Page 1

1

TRANSOM TRANSDUCER Installation Guide

The transom mount installation allows adjustment of both running angle and depth after the

transducer is mounted, which enables you to tune the installation for best results.

NOTE: Due to the wide variety of hulls, only general instructions are presented in this installation

guide. Each boat hull represents a unique set of requirements that should be evaluated prior to

installation. For detailed information about installing transducers on different hull types,

download the Transducer Installation Resource Guide from our Web site at humminbird.com.

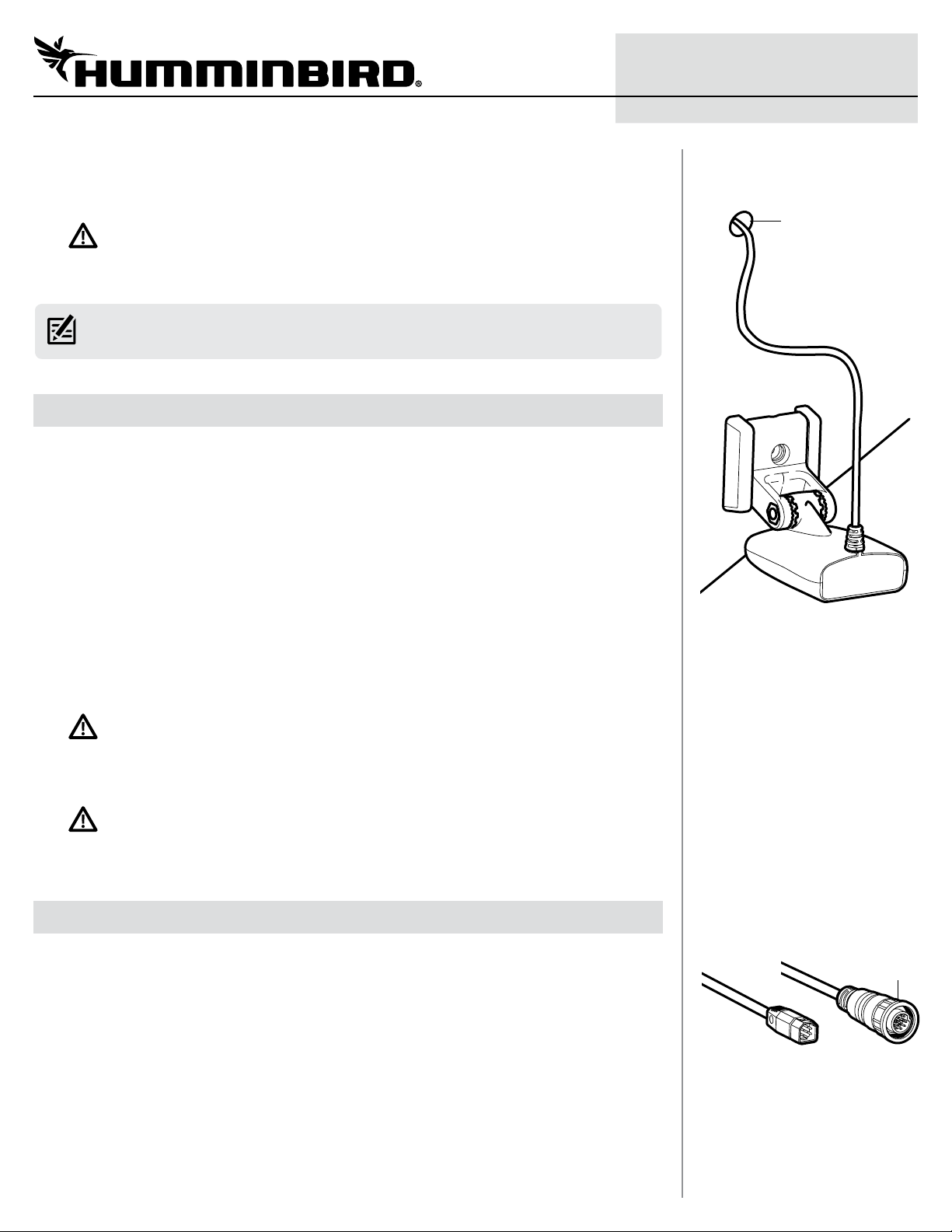

NOTE: Your transducer may not look exactly like the transducer shown in the illustrations, but it

will mount in exactly the same way.

I P

Install the control head before you start the transducer installation. See the control head

installation guide.

Review your boat manufacturer’s owner’s manual for recommended transducer installation

locations and cable routing methods. You will also need your transom angle.

Read and understand your boat’s warranty before starting this installation.

532314-3_B

Read the instructions in this guide completely and understand the mounting guidelines

before beginning this installation.

Visit our Web site at humminbird.com for additional information and resources for transducer

installations. Also, visit youtube.com/humminbirdtv for informational videos.

Confirm your boat is level for the installation.

Consider your speed requirements.

Traveling over 65 mph with the transducer in the water is not recommended with the XNT 9

SI 180 T, XNT 9 DB 74 T, XNT 14 74 T, and XNT 9 MSI 150 T transducers, as damage may occur.

If speed above 65 mph is critical, see the FAQ (Frequently Asked Questions) section of our Web

site at humminbird.com.

Down Imaging® provides the maximum detail at slower speeds, however, high-speed

performance is available in the Down Imaging and traditional sonar views. If high-speed

operation is critical with your Down Imaging transducer, you may want to consider an Inside

the Hull transducer.

SIDE IMAGING® NOTE: The Side Imaging transducer CANNOT be installed inside the hull of

the boat.

Supplies: In addition to the supplied hardware, you will need a powered hand drill and various

drill bits, various hand tools, including a ruler or straightedge, a level, a socket driver, marker

or pencil, safety glasses and dust mask, marine-grade silicone sealant, dielectric grease

(optional), and a 12" plumb line (weighted string or monofilament line [optional]). You may

also need extension cables and hardware for routing the cable to the control head.

Page 2

2

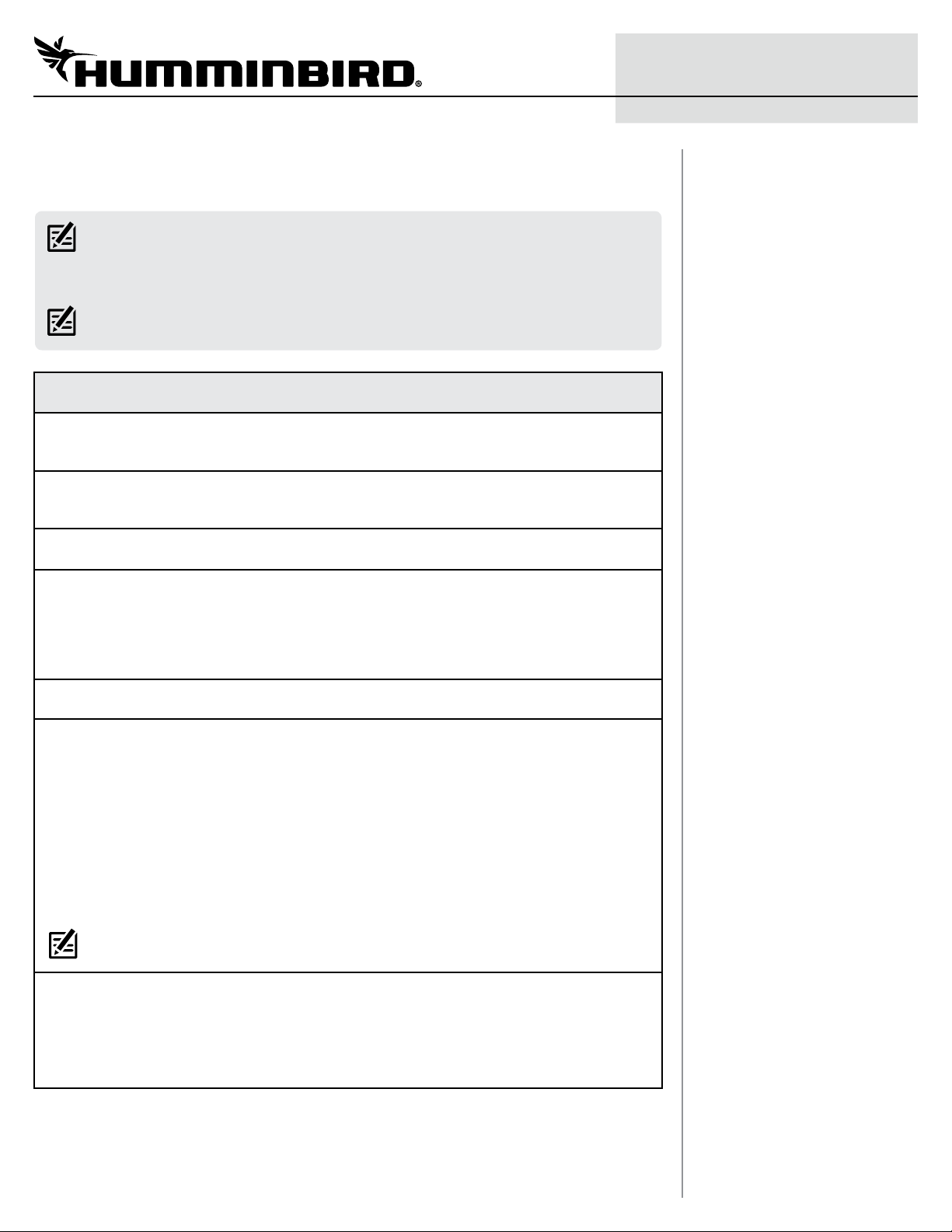

1 3 4 5 62

TRANSOM TRANSDUCER Installation Guide

T-F M G

It is very important to locate the transducer in an area that is relatively free of turbulent water.

Consider the following to find the best location with the least amount of turbulence:

Avoid areas where there is turbulent water flow. Turbulent water is normally confined to areas

1

immediately aft of ribs, strakes, or rivets on the bottom of the boat, and in the immediate area

of the propeller(s). The best way to locate turbulence-free water is to view the transom while

the boat is moving.

Observe your propeller’s direction of rotation (in forward, as you're facing the stern of the boat

2

from behind). Clockwise propellers create more turbulence on the port side. Counterclockwise

propellers create more on the starboard side.

Ensure there is adequate distance from the propeller(s). On outboard or inboard/outboard

3

boats, it is best to locate the transducer at least 15" (38.1 cm) to the side of the propeller(s).

532314-3_B

7

Unobstructed View: This jack plate

installation gives the transducer

safe distance from the motor and

turbulence. The Side Imaging has a

clear view side-to-side.

The ideal mounting location (right of the propeller[s]). It is important to note that if you plan

4

to trailer your boat, do not mount the transducer too close to trailer bunks or rollers to avoid

moving or damaging the transducer during loading and unloading of the boat.

For boats with stepped hulls, it may be possible to mount the transducer on the step. Do not

5

mount the transducer on the transom behind a step to avoid popping the transducer out of the

water at higher speeds.

The transducer must be mounted so that it is parallel with the waterline, but fully submerged

6

in the water during operation.

If you have a Side Imaging transducer, the transducer must NOT have anything obstructing the

7

‘view’ of the side looking beams. For example, nothing can be in the line of sight of these beams

(not a hull, motor, or other transducer, etc.)

NOTE: You may need to tilt the motor up and out of the way when using the side looking

beams.

Deadrise: The hydrodynamic shape of your transducer allows the sonar beams to point down

without deadrise adjustment.

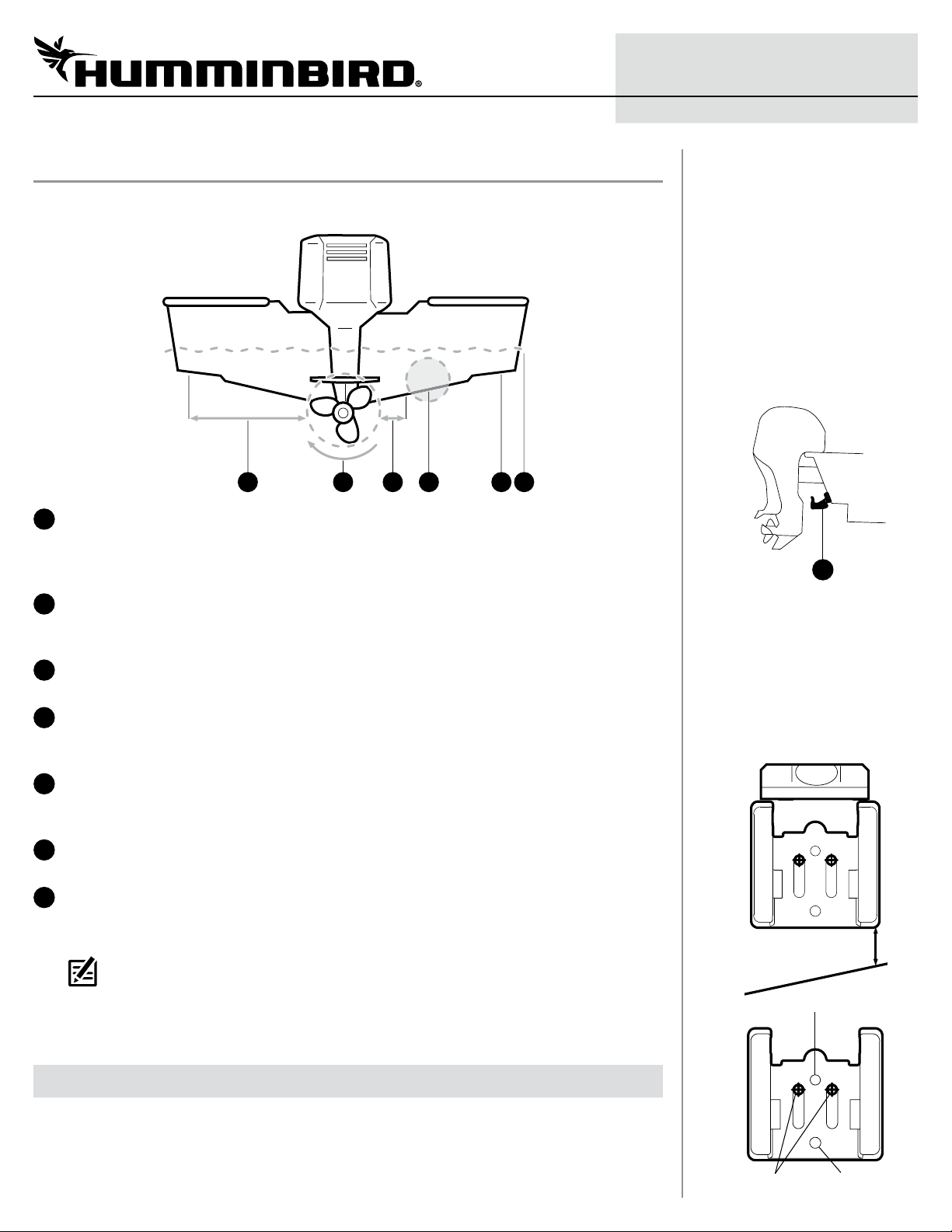

| Prepare the Mounting Location

1

1. Confirm the boat is level on the trailer (both from port to starboard and from bow to stern).

2. Hold the mounting bracket against the transom of the boat in the location you have selected.

Align the bracket horizontally, using the level. Make sure that the lower screw hole protrusion

does not protrude past the bottom of the hull.

Using the Mounting Bracket

to Mark the Initial Drill Holes

LEVEL

1/4" for fiberglass

1/8" for aluminum

4th hole

mark initial

drill holes

3rd hole

Page 3

3

TRANSOM TRANSDUCER Installation Guide

3. Refer to the minimum clearance requirement between the bottom of the bracket and the

bottom of the transom for your boat type below:

1/4" (6 mm) clearance for fiberglass boats

1/8" (3 mm) clearance for aluminum boats

NOTE FOR ALUMINUM BOATS: For flat-bottomed aluminum boats, some additional

adjustment may be needed to accommodate the rivets on the bottom of the boat (the gap

may need to be a little smaller than 1/8"). This will help you to avoid excessive turbulence at

high speeds.

If your propeller moves clockwise, mount the transducer on the starboard side, and align the

bottom right corner of the mounting bracket with the bottom of the boat. If your propeller

moves counterclockwise, mount the transducer on the port side, and align the bottom left

corner of the mounting bracket with the bottom of the boat.

4. Continue to hold the bracket on the transom of the boat, and use a pencil or marker to mark

the two initial drill holes (see Using the Mounting Bracket to Mark the Initial Drill Holes). Mark

the drill holes near the top of each slot, making sure that your mark is centered in the slot.

NOTE: The third hole should not be drilled until the angle and height of the transducer is finalized,

which you will not do until a later procedure.

532314-3_B

Installing the Ratchets in Position 1

knuckle

ratchet

rib at

position 1

bead

Fitting the Pivot Arm

over the Ratchet

5. Confirm that the drill bit is perpendicular to the actual surface of the transom, (NOT parallel

to the ground), before you drill. Using a 5/32" (4 mm) bit, drill the two holes only to a depth of

approximately 1" (25.4 mm).

NOTE FOR FIBERGLASS HULLS: It is best to start with a smaller bit and use progressively

larger drill bits to reduce the chance of chipping or flaking the outer fiberglass coating.

| Assemble the Transducer and Initial Mounting

2

In this procedure, you will assemble the transducer using the hardware provided, then mount it and

make adjustments to its position without locking it in place.

1a. If your transom is angled at 14 degrees (a common transom angle for many boats), use

position 1 for the ratchets.

1b. If you have a different transom angle or do not know your transom angle, refer to the

Transducer Installation Resource Guide on our Web site at humminbird.com for detailed

instructions.

2. Place the two ratchets, one on either side of the transducer knuckle, so that the beads on each

ratchet line up with the desired position number on the knuckle (see Installing the Ratchets in

Position 1). If you are setting the ratchets at position 1, the beads on each ratchet will line up

with the rib on the transducer knuckle to form one continuous line on the assembly.

NOTE: The ratchets are keyed. Make sure that the square teeth on each ratchet face the square

teeth on the transducer knuckle, and the triangular teeth face outward.

Inserting the Pivot Bolt

Inserting the Pivot Arm Assembly

into the Mounting Bracket

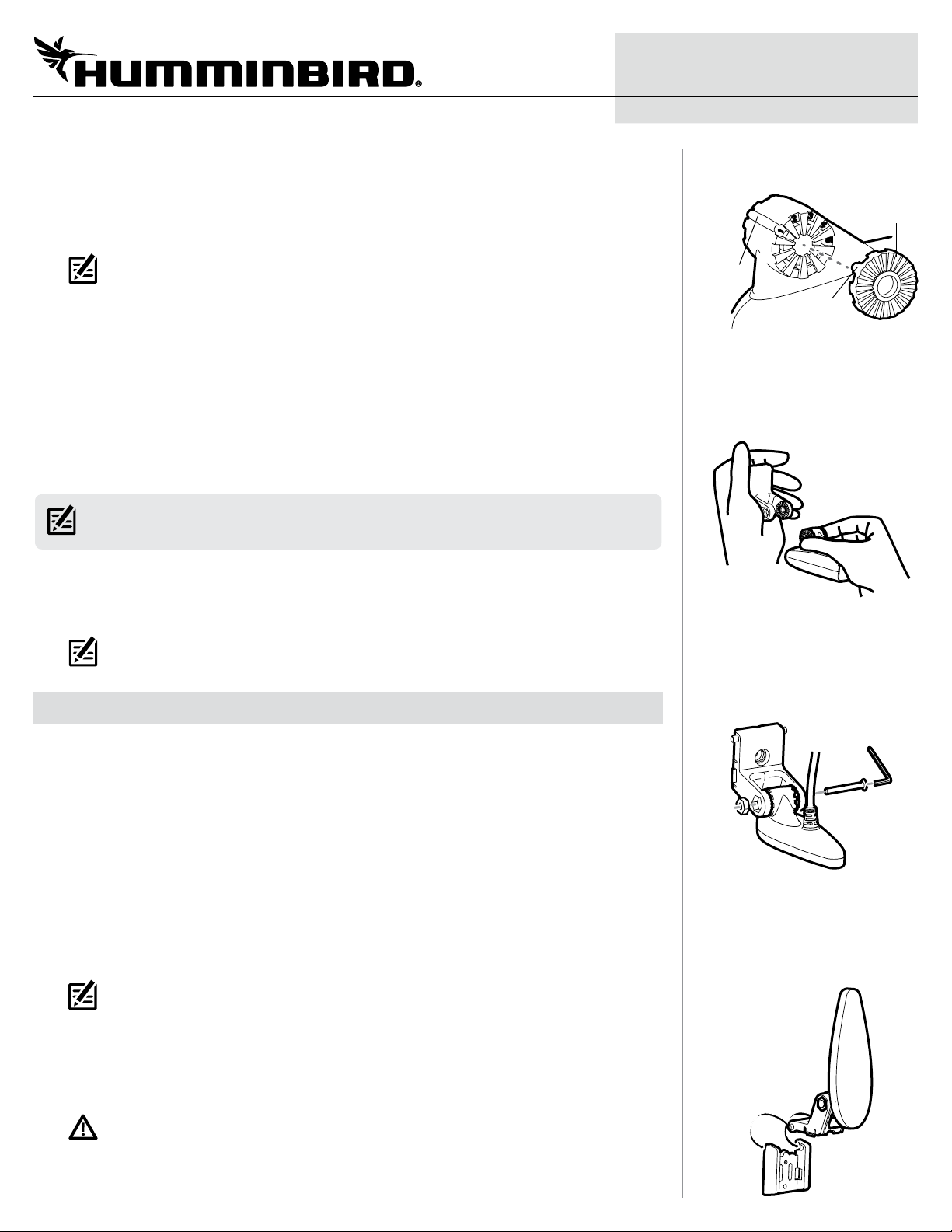

3. Hold the ratchets on the transducer knuckle until it snaps into place with the other hand. Refer

to the illustration

Fitting the Pivot Arm over the Ratchet.

4. Put the pivot bolt through the assembly to hold it in position and loosely install the nut, but do

NOT tighten the nut at this time (see Inserting the Pivot Bolt).

CAUTION! Do not use a high speed driver on this combination of fasteners. Hand-tighten only.

5. Insert the pivot arm assembly into the mounting bracket (see Inserting the Pivot Arm Assembly

into the Mounting Bracket). Do NOT snap the assembly closed, as you will need to access the

mounting bracket in the next step.

Page 4

4

TRANSOM TRANSDUCER Installation Guide

NOTE: If the pivot assembly is snapped closed over the mounting bracket, use a flat head

screwdriver or similar tool to gently pry the assembly away from the mounting bracket.

6. Align the mounting bracket transducer assembly with the drilled holes in the transom. With a 5/16"

socket driver, mount the assembly to the transom using the two #10 - 1" long screws provided.

NOTE: Make sure that the mounting screws are snug, but do not fully tighten the mounting

screws at this time to allow the transducer assembly to slide for adjustment purposes.

7. Snap the pivot arm down into place.

| Confirm the Mounting Angle

3

You will need to adjust the initial angle of the transducer both vertically and horizontally to confirm

the transducer mounting angle.

1. Adjust the transducer assembly vertically, until the seam on the leading edge of the transducer

(see

2. Adjust the initial angle of the transducer from back to front by rotating the transducer until

the side seam on the transducer is almost parallel with the bottom of the boat, one click at a

time in either direction (see Adjusting the Initial Transducer Angle).

Downward Slant: The transducer has a natural downward slant of 4 to 5 degrees from leading edge

(closest to the boat transom) to trailing edge (farthest away from the boat). Looking at the back of

the transducer, the seam should be slightly below the bottom of the hull.

Down Imaging Transducers: A downward slant is not required for Down Imaging Transducers. Adjust

the running angle so that the transducer is parallel to the water and submerged in the water.

below) is level and just slightly below the hull.

1

532314-3_B

Mounting the Assembly

to the Transom

Adjusting the Transducer

Mounting Position

Adjusting the Initial Transducer Angle

2

3

1

4

5

Leading edge (the edge closest to the transom of the boat).

1

One click too high: the transducer is tilted out of the water and cannot maintain a sonar signal.

2

Trailing edge (the edge farthest away from the boat).

3

Correctly aligned: the transducer side seam is parallel with the water line.

4

One click too low: the deeper the transducer is in the water, the more likely that a rooster tail of

5

spray will be generated at high speeds. You also risk the transducer being struck and damaged

by objects in the water, so make sure that the transducer is as high as it can be and still be

submerged in the water.

LEVEL

4

Correctly aligned.

Adjusting the Horizontal

Transducer Angle

LEVEL

3. Continue to adjust until the transducer assembly until the bracket is also level from port to

starboard (horizontally level as you look at the transducer from behind the boat) (see Adjusting

the Horizontal Transducer Angle).

Page 5

5

TRANSOM TRANSDUCER Installation Guide

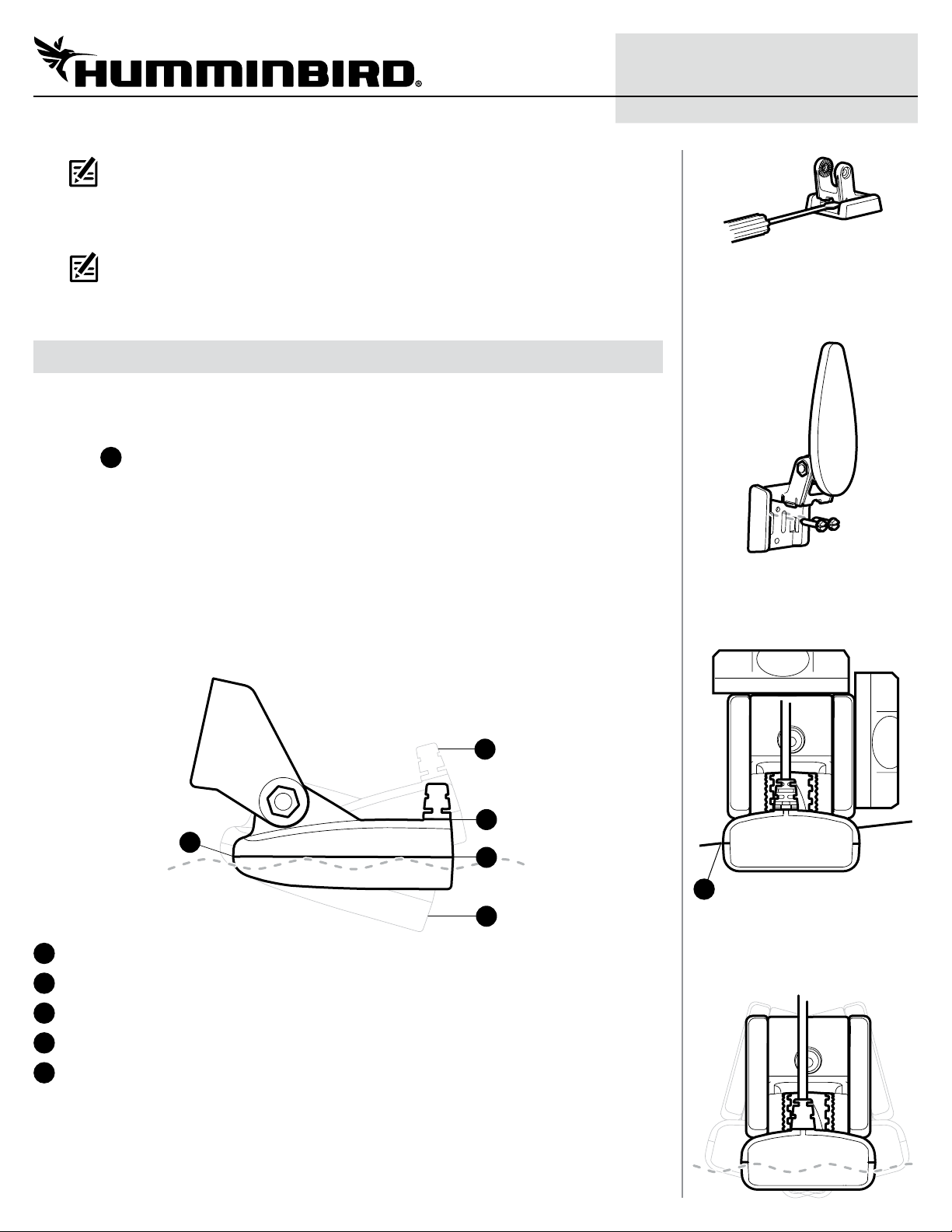

4. Once finalized, mark the correct position on the transom by tracing the silhouette of the

transducer mounting bracket with a pencil or marker.

5. Tighten the pivot bolt, using the pivot screw and nut to lock the assembly. Hand-tighten only!

CAUTION! Do not use a high speed driver on this combination of fasteners. Hand-tighten only.

6. Snap open the assembly and hand-tighten the two mounting screws, then snap the assembly

closed.

NOTE: You will drill the third mounting hole and finalize the installation after you route the cable

and test and finish the installation in the following procedures.

| Route the Cable

4

You can route the cable over the transom or through a hole in the transom above the waterline.

Your boat may have a pre-existing wiring channel or conduit that you can use to route the cable.

Select the routing method that is best for your boat configuration, and purchase any extension

cables, cable clips, clamps, etc. as needed.

Δ It is best to route the cable to the side of the transducer so the transducer will not damage

the cable during movement.

Δ The transducer can pivot up to 90 degrees in the bracket. Allow enough slack in the cable for

this movement.

Δ If you drill any holes, fill them with marine-grade silicone sealant.

Δ Excess Cable: If there is excess cable that needs to be gathered at one location, dress the

cable routed from both directions so that a single loop is left extending from the storage

location. Doubling the cable up from this point, form the cable into a coil. Storing excess cable

using this method can reduce electronic interference.

532314-3_B

Routing the Cable

Fill drill holes with

marine-grade silicone

sealant.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the cable

insulation. Route the cable as far as possible from any VHF radio antenna cables or

tachometer cables to reduce the possibility of interference. If the cable is too short,

extension cables are available to extend the transducer cable up to a total of 50'. For

assistance, contact Humminbird® Technical Support.

CAUTION! Do NOT mount the cables where the connectors could be submerged in water or

flooded. If cables are installed in a splash-prone area, it may be helpful to apply dielectric

grease to the inside of the connectors to prevent corrosion. Dielectric grease can be

purchased separately from a general hardware or automotive store.

| Connect the Cable

5

1. Connect the transducer cable to the transducer port on the control head or cable connector

(if applicable).

The connector is keyed to prevent reversed installation, and insertion should be easy. Do not

force the connectors into the ports.

If the cable connector is round, hand-tighten the screw nut to secure the cable connection.

Hand-tighten only!

Refer to your control head installation guide for additional details.

Transducer Connectors

Hexagon-Shaped

Connector

screw

nut

Round

Connector

Page 6

6

TRANSOM TRANSDUCER Installation Guide

| Test and Finish the Installation

6

Once you have installed the control head, the transducer, and have routed all the cables, you must

perform a final test before locking the transducer in place.

Testing should be performed with the boat in water deeper than 2 feet. The transducer should be

fully submerged because the sonar signal cannot pass through air.

WARNING! The transducer must be fully submerged in water during operation because the sonar

signal cannot pass through air. Air pinging can damage the transducer.

Test the Transducer Installation on the Control Head

1. Press the POWER key to turn on the control head.

If the transducer is detected, the control head will start Normal mode.

2. Select a Sonar View to display on-screen.

HELIX®: Press and hold the VIEW key. Select Sonar > Sonar View.

SOLIX®: Press the HOME key. Select a Sonar View.

Other: See your control head operations manual.

3. If the bottom is visible on-screen with a digital readout for Depth, the unit is working properly.

Gradually increase the boat speed to test high-speed performance. If the unit functions well

at low speeds, but begins to skip or miss the bottom at higher speeds, the transducer requires

adjustment.

532314-3_B

NOTE: Down Imaging provides the maximum detail at slower boat speeds, however high

speed performance is available in the Down Imaging and traditional sonar views.

4. If you have the correct angle set on the transducer, yet lose a bottom reading at high speed,

adjust the height and the running angle in small increments to give you the ideal transducer

position for your boat. First, adjust the height in small increments.

5. If you are still not getting good high speed readings, you may need to disassemble the

transducer mounting assembly and re-position the ratchets.

If you do change the transducer position, re-trace the position of the mounting bracket

before proceeding.

NOTE: It is often necessary to make several incremental transducer adjustments before

optimum high speed performance is achieved. Due to the wide variety of boat hulls, however,

it is not always possible to obtain high speed depth readings.

Finalize the Transducer Installation

Once you have reached a consistently good sonar signal at the desired speeds, you are ready to lock

down the transducer settings.

6. Force the pivot to the Up position to gain access to the mounting screws, then re-align the

mounting bracket against the transom of the boat to match the traced silhouette. Check the

bracket position with the level again to make sure it is still level, then mark the third mounting

hole using a pencil or marker.

7. Unscrew and remove the mounting screws and the transducer assembly and set aside.

8. Drill the third mounting hole, using a 5/32" (4 mm) drill bit.

9. Use a marine-grade silicone sealant to fill all three drilled mounting holes, especially if the

holes penetrated the transom wall.

10. Re-position the transducer assembly against the transom of the boat, then hand-install all

three screws. Make sure that the transducer location and the pivot angle have not changed,

then fully tighten all three mounting screws. Hand-tighten only!

11. Snap the pivot back down. If you have performed the preceding procedures correctly, the

transducer should be level and at the right height for optimal operation.

Page 7

7

TRANSOM TRANSDUCER Installation Guide

| Lock Down the Transducer (Optional)

7

NOTE: You have the option to lock down the Two Piece Kick Up bracket if you do not want the

transducer to kick up. Please be aware, however, that the transducer can be damaged if it is locked

down and it strikes debris in the water.

1. To lock down the transducer, trace the position of the mounting bracket. Force the pivot to

the Up position to gain access to the mounting screws, then re-align the mounting bracket

against the transom of the boat to match the traced silhouette. Check the bracket position

with the level again to make sure it is still level, then mark the fourth mounting hole using a

pencil or marker (see Using the Mounting Bracket to Mark the Initial Drill Holes). Unscrew and

remove the mounting screws and the transducer assembly and set aside.

2. Drill the fourth mounting hole, using a 9/64" drill bit. Use a marine-grade silicone sealant to fill

all four drilled mounting holes, especially if the holes penetrate the transom wall.

3. Re-position the transducer assembly against the transom of the boat, then hand install the

first three screws (two on the outside edges and one in the 3rd mounting hole). Make sure

that the transducer location and the pivot angle have not changed, then fully tighten all three

mounting screws (see Fully Tightening All Three Mounting Screws). Hand-tighten only!

4. Snap the pivot back down. Install the #8 x 1" wood screw into the 4th hole to lock down the

pivot arm. Hand-tighten only!

532314-3_B

Fully Tightening All Three

Mounting Screws

S U A T C H

The control head will automatically select the transducer that was included with your control head.

If a compatible accessory transducer is connected, you will need to set the transducer type on the

control head. When you select the transducer type, the related views and menus will be added to

the system.

Δ For additional configuration information, download the control head operations manual from

our Web site at humminbird.com.

Page 8

8

TRANSOM TRANSDUCER Installation Guide

M

If your transducer remains in the water for long periods of

time, slush, algae and other marine growth can reduce the

effectiveness of the transducer. Periodically clean the face

of the transducer with a mild, marine-safe and plastic-safe

soap or solution.

If your transducer remains out of the water for a long

period of time, it may take some time to wet the transducer

after it is returned to the water. Small air bubbles can cling

to the surface of the transducer and interfere with proper

operation. These bubbles will dissipate with time, or you may

wipe the face of the transducer with your fingers after the

transducer is in the water.

532314-3_B

Contact Humminbird

Web site: humminbird.com

E-mail: service@humminbird.com

Telephone: 1-800-633-1468

Direct Shipping: Humminbird

Service Department

678 Humminbird Lane

Eufaula, AL 36027 USA

WARNING! Disassembly and repair of this electronic unit should

only be performed by authorized service personnel. Any modification

of the serial number or attempt to repair the original equipment or

accessories by unauthorized individuals will void the warranty.

WARNING! The transducer must be fully submerged in water during

operation because the sonar signal cannot pass through air. Air

pinging can damage the transducer.

NOTE: Download Humminbird installation guides and operations

manuals from our Web site at humminbird.com.

NOTE: Product specifications and features are subject to change

without notice.

ENVIRONMENTAL COMPLIANCE STATEMENT: It is the intention of Johnson

Outdoors Marine Electronics, Inc. to be a responsible corporate citizen,

operating in compliance with known and applicable environmental

regulations, and a good neighbor in the communities where we make or

sell our products.

WEEE DIRECTIVE: EU Directive 2002/96/EC “Waste of Electrical and

Electronic Equipment Directive (WEEE)” impacts most distributors,

sellers, and manufacturers of consumer electronics in the European

Union. The WEEE Directive requires the producer of consumer electronics

to take responsibility for the management of waste from their products to

achieve environmentally responsible disposal during the product life cycle.

WEEE compliance may not be required in your location for electrical &

electronic equipment (EEE), nor may it be required for EEE designed and

intended as fixed or temporary installation in transportation vehicles such

as automobiles, aircraft, and boats. In some European Union member

states, these vehicles are considered outside of the scope of the Directive,

and EEE for those applications can be considered excluded from the WEEE

Directive requirement.

This symbol (WEEE wheelie bin) on product indicates the product

must not be disposed of with other household refuse. It must be

disposed of and collected for recycling and recovery of waste EEE.

Johnson Outdoors Marine Electronics, Inc. will mark all EEE

products in accordance with the WEEE Directive. It is our goal to comply in

the collection, treatment, recovery, and environmentally sound disposal

of those products; however, these requirements do vary within European

Union member states. For more information about where you should

dispose of your waste equipment for recycling and recovery and/or your

European Union member state requirements, please contact your dealer

or distributor from which your product was purchased.

© 2019 Johnson Outdoors Marine Electronics, Inc. All rights reserved.

Page 9

9

TRANSDUCTEUR TRANSOM Guide d'Installation

L'installation sur le tableau arrière permet l'ajustement de l'angle de marche et de la profondeur

une fois le transducteur monté, ce qui vous permet d'ajuster l'installation pour obtenir de meilleurs

résultats. Lisez les instructions dans ce guide de transducteur complètement à comprendre les

directives de montage avant de commencer l'installation.

REMARQUE

des directives d’installation générales. Chaque bateau présente des exigences particulières qu’il

faut évaluer avant l’installation. Pour obtenir des informations détaillées sur l'installation de

transducteurs sur différents types de coque, téléchargez le Guide des ressources d'installation

des transducteurs sur notre site Web humminbird.com.

REMARQUE

illustrés. Le montage est toutefois exactement le même.

: En raison de la grande variété de coques, nous ne présentons dans cette notice que

: L'apparence de votre transducteur peut être différente de celledes transducteurs

P 'I

Installez la tête de commande avant de commencer l'installation du transducteur. Consultez le

guide d'installation de la tête de commande.

Consultez le manuel du propriétaire de votre bateau pour connaître les emplacements

d'installation des transducteurs recommandés et les méthodes d'acheminement des câbles.

Vous aurez également besoin de votre angle de traverse.

532314-3_B

Lisez et comprenez la garantie de votre bateau avant de commencer cette installation.

Visitez notre site Web à humminbird.com pour plus d'informations et de ressources sur les

installations de transducteurs. Visitez également youtube.com/humminbirdtv pour obtenir

des vidéos d'information.

Confirmez que votre bateau est à niveau pour l'installation.

Tenez compte de vos exigences de vitesse.

Voyager à plus de 65 km / h avec le transducteur dans l'eau n'est pas recommandé avec

les transducteurs XNT 9 SI 180 T, XNT 9 DB 74 T, XNT 14 74 T et XNT 9 MSI 150 T, car ils

peuvent être endommagés. Si la vitesse au-delà de 105 km/h (65 mph) est critique, consultez

la section FAQ (Foire aux questions) de notre site Web à l’adresse humminbird.com.

Down Imaging fournit des détails optimaux aux vitesses d’embarcation plus lentes ; toutefois

des performances sont possibles à grande vitesse dans l’affichage sonar traditionnel et Down

Imaging. Si le fonctionnement à haute vitesse est critique, vous pourriez envisager d’utiliser un

transducteur pouvant être monté à l’intérieur de la coque plutôt qu’un modèle se montant sur

le tableau arrière.

REMARQUE D'IMAGERIE LATÉRALE : Le transducteur à imagerie latérale NE PEUT être installé à

l’intérieur de la coque du bateau.

Matériel : En plus du matériel fourni, vous aurez besoin d’une perceuse électrique et de forets,

ainsi que de divers outils à main, dont une règle ou règle d’ajusteur, un niveau, une clé à douille, un

marqueur ou crayon, des lunettes de sécurité, un masque antipoussières, un agent d’étanchéité

à base de silicone de qualité marine, la graisse diélectrique (facultatif), et un fil à plomb 12

po (fil ayant une extrémité pesée ou ligne monofilament) (facultatif). Vous pouvez aussi avoir

besoin de câbles d'extension et de matériel pour la pose du câble à la tête de commande.

Page 10

10

1 3 4 5 62

TRANSDUCTEUR TRANSOM Guide d'Installation

D

Il est très important de positionner le transducteur à un endroit relativement libre de turbulences.

Tenez compte des facteurs suivants pour déterminer l’emplacement où il y aura le moins de

turbulences.

Évitez les zones où il y a un écoulement d'eau turbulent. Eau turbulente se limitent normalement

1

aux zones situées directement à l’arrière des membrures, virures ou rangées de rivets sous le

bateau et dans la zone immédiate de l’hélice (des hélices). La meilleure façon de localiser un

emplacement libre de turbulences est de regarder le tableau arrière lorsque le bateau se

déplace.

532314-3_B

Observez le sens de rotation de votre hélice (en marche avant, lorsque, situé à l’arrière du

2

bateau, vous faites face à la poupe). Les hélices à rotation horaire créent plus de turbulences à

bâbord. Les hélices antihoraire créent plus sur le côté tribord.

Assurez-vous qu'il y a une distance suffisante par rapport à l'hélice(s). Sur les bateaux munis

3

d’un moteur hors-bord ou semi-hors-bord, il vaut mieux placer le transducteur à une distance

d’au moins 380 mm (15 po) à côté de l’hélice (des hélices).

L'emplacement de montage idéal (à droite de l'hélice[s]). Il est important de noter que si vous

4

envisagez de remorquer votre bateau, ne montez pas le transducteur trop près des couchettes

ou des rouleaux de la remorque pour éviter de déplacer ou d'endommager le transducteur

pendant le chargement et le déchargement du bateau.

Sur les bateaux ayant une coque à décrochement, il est possible de monter le transducteur sur

5

le décrochement. Ne montez pas le transducteur sur le tableau arrière, derrière un décrochement,

sinon le transducteur pourrait émerger de l’eau à haute vitesse.

Le transducteur doit être monté de manière à être parallèle à la ligne de flottaison, mais

6

complètement immergé dans l'eau pendant le fonctionnement.

Si vous avez un transducteur à imagerie latérale, il ne doit y avoir AUCUN obstacle obstruant

7

les faisceaux latéraux, c'està- dire que rien ne doit se trouver dans le champ d'action de ces

faisceaux (pas de coque, moteur, autre transducteur, etc.).

REMARQUE : Vous pourriez avoir à incliner le moteur vers le haut et hors du champd'action

des faisceaux latéraux lorsque vous les utilisez.

Relevé de varangue : La forme hydrodynamique du transducteur lui permet de pointer directement

vers le bas, sans qu’il soit nécessaire de régler l’angle de relevé de varangue.

7

Vue dégagée : La plaque de la

prise donne au transducteur une

distance sécurisée loin du moteur

et de ses turbulences. L’imagerie

latérale dispose d’une vue dégagée

d’un côté à l’autre.

Page 11

11

TRANSDUCTEUR TRANSOM Guide d'Installation

| Préparation de l’emplacement de montage

1

1. Assurez-vous que le bateau est de niveau sur la remorque, (tant de bâbord à tribord que de la

poupe à la proue).

2. Maintenez le support de montage contre le tableau arrière du bateau, à l’endroit déterminé

au préalable.

Alignez le support horizontalement à l’aide du niveau. Assurez-vous que le coin inférieur du

support ne dépasse pas du fond de la coque.

3. Reportez-vous à l'exigence de dégagement minimum entre le bas du support et le bas du

tableau arrière pour votre type de bateau ci-dessous :

6 mm (1/4 po) pour fibre de verre

3 mm (1/8 po) pour aluminium

REMARQUE POUR LES BATEAUX EN ALUMINIUM : Si vous avez un bateau en aluminium à

fond plat, certains réglages additionnels pourraient s'avérer nécessaires pour composer

avec les rivets au fond du bateau (c'est-à-dire que l'écart pourrait devoir être d’un peu

moins que 3 mm [1/8 po]). Cela vous aidera à réduire les turbulences à grande vitesse.

Si votre hélice tourne dans le sens horaire, montez le transducteur à tribord, puis alignez le

coin inférieur droit du support de montage avec le fond du bateau. Si votre hélice tourne dans

le sens antihoraire, montez le transducteur à bâbord, puis alignez le coin inférieur gauche du

support de montage avec le fond du bateau.

532314-3_B

Utilisation du support de

montage pour marquer les

trous à percer initialement

NIVEAU

6 mm (1/4 po) pour fibre de verres

3 mm (1/8 po) pour aluminium

4e trou

4. Continuez à maintenir le support sur le tableau arrière du bateau, and use puis servez-vous d’un

crayon ou d’un marqueur pour marquer l’emplacement des deux trous de montage (voir Utilisation

du support de montage pour marquer les trous à percer initialement). Marquez les trous à percer

près du haut de chaque fente, en vous assurant que la marque est centrée dans la fente.

REMARQUE : Vous ne devriez pas percer le troisième trou avant d’avoir déterminé la position

angulaire et en hauteur finale du transducteur, que vous déterminerez au cours d’une procédure

ultérieure.

5. Assurez-vous, avant de percer, que le foret de la perceuse est perpendiculaire à la surface

du tableau arrière, et NON parallèle au sol. À l’aide d’un foret de 4 mm (5/32 po), percez

seulement deux trous, d’une profondeur approximative de 25,4 mm (1 po).

REMARQUE POUR LES COQUES EN FIBRE DE VERRE : Pour les coques en fibre de verre, il vaut

mieux commencer avec un foret d'un diamètre plus petit et utiliser des forets d'un diamètre

plus grand par la suite, afin de réduire les chances d'écailler le revêtement extérieur.

| Assemblage du transducteur et montage initial

2

Au cours de cette procédure, vous assemblerez le transducteur à l’aide de la quincaillerie fournie,

puis le monterez et ajusterez sa position sans le bloquer en place.

1a. Si le tableau arrière est à un angle de 14 degrés (un angle commun pour le tableau arrière de

nombreux bateaux), réglez les mécanismes à rochet à la position 1.

1b. Si vous avez un angle de traverse différent ou ne connaissez pas votre angle de traverse,

reportez-vous au Guide de ressources d'installation du transducteur sur notre site Web à

humminbird.com pour obtenir des instructions détaillées.

2. Placez les deux mécanismes à rochet de chaque côté du joint d’articulation du transducteur,

de façon à ce que les denticules de chaque mécanisme à rochet s’alignent à la position

numérotée voulue du joint d’articulation (voir Installation des rochets en position 1). Si vous

réglez les mécanismes à rochet à la position 1, les denticules de chaque mécanisme à rochet

s’aligneront avec la nervure du joint d’articulation du transducteur pour former une ligne

continue dans l’assemblage.

marquage des trous

à percer initialement

Installation des rochets en position 1

nervure

à la

position 1

denticule

Montage du bras pivot sur

les mécanismes à rochet

3e trou

joint

d'articulation

rochet

Page 12

12

TRANSDUCTEUR TRANSOM Guide d'Installation

REMARQUE : Les mécanismes à rochet sont clavetés. Assurez-vous que les dents carrées de

chaque mécanisme à rochet s’imbriquent dans celles du joint d’articulation du transducteur et

que les dents triangulaires font face vers l’extérieur.

3. Maintenez les mécanismes à rochet sur le joint d’articulation du transducteur d’une main et,

de l’autre main, montez sous pression le bras de pivot sur les mécanismes à rochet. Reportezvous à l'illustration Montage du bras pivot sur les mécanismes à rochet.

4. Glissez le boulon pivot dans l’assemblage pour le consolider et vissez librement l’écrou (NE le

serrez PAS trop pour le moment) (voir Insertion du boulon pivot).

MISE EN GARDE ! Ne pas utiliser de visseuse à grande vitesse avec cet ensemble de

dispositifs de fixation. Serrer à la main seulement.

5. Insérez l’ensemble bras de pivot dans le support de montage (voir Insertion de l’ensemble

pivot dans le support de montage). NE fermez PAS l’assemblage sous pression, car vous

aurez besoin d’accéder au support de montage à la prochaine étape.

REMARQUE : Si l’ensemble pivot s'est refermé sous pression sur le support de montage,

servez-vous d'un tournevis à tête plate ou d'un outil similaire pour disjoindre l'ensemble

pivot du support de montage.

6. Alignez le support de montage du transducteur avec les trous percés dans le tableau arrière.

À l’aide d’un tournevis à douille de 8 mm (5/16 po), montez l’ensemble au tableau arrière avec

les deux longues vis n° 10 - 25,4 mm (1 po) fournies.

532314-3_B

Insertion du boulon pivot

Insertion de l’ensemble pivot

dans le support de montage

REMARQUE : Assurez-vous que les vis de montage maintiennent le support en place, mais

ne les serrez pas à fond pour le moment afin de permettre à l’ensemble transducteur de

glisser à des fins d’ajustement.

7. Placez le bras de pivot en position.

| Confirmer l'angle de montage

3

Vous devrez ajuster l'angle initial du transducteur à la fois verticalement et horizontalement pour

confirmer l'angle de montage du transducteur.

1. Réglez la position verticale de l’ensemble transducteur de façon à ce que la ligne de joint du

bord d’attaque du transducteur (voir

ci-dessous) soit de niveau et juste un peu plus bas

1

que la coque.

2. Réglez l’angle initial du transducteur d’arrière en avant en le faisant pivoter, un clic à la fois,

dans une direction ou l’autre, jusqu’à ce que la ligne de joint latérale du transducteur soit

presque parallèle avec le fond du bateau. (voir Ajustement de l'angle initial du transducteur).

Inclinaison vers le bas : Il existe une déclivité naturelle de 4 à 5 degrés du bord d’attaque au bord

de fuite du transducteur. D’un point de vue situé à l’arrière du transducteur, la ligne de joint devrait

être légèrement sous le fond de la coque.

Transducteurs à imagerie de fond : Aucune inclinaison vers le bas n'est requise pour les

transducteurs à imagerie de fond . Ajustez l'angle de fonctionnement de sorte que le transducteur

soit parallèle à l'eau et immergé dans l'eau.

Montage de l’ensemble

au tableau arrière

Ajustement de l'emplacement

de montage du transducteur

NIVEAU

NIVEAU

4

Bon alignement.

Page 13

13

TRANSDUCTEUR TRANSOM Guide d'Installation

Ajustement de l'angle initial du transducteur

2

3

1

Bord d’attaque (le bord le plus près du tableau arrière du bateau).

1

Un clic trop haut : le transducteur est incliné hors de l'eau et ne peut pas maintenir un signal

2

sonar.

Bord de fuite (bord le plus éloigné du bateau).

3

Bon alignement : la couture latérale du transducteur est parallèle à la ligne d'eau.

4

4

5

532314-3_B

Réglage de l'angle du

transducteur horizontal

Un clic trop bas : plus le transducteur est submergé profondément dans l’eau, plus grande

5

est la probabilité qu’il laisse un sillage important à grande vitesse. Vous risquez également

que le transducteur soit heurté et endommagé par des objets dans l'eau, assurez-vous que le

transducteur se situe aussi haut que possible, tout en restant submergé, pour réduire cet effet.

3. Continuez à ajuster jusqu’à ce que le support soit aussi de niveau, de bâbord à tribord (de

niveau à l’horizontale, d’un point de vue situé derrière le bateau) (voir Réglage de l'angle du

transducteur horizontal).

4. Une fois finalisé, marquez la bonne position sur le tableau arrière en traçant le contour du

support de montage du transducteur à l’aide d’un crayon ou d’un marqueur.

5. Serrez le boulon pivot à l’aide de la vis pivot et de l’écrou pour bloquer l’assemblage. Serrez la

vis à la main seulement !

MISE EN GARDE! Ne pas utiliser de visseuse à grande vitesse avec cet ensemble de dispositifs de

fixation. Serrer à la main seulement.

6. Ouvrez l’ensemble et serrez les deux vis de montage à la main, puis refermez l’ensemble sous

pression.

REMARQUE : Vous percerez le troisième trou de montage et compléterez l’installation après avoir

acheminé le câble et effectué des essais dans les procédures suivantes.

| Acheminement du câble

4

Vous pouvez faire passer le câble par dessus le tableau arrière du bateau ou à travers un trou

dans le tableau ci-dessus la ligne de flottaison. Il se peut que votre bateau soit déjà muni d’une

canalisation ou conduite de câblage, que vous pourriez utiliser pour acheminer le câble du

transducteur. Sélectionnez la méthode de routage qui est le mieux pour la configuration de votre

bateau, et acheter de câbles d'extension, des serre-câbles, pinces, etc, si nécessaire.

Δ Il vaut mieux acheminer le câble à côté du transducteur afin que le transducteur ne

l’endommage pas lors du déplacement du bateau.

Δ Le transducteur peut pivoter d’un angle maximal de 90 degrés sur le support. Laissez assez

de mou dans le câble pour accommoder ce mouvement.

Acheminement du câble

Remplir les trous avec du

mastic silicone de qualité

marine.

Page 14

14

TRANSDUCTEUR TRANSOM Guide d'Installation

Δ Si vous percez des trous, les remplir avec du mastic silicone de qualité marine.

Δ Câble excédentaire : Si le câble est un peu long et que vous devez ranger l’excédent quelque

part, placez le câble que vous aurez tiré des deux directions de façon à ne former qu’une seule

boucle. Doublez le câble à partir de ce point et enroulez-le en spirale. Le fait de ranger l’excès

de câble de cette manière peut contribuer à réduire les interférences électroniques.

MISE EN GARDE ! Ne coupez pas le câble du transducteur pour le raccourcir et essayez de ne

pas endommager le revêtement isolateur du câble. Gardez le câble le plus à l’écart possible

de tout câble d’antenne de radio VHF ou de câble de tachymètre, afin de limiter les

possibilités d’interférence. Si le câble du transducteur est trop court, vous pouvez vous

procurer des rallonges pour le prolonger jusqu’à une longueur totale de 15 m (50 pi). Pour

obtenir de l’aide, communiquez avec le support technique Humminbird.

MISE EN GARDE ! Ne montez PAS les câbles dans un endroit où les connecteurs pourraient

être submergés. Si les câbles sont installés dans une zone où des éclaboussures sont

possibles, il est préférable d'appliquer de la graisse diélectrique sur l'intérieur des

connecteurs pour éviter la corrosion. Vous pouvez acheter la graisse diélectrique

séparément dans une quincaillerie ou un magasin d'équipement automobile.

| Branchement du câble

5

1. Branchez le câble de la sonde au port de transducteur sur la tête de commande ou connecteur

de câble (le cas échéant).

Le connecteur est claveté afin de prévenir une installation inversée. L'insertion devrait être

aisée. Ne forcez pas les connecteurs dans les ports.

532314-3_B

Connecteurs du transducteur

vis

écrou

Si le connecteur de câble est rond, serrez l'écrou à la main pour sécuriser le branchement.

Serrez la vis à la main seulement !

Consultez votre commande guide d'installation de la tête pour plus de détails.

| Essais et fin de l’installation

6

Lorsque vous avez terminé l’installation de la tête de commande et du transducteur et que vous

avez acheminé tous les câbles, vous devez effectuer des essais avant de bloquer le transducteur

en position.

Essais doivent être effectués bateau dans les eaux profondes de 60 cm (2 pi) ou plus. Le transducteur

doit être complètement immergée car le signal sonar ne peut pas passer à travers l'air.

AVERTISSEMENT ! Le transducteur doit être complètement submergé dans l'eau pendant le

fonctionnement car le signal du sonar ne peut pas traverser l'air. Un cliquetis d'air peut

endommager le transducteur.

Testez l'installation du transducteur sur la tête de commande

1. Appuyez sur la touche Mise en marche (POWER) une fois pour mettre la tête de commande

en marche.

Le tête de commande active le mode de fonctionnement normal si un transducteur est

détecté.

2. Sélectionnez une vue sonar à afficher à l'écran.

HELIX : Appuyez sur la touche AFFICHAGE et tenez-la enfoncée. Sélectionnez Sonar > Vue

sonar.

SOLIX : Appuyez sur la touche Accueil. Sélectionnez une vue sonar.

Autre : Consultez le guide d'utilisation de votre tête de commande.

3. Si le fond et un indicateur numérique de la profondeur sont visibles à l’écran, c’est que

l’appareil fonctionne adéquatement.

Connecteur

hexagonal

Connecteur

rond

Page 15

15

TRANSDUCTEUR TRANSOM Guide d'Installation

Si l’appareil fonctionne correctement, augmentez progressivement la vitesse du bateau pour

tester le rendement à grande vitesse. Si l’appareil fonctionne adéquatement à basse vitesse

mais que la représentation du fond devient erratique à vitesse plus élevée, il faut ajuster la

position du transducteur.

REMARQUE : Down Imaging fournit des détails optimaux aux vitesses d’embarcation plus

lentes ; toutefois des performances sont possibles à grande vitesse dans l’affichage sonar

traditionnel et Down Imaging.

4. Si l’angle du transducteur est bien réglé, mais que vous perdez la lecture du fond à grande

vitesse, ajustez la hauteur et l’angle de marche progressivement afin d'obtenir la meilleure

position de transducteurm pour votre bateau. En premier lieu, ajustez graduellement la hauteur.

5. Si vous n’obtenez toujours pas de bons résultats à grande vitesse, vous pourriez avoir à

démonter l’ensemble transducteur et à repositionner les mécanismes à rochet.

Si vous décidez de changer la position du transducteur, retracez au préalable la position du

support de montage.

REMARQUE : Il est souvent nécessaire d’effectuer plusieurs réglages incrémentaux du

transducteur avant d’obtenir le meilleur rendement à grande vitesse. Toutefois, en raison de

la grande variété de coques de bateaux, il n'est pas toujours possible d'obtenir de bonnes

lectures du fond à grande vitesse.

Finaliser l'installation du transducteur

Lorsque vous aurez réussi à obtenir régulièrement de bons retours sonar aux vitesses désirées,

vous serez prêt à bloquer les réglages du transducteur.

6. Réalignez le support de montage avec le contour tracé sur le tableau arrière du bateau. Vérifiez

à nouveau la position du support à l’aide d’un niveau pour vous assurer qu’il est toujours de

niveau, puis marquez l’emplacement du troisième trou de montage avec un crayon ou un

marqueur.

7. Retirez les vis de montage et l’ensemble transducteur et mettez-les de côté pour l’instant.

8. Percez le troisième trou de montage à l’aide d’un foret de 4 mm (5/32 po).

9. Remplissez les trois trous de montage d’un agent d’étanchéité à base de silicone de qualité

marine, surtout si les trous traversent le tableau arrière.

10. Replacez l’ensemble transducteur sur le tableau arrière du bateau, puis serrez les vis de

montage à la main. Assurez-vous que l’emplacement du transducteur et l’angle du pivot n’ont

pas changé, puis serrez à fond les trois vis de montage. Serrez la vis à la main seulement !

11. Si vous avez suivi les procédures précédentes correctement, le transducteur devrait être de

niveau et à la bonne hauteur pour assurer son fonctionnement optimal.

532314-3_B

Serrez complètement

les trois vis de fixation

| Verrouillage du transducteur (facultatif)

7

REMARQUE : Vous avez la possibilité de verrouiller le support de montage en deux pièces si vous

ne désirez pas que le transducteur pivote. Il convient de noter, cependant, que le transducteur

peut être endommagé s’il heurte des débris dans l’eau alors qu’il est verrouillé.

1. Pour verrouiller le transducteur, tracez la position du support de montage. Forcez le pivot à

la position élevée pour avoir accès aux vis de montage, puis réalignez le support de montage

avec le contour tracé sur le tableau arrière du bateau. Vérifiez à nouveau la position du support

à l’aide d’un niveau pour vous assurer qu’il est toujours de niveau, puis marquez l’emplacement

du quatrième trou de montage avec un crayon ou un marqueur (voir Utilisation du support

de montage pour marquer les trous à percer initialement). Retirez les vis de montage et

l’ensemble transducteur et mettez-les de côté pour l’instant.

2. Percez le quatrième trou de montage à l’aide d’un foret de 5 mm (9/64 po). Remplissez les

quatre trous de montage d’un agent d’étanchéité à base de silicone de qualité marine, surtout

si les trous traversent le tableau arrière.

Page 16

16

TRANSDUCTEUR TRANSOM Guide d'Installation

3. Replacez l’ensemble transducteur sur le tableau arrière du

bateau, puis serrez les vis de montage à la main (deux sur les

bords extérieurs et un dans le troisième trou de montage).

Assurez-vous que l’emplacement du transducteur et l’angle

du pivot n’ont pas changé, puis serrez à fond les trois vis de

montage (voir Serrez complètement les trois vis de fixation).

Serrez la vis à la main seulement !

4. Replacez le pivot en position inférieure. Installez une vis à bois

No 8 x 1 po (25,4 mm) dans le 4ème trou pour verrouiller le

bras de pivot. Serrez la vis à la main seulement !

C

La tête de commande sélectionnera automatiquement le

transducteur livré avec votre tête de commande. Si un transducteur

accessoire compatible est connecté à la tête de commande,

configurez le type de transducteur dans le tête de commande

comme suit. Lorsque vous sélectionnez le type de transducteur, les

vues et menus associés sont ajoutés au système.

Δ Pour plus d'informations sur la configuration, téléchargez le

manuel d'utilisation de la tête de commande sur notre site

Web humminbird.com.

E

Si le transducteur demeure à l’eau pendant de longues

périodes, les salissures peuvent réduire l’efficacité du

transducteur. Nettoyez périodiquement la façade du

transducteur avec un savon ou liquide doux et sans danger

pour le plastique et pour le milieu biologique marin.

Si le transducteur est sorti de l’eau pendant une période

prolongée, il faut le laisser reposer un certain temps

après l’avoir remis dans l’eau. De petites bulles d’air

peuvent adhérer à la surface du transducteur et gêner son

fonctionnement. Ces bulles se dissipent avec le temps; vous

pouvez également essuyer la surface du transducteur avec

les doigts après l’avoir remis dans l’eau.

532314-3_B

Pour communiquer avec Humminbird

site Web : humminbird.com

Courrier électronique : service@humminbird.com

Téléphone : 1-800-633-1468

Adresse d'expédition directe : Humminbird

Service Department

678 Humminbird Lane

Eufaula, AL 36027 USA

AVERTISSEMENT ! La réparation et/ou le démontage de cet appareil

électronique doit être effectué uniquement par un personnel

d'entretien autorisé. Toute modification du numéro de série et/ou

réparation par un personnel non autorisé entraînera l'annulation de

la garantie.

AVERTISSEMENT ! Le transducteur doit être complètement

submergé dans l'eau pendant le fonctionnement car le signal du

sonar ne peut pas traverser l'air. Un cliquetis d'air peut endommager

le transducteur.

REMARQUE : Les guides d'utilisation et d'installation sont

téléchargeables sur notre site Web à l'adresse humminbird.com.

REMARQUE : Les caractéristiques et spécifications de ce produit

peuvent être modifiées sans préavis.

DÉCLARATION DE CONFORMITÉ AVEC L’ENVIRONNEMENT : Johnson

Outdoors Marine Electronics, Inc. entend agir en de façon responsable, et

respecter la réglementation environnementales connues et applicables et

la politique de bon voisinage des communautés où elle fabrique et vend

ses produits.

DIRECTIVE DEEE : La directive EU 2002/96/CE sur les « déchets

d’équipements électriques et électroniques (DEEE) » concerne la plupart

des distributeurs, vendeurs et fabricants d’équipements électroniques

grand public dans l’Union européenne. La directive DEEE requiert que le

producteur d’équipements électroniques grand public prenne en charge la

gestion des déchets de leurs produits et mettent en oeuvre leur élimination

en respectant l’environnement, pendant le cycle de vie du produit.

Il est possible que la conformité à la directive DEEE ne soit pas requise sur

le site pour les équipements électriques et électroniques (EEE), ou pour les

équipements EEE conçus et destinés à des installations temporaires ou

fixes sur les véhicules de transport tels que les automobiles, les aéronefs

ou les bateaux. Dans certains pays membres de l’Union européenne, ces

véhicules n’entrent pas dans le domaine d’application de la directive, et les

EEE pour ces applications peuvent être considérés exclus de la conformité

à la directive WEEE.

Ce symbole (poubelle DEEE) figurant sur le produit indique qu’il ne

doit pas être mis au rebut avec les autres déchets ménagers. Il doit

être éliminé et recueilli pour le recyclage et la récupération des

équipements EEE à mettre au rebut. Johnson Outdoors Marine

Electronics, Inc. marque tous les produits EEE conformément à la directive

DEEE. Notre but est de respecter les directives sur la collecte, le traitement,

la récupération et la mise au rebut de ces produits en respectant

l’environnement ; ces exigences varient toutefois d’un état membre à

l’autre de l’Union européenne. Pour obtenir d’autres renseignements sur

les sites d’élimination des déchets d’équipements en vue de leur recyclage

et de leur récupération et/ou sur les exigences des états membres de

l’Union européenne, renseignez-vous auprès du distributeur ou du lieu

d’achat de votre produit.

© 2019 Johnson Outdoors Marine Electronics, Inc. Tous droits servés.

Loading...

Loading...