Page 1

IDS

Decoder Controller

Two-wire Decoder Control

in an Advanced Industrial

Package for the Largest

Installations

Programming and

Operations Manual

®

Page 2

Page 3

TABLE OF CONTENTS .....................................................

Introduction .......................................................................................................................................................... 1

How IDS Works............................................................................................................................................... 1

Field Controller Programs..................................................................................................................................... 1

IDS Option & Settings Displays............................................................................................................................. 2

Programming and Operations ...............................................................................................................................3

Emergency Functions (OFF and Pause).............................................................................................................3

OFF................................................................................................................................................................. 3

Rain Shutdown................................................................................................................................................ 3

Pause .............................................................................................................................................................3

Controller Setup ...................................................................................................................................................4

Field Controller Settings .................................................................................................................................. 4

Set Address ....................................................................................................................................................6

Set Time ......................................................................................................................................................... 6

Set Date.......................................................................................................................................................... 6

Set Main % Scale ............................................................................................................................................ 7

Set Schedule Length........................................................................................................................................ 7

Set Schedule Day ............................................................................................................................................ 7

Set Day Change...............................................................................................................................................8

Set FCP Inhibit ................................................................................................................................................ 8

Set Response.................................................................................................................................................. 9

Set MR Runtime.............................................................................................................................................. 9

Set MR Pump................................................................................................................................................ 10

Set PINs .......................................................................................................................................................10

Writing a Field Controller Program ..................................................................................................................... 11

Naming a Program ........................................................................................................................................ 11

Typing Instructions ....................................................................................................................................... 11

Assigning a Schedule to a Field Controller Program........................................................................................ 11

Assigning a Start Time to a Field Controller Program ...................................................................................... 13

Programming Stations: Run Times, Events, and Blocks................................................................................... 14

To Program Individual Stations ...................................................................................................................... 14

Blocks .......................................................................................................................................................... 16

Station Options (Changing Events) ................................................................................................................ 18

Program Advanced Options................................................................................................................................. 21

Edit Program Name ....................................................................................................................................... 21

Set Program % Scale .................................................................................................................................... 21

Cycles........................................................................................................................................................... 21

Cycle Delay ................................................................................................................................................... 22

Skip Days ..................................................................................................................................................... 23

Pump............................................................................................................................................................ 24

End Time ......................................................................................................................................................24

Manual Starts ..................................................................................................................................................... 25

Semi-Automatic Program Operation.................................................................................................................... 26

To Semi-Automatically Start a Program .......................................................................................................... 26

Presets ............................................................................................................................................................... 27

To Create a Preset .........................................................................................................................................27

Page 4

TABLE OF CONTENTS (CONTINUED) .....................................

To Start a Preset ........................................................................................................................................... 28

Field Controller Advanced Options...................................................................................................................... 28

Remove a Program........................................................................................................................................ 28

Remove Preset.............................................................................................................................................. 29

Edit Decoders................................................................................................................................................ 29

View SYS Events ........................................................................................................................................... 30

Remove SYS Events ...................................................................................................................................... 30

Radio Transmit (Xmit) Test ............................................................................................................................ 30

Maintenance Radio Operations (Optional) .......................................................................................................... 31

Maintenance Radio Commands ...................................................................................................................... 31

Sending a Maintenance Radio Command ........................................................................................................ 31

Central Control Options ...................................................................................................................................... 32

Maintenance Radio Functions & Commands........................................................................................................ 33

Display Messages (Status, Errors & Other Conditions)........................................................................................ 34

Status Displays ............................................................................................................................................. 34

Other Messages ............................................................................................................................................34

IDS Series Specifications ...................................................................................................................................36

IDS Troubleshooting and Frequently Asked Questions ......................................................................................... 37

Index .................................................................................................................................................................. 38

Page 5

INTRODUCTION ...............................................................

IDS is a unique, standalone irrigation controller, using

only a single twisted-pair of wires (or “path”) to operate up to 103 decoder stations. IDS actually provides

five two-wire paths to permit efficient wiring in several

directions.

How IDS Works

Decoders operate 24VAC valve solenoids to turn on

irrigation. The decoders are installed along a two-wire

path, and the IDS controller sends both power and

signals over the same two wires.

Each decoder has a unique 8-digit Serial Number,

printed on the side of the decoder. The decoder Serial

Numbers are assigned to controller station numbers

by the system operator (either from the keypad, or the

optional IDSCD Decoder Manager software). This unique

ID number is used to signal the decoder that IDS wants

to operate.

IDS operates both single and multi- station decoders.

The ID4 decoder has four independently addressable

station outputs (the decoder has a 7-digit number,

followed by a 1, 2, 3, or 4, to indicate each station).

Decoder systems should also include grounded surge

protection modules in the two-wire paths, although they

are not programmable and are not addressed by

the controller.

Two Controllers in One: The IDS actually has two different “brains” for storing and running two different kinds

of irrigation programs. The keypad on the controller

can create and run Field Controller Programs. The other

type of programming is generally not used in IDS, but

is designed to accept downloaded station events from a

very specialized central computer.

Field Controller Programs (FCPs) are the Programs

numbered 1 through 64, which you can write from

the keypad. You can change them in the field at any

time. They will run at the start times you specify and

do exactly what you tell each one to do. Most of this

manual is concerned with configuring and operating

FCPs through the keypad. There are also some references to System Events (sometimes shown as SYS).

These references are explained, but generally not used.

FIELD CONTROLLER PROGRAMS ................................

Field Controller Programs, or FCPs, are the irrigation

programs used for daily irrigation. They can also be

started by an operator whenever irrigation is desired.

There are 64 programs which can be divided up any way

you want. Each FCP may have up to 30 events, and can

be programmed to cycle (or repeat) up to 15 times, or

continuously. FCPs are also permitted to overlap, meaning that more than one program (up to 20, in fact) can

operate at once.

1

Page 6

IDS OPTION & SETTINGS DISPLAYS ...........................

Options

(Press Options button

from time/ date display)

Pause Watering

List FC Settings

Edit FC Settings

Block Programming

Create

Edit

Remove

Remove Program

Remove Preset

Edit Decoders

View SYS Events

Rem SYS Events

Radio Xmit Test

( Radio controllers only)

Edit FC Settings

(From Options, Edit FC

Settings)

Address

Time

Date

Main % Scale

Schedule Length

Schedule Day

Day Change

FCP Inhibit?

Response

MR Runtime

MR Pump

PINs

EXIT OFF

PROGRAM

SELECT

SCHEDULE

Program Advanced

Options

(Options when a Program

or Preset name is

selected)

Edit Program Name

Set Program % Scale

Cycles

Cycle Delay

Skip Days

Pump

End Time

IDS

STATIONS OPTIONS

Schedule Options

(Options when Schedule

is selected)

Daily (up to 31-day

schedule)

Day of Week

(SMTWTFS)

Station Options

(Options when a Station

is selected)

Remove Event

Cluster Events

Move Event

Insert Event

PRESETS

MANUAL

START

NEXTBACK

1. Stops all irrigation; enables and disables Rain

Shutdown.

2. Sets run times and order for stations and Blocks.

3. Accesses multiple options and controller settings.

Different sets of options appear, depending on mode

controller is in (with other keys).

4. Saves field inputs and edits.

5. Selects between fixed choices in the display, and

selects Rain Shutdown yes/no when OFF

is pressed.

6. Alphanumeric buttons for data entry.

7. Clears display error messages; erases Program

Name in Edit mode.

8. Determines type of schedule and actual water days

On/Off for the selected Program.

123

abc def

456

ghi jkl mno

789

pqrs tuv

CLEAR

wxyz

ENTER

TOGGLE

0

9. Navigate backward/forward through displays, Programs, and Option choices.

10. Defines Start Time for automatic Programs;

launches Preset programs immediately.

11. Starts one or more stations immediately.

12. Cycles through available Preset names, allows

access for creation or editing, or immediate start

with Start button.

13. Cycles through available Program names, allows

access for creation or editing, or immediate start

with Start button.

14. Escapes current function and exits to next

highest level.

2

Page 7

PROGRAMMING AND OPERATIONS ...........................

Note: The IDS keypad display has a built-in timer and

will automatically exit any programming mode after 3

minutes if left untouched. If you are using the password

protection feature, you will be required to log back in

once this has happened. Any data not saved will be lost

if the controller auto-exits.

Emergency Functions ( OFF and Pause)

EXIT OFF

IDS

PROGRAM

SELECT

PRESETS

MANUAL

START

NEXTBACK

OFF: If you need to stop all irrigation at a controller

immediately, press the OFF button to the right of the

display. You may see a brief message, STOPPING ALL

IRRIGATION, followed by:

EXIT OFF

Rain Shutdown: Rain Shutdown turns off all automatic

functions permanently, until a human operator manually

removes the controller from the Rain Shutdown mode

(from the IDS keypad or a central computer). If you

want to enter the Rain Shutdown mode, press ENTER.

The display will show:

SCHEDULE

STATIONS OPTIONS

123

abc def

456

ghi jkl mno

789

pqrs tuv

CLEAR0TOGGLE

wxyz

ENTER

To turn off Rain Shutdown (and restore the controller to

automatic operations): When the display shows RAIN

SHUTDOWN!, press OFF. The display will show:

EXIT OFF

Press ENTER, and the controller will return to the

automatic mode.

Pause: The IDS controller features dynamic pause,

which will suspend all irrigation at the controller temporarily. This will apply to manual, semi-automatic, automatic and Preset Programs. The irrigation will remain

paused until resumed by a human operator or until 30

minutes have elapsed. The controller will resume irrigating where it left off. Note that Pause will cause the end

of the “water window” to be ignored – the end time of

the paused Program will be pushed back for the duration of the Pause.

EXIT OFF

IDS

PROGRAM

SELECT

PRESETS

MANUAL

START

NEXTBACK

To Pause a Controller: Press OPTIONS. The display

will show:

EXIT OFF

SCHEDULE

STATIONS OPTIONS

123

abc def

456

ghi jkl mno

789

pqrs tuv

CLEAR0TOGGLE

wxyz

ENTER

EXIT OFF

You will have to remember to place the controller

back into automatic operation when irrigation is

required again.

If you do not want to enter Rain Shutdown, press the

OFF button again (upper right of the keypad) or any

other button except ENTER. This will simply shut down

all current irrigation until the next scheduled Start Time.

Note that if another automatic Program was scheduled

to start one minute later, the controller will begin irrigating again in one minute.

Press ENTER to select the Pause option. The display

will show:

EXIT OFF

“YES” will be capitalized. To Pause the controller, press

ENTER. The display will then show:

EXIT OFF

This will Pause all irrigation at the controller.

3

Page 8

PROGRAMMING AND OPERATIONS (CONTINUED)............

To resume watering, press ENTER while the display

says Resume Watering? The display will then show:

EXIT OFF

Press ENTER with YES capitalized, and the controller

will resume irrigating where it left off when you paused

it. No irrigation will be missed, only delayed. After 3

minutes, the Resume Watering? display will disappear, but the display will continue to flash PA U SE with

the amount of time left to automatic resume. Press

OPTIONS to return to the Resume Watering? dis-

play.

Note that if the controller was paused for 20 minutes,

the currently active and any subsequent stations will be

moved back in time 20 minutes.

If the Program would normally have ended at 5:30 AM, it

would now end at 5:50 AM.

If you forget to Resume irrigation after placing the

controller into Pause, it will automatically resume after

30 minutes. (The “no” selections will be in lower case.

Press the TOGGLE button to switch between YES and

NO. If you do not want to pause/ resume the irrigation,

TOGGLE to NO and press ENTER, or simply press

EXIT.)

Also, if the optional End Time has been set for any

program(s), it is possible to Pause before a program

has reached its End Time, and then Resume after the

End Time. In this unlikely (but possible) event, the

program would finish irrigating with the current Cycle

(even though the End Time has elapsed), but would not

start any additional Cycles. End Times have no effect

on Manual starts (which will always Resume and finish

normally).

CONTROLLER SETUP ......................................................

Setting up an IDS controller can be very simple. There

are a few essential steps to get a controller running

your programs, once it is installed and connected to the

decoders. The bare minimum steps are:

• Set the controller’s time and date

• Assign individual stations to decoder serial

numbers (see Edit Decoders)

• Create a Program

• Set up a Day Schedule

• Set up a Start Time

• Assign Stations and station Run Times to the Program

Following are in-depth descriptions of all controller

functions, but if you complete the basic steps above,

you are ready for automatic irrigation.

When you start up a brand new IDS controller, or if you

have erased the controller memory and are reprogramming from scratch, you must set up some basic operating information first.

Field Controller Settings

Press the OPTIONS button. The display will show

“ Pause Watering?” Press the OPTIONS button

again. The display will show “List FC Settings?” (“FC”

always means “Field Controller”). Press ENTER. The

display will automatically sequence the current information for the field controller in the following format:

Version Number: The version of field controller software

installed in the IDS. Note the version number whenever

possible, before calling Hunter or your Distributor with

technical issues.

Time: On start up, this may be incorrect, but it will

show the time of day that IDS thinks it is.

Date: On start up, this may be incorrect, but it will show

the day of week and year that IDS thinks it is.

Size: Controller should be configured to 103 stations.

System Address: The unique identification number

for a particular IDS controller in an optional central

system. You may leave this set to “0” for standalone

IDS operations.

Main Percent Scale: Indicates that the controller will

operate each station for 100% of its scheduled

Run Time.

Schedule Length: An IDS may be programmed on a

multiple day schedule (from 1 to 31 days). This shows

the actual schedule length of the controller.

4

Page 9

CONTROLLER SETUP (CONTINUED) ......................................

Day of Schedule: This shows which day (of the schedule in the previous setting) that the controller thinks

it is.

Day Change: The time at which the schedule day

changes. The default is midnight, but you may change

the time to any hour of the day.

Prg Inhibit is OFF: This setting is only meaningful

in central systems, and shows the status of the Field

Controller Programs (FCPs). If they have been inhibited, they will not run. In IDS controllers, inhibit should

always be set to “ OFF”.

The following items will only appear if the controller has

an Address set (to some number other than “0”):

System Response: This setting is only meaningful in

central systems, and shows how much communicating

the IDS controller will perform with a central computer.

System Event Day: This feature is not used in IDS

controllers. This is only used in central systems which

calculate “look ahead” schedules and download them to

the controller.

LineOn : 280ma

The actual milliamp measurement will vary, and partly

depends on whether any stations are operating. The

standby draw usually starts around 0-100ma, depending

on temperature, but each decoder in- line will add about

1 milliamp on a standby basis. As decoders are activated, they will add approximately 20ma per solenoid to

the line draw.

If you continue to press the OPTIONS button, you will

cycle through all of the available controller options:

Pause Watering? Stops irrigation temporarily; restarts

where it left off (with Resume command).

List FC Settings? Automatically displays vital Field

Controller settings.

Edit FC Settings? Allows you to change vital Field Controller settings.

Block Prgraming? Allows you to group multiple stations into a single block for programming purposes. See

Blocks on page 16.

System Day Change: This feature is not used in IDS

controllers. It is a day change time that is downloaded

from a central computer, and is not the same as the

controller’s Day Change time setting.

Maint Radio Run Time: This is the default time-out for

stations started with a Maintenance Radio without a run

time specified. If you forget to turn the station off, IDS

will turn it off for you in 30 minutes.

Maint Radio Pump: This specifies whether the Pump

output turns on whenever a station is started by a Maintenance Radio command.

After the above status messages, the final display

will be:

Ctrl Uptime: The length of time this controller has been

operating since the last time the power was turned on,

or restored after a power outage. This is displayed in

days, hours, minutes and seconds.

When the controller has finished sequencing through

the FC Settings, it will show the current day and time,

and power draw. There may be a “ POWER OUTAGE”

message flashing in the display. Press the CLEAR

button to clear this message.

Remove Program? Allows you to delete a single program, including all station run times.

Remove Preset? Allows you to delete a single Preset,

including all station run times.

Edit Decoders? Allows setup and/or changes to

decoder/ station assignments.

View SYS Events? Not used in IDS. Allows view of

downloaded System Program events.

Del SYS Events? Not used in IDS. Allows deletion of

downloaded System Program events.

Radio Xmit Test? ( Radio controllers only) Generates a

5-second test tone for diagnostics.

Edit FC Settings: Of all the Field Controller options, this

is the most vital to set up on a new installation. Many

of the powerful features of IDS will not work, or will not

work as intended, until these settings are made.

Press OPTIONS 3 times and the display will show

“ Edit FC Settings?” In this menu, you are able to

change many of the settings displayed in the “List FC

Settings” menu above.

On the line beneath the time, the display will also show

“ LineOn” followed by the current draw, in milliamps:

Press ENTER, and the display will show “Set

Address?”

5

Page 10

CONTROLLER SETUP (CONTINUED) ......................................

You may now press ENTER, to set or change the

Address, or press OPTIONS again, to view further set-

tings. You can also use the BACK and NEXT buttons

to move backward and forward through the settings.

Whenever the display shows a setting you want to

change, press ENTER to edit it.

Set Address

A standalone IDS controller does not need an address

(it may be left at “0”). However, the IDS Field Controller

cannot communicate with a Maintenance Radio or a central system until it has an Address. Each controller must

then have a unique 3-digit number, so that the central

interface and/or Maintenance Radio can direct communications to the correct controller. If you need to set

an address, when the display shows “Set Address?”,

press ENTER. The display will show:

The current am/pm selection will be capitalized.

The other selection will be in lower case. Press the

TOGGLE button to switch between AM and PM. When it

is correct, press ENTER. The display will show:

Press ENTER to set the time. The display will briefly

show SAVED! and the time you have set. After a

moment, the display will revert to:

EXIT OFF

EXIT OFF

EXIT OFF

EXIT OFF

Type the address you want with the number buttons on

the keypad and press ENTER. The display will show

“SAVED! Address = 2” (example).

The address is now saved. You can use any 1, 2, or

3-digit number, and controllers in a central system do

not need to be sequentially numbered. However, each

controller must have a unique address. If more than one

controller has the same numeric address, the system

will become confused and errors will occur.

Once the address is set, you may use the OPTIONS,

BACK, or NEXT buttons to view more options, or you

may press EXIT to leave the Edit Settings mode.

Note: If you set an address in a standalone controller,

when no central system is present, the display will show

the message “No Network Link” after a few minutes.

This is normal and will not affect irrigation. It simply

indicates that no central system has been heard from.

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

Set Date

To set the Date, press ENTER at this display. The display will then show:

EXIT OFF

Note: IDS dates are always shown in North American

format (month/day/year).

Type the number for the correct month (1-12), in this

case “3” for March, and press ENTER (you can also

use the BACK/NEXT buttons to move around in the

Date). The display will then show:

EXIT OFF

Set Time

To set the time, press ENTER. The display will show:

EXIT OFF

Type the correct time (1:15, for example, in hour, then

minute format), and press ENTER. The display

will show:

6

Type the number for today’s date (“8” in this example),

and press ENTER. The display will show:

EXIT OFF

Type the correct year, and press ENTER. The display

will show:

Page 11

EXIT OFF

Press ENTER to set the date. The display will briefly

show SAVED! and the date you have set. After a

moment, the display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

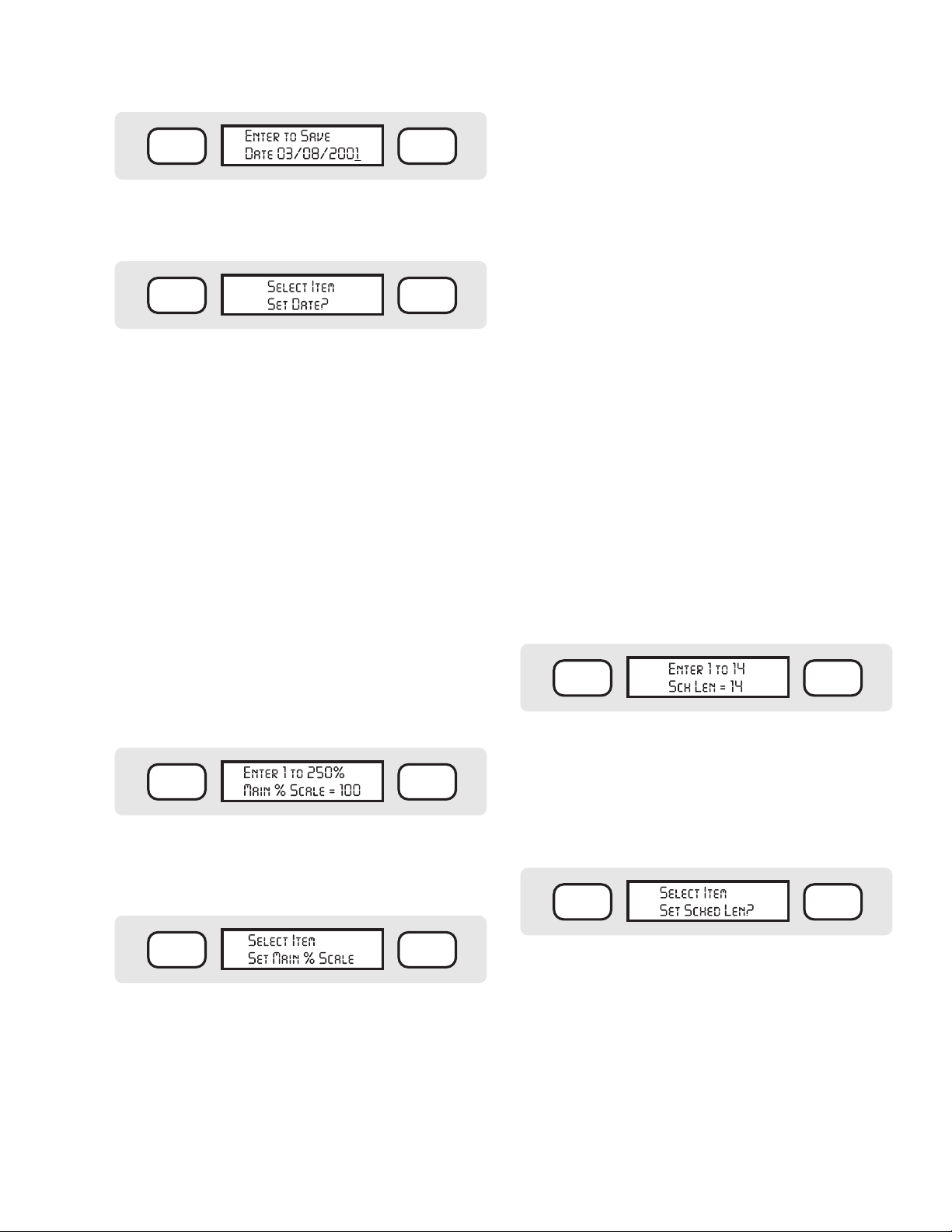

Set Main % Scale

“ % Scale” allows you to reduce or increase all of the

Run Times in the controller by the selected percentage

(from 1 to 250%, in 1% increments). This enables you

to quickly adjust the amount of irrigation for weather or

other conditions without changing the basic programs.

At 50%, each Run Time will only run half as long, and

at 150%, each Run Time will run one-and-half times

as long.

Note: In the Program Options, you can also scale individual Programs separately. The effects of % scaling are

cumulative. See Set Program % Scale on page 21.

Once the Main % Scale has been changed, the scaled

run times for all stations will be displayed when the Stations button is pressed in any Program. To return to the

original (or base) run times, repeat the procedure above

and change the Main % Scale to 100%.

Set Schedule Length

The Schedule Length is the number of days in a complete IDS watering period, and allows the controller to

track programs which do not water every day. If you

only water a certain plant type every other day, for

example, you could enter a 2-day Schedule, and schedule that program to water on just one of the days. The

Schedule Length is tracked for the entire controller. To

set the watering Schedule for individual programs, go

to the individual Program and press SCHEDULE (see

Schedule on page 11).

If you are not sure what schedule you need, start out

with a 7-day schedule (so that it matches the number of

days in a calendar week). You can always change it later.

If you always water everything every day, you can also

just set a 1- Day schedule.

To Set the Schedule Length: Press ENTER at the “Set

Sched Len?” display. The display will then show:

EXIT OFF

To set the Main % Scale from the Edit FC Settings mode,

press ENTER at this display. The display will show:

EXIT OFF

Type the percentage you want with the number buttons

on the keypad, and press ENTER. The display will

briefly show “SAVED!” and the new % Scale amount.

After a moment, the display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

Note that whenever the controller is scaled up or down

(to any value other than 100%), a “+” or “-” sign will

appear as a reminder in the upper left corner of the

status display (before the Day and Time information).

The default Schedule Length (the way IDS comes “out of

the box”) is 14 days: the maximum is 31 days. Type the

number of the new Schedule Length (any number from

1 to 31) with the number buttons on the keypad, and

press ENTER. The display will briefly show “SAVED!”

and the new Schedule Length selection. After a moment,

the display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

Set Schedule Day

The Schedule Day shows which day of the Schedule

the controller thinks it is. For example, if you had set

a 7-day schedule for a Schedule Length (above), you

could tell the controller that today is Day 1 of the 7-day

schedule, meaning Sunday. If today happens to be

7

Page 12

CONTROLLER SETUP (CONTINUED) ......................................

Wednesday, you could tell it that today is Day 4 (of the

7-day schedule).

Another example would be if most of your irrigation

occurred every day, but a few programs only run every

other day (regardless of the day of the week). You

could set up a 2-day Schedule Length, and then tell the

controller which of the two days today is (1 or 2). In the

Program Schedule (see Schedule on page 11) you can

specify which days the individual Programs will water.

To Set the Schedule Day (for today): Press ENTER

at the “Set Sched Day?” display. The display will

then show:

EXIT OFF

Type the number of the new Schedule Day with the

number buttons on the keypad, and press ENTER.

The display will briefly show “SAVED!” and the new

Schedule Day selection. After a moment, the display will

revert to:

You may only set the Day Change to an exact hour (no

minutes).

To Set the Day Change: Press ENTER at the “ Set Day

Change?” display. The display will then show:

EXIT OFF

Type the number for the Day Change hour (8, in this

example) with the number buttons on the keypad, and

press ENTER. The display will show:

EXIT OFF

The current selection will be capitalized. Other selections will be in lower case. Press the TOGGLE button

to switch between AM and PM. When it is correct, press

ENTER. The display will show:

EXIT OFF

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

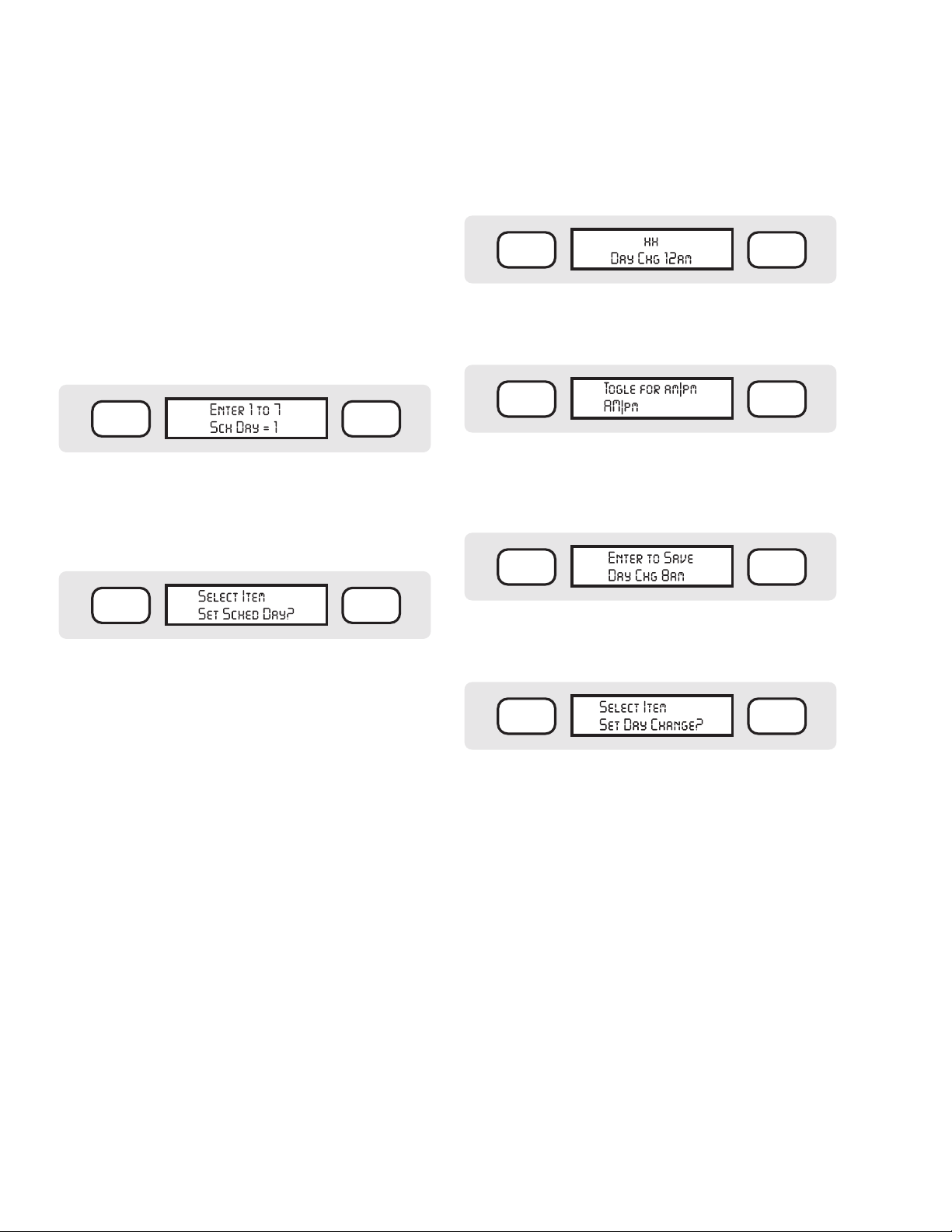

Set Day Change

The programmable Time of Day Change option allows

you to tell the controller at what time one day changes

into another, when using the Daily Schedule option.

The default is, of course, midnight (12 AM). However,

this occurs right during the middle of many nightly

“water windows”. If you water a certain schedule every

other day, and the irrigation spans across midnight, you

may lose the irrigation programs which technically fall

on a non-irrigation day (past midnight).

To prevent this and similar confusion, you may specify

a different hour for your irrigation days to change. Usually this is done after all irrigation is completed. If your

night’s irrigation is completed by 7 in the morning, you

might wish to set the Day Change to 8:00 AM. Then, all

of your irrigation will fall within a single “irrigation day.”

Note: Time of Day Change only applies to Daily schedules. Day of Week schedules (Monday, Tuesday, etc.)

always change at midnight.

Press ENTER to set the Day Change. The display will

briefly show SAVED! and the time of Day Change hour

you have set. After a moment, the display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

Set FCP Inhibit

FCPs (Field Controller Programs) are the Programs

numbered from 1 through 64 in the Field Controller. This

setting is normally not used in IDS, and should be left at

“ OFF”. (The controllers may also irrigate with a master

system program from a central computer. FCP Inhibit

will prevent all of the numbered FCPs from running.)

Remember that FCP Inhibit on means the FCPs will

not run. FCP Inhibit set to off means the FCPs will run

normally.

To Set FCP Inhibit: Press ENTER at the “Set FCP

Inhibit?” display. The display will then show:

8

Page 13

EXIT OFF

The display will flash “SAVED!” and your selection.

After a moment, the display will revert to:

The current selection will be capitalized (default is

OFF). The “on” selection will be in lower case. Press

the TOGGLE button to switch between OFF and ON.

When it is correct, press ENTER. The display will flash

“SAVED!” and your selection. After a moment, the

display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

Set Response

This setting is normally not used in IDS. It sets the level

of Field Controller response to a central computer (if it

is present and communicating).

The default setting is to “NONE”. The controller can

also be set to “PARTIAL” or “FULL.”

In the Partial Response setting, the field controller will

report any alarm conditions (such as Fuse Open, Overload, Power Outage, etc.) to a central system. In the

Full Response setting, the Field Controller will report all

events as they occur, including every station start and

station stop, as well as alarms.

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

EXIT OFF

Set MR Runtime

MR = Maintenance Radio. This determines the timeout timer setting for stations started by a Maintenance

Radio without specified Run Times. If you simply start

a station with Maintenance Radio without a specific

run time, this setting will automatically shut it off after

the time shown, to prevent flooding and damage. The

default value is 30 minutes. You may select a longer

or shorter setting, from 1 minute to 18 hours, for this

safety feature.

To Set MR Runtime: Press ENTER at the “ Set MR

Runtime?” display. The display will then show:

EXIT OFF

Type the number for the default Maintenance Radio

timer (example: 20 minutes) with the number buttons

on the keypad, and press ENTER. The display

will show:

Setting Response to NONE can also allow the controller to have an address set for optional Maintenance

Radio operations, without showing the “ No Network

Link” message (this appears when a controller has an

address, but is unable to hear communications from an

optional central system).

In standalone applications, Response is generally set to

NONE.

To Set Response: Press ENTER at the “Set

Response?” display. The display will then show:

EXIT OFF

The current selection will be capitalized (default is

NONE). The “full” selection will be in lower case. Press

the TOGGLE button to switch between NONE, PAR-

TIAL, and FULL. When it is correct, press ENTER.

EXIT OFF

Press ENTER to set the MR Runtime. The display will

briefly show SAVED! and the MR Runtime you have

set. After a moment, the display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

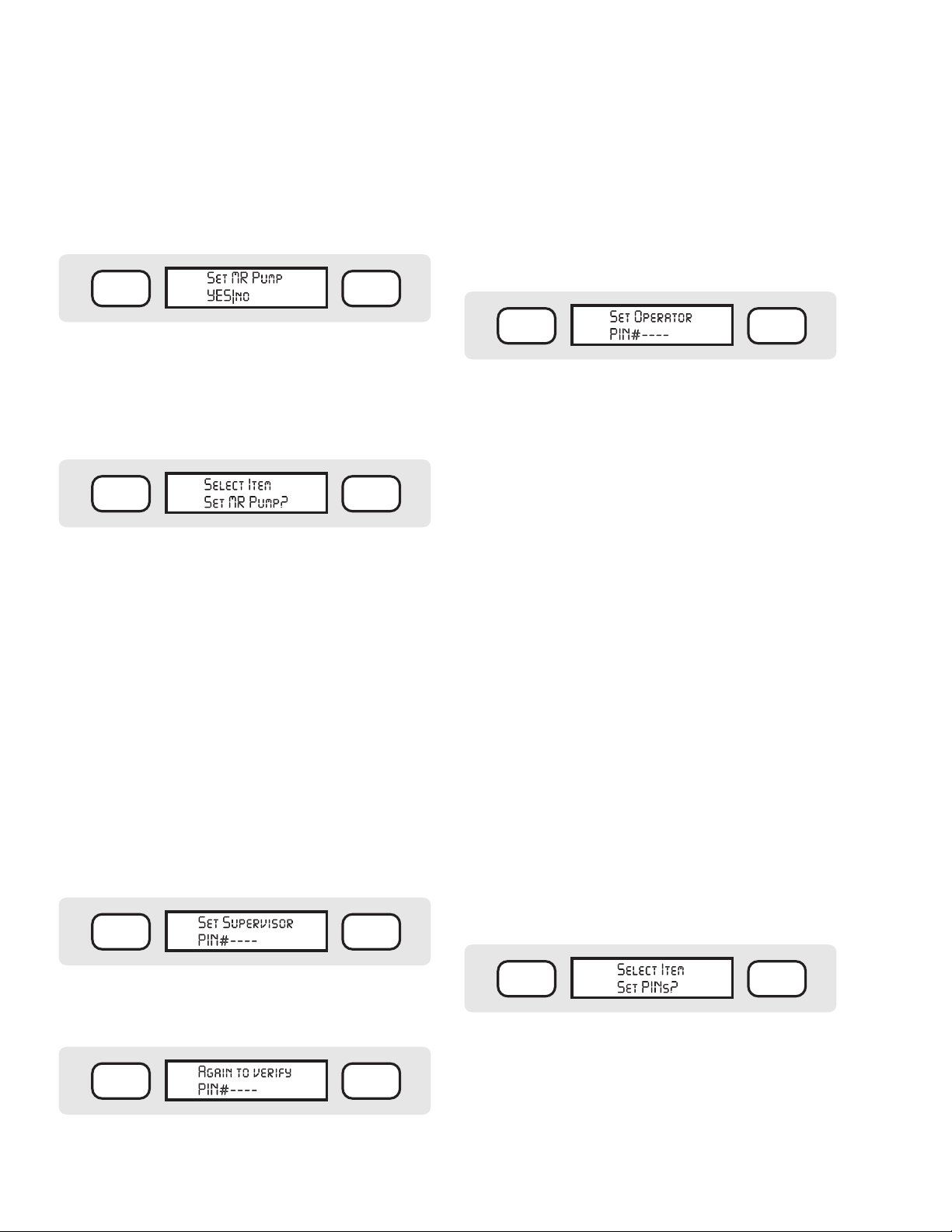

Set MR Pump

MR = Maintenance Radio. This determines whether the

Pump decoder station in the Field Controller will be

activated whenever Maintenance Radio starts stations. If

9

Page 14

CONTROLLER SETUP (CONTINUED) ......................................

you are using the Pump output to activate a Pump Start

Relay or a Master Valve, you can choose to have that

output come on whenever a Maintenance Radio command starts a station.

To Set MR Pump: Press ENTER at the “Set MR

Pump?” display. The display will then show:

EXIT OFF

The current selection will be capitalized (default is

YES). The “no” selection will be in lower case. Press

the TOGGLE button to switch between YES and NO.

When it is correct, press ENTER. The display will flash

“SAVED!” and your selection. After a moment, the

display will revert to:

EXIT OFF

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

Set PINS

The IDS controller has 2 levels of optional password

protection:

• The Supervisor level can perform all programming

functions.

• The Operator level can perform basic functions

(START and STOP commands) which do not affect

the automatic programs and their options.

Each level of access can be protected by a 4-digit Personal Identification Number (PIN).

To Set PINs: Press ENTER at the “Set PINs?” display.

The display will then show:

EXIT OFF

Type exactly the same PIN number again and press

ENTER. The display will show “SAVED!”.

If you fail to enter the same number the second time, the

display will show ERROR! You will then need to reenter

the PIN and enter the confirmation a second time.

Once the PIN has been entered correctly, the display

will show:

Repeat the sequence above to enter an Operator’s PIN

number. You are not required to enter a second level

of password protection. If you do not want an Operator level, simply press ENTER at this display without

entering anything.

If the second (verification) entry of either Supervisor or

Operator level PINs is in an error, no PIN has been created.

EXIT OFF

You may change the passwords at any time, but you

must first log on to the controller with the existing

Supervisor-level PIN. If you forget your PIN, it is still

possible to clear the password settings. Contact your

distributor or Hunter Technical Services for help to clear

the password settings.

When you press the EXIT button at any time on the

keypad, it will exit the function you are in and return to

the next-highest level in the controller. After you exit all

the way back to the normal time/ date display, and press

EXIT again, the display will show “ LOGGED OFF”.

This means that a valid PIN must be entered to log back

on before any programming or operations take place (if

PINs are enabled). If you do not log off when finished,

the controller will log off automatically after 3 minutes

of no activity.

When the PIN settings are complete, press ENTER.

The display will flash “SAVED!” and your selection.

After a moment, the display will revert to:

Type any 4 digits (there must be exactly four, from 0001

to 9999) which you will be able to remember, and press

ENTER. The display will show:

EXIT OFF

10

You may now press the OPTIONS, BACK, or NEXT

buttons to view more options, or you may press EXIT

to leave the Edit Settings mode.

EXIT OFF

Page 15

WRITING A FIELD CONTROLLER PROGRAM.............

Press the PROGRAM SELECT button. The display

will show:

EXIT OFF

This indicates that you are in Program # 1, with 0 out

of 64 total Programs in use. The numbers may vary if

there are already programs in the controller’s memory.

There may already be a program name in place of the

dashes. You can edit any Program at any time. For now,

we will work on Program 1 as the controller came “out

of the box.”

Naming a Program

Press the OPTIONS button. The display will show

“ Edit Prg Name?”

Press ENTER. The bottom line of the display will show

“ Alpha entry mode”, and the cursor will be flashing on

the first space.

Use the buttons on the keypad to type in a name for the

Program. You may mix letters and numbers to create

accurate names for each Program (up to 10 total characters long).

Typing Instructions

Each number button also has a series of letters of the

alphabet assigned to it. While the display says “ Alpha

entry mode” the buttons will type letters only. Press

the button rapidly to display the letter you want. If you

release the button for more than about 1 second, the

letter will be selected and the cursor will advance to the

next position.

To create a dash instead of a character, press the NEXT

button to skip over a space and resume typing.

To delete a character and leave the space blank, press

the “1” (one) or “0” (zero) buttons once when in the

Alpha entry mode. They do not have letter assignments

and will create a blank space.

You can also create special symbols with the “1” (one)

or “0” (zero) buttons when in the Alpha entry mode.

With the first button press, they create a blank space.

If you continue to press them rapidly, they will cycle

through the following symbols:

To type numbers, press the TOGGLE button. The

bottom line of the display will show “Num entry

mode”. Now the buttons will type the number on the

button, instead of the letters. To delete a number and

leave a space, TOGGLE back to Alpha entry mode

and use the “1” or “0”, then TOGGLE back to Num

entry mode to continue typing numbers.

When the name in the display is correct, press ENTER.

The display will show “SAVED!” for a moment, then

return to:

EXIT OFF

Where ## is the number of the program, and xxxxxxxxxx

is the new Program name you have entered.

To type the word “TURF”, for example, press the “T”

button (#8) once, and wait for a second. You may hear a

faint beep, and the cursor will advance to the next space.

Press the #8 button twice, rapidly, to display the second

letter “U”. Wait for a second, and the cursor will

advance to the next position. Press the 7 button to type

an “R”. Wait for the cursor to advance, and then press

the #3 button three times in a row to type “F”. The display should now read “TURF”.

If you make a mistake, you can use the BACK and

NEXT buttons to position the cursor on any existing

space, and type a new character. To erase an entire

Program Name, press CLEAR. Be careful, because

CLEAR erases the entire name, not just the space at

the cursor.

Press the EXIT button to leave the Edit Prg Name

programming. The display will return to the Program

Select level, and will show the new name of

the Program.

Assigning a Schedule to a Field Controller Program

The Schedule for a Program determines the days on

which the Program will run. There are two types of

Schedules: Daily or Day of Week.

Daily: Uses the controller calendar to determine the

watering schedule (see Set Schedule Length on page

12). TOGGLE each day, Ye s or No.

11

Page 16

WRITING A FIELD CONTROLLER PROGRAM (CONT.)....

Day of Week: Uses the days of the week (Monday, Tuesday, etc.) to determine the watering schedule. TOGGLE

each day from Capital (water) to lower case (no water).

Press the PROGRAM SELECT button repeatedly

until the name or number of the Program you want

appears in the display. Once you have pressed PRO-

GRAM SELECT, you can also use the BACK and

NEXT buttons to go backward or forward through the

available Programs.

EXIT OFF

IDS

PROGRAM

SELECT

PRESETS

MANUAL

START

NEXTBACK

When the Program you want appears in the display,

press the SCHEDULE button. If the Program has no

Schedule assigned yet, the display will show:

SCHEDULE

STATIONS OPTIONS

123

abc def

456

ghi jkl mno

789

pqrs tuv

CLEAR0TOGGLE

wxyz

ENTER

Day 1-7 shows the number of days in the controller

calendar (as set in the Edit FC Settings selections). If

the calendar is longer than 7 days, the remaining days

will be shown on other “pages” when you finish setting

up the first seven days.

The “Y”s show Yes for each of the days (default setting

is all days to Yes, regardless of how many days are in

the controller calendar). A “Y” means the Program will

run on that day; an “n” means it will not.

To set the days for Yes or no, press the TOGGLE

button. TOGGLE will change the setting for the day

from “Y” to “n”. When the day is set correctly, use

the NEXT key to advance to the next day, and press

TOGGLE again to set up the day. Continue through all

the days of the calendar. If there are more than 7 days,

when you press NEXT after the 7th day is set, the display will show the next “page” of days (Days 8-14).

Do not press ENTER until all the days are set correctly. If you accidentally press ENTER before you are

finished, the display will show “ Enter to Save”. Press

EXIT instead, then press the SCHEDULE button again

to re-enter the scheduling mode.

EXIT OFF

You may press SCHEDULE again to see the Day of

Week option (you can also use TOGGLE, or BACK and

NEXT, to move between the options).

Note: If the Program already has a Schedule assigned,

the SCHEDULE button will immediately show the

existing Schedule. If you want to change to the other

type of Schedule, press the OPTIONS button, and

TOGGLE between the selections as described above.

When the display shows the option you want to use,

press ENTER.

If you select Daily, the display will show something like:

EXIT OFF

The cursor will be flashing under the “Y” corresponding

to the current day.

Prg## will show the Program number selected.

After you have set up the entire Daily Schedule for

the Program, press ENTER. The display will show

“Enter to Save”. Press ENTER again. The display

will briefly show “SAVED!”, and then will return to the

Program Name.

Example: A controller has a 14-day schedule. You want

to set up a Program to irrigate Monday and Thursday

of the first week, and Tuesday and Friday of the second

week. Monday is the first day (“ Day 1”) of the Schedule.

Use the NEXT button and the TOGGLE to create:

EXIT OFF

After the 7th day, press NEXT again, and the display

will advance to Days 8 through 14.

Continue to press NEXT and use TOGGLE to configure the second week:

EXIT OFF

Today= # will display what today’s number is, in the

controller calendar, as in Day 2 of a 14- day schedule.

12

After you have set up the entire Daily Schedule for the

Program, press ENTER. The display will show “Enter

Page 17

to Save”. Press ENTER again. The display will briefly

show “SAVED!”, and then will return to the Program

Name.

To Change a Schedule Which has Already Been Set:

Press the PROGRAM SELECT button until the Pro-

gram you want to change appears in the display.

If you select Day of Week, the display will show some-

thing like:

EXIT OFF

The Program number for the selected Program will be

displayed. DOW = will show which day of the week

today is. The S•M•T•W•T•F•S display represents each

day of the week. The cursor will be under the day of

the week that the controller thinks it is (in the example

above, Tuesday).

Capital letter days are watered. Lower-case lettered days

are non-water days.

Press the TOGGLE button to change the capital “T” (or

any other letter) to a lower-case “t”. Press TOGGLE

again, and the day will change back to a capital “T”.

Press the NEXT (or BACK) button to move to a different day. Create capital letters for each day you want to

water, and lower-case letters for each day you want

to skip.

When the whole week is configured correctly, press

ENTER. The display will briefly show “SAVED!”, and

then will return to the Schedule days you have created.

Example: You want the Program to water all weekdays,

but not weekends. In DOW mode, use the TOGGLE

and NEXT buttons to create:

EXIT OFF

This shows that Sunday and Saturday will not be water

days, but that the rest of the days will irrigate.

Press the SCHEDULE button. The display will show

the type of Schedule currently set up for the Program.

Press the OPTIONS button. The display will show:

EXIT OFF

Type of schedule

You may then press SCHEDULE, or use the BACK

and NEXT buttons, to cycle through the choices available. When the display shows the type of Schedule you

want, press ENTER. Complete the steps for the Schedule types shown above to finish the new schedule.

Assigning a Start Time to a Field Controller Program

The Start Time for a Program determines the time of day

at which the Program will run.

Press the PROGRAM SELECT button repeatedly

until the name or number of the Program you want

appears in the display. Once you have pressed PRO-

GRAM SELECT, you can also use the BACK and

NEXT buttons to go backward or forward through the

available Programs.

EXIT OFF

IDS

PROGRAM

SELECT

PRESETS

MANUAL

START

NEXTBACK

SCHEDULE

STATIONS OPTIONS

123

abc def

456

ghi jkl mno

789

pqrs tuv

CLEAR0TOGGLE

wxyz

ENTER

Press EXIT to leave the Schedule editing mode. The

display will show:

EXIT OFF

You must press the ENTER button with YES capitalized to save the new Program Schedule. If you want to

discard it, press the TOGGLE button to capitalize NO

and press ENTER, and the Schedule will not be saved.

When the Program you want appears in the display,

press the START button. The display will show:

EXIT OFF

You can actually perform two different functions from

here.

13

Page 18

WRITING A FIELD CONTROLLER PROGRAM (CONT.)....

If you press START again, the program will begin run-

ning immediately (so, be careful!). This is the Semiautomatic Start feature.

If you press ENTER, the display will show:

EXIT OFF

The “Prg01” will indicate the Program number you

selected. “XXXXXXXXXX” will be the name of the

Program, if applicable. “Start =” will show the actual

Start Time of day, or OFF if no Start Time has been

programmed yet.

To enter or change a Start Time, simply begin typing

with the number buttons on the keypad. The number will

appear in the display in place of the word OFF or the

previous Start Time. It is not necessary to enter leading

zeroes. For example, to create a Start Time of 9:30 PM,

type 9 3 0 and press ENTER.

The display will then add AM|pm to the time. Press the

TOGGLE button to change between AM and PM. When

the time is correct, press ENTER. The display will

show “ Enter to Save”. Press ENTER again, and the

display will show SAVED! and the time you have set for

the Start Time.

The controller will automatically start the Program at

the time shown (you can also enter multiple cycles, and

cycle delays, for the Program; this is described in detail

in the Programming Advanced Options section).

of the X, you can program a 1, 2, 3, or 4 to tell it which

station you want to program, or activate. The color-code

for each of the four stations is printed on the side of the

decoder (1=black, 2=yellow, 3=green, 4=white). A single

ID4, therefore, can represent up to four stations in the

IDS controller.

A run time is the length of time for which the station will be activated, or in other words, how long the

sprinklers it controls will run. Each station run time is

separately programmed. Run times may be programmed

in 1- minute increments, from 1 minute to 18 hours, 12

minutes, in hh:mm format.

A station may appear in more than one Program, and it

may appear in the same Program more than once. Stations may run in any order, and are not required to run

sequentially in numerical order.

An Event refers to the order in which the station will

run. You can run any station in any order, by setting its

Event number. Events always occur in sequence, from

#1 to the last event. You can assign any station # to any

Event #. Each Program may have up to 30 Events.

To Program Individual Stations

Press the PROGRAM SELECT button repeatedly

until the name or number of the Program you want

appears in the display. Once you have pressed PRO-

GRAM SELECT, you can also use the BACK and

NEXT buttons to go backward or forward through the

available Programs.

EXIT OFF

Programming Stations: Run Times, Events, and Blocks

A Station is a single electrical output to a solenoid on a

valve, originating from the field controller. In decoder

systems, each station is a uniquely-numbered decoder

output along the two-wire path. The IDS controller

may have up to 103 stations, plus a separate Pump

decoder output.

The ID1 single- station decoder may be connected to up

to 2 solenoids. However, they will both start at once,

and are treated as a single station for programming

purposes. The unique 8-digit Serial Number printed on

the actual decoder is associated with a station number

in the IDS controller.

The ID4 four- station decoder has 4 separate outputs,

and each one is a true, independent station. The ID4

has a unique 7-digit number, followed by an X. In place

14

IDS

PROGRAM

SELECT

PRESETS

MANUAL

START

NEXTBACK

When the Program you want appears in the display,

press the STATIONS button. The display will show:

EXIT OFF

Or actual numbers or 9:30 PM or 9:30 PM – 10:45 PM

This initial display shows the total time for the Program

selected, and the start and end times for the Program. If

SCHEDULE

STATIONS OPTIONS

123

abc def

456

ghi jkl mno

789

pqrs tuv

CLEAR0TOGGLE

wxyz

ENTER

Page 19

it is a new Program, or the Start Time has been cleared,

the second line will show “No Start Time”. If there is

already a Start Time, that time will be shown. If Station

Run Times already exist, the Start and the end time for

the Program will be shown.

For example, if a Program contains 32 minutes of

irrigation, and is set to begin at 8:00

PM, the display

would show:

You can continue in this manner until all the stations

you want in the selected Program are programmed.

Remember that you can enter any stations, in any order.

Example:

EXIT OFF

Total is 0:32

8:00pm – 8:32pm

If Continuous cycles have been selected for a Program,

the display will differ, depending on your settings (see

XXXCycles).

Press the STATIONS button again. The display will

show (example):

EXIT OFF

...or, if the station has never been programmed before,

as at initial installation, it will show:

EXIT OFF

This will show the station information for the first

“Event” in the Program. The Program selected is shown

in the upper left. The Event number is in the upper right.

The station or block is in the lower left. The actual Run

Time for the station is in the lower right.

To program a new Station Run Time, verify that the

cursor is under the Station number. (At the station

number position, you can also press the TOGGLE

button to change from a Station to a Block. If you select

a Block, the number will refer to a Block number, not

an individual station. See Blocks on page 16 for more

information.)

Type the number of the station or Block you want. Press

ENTER.

The cursor will advance to the Run Time field. Type the

Run Time you want for that station or Block (up to 18

hours and 12 minutes), and press ENTER.

Event# Station# Run Time

(hours:minutes)

1 3 0:10

2 5 0:08

3 7 0:12

4 8 0:04

5 6 0:20

6 4 0:11

7 2 0:08

8 10 0:10

9 1 0:12

10 9 0:05

Event #1 will begin at the assigned Start Time for the

Program (9:30

PM) and run for 10 minutes. Event #2 will

follow immediately after it (Station #5 for 8 minutes),

then Event #3, and so forth. The total Run Time for the

Program is 100 minutes, so the end time shown will be

11:10 PM.

You may find it easiest to simply run the stations in

numerical order (where Event #1 = Station #1, Event #2

= Station #2, etc.), but IDS has the flexibility to run stations in any order.

When you have finished entering the Run Times for all

the stations you want in the Program, press the EXIT

button. The display will show:

EXIT OFF

The “YES” will be capitalized. To continue saving

the changes, press ENTER. The display will flash

“SAVED!” and your selection. After a moment, the

display will revert to the Program Name.

You must now press the STATIONS button to

advance to the next event, and program another station

(or Block).

If you just want to exit and not save the changes, press

TOGGLE to change “no” to “NO” and press ENTER

15

Page 20

WRITING A FIELD CONTROLLER PROGRAM (CONT.)....

The changes will be discarded, and the Run Times will

be left the way they were.

Blocks

A Block is a group of more than one station (up to 8

per block) which will activate all at once, which are

given a single run time, and which may be included in

a sequence just like a single station. A Block counts

as a single Event regardless of how many stations are

assigned to it. It is technically possible to create a Block

of only 1 station, but this defeats the purpose of

this feature.

When multiple stations are activated in a Block, they are

actually staggered at 1-second intervals to prevent the

simultaneous electrical inrush draw of all the solenoids.

Blocks may be used to help you in several ways. They

allow you to program and adjust large numbers of

sprinklers with fewer keystrokes, since many sprinklers

of similar types will have identical run times.

Blocks can also irrigate more efficiently than single

stations, because the “cloud” of spray from multiple

sprinklers running simultaneously cools hot surfaces,

and reduces the evaporation of individual sprinkler

applications.

Block #2

Block #1

If you group similar sprinklers with similar flow capacities into Blocks, you can have a fairly constant level of

flow, even for a large number of sequencing Events.

By permitting Blocks to sequence ( simultaneous groups

of 4 stations on an ornamental slope, for example),

large areas can be irrigated with fewer Programs and

less complicated sequences.

Block #3

Blocks may also be included in Preset programs, and

can be used to “syringe” overheated turf areas more

efficiently and quickly. One or two Blocks can wet an

entire turf area in a single run time or two.

16

Page 21

Creating Blocks: Blocks are created, edited, or deleted

at the Field Controller Option level. Each Field Controller

may have up to 64 Blocks, which are always the same,

regardless of which Programs they are included in.

With no programs selected, from the basic time date

display on the controller, press the OPTIONS button

approximately 4 times until the display shows:

EXIT OFF

Press ENTER. The display will show:

EXIT OFF

To create a Block, press ENTER. The display will show:

EXIT OFF

Press ENTER. The display will show:

EXIT OFF

Press OPTIONS again. The display will show:

EXIT OFF

Press OPTIONS again. The display will show:

EXIT OFF

To edit an existing Block, press the OPTIONS button

until Edit a Block? is shown, and press ENTER. The

display will show:

EXIT OFF

Type the station number for the first station in the block,

and press ENTER. The display will show:

EXIT OFF

Type the next station number and press ENTER, and so

on, up to 8 stations. When the block is complete, press

ENTER again. The display will show “SAVED!” and

will return to the Create A Block? message. You may

then create another Block, or press EXIT to leave the

Block mode.

Note that run times and Events are not assigned to

Blocks here. This only creates the Blocks, by assigning

stations to them. The actual run times are assigned to

the Blocks in the individual Programs, under the Stations button functions.

Editing and Removing Blocks: Once Blocks are created,

they may be edited, or removed altogether. With no

Programs selected, from the basic time date display on

the controller, press the OPTIONS button 4 times until

the display shows:

EXIT OFF

This list will always show all of the currently

existing Blocks

In this example, the controller already has more than 5

Blocks created, and the arrow symbol is prompting you

to press the NEXT button to view more Block numbers.

Type the number of the Block you want to edit (for

example, “3”) and press ENTER. The display will then

show the station numbers included in that block, and

will also show “---” for any unoccupied spaces in the

Block. You may now add more stations, or remove existing stations from the Block.

To remove a station from an existing Block, press the

NEXT button to advance to the station, and press

CLEAR or “0” (zero). Press ENTER.

To add a new station to an existing Block, press

the NEXT button to advance to the next blank spot

(---), type in the number of the new station, and press

ENTER. It is not necessary to enter leading zeroes. For

example, to add station 7 to a Block, simply type “7” at

a blank spot and press ENTER. You may then advance

to the next blank spot and enter, change, or remove

more stations in the Block.

You may also replace one station in an existing Block

with another. Press NEXT to advance to the station you

17

Page 22

WRITING A FIELD CONTROLLER PROGRAM (CONT.)....

want to replace, simply type the new station number

right over it, and press ENTER. This will remove the

original station, and add the new station in its place.

When the Block editing is complete, press ENTER

again. The display will ask:

EXIT OFF

If you want to save the Block edits, press ENTER (with

the YES capitalized). The display will show:

EXIT OFF

The display will then revert to the Edit a Block? option

level.

To remove an existing Block, press the ENTER button

when Remove a Block? is shown. The display will

show:

specific event is to continue pressing the STATIONS

button until the display shows the Event you want to

edit. When the specific Event is shown in the display,

press the OPTIONS button. The OPTIONS button will

cycle through the Station-level options, which are as

follows:

EXIT OFF

EXIT OFF

EXIT OFF

EXIT OFF

EXIT OFF

In this example, the controller already has more than 5

Blocks created, and the arrow symbol is prompting you

to press the NEXT button to view more Block numbers.

Type the number of the Block you want to remove (for

example, “2”) and press ENTER. The display will show

REMOVED and the block will be permanently deleted.

Station Options (Changing Events)

As noted above, stations or Blocks can run in any order.

You do this by editing Events. There are several options

available to edit Events.

Remember: The Event refers to the order in which the

station will run. You can run any station in any order,

by setting its Event number. Events always occur in

sequence, from #1 to the last event. You can assign any

station # to any Event #.

Events are part of a specific Program, so the first step is

to press PROGRAM SELECT on the keypad until the

Program you want to edit appears in the display.

Then press the STATIONS button once. The display

will show the current total run time of the Program.

The easiest way to access most of the functions for a

Delete an Event: To delete the data in an existing Event,

press ENTER when the displays shows Delete an

Event? The display will then ask, Delete data in Event

#x? (where x = the number of the Event you were on).

Press ENTER. The display will show OK! and the Event

will be deleted.

Note that you don’t really delete Events, but the data in

the Events. In effect, the whole sequence of stations or

Blocks will move backward one Event, to fill the slot that

was just deleted.

Example: If the existing Events were as follows:

Event # 1 2 3 4

Station # 5 6 7 8

...and you then delete the data in Event #2, the new

Event list would look like:

Event # 1 2 3

Station # 5 7 8

Since there are only 3 remaining stations, the last Event

is now #3.

Cluster Events?: “ Cluster” is a mass-programming

function for large groups of similar stations. When you

first program a controller, you may want to set up all the

18

Page 23

same types of sprinklers with the same run time, see

what happens, and adjust individual stations from there.

“ Cluster” lets you assign a single run time to large numbers of sequentially numbered stations, with a minimum

number of keystrokes.

Press ENTER to cluster the stations and run times you

entered. The display will briefly show “OK!” and then

return to the Cluster Event? Option. Press EXIT if you

are done programming stations, and the display will

return to the Stations display.

To do this, the Cluster command will assign a consecutive sequence of station numbers to a consecutive

sequence of Event numbers, with a single run time

for all.

To cluster Events, press STATIONS to get to the sta-

tion where you want to begin a Cluster (often station 1),

and press OPTIONS until the display shows Cluster

Events? Press ENTER. The display will show:

EXIT OFF

Where x = the number of the Event you were on.

Type the number of the Event you want, or just press

ENTER to accept the choice offered. The display

will show:

EXIT OFF

Since 30 is the maximum number of Events in a Program, the controller will always offer to cluster up to

Event #30. You may type any existing Event number

higher than the starting Event to cluster to, and press

ENTER. The display will then show:

The controller will then assign the run time to every station in the cluster, beginning with the lowest numbered

station and ending at the last one in the cluster.

When you have finished entering the Run Times for all

the stations you want in the Program, press the EXIT

button. The display will show:

EXIT OFF

If you want to save the new Run Times, press ENTER

(with the YES capitalized). The display will show:

EXIT OFF

The display will then revert to the Program Name display.

Example:

EXIT OFF

EXIT OFF

EXIT OFF

You may start at any station number. Simply type the

number of the station at which you want to begin, and

press ENTER. The display will then show:

EXIT OFF

Type the run time you want all the clustered stations to

use. The display will then show:

EXIT OFF

EXIT OFF

EXIT OFF

The controller will create 12 Events, from 001 to 012.

Stations 5 through 16 will run in sequence, for 10 minutes apiece.

Move an Event: You can also move the data from one

event to another location in a Program, if you want a

19

Page 24

WRITING A FIELD CONTROLLER PROGRAM (CONT.)....

Figure 1

specific station to keep its run time, but activate in a

different order.

In Figure 1, you might want to move station #6 (Event

#2) to activate after station #14 (Event #10).

To move an Event, press STATIONS until the Event you

want to move appears in the display. Press OPTIONS

until “ Move an Event?” appears in the display. Press

ENTER. The display will show:

EXIT OFF

Press ENTER (you may also type in a different Event

number). The display will show:

EXIT OFF

Type the Event # you want to move the data to (#10,

in this example), and press ENTER. The display will

briefly show OK, and revert to the Move Event? display.

within the 12 numbers. You cannot have an “empty”

Event in the middle of a sequence. Trying to move to

Event #13 would cause the ERROR! message.

Insert an Event: You can insert a new Event in between

existing Events. In the example above, you might want

to insert station #4, with a run time of 7 minutes, in

between stations #8 and #9 (Events 3 and 4).

Press the STATIONS button to advance to the Event

where you want to insert an Event (Event #4, in the

example). Press the OPTIONS button until the display

shows Insert an Event? Press ENTER. The display

will show:

EXIT OFF

Press ENTER. The display will briefly show OK! and

will then revert to the Insert Event? option. You have

now created a blank Event at Event #4. The stations and

Event that were at #4 are now at Event #5, and the rest

of the sequence has been pushed back, to make room

for the new Event.

As you can see in Figure 2, the Event data has been

moved. Note that the other Events move forward to fill

the slot formerly occupied by station #6. No data was

lost. Only the order in which the stations will activate

has changed.

Note: If you try to move an Event # that does not exist,

or try to move an Event to an impossible #, the display

will briefly show ERROR! and return you to the option.

If you only have 12 Events, you can only move an Event

Figure 2

Figure 3

20

You may now press STATIONS until you arrive at the

blank Event, and fill it in (in Figure 3, Station #4 with

a run time of 7 minutes). The new Event data has been

inserted. Note that the later Events move back to make

room for the new Event. You have only inserted a new

Event into the Program sequence.

Page 25

PROGRAM ADVANCED OPTIONS..................................

The previous sections covered the basic concepts of

writing a Program from the IDS controller keypad:

Program, Schedule, Start Time, and Station run times,

as well as Blocks and Events.

The Program Options provide additional power and flexibility at the individual Program level.

They are: