INSTALLATION & MAINTENANCE INSTRUCTIONS

MODEL SW-2

Your humidifier has been designed and engineered to

give, with proper care, many years of trouble free

service. Therefore, if this unit ceases to operate

properly, we suggest you contact your local dealer. If

we, at Humidity Source, can be of any assistance to

you, please feel free to write, call or e-mail.

IMPORTANT

This space type humidifier is designed so that it may

be shelf mounted. The shelf should be at least 18”

(45.7cm) below the ceiling and 6 feet (1.8m) above

floor. The directional vapor dome should be positioned

to diffuse moisture without striking any obstructions

closer than six feet and maintain 24” minimum between

each side of the humidifier and any wall or obstruction.

PROCEDURE

Run a water supply line using 1/4” o.d. copper or

plastic tubing or 1/8” pipe. Keep the line to the rear of

the unit to avoid creating an obstruction.

Flush water feed lines before making final connection

to avoid having cutting oil, pipe scale, or chips which

may clog the float valve.

Turn on water valve, adjust water level to 1” below the

overflow connection.

Adjustment is easily made using the adjusting thumb

screw for higher or lower water level as illustrated.

SERVICE & REPAIR

Should this humidifier need service or repair some time

in the future, return only atomizing unit direct to the

factory.

CARE OF THE MACHINE

Due to air washing while the humidifier is in operation,

a deposit of dirt and dust may settle in the bottom of

the water reservoir and screen, and it is recommended

that both be cleaned regularly.

24”

Top View

24”

IN ROOM MOUNTED HUMIDIFIER

Periodically the atomizing unit should be taken from

the reservoir and given a careful visual check. The

pump tube should be spun by hand to make sure that it

is free to revolve without binding. See maintenance

instructions.

Shut –off

valve

¼” water

supply

¼” comp.

connection

water supply

¼” female pipe

overflow connection

to drain

Typical Installation

No obstruction within

the dimensions indicated to

prevent wetting objects.

Ceiling

18”

6’ Minimum

To Wall

6’ Minimum

To Floor

WIRING

The atomizer motor draws .67 Amps at 115 Volts A.C.

single phase and 60 Hz service.

Provide standard electric receptacle to receive electric

cord from humidifier. Have the hot leg of service to this

receptacle wired in series with the humidistat terminals

and use a standard disconnect switch if required. See

wiring diagram.

This humidifier may be run continuously or operated by

means of a humidistat.

Our standard human hair element humidistat model P825 is correct for most applications maintaining up to

60% RH.

For humidors and other high humidity applications, or

for more precise control, use the electronic humidistat

model W351A. This model also has an optional digital

display module to indicate the set point and the actual

R.H. in the room.

Screen

Remove impeller

cap

Reservoir Wall

Float Valve Operation

Pressure Range 10-150 psig

Atomizing Unit

1-A

1-B

Sight into bottom

These openings

must be clear

Adjusting

Thumb Screw

Pump Tube

Impeller Cap

of tube

1-C

Mounting

Washer

Mounting

Nut

1/8” MPT

OPERATION

Positive capacity atomizing humidifiers produce a mist that

will quickly evaporate into the air if there is no impingement

of water particles against barrier surfaces before the water

particles against barrier surfaces before the water is

completely absorbed. Strict attention to minimum clearance

dimensions must be adhered to in order to avoid

condensation.

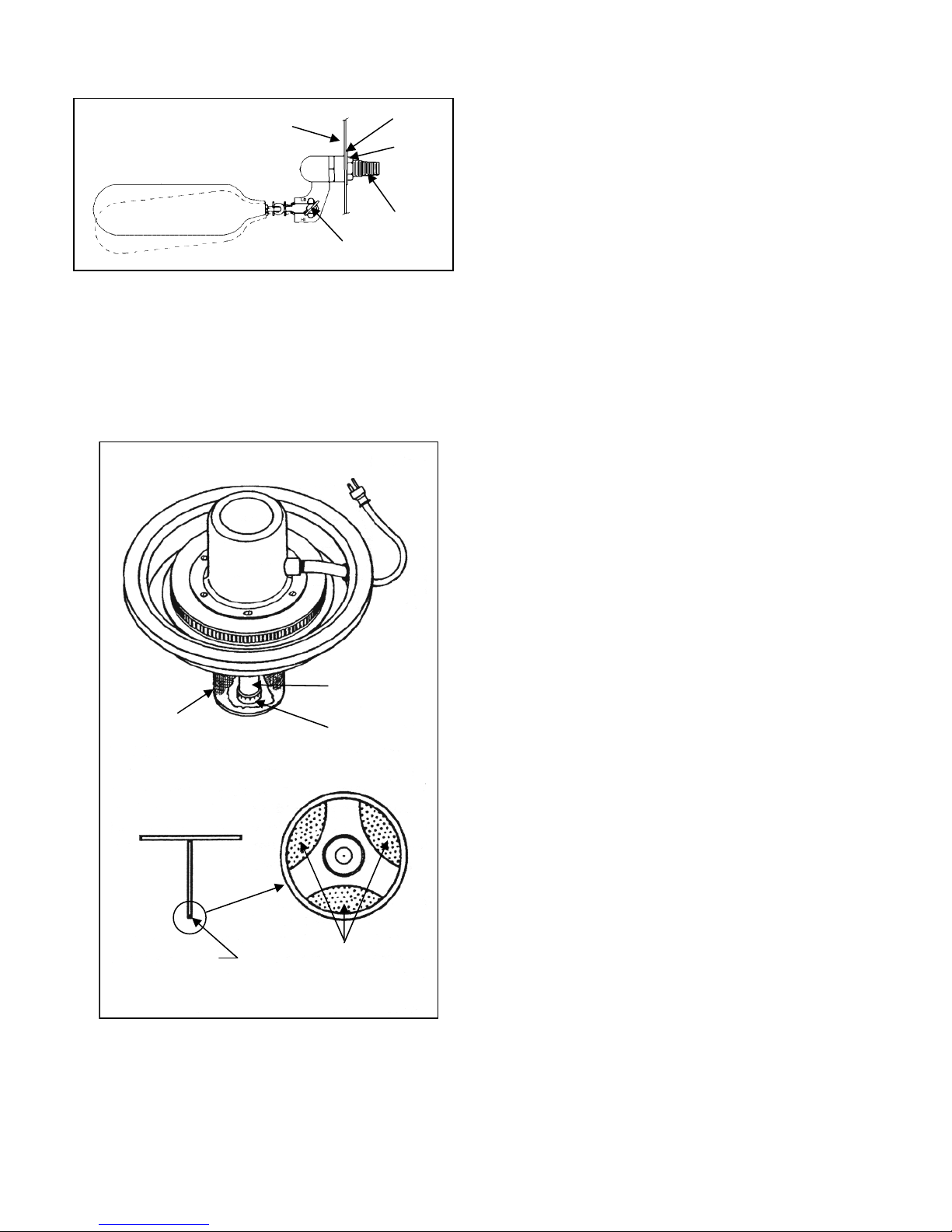

MAINTENANCE

Unplug electric cord & remove dome. Carefully lift atomizing

unit out of reservoir (Figure 1). Hold atomizing unit firmly

and remove the perforated screen (1-A) by turning it slightly

to the left until the four lugs are in line with the slots. To

remove the impeller cap (1-B), hold a flat file or the back of a

table knife flat against the side of the tube and gently tap the

cap which is held in place by a pressed fit. After the cap has

been removed, the inside of the tube is visible and it is

simple matter to clean it with a piece of cloth on the end of a

screwdriver or a small round brush.

There are three ports through which water makes its way

from the pump tube to the top of the rotating disc (1-C).

These ports should be cleaned out with the aid of a wire.

See drawing on this page.

Replace the impeller cap by tapping it evenly back into

place, using plastic handle on screwdriver.

Remove water from reservoir & rinse. Fill reservoir with

white vinegar or other mild acid solution. Replace dome &

atomizer on reservoir & block outlet of dome with plastic

wrap & a rubber band. Run atomizer for ½ hour or until

minerals are completely dissolved. If necessary, rinse with

diluted chlorine bleach solution. Rinse with clean water and

return to service. For hard water problems, see

“demineralized water” below.

Inspect float valve assemble periodically, & replace when

necessary, or every few years.

DEMINERALIZED WATER

If local water supply has a high mineral content, (call water

company & ask for “total dissolved solids” or T.D.S.) This

mineral will create tiny particles of airborne “white dust”

when the mist evaporates in the air.

To eliminate this dust, use an ion exchange or a reverse

osmosis demineralizer. See Humidity Source data sheets

for “DI” & “RO” demineralizing filters.

Figure 1

C

er

W351 Humidistat

Electronic Sensor

COM

PWR

OUT

Wiring Diagram If Using P-825 Humidistat Installation

Humidifi

Receptacle

Humidity Source P-825

Wall Humidistat

120 VAC

L1

L

2

Neutral Hot

H

L

W351A Wiring Diagram If Using W351 On/Off Controller

Controller Power Module Digital Display

W351A Y350R D351

COM

VDC

SEN

120 VAC

To Humidifier

y

MODEL SW-2 REPLACEMENT PARTS

Description Part Number

Dome Strap Assembly 079590

Dome 905026

Channel Rubber 905582

Atomizing Assembly WF/525/9/2

Rubber Mounts (3) 80096

Impeller Cap 905587

Cylindrical Screen 905543

P-825 Humidistat

Human Hair Element

Standard

Humidifier Accessories

W351 Humidistat

Electronic Sensor

For high humidity

And/or close

tolerances

Float Valve Assembly 079057

Reservoir 905608

Humidity Source Reverse Osmosis water

Treatment systems. Sizes range from industrial

capacities down to individual room units.

Humidity Source LLC 90 Dayton Ave. Passaic, New Jersey 07055

Phone 973-916-1001 e-mail Humidit

Source@aol.com

Loading...

Loading...