STG-900-KIT and STG-900-KIT-B

OWNER’S MANUAL

STG-900-KIT / STG-900-KIT-B

Synthetic Turf Rotor and Vault System

Valve Adjacent to Head System

Table of Contents

3 Installation Instructions for Hunter STG-900-KIT and STG-900-KIT-B

3 .... Synthetic Turf Rotor and Vault System

3 .... Setting the ST-173026-B Vault

3 .... Incoming Plumbing Location

4 ....Incoming Plumbing Elevation

4 ....Specication List for Installation Detail Drawings

5 .... Installing the ST-2008-VA Swing Joint

5 .... Installing the Quick Coupler and Inlet Piping

6 .... Attaching the ST-VBF-K Kit to the ST-2008-VA Swing Joint

6 .... Installing the Rotor Rubber Cover Kit

6 .... Attaching the Rotor to the ST-VBVF-K Kit

6 .... Setting the Rotor to Initial Grade

7 .... Setting the Rotor to Final Grade

7 .... Cable Connections

7 .... Setting the Rotor’s Arc Orientation and Arc Adjustment

8 .... Upper Snap Ring Removal

9 .... Riser Assembly Removal

9 .... Arc Adjustment Preparation

9 .... Arc Adjustment Procedure

10 .... Replacing the Riser into the Rotor Body

10 .... Upper Snap Ring Installation

10 .... Logo Cap Installation

11 .... Tack/Glue Board for Vault

11 .... Filling Irrigation Mainline Piping

11 .... Control Valve Flow Adjustment

SCAN

for help

https://hunter.help/stg900

Page 2

RESIDENTIAL & COMMERCIAL IRRIGATION | Built on Innovation

®

Installation Instructions for Hunter STG-900-KIT and STG-900-KIT-B

Synthetic Turf Rotor and Vault System

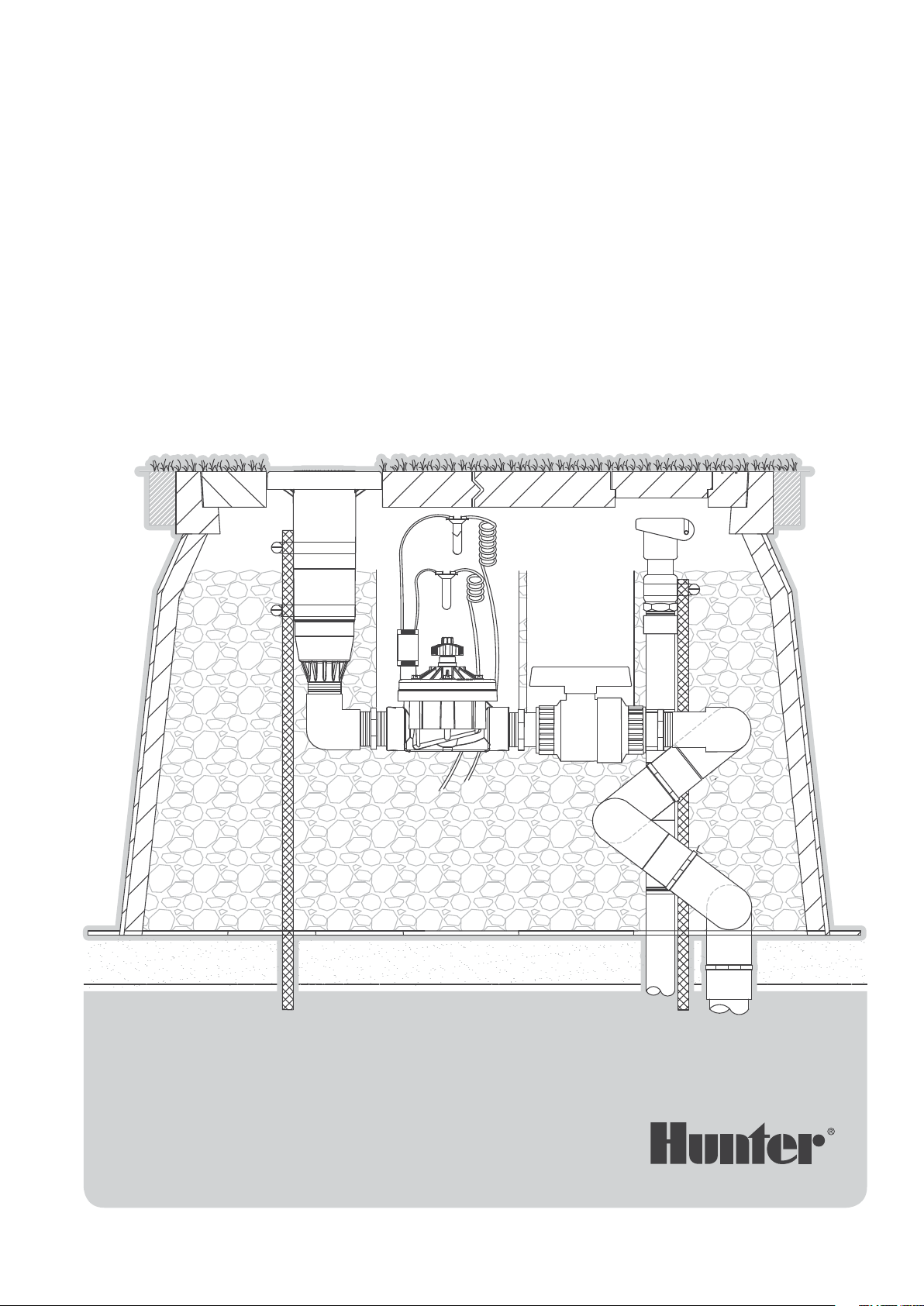

The Hunter STG-900-KIT synthetic turf rotor and vault

system is a special combination of products designed

specically to meet the unique needs of irrigation on synthetic

turf elds. Synthetic turf elds are a non-serviceable surface,

meaning they are not easily excavated and restored to original

condition without huge expense and specialized procedures.

As a result and to the extent possible, all serviceable

components of the irrigation system must be accessible from

the surface. The Hunter STG-900-KIT makes installation and

adjustment straightforward and exible. The STG-900-KIT

also provides easy access for the ongoing maintenance needs

of the end user.

Setting the ST-173026-B Vault

Set the vault according to the installation specications

provided by the irrigation consultant. It must rest upon a

compacted base material per the eld specications. If the

vault is to be set directly upon the gravel of the drainage

system, the gravel should be compacted and the vault set

upon six bricks for stabilization.

The elevation to grade of the vault must be precise and is

determined by the eld and irrigation specication. In many

installations, the elevation for the vault is specied such that

the upper rim of the vault is level with the tack/glue board

that surrounds the eld. The vault’s elevation can also be

aected by the type of material, if any, that will be attached

to the vault’s upper surface. Sometimes this will be the eld’s

synthetic “carpet” or the adjacent running track material.

Some customers prefer no attachments to the covers

because they want a player running toward the vault to see it

and take corrective action.

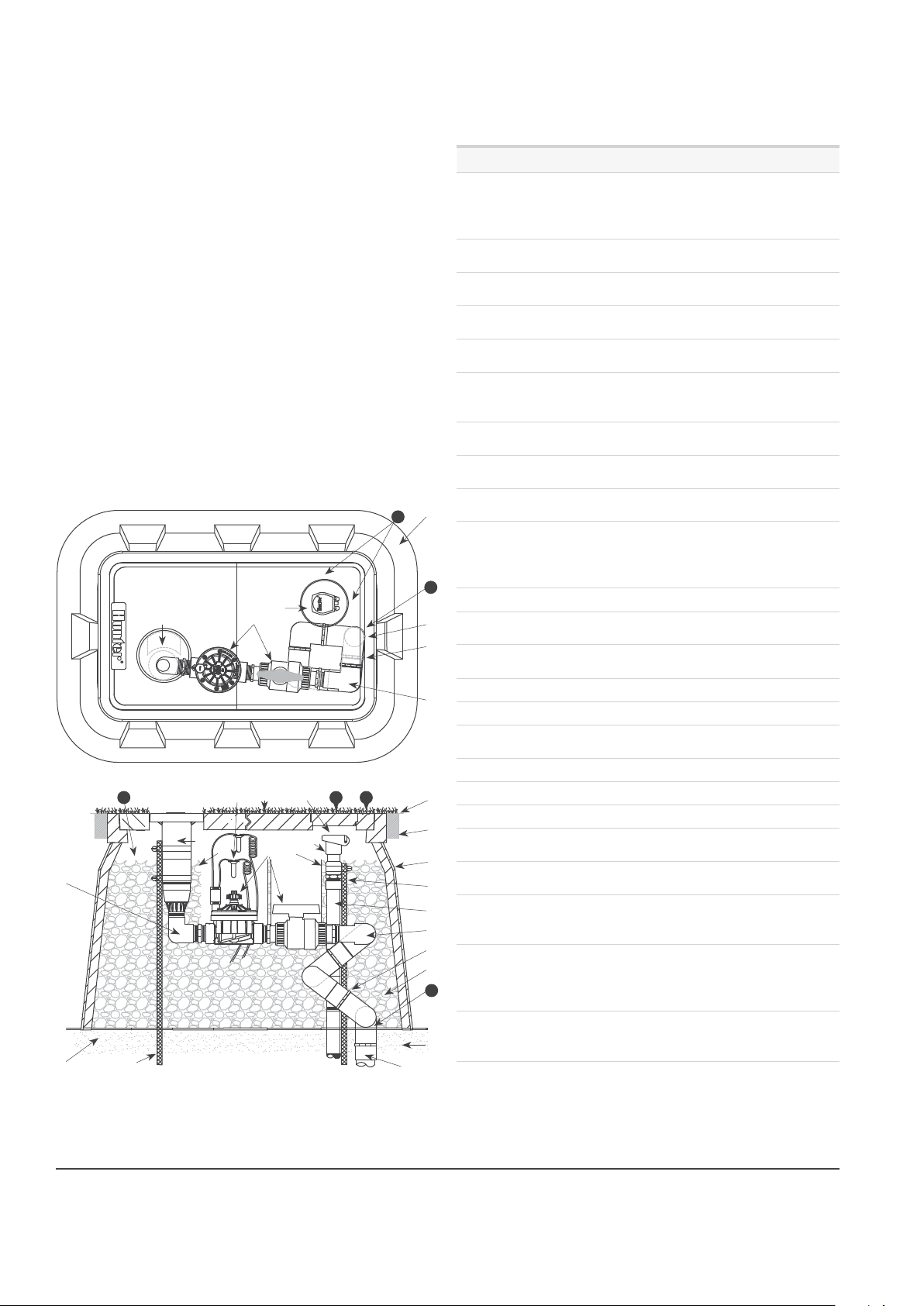

Incoming Plumbing Location

The swing joint’s inlet piping location and depth is critical.

This location and depth in conjunction with the special multiaxis vertical alignment (VA) swing joint allows the rotor to be

placed and leveled within the hole in the vault’s cover. Use

the top view of the following installation detail as a reference.

The bottom of the top view drawing represents the on-eld

side of the vault and the top of the drawing represents the

o-eld side. Next, note that the swing joint inlet is centered

along the right side wall of the vault’s upper rim (#23). The

swing joint’s inlet piping must not be any closer to the rotor

hole in the cover than this location. The swing joint’s inlet can

move outward to the point where it is centered under the

vault’s upper rim.

The quick coupler inlet piping must align with the quick

coupler access hole in the vault’s cover. Use the top view

illustration as a reference below. The rim of the vault is the

exposed upper surface that surrounds the vault’s covers once

they are installed. The quick coupler inlet piping needs to be

5" (12.7 cm) from the inner rim of the vault at the top and 5"

(12.7 cm) from the inner rim of the vault on the right side (#24).

With the STG-900-KIT, there is a direct and required

relationship between the location of the vault, the location

of the incoming plumbing, and the location and depth of the

drainage system. In order for the irrigation sprinkler (rotor)

to be properly positioned within the hole in the vault’s cover,

the swing joint’s inlet piping must be placed at the specied

location and depth. In order for the quick coupler valve to be

accessible and functional once installed, the quick coupler’s

supply pipe must be installed in the correct location and the

valve must be at the correct height within the vault. In order

for the vault to drain properly, it must have access to the

drainage system, and the drainage system must be lower in

elevation than the vault’s base (26" or 66 cm).

Vault Dimensions:

Two-piece cover - Upper Rim 20" x 33" (50.8 cm x 83.8 cm), Cover 17" x 30" (43.2 cm x 76.2 cm),

Depth 26" (66 cm), Base 27" x 41" (68.5 cm x 104.1 cm)

|

Visit hunterindustries.com/support

Page 3

Installation Instructions for Hunter STG-900-KIT and STG-900-KIT-B

Incoming Plumbing Elevation

The swing joint’s inlet piping location and depth is also

crucial. This location and depth in conjunction with the

VA swing joint allows the rotor to be placed and leveled

within the hole in the vault’s cover. Use the side view of the

following installation detail as a reference. Note that the VA

swing joint’s rst horizontal section is resting at a level that is

at the same level as the bottom of the vault (#22). This depth

is 26" (66 cm) from the top of the vault.

The quick coupler inlet piping (#13) must align with the quick

coupler access hole in the vault’s cover (#24). Also, in order

for the quick coupler key with its handle attached to operate

the quick coupler valve, the quick valve must be installed

as close to the underside of the main cover as possible. Use

the side view illustration shown below as a reference. The

quick coupler must be installed so that the nal elevation is

approximately ½" (1.2 cm) below the underside of the main

vault cover (#20).

O-Field Side

24

➊

⑪

➎

➏

⑫

⑭

⑩

On-Field Side

➒

⑱

21

➎

⑲

➋

⓴

⑪

➏ ➑➐

⑯

23

24

⑰

⑫

View from On-Field Side

Specication List for Installation Detail Drawings

ITEM DESCRIPTION

Hunter ST-173026-B composite vault and two-piece

polymer-concrete lid assembly with cast-in opening

1

to support rotor lateral thrust plus cast in opening

with circular cover for quick coupler access

Optional synthetic turf or running track material

2

attached to covers

Finished grade set to eld perimeter tack/glue

3

board or as per specication

2"x 4" (5.1 cm x 10.1 cm) tack/glue board as per

4

specication all sides

Hunter STG-900 rotor with rubber cover kit 473900

5

installed

Hunter ST-VBVF-K kit; includes Hunter ICV-151G, 1½"

6

ball valve (235 PSI rated) plus Acme pivot connection

ttings

Control valve sleeve, 8" (20.3 cm) diameter x 11"

7

(27.9 cm) tall with two notched sections for piping

Ball valve sleeve, 6" (15.2 cm) diameter x 11" (27.9

8

cm) tall with two notched sections for piping

Hunter 239800 rotor adapter tting with two Acme

9

pivot points

Prefabricated 2" (5.1 cm) PVC Hunter ST-2008-VA

swing joint with six Acme pivot points to provide

10

multi-axis articulation and alignment of rotor to the

23

➌

➍

➊

⑯

⑬

⑩

⑭

⑮

22

opening in vault cover

11 Hunter HQ-5RC quick coupling valve

Supply piping and tting – 2" (5.1 cm) minimum

12

from mainline through to ST-2008-VA swing joint

Schedule 80 PVC riser supply piping and tting; 1"

13

(2.5 cm) minimum

14 Acme threaded pivoting points (nine total)

15 ⁄" (1.9 cm) minus washed gravel

⁄" x 30" (1.6 cm x 76.2 cm) rebar stake and stainless

16

steel strapping

17 Compacted eld base material as per specication

18 Provide drainage via access to eld drainage system

19 Waterproof connections per specication

Top of quick coupler set ½" (1.3 cm) below underside

20

of vault cover

Gravel level 5" (12.7 cm) below the underside of the

21

vault cover (to bottom of rotor’s compartment)

Elevation of swing joint’s inlet: set second pivot

22

point on swing joint with bottom of vault per side

view detail drawing (26" (66 cm) below vault top)

Location of swing joint’s inlet: set inlet at edge

between vault covers and locate 5" (12.7 cm) from

23

the top of cover per top view detail drawing – inlet

must not be set closer to rotor than shown

Location of quick coupler inlet piping: measure inlet

24

piping location at top right corner of vault, 5" (12.7

cm) from top edge and 5" (12.7 cm) from side edge

Page 4

RESIDENTIAL & COMMERCIAL IRRIGATION | Built on Innovation

®

Loading...

Loading...