Page 1

1

High Speed Transducer

THANK YOU

Thank you for choosing Humminbird, America’s #1 name in depthsounders. Humminbird has built its

reputation by manufacturing top-quality, thoroughly reliable marine equipment. Genuine Humminbird

accessories offer the opportunity to upgrade and expand the capabilities of your Humminbird product.

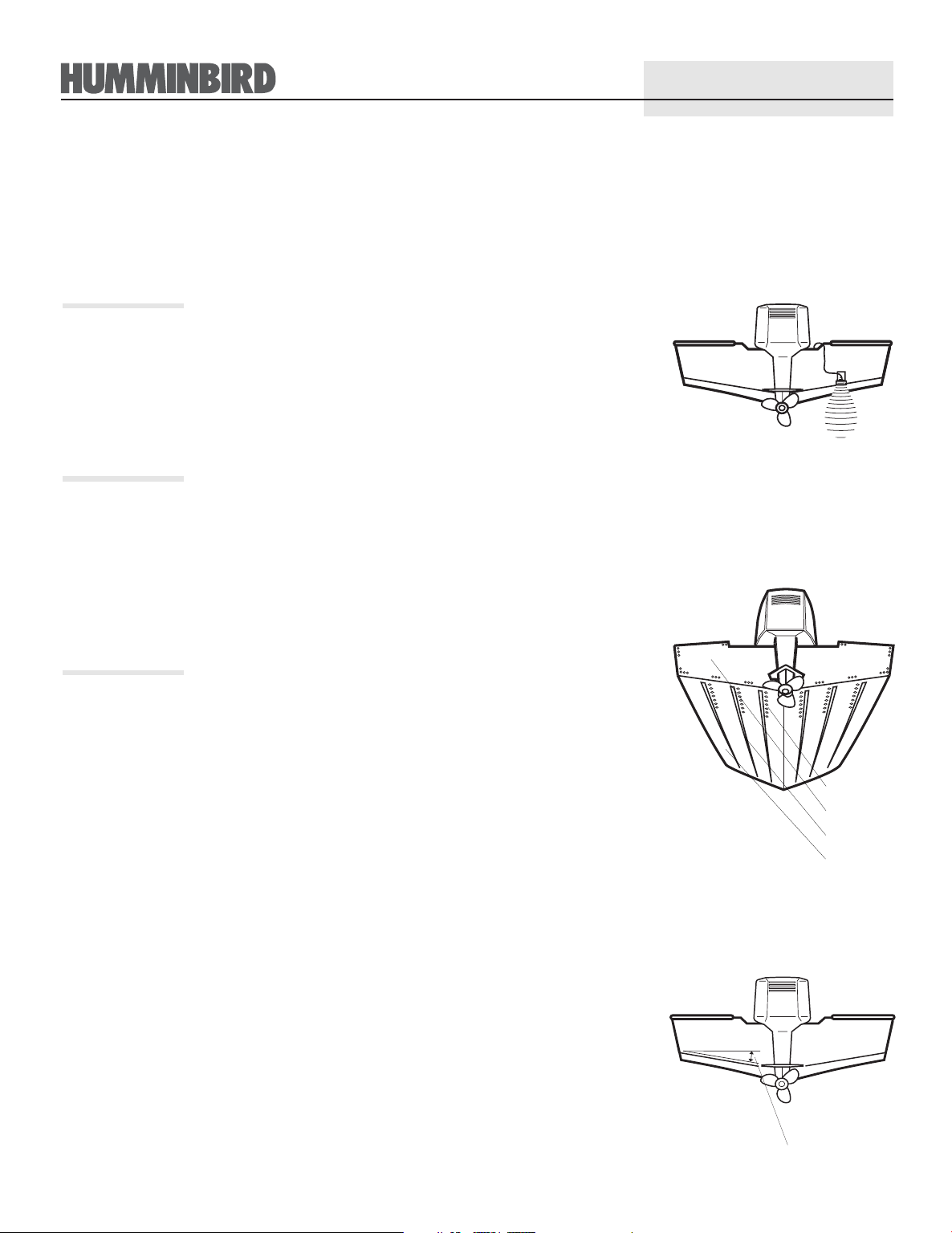

There are a number of ways to install a transducer on your boat.

ABOUT TRANSOM

MOUNT

INSTALLATION

BEFORE YOU START

The transom mount installation provides the least loss of signal since

the transducer is mounted outside the boat hull. This installation also

allows adjustment of both running angle and depth after the transducer

is mounted, which enables you to tune the installation for best results.

Transom Mounted Transducer

Following are instructions for the installation of the High Speed

Transducer. We encourage you to read these instructions carefully to

get full benefit from your Humminbird accessory.

If you find that items are missing from your installation kit, call our

Customer Resource Center Support Hotline. In addition to the

hardware supplied with your transducer, you will need a powered hand

drill and various drill bits, Phillips and flat-head screw drivers, a ruler or

measuring tape, pen or pencil, and Silicone sealant.

LOCATING THE TRANSDUCER

As a boat moves through the water, turbulence is generated by the

weight of the boat, and the thrust of the prop. This turbulent water is

normally confined to areas immediately aft of ribs, strakes, or rows of

rivets on the bottom of the boat, and in the immediate area of the

propeller(s). It is very important to locate the transducer in an area of

relatively turbulence-free water. If the prop(s) are forward of the

transom, it may be impossible to find an area clear from turbulence,

and a different mounting technique should be considered.

If possible, viewing the transom of the boat while the boat is moving

will provide the best means of locating clean water, and if maximum

high-speed operation is a high priority, this is the recommended

method. If this is not possible, select an area on the transom where the

hull forward of this location is smooth and free of protrusions or ribs.

Another consideration is the angle of deadrise. The transducer, when

mounted, should point straight down. The design of the transducer will

allow a deadrise of 15 degrees and remain pointed straight down.

Unlike many transducers, the XHS-6-24 has a hydrodynamic shape

that allows transom mount usage at angles greater than 15°. The sonar

return will be from directly below the boat at the transducers location.

Rivets

Transom

Strakes

Hull

Deadrise Angle

Page 2

2

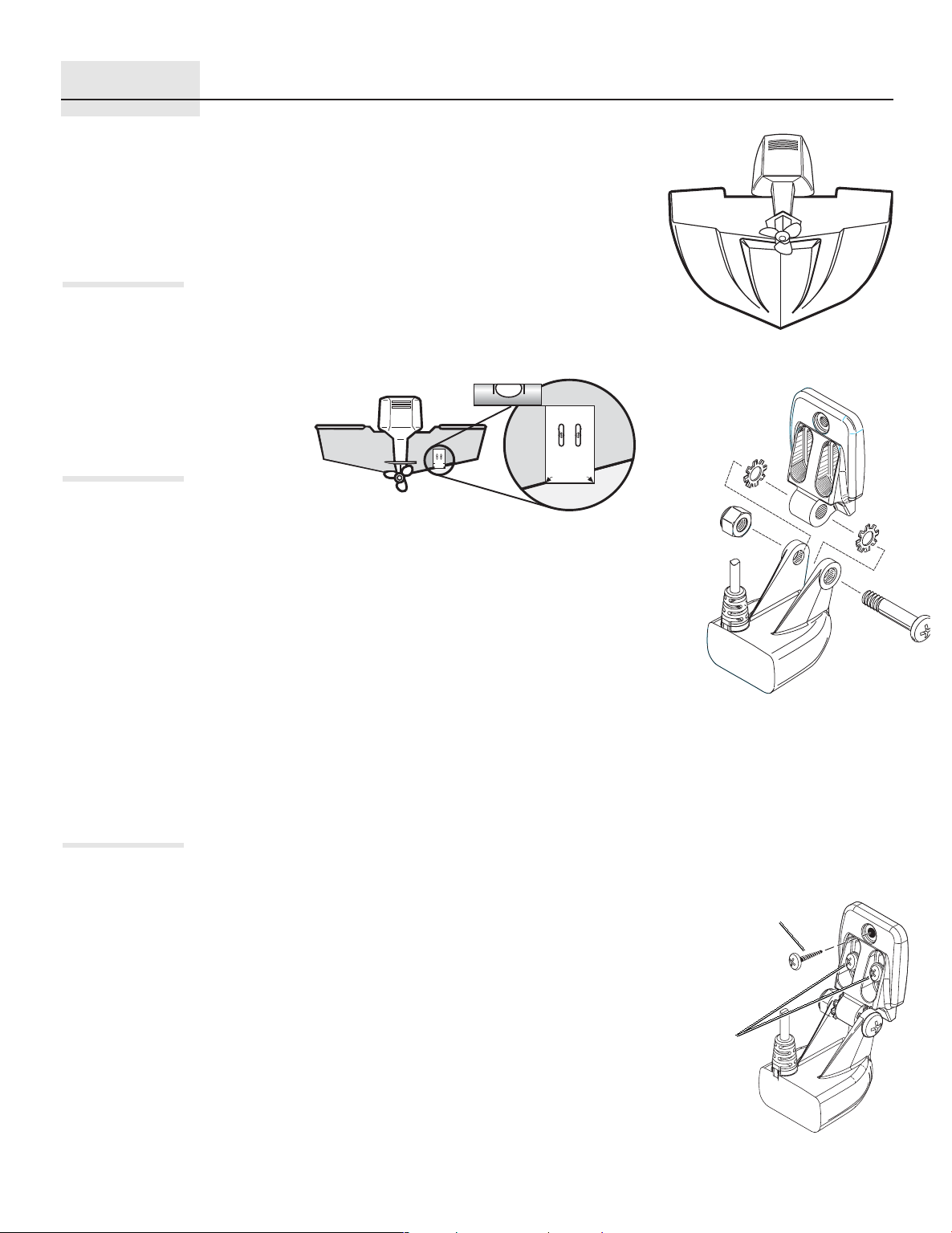

MOUNTING THE BRACKET

ASSEMBLING THE TRANSDUCER

ATTACHING THE

TRANSDUCER

On boats with stepped hulls, it may be possible to mount the

transducer on the step. Mounting the transducer on the transom

behind a step will reduce or make impossible high speed operation.

This area of the transom, behind a step, will not be in contact with the

water at high speed.

If the boat is trailered do not mount the transducer close to where

trailer bunks or rollers will impact with the transducer during loading

and unloading of the boat.

Ensure a turbulence free location at lease

15" from the prop(s) and not inline with

trailer bunks or rollers.

Level

TOP

Use 5/32" drill bit

DrillDrill

TOP

Use 5/32" drill bit

Drill Drill

DO NOT LET DEADRISE

INTERSECT THIS LINE

PLACE EITHER CORNER

ON DEADRISE ANGLE

PLACE EITHER ARROW

ON DEADRISE ANGLE

Once you have identified the location, use the mounting template on

page 4. This template locates the two mounting holes which must be

drilled. Note that there are two sets of holes, one for a fiberglass hull

and another set for an aluminum hull.

Hold the template on the transom of the boat in the location you

have selected. Align the template vertically.

Using a pencil or punch, mark the two mounting holes onto the

transom. Use the mounting bracket itself to confirm your marks.

Using a

⁵⁄₃₂"(4mm)

bit, drill the holes to a depth of approximately 1".

On fiberglass hulls, it is best to use progressively larger drill bits to

reduce the chance of chipping or flaking the outer coating.

The third hole should not be drilled until the angle and height of

the transducer is finalized.

Use a silicone sealant to fill the drilled holes, especially if the holes

penetrated the transom wall.

Attach the transducer body to the pivot as shown in the illustration at

right, using the Pivot bolt to couple the transducer ears to the

mounting bracket. The toothed washers must fit on the inside of the

transducer ears, between the pivot and the ears.

Use a #3 Phillips screw diver to hand tighten the transducer

assembly. Do not fully tighten the assembly at this time.

Stepped Hull

C

D

E

A – Mounting Bracket

B – Pivot

C – Star lock washers go between A & G.

D – Nut

E – Cable

¹⁄₄

F – Pivot Bolt

G – Transducer

Transducer Assembly

Drill and install the

third screw only after

final adjustments.

Use silicone

sealant to seal

the drilled holes

-20, #3 Phillips Drive

A

BB

C

F

G

Align the transducer assembly with the drilled holes in the transom.

Mount the transducer assembly to the transom using two wood

screws and washers as shown. Do not fully tighten the mounting

screws at this time.

Washers

&

Screws

Attaching the Bracket

Page 3

RUNNING POSITION ADJUSTMENT

Transducer bottom

Cut and use for Fiberglass Hulls

Cut and use for Alum

¹⁄₂"

Aluminum

Fiberglass

Transducer Running Angle

inum

Transducer

Guide

ulls

H

Hull

Place on bottom of hull

Align with transom.

3

The running position of the transducer is now completely adjustable. Subsequent adjustment

may be necessary to tweak the installation after high speed testing. The mounting bracket

allows height and tilt adjustment, the pivot screws allow angle adjustment.

Use the supplied pivot angle template (2) for initial setting of the pivot angle to 3° to 5°. This

template also sets the distance below the hull dependent on hull type. Additionally the template

positions the bottom of the transducer

you cut the template for your type of hull. Hand tighten the assembly to a firm tightness for initial

testing.

After the Humminbird unit is installed and the transducer installation is tested, it may be

necessary to adjust the depth and/or running angle of the transducer. First adjust the depth

below the hull in increments of

operation is continuing to show gaps in the readout, adjust the running angle by moving the

trailing end of the transducer down in increments of

Hand tighten the mounting screws, do not apply excess torque. The third and final mounting

screw should not be installed until all adjustments have been finalized.

³⁄₁₆

" for fiberglass and

¹⁄₈

". If the top of the bracket slots are reached and high speed

¹⁄₈

".

³⁄₈

" for aluminum hulls. Ensure that

ROUTING THE

CABLE

5¹⁄₂"

Routing the Cable

1¹⁄₂"

After the final testing and adjustments have been completed use a

⁵⁄₃₂

" (4mm) bit, drill a third

hole at the top of the bracket and hand install the third mounting screw. Hand tighten all screws.

The pivot bolt may need to be tightened again after the plastic has conformed to the pressures

used for initial setup.

The transducer cable has a low profile connector that must be routed to the point where the

depthsounder is mounted. Every boat is different and there may be several ways to route the cable.

If you choose to pass the cable through the transom of the boat, a

⁵⁄₈

" hole must be drilled

above the water line. Fill this hole with silicone sealant, and use an escutcheon plate to dress the

entry hole. This will require two #8 x

" screws and drilled holes of

⁹⁄₆₄

" diameter.

⁵⁄₈

Remember that the transducer may give way in the pivot angle should an object be struck and

sufficient cable slack should be allowed for this movement. It is best to route the cable to the

Page 4

High Speed Transducer

PLACE EITHER ARROW

ON DEADRISE

ANGLE

TOP

Remove and use for

Transducer Installation

Use ⁵⁄₃₂" drill bit & drill

two holes for hull type

Drill ●

Drill ●

Drill ■

Drill ■

4

side of the transducer so the cable will not be damaged by the

rotating transducer.

Cable clamps are provided to secure the cable to the transom,

and use the same type of screws as the escutcheon plate.

Inside the boat, there is often a channel or conduit which is

used for other wiring, which can be used to route the transducer

cable forward. Avoid routing the cable in areas where it may

be damaged or interfere with normal boating operations.

The transducer cable should not be cut or shortened, and

care should be used not to damage the cable insulation. If

excess cable needs to be gathered at one location, dress the

routing of cable from both directions so that a single loop is left

extending from the storage location. Doubling the cable up from

this point, form the cable into a coil. Storing excess cable with

this method can reduce electronic interference.

Also, be sure to route the cable as far as practical from the

antenna cable of VHF radios to reduce the possibility of

interference.

This accessory works with a number of Humminbird

depthsounder products. Some products may require

disassembly of the depthsounder mounting bracket in order to

connect the cable. Refer to the operations manual for your

depthsounder.

If you find that the cable is too short for your application,

extension cables are available at a reasonable cost which can

extend the transducer cable up to 50'. Call Humminbird

Customer Support for more information.

Confirm the pivot angle has not changed.

MAINTENANCE

If your boat remains in the water for long periods of time,

algae and other marine growth can reduce the effectiveness of

the transducer. Periodically clean the face of the transducer

with liquid detergent.

If your boat remains out of the water for a long period of

time, it may take some time to wet the transducer when

returned to the water. Small air bubbles can cling to the

surface of the transducer and interfere with proper operation.

These bubbles will dissipate with time, or you may wipe the

face of the transducer with your fingers after the transducer is

in the water.

Storing excess Cable

For use with bracket PN 404329-1

Fiberglass Fiberglass

Level

TOP

Use 5/32" drill bit

DrillDrill

PLACE EITHER CORNER

ON DEADRISE ANGLE

TOP

Use 5/32" drill bit

Drill Drill

DO NOT LET DEADRISE

INTERSECT THIS LINE

PLACE EITHER CORNER

ON DEADRISE ANGLE

AluminumAluminum

15", 40cm

from prop(s).

Fiberglass

Aluminum

Transducer

Guide

CUSTOMER RESOURCE CENTER

If you have any questions, call our Humminbird Customer

Resource Center Hotline:

1-334-687-0503

Cut and use for Fiberglass Hulls

Transducer bottom

Cut and use for Aluminum Hulls

¹⁄₂"

Throughout the U.S. and Canada, hours are MondayFriday, 8:15 a.m. to 5:00 p.m. Central time.

Or visit our web site: www.humminbird.com for

Product

Support and troubleshooting guides.

If after reading “Troubleshooting” you determine your

unit needs factory service, please attach a description of

the problem and send it with the unit to the address

below.

If you are including a check, please attach it to the unit.

Align with transom.

Place on bottom of hull

Hull

Humminbird

Service Department

108 Maple Lane

Eufaula, AL 36027

Further information on Humminbird products can be

found at:

www.humminbird.com

pn530505-2 r11107E

Loading...

Loading...