Page 1

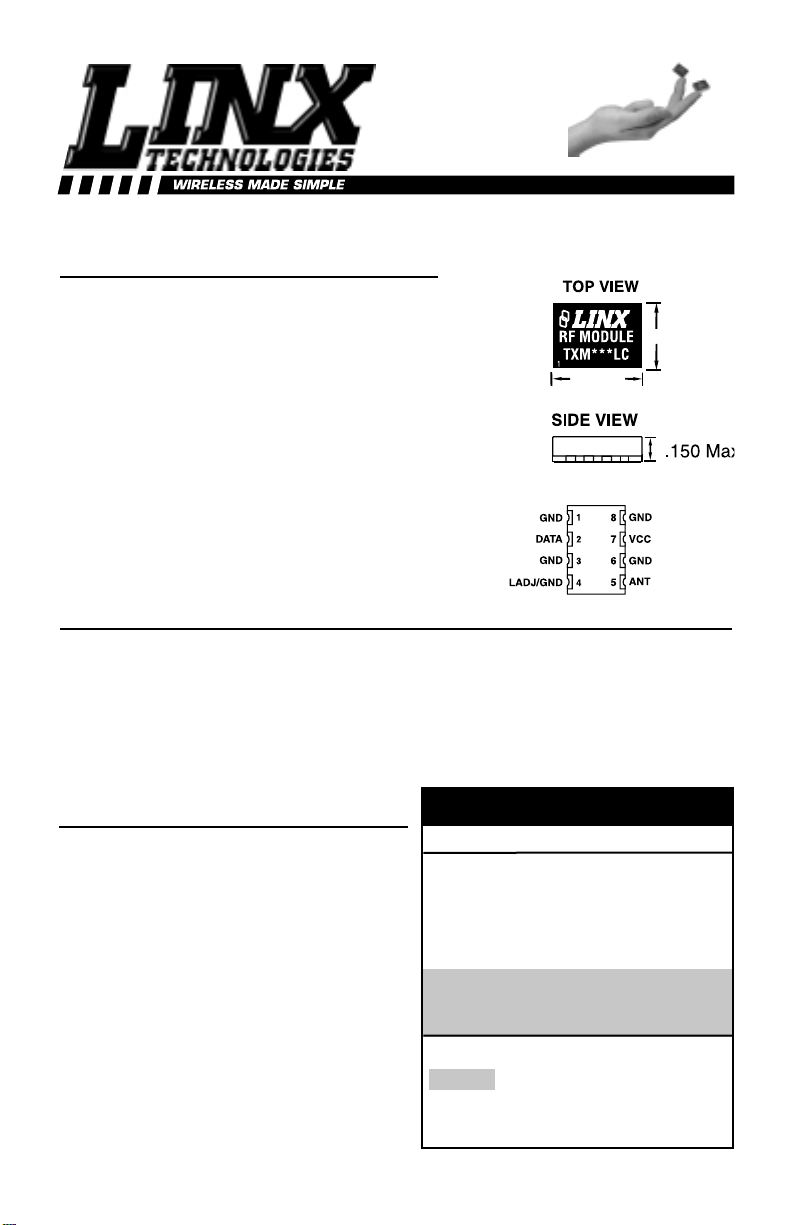

TOP VIEW

.360

.500

PINOUTS

LC SERIES TRANSMITTER MODULE DATA GUIDE

■ Remote control

■ Keyless entry

■ Garage / Gate openers

■ Lighting control

■ Medical monitoring / Call systems

■ Remote industrial monitoring

■ Periodic data transfer

■ Home / Industrial automation

■ Fire / Security alarms

■ Remote status / Position sensing

■ Long-range RFID

■ Wire Elimination

APPLICATIONS INCLUDE:

■ Low Cost

■ No External RF Components

Required

■ Ultra-low Power Consumption

■ Compact Surface-Mount Package

■ Stable SAW-based Architecture

■ Supports Data Rates to 5,000 bps

■ Wide Supply Range (2.7-5.2 VDC)

■ Direct Serial Interface

■ Low Harmonics

■ No Production Tuning

The LC Series is ideally suited for volume use

in OEM applications such as remote control,

security, identification, and periodic data

transfer. Packaged in a compact SMD package,

the LC transmitter utilizes a highly optimized

SAW architecture to achieve an unmatched

blend of performance, size, efficiency and cost.

When paired with a matching LC series

receiver, a highly reliable wireless link is

formed, capable of transferring serial data at

distances in excess of 300 Feet. No external RF

components, except an antenna, are required,

making design integration straightforward, even

for engineers lacking previous RF experience.

TXM-315-LC

TXM-418-LC

TXM-433-LC

PHYSICAL DIMENSIONS

DESCRIPTION:

FEATURES:

Revised 12/21/01

PART # DESCRIPTION

EVAL-***-LC Basic Evaluation Kit

MDEV-***-LC Master Development Kit

TXM-315-LC Transmitter 315 MHZ

TXM-418-LC Transmitter 418 MHZ

TXM-433-LC Transmitter 433 MHZ

RXM-315-LC Receiver 315 MHZ

RXM-418-LC Receiver 418 MHZ

RXM-433-LC Receiver 433 MHZ

*** Insert Frequency

Not covered in this manual

LC Transmitters are supplied in tube

packaging - 50 pcs.per tube.

ORDERING INFORMATION

Page 2

Page 3

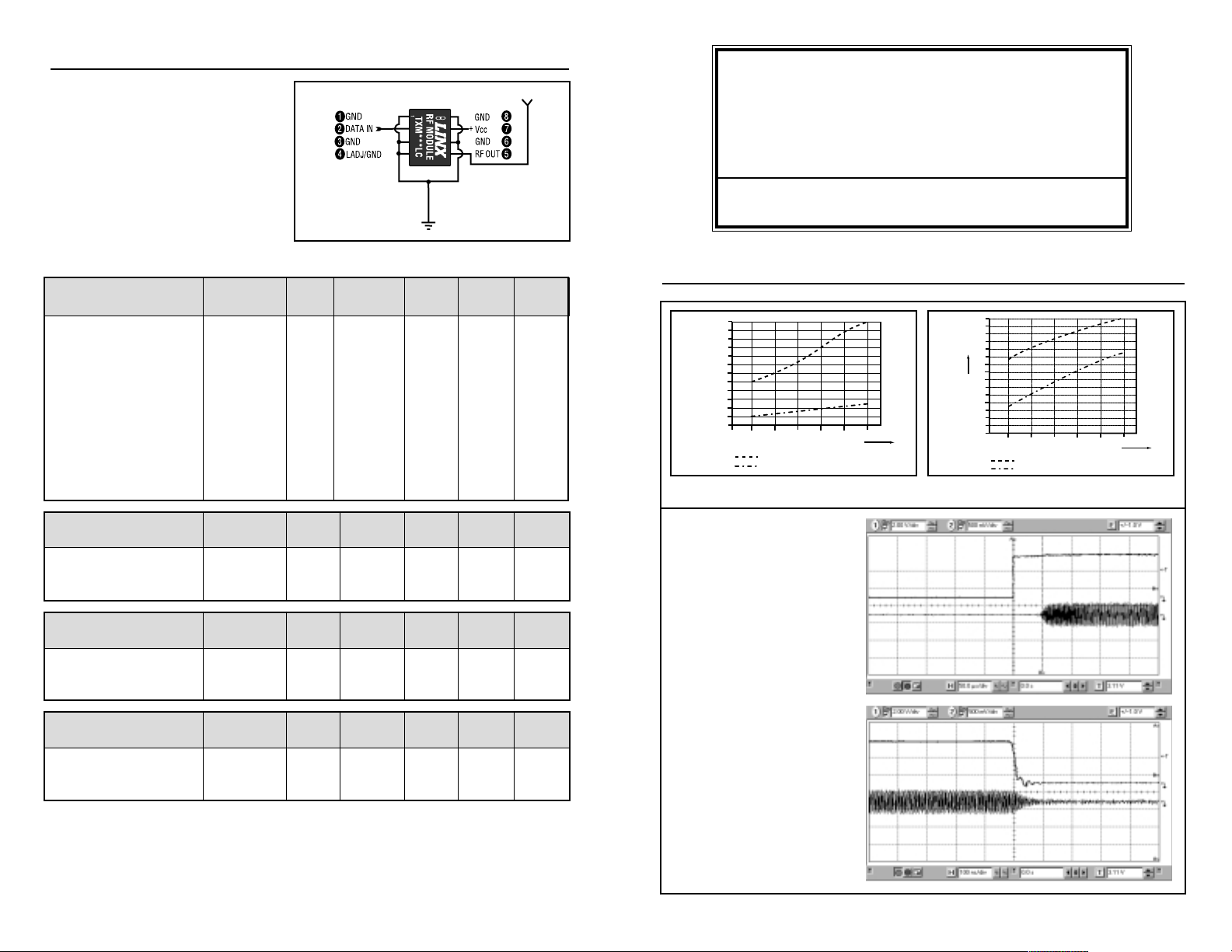

PERFORMANCE DATA– TXM-***-LC

Page 2

Parameter

LCTX 418MHz Designation Min. Typical Max. Units Notes

Frequency of Carrier F

C

417.925 418 418.075 MHz –

Harmonic Emissions P

H

– – -40 dBc 4

Parameter

LCTX 315MHz Designation Min. Typical Max. Units Notes

Frequency of Carrier F

C

314.925 315.0 315.075 MHz –

Harmonic Emissions P

H

––-40 dBc 4

Parameter

LCTX 433MHz Designation Min. Typical Max. Units Notes

Frequency of Carrier F

C

433.845 433.92 433.995 MHz –

Harmonic Emissions P

H

––-45 dBc 4

figure 1:Test/Basic application circuit

ABOUT THESE MEASUREMENTS

The performance parameters listed

below are based on module

operation at 25°C from a 3.3Vdc

supply unless otherwise noted.

Figure 1 at the right illustrates the

connections necessary for testing

and operation. It is recommended

that all ground pins be connected

to the groundplane.

Absolute Maximum Ratings:

Supply voltage VCC, using pin 7 -0.3 to +6 VDC

Operating temperature -30°C to +70°C

Storage temperature -45°C to +85°C

Soldering temperature +225°C for 10 sec.

Any input or output pin -0.3 to V

CC

*NOTE* Exceeding any of the limits of this section may lead to

permanent damage of the device. Furthermore, extended operation at

these maximum ratings may reduce the life of this device.

1. Current draw with data pin held continuously high.

2. Current draw with 50% mark/space ratio.

3. Current draw with data pin low.

4. RF out connected to 50Ω load.

5, Ladj (pin 4) through 430Ω resistor.

Notes:

Parameters

LCTX 433, 418, 315MHz Designation Min. Typical Max. Units Notes

Operating V oltage Range V

CC

2.7 – 5.2 Volts –

Current Continuous I

CC

– 3.0 6.0 mA 1, 5

Current Average I

CA

– 1.5 – mA 2, 5

Current In Sleep I

SLP

–– 1.5 µA 3

Data Input Low V

IL

0 – 0.4 Volts –

Data Input High V

IH

2.5 – V

CC

Volts –

Oscillator Start-up Time T

OSU

–– 80 µS 4

Oscillator Ring-down Time T

ORD

––100 nSec 4

Output Power P

O

-4 0 +4 dBm 4

0

-1

-4

-5

-6

-7

2.5

3.0

3.5

4.0 4.5

-2

-3

SUPPLY VOLTAGE

+1

+3

+2

+4

+5

+6

+7

+8

5.0

(V)

2.5

3.0

3.5

4.04.0 4.54.5

5.0

(V)(V)

SUPPLY VOLTAGESUPPLY VOLTAGE

1

3

2

4

5

6

7

8

9

10

11

12

0

With 430Ω resistor at Iadj (pin)

With Iadj tied to ground

Supply Current (mA)

0

-1

-4

-5

-6

-7

2.5

3.0

3.5

4.0 4.54.5

-2

-3

SUPPLY VOLTAGESUPPLY VOLTAGE

+1+1

+3+3

+2

+4+4

+5+5

+6+6

+7+7

+8+8

5.0

(V)

dBm

With 430Ω resistor at Iadj (pin)

With Iadj tied to ground

pg

Output Power

figure 4: Typical Oscillator

Turn-On Time

figure 2: Consumption vs. Supply Voltage

TYPICAL PERFORMANCE GRAPHS

figure 5: Typical Oscillator

Turn -Off Ti me

figure 3: Typical RF power into 50Ω

Data

Carrier

Data

Carrier

Page 3

Page 5

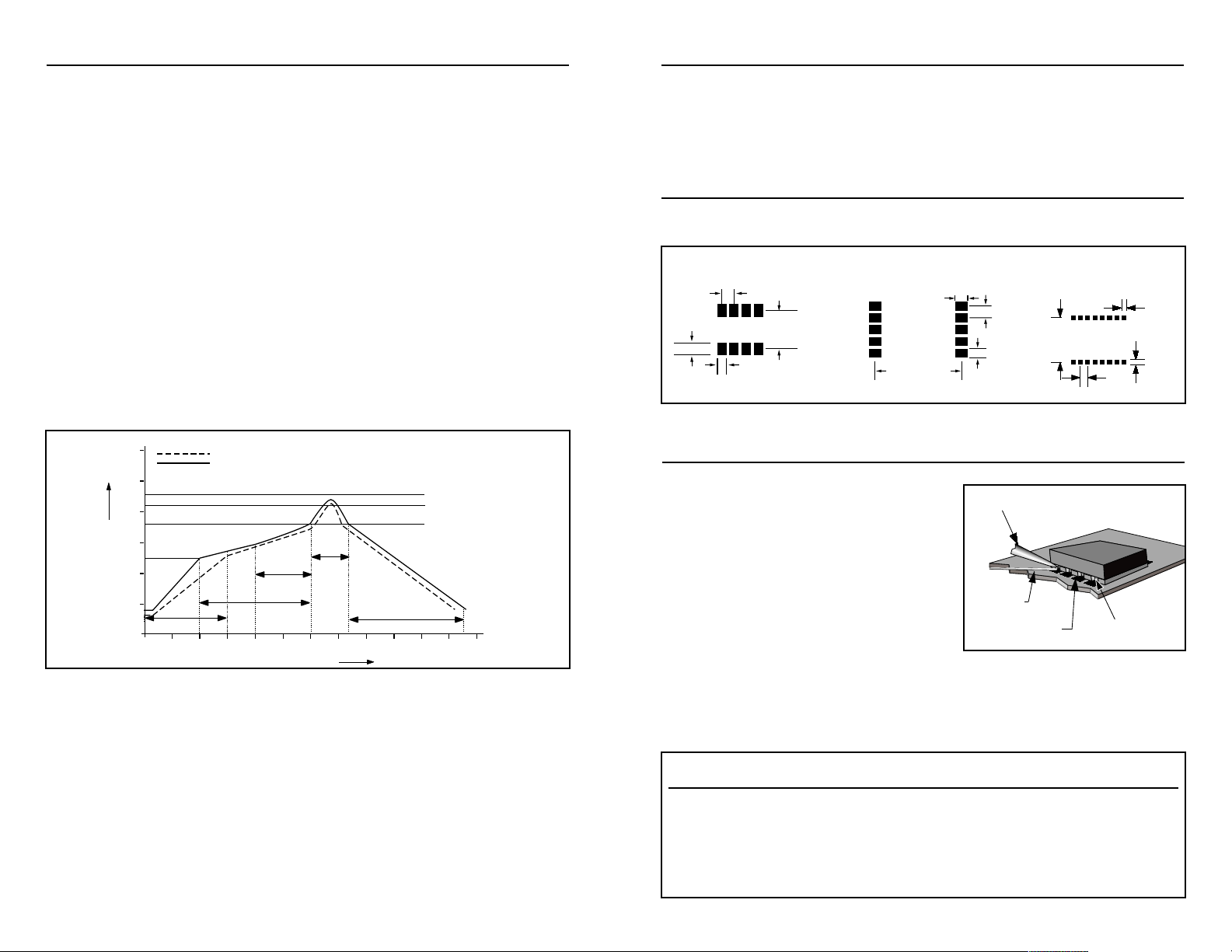

PRODUCTION GUIDELINES

The LC modules are packaged in a hybrid SMD package which has been

designed to support hand- or automated-assembly techniques.Since LC devices

contain discrete components internally, the assembly procedures are critical to

insuring the reliable function of the LC product.The following procedures should

be reviewed with and practiced by all assembly personnel.

PAD LAYOUT

The following pad layout diagrams are designed to facilitate both hand and

automated assembly.

TRANSMITTER HAND ASSEMBLY

The LC transmitter's primary mounting

surface is eight pads located on the bottom

of the module. Since these pads are

inaccessible during mounting, castellations

that run up the side of the module have

been provided to facilitate solder wicking to

the module's underside. If the recommended pad placement (Rev.2) has been

followed, the pad on the board will extend

slightly past the edge of the module.Touch

both the PCB pad and the module

castellation with a fine soldering tip. Tack

one module corner first, then work around

the remaining attachment points using

care not to exceed the solder times listed

below.

Absolute Maximum Solder Times

Hand-Solder Temp. TX +225°C for 10 Sec.

Hand-Solder Temp. RX +225°C for 10 Sec.

Recommended Solder Melting Point +180°C

Reflow Oven: +220° Max. (See adjoining diagram)

figure 7: Suggested Pad Layout

Figure 8: LC-TX Soldering Technique

0.100"

0.310"

0.100"

0.070"

.100

0.150

.070

0.775

TX Layout Pattern Rev. 2

(Not to Scale)

LC-P RX Layout Pattern Rev. 3

Pinned SMD Version

(Not to Scale)

LC-S RX Layout Rev. 1

Compact SMD Version

(Not to Scale)

Page 4

TRANSMITTER AUTOMATED ASSEMBLY

For high-volume assembly most users will want to auto-place the modules. The

modules have been designed to maintain compatibility with most pick-and-place

equipment; however, due to the module's hybrid nature certain aspects of the

automated assembly process are far more critical than for other component

types.

Following are brief discussions of the three primary areas where caution must be

observed.

Reflow T emperature Profile

The single most critical stage in the automated assembly process is the reflow

process. The reflow profile below should be closely followed since excessive

temperatures or transport times during reflow will irreparably damage the

modules. Assembly personnel will need to pay careful attention to the oven's

profile to insure that it meets the requirements necessary to successfully reflow

all components while still meeting the limits mandated by the modules

themselves.

Shock During Reflow Transport

Since some internal module components may reflow along with the components

placed on the board being assembled, it is imperative that the module not be

subjected to shock or vibration during the time solder is liquidus.

Washability

The modules are wash resistant, but are not hermetically sealed. They may be

subject to a standard wash cycle;howev er, a twenty-four-hour drying time should

be allowed before applying electrical power to the modules. This will allow any

moisture that has migrated into the module to evaporate, thus eliminating the

potential for shorting during power-up or testing.

figure 6: Required reflow profile

0.065"

0.610"

0.100"

0.070"

300

°C

250

200

Temperature

150

100

50

Ideal Curve

Limit Curve

125°C

Preheat Zone

Ramp-up

1-1.5 Minutes

0

30 90 150 210 270 330 360

2-2.3 Minutes

600

Forced Air Reflow Profile

220°C

210°C

180°C

Reflow Zone

Soak Zone

2 Minutes Max.

120 180 240 300

20-40 Sec.

Cooling

Time (Seconds)

Soldering Iron

Tip

Solder

PCB Pads

Castellations

Page 4

Page 7

Output Isolation

& Filter

RF Amplifier

Keyed Output

Vcc

SAW

Oscillator

Data In

300-5000 BPS

50 Ω RF OUT

(Ant.)

figure 11: LC Series Transmitter Block Diagram

MODULE DESCRIPTION

The LC-TXM is a low-cost, high-performance SAW-(Surface Acoustic Wave) based

CPCA (Carrier-Present Carrier-Absent) transmitter capable of sending serial data at

up to 5,000 bits/second. The LC’s compact surface-mount package integrates easily

into existing designs and is equally friendly to prototype and volume production.The

LC’s ultralow power consumption makes it ideally suited for battery powered

products. When combined with a Linx LC series receiver a reliable RF link capable

of transferring data over line-of-sight distances in e xcess of 300 feet (90M) is formed.

THEORY OF OPERATION

The LC-TXM transmits data using CPCA (Carrier-Present Carrier-Absent)

modulation. This type of AM modulation is often referred to by other designations

including CW and OOK. This type of modulation represents a logic low ‘0’ by the

absence of a carrier and a logic high ‘1’by the presence of a carrier. This modulation

method affords numerous benefits. Three of the most important are: 1) Costeffectiveness due to design simplicity. 2) No minimum data rate or mark/space ratio

requirement.3) Higher output power and thus greater range in countries (such as the

US) where output power measurements are averaged over time. (Please refer to

Linx application note #00130).

The LC-TXM is based on a simple but highly optimized architecture which achieves

a high fundamental output power with low harmonic content.This insures that most

approval standards can be met without external filter components.The LC transmitter

is exceptionally stable over time, temperature, and physical shock as a result of the

precision SAW (Surf ace Acoustic Wave) frequency reference .Due to the of the SAW

device most of the output power is concentrated in a narrow bandwidth. This allows

the receiver’s pass opening can be quite narrow, thus increasing sensitivity and

reducing susceptibility to near-band interference. The quality of components and

overall architecture utilized in the LC series is unusual in a low-cost RFdevice and is

one reason the LC transmitter is able to outperform far more expensive products.

THE DATA INPUT

A CMOS/TTL level data input is provided on pin 2.This pin is normally supplied with

a serial bitstream input directly from a microprocessor, encoder, or UART. During

standby or the input of a logic low, the carrier is fully suppressed and the transmitter

consumes less than 2µA of current. During a logic high the transmitter generates a

carrier to indicate to the receiver the presence of a logic 1.The applied data should

not exceed a rate of 5,000 bits/sec.The data input pin should always be driven with

a voltage common to the supply voltage present at pin 7 (Vcc).The data pin should

never be allowed to exceed the supply voltage (Vcc).

Page 6

PIN DESCRIPTIONS:

Pin 1 GROUND

Connect to quiet ground or groundplane.

Pin 2 DATA IN

Serial data input pin.TTL and CMOS compatible.

Pin 3 GROUND

Connect to quiet ground or groundplane.

Pin 4 LADJ/GND

Output power level adjustment. Connect to ground

for 3V operation. Connect to ground through 430

Ohm resistor for 5V operation. (see graph on

page 3 and page 10)

Pin 5 RF OUT

Connect to 50Ω matched antenna.

Pin 6 GROUND

Connect to quiet ground or groundplane.

Pin 7 POSITIVE SUPPLY (Vcc 2.7-6 VDC)

The supply must be clean (<20 mV pp), stable and

free of high-frequency noise. A supply filter is

recommended unless the module is operated from its own regulated supply or

battery.

Pin 8 GROUND

Connect to quiet ground or groundplane.

POWER SUPPLY REQUIREMENTS

The transmitter module requires a clean, wellregulated power source.While it is preferable to power

the unit from a battery, the unit can also be operated

from a power supply as long as noise and ‘hash’ are

kept to less than 20 mV. A 10Ω resistor in series with

the supply followed by a 10µF tantalum capacitor from

Vcc to ground as shown at the right will help in cases

where the quality of supply power is poor.

figure 10: Supply Filter

PHYSICAL PACKAGING

The transmitter is packaged as a hybrid SMD module with eight pads spaced

0.100" apart on center. The SMD package is equipped with castellations which

allow for side introduction of solder.This simplifies prototyping or hand assembly

while maintaining compatibility with automated pick-and-place equipment.

Modules are available in tube or tape-and-reel packaging (see page 1 for

ordering information).

figure 9: LC -TXM Physical

Package

10R

.290

.042

.103.103

TOP VIEW

.505

SIDE VIEW

BOTTOM VIEW

1 2 3 4

8 7 6 5

.365

.150 Max.

.060 x .060

Typ.

.100 (Typ.)

Page 5

Page 9

BOARD LAYOUT CONSIDERATIONS

If you are at all familiar with RF de vices you

may be concerned about specialized board

layout requirements. Fortunately, because

of the care taken by Linx in designing the

LC series, integration is very

straightforward. This ease of application

results from the advanced multi-layer

construction of the module. By adhering to

the following layout principles and

observing a few basic design rules, you can

enjoy a straightforward path to RF success.

1. A groundplane should be placed under

the module as shown.It will generally be

placed on the bottom layer. The amount

of overall plane is also critical for the

correct function of many antenna styles and is covered in the next section.

2. Observe appropriate layout practice between the module and its antenna. A

simple trace may suffice for runs of less than .25" but longer distances should be

covered using 50Ω coax or a 50Ω microstrip transmission line. In order to

minimize loss and detuning, a microstrip transmission line is commonly utilized.

The term microstrip refers to a PCB trace running over a groundplane, the width

of which has been calculated to serve as a 50Ω transmission line.This effectively

removes the trace as a source of detuning.The correct trace width can be easily

calculated using the information below.The width is based on the desired

characteristic impedance, the thickness of the PCB, and its dielectric constant.

figure 13: Example of proper

groundplane

Effective

Dielectric Width/Height Dielectric Characteristic

Constant (W/d) Constant Impedance

4.8 1.8 3.59 50.0

4 2 3.07 51.0

2.55 3 2.12 48.0

figure 14: Microstrip formulas (Er = Dielectric constant of pc board material)

Page 8

Notes:

1) DIP Switch used to set ID code. A 3-position switch was chosen for this example but all or none of the

address bits may be used. Settings of the Receiver and Transmitter must match for signal to be recognized.

figure 12: Basic Remote Control Transmitter Circuit

TRANSMITTING DATA

Once a reliable RF link has been established, the challenge becomes how to

effectively transfer data across it. While a properly designed RF link provides reliable

data transfer under most conditions, there are still distinct differences from a wired

link that must be addressed. Since the LC modules do not incorporate internal

coding/decoding, a user has tremendous flexibility in how data is formatted and sent.

It is always important to separate what type of transmissions are technically possible

from those that are legally allowable in the country of intended operation.You may

wish to review application notes #00125 and #00140 along with Part 15 Sec. 231 for

further details on acceptable transmission content.

Another consideration is that of data structure or protocol. If you are not familiar with

the sending serial data in a wireless environment read Linx application note #00232

(Considerations for sending data with the LC series). This application note details

important issues such as the effect of start-up times, pulse stretching and shortening

and the relationship between data and output power in a CPCA-based transmitter.

These issues should be understood prior to commencing a design effort.

If you want to send simple control or status signals such as button presses or switch

closures, consider using an encoder and decoder IC set availab le from a wide range

of manufacturers including:Microchip (Keeloq), Holtek, and Motorola.These IC’s take

care of all encoding, error checking, and decoding functions and generally provide a

number of data pins to which switches can be directly connected. Address bits are

usually provided for security and to allow the addressing of multiple receivers

independently. Additionally, it is a simple task to interface with inexpensive

microprocessors such as the Microchip PIC or one of many IR, remote control,

DTMF, and modem IC’s.

Shown below is an example of a basic remote control transmitter utilizing a encoder

chip from Holtek.When a key is pressed at the transmitter, a corresponding pin at the

receiver goes high. A schematic for the receiver/decoder circuit may be found in the

LC receiver guide.

GROUNDPLANE

ON BOTTOM LAYER

Page 6

Page 11

ANTENNA CONSIDERATIONS

The choice of antennas is one of the most critical and often overlooked design

considerations. The range, performance, and legality of an RF link is critically

dependent upon the type of antenna employed. Proper design and matching of an

antenna is a complex task requiring sophisticated test equipment and a strong

background in principles of RF propagation. While adequate antenna performance

can often be obtained by trial and error methods, you may also want to consider

utilizing a professionally designed antenna such as those offered by Linx. Our lowcost antenna line is designed to ensure maximum performance and compliance with

Part 15-attachment requirements. The pur pose of the following sections is to give

you a basic idea of some of the considerations involved in the design and selection

of antennas. For a more comprehensive discussion please review Linx applications

note #00500 “Antennas: Design, Application, Performance”.

THE TRANSMITTER ANTENNA

The transmitter antenna allows RF energy to be efficiently radiated from the output

stage into free space. In modular designs such as the LC, a transmitter’s output

power is often slightly higher than the legal limit.This allows a designer to utilize an

inefficient antenna in order to achieve full legal power while meeting size, cost, or

cosmetic objectives. For this reason a transmitter's antenna can generally be less

efficient than the antenna used on the receiver.

It is usually best to utilize a basic 1/4-wave whip for your initial concept evaluation.

Once the prototype product is operating satisfactorily, a production antenna should

be selected to meet the cost, size and cosmetic requirements of the product.

Maximum antenna efficiency is always obtained when the antenna is at resonance.

If the antenna is too short, capacitive reactance is present; if it is too long, inductive

reactance will be present. The indicator of resonance is the minimum point in the

VSWR curve. You will see from the following example that antenna (A) is resonant

at too low a frequency, indicating excessive length, while antenna (C) is resonant at

too high a frequency, indicating the antenna is too shor t. Antenna (B), however, is

“just right.”

Antenna resonance should not be confused with antenna impedance.The difference

between resonance and impedance is most easily understood by considering the

value of VSWR at its lowest point. The lowest point of VSWR indicates the antenna

is resonant, but the value of that low point is determined by the quality of the match

between the antenna, the

transmission line, and the

device to which it is

attached.

To fully appreciate the

importance of an antenna

that is both resonant and

matched consider that an

antenna with a VSWR of

1.5 will effectively transmit

approximately 95% of its

power while an antenna

with a VSWR of 10 will only

transmit about 30%.

Page 10

3. Depending on the type of antenna being used and duty cycle of incoming data,

the output power of the LC module may be higher than FCC regulations allow.

The output power of the module is intentionally set high since many designers

pair the module with an inefficient antenna in order to realize cost or space

savings. Since attenuation is often required it is generally wise to provide for its

implementation.

Two methods of attenuation are available using the LC module. First, a resistor

may be placed in series with Pad 4 (LVL. ADJ.) to achieve up to a 7 dB reduction

in output power.The resistor value is easily determined from the diagram below.

Do not exceed the resistance values shown as transmitter instability may result.

This method can also be used to reduce transmission range and power

consumption.

OUNDPLANE

ON LO

WER LA

YER

OUND

OUND

figure 16: Attenuation pad layout

figure 15: Power Output vs. LADJ Pad Resistor Value

Another method commonly used to achieve attenuation, particularly at higher

levels, is the use of a T-pad. A T-pad is a 3-resistor network that allows for va riable

attenuation while maintaining the quality of match to the antenna. It is usually

prudent to allow space for the addition of a T-pad. For further details on T-pads

please refer to Linx application note #00150.

+8

+7

+6

+5

+4

+3

+2

5V

+1

0

-1

-2

Output Power dBm

-3

3V

-4

51 100 150 200 240 300 360 430 510 560 620 680 750 820 910 1.1K

L

Pin Resistor Value

ADJ

CIRCUIT

ANT.

R1

R1

ANT. OUT

R2

GND

PADS FOR SMT

PADS FOR SMT

TYPICAL LAYOUT

WITH PROVISION FOR ATTENUATION

ANT.

RESISTORS

RESISTORS

GRGROUNDPLANE

GROUNDPLANE

ON LOWER LAYER

ON LO

WER LA

YER

GRGROUND

GROUNDGRGROUND

GROUND

DESIRED FREQUENCY

AB C

Page 7

GUIDELINES FOR ACHIEVING OPTIMUM ANTENNA PERFORMANCE

1. Proximity to objects such as a user’s hand or body, or metal objects will cause

an antenna to detune. For this reason the antenna shaft and tip should be

positioned as far away from such objects as possible.

2. Optimum performance will be obtained

from a 1/4- or 1/2-wave straight whip

mounted at a right angle to the

groundplane. In many cases this isn’t

desirable for practical or ergonomic

reasons; thus, an alternative antenna

style such as a helical, loop, patch, or

base-loaded whip may be utilized.

3. If an internal antenna is to be used, keep it away from other metal components,

particularly large items like transformers, batteries, and PCB tracks and

groundplanes. In many cases, the space around the antenna is as impor tant

as the antenna itself.

4. In many antenna designs, particularly

1/4-wave whips, the groundplane acts

as a counterpoise, forming, in essence,

a 1/2-wave dipole. For this reason

adequate groundplane area is

essential. The groundplane can be a

metal case or ground-fill areas on a

circuit board.Ideally , the groundplane to

be used as counterpoise should have a surface area ≥ the overall length of the

1/4-wave radiating element;however , Linx recognizes that this is impossib le f or

most compact designs, so all Linx antennas are characterized using a 4.5” X

4.5” groundplane with the antenna centered and oriented at a 90° angle. Such

an orientation is often not practical due to size and configuration constraints.

In these instances a designer must make the best use of the area available to

create as much groundplane in proximity to the base of the antenna as

possible.In instances where the antenna is remotely located or the antenna is

not in close proximity to a circuit board plane or grounded metal case, a small

metal plate may be fabricated to maximize antenna perfor mance.

5. Remove the antenna as far as possible from potential interference sources.

There are many possible sources of internally generated interference.

Switching power supplies, oscillators, even relays can also be significant

sources of potential interference. Remember, the single best weapon against

such problems is attention to placement and layout.Filter the module’s power

supply with a high-frequency bypass capacitor. Place adequate groundplane

under all potential sources of noise. Shield noisy board areas whenever

practical.

6. In some applications it is advantageous to place the transmitter and its

antenna away from the main equipment.This avoids interference problems and

allows the antenna to be oriented for optimum RF performance. Always use

50Ω coax such as RG-174 for the remote feed.

Page 13

Helical Style

Whip Style

Loop Style

1/4-wave wire lengths

for LC frequencies:

315Mhz=8.9"

418Mhz=6.7"

433Mhz=6.5"

Where:

L=length in feet of quarter-wave length

F=operating frequency in megahertz

COMMON ANTENNA STYLES

There are literally hundreds of antenna styles that can be successfully employed with the

LC Series. Following is a brief discussion of the three styles most commonly utilized in

compact RF designs.Additional antenna information can be found in Linx application notes

#00500, #00100, #00126 and #00140.

Linx also offers a broad line of antennas and

connectors which offer outstanding performance and cost-effectiveness.

A whip-style monopole antenna provides outstanding overall

performance and stability. A low-cost whip can be easily fabricated from

wire or rod, but most product designers opt for the improved

performance and cosmetic appeal of a professionally made model. To

meet this need, Linx offers a wide variety of straight and reduced-height

whip-style antennas in permanent and connectorized mounting styles.

The wavelength of the operational frequency determines an antenna's

overall length. Since a full wavelength is often quite long, a partial 1/4wave antenna is normally employed. Its size and natural radiation

resistance make it well matched to Linx modules.The proper length for

a 1/4-wave antenna can be easily found using the formula below. It is

also possible to reduce the overall height of the antenna by using a

helical winding. This decreases the antenna's bandwidth but is an

excellent way to minimize the antenna's physical size for compact

applications.

A helical antenna is precisely formed from wire or rod.A helical antenna

is a good choice for low-cost products requiring average rangeperformance and internal concealment. A helical can detune badly in

proximity to other objects and its bandwidth is quite narrow so care must

be exercised in layout and placement.

A loop- or trace-style antenna is normally printed directly on a product's

PCB.This makes it the most cost-effective of antenna styles. There are

a variety of shapes and layout styles which can be utilized.The element

can be made self-resonant or externally resonated with discrete

components. Despite its cost advantages, PCB antenna styles are

generally inefficient and useful only for short-range applications. Loopstyle antennas are also very sensitive to changes in layout or substrate

dielectric which can introduce consistency issues into the production

process. In addition, printed styles initially are difficult to engineer,

requiring the use of expensive equipment including a network analyzer.

An improperly designed loop will have a high SWR at the desired

frequency which can introduce substantial instability in the RF stages.

Linx offers a low-cost planar antenna called the “SPLATCH” which is an

excellent alternative to the sometimes problematic PCB trace style.This

tiny antenna mounts directly to a product's PCB and requires no testing

or tuning. Its design is stable even in compact applications and it

provides excellent performance in light of its compact size.

L =

234

F

MHz

Page 12

figure 17: Groundplane orientation

figure 18: External antenna mounting

OPTIMUM

USEABLE

NOT RECOMMENDED

CASE

NUT

GROUNDPLANE

(MAY BE NEEDED)

Page 8

Page 15Page 14

SURVIVING AN RF IMPLEMENTATION

Adding an RF stage brings an exciting new dimension

to any product.It also means that additional effort and

commitment will be needed to bring the product

successfully to market. By utilizing premade RF

modules, such as the LC series, the design and

approval process will be greatly simplified. It is still

important, however, to have an objective view of the

steps necessary to insure a successful RF

integration. Since the capabilities of each customer

vary widely it is difficult to recommend one particular

design path, but most projects follow steps similar to

those shown at the right.

In reviewing this sample design path you may notice

that Linx offers a variety of services, such as antenna

design, and FCC prequalification, that are unusual for

a high-volume component manufacturer. These

services, along with an exceptional level of technical

support, are offered because we recognize that RF is

a complex science requiring the highest caliber of

products and support. “Wireless Made Simple” is

more than just a motto, it’s our commitment. By

choosing Linx as your RF partner and taking

advantage of the resources we offer, you will not only

survive implementing RF, you may even find the

process enjoyable.

TYPICAL STEPS FOR

IMPLEMENTING RF

HELPFUL APPLICATION NOTES FROM LINX

It is not the intention of this manual to address in depth many of the issues that

should be considered to ensure that the modules function correctly and deliver

the maximum possible performance.As you proceed with your design you may

wish to obtain one or more of the following application notes, which address in

depth key areas of RF design and application of Linx products.

00232 General considerations for sending data with the LC Series

00500 Antennas: Design, Application, Performance

00130 Modulation techniques for low-cost RF data links

00125 Considerations for operation in the 260 Mhz to 470 Mhz band

00100 RF 101: Information for the RF challenged

00110 Understanding the performance specifications of receivers

00140 The FCC Road: Part 15 from concept to approval

00150 Use and design of T-Attenuation Pads

NOTE # LINX APPLICATION NOTE TITLE

LEGAL CONSIDERATIONS

When working with RF, a clear distinction must be made between what is technically

possible and what is legally acceptable in the country where operation is intended.

Many manufacturers have avoided incorporating RF into their products as a result of

uncertainty and even fear of the approval and certification process. Here at Linx our

desire is not only to expedite the design process, but also to assist you in achieving

a clear idea of what is involved in obtaining the necessary approvals to mar ket your

completed product legally.

In the United States the approval process is actually quite straightforward. The

regulations governing RF devices and the enforcement of them are the responsibility

of the Federal Communications Commission. The regulations are contained in the

Code of Federal Regulations (CFR), Title 47. Title 47 is made up of numerous

volumes; however, all regulations applicable to this module are contained in volume

0-19. It is strongly recommended that a copy be obtained from the Government

Printing Office in Washington, or from your local government book store. Excerpts of

applicable sections are included with Linx evaluation kits or ma y be obtained from the

Linx Technologies web site (www.linxtechnologies.com). In brief, these rules require

that any device which intentionally radiates RF energy be approved, that is, tested,

for compliance and issued a unique identification number .This is a relatively painless

process. Linx offers full EMC pre-compliance testing in our HP/Emco-equipped test

center. Final compliance testing is then performed by one of the many independent

testing laboratories across the country. Many labs can also provide other

certifications the product may require at the same time, such as UL, CLASS A/B, etc.

Once your completed product has passed, you will be issued an ID number which is

then clearly placed on each product manufactured.

Questions regarding interpretations of the Part 2 and Part 15 rules or measurement

procedures used to test intentional radiators, such as the LC modules, for

compliance with the Part 15 technical standards, should be addressed to:

Federal Communications Commission

Equipment Authorization Division

Customer Service Branch, MS 1300F2

7435 Oakland Mills Road

Columbia, MD 21046

Tel: (301) 725-1585 / Fax: (301) 344-2050 E-Mail: labinfo@fcc.gov

International approvals are slightly more complex, although many modules are

designed to allow all international standards to be met. If you are considering the

export of your product abroad, you should contact Linx Technologies to determine

the specific suitability of the module to your application.

All Linx modules are designed with the approval process in mind and thus much of

the frustration that is typically experienced with a discrete design is eliminated.

Approval is still dependent on many factors such as the choice of antennas, correct

use of the frequency selected, and physical packaging.While some extra cost and

design effort are required to address these issues, the additional usefulness and

profitability added to a product by RF makes the effort more than worthwhile.

NOTE: LC Series Modules are designed as component devices which require

external components to function. The modules are intended to allow for full P art

15 compliance; however, they are not approved by the FCC or any other agency

worldwide. The purchaser understands that approvals may be required prior to

the sale or operation of the device, and agrees to utilize the component in keeping

with all laws governing its operation in the country of operation.

DECISION TO UTILIZE RF IS MADE

RESEARCH RF OPTIONS

ORDER EVALUATION KIT(S)

TEST MODULE(S) WITH

BASIC HOOKUP

LINX MODULE IS CHOSEN

INTERFACE TO CHOSEN

CIRCUIT AND DEBUG

CONSULT LINX REGARDING

ANTENNA OPTIONS AND DESIGN

LAY OUT BOARD

SEND PRODUCTION-READY

PROTOTYPE TO LINX

FOR EMC PRESCREENING

OPTIMIZE USING RF SUMMARY

GENERATED BY LINX

SEND TO PART 15

TEST FACILITY

RECEIVE FCC ID #

COMMENCE SELLING PRODUCT

Page 9

Page 16

U.S. CORPORATE HEADQUARTERS:

Linx Technologies is continually striving to improve the quality and function of its products; for

this reason, we reserve the right to make changes without notice.The information contained in

this Data Sheet is believed to be accurate as of the time of pub lication.Specifications are based

on representative lot samples. Values may var y from lot to lot and are not guaranteed. Linx

Technologies makes no guarantee, warranty, or representation regarding the suitability of any

product for use in a specific application. None of these devices is intended for use in

applications of a critical nature where the safety of life or property is at risk.The user assumes

full liability for the use of product in such applications.Under no conditions will Linx Technologies

be responsible for losses arising from the use or failure of the device in any application, other

than the repair, replacement, or refund limited to the original product purchase price. Some

devices described in this publication are patented. Under no circumstances shall any user be

conveyed any license or right to the use or ownership of these patents.

Disclaimer

© 1999 by Linx Technologies, Inc. The stylized

Linx logo, Linx, and “Wireless Made Simple”

are the trademarks of Linx Technologies, Inc.

Printed in U.S.A.

LINX TECHNOLOGIES, INC.

575 S.E. ASHLEY PLACE

GRANTS PASS, OR 97526

Phone: (541) 471-6256

FAX: (541) 471-6251

http://www.linxtechnologies.com

Loading...

Loading...