100mm

100mm

Page 48

Page 51

Page 49

Page 52

Loading...

Loading...