Page 1

WIRELESSFLOWSENSOR

Owner’s Manual and Installation Guide

Wireless Flow Sensor for Use with Compatible Hunter Controllers

WFS

Hunter Wireless-Flow-Sync

Page 2

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................ 3

WFS COMPONENTS ........................................................................................................ 4

SYSTEM OVERVIEW AND WFS OPERATION ................................................................. 6

INSTALLING THE WFS SENSOR & FCT TEE ................................................................... 8

INSTALLING THE WFS SENSOR INTO THE FCT FITTING ............................................ 12

CONNECTING THE WFS TO THE IRRIGATION SYSTEM ............................................. 14

SYSTEM CONSIDERATIONS ............................................................................................ 17

TROUBLESHOOTING GUIDE ..........................................................................................20

SPECIFICATIONS AND CALIBRATION ............................................................................23

Page 3

INTRODUCTION

The Hunter WFS allows flow-capable

controllers, such as the Hunter ACC and I-Core,

to monitor actual flow in irrigation systems.

With proper setup at the controller, this allows

the controller to record and report actual flow

in liters or gallons. Flow learning controllers can

also use WFS to learn typical flow for each zone

of irrigation, and monitor during watering for

high and low flow conditions.

WFS equips controllers to respond on

their own to incorrect system performance,

preventing damage to landscape and wasted

water resources.

3

Page 4

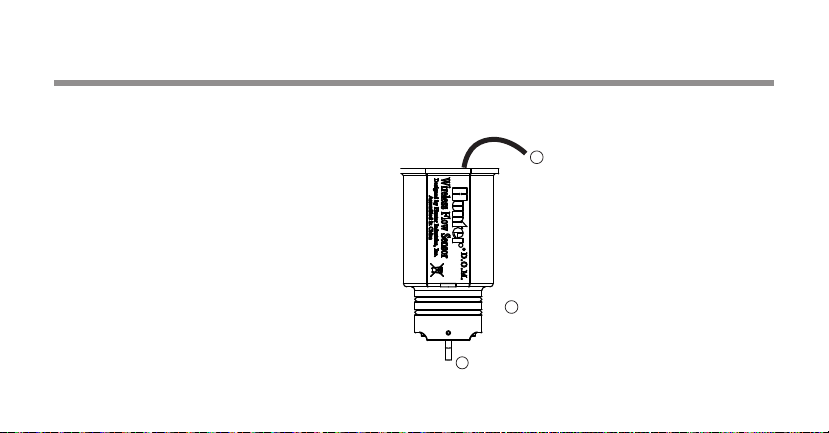

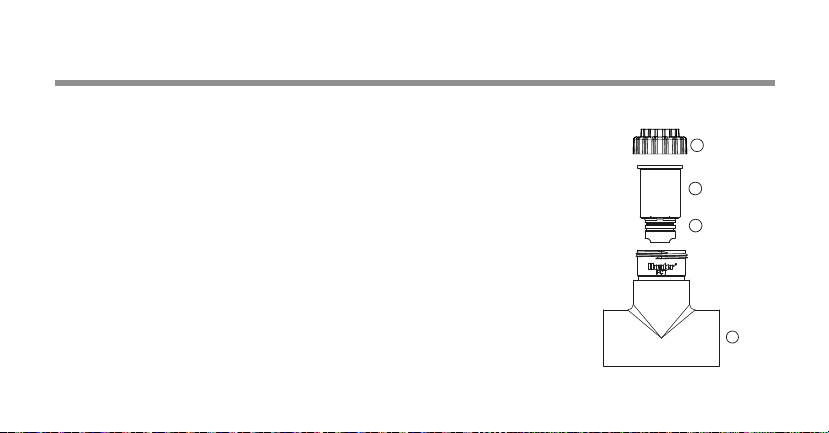

WFS COMPONENTS

This section will give you a brief overview

of some of the components of the

Wireless-Flow-Sync system.

1. Impeller: Rotates when ow is occurring

2. O-rings:

sensor body

3. Wire:

transmitter

4

Provides sealing of sensor in

Black wire connects to the sensor

3

2

1

Page 5

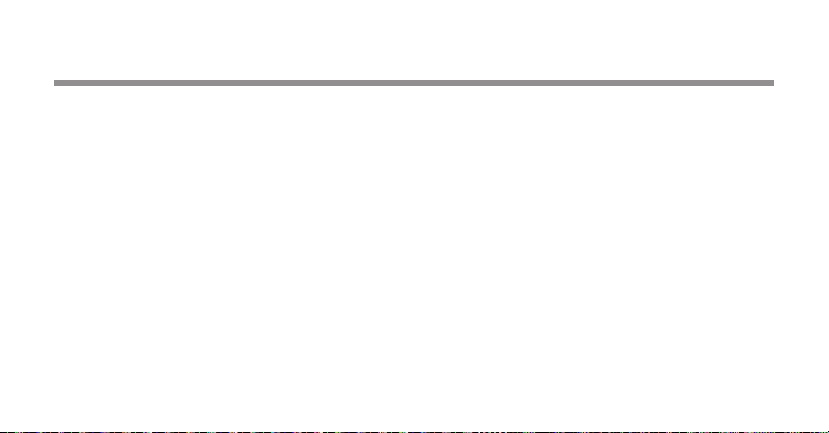

WFS TEE ASSEMBLY

1. Flow-Sync Tee: The Tee is installed into the irrigation system and houses the WFS

2. O-rings:

3. Plug:

4. Cap:

Provides sealing of plug in sensor body

(replace with WFS at Installation)

To seal plug to Flow-Sync-Tee

4

3

2

1

5

Page 6

SYSTEM OVERVIEW AND WFS OPERATION

The WFS is typically installed near the point of

connection, in an appropriately-sized FCT Tee.

The WFS transmitter can connect to a host controller up to 500ft/152M away.

WFS sensors operate with an impeller

positioned in the flow through the pipes.

As the impeller turns, pulses are generated to

the controller, which converts them to gallons or

liters, depending on the Units of Measurement

selection in the controller.

WFS Sensor is a reporting device, and does not

respond to flow situations on its own. WFS is

6

almost always installed in conjunction with a

Master Valve, which can stop flow in a damaged

pipe when high flow conditions are detected.

Page 7

WFS ICORE

WIRING

7

Page 8

INSTALLING THE WFS SENSOR AND FCT TEE

The WFS Sensor is designed to install within an

FCT tee fitting, sized for the pipe in which it will

be installed.

For international applications, optional slip-BSP

adapters are available separately for sizes up to

75 mm.

HFS FCT Tee Fitting Models (All tees are glue/slip type fittings)

Model Material Diameter (US) Diameter (mm)

FCT 100 Schedule 40 (white) 1" 25 mm

FCT 150 Schedule 40 (white) 1.5" 37 mm

FCT 158 Schedule 80 (gray) 1.5" 37 mm

FCT 200 Schedule 40 (white) 2" 50 mm

FCT 208 Schedule 80 (gray) 2" 50 mm

FCT 300 Schedule 40 (white) 3" 75 mm

FCT 308 Schedule 80 (gray) 3" 75 mm

FCT 400 Schedule 40 (white) 4" 100 mm

8

BSP Adapters

Diameter (mm) Model

25 mm 795700

37 mm 795800

50 mm 241400

75 mm 477800

Page 9

INSTALLATION

Install the FCT tee fitting first, then install the

WFS Sensor into the fitting.

Observe the following general rules when choosing

the sensor location and preparing to install:

• Flush system with plug in place before

installing the WFS sensor, to prevent damage

to the impeller.

• Always install WFS together with a Master

Valve, to provide overflow protection.

• Install the WFS and Master Valve as

near the point of connection to the water

supply as possible.

• WFS requires a section of straight

pipe on either side of the tee fitting to provide

accurate measurement of flow. Tees, ells,

and other fittings cause turbulence which

affects accuracy.

• There must be a length of straight pipe at least

10 times the diameter of the pipe upstream

from the WFS (toward the water supply).

• There must be a length of straight pipe at least

5 times the diameter of the pipe in the downstream direction (toward the sprinklers).

9

Page 10

• Example: FCT-200 is installed in a 2”/50 mm

diameter pipe. The tee should have 20”/50

cm of straight pipe upstream, and 10”/25 cm

straight pipe downstream.

• Install the WFS and FCT assembly in a sturdy

irrigation valve box.

• WFS has an impeller which will turn in the flow

of water. If the water source is not a public

water supply, add a filter upstream from the

Master Valve and WFS to protect the impeller

from rocks or stones, which may damage the

impeller.

10

The FCT tee fitting is designed for glue (“slip”)

connection. Use approved PVC solvent-welding

glue to install either threaded fittings, or directly

into the irrigation pipe if desired.

Metric thread adapters are available and are

listed in this manual on page 8.

Avoid excess glue when attaching

fittings. Uncured blobs of excess glue

on the fitting’s interior can interfere

with paddlewheel operation.

Page 11

EXAMPLE OF INSTALL

*NOTE: Not to scale.

11

Page 12

INSTALLING THE WFS SENSOR INTO THE FCT FITTING

The FCT tee fitting comes with a plug that allows

for installation of the FCT into the irrigation

system prior to installing the Sensor. This allows

the FCT tee to be installed separately from the

sensor and prevents damage to the sensor during

installation of the body.

NOTE: Do not attempt to remove the

sensor plug or sensor while the system

is under pressure

12

To install the sensor into the body:

1.

Turn the system pressure o.

2.

Unscrew the cap from the top of the FCT (gure 1).

3.

Use pliers or a screwdriver and carefully pry the

plug from the FCT tee.

4.

Insert the sensor into the FCT. The sensor has a

at side that engages with a at on the inside of

the sensor body (gure 2).

Page 13

INSTALLING THE WFS SENSOR INTO THE FCT FITTING

5. Hand tighten the WFS sensor cap. (gure 3).

NOTE: Never glue the HFS sensor

into the fitting! The threaded cap is

designed to seal under pressure

Figure 1 Figure 3

Figure 2

13

Page 14

CONNECTING THE WFS TO THE IRRIGATION SYSTEM

WARNING! WFS is only designed for low-voltage

connection to approved irrigation controller flow

terminals. Do not install in high-voltage 110V or

230V circuits.

WFS has one wire lead which leads to the

transmitter. The transmitter may be placed up to

500ft/152m from the controller.

Connecting the Receiver

Pro-C

Wire the leads from the receiver to the SEN

terminals.

14

Page 15

ACC & ICORE

ACC Controller I-Core Controller

INSTALLATION

Use terminals S1 or S2

15

Page 16

Proper irrigation system design and operation

assures optimum performance of the WFS in

monitoring for potential high flow conditions.

WFS is primarily designed to shut off the irrigation system in the event of a catastrophic system

failure such as a main line or lateral line break.

However, depending upon the design of the

16

irrigation system, the WFS can offer increased

protection when components such as sprays or

rotors are damaged or removed due to vandalism. The following may be helpful in making your

WFS operate at its optimum level.

Page 17

SYSTEM CONSIDERATIONS

Working With WFS

Hunter flow-capable controllers are designed

to measure and record actual flow, shut off

irrigation when a high flow condition occurs, and

identify which stations caused the condition.

The controller’s Learn mode samples each station

individually, and learns a typical flow for each

station in the system. During actual irrigation,

the flow can be observed at the controller. Actual

flows are recorded and stored in the controller

facepack. The ACC or I-Core controller will also

compare actual flows to the estimated total of all

active stations, to see if there is an unacceptable

difference, indicating a leak or break.

Consult the controller documentation closely for

setup and operation of flow monitoring. It is

vital to set the correct pipe size, so that the

controller interprets the flow data correctly. It is

also important to set adequate overage amounts

(minimum is 15% over normal) and delays

(default is one minute) to prevent false alarms.

17

Page 18

Mainline Pressure Fluctuation

Some water sources may have varying pressure

depending upon the demand for water upstream

of the point of connection. During times of heavy

demand, system pressure through the mainline

may drop.

This is why the flow limit percentage and delay

periods (set in the controller) are important,

as false alarms lead to a lack of confidence in

the system.

18

Additionally, excess air in irrigation piping causes

the WFS impeller to spin freely during

station startup, which may cause temporarily

high readings. This problem may be reduced by

installing check valves in the system, and by

setting the alarm delay values to prevent

premature alarms.

Page 19

Proper System Maintenance and Operation

It is important that your irrigation system

be maintained and is functioning properly for

optimum performance. Check your irrigation

system for any broken components or leaks

also, making sure that all sprinklers are operating

within the pressure ranges recommended by

the manufacturer.

19

Page 20

Hunter controllers equipped with flow terminals

will have approximately 20 VDC present on the

flow sensor terminals, with no flow input.

20

When flow begins, the voltage will pulse. On a

standard voltmeter, the voltage will appear to

drop, or pulsate. On voltmeters equipped with a

frequency counter, the pulse frequency can be

measured in Hz.

Page 21

TROUBLESHOOTING GUIDE

Problem Cause Solution

WFS not reading Water shut o Verify that no isolation valves are closed, and

Controller not congured Check controller ow sensor setup. Enter

Damaged sensor- Impeller damage

(debris in water) or WFS

electronics damage (lightning)

that the water source is on.

sensor size (and location, for sensor decoders)

and other sensor information as required.

Replace sensor.

21

Page 22

TROUBLESHOOTING

Problem Cause Solution

WFS not reading correctly Controller congured incorrectly Set correct ow sensor size and

type at controller.

Turbulent ow at sensor Insure that straight pipe is on either

Frequent false alarms Station settings too sensitive Increase overow percentage (and

Wide range of ows for a single

station

side of ow meter.

underow if available).

Increase overow and underow

percentages, and delay interval.

22

Page 23

SPECIFICATIONS

Operating Specications

Temperature Pressures Humidity

0 to 140ºF/60ºC up to 200 psi/13.7 bar up to 100%

Flow Range

Flow-Sync

Sensor

Diameter

1" 2 17

1½" 5 35

2" 10 55

3" 28 120

4" 34 195

* Minimum recommended ow for the highest ow zone for

your system

** Good design practice dictates the maximum ow not to

exceed 5/sec. Suggested maximum ow is based upon

Class 200 IPS plastic pipe

Operating Range (Gpm)

Minimum

*

Suggested Maximum**

23

Page 24

FCT TEE FITTING SPECS.

Maximum Distance Between WFS Transmitter and Receiver 500ft/152m

Dimensions

FCT Tee Fitting Height Width Length

FCT 100 4.8″/12 cm 2.3"/6 cm 4.5"/11 cm 10"/25 cm 5"/13 cm

FCT 150 5.4″/14 cm 2.3"/6 cm 4.6"/12 cm 15"/38 cm 8"/20 cm

FCT 158 5.4″/14 cm 2.3"/6 cm 5.1"/13 cm

FCT 200 6″/15 cm 2.7"/7 cm 4.7"/14 cm 20"/50 cm 10"/25 cm

FCT 208 6″/15 cm 2.7"/7 cm 5.4"/14 cm

FCT 300 7″/18 cm 4"/10 cm 6.2"/16 cm 30"/76 cm 15"/38 cm

FCT 308 7″/18 cm 4.2"/11 cm 6.4"/16 cm

FCT 400 8″/20 cm 5"/13 cm 6.2"/16 cm 40"/1 m 20"/50 cm

Straight Pipe

upstre am (Ø x 10)

Straight Pipe

downst ream (Ø x 5)

24

Page 25

WFS Calibration Factors

Hunter controllers allow selection of the correct

pipe size by FC T model number. No further

calibration is needed.

If “Other ” is selected, K-factor and Oset

information may be entered directly. Following

are K-factor and Oset values for best results

with each available FCT model.

Flow Sensor Values

Hunter Flow Sensor K-Factor Oset

HFSFCT100

HFSFCT150

HFSFCT158 0.92 1.22

HFSFCT200 2.13 0.23

HFSFCT208 1.7 2 1.70

HFSFCT300 4.61 0.18

HFSFCT308 5.87 1.07

HFSFCT400 8.77 0.48

0.44 0.39

1.13 0.00

25

Page 26

RATINGS

WFS-R

ࣅ For connection to Hunter controllers only

ࣅ 24 V~ 50/60 Hz 10 mA 0.02W

ࣅ IP 43

ࣅ Ta 50 C

WFS-T

ࣅ Batteries: 3 x 1.5 V AA or Hunter lithium pack WFSLITHBATT

ࣅ IP 67

ࣅ Ta 50 C

26

Page 27

FCC Notice:

This device complies with part 15 of the FCC Rules. (1) this device may not cause interference, and (2) this device must accept any interference,

including interference that may cause undesired operation of the device..

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

The user is cautioned that changes and modifications made to the equipment without the approval of the manufacturer could void the user’s authority to

operate this equipment.

Industry Canada Notice:

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may

not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux

deux conditions suivantes: (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Page 28

RESIDENTIAL & COMMERCIAL Built on Innovation

Diamond Street | San Marcos, California USA

Learn more. Visit hunterindustries.com

®

© Hunter Industries Incorporated

LIT--OM-WFS-US A /

Loading...

Loading...