Page 1

Commercial Irrigation Controller

RAIN SENSOR

ACTIVE BYPASS

SYSTEM OFF

MANUAL OPERATION

SETTINGS

ADVANCED FEATURES

SET SENSOR OPERATION

CYCLE AND SOAK

SET CURRENT DATE / TIME

SET PROGRAM START TIMES

SET STATION RUN TIMES

SET DAYS TO WATER

SET SEASONAL ADJUSTMENT

SET PUMP OPERATION

Owner’s Manual and Installation Instructions

IC-600PL 6-station Controller expandable to 30 stations, Plastic Cabinet

IC-600M 6-station Controller expandable to 42 stations, Metal Cabinet

IC-600PP 6-station Controller expandable to 42 stations, Plastic Pedestal

IC-600SS 6-station Controller expandable to 42 stations, Stainless Steel

Page 2

SET CURRENT DATE / TIME

SET PROGRAM START TIMES

SET STATION RUN TIMES

SET DAYS TO WATER

SET SEASONAL ADJUSTMENT

SET PUMP OPERATION

Page 3

TABLE OF CONTENTS

INTRODUCTION ........................................................................................... 2

I-CORE INTERFACE AND KEY COMPONENTS ............................................. 2

I-CORE WIRING COMPARTMENT AND INTERIOR ........................................ 3

MOUNTING THE CONTROLLER TO WALL .................................................... 4

Wall Mount for Plastic and Metal Cabinet .................................................... 4

MOUNTING THE CONTROLLER (METAL PEDESTAL) .................................... 5

Pedestal Mount for Metal/Stainless Cabinet ................................................ 5

MOUNTING THE CONTROLLER (PLASTIC PEDESTAL) .................................. 5

Plastic Pedestal Mounting ........................................................................... 5

CONNECTING AC POWER ........................................................................... 6

For 120V Operation.................................................................................... 6

For 230V Operation.................................................................................... 6

CONNECTING EARTH GROUND .................................................................. 7

CONNECTING THE POWER AND STATION MODULES ................................ 8

Station Module Installation ......................................................................... 8

Power Module Installation .......................................................................... 8

CONNECTING VALVE WIRES ........................................................................ 9

Connecting Station Valve Wires .................................................................. 9

Connecting a Master Valve or Pump Start Relay ........................................... 9

CONNECTING A WEATHER SENSOR (OPTIONAL AND NOT INCLUDED) .. 10

Bypassing the Sensor(s) ............................................................................ 10

Sensor Bypass Switch ............................................................................... 10

CONNECTING A HUNTER SOLAR SYNC .................................................... 11

CONNECTING A FLOW SENSOR (OPTIONAL) ........................................... 12

CONNECTING A REMOTE CONTROL (OPTIONAL) .................................... 13

POWER FAILURES ....................................................................................... 14

QUICK START .............................................................................................. 14

CONTROLLER PROGRAMMING.................................................................. 15

Setting Current Date and Time ................................................................. 15

Setting Program Start Times ..................................................................... 15

Setting Station Run Times

(Length of Watering for Each Station)

Selecting Specic Days of the Week to Water ............................................ 16

Selecting Odd or Even Days to Water ...................................................... 16

Selecting Interval Watering ....................................................................... 16

Set Seasonal Adjustment .......................................................................... 17

Set Pump Operation ................................................................................. 18

Cycle and Soak ........................................................................................ 18

Set Sensor Operation ............................................................................... 18

Manual Program ....................................................................................... 20

Manual Station ......................................................................................... 20

Learn Expected Flow ................................................................................ 20

System Off ............................................................................................... 21

ADVANCED FEATURES ............................................................................... 22

Set Language ........................................................................................... 22

Set Units .................................................................................................. 22

Sensor Conguration ................................................................................ 22

Sensor Options ........................................................................................ 22

Congure a non-Hunter Flow Sensor ......................................................... 22

Flow Operation ........................................................................................ 23

Station Delay ........................................................................................... 24

No Water Window .................................................................................... 24

Firmware Info ........................................................................................... 24

Easy Retrieve™ Memory ............................................................................ 24

To save your watering program into memory: ............................................ 25

To restore the saved program: .................................................................. 25

Total Watering Time ................................................................................. 25

Erase All .................................................................................................. 25

LCD Adjust .............................................................................................. 26

Flow Totalizer ........................................................................................... 26

Solar Sync Delay....................................................................................... 26

PROGRAMMING SOLAR SYNC SETTINGS .................................................. 27

Programming Region & +/– Water Adjustment Setting .............................. 27

Clearing ET memory ................................................................................. 28

Check Sensor ........................................................................................... 28

........................................................ 15

Programming Solar Sync Delay ................................................................. 28

HIDDEN FEATURES ..................................................................................... 29

Programmable Rain Off ............................................................................ 29

One Touch Manual Start and Advance ...................................................... 29

Test Program Operation ........................................................................... 29

Complete Flow Monitoring Procedure ....................................................... 29

CONTROLLER DIAGNOSTICS AND TROUBLESHOOTING .......................... 31

System Status Dashboard ......................................................................... 31

Sensor Status ........................................................................................... 31

Station Status ........................................................................................... 31

Flow Status .............................................................................................. 31

HUNTER QUICK CHECK

TROUBLESHOOTING .................................................................................. 34

I-CORE: INSTITUTIONAL/COMMERCIAL CONTROLLER

(IC-600PL & IC601PL) – PLASTIC CABINET

I-CORE: INSTITUTIONAL/COMMERCIAL CONTROLLER

(IC-800M & IC-800SS) – METAL CABINET

I-CORE PLASTIC PEDESTAL ........................................................................ 38

SPECIFICATIONS ......................................................................................... 39

Operating Specications .......................................................................... 39

Electrical Specications ............................................................................ 39

Dimensions .............................................................................................. 39

Default Settings ....................................................................................... 39

FCC NOTICE ............................................................................................... 39

™

........................................................................... 33

................................................. 36

................................................... 37

1

Page 4

INTRODUCTION

2

The Hunter I-Core controller is a full-featured controller for demanding commercial and high-end residential applications. Versatility is what makes the I-Core

one of Hunter’s highest performing irrigation controllers.

I-Core features include:

• Modular design expandable from 6 to 30 stations

(plastic cabinet) and 6 to 42 stations (metal/stainless cabinet)

• 4 fully independent programs

• Diagnostic Dashboard™ monitors system operation and provides

real-time sensor and controller status

• Real-time ow monitoring

• Remote control ready with factory installed SmartPort

• Seasonal adjustment independent by program: Can be set globally,

monthly, or through Solar Sync

• Water Window Manager™: User dened hours when watering is

allowed

• Easy Retrieve™ Memory: Saves preferred program in memory

• Large, backlit display for easy programming

• Multi-language programming capability

• Automatic short circuit protection

• Built in Solar Sync capability

®

Note:

- This product should not be used for anything other than what is

described in this document.

- This product should only be serviced by trained and authorized personnel.

- This product is designed for continuous outdoor use from 0˚ F/-18 ˚ C

to 140˚ F/60˚ C.

- These units have an IP44 rating.

- This controller is not intended for use by young children or inrm

persons without supervision; young children should be supervised to

ensure that they do not play with the appliance.

I-CORE INTERFACE AND KEY COMPONENTS

1.

LCD Display

2.

+ Button

3.

– Button

4. ▲ ▼ (Up and Down Arrow Buttons) – Used to move up and down

through adjustable functions in various screens, and change selections

in certain screens

5. ◄ ► (Left and Right Arrow Buttons) – Used to move left and right

in various screens, and change important selections such as Stations,

Start Times, and Water Days

6.

PRG

and also starts the test program

7.

Programming Dial

of the I-Core. The most basic automatic watering is set up in the rst 4

dial positions

8.

Rain Sensor Bypass Switch

one is installed

9.

System Status Dashboard

information regarding sensor status, valve operation, and ow

monitoring

10.

Removable Facepack

controller for remote programming

– Backlit, adjustable contrast display

– Increases ashing value depending on function

– Decreases ashing value depending on function

(Program Button) – Selects one of the automatic Programs (A–D),

– Used to access all of the programming functions

– Allows user to bypass weather sensor if

– LED lights provide system status

– I-Core facepack can be removed from

9

1

5

3

4

6

8

RAIN SENSOR

ACTIVE BYPASS

MANUAL OPERATION

ADVANCED FEATURES

SET SENSOR OPERATION

SYSTEM OFF

SETTINGS

CYCLE AND SOAK

SET CURRENT DATE / TIME

SET PROGRAM START TIMES

SET STATION RUN TIMES

SET DAYS TO WATER

SET SEASONAL ADJUSTMENT

SET PUMP OPERATION

7

10

2

Page 5

S1 S1 S2 S2 CC

GND AC1AC2 REM C

P/MV

I-CORE WIRING COMPARTMENT AND INTERIOR

1.

Battery Compartment

controller without AC power.

2.

Battery Compartment

installed (location is on the back of the facepack).

3. Release for Facepack – Pull on the release tab and the facepack can be removed from the facepack frame.

4. Ribbon Cable – Cable that transmits information between the facepack and the inner controller assembly.

5. Slide Lock Bar for Output Modules – Sliding the Slide Lock Bar turns the controller’s power on or off. Permits the addition or removal of output

modules and locks the modules into place in the Power On position.

6. Power Module – This module provides power to the controller. This module must be in place for the controller to operate.

7. Station Module(s) – The addition of 6 station modules allows the ability to expand your I-Core from 6 to 30 stations (plastic cabinet) and 6 to 42

stations (metal cabinet and plastic pedestal). Each station module corresponds to six station screw terminals.

8. Power and Accessory Terminals – Connections for Power, Sensors, Pump/Master Valve, and other accessory connections.

9. Station Terminals – Connections for station wires; only terminals with corresponding Station Output Modules will be active and recognized by the

controller.

10. Communication Port – Connection for future use with Central Control Communications.

11. Earth Ground Lug – For connection of earth ground copper wire (for surge protection only). Do not connect valve commons or the incoming service

ground wire.

12. Transformer – A transformer is installed in the controller to supply 24VAC power to the controller. Transformer allows for either 120VAC or 230VAC

connections.

13. AC Wiring Compartment (Junction Box) – For connection of 120/230VAC power.

14. Conduit Opening – 1 to 1 ½" (25 mm to 38 mm) for eld wiring into controller.

(9-volt alkaline battery) – The alkaline battery (not included) keeps time during power outages. The user may also program the

(CR2032 3-volt lithium) – The lithium battery provides backup timekeeping during power outages and when the 9-volt is not

15. SmartPort® – Integrated connector for ICR/SRR/ROAM receiver (on side of cabinet).

Explanation of Symbols

AC

Consult Documentation

Hazardous Voltage Present

Double Insulated

8

6

4

2

3

1

7

5

15

10

11

9

12

13

14

3

Page 6

MOUNTING THE CONTROLLER TO WALL

S1 S1 S2 S2 CC

GND AC1AC2 REM C

P/MV

Wall Mount for Plastic and Metal Cabinet

All necessary mounting hardware is included with your controller and

should be suitable for most installations.

Tools required:

• Long drill bit and extension Philips screwdriver or bit (for use with long

extension) – magnetic recommended Wire strippers

NOTE: This controller must be installed in compliance

with local electrical codes.

A

B

C

Location Requirement: A) A switch or circuit-breaker shall be included in

building installations; B) the switch or breaker shall be in close proximity

to the controller and within easy reach of the operator; C) the switch or

breaker shall be marked as the disconnecting device for the controller;

D) the switch or circuit breaker used must comply with IEC 60947-1 and

IEC 60947-3.

Select a location for your controller that can be easily accessible, has

a at wall surface, and is within close proximity to a 120VAC(10A) or

230/240VAC(5A) power source.

In outdoor installations, avoid direct exposure to sprinkler spray. Shaded or

partially shaded areas are preferable to prolonged direct sunlight.

1. Using the enclosed mounting template, mark the mounting hole

locations on the wall. It should be mounted at eye level if possible.

2. Drill a ¼" (6 mm) hole at each mark.

3. Install screw anchors into holes if attaching the controller to drywall,

masonry, or plaster walls.

4. Open the controller and inner door. The inner door will swing out of

the way to provide full access to the controller mounting holes.

5. Holding the controller cabinet, line up the holes in the cabinet with

the wall anchors or pilot holes.

6. Drive a screw through each hole and secure snugly but do not

over tighten.

7.

OPTIONAL:

Locate the positioning hanger in the upper center of the

controller (A). Install one screw (B) in this hanger position and hang

the controller from the keyhole slot. Place a level on the top of the

controller cabinet and level. Locate and drive a screw in each of the

remaining screw holes (C), and secure snuggly but do not over tighten

the screws.

4

Page 7

MOUNTING THE CONTROLLER (METAL PEDESTAL)

AC Power Wire S/P

Pedestal Mount for Metal/Stainless Cabinet

Location Requirement:

building installations; B) the switch or breaker shall be in close proximity

to the controller, and within easy reach of the operator; C) the switch or

breaker shall be marked as the disconnecting device for the controller; D)

the switch or circuit breaker used must comply with IEC 60947-1 and IEC

60947-3.

Select a location for your controller that can be easily accessible, and is

within close proximity to a 120VAC(10A) or 230/240VAC(5A) power source.

1. Set concrete forms using the installation instructions provided with the

controller. Allow 2"(50 mm) of the conduit sweep above the surface of

the concrete pad.

2. Assemble the mounting template. Twist one nut on each of the four

J-bolts and slide each bolt through the template. Put a washer and

nut on each J-bolt to secure it to the template (allow 2 ½" [64 mm] of

thread protruding above each nut).

3. Level the mounting template before the concrete sets. Uneven

surfaces may cause the pedestal to distort, preventing proper sealing

of the doors.

4. Allow the concrete to cure for at least 24 hours. After the concrete

sets, remove the nuts and washers from the four J-bolts, and slide the

pedestal over the bolts. Secure the pedestal to the bolts using the

enclosed washers and nuts.

A) A switch or circuit-breaker shall be included in

³∕8" (9.5 mm) Mounting Nut (8)

8" (9.5 mm) Mounting Nut (8)

³∕

5. Remove the door and faceplate of the I-Core and attach the metal

cabinet of the I-Core to the top of the pedestal using the enclosed

hardware in the pedestal.

6. Replace the pedestal door rst and then replace the faceplate and the

cabinet door. The pedestal door cannot be removed or replaced when

the cabinet door is closed.

½" (13 mm)Conduit Nut

½" (13 mm)Conduit Nut

¾" (20 mm)Washer (4)

2" (50 mm)Conduit Nut

2" (50 mm)Conduit Nut

Mounting Plate

MOUNTING THE CONTROLLER (PLASTIC PEDESTAL)

Plastic Pedestal Mounting

Location Requirement:

building installations; B) the switch or breaker shall be in close proximity

to the controller, and within easy reach of the operator; C) the switch or

breaker shall be marked as the disconnecting device for the controller; D)

the switch or circuit breaker used must comply with IEC 60947-1 and IEC

60947-3.

Select a location for your controller that can be easily accessible, and is

within close proximity to a 120VAC(10A) or 230/240VAC(5A) power source.

1. Set concrete forms using the installation instructions provided with the

controller. Allow 2"(50 mm) of the conduit sweep above the surface of

the concrete pad.

2. Assemble the mounting template. Twist one nut on each of the four

J-bolts and slide each bolt through the template. Put a washer and

nut on each J-bolt to secure it to the template (allow 2 ½" [64 mm] of

thread protruding above each nut).

3. Level the mounting template before the concrete sets. It is important

with plastic pedestals to ensure a smooth mounting surface. Uneven

surfaces may cause the pedestal to distort, preventing proper sealing

of the doors.

4. Allow the concrete to cure for at least 24 hours. After the concrete

sets, remove the nuts and washers from the four J-bolts, and slide the

pedestal over the bolts. Secure the pedestal to the bolts using the

enclosed washers and nuts.

A) A switch or circuit-breaker shall be included in

(3" [7.6 cm] Max Above Concrete)

21" (53 cm) Min

4" (10 cm)

12.50" (31.8 cm)

26" Min (66 cm)

Thread Length 2.50" (6.4 cm) Min

Above Concrete

Field Wiring

(3" [7.6 cm] Max Above Concrete)

Template

5" (12.7 cm)

5

Page 8

CONNECTING AC POWER

NOTE: It is recommended that a licensed electrician perform the following power installation.

The I-Core can operate with either 120VAC or 230VAC power. Supply wires must be 14AWG or larger.

1. Turn AC power off at the source, and verify that it is off.

2. Remove the cover from the junction box.

3. Strip approximately ½" (13 mm) of insulation from the end of each of the AC power wires.

4. Route the wires through the conduit opening inside the junction box.

Do NOT connect the primary AC 120/230V electrical ground wire to the earth ground lug.

For 120V Operation

1. Connect the incoming black power wire (HOT) with the black wire lead

from the transformer.

2. Connect the incoming white wire (NEUTRAL) with the blue lead from

the transformer.

3. Connect the incoming green wire (GROUND) with the green and

yellow wire from the transformer.

4. Cap the unused brown wire coming from the transformer. Replace

cover of the junction box and screw into place.

Junction Box without Terminal Strip (120 Volt)

230 Brown Wire

(230 Volt)

Black Wire

120 Black Wire

(120 Volt)

Blue Wire

(Neutral)

White Wire

(Neutral)

For 230V Operation

1. Connect the incoming brown power wire (HOT) with the brown wire

lead from the transformer.

2. Connect the incoming blue wire (NEUTRAL) with the blue lead from

the transformer.

3. Connect the incoming green wire (GROUND) with the green and

yellow wire from the transformer.

4. Cap the unused black wire coming from the transformer. Replace

cover of the junction box and screw into place.

Junction Box with Terminal Strip (230 Volt)

230 Brown Wire

(230 Volt)

120 Black Wire

(120 Volt)

Blue Wire

(Neutral)

Brown Wire

(230 Volt)

Blue Wire

(Neutral)

Green Wire

(Ground)

6

Green Wire

(Ground)

Green Wire

(Ground)

Green Wire

(Ground)

Page 9

CONNECTING EARTH GROUND

S1 S1 S2 S2 C C

GND AC1 AC2 REM C

P/MV

The I-Core features a ground lug, which is isolated from the primary AC power, and is used to ground incoming surges from the

communications and output valve wires.

Do NOT connect the primary AC 120/230V electrical ground wire to the

earth ground lug.

1. Use #10 (6 mm) or #8 (10 mm) bare wire to connect the controller

to the ground rod. Route the earth ground wire into the wiring

compartment through the 1 ½" conduit opening at the bottom of the

cabinet. Do not route the ground wire through the same conduit as

the incoming primary AC power.

2. Loosen the ground lug screw; insert the ground wire into the ground

lug and tighten the screw to secure the ground wire. Do not over

tighten.

Acceptable grounding consists of an 8' (2.5 m) copper-clad rod or stake, or

a 4" x 96" (100 mm x 240 cm) copper plate, or both, placed in the earth at

least 8' (2.5m) away from the controller, and with the ground wire at right

angles to the communications and valve wires, if possible. Ideal grounding

resistance would be 10 Ohms or less as measured with a “megger”

or similar device. Please consult the ASIC reference for more detailed

information on proper grounding techniques.

Ground Wire

7

Page 10

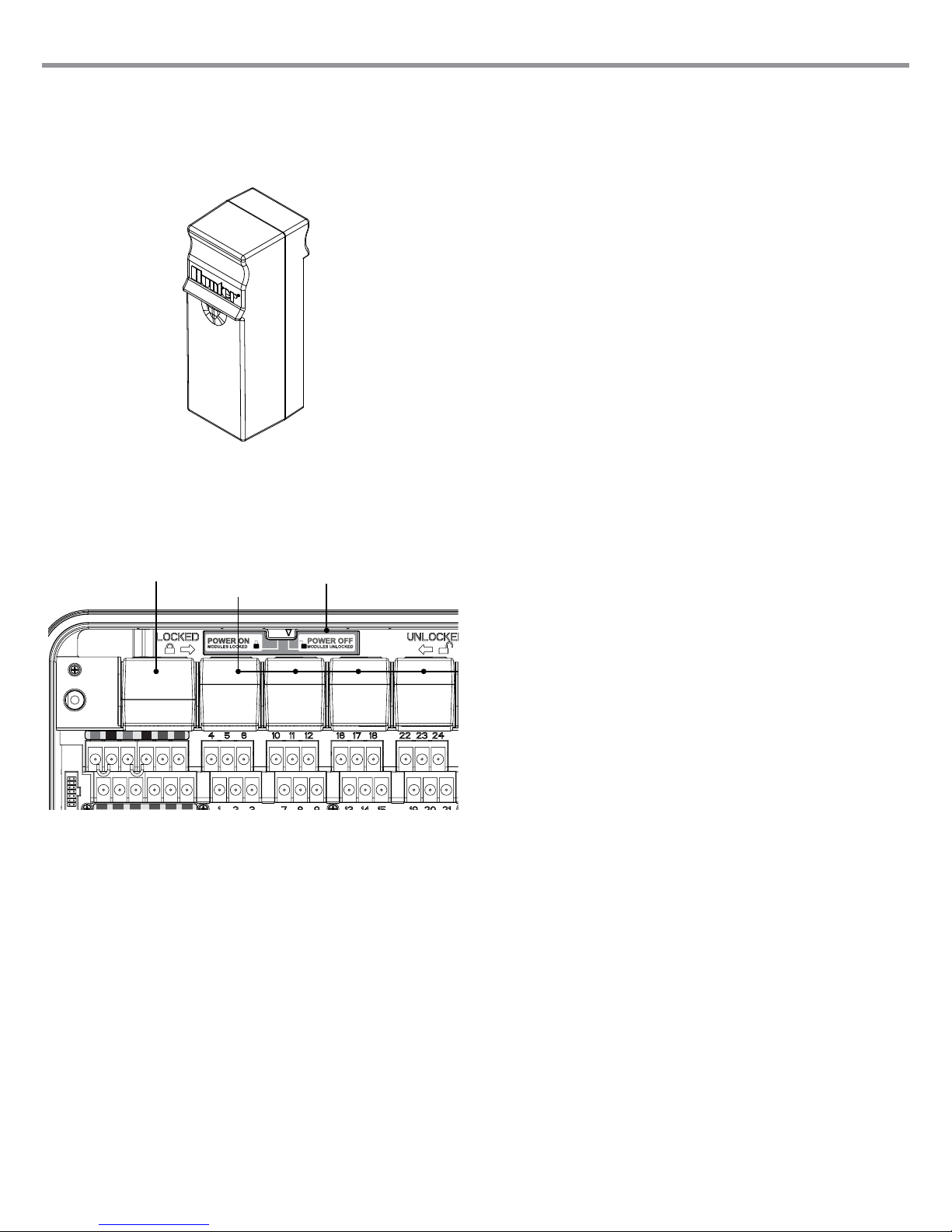

CONNECTING THE POWER AND STATION MODULES

S1 S1 S2 S2 CC

The I-Core controller is supplied with one factory installed power module

and one station module for six stations. Additional station modules may be

added in six station increments to expand the controller’s station capability.

The plastic cabinet I-Core can be expanded to a size of 30 stations, and the

metal cabinet and plastic pedestal I-Core can expand to 42 stations.

STATION MODULE

Power Module

Station Modules

Slide Lock

Station Module Installation

1. Open the inner facepack door and locate the Slide Lock. Move the

Slide Lock bar to the POWER OFF position.

2. The module needs to be inserted into the rst open module slot

position from the left or next available position in the back of the

controller. Do not skip slots by leaving them empty.

3. Insert the module with the gold tab on the top of the module facing

up. Slide the module straight in until it clicks into place.

4. Slide the Slide Lock into the POWER ON position.

5. The controller will automatically identify any new modules that have

been added. You can turn the dial to SET STATION RUN TIMES to

conrm the correct number of stations have been acknowledged.

Power Module Installation

The I-Core power module supplies power to the facepack and accessory

terminals. It typically does not need to be removed, however can be

replaced for servicing.

1. To install the Power Module, open the inner facepack door,

and locate the module lock bar. Move the Slide Lock bar to the

POWER OFF position.

2. Insert the power module into the rst slot position from the left, with

the gold tab on the top of the module facing up. Slide the module

straight in until it clicks into place.

3. Move the Slide Lock to the POWER ON position.

4. The Power Module must be in place in order for the controller to

operate and function.

8

Page 11

CONNECTING VALVE WIRES

S2 C C

REM C

P/MV

S1 S1 S2 S2 C C

GND AC1 AC2 REM C

P/MV

Connecting Station Valve Wires

Each station module that has been inserted has a grouping of six station

screw terminals corresponding to that particular expansion slot. Once a

station module is installed in a module slot, the station screw terminals

assigned to that module, which are located directly below the station

module, become active.

Each station output is rated for 0.56A max, or enough to operate two

Hunter AC solenoids simultaneously.

1. Route valve wires between control valve location and the controller.

2. At the valves, attach a common wire to either solenoid wire of all the

valves. This is most commonly a white colored wire. Attach a separate

control wire to the remaining wire of each valve. All valve wire splice

connections should be done using waterproof connectors.

3. Open the faceplate at the controller to expose the numbered station

terminals.

4. Route valve wires through the conduit and attach the conduit to the

controller at the 1 ½" (37.5 mm) opening at the bottom of the cabinet.

5. Strip ½" (13 mm) of insulation from the ends of all the wires. Secure

the valve common wire to one of three C (Common) terminals located

of the Power and Accessory terminals. All three common terminals are

active, so the valve common wire may be connected to either one.

Attach all the individual valve control wires to the appropriate station

terminals.

Valve

Wires

Valve 4

The Master Valve or Pump Start Relay connection is located on the

bottom row of the Power and Accessory Terminals, and is labeled P/MV.

This terminal will supply 24 VAC, 0.32A max, for a single Master Valve

solenoid. For a Pump Start Relay, the relay holding current draw must

not exceed 0.28 amps. If using a Pump Start Relay, it is recommended

that the controller be mounted at least 15' (4.5 m) away from both the

pump start relay and the pump. When a pump is to be operated by

the controller, a pump start relay must be used. Do not connect the

controller directly to the pump — damage to controller will result.

1. Route valve wires between Master Valve or Pump Start Relay location

and the controller.

2. At the Master Valve, attach a common wire to either solenoid wire of

the valve. Attach a separate control wire to the remaining solenoid

wire. At the Pump Start Relay, attach either wire to one of the yellow

wires coming from the Pump Start Relay. Attach the remaining wire to

the other yellow wire at the Relay. All wire splice connections should

be done using waterproof connectors.

3. Open the inner facepack door at the controller.

4. Route the valve wires into the controller via the eld

wire conduit.

5. Connect either wire from the Master Valve or Pump start Relay to the

P/MV terminal located on the bottom row of the Power and Accessory

terminals. Connect the remaining wire to the C (Common) terminal

that is located directly to the left of the P/MV terminal.

The Master Valve or Pump Start Relay can be activated according to a

particular station. The conguration of assigning the Master Valve or Pump

Start Relay according to a particular station will be covered in the Set Pump

Operation (pg. 18).

Valve 3

Valve 2

Valve 1

Valve Common Wire

Connecting a Master Valve or Pump Start Relay

Complete this section only if you have a Master Valve or Pump Start Relay

installed. The I-Core controller works with a normally closed master valve

that is typically installed at the supply point of the main line that opens only

when the automatic system is activated. A pump start relay is an electrical

device that uses the irrigation controller to activate a pump to provide

water to your system.

To P/MV or

Pump Start Relay

9

Page 12

CONNECTING A WEATHER SENSOR (OPTIONAL AND NOT INCLUDED)

S1 S1 S2 S2 C C

GND AC1 AC2 REM C

P/MV

The I-Core controller has the ability of connecting two Hunter Sensors

(three with I-Core Metal) including:

• Mini-Clik

®

• Rain Clik™

(including Wireless Rain Clik, Wireless Rain Freeze-Clik)

• Freeze-Clik

• Wind-Clik

®

®

• Mini-Weather Station (MWS)

• Solar Sync and Wireless Solar Sync ET Sensor

With the I-Core controller, Clik sensors can be programmed to shut down

individual stations, not necessarily the entire controller. Each sensor can be

given its own response instructions according to each station. Hunter Clik

sensors are usually normally closed, and open on alarm. This signals the

controller to suspend watering when precipitation, freeze or wind events

occur. The sensor connects directly to the sensor terminals, which also

allows you to override the sensor by using the Rain Sensor bypass switch

on the face of the controller.

1. To connect Clik sensors, locate the 2 pairs of sensor terminals in the

Power and Accessory Terminal section, labeled S1, S1 and S2, S2 (S3

available on I-Core Metal).

2. Route the wires from the Clik sensor through any of the available

knockouts into the controller cabinet.

3. The sensor connections are made in dedicated pairs. Remove the

sensor jumper wire from one pair of S1 or S2 terminals. Attach one

sensor wire to each of the two S1

or S2 terminals.

4. To connect the Wireless Rain Clik or Wireless Rain Freeze Clik, the

blue and white wires will be connected to the corresponding sensor

terminal as stated above: One into the rst S1 terminal and the other

into the second S1 terminal. Connect one of the yellow wires to the

AC1 terminal and the other yellow wire to the AC2 terminal.

Bypassing the Sensor(s)

If the rain sensor is ACTIVE and automatic or manual operation is required,

simply move the Bypass switch to Bypass.

Weather Sensor

If the rain sensor switch is left in the ACTIVE position but no sensor is

connected and the jumper wire has been removed, the display on the

I-Core will indicate that the sensor is ACTIVE. This will also be indicated

in the System Status dashboard to the left of the display. The sensor light

will be illuminated RED for ACTIVE, thus having an open circuit. As long as

the sensor is in the ACTIVE mode, any station that has been programmed

to the ACTIVE sensor will not be allowed to water, and will be put into

Suspend mode. If you do not have a sensor and want to eliminate this

possible problem, simply keep the rain sensor switch in the bypass mode,

or install the jumper wire between the sensor terminals if it has been

removed.

Programming of the sensors will be discussed in the Set Sensor Operation

section of Programming and Operation (pg. 18).

Sensor Bypass Switch

This switch will either enable or disable a Rain or Freeze sensor that has

been connected to the controller. When the switch is in the Active position,

the controller will adhere to the state of the sensor and shut down irrigation

if the sensor is in an open state. If the sensor is in a closed state, the

controller will operate as normal. If the sensor is in an open state, but you

would like your automatic irrigation to operate as normal, simply move the

switch to the Bypass position. The sensor will now be overridden and the

controller will operate as programmed.

Once the Sensor Bypass Switch is in the Active position the System Status

Dashboard will acknowledge the switch is in the Active position, and the

Sensor Status light will light up. If the sensor is in an open state, the System

Status Sensor light will be Red. If the sensor is in a closed state, the System

Status Sensor light will be Green.

If you do not have a sensor installed, the position of the Rain Sensor switch

can be in either the Active or the Bypass mode. This is true as long as

the jumper wire connecting the two sensor terminals remain in place. If a

jumper wire has been removed, it will be necessary to keep the Rain Sensor

switch in the Bypass mode, otherwise no automatic irrigation will occur.

10

Page 13

S1 S1 S2 S2 C C

GND AC1 AC2 REM C

P/MV

CONNECTING A HUNTER SOLAR SYNC

The Solar Sync is a “smart“ control system that, when connected to the

I-Core, will automatically adjust your controller’s station run times based

upon changes in local climate conditions. The Solar Sync incorporates a

solar and temperature sensor to determine evapotranspiration, also known

as ET. It also utilizes a Rain Clik and Freeze-Clik to shut down your irrigation

when conditions arise.

The I-Core now has the Solar Sync software built into the controller. New

I-Core controllers with built in Solar Sync are easily identied by the new

SOLAR SYNC SETTINGS dial position on the facepack. Because the new

I-Core has built in Solar Sync software, the Solar Sync Sensor is the only

item to be connected to the controller. The Solar Sync module will not be

used and is not compatible with I-Core controllers that have Solar Sync

software built in.

1. To connect the Solar Sync Sensor route the black and green sensor

wires into the controller and connect them to the two S1 terminal

positions. It does not matter which wire goes to which S1 terminal, but

the S1 terminal must be used when connecting a Solar Sync sensor.

2. Mount the Solar Sync sensor in a location that receives as much

sunlight as possible for best results. (see Solar Sync owner’s manual for

more details on sensor location)

3. The Solar Sync Sensor must now be assigned to the SEN1 location

in the controller. Turn the dial to the ADVANCED FEATURES position.

4. Use the ▼ button to scroll to Sensor Conguration and press the +

button.

5. In the SEN1 position use the + button to scroll through the options

until Solar Sync is shown. The I-Core now recognizes that a Solar Sync

sensor has been connected.

SOLAR SYNC Module

Do not install

If connecting a

Wireless Solar Sync

to the I-Core, steps 1-5 are the same

except in step 1, you will be connecting the green and black wires from

the Wireless Solar Sync Receiver to the S1 terminal positions. The Wireless

Solar Sync Receiver then communicates with the Wireless Sensor.

The Solar Sync can be programmed to adjust station run times by program.

To set the I-Core to Solar Sync Adjust mode:

1. Turn the dial to Set Seasonal Adjustment. Use the PRG Button to

select the desired program.

2. Press the +/– button to select By Solar Sync Seasonal Adjust mode.

Repeat for other programs if needed (See Sensor Conguration on

page 22).

Once a Solar Sync is connected and programmed the station run times

will be adjusted according to the ndings of the Solar Sync. The Solar

Sync will automatically adjust station run times and can be programmed

independently for each of the four I-Core programs. The Rain Clik and

Freeze-Clik sensor incorporated in the Solar Sync can be programmed by

station which is discussed in the Set Sensor Operation section.

SOLAR SYNC Sensor

Black

Green

11

Page 14

CONNECTING A FLOW SENSOR (OPTIONAL)

S1 S1 S2 S2 C C

GND AC1 AC2 REM C

P/MV

The I-Core is designed to operate primarily with the Hunter HFS Flow

Sensors. However, some non-Hunter ow sensors can be used.

1. To connect a Hunter HFS Flow Sensor, route the pair of 18 AWG

(1 mm) wires from the sensor into the cabinet (max distance of

1,000 ft.).

2. Locate a pair of S1 or S2 (S3 available on I-Core Metal) sensor red and

black terminals on the Power and Accessories Terminals. Remove the

jumper wire from one pair or S1 or S2 terminals. You may use either

pair of S1 or S2 sensor terminals for a ow sensor. Connect the red

wire from the HFS to the red terminal, and the black wire from the HFS

to the black terminal.

3. I-Core allows you to connect two ow sensors at one time. In that

case, one of the ow sensors would connect to the red S1 terminal

and the black S1 terminal, while the second ow sensor would

connect to the red S2 terminal and the black S2 terminal.

NOTE: I-Core has only one Pump/Master Valve output.

If 2 ow sensors are used on 2 different points of

connection, only one of them will have a master valve

available for alarm shutdowns unless the single PMV is

congured to operate 2 master valves simultaneously.

Black Wire

Red Wire

Flow setup, learning, and conguration will be described later in the manual

under Advanced Features (pg. 22). A complete step by step Flow Monitoring

procedure is also available in the Hidden Features section (pg. 29).

NOTE: If a ow sensor is going to be connected to the

controller and ow will be monitored, there is critical

information that needs to be read in the Controller

Diagnostics and Troubleshooting section under System

Status Dashboard Flow. It is very important to

understand how the controller will monitor ow under

certain circumstances and what diagnostic testing will

be performed in alarm situations.

HFS

Hunter HFS

12

Page 15

CONNECTING A REMOTE CONTROL (OPTIONAL)

The I-Core controller has factory installed SmartPort®. This provides a

remote ready connection for Hunter ICR, ROAM, and SRR remotes.

To connect a remote, remove the weather resistant rubber cover on the

SmartPort, align the remote receiver’s pins with the connector, and push

rmly until the receiver is fully seated. Refer to the remote control owner's

manual for further information on how to operate your Hunter remote.

The I-Core can overlap remote commands allowing up to ve valves to

run simultaneously. Therefore, if a station is being operated and a remote

command is sent to activate another station, that station will not turn off

the existing station, but run both stations simultaneously.

If ve valves are running and a new remote command is received to start

another event, the command will be ignored. No new remote commands

will be accepted until one of the ve events completes watering. I-Core

can run automatic programs and manual stations simultaneously. Each

command will be displayed on the screen, indicating the event is watering,

in the order the event took place.

Remote commands will also be allowed if the controller is in the OFF

position. With the dial in the OFF position, the controller will respond to

single station or program manual commands. In the OFF position, the

display will not indicate that a station is watering; you will only see the

System Status Dashboard Light turn green next to Station, indicating that

there is a station running. When the controller receives a Manual Program

remote command, the controller will only activate the stations within the

Program. If a station within the Program is programmed to a sensor that is

Active, that particular station will not operate and will be put into suspend

mode. The controller will count down that station’s programmed run time

without actually running the station.

If there are stations within the program that follow this station numerically

and are NOT programmed to the sensor, these stations will run and the

controller will observe the remote command and follow through the rest of

the program. The programming of stations to a sensor will be discussed in

the Set Sensor Operation section of the manual (pg. 18).

Receiver

Transmitter

13

Page 16

POWER FAILURES

Due to the possibility of power failures, the I-Core has nonvolatile memory

to preserve programming data indenitely. The 9-volt battery is required

for programming of the controller in the absense of AC power. Both the

9-volt battery and lithium battery (if a 9-volt battery is not installed), will

maintain the current time and day during power outages. If the power goes

out, the display will acknowledge there is No A/C Power. No stations will

water if the display reads No A/C Power, until AC power is restored to the

controller.

QUICK START

The I-Core controller offers maximum scheduling exibility including

four programs, each with up to eight daily start times, permitting plants

with different watering requirements to be separated on different day

schedules. Multiple start times permit morning, afternoon, and evening

watering, perfect for the establishment of new lawns and thirsty annual

owers. A built in 365-day calendar clock accommodates odd/even

watering restrictions without requiring monthly reprogramming. You may

simply designate days of the week you want to water for ease or use the

convenient interval day watering. All of this and more will be explained in

detail throughout the programming and operation section. You will begin

to notice just how easy the I-Core programming can be and the capabilities

of advanced features the I-Core offers to set this controller apart from its

competition.

The following are basic programming instructions to initially program

your I-Core controller. If more complex programming is required, please

reference the I-Core Programming following this page.

1. Set Current Date/Time: Use the ◄ and ► buttons to navigate, and

the + / – buttons to change the ashing selection to the correct Date

and Time.

2. Set Program Start Times: Each automatic program has 8 start

times available. Use the ◄ and ► buttons to navigate through the

different start times, and the + / – buttons to change the time. The

time changes in 15 minute increments, and by holding down the

+ / – buttons the time will scroll faster. Use the PRG button to select

individual programs.

NOTE: The number shown on the screen does not

indicate a station number, but indicates an individual

start time for that particular Program.

5. Set Pump Operation (optional): The Pump/Master Valve output may

be set by station. If a Pump/Master Valve is in use you need to make

sure the stations are set to On. If no Pump/Master Valve is in use, this

is not required. The ◄ and ► buttons scroll through the stations and

the + / – buttons set the stations to On or Off.

6. Return the Dial to the Run Position: This is all that is required for

the most basic operations. The I-Core will water automatically in any

dial position except OFF, with the previous steps discussed being

programmed.

7. Test Program: The test program will start every station in the

controller sequentially, in numerical order, for the specied time. Turn

the dial to the RUN position. Hold down the PRG button for three

seconds. The screen will change automatically and display station

number 1 and a ashing run time of 0:00. Enter the desired run time in

hours: minutes by using the + / – buttons. Within ve seconds the test

program will begin. Test program will operate stations in sequential

order.

8. Manual Start: With the dial in the RUN position, there is a shortcut

to manually start a program. Press and hold the ► button. The screen

will change and indicate station 1 and the programmed run time

for Program A. If you would like to change the Program you want

to manually run, release the ► button and press the PRG button to

change the Program selection. The manual program will start in a few

seconds.

3. Set Station Run Times: This dial position allows you to assign a

station’s run time with a particular program. If you need to change

the program, you are assigning a station run time, simply press the

PRG button. Use ◄ and ► buttons to navigate through the station

numbers, and the + / – buttons to change the length of run time in

hours: minutes.

4. Set Days to Water: Use the PRG button to select the Program. Use

the ▲ or ▼ buttons to move the ► cursor next to a day, and then use

the + / – buttons to indicate a water day or a non water day. When

using Days of the Week scheduling, a will indicate a water day, and

a _ will indicate a No-Water Day. The ◄ and ► arrow buttons will

change the schedule type, including Days of the Week, Odd/Even

Days, and Interval Watering.

NOTE: For Days of the Week scheduling, a check mark

indicates a water day, and no check mark indicates a

non water day. When programming Odd/Even and

Interval watering schedules, the X that appears next to

the day will indicate a non water day for that schedule,

and all other days with no X will be available water days

depending on the schedule programmed.

14

Page 17

CONTROLLER PROGRAMMING

Setting Current Date and Time

The SET CURRENT DATE AND TIME dial position allows you to set the

current date and time in your I-Core controller.

1. Turn the dial to the SET CURRENT DATE/TIME position.

2. The year will be ashing in the display. Use the + / – button to change

the year. Press the ► button to proceed.

3. The month will be ashing. Use the + / – button to change the month.

Press the ► button to proceed.

4. The day will be ashing. Use the + / – button to change the day. Press

the ► button to proceed and set the time.

5. Use the + / – button to select AM, PM, or 24 HR. Press the ► button.

6. Use the + / – button to set the hour. Press the ► to set the minutes.

Use the + / – button to change the minutes until they are correct. The

correct date and time have now been set. Always return the dial to the

RUN position when you are nished programming the controller.

Setting Program Start Times

The SET PROGRAM START TIMES mode allows you to program start times

for each of the four programs (A, B, C, or D) independently. Up to eight

start times per day can be set for each program.

NOTE: Two programs are allowed to run at the same

time if there Start Times coincide or overlap. This is an

important element to consider when programming the

Start Times if the hydraulics of your system do not allow

for more than one station to run at the same time.

1. Turn the dial to the SET PROGRAM START TIMES position.

2. Program A and start time 1 will be displayed. If necessary, you can

select Program B, C, or D by pressing the PRG button.

3. The program start time will be ashing. Use the + / – button to

change the start time. The time will change in 15 minute increments.

Press the ► button to select an additional start time if you would

like more than one watering cycle per day to occur for that program.

Programs A, B, C have eight start times per day, while program D has

16 start times. Press the PRG button to change between programs A,

B, C, and D to assign a start time to the particular program.

4. To eliminate a program start time turn the dial to the SET PROGRAM

START TIMES position, use the PRG button to select the program and

the ► button to select the start time you would like to eliminate. Press

the + / – button until you reach 12:00 AM. Press the – button once more

and the display will show dashed lines --:--, indicating no start time.

If a program start time is skipped (for example, a start time is set for 1 and

3), the start time will be accepted, but when returning to this dial position,

the start times will be moved to sequential order (the Start Time 3 will be

moved to 2).

If an earlier start time is set for a higher-numbered start (for example,

start time 1 is set to 4:00 AM, and start time 2 is set to 3:00 AM), when

returning to this dial position the start times will have been reorganized in

chronological order. The lowest numbered start time will always have the

earliest time of day (in the example, the start time 1 will be at 3:00 AM and

start time 2 at 4:00 AM).

NOTE: One start time will activate all stations

sequentially that are assigned to a program. Multiple

start times are typically used when separate morning,

afternoon, or evening watering cycles are required. You

cannot enter a start time for each station. If you only

want to water your stations once a day within a particular

program, you would only program start time 1. The rest

of the start times 2 through 8 would be left blank --:--.

The I-Core controller has the ability to operate ve Hunter valves at one

time, and, therefore, allows for more than one program to run at the same

time. Only two programs can be allowed to run concurrently. If you set two

programs to have the same start time, or their start times overlap, both

programs will run concurrently. This is a great feature if you have a short

water window and the available water to feed multiple stations; however, it

could become an issue if the ow of your irrigation system cannot support

operating multiple stations at the same time.

If you do not have the available water to operate multiple stations at one

time, you will need to consider and calculate when each program will nish,

or review the Total Watering Time for each program within the ADVANCED

FEATURES dial position. Each Program’s Start Time must be programmed

to start after the previous Program nishes in order to eliminate the

possibility of multiple Programs watering at once.

Setting Station Run Times

(Length of Watering for Each Station)

The SET STATION RUN TIMES mode allows you to enter a length of run

time for each station assigned to a particular program. Each station that

has a run time associated with a program will be activated and operate one

after another sequentially with each start time for that program.

1. Turn the dial to the SET STATION RUN TIMES position.

2. The display will show the station number and program. Use the PRG

button to select a program.

3. Use the + / – button to change the station run time on the display.

4. Use the ► button to advance to the next station for which you would

like to enter a run time.

5. When nished entering run times, rotate the dial to the RUN position.

By pressing the PRG button, you can move between programs while

staying on the same station. However, it is recommended that one program

is completed before going on to the next program.

15

Page 18

CONTROLLER PROGRAMMING (CONTINUED)

NOTE: When entering run times the Seasonal Adjusted

run time will be displayed in the lower right corner of

the display. The default Seasonal Adjustment setting is

100%. If the ACTUAL value is different from the

PROGRAMMED value, the Seasonal Adjustment has

been changed from the default of 100% to a new value.

The ACTUAL run time is the duration the station will water based upon the

seasonal adjustment value. Detailed information on Seasonal Adjustment

can be found in the Set Seasonal Adjustment section (pg. 17).

Setting Days to Water

SET DAYS TO WATER mode allows you to select days you would like to

water for each program independently.

1. Turn the dial to SET DAYS TO WATER position.

2. Program A water days will be displayed. Use the PRG button to select

your desired program (A, B, C, or D).

3. Use the ◄ and ► button to change from 1) Specic Days of the Week;

2) Odd Day Watering; 3) Even Day Watering; or 4) Interval Day

Watering. Each program can only be assigned one type of water day

option at a time.

Selecting Odd or Even Days to Water

This feature uses numbered days of the month for watering instead of

specic days of the week. (For example, Odd Days 1st, 3rd, 5th, etc. and

Even Days 2nd, 4th, 6th, etc.)

1. Turn the dial to SET DAYS TO WATER position.

2. Use the PRG button to select your desired program (A, B, C, or D).

3. Press the ◄ and ► button until Odd Days watering or Even Days

watering is shown on the display.

4. In either the Odd or Even Days mode, there will be a **NO WATER

DAYS** description ashing on the display. Within the Odd or Even

mode you can select days that watering will NOT take place. This is a

feature that is frequently used to omit watering on a specic day, for

example, a mowing day. Press the ▲ or ▼ buttons to move through

the days of the week and press the + button for the days that you DO

NOT want to water. By pressing the + button on a specic day, an X

will appear indicting that the day is a Non-Water Day.

Selecting Specic Days of the Week to Water

1. Turn the dial to SET DAYS TO WATER position.

2. Use the PRG button to select your desired program (A, B, C, or D).

3. Use the ◄ and ► button to select Days of The Week watering mode.

Water Days will be displayed at the bottom of the screen. With the

cursor on Monday, press the + button to activate the day or the –

button to cancel watering for that day. A indicates a water day, and

a _ indicates a non-water day. After pressing the + / – button on a

specic day the cursor will automatically move to the next day. Press

the ▲ or ▼ buttons to move quickly to a specic day without making

a water or non water selection.

This is program specic so you will need to repeat these steps for each

required program.

5. To change a Non-Water Day, use the ▲ or ▼ buttons to go to that

day and press the – button. The X will disappear, and the day will be

available for Odd or Even watering again.

NOTE: The 31st of any month and February 29th are

always “OFF” days when Odd watering is selected.

Selecting Interval Watering

This feature is convenient if you want to have a more consistent watering

schedule without having to worry about the day of the week or the date.

The interval number you select is the actual interval of days on which

watering will occur. For example, if you have an interval of 3 days watering

every third day. The days remaining (Remaining) indicates how many days

until the next watering occurs. For example, if you select interval 3 with 1

days remaining, watering will begin tomorrow at the scheduled time. At

midnight the days remaining will change from 1 to 0, indicating that the

controller will water that day.

1. Turn the dial to the SET DAYS TO WATER position.

2. Use the PRG button to select your desired program

(A, B, C, or D).

3. Press the ◄ and ► button until Interval Days is displayed. The

Interval will be ashing. Use the + / – button to select the interval of

days on which watering will occur.

4. Press the ▼ button once to program days remaining, if required. One

day remaining means it will begin watering the next day.

16

Page 19

CONTROLLER PROGRAMMING (CONTINUED)

5. In the Interval Watering mode, there will be a No Water Days

description on the display. Within the Interval Watering mode you

can select days that watering will not take place. This is a feature that

is frequently used to omit watering on a specic day, for example, a

mowing day. Press the ▼ button until the cursor points to Monday.

Once the cursor points to Monday the No Water Days description will

start ashing. Press the ▲ or ▼ buttons to move through the days of

the week and press the + button for the days that you DO NOT want

to water. By pressing the + button on a specic day, an X will appear

indicting that the day is a Non-Water day.

6. To change a No Water Day, use the ▲ or ▼ buttons to go to that

day and press the – button. The X will disappear, and the day will be

available for Interval watering again.

7. After programming water days, rotate the dial back to the RUN

position.

Set Seasonal Adjustment

Seasonal Adjustment is used to make run time changes without having to

reprogram all of the individual station run times. This feature is perfect for

making small changes that are necessary as weather conditions change due

to seasonality. For example, during hotter times of the year, your landscape

may require a bit more water. Seasonal adjust can be increased so that

stations will run longer than the programmed time. Conversely, as fall

approaches, the seasonal adjust can be reduced to allow for shorter station

watering durations.

There are three separate seasonal adjust modes that can be used

independently for each Program. Again, the selections are by program,

and the steps need to be taken for each program:

Global Seasonal Adjust (PRG Global) – This selection is a program global

seasonal adjustment, which increases or decreases station run times by

a xed %. All stations that have a run time within the Program will be

adjusted according to the Global Seasonal Adjust value.

Monthly Seasonal Adjust (By Month) – All of the seasonal adjustment

values for the full year can be programmed into the controller at one time.

Each month, the controller will switch to the new seasonal adjust value.

1. Turn the dial to SET SEASONAL ADJUSTMENT. Use the PRG button

to select the desired program.

2. Press the + / – button to select By Month seasonal adjust mode.

3. While in the By Month mode, press the ▼ button and the seasonal

adjust valve forJanuary will start ashing, and the ► cursor will

indicate January.

4. Press the + / – button to increase or decrease the seasonal adjust

value between 0 and 300% for the month selected, which will affect all

the stations for the Program you have selected.

5. By pressing the ▲ or ▼ buttons, you may scroll through the months to

select the specic month you want to adjust.

1. Turn the dial to SET SEASONAL ADJUSTMENT. Use the PRG button

to select the desired program.

2. Press the + / – button to select the PRG Global seasonal adjust mode.

3. While in the PRG Global mode, press the ▼ button and the

percentage will start ashing.

4. Press the + / – button to increase or decrease the global seasonal

adjust value between 0 and 300%, which will affect all the stations

within the program you have selected.

Solar Sync Adjust (By Solar Sync) – This mode allows seasonal adjustment

to occur on a daily basis when a Hunter Solar Sync is connected to the

controller. This provides for the maximum amount of water saving while

promoting healthy plant material. Solar Sync will change the seasonal

adjust % daily based upon weather conditions.

1. Turn the dial to SET SEASONAL ADJUSTMENT. Use the PRG button

to select the desired program.

2. Press the + / – button to select By Solar Sync seasonal adjust mode.

17

Page 20

CONTROLLER PROGRAMMING (CONTINUED)

The Solar Sync will take over and the percentage will change according to

the ndings of the Solar Sync sensor. If you set seasonal adjust mode to

Solar Sync and you DO NOT have a Solar Sync connected, the controller

will automatically keep the seasonal adjust percentage at 100%.

There are also further steps in programming of the I-Core to assign the

Solar Sync, Rain, and Freeze sensor to shut down specic stations. This will

be detailed in this manual under Advanced Features, Sensor Conguration,

and Set Sensor Operation.

Set Pump Operation

The default is for all stations is Pump/Master Valve circuit ON. The Pump/

Master Valve circuit can be set ON or OFF by station, regardless of which

program the station is assigned. This feature may be utilized on systems

where it is desirable for a booster pump to operate with certain zones.

It could also be used for systems that have two points of connection and

some valves need a master valve/pump start to turn on and other valves

operate on a different water source that do not need the master valve/

pump start.

To Set Pump Operation:

1. Turn the dial to SET PUMP OPERATION position.

2. Press the ◄ and ► buttons to select a particular station.

3. Use the + / – button to turn the Pump/Master Valve circuit ON or OFF

for a specic station.

4. When nished, turn the dial back to the RUN position.

Cycle and Soak

The Cycle and Soak feature allows you to split a station’s run time into more

usable, shorter watering durations. This feature is useful when applying

water to slopes and tight soils because it automatically applies water more

slowly, helping to prevent run off from occurring. You should enter the

Cycle time as a fraction of the station’s watering time, and the Soak time as

the minimum number of minutes required before watering can occur again

for the next Cycle. The total number of cycles is determined by taking the

total programmed station run time and dividing it by the Cycle time.

Example: Station 1 requires 20 minutes of watering, but after 5 minutes,

runoff occurs. However, after 10 minutes all the water is absorbed.

The solution would be to program 20 minutes for the station run time,

5 minutes for the Cycle time, and 10 minutes for the Soak time.

3. Cycle will ash OFF. Use the + / – button to set the Cycle time. You

may select a maximum Cycle time of up to 60 minutes.

4. Press the ▼ button to set the Soak time. Use the + / – button to set

the Soak time. You may select a maximum Soak time of up to 120

minutes.

5. Rotate the dial to the RUN position when nished programming all

Cycle and Soak times for yourdesired stations.

It may be benecial to understand how the cycle and soak application

process works. For example, Station 1 has been programmed to have a

5 minute cycle time and a 10 minute soak time. Station 1 may not exactly

come back on for its second cycle immediately after 10 minutes of soaking.

If there are other stations within the program that have run time after

Station 1, the program in numerical order will continue to run each station

that has a run time in the Program before it goes back to Station 1 for

another cycle. The Program will water each station for its programmed run

time or rst cycle time, before it looks back at station 1 to complete its

cycle and soak. If no other stations in the Program have a cycle and soak

programmed, then Station 1 will continue with its second cycle after all

stations have completed and then go into cycle and soak one after another

until the total run time has completed.

Set Sensor Operation

The SET SENSOR OPERATION dial position is specically used to set

a response for a sensor to a station. The I-Core controller is capable of

monitoring two individual Clik-type sensors, including the Solar Sync rain/

freeze sensor. You may have a combination of two Clik sensors, one Clik

sensor and one ow sensor, one Clik sensor and a Solar Sync rain/freeze

sensor, or two ow sensors. The I-Core Metal version controller has an

additional sensor terminal, allowing up to 3 sensors to be installed and

programmed. Additional programming assignment of the sensor(s) to

stations MUST be done in order for the sensors to shutdown irrigation.

The programming of the two available sensor inputs is described in the

Advanced Features section under Sensor Conguration (see pg. 22) and

must be completed prior to setting sensor operation.

NOTE: If using a Solar Sync it will show as a Clik sensor.

There is not a special distinction or selection for the

Solar Sync, and will be described as a Clik sensor for the

remainder of this section.

If two Clik sensors are installed, the display in the SET SENSOR

OPERATION dial position will allow you to program a response for each

sensor according to a particular station. A Sensor Response will either

show a , indicating that the sensor will shut down irrigation, or _ ,

indicating that the station will ignore the state of the sensor and continue in

its normal operation.

NOTE: If using a Solar Sync, the Solar Sync sensor

terminal will automatically be used for both Rain and

Freeze inputs as well as weather adjustment

information. The display will show which sensor has

caused a shutdown.

1.

Turn the dial to CYCLE AND SOAK position

2. Use the ◄ and ► buttons to select the station that you would like to

program Cycle and Soak.

18

Page 21

CONTROLLER PROGRAMMING (CONTINUED)

Both sensors programmed for Station 1

Sensor 1 only programmed for Station 1

Rotate the dial to the SET SENSOR OPERATION position.

1. Use the ◄ and ► buttons to select the station that you would like to

program a sensor response.

2. The default is to have the sensor input active for each station,

therefore indicating a . The cursor will be ashing on either SEN1 or

SEN 2. Use the + button to enable sensor operation or the – button to

disable the sensor.

3. Rotate the dial to the RUN position when nished programming

sensor operation for the desired stations.

If you have two ow sensors congured to each one of the sensor

terminals, you will not be given the option to select a response for a

weather sensor. When you turn the dial to SET SENSOR OPERATION, the

screen will display No Clik or WRC. The conguration of the Flow sensors

will be discussed in the ADVANCED FEATURES dial position.

Sensor 2 only programmed for Station 1

No sensor programmed for Station 1

Rotate the dial to the SET SENSOR OPERATION position.

1. Use the ◄ and ► buttons to select the station that you would like to

program a sensor response.

2. The default is to have the sensor input active for each station,

therefore indicating a . The ► cursor will be ashing on SEN1.

Use the + button to enable sensor operation or the – button to

disable the sensor.

3. Once SEN1 has been programmed the ► cursor will move to SEN2.

Use the + / – button to enable or disable SEN2 for the station.

4. Rotate the dial to the RUN position when nished programming

sensor operation for the desired stations.

If one Clik sensor and one Flow sensor are installed, the screen in Set

Sensor Operation will show only one option of selecting a sensor response

for the one Clik Sensor. The Clik sensor will either appear as SEN1 or SEN2,

depending on which sensor terminals that Clik sensor was connected. You

will give the sensor a if you want the sensor to shut down irrigation, or

a _ if you do not want the irrigation to shut down in the case of a sensor

state change. The ow sensor conguration will not appear as an option to

change in the Set Sensor Operation screen. The programming of the Flow

sensor will be done in the ADVANCED FEATURES dial position and will be

discussed further in that section.

SEN 2 is congured for a Flow Sensor

SEN 1 and SEN 2 are congured for Flow Sensors

Once you have installed and programmed a sensor and set a response

to your desired stations, the controller will acknowledge the state of the

sensor. When the sensor is Inactive or in a closed state, the System Status

Dashboard will have a green light next to Sensor, indicating that irrigation

will occur as normal. If the sensor is in the Active mode or open state, the

controller will display a red light in the System Status Dashboard next to

Sensor. This indicates that the sensor is active and certain automatic irrigation will not occur. When a sensor becomes active the controller will also

indicate the status of the sensor on the display in the RUN position.

Once a sensor becomes active, the controller will put irrigation in a

suspend mode. The controller will acknowledge a program’s start time and

the display will indicate where the program would be watering. However,

whether or not the station is set to respond to the sensor will determine if

the station turns on or not. If the station is set to respond to the sensor, the

display will count down the stations run time and indicate that the station is

Suspended. If the sensor state changes and becomes inactivate, the station

will resume watering at the given run time on the screen. If a station is not

set to respond to a sensor, the station will water as normal and ignore the

state of the sensor.

SEN 1 is congured for a Flow Sensor

A remote single station command will override the sensor state, whether

the station is set to respond or not, and that station will water for the

desired run time. When you activate a manual program command by

19

Page 22

CONTROLLER PROGRAMMING (CONTINUED)

a remote, the controller will acknowledge the stations that have been

programmed to respond to a sensor and those stations will not water and

be in Suspend Mode.

The same rules apply for activating a station or program manually by

turning the dial to the manual position. A manual single station will override

an active sensor; however, a manual program will adhere to the rules of

shutting down irrigation if the station within the program is set to respond

to the sensor.

Manual Operation

This dial position enables immediate operation of either a single station

or an automatic program. It also is used to Learn Expected Flow, which

is a key element in ow monitoring. You may run more than one manual

program or station at the same time, because the I-Core has the ability to

run up to ve stations or events at once. To initiate multiple events, you

will need to turn the dial from MANUAL OPERATION to RUN and then

return to the MANUAL OPERATION dial position to begin the initiation

of another event. Use the ▲ or ▼ buttons to navigate through the manual

feature selections. When the ► cursor is pointing to the selection you want,

simply press the + button to select the feature.

5. After the manual program begins, you may also use the ► button to

scroll to a particular station or advance to a station more quickly. It is

important to know that once you advance to the next station by using

the ► button you will not be able to return to the previous station.

Manual Station

Manual Station allows any individual station to be started immediately.

1. Use the ◄ or ► buttons to select a particular station.

2. Use the + button to increase the ashing run time on the screen until

the desired run time is achieved. You can assign a run time from 1

minute to 12 hours.

3. Turn the dial to RUN, and the station will begin irrigating.

Up to ve Hunter valves can be operated simultaneously.

Learn Expected Flow

This feature is used to learn station ows and is the nal element that needs

to be programmed in the controller in order for ow monitoring to occur.

You may learn expected ows by particular stations, or you may learn all

the stations at once. It is important that the following programming steps

must be completed before you are able to learn ow: (1) You must select

a ow sensor in the Sensor Conguration screen in Advanced Features; (2)

You must program the station ow to be monitored, which is found in the

Flow Operation screen in Advanced Features; and (3) The station must have

a programmed run time in the SET STATION RUN TIMES dial position.

A complete Flow Monitoring procedure will be discussed in the Flow

Monitoring section in the manual (pg. 29).

Manual Program

This will allow an entire program to be run immediately to be started at any

station. It is important to know that if a particular station is selected as the

starting point it will run from that that point, to the end. The manual will not

go back and run the stations that were initially skipped in the program.

1. Press the PRG button to select the program you would like to run.

2. Turn the dial to RUN to start the program at the beginning. Each

station will run for its automatic programmed time (including cycle

and soak) settings, and the stations with no run time in the selected

program will be skipped. You may increase the run time for the rst

station in the manual sequence, however, each station following will

run for its automatic program time.

3. To start later in the program at a higher numbered station, use the ◄

or ► buttons to select the station you want the manual to start on.

4. Turn the dial to RUN and the manual program will begin from the

desired station. The manual will continue until the last station in the

Program and then stop.

If a sensor is not selected in the Sensor Conguration screen, a station’s ow

is not set to be monitored or stations do not have programmed run times,

the controller will not allow you to learn expected ow. If the user has not

selected a ow sensor in the Sensor Conguration screen, the controller will