Page 1

USERGUIDE

Page 2

CHAPTER 1:

INTRODUCTION 1

ATP ................................................................................................................................................................ 1

PH .................................................................................................................................................................. 1

TEMPERATURE .................................................................................................................................................. 1

CONDUCTIVITY .................................................................................................................................................. 1

CONCENTRATION ............................................................................................................................................... 1

CHAPTER 2:

MATERIALS AND EQUIPMENT 2

INCLUDED IN THE BOX ........................................................................................................................................ 2

ATP SUPPLIES (PURCHASED SEPARATELY) .............................................................................................................. 2

CONDUCTIVITY AND CONCENTRATION SUPPLIES ....................................................................................................... 2

PH SUPPLIES ..................................................................................................................................................... 2

TEMPERATURE SUPPLIES ..................................................................................................................................... 2

CHARGING THE MVP ICON ................................................................................................................................ 2

CHARGING BEST PRACTICES ................................................................................................................................. 2

CHAPTER 3:

MVP ICON AT A GLANCE 3

INSTRUMENT OVERVIEW ..................................................................................................................................... 3

HOME SCREEN AND NAVIGATION ......................................................................................................................... 3

CALIBRATING THE TOUCH SCREEN ......................................................................................................................... 4

SELF-DIAGNOSTIC .............................................................................................................................................. 4

CHAPTER 4:

POINTS 5

POINTS ............................................................................................................................................................ 5

SELECTING A TEST POINT ..................................................................................................................................... 5

FINDING A TEST POINT ....................................................................................................................................... 6

CHAPTER 5:

PLANS 7

PLANS ............................................................................................................................................................. 7

SELECTING A SAMPLE PLAN ................................................................................................................................. 7

SAMPLE PLAN TRACKER ...................................................................................................................................... 7

SHUFFLE .......................................................................................................................................................... 8

CHAPTER 6:

RESULTS 9

RESULTS .......................................................................................................................................................... 9

FINDING RESULTS ............................................................................................................................................ 10

DELETING RESULTS .......................................................................................................................................... 10

CHAPTER 7:

DEVICE 11

DEVICE .......................................................................................................................................................... 11

CALIBRATION .................................................................................................................................................. 11

PREFERENCES .................................................................................................................................................. 11

STATUS .......................................................................................................................................................... 11

ABOUT .......................................................................................................................................................... 12

DELETE .......................................................................................................................................................... 12

I

Page 3

CHAPTER 8:

TAKING A READING 13

ATP .............................................................................................................................................................. 13

TAKING AN ATP READING ........................................................................................................................... 13

PH ................................................................................................................................................................ 14

TEMPERATURE ................................................................................................................................................ 14

CONDUCTIVITY ................................................................................................................................................ 14

CONCENTRATION ............................................................................................................................................. 15

CHAPTER 9:

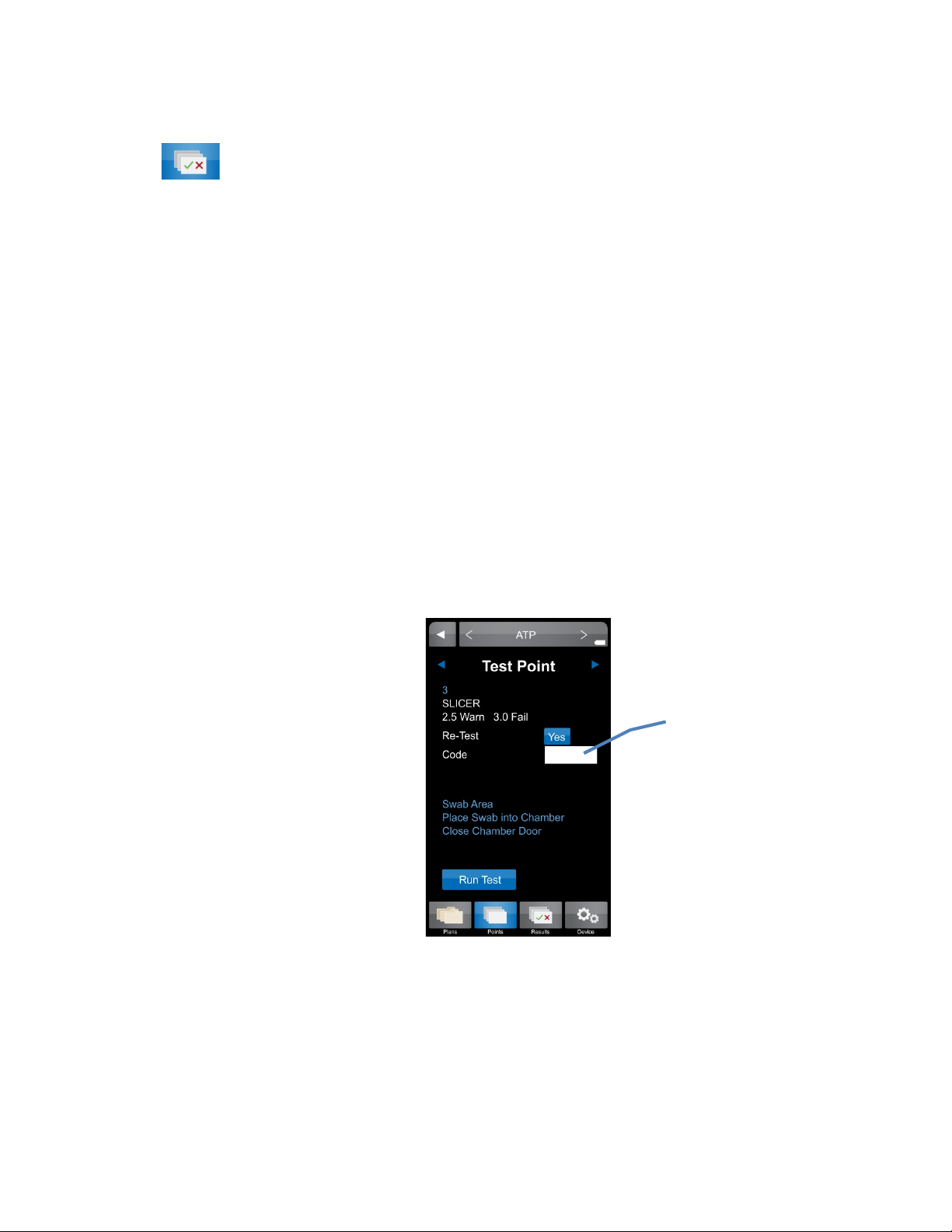

RE-TEST FUNCTION 16

RE-TESTS ....................................................................................................................................................... 16

HOW TO RE-TEST A SAMPLE .............................................................................................................................. 16

CHAPTER 10:

QUICK TEST FUNCTION 17

QUICK TESTS .................................................................................................................................................. 17

TAKE A QUICK TEST .......................................................................................................................................... 17

LOCATE A QUICK TEST RESULT ON THE ICON ........................................................................................................ 17

CHAPTER 11:

CODE FIELD 18

CODE FIELD .................................................................................................................................................... 18

ENTERING A CODE ........................................................................................................................................... 18

VIEWING A CODED RESULT ................................................................................................................................ 18

CHAPTER 12:

CUSTOM FIELDS 19

CUSTOM FIELDS .............................................................................................................................................. 19

VIEWING CUSTOM FIELDS ON THE ICON .............................................................................................................. 19

CHAPTER 13:

CALIBRATION / VERIFICATION 20

CALIBRATION .................................................................................................................................................. 20

ATP .............................................................................................................................................................. 20

PH ................................................................................................................................................................ 22

TEMPERATURE ................................................................................................................................................ 22

CONDUCTIVITY ................................................................................................................................................ 22

CONCENTRATION ............................................................................................................................................. 23

CHAPTER 14:

MVP ICON DASHBOARD SOFTWARE AT A GLANCE 24

INTRODUCTION ............................................................................................................................................... 24

SYSTEM REQUIREMENTS ................................................................................................................................... 24

CHAPTER 15:

INSTALLATION 25

INSTALLING THE MVP ICON DASHBOARD SOFTWARE ............................................................................................ 25

USB DRIVER INSTALLATION FOR VISTA ................................................................................................................ 25

CHAPTER 16:

DASHBOARD 26

WHAT IS THE ICON DASHBOARD? ...................................................................................................................... 26

ATP SWABS TO TARGET WIDGET ........................................................................................................................ 27

II

Page 4

SETTING ATP SWAB TARGET ............................................................................................................................. 27

ATP RE-TESTS WIDGET .................................................................................................................................... 27

SETTING ATP RE-TEST TARGET .......................................................................................................................... 27

NEXT CALIBRATION WIDGET .............................................................................................................................. 28

SETTING THE CALIBRATION FREQUENCY TARGET .................................................................................................... 28

DEVICE EXCLUSION LIST .................................................................................................................................... 28

ATP FAIL RATE GRAPH ..................................................................................................................................... 29

ATP RE-TEST RATE GRAPH ............................................................................................................................... 29

ATP PASS/WARN/FAIL RATE GRAPH .................................................................................................................. 30

CUSTOMIZING DASHBOARD GRAPHS ................................................................................................................... 30

CHAPTER 17:

CREATING TEST POINTS 31

ABOUT CREATING TEST POINTS .......................................................................................................................... 31

ATP TEST POINTS ............................................................................................................................................ 31

PH TEST POINTS .............................................................................................................................................. 32

TEMPERATURE TEST POINTS .............................................................................................................................. 32

CONDUCTIVITY TEST POINTS .............................................................................................................................. 32

CHEMICAL STANDARDS ..................................................................................................................................... 33

CONCENTRATION TEST POINTS ........................................................................................................................... 33

EDITING A TEST POINT ...................................................................................................................................... 34

TO EDIT A TEST POINT ...................................................................................................................................... 34

DELETING A TEST POINT .................................................................................................................................... 34

CHAPTER 18:

CREATING CUSTOM FIELDS 35

ASSIGNING CUSTOM FIELDS ............................................................................................................................... 35

CHAPTER 19:

CREATING SAMPLE PLANS 36

ABOUT SAMPLE PLANS ..................................................................................................................................... 36

CREATING A SAMPLE PLAN ................................................................................................................................ 36

ASSIGNING TEST POINTS TO A SAMPLE PLAN ......................................................................................................... 36

VIEWING ASSIGNED TEST POINTS IN A SAMPLE PLAN .............................................................................................. 36

EDITING OR DELETING A SAMPLE PLAN ................................................................................................................ 37

MVP COLLECTIONS ......................................................................................................................................... 37

CREATING AN MVP COLLECTION ........................................................................................................................ 37

EDITING OR DELETING AN MVP COLLECTION ........................................................................................................ 37

CHAPTER 20:

ICON SOFTWARE REPORT SETUP 38

REPORT SETUP MENU ...................................................................................................................................... 38

REPORT TYPE .................................................................................................................................................. 38

DATE RANGE .................................................................................................................................................. 38

COMPUTED DATA ............................................................................................................................................ 39

CHART TYPE ................................................................................................................................................... 39

CREATED BY ................................................................................................................................................... 39

DESCRIPTION .................................................................................................................................................. 39

TEST POINT TYPE ............................................................................................................................................. 39

TEST POINT SET SELECTION ............................................................................................................................... 39

SAVED REPORT ................................................................................................................................................ 40

COMPANY LOGO ............................................................................................................................................. 40

PRINT FUNCTION ............................................................................................................................................. 40

III

Page 5

CHAPTER 21:

ACTION REPORTS 41

WHAT ARE ACTION REPORTS? ........................................................................................................................... 41

TYPE OF ACTION REPORTS ................................................................................................................................. 41

FAIL RATE REPORT ........................................................................................................................................... 41

PASS/WARN/FAIL REPORT ................................................................................................................................ 42

RE-TEST REPORT ............................................................................................................................................. 43

MIN/MAX/AVERAGE REPORT ............................................................................................................................ 44

SORTING GRAPHS AND DATA TABLES ................................................................................................................... 44

ZOOM FUNCTION ............................................................................................................................................ 44

CHAPTER 22:

TRENDING REPORTS 46

WHAT ARE TRENDING REPORTS? ........................................................................................................................ 46

SORTING OPTIONS ........................................................................................................................................... 46

GROUPED DATA .............................................................................................................................................. 47

TYPE OF TRENDING REPORTS ............................................................................................................................. 47

PASS/WARN/FAIL SUMMARY ............................................................................................................................ 47

AVERAGE TEST POINT SUMMARY ........................................................................................................................ 48

TEST POINT TREND .......................................................................................................................................... 49

RE-TEST TREND ............................................................................................................................................... 51

CHAPTER 23:

HACCP REPORTS 53

WHAT ARE HACCP REPORTS? ........................................................................................................................... 53

TYPE OF HACCP REPORTS ................................................................................................................................ 53

ATP SWAB USAGE ........................................................................................................................................... 54

CALIBRATION / VERIFICATION............................................................................................................................. 54

TEST POINT FREQUENCY ................................................................................................................................... 55

SAMPLE PLAN SUMMARY .................................................................................................................................. 56

CHAPTER 24:

RAW DATA 57

SORTING ........................................................................................................................................................ 57

VIEWING RESULTS BY SAMPLE PLAN .................................................................................................................... 57

PRINTING DATA ............................................................................................................................................... 57

EXPORTING DATA TO EXCEL OR LIPS PROGRAM .................................................................................................... 57

CONVERTING QUICK TESTS INTO A NEW TEST POINT .............................................................................................. 58

ANALYZING MVP COLLECTION DATA .................................................................................................................. 60

HOW TO ANALYZE DATA MVP COLLECTIONS IN RAW DATA .................................................................................... 60

PRINTING MVP COLLECTIONS ............................................................................................................................ 60

CHAPTER 25:

DEVICE COMMUNICATION 61

SYNCING THE ICON TO A DATABASE .................................................................................................................... 61

COMMUNICATION SCENARIOS ............................................................................................................................ 62

DELETING TEST POINTS FROM DATABASE ............................................................................................................. 63

RE-USING A DELETED TEST POINT ........................................................................................................................ 63

IV

Page 6

CHAPTER 26:

DATABASE MANAGEMENT 64

CREATING AN ICON DATABASE .......................................................................................................................... 64

IMPORTING AN ICON DATABASE ........................................................................................................................ 64

IMPORTING DATA FROM MVP TRAX .................................................................................................................. 64

ARCHIVING A DATABASE .................................................................................................................................... 65

EXPORTING TO EXCEL ....................................................................................................................................... 66

EXPORTING TO CSV ......................................................................................................................................... 66

EXPORTING TO LIP PROGRAM ............................................................................................................................ 66

IMPORTING FROM EXCEL ................................................................................................................................... 67

CHAPTER 27:

ICON SETUP 68

PREFERENCES .................................................................................................................................................. 68

CHANGING SCREEN TIMING SETTINGS ................................................................................................................... 68

PASSWORDS ................................................................................................................................................... 69

DELETE RESULTS FROM ICON VIA SOFTWARE ....................................................................................................... 69

FASTENING THE ICON SHOULDER STRAP.............................................................................................................. 70

CHAPTER 28:

ICON SOFTWARE SETTINGS 71

PREFERENCES .................................................................................................................................................. 71

USER INFO ..................................................................................................................................................... 71

HELP ............................................................................................................................................................. 73

CHAPTER 29:

TROUBLESHOOTING 74

MVP ICON INSTRUMENT ERROR MESSAGES........................................................................................................ 74

MVP ICON INSTRUMENT ................................................................................................................................. 76

MVP ICON SAMPLING DEVICES ........................................................................................................................ 76

MVP ICON PH/TEMPERATURE PROBE ............................................................................................................... 77

MVP ICON TEMPERATURE PROBE ..................................................................................................................... 78

MVP ICON CONDUCTIVITY PROBE ..................................................................................................................... 78

CHAPTER 30:

APPENDIX A SOFTWARE / FIRMWARE UPDATE PROCEDURE 79

DASHBOARD SOFTWARE UPDATE ........................................................................................................................ 79

ICON FIRMWARE UPDATE ................................................................................................................................ 79

CHAPTER 31:

APPENDIX B SOFTWARE / FIRMWARE DOWNGRADE PROCEDURE 80

FIRMWARE DOWNGRADE PROCEDURE ................................................................................................................. 80

V

Page 7

Introduction

The LIGHTNING MVP ICON™ is a multi-parameter HACCP monitoring system to monitor key

quality indicators such as ATP, pH, temperature, conductivity, and concentration. The included

MVP ICON Dashboard software allows for easy trending and analysis of results. The software’s

dashboard provides an overview of key control metrics at a glance.

Below is a description of each of the parameters measured by the MVP ICON.

ATP

Adenosine triphosphate (ATP) is present in all living cells including food residues, bacteria, yeast

and molds. Testing for ATP is highly useful as an indicator of cleaning verification within a food

manufacturing facility. Detecting its presence indicates a surface or liquid contains organic

matter. If ATP is present, the potential exists for contamination of food or beverages coming into

contact with the surface or liquid containing ATP. Surfaces contaminated with ATP lead to issues

with product quality and pose a threat to public health.

pH

Monitoring the pH of foods is a vital step in producing a safe, quality product. Maintaining the

appropriate pH level is an important factor in food manufacturing as pH is often related to the

physical and chemical reactions that take place during production.

Temperature

Certain manufacturers produce foods that require the product to maintain a specific temperature

during the production process. Monitoring temperature prevents products from allowing certain

organisms to grow and thrive, therefore contaminating the product and leading to public health

and product quality issues.

Conductivity

Conductivity, measured in microSiemens (µS), is a material’s ability to conduct an electrical

current.

Concentration

Accurately measuring cleaner and sanitizer concentrations is a crucial element to protecting food

quality. Excessively high concentrations of chemicals are costly and can lead to the damage of

equipment, product, and potentially harm operators in contact with the solution. If a chemical’s

concentration is too low, it can allow for the potential growth of pathogenic organisms leading to

public health and product quality issues.

1

Page 8

Materials and Equipment

The LIGHTNING MVP ICON is a multi-parameter HACCP monitoring system. The MVP ICON

utilizes accessory probes and sampling devices to measure and record key HACCP parameters

including ATP, pH, temperature, conductivity, and concentration. The included MVP ICON

Dashboard software allows for easy trending and analysis of results. The software’s dashboard

provides an overview of key control metrics at a glance.

Included in the Box

• MVP ICON instrument

• MVP ICON Dashboard software CD

• USB cable

• AC adapter (US)

• International adapters

• Shoulder strap

ATP Supplies (Purchased Separately)

• LIGHTNING MVP ICON Surface Sampling Device - for detection of ATP on surfaces

• LIGHTNING MVP ICON Liquid Sampling Device - for detection of ATP in Clean in Place

(CIP) rinse water and other liquid samples

• LIGHTNING MVP ICON ATP Calibrator Set – for calibration and verification of the ICON

instrument for accurate detection of ATP

• LIGHTNING MVP ICON ATP Positive Control – a lyophilized, stable preparation of a known

concentration of ATP for routine verification of the ICON system’s performance

Conductivity and Concentration Supplies

• ICON Conductivity Probe - for measuring conductivity of liquids and determining

chemical concentration of sanitizers and cleaners

• Conductivity Standard (500 µs) – for calibration of ICON Conductivity Probe

pH Supplies

• ICON pH Probe – for measuring pH and temperature of solutions

• pH Calibration Standards (pH 4.00, pH 7.00, and pH 10.00) – for calibration of ICON pH

Probe

Temperature Supplies

• ICON Temperature Probe – for measuring product temperatures

Charging the MVP ICON

To charge the MVP ICON battery, use the provided adaptor and plug into a wall outlet. The

battery will take approximately 2 – 4 hours to fully charge to 100%.

Charging Best Practices

• Utilize the ICON until the instrument displays Code 11 – Low Battery, then charge to

100% via the wall outlet.

• Do not leave the ICON plugged into the wall outlet overnight. Doing so will overcharge

the battery and shorten its lifespan.

NOTE: The MVP ICON battery will not charge from a computer via a USB connection. This will

utilize more battery power, potentially draining the charge.

2

Page 9

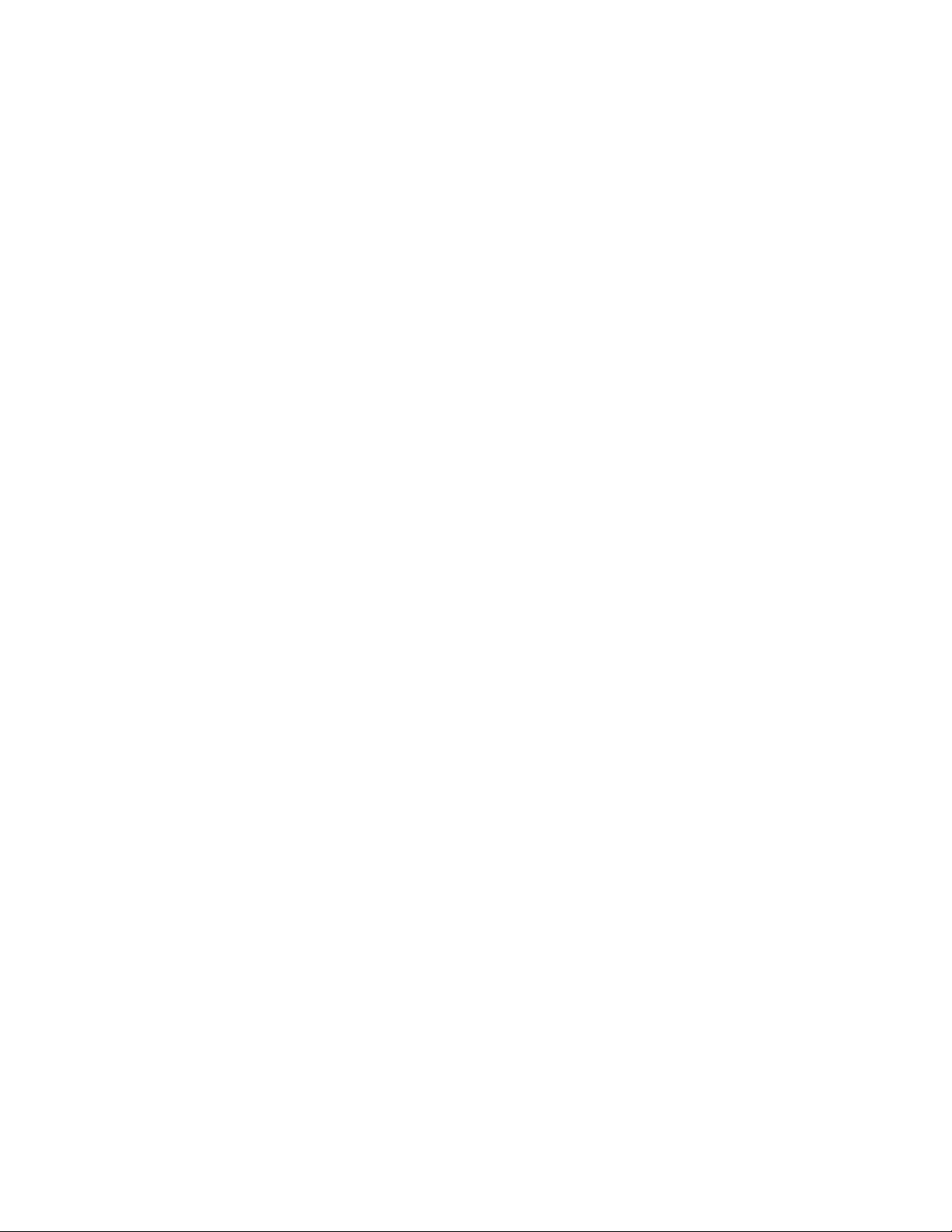

MVP ICON at a Glance 1

Battery Indicator

Instrument Overview

Home Screen and Navigation

The MVP ICON features a pressure-sensitive color touch screen display that can be operated

while wearing gloves and is suitable for use under all lighting conditions.

The home screen of the ICON lists pertinent statistics about the unit based on the parameter

selected, including:

• Number of test points, sample plans, and results stored on the instrument

• Available memory

• Serial number

• Date of last ATP calibration

• Last date of upload to ICON software

• Available battery charge

The parameter selection bar at the top of the screen is used to select the desired parameter

(ATP, pH, Temperature, Concentration, or Conductivity) for taking new readings or viewing

stored results.

3

Page 10

The buttons on the bottom of the screen are used to access the following functions:

Switch between

Move back

Access a list of sample plans,

change instrument settings

• Plans – allows the user to select a specific sample plan

• Points – allows the user to select a specific test point

• Results – provides a list of recorded results for each test point

• Device – provides access to the instrument specific settings including screen brightness,

volume, language, date and time, deleting results, and calibration

one screen

measurement

parameters

test points, results, or

To preserve battery life, the ICON screen will automatically dim after one minute of inactivity and

turn dark after two minutes. To awaken the instrument, simply touch the screen or power

button. After five minutes of inactivity the ICON will completely shut down (

See Chapter

customizing these settings).

C

alibrating the Touch Screen

It is recommended to calibrate the touch screen, should it freeze or become difficult to navigate.

Connect the MVP ICON to the Dashboard software.

• Select ICON Setup from the top toolbar menu

• Select “Calibrate Display”

• The ICON instrument will then enter its screen calibration mode

• Follow the prompts on the screen, ensuring to touch the tip of each arrow for the most

precise and accurate calibration.

Note: Calibrating the touch screen requires precisely touching specific areas of the screen. This

procedure should be performed using the blunt end of a pen, an ICON sampling device, or similar

stylus-like object.

Self-Diagnostic

When the ICON is powered on, the instrument will perform a 45-second self-diagnostic and

record a baseline reading. The chamber must be empty during the initial start-up procedure.

25 for

4

Page 11

Quick Test

Test point name

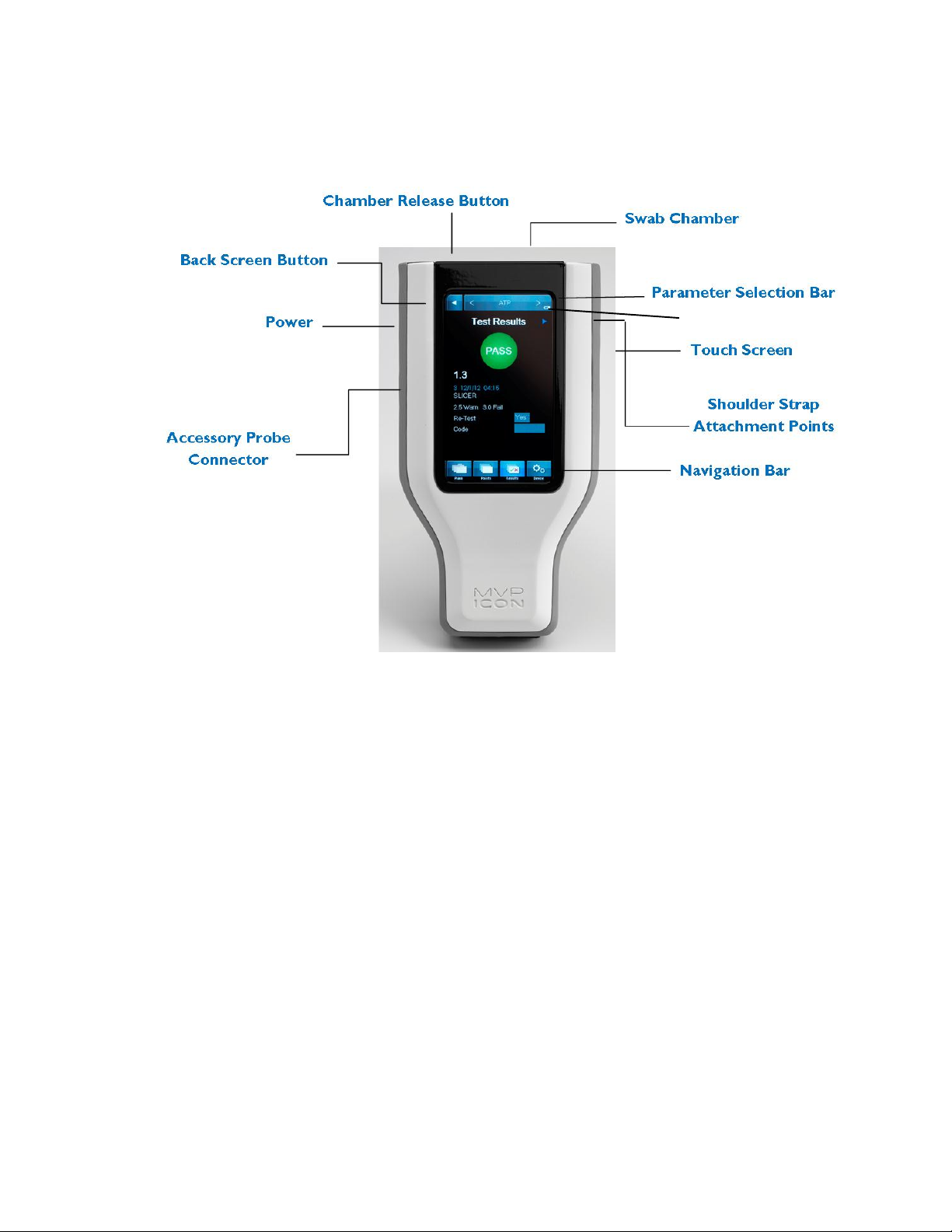

Points 2

Points

The “Points” tab on the bottom menu of the ICON contains a list of all created test points in

numerical order, independent of sample plan assignment.

Selecting a Test Point

• Scroll through a list of test points in numeric order using the scroll bar on the right side of

the screen.

Search for a specific

test point

Test point number

Further details for each test point can be found by selecting the desired test point.

Test point number, name,

and Warn/Fail thresholds

Instructions for

inserting swab

Press to run

sample

5

See Chapter 8

Scroll Bar

Total number of test

points assigned

Re-Test

See Chapter 7

Code

See Chapter 9

Page 12

Finding a Test Point

If a test point (or range of test points) is not readily available on the instrument screen, the

“Find” feature within “Points” can be used to search for specific test points.

• To search for a range of test points enter the first and last test point number in the

range.

• To search for a single test point enter the test point number as the beginning of the

range and leave the end of the range blank.

Note: To clear a field entry, press the “X” next to the associated field.

• The < and > buttons on the bottom of the key pad will clear entries or tab to the next field.

Enter individual test

point number or range

Use these buttons to

clear entries or tab

to next field

6

Page 13

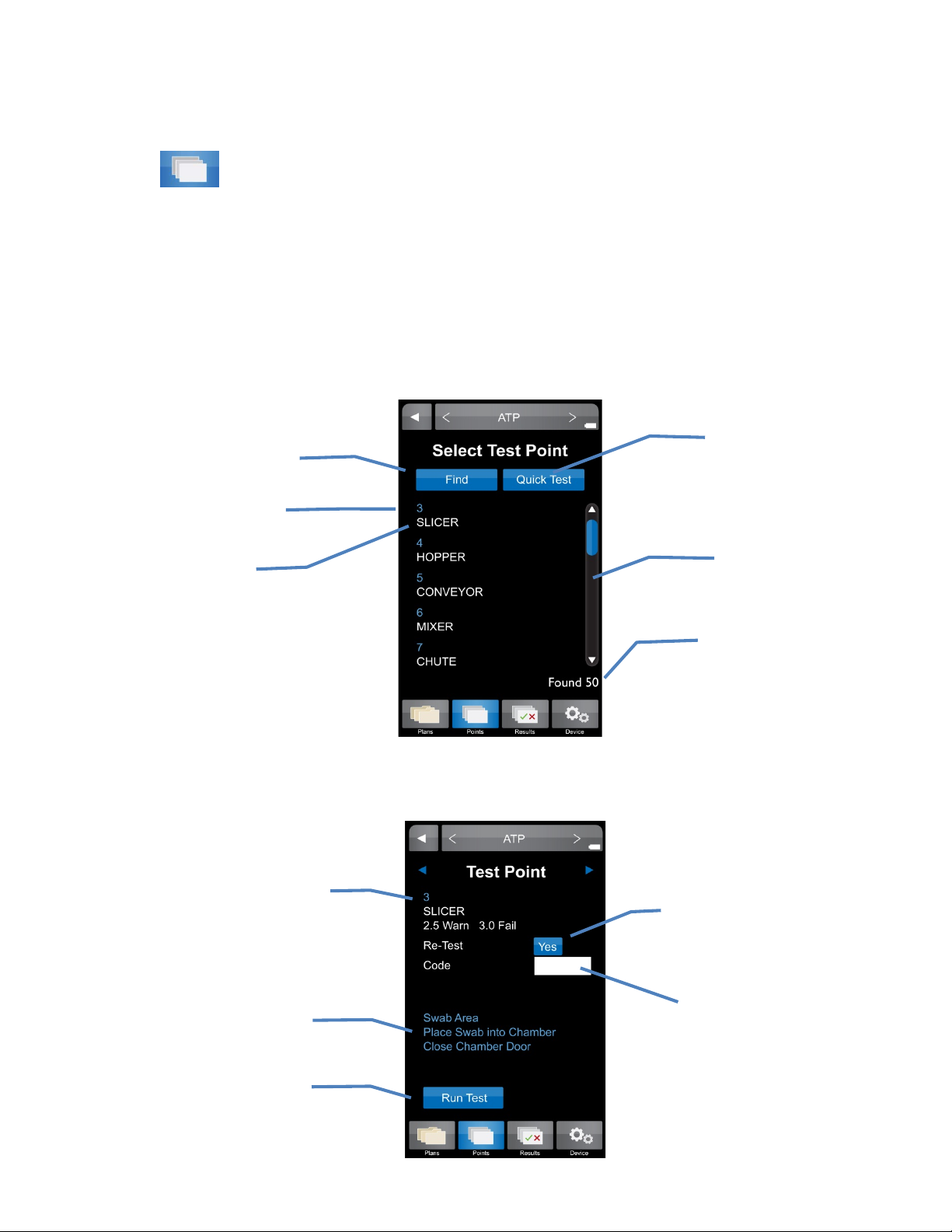

Plans 3

List of

Number of available

Number of test points assigned

Plans

To view a list of available sample plans for a desired parameter, select the “Plans” tab on the

bottom menu of the ICON instrument. Sample plans are a customized grouping of test points. A

sample plan can represent a group of test points in a particular production area, direct versus

indirect locations, or even a work shift or day of the week. Sample plans are listed by name and

include the number of assigned test points in each plan.

sample plans

Selecting a Sample Plan

• To select a particular sample plan, lightly press on the desired sample plan name.

• Once selected, a list of test points will be displayed in numeric order. Select desired test

point and proceed with taking a reading.

Sample Plan Tracker

The progress of testing within a sample plan is automatically tracked on the MVP ICON display.

Each time a test point is sampled within a plan, a correlating colored result appears next to the

test point. This visual indicator not only identifies which test point has been tested within the

plan, it also serves as identification for which test points require re-cleaning and re-testing (warns

and/or failed results). Once a point has been tested within an individual sample plan, a blue

rectangle appears next to the sample plan name on the main “Plans” menu.

The progress of multiple sample plans is automatically and simultaneously tracked. To clear the

progress of an individual sample plan, simply press “Reset Plan” from within the individual plan’s

display. To clear the progress of all tracked plans, press “Reset All Plans” from the main “Plans”

menu.

to sample plan

Scroll bar

sample plans

7

Page 14

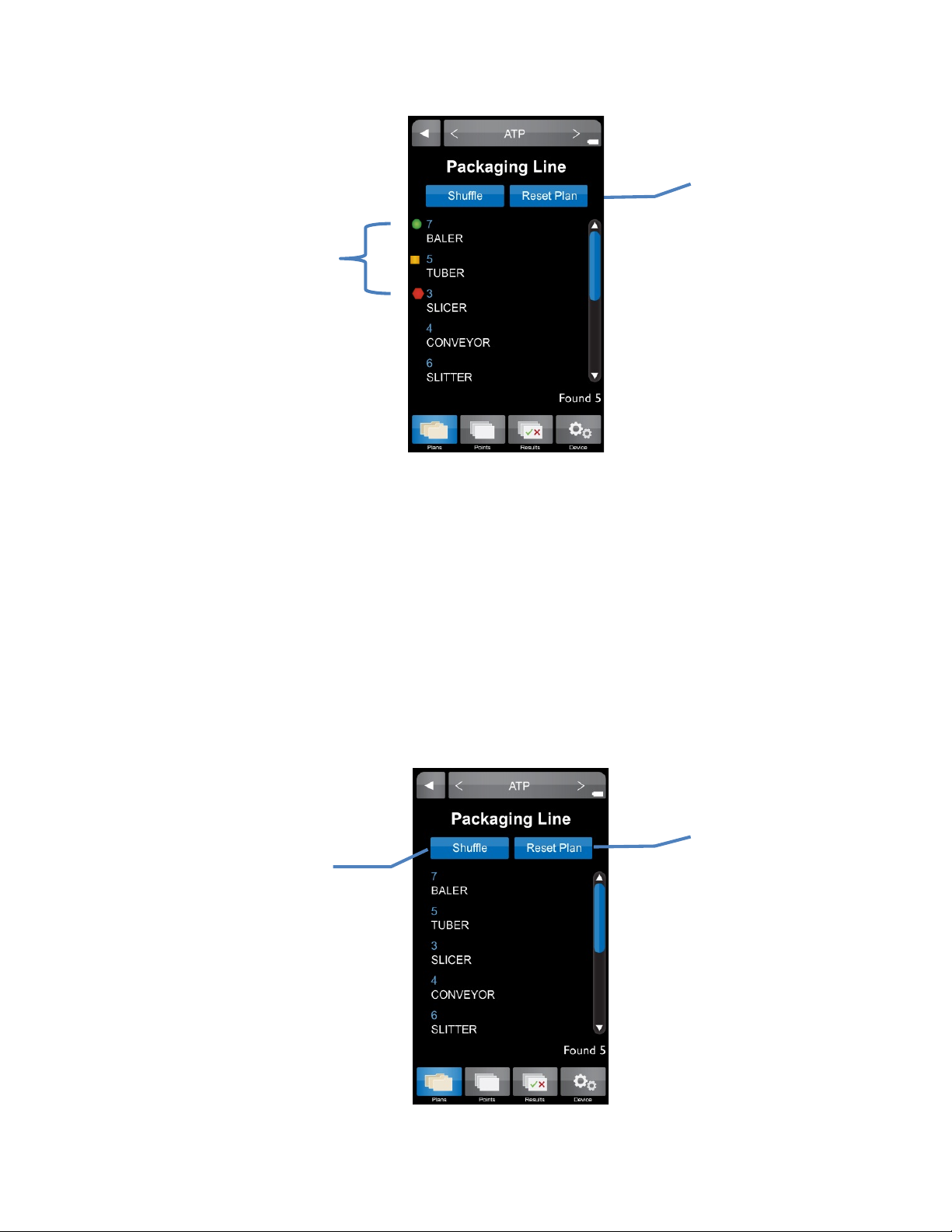

Press to shuffle

test points

Green indicates

Shuffle

The order of test points within a sample plan can be randomized or “shuffled.” This feature can

be used to ensure that all test points have an equal probability of being tested. To shuffle test

points:

a pass result,

yellow for warn,

red for fail

• Select the desired sample plan (as described above).

• Press the blue “Shuffle” button located above the test point list.

• Select first test point in newly shuffled list and proceed to taking test.

• To reset the test points in the plan back to numeric order, press the “Reset Plan” button

located next to “Shuffle”.

Press to clear the

tracker’s progress for

an individual plan

Press to restore test

points to original order

8

Page 15

Test point name

Use scroll bar to move

through list of results

Visual indicator of result

Test point number,

Test point name

Test point thresholds

Re-test

See Chapter 7

Next test point

Previous test point

date, and time of result

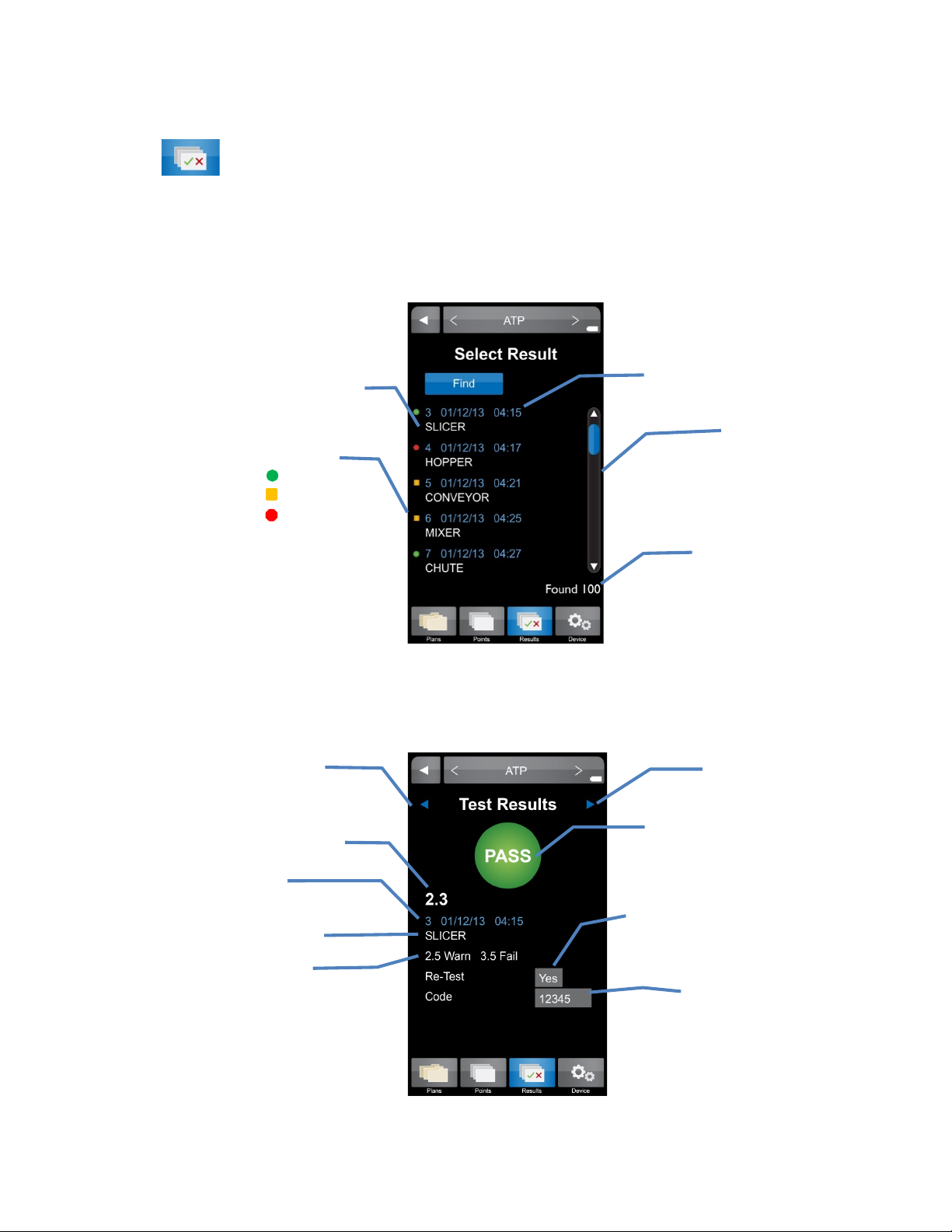

Results 4

Results

To view a list of stored results for the desired parameter select the “Results” tab on the bottom

menu of the ICON instrument. Results are listed in numeric order by test point number and the

most recent result for each test point is displayed.

Further details for each result can be found by selecting the desired test point.

Pass

Warn

Fail

MVP ICON reading

Test point number, date

and time of result

Total number of

results found

Result

Code

See Chapter 9

9

Page 16

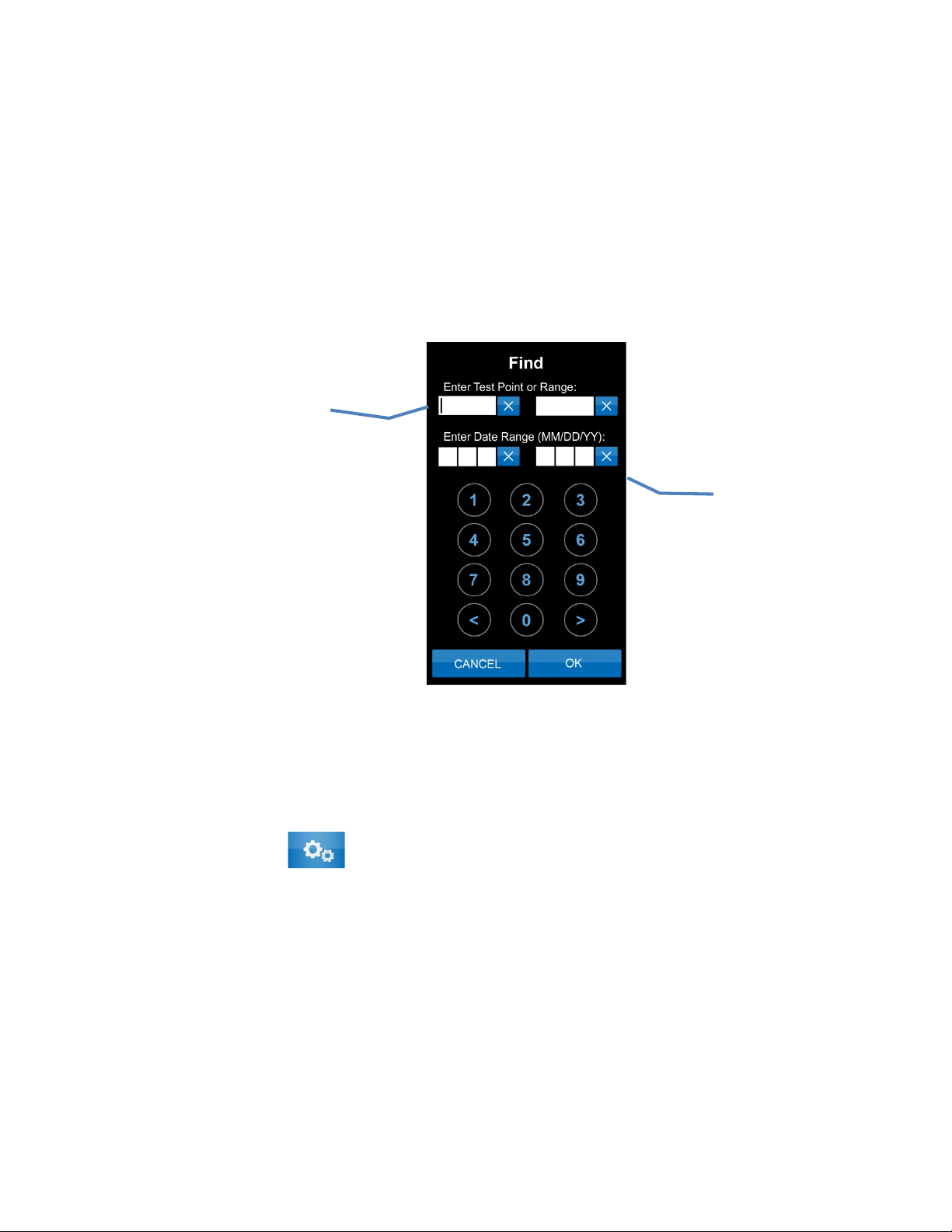

Finding Results

To search for a specific result or range of results touch the “Find” button at the top of the

“Results” screen.

• To search for a range of test points enter the first and last test point number in the

range.

• To search for a single test point enter the test point number as the beginning of the

range and leave the end of the range blank.

• To search for results from a specific date range enter the beginning and ending dates for

the range.

• To search for results from a specific day enter the desired date as the beginning of the

range and leave the ending date blank.

Search for individual

or range of test

points

Search for single

day or range of

dates

Deleting Results

Results can be deleted directly from the MVP ICON instrument using the delete function found in

the “Device” tab. (See Chapter

5 for more details)

10

Page 17

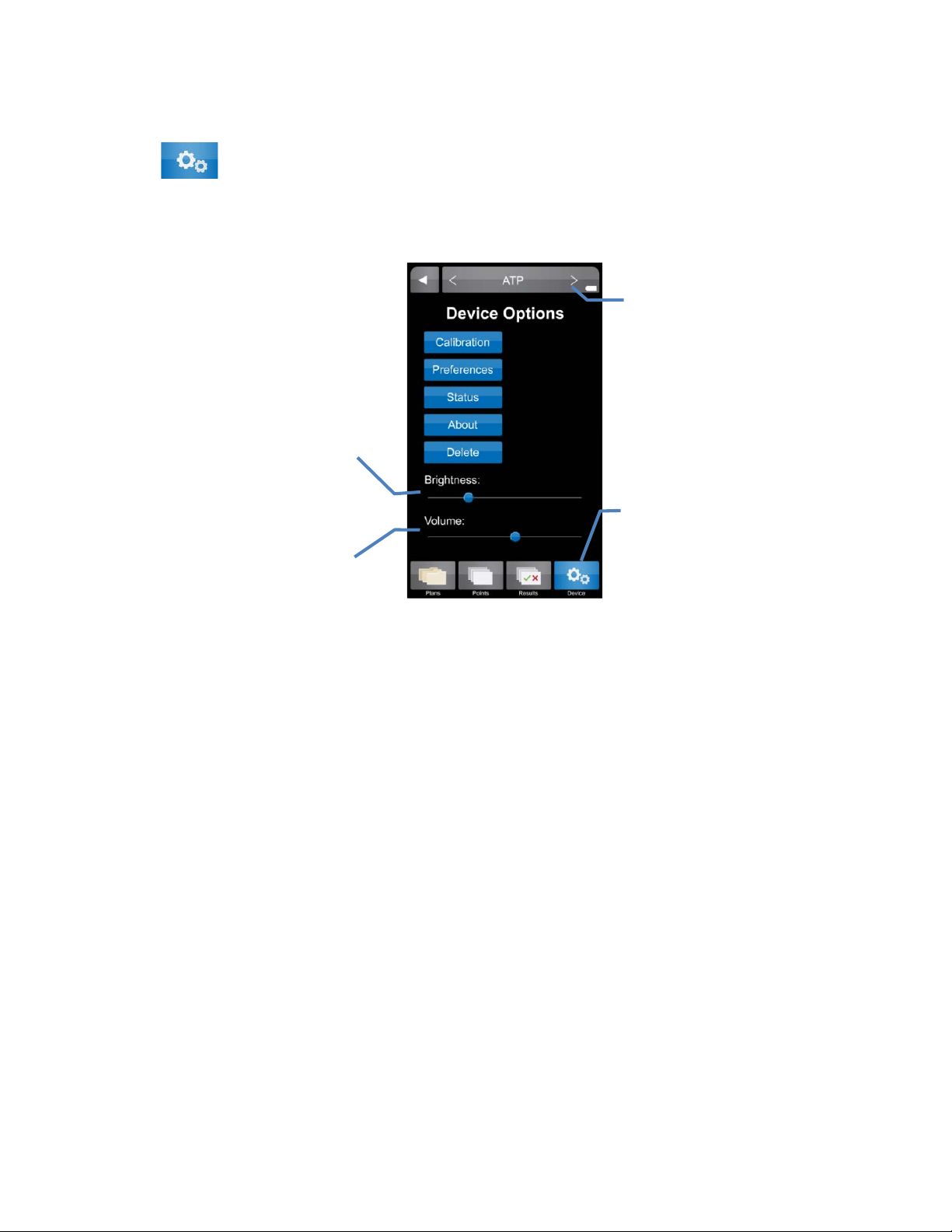

Device 5

Adjust display

brightness

Adjust audible

Device

Device settings for the ICON can be accessed by selecting the “Device” tab at the bottom of the

ICON screen.

alert volume

Calibration

Allows for calibration of the MVP ICON for the specific parameter selected (ATP, pH,

Temperature, Conductivity, or Concentration; See Chapter

11).

TP parameter includes procedures for system verification using LIGHTNING MVP ICON ATP

A

Positive Control and LIGHTNING MVP ICON Calibrator Set (see Chapter 11).

Preferences

Allows user to customize the language, date, time, temperature and RLU display

• Time – Time can be displayed in either a 12-hour (2:00 PM) or 24-hour format (14:00).

• Date – Date can be displayed as either Month/Day/Year or Day/Month/Year.

• Language – The following languages are available for the MVP ICON: English, French,

Spanish, German, and Portuguese.

• Show RLU – ATP results are displayed as Zones of Cleanliness; results can also be

displayed as Relative Light Units or RLU’s.

• Temperature – Temperature can be displayed as either °F or °C.

Status

Includes diagnostic information used to troubleshoot the instrument such as:

• Sample Chamber door status (open/closed)

• Charger status (battery/AC)

• Battery voltage

Change selected

parameter

Access Device

settings

11

Page 18

About

Displays instrument specific information:

• Serial number

• Hardware version

• Firmware version

Delete

Allows user to delete result for the selected parameter (optional password protection)

Results can be deleted as:

• Individual results

• A group of specific test points

• Results from a specific date range

To Delete a Result

• From the “Device” menu, select “Delete”. Ensure the device displays the desired

parameter.

• Search for result or range of results to delete in same manner as “Results” menu (

see

Chapter 4).

hen individual or range of results has been selected, press “Delete”.

• W

• A warning will appear to ensure user wishes to proceed.

• Select “Yes” to continue or “No” to return to previous screen.

• If “Yes” is selected the optional password screen will appear (if required).

• Enter correct password to delete results.

• The screen will validate results have been deleted.

Note: The ICON screen will freeze until results are deleted. A confirmation screen will indicate the

desired results were deleted.

Search for individual or

range of results

Press to delete results

Number of results

12

Page 19

Taking a Reading 6

TAKING AN ATP READING

Swab surface

Activate swab

Insert activated

swab into ICON

Select test point or

quick test

Result displayed

1 2356

Figure 1

Insert swab with

left and right

4

ATP

• Select “ATP” mode in the top menu bar from any screen. Use < or > arrows to toggle

through modes.

• Select “Points” from the bottom icon menu

• Select desired test point or use the scroll bar to scroll through the list of available test

points.

Note: To locate a test point not currently displayed, please reference Chapter 2 – “Finding

a Test Point”.

• At the “Test Point” screen, designate if sample is a “Re-Test” (

• Enter an optional customized code (

see Chapter

9)

see Chapter

7).

• Follow the directions in blue to swab the area and insert the sampling device.

Note: When inserting a sampling device into the MVP ICON, ensure the flat

sides of the swab chamber face left to right. Do not force the sampling

device into the MVP ICON (see Figure 1).

• Press “Run Test”

• Screen will show “Test in Progress” with a countdown to completion.

Note: Please reference the Directions for Use included with the LIGHTNING

MVP ICON Surface or Liquid Sampling Devices for additional information.

two flat sides facing

13

Page 20

pH

Please reference the Directions for Use included with the ICON pH Probe for preparation of the

probe prior to use.

• Ensure the ICON pH Probe is properly connected to the side of the device (probe adapter

surface with arrows should face the back of ICON).

• Select “pH” mode in the top menu bar from any screen. Use < or > arrows to toggle

through modes.

• Select “Points” from the bottom icon menu.

• Select desired test point or use the scroll bar to scroll through the list of available test

points.

• Designate if the sample is a “Re-Test” (

• E

nter an optional customized code (see Chapter 9).

see Chapter

7).

• Follow the directions in blue for inserting probe into sample.

• Press “Run Test”.

Note: Squeeze sides of probe adapter to release and disconnect from ICON.

Temperature

Please reference the Directions for Use included with the ICON Temperature Probe for proper

technique and cleaning of the probe prior to use.

• Ensure the ICON Temperature Probe is properly connected to the side of the device

(probe adapter surface with arrows should face the back of ICON).

• Select “Temperature” mode in the top menu bar from any screen. Use < or > arrows to

toggle through modes.

• Select “Points” from the bottom icon menu.

• Select desired test point or use the scroll bar to scroll through the list of available test

points.

• Designate if the sample is a “Re-Test” (

see Chapter

7).

• Enter an optional customized code (see Chapter 9).

• Follow the directions in blue for inserting probe into sample

• Press “Run Test”.

Note: Squeeze sides of probe adapter to release and disconnect from ICON.

Conductivity

Please reference the Directions for Use included with the ICON Conductivity Probe for

preparation of the probe prior to use.

• Ensure the ICON Conductivity Probe is properly connected to the side of the device

(probe adapter surface with arrows should face the back of ICON).

• Select “Conductivity” mode in the top menu bar from any screen. Use < or > arrows to

toggle through modes.

• Select “Points” from the bottom icon menu.

• Select desired test point or use the scroll bar to scroll through the list of available test

points.

• Designate if the sample is a “Re-Test” (see Chapter 7).

nter an optional customized code (see Chapter 9).

• E

• Follow the directions in blue for inserting probe into sample.

• Press “Run Test”.

Note: Squeeze sides of probe adapter to release and disconnect from ICON.

14

Page 21

Concentration

Please reference the Directions for Use included with the ICON Conductivity Probe for

preparation of the probe prior to use.

Before Taking a Concentration (ppm) Reading

Prior to taking a Concentration reading (ppm), it is important to ensure the chemical standard

assigned to each test point has been properly calibrated. Please see Chapter

11 – Calibration for

instructions on calibrating the chemical standard.

N

ote: A Concentration test point cannot be tested unless the chemical standard has been

calibrated and saved prior to taking the reading.

Taking a Concentration Reading

• Ensure the ICON Conductivity probe is properly connected to the side of the device

(probe adapter surface with arrows should face the back of ICON).

• Select “Concentration” mode in the top menu bar from any screen. Use < or > arrows to

toggle through modes.

• Select “Points” from the bottom menu.

• Select desired test point or use the scroll bar to scroll through the list of available test

points.

• Designate if the sample is a “Re-Test” (

nter an optional customized code (see Chapter 9).

• E

see Chapter

7).

• Follow the directions in blue for inserting probe into sample.

• Press “Run Test”.

Note: Squeeze sides of probe adapter to release and disconnect from ICON.

Note: The “Test Source Water” button, located next to “Run Test,” allows for source water to be

tested with each sample, should it vary from the source water used to prepare the calibrated

chemical standard. If the source water is similar to the chemical standard, it is not necessary to

the test the source water with each sample.

15

Page 22

Re-Test Function 7

Prior to Reading Sample

After Sample is Measured

Press to mark

or “No”

Press to mark

or “No”

Re-Tests

A test result for any of the MVP ICON parameters can be coded as a “re-test.” When testing for

ATP, areas that show high ATP readings should be re-cleaned and re-tested to verify adequate

cleaning. A test point can be coded as a re-test either at the time the sample was taken or at the

results screen.

How to Re-Test a Sample

• Select the desired test point through the “Points” or “Plans” menu options. Please refer

to Chapter 6 for taking an initial reading.

• To designate the test point is a re-test before the sample is measured, press the blue

button next to “Re-Test” until “Yes” appears.

• To indicate a re-test after the sample was taken, press the button next to “Re-Test” at

the “Test Results” screen.

re-test as “Yes”

re-test as “Yes”

16

Page 23

Quick Test Function 8

Quick Tests

The Quick Test function on the ICON allows for a test measurement to be taken without saving

the results to a test point. This can be useful for training or other instances where saving test

results is not needed. However, users have the option of saving results and converting to

assigned test points once the data is updated to the ICON Dashboard software.

See Chapter

Test feature and convert into an assigned test point.

T

ake a Quick Test

• Select “Points” from the lower ICON menu.

• At the “Select Test Point” screen, press the “Quick Test” button at top in blue.

• Enter Quick Test password, if applicable.

• At the “Test Point” screen, the Quick Test can be coded as a “Re-Test” with optional

• Follow screen directions to swab area and insert swab in chamber.

• Press “Run Test”.

• Press “Save” to save Quick Test results onto the unit or “Discard” to return to the prior

Locate a Quick Test Result on the ICON

The newly saved Quick Test result can now be located under “Results” from the lower ICON

menu in three different ways:

• Scroll to the bottom of the results menu.

• Select “Find” and enter test point or test point range.

• Select “Find” and enter date or date range.

22 – ICON Instrument Setup for instructions on how to password protect the Quick

Note: Quick Test can only be taken from the “Points” menu and is applicable for all

parameters.

Note: If a Quick Test password was not enforced via the ICON Software, user will be

guided directly to “Test Point” screen.

customized code (

N

ote: Quick Test can also be labeled as a re-test after the sample has been measured.

screen.

see Chapters

7 and 9, respectively).

17

Page 24

Code Field 9

Enter a customized

Code Field

The “Code” field on the ICON is a place to enter additional identifying information about an

assigned test point into the instrument at the time of testing. For example, a numeric code could

be entered prior to taking a sample to identify a particular sanitation worker, product, or location

within the facility not previously identified during test point setup in the software. The code field

on the ICON is a numeric value only. Any meaning correlating to this code should be documented

separately for reference.

Entering a Code

Codes are entered after a test point has been selected, either through “Points” or “Plans” and

must be entered prior to measuring the sample.

• Select desired test point via “Points” or “Plans”.

• At the “Test Point” screen, locate the “Code” field and lightly press the white box .

• Enter the desired code, up to 4 digits.

Note: This field is not password protected. Any 1 – 4 digit code can be entered on this

screen.

• The code will now be populated in the “Code” field and will be associated with that

particular result.

Viewing a Coded Result

• Any test point with an assigned code can be viewed in the “Results” section of the ICON

menu.

• Coded results are also available in “Raw Data” within the ICON Software, once uploaded

(see Chapter

20 – Raw Data for more information).

code here

18

Page 25

Custom Fields 10

Custom Fields

“Custom Fields” present another opportunity to enter customized information about test points

and are established within the ICON Software. The three custom fields can be populated with

information such as a test point’s associated product, location within the facility (ex. Room 3),

and the type of surface being sampled (ex. Stainless Steel).

Please see Chapter 15 – Creating Test Points for more information on setting up “Custom Fields”

within the ICON Software.

iewing Custom Fields on the ICON

V

• Select desired test point via “Points” or “Plans”.

• All custom field entries for the assigned test point will be displayed directly below the

• Custom field designations are also available in “Raw Data” within the ICON Software,

Custom

Field

entries

“Code” field prior to measuring the sample.

once uploaded.

19

Page 26

Calibration / Verification 11

Calibration

The MVP ICON’s parameters can be manually calibrated on-site to ensure the instrument is

working at its optimal performance. In addition, the ATP calibration function also features

“Verification” which records and stores the positive and negative control readings for both the

sampling device and calibrator set.

ATP

The MVP ICON is calibrated at the factory; however, users should also calibrate the ICON prior to

first use. It is also recommended to run positive control verifications every other day and

calibrate when necessary. The calibration rods last for five years. The ICON is calibrated for ATP

using a standardized two-point calibration procedure. This function requires the LIGHTNING MVP

ICON Calibrator Set which includes the necessary luminescent and non-luminescent calibrators to

perform the operation.

To insert the calibration rod into the MVP ICON, hold the calibrator by the wider end with two

flat sides and insert the opposite end into the ICON. Ensure the flat sides of the calibrator’s base

chamber are facing left to right.

Calibration

• Ensure the device is in ATP mode.

• Select “Device” from the ICON’s lower menu.

• From the “Device Options” screen select “Calibration”; press “Calibrate”.

• Enter the Reference Value (found on the luminescent calibrator’s label).

• “Insert Luminescent Calibrator” and close the chamber door; press “Calibrate”.

• Remove luminescent calibrator, insert non-luminescent calibrator, close door and press

An error message will be displayed if results are not within the ICON’s specification. Typical

causes for failed calibration include: readings too high or low for the luminescent or nonluminescent calibrators, light leaks within the chamber, or a build-up of static. Refer to the

calibrator’s Directions for Use for additional information. For assistance, contact BioControl

Technical Support at 800.245.0113.

If successful, the date of calibration will appear on the ICON’s home screen and the record will

upload into the software database upon the next synchronization between the instrument and

software.

System or Swab Performance Verification

Verification is designed to ensure the instrument and swabs are working correctly. The

LIGHTNING MVP ICON ATP Positive Control provides a sample which produces a positive ATP

result when assayed with the MVP ICON system. It is recommended to run ATP Positive Controls

every other day and incorporate results into an overall Quality Control program.

Positive Control Procedure

Requires ATP Positive Controls

• Ensure instrument is in ATP mode.

• Select “Device” from the ICON’s lower menu.

“Calibrate”.

20

Page 27

• From “Device” screen select “Calibration”.

• Press the “Positive Control” button under the “Verification” menu in ATP Calibration

mode.

• Open the ATP Positive Control vial.

• Insert a LIGHTNING MVP ICON Surface Sampling Device and completely dissolve the

positive control pellet onto the tip of the swab.

Note: Take care to ensure the swab tip does not touch any surface other than the inside

of the vial.

• Activate the swab, insert into the chamber with swab chamber facing left to right, and

close the chamber door.

• Press “Verify” to run the verification.

The result for a positive control should read between 3.1 – 4.3 Zones.

• Results greater than 4.3 indicate a potential contamination of either the swab or positive

control. Re-test in duplicate and average the two results.

• Between 2.6 – 3.0 Zones, more thorough swabbing of the vial may be required.

• Below 2.6 Zones, ensure the device was properly activated. If device was activated

properly, it may indicate a problem with the instrument, device, or positive controls.

Repeat the test with a new vial of positive control and new sampling device.

• If verification fails again, calibrate the instrument and repeat verification with a new vial

of positive control and sampling device.

• If still out of range, contact BioControl Technical Support at 800.245.0113.

Negative Control Procedure

A negative control is an unused but activated swab.

• Press the “Negative Control” button under the Verification menu in ATP Calibration.

• Activate the swab, insert into the chamber with the swab chamber facing left to right,

and close the chamber door.

• Press “Verify” to run the verification.

The result for a negative swab should read between 1.0 – 2.5 Zones.

LIGHTNING MVP ICON Instrument Verification

To verify if the instrument is reading correctly, the luminescent and non-luminescent calibrators

are used.

The luminescent calibrator consists of a

14

C radioactive source which emits a very low level (5x105

d.p.m. or 0.225 microcuries) of low-energy β radiation in a plastic scintillating matrix. This matrix

is configured to provide a constant light output at a sufficiently high level in order to perform

consistent verification and calibration over the shelf-life of the calibrator.

The non-luminescent calibrator provides a reliable low-end or “dark” source reading.

Luminescent Calibrator Procedure

• Under the “Verification” menu in ATP Calibration, select “Luminescent Calibrator”.

• Insert the luminescent calibrator and close the chamber door.

• Press “Verify”.

In a properly calibrated MVP ICON, the calibrator should read within 0.1 Zones of the zone value

displayed on the calibrator’s label.

21

Page 28

Non-Luminescent Calibrator Procedure

• Under the “Verification” menu in ATP Calibration, select “Non-Luminescent Calibrator”.

• Insert the non-luminescent calibrator and close the chamber door.

• Press “Verify”.

The non-luminescent calibrator should read 1.0 – 1.5 Zones. Readings outside this range can

indicate problems with the instrument. If the verification fails, calibrate the ICON. If the

calibration fails, contact BioControl technical Support.

pH

The pH calibration process uses three standard buffers (pH 4.00, 7.00, and 10.00). This threepoint calibration allows for the probe to be used across the entire pH range. For optimal

accuracy, the ICON pH probe should be calibrated before first use, at the beginning of each day

and when changing test materials.

Calibration Procedure

Prior to performing calibration, rinse the pH probe with deionized or distilled water. Soak in pH

7.00 buffer for at least 10 minutes prior to calibration and ensure the standard is mixed well.

• Connect the pH probe to the instrument, ensuring arrows on the adaptor face the back

of the instrument.

• Verify the ICON is in pH mode.

• Select “Device” from the ICON’s lower menu.

• Insert the probe into the 7.00 standard solution and press “Calibrate”.

• When prompted, insert the probe into the 10.00 standard solution and press “Calibrate”.

• When prompted, insert the probe into the 4.00 standard solution and press “Calibrate”.

Note: If the probe will not calibrate, it usually indicates a failing probe or contaminated buffers.

Be sure to keep buffers sealed when not in use. Do not use expired buffers.

Temperature

The ICON Temperature probe is calibrated using a single-point calibration process. Any known

temperature within operating range may be selected for calibration. Calibration is most accurate

when a temperature point close to the sample temperature is selected.

Calibration Procedure

• Connect the Temperature probe to the instrument, ensuring arrows on the adaptor face

the back of the instrument.

• Verify the ICON is in Temperature mode.

• Select “Device” from the ICON’s lower menu.

• Select “Calibration”.

• Enter the Reference Value (instrument will indicate either ˚F or ˚C based on settings).

• Insert probe into the reference sample of a known temperature entered above.

• Press “Calibrate”.

Conductivity

The ICON Conductivity probe reads in microSiemens (µS) for conductivity and requires the use of

a conductivity standard close to the target reading. The average conductivity standard in North

America is 500 µS. Rinse the Conductivity probe with deionized or distilled water and soak the

probe in the conductivity standard for at least two minutes prior to calibration.

22

Page 29

Calibration Procedure

• Connect the Conductivity probe to the instrument, ensuring arrows on the adaptor face

the back of the instrument.

• Verify the ICON is in Conductivity mode.

• Select “Device” from the ICON’s lower menu.

• Enter the Reference Value in microSiemens (µS).

• Insert the probe into the sample.

• Press “Calibrate”.

If the ICON is unable to calibrate the Conductivity probe, it is usually due to contamination or

otherwise incorrect standards or buffers. Ensure the standard is well-mixed and try the

calibration again. If unable to calibrate, contact BioControl Technical Support at 800.245.0113.

Concentration

To calibrate the Conductivity probe for measuring the concentration of specific

cleaning/sanitizing chemicals the probe must first be calibrated for conductivity as directed in the

preceding section – see Conductivity Calibration Procedure.

Next, a chemical standard must be prepared for each specific cleaning/sanitizing chemical to be

tested. The chemical standard is prepared by carefully mixing the chemical with the available

source water at the precise concentration for its intended use, per the manufacturer’s directions

(i.e. 200 ppm).

A corresponding chemical standard must also be created in the MVP ICON Dashboard software

and transferred to the ICON before the calibration procedure can be performed (

See Ch

apter

15).

alibration Procedure

C

• Connect the Conductivity probe to the instrument, ensuring arrows face the back of the

instrument.

• Verify the ICON is in Concentration mode.

• Select “Device” from the ICON’s lower menu.

• Select the desired standard.

• Insert the probe into the source water and press “Calibrate”.

• Insert the probe into the chemical standard and press “Calibrate”.

Note: The probe should be rinsed with deionized water between reading the source water and

chemical standard.

If the calibration is unsuccessful, remix the sanitizer or cleaner and try to calibrate again. If

unable to calibrate, please contact BioControl Technical Support at 800.245.0113.

The calibration procedure should be repeated whenever

• A new lot of sanitizer is to be used.

• A new vendor of sanitizer is used.

• The same sanitizer is used at a different ppm concentration.

23

Page 30

MVP ICON Dashboard Software at a Glance 12

Introduction

The innovative dashboard on the software’s home screen provides a quick overview of key

metrics and allows for immediate, corrective action. Detailed analysis reports provide

comprehensive data to identify hot-spots within the facility, track and trend data, and generate

audit-ready HACCP reports.

System Requirements

Windows XP, Vista, Windows 7, or Windows 8

Minimum memory requirement 512 MB; recommend at least 1GB or more of RAM

At least 16 GB of hard disk space

WXGA video resolution of 1280 x 800 or better

Mouse or other pointing device

One available USB port

CD Drive

Printer (optional)

Adobe PDF to print (optional)

24

Page 31

Installation 13

Installing the MVP ICON Dashboard Software

The MVP ICON Dashboard Software is included with the MVP ICON system and is loaded onto a

CD for installation. It is also available on the BioControl Web site at www.biocontrolsys.com

Contact BioControl Technical Support for more information on downloading software.

Note: Ensure the computer is assigned administrative rights prior to installation.

Installing the software:

• Insert software disc into computer CD drive.

• Follow the Install Wizard prompts by clicking “Next”.

• Connect ICON to computer, when prompted for driver installation.

• Click “Finish” to complete installation and install the desktop icon.

• Launch program from the desktop icon.

Note: When installing virtually on multiple user’s desktop, be sure to copy and paste the

installation folder onto each desktop and perform installation from hereby checking the

“setup.exe” file.

USB Driver Installation for Vista

Vista operating systems may require additional steps when installing USB drivers for the MVP

ICON Dashboard software. The software and drivers are included on the software installation CD

and can also be found on the BioControl Web site at www.biocontrolsys.com

their Customer IKD to log in.

Please follow the steps below for installing USB drivers on Vista operating systems.

• Insert the MVP ICON Dashboard software CD and follow the installation prompts. When

the driver installation prompt appears, select OK.”

• The software will continue its installation process, however, the following message may

appear, “MVP ICON driver did not install correctly. Follow any pending prompts to locate

the driver or review the manual for guidance.” If this message occurs, press “OK.”

• Turn on the MVP ICON instrument and plug into the computer’s USB port. At the “Found

New Hardware” message select, “Locate and install driver software.” Follow the prompts

to locate the driver from the software CD.

If the installation CD is not available, select, “I don’t have the disc, show me other options” and

browse to C: Program Files. Select the “BioControl Systems, Inc.” folder, then select the “Driver”

folder and click “Next” when prompted.

• A pop-up message will appear, “Would you like to install this device software?” Select

“Install.”

• The driver installation process will finish and the associated communications port will be

displayed.

For additional assistance, please contact BioControl Technical Support at 800.2456.0113.

. Users will need

.

25

Page 32

Dashboard 14

Example of ICON Software Dashboard

What is the ICON Dashboard?

The MVP ICON Dashboard software’s home screen displays a dashboard which provides an

overview of key program control metrics at-a-glance. This unique feature provides quality

assurance managers with an overall picture of the behavior and health of their HACCP and

hygiene program by highlighting where potential problems reside within the facility, or with the

execution of the program, to guide corrective action for immediate resolution. The dashboard

can be accessed from any screen in the software by clicking at the top of the screen.

26

Page 33

ATP Swabs to Target Widget

Allows users to set a target for the number of ATP swabs used and measure active usage against

this target. This data provides a quick assessment if the correct amount of swabs are being used,

indicating sufficient testing is taking place, or if testing needs to increase to ensure the plan is on

track.

The reading is based on the total amount of ATP test results uploaded to the ICON software

compared to the defined target quality goal for a given period.

• For example, if the target number of swabs is 200 per month and the ICON software

contains 50 test results for that time period, the ATP Swabs to Target percentage is 25%.

• Quick-test results are not included in the total ATP test results unless they are

subsequently saved and converted.

Setting ATP Swab Target

• Select the dropdown arrow at the top corner of the “% ATP Swabs to Target” widget.

• Select target frequency (Weekly, Monthly, Quarterly, Annually).

• Enter the target number of swabs based on the time period (ex. 300 per month, 75 per

week, etc.).

• Select “OK”.

When the target and frequency are indicated, the percentage of swabs used will automatically

update based on the total amount of results uploaded to the software.

ATP Re-Tests Widget

Defines how many test points have been coded as a re-test over a period of time. Re-tests are

commonly performed if a test point has produced a warn and/or fail result, therefore, the higher

the percentage of re-tests, the more often a test point has been re-cleaned and re-tested. Results

can be viewed Weekly, Monthly, Quarterly, or Annually.

Setting ATP Re-Test Target

• Select the dropdown arrow at the top corner of the “% ATP Re-Test” widget.

• Select the desired frequency (Weekly, Monthly, Quarterly, Annually).

• Check “Warnings Included” if your program requires all “warn” results to be re-cleaned

and re-tested.

• Select “OK”.

Note: It is critical before testing with the MVP ICON to determine if only failed results will be retested or if results with both a fail and warn reading will be re-tested, per your standard

operating procedures. This impacts how the re-test data is displayed in the graph.

27

Page 34

Next Calibration Widget

The “Next Calibration” feature alerts the user to the next required date of calibration for the

ICON instrument, based on their HACCP and hygiene monitoring program. Each time an

instrument is connected to the software, the “Next Calibration” feature will identify the unit by

its serial number and will reflect the next required date of calibration. If multiple units are synced

to a database, the software will reflect the unit that is due next for calibration.

This application helps comply with HACCP programs to ensure all instruments are calibrated on a

timely basis and is a useful tool for audits.

The due date is color-coded to reflect calibration urgency.

• Green indicates the instrument is within 80 percent of its next calibration due date.

• Yellow warns the user they are within 90 percent of their due date.

• Red indicates the unit is beyond its calibration due date.

Setting the Calibration Frequency Target

• Select the dropdown arrow at the top corner of the “Next Calibration” widget.

• Select the desired calibration frequency (Weekly, Monthly, Quarterly, Annually).

• Select “OK”.

Device Exclusion List

To exclude an inactive ICON from appearing in the Next Calibration widget:

• Select the dropdown arrow at the top corner of the “Next Calibration” widget.

• Press the “Device Exclusion List” button.

• Check the box next to the serial number of the desired ICON. The excluded serial number

no longer factors into the Next Calibration rotation.

Note: To allow the ICON to be placed back into rotation, simply uncheck the box next to the

desired serial number.

28

Page 35

Percentage each test

Percentage each test

Listed from lowest

greatest

ATP Fail Rate Graph

The first of the three graphs at the bottom of the dashboard is “ATP Fail Rate.” This graph guides

the quality team to problematic areas in the facility requiring prompt attention for immediate

resolution.

Results are ordered from test points with the highest percentage of failed ATP results to lowest.

Test point numbers

point failed

ATP Re-Test Rate Graph

The middle graph on the dashboard displays the “ATP Re-Test Rate” by test point. This graph

illustrates the percentage of times a test point was re-cleaned and re-tested over a designated

period to highlight potential problem areas needing more thorough cleaning. In addition, QA

Managers can verify if the sanitation protocol for re-cleaning failed test points is adequately

followed.

Note: It is critical before testing with the MVP ICON to determine if only failed results will be retested or if results with both a fail and warn reading will be re-tested, per your standard

operating procedures. This impacts how the re-test data is displayed in the graph.

Test point numbers

point was re-tested

percentage re-test to

29

Page 36

ATP Pass/Warn/Fail Rate Graph

Combined percentage total

Test Point Numbers

= % Warn results

= % Pass results

= % Fail results

Key:

This stacked column graph presents the percentage of pass, warn, and fail results for all selected

test points over a period of time. This graph directs the sanitation crew to areas in the facility

requiring special attention identifying those test points that have higher warn and fail rates.

Customizing Dashboard Graphs

• Select the dropdown arrow at the top corner of the appropriate graph.

• Select by test point (individual, range, or all) or by all test points assigned to a particular

sample plan.

• Select time period by Daily, Weekly, Monthly, Quarterly or Annually by max date range.

• Select “OK” to run the report.

of pass/warn/fail results for

each test point

30

Page 37

Creating Test Points 15

Test Point Setup Screen - ATP

About Creating Test Points

The MVP ICON Dashboard software allows for a wide range of test point setup and customization

options to ensure each unique area in the facility is identified by all necessary and applicable

information.

The ICON software also provides the ability to create sample plans to which a test point (or

multiple test points) can be assigned. Sample plans are a helpful way to organize a subset of test

points within a facility for better identification and to guide the sanitation crew during testing.

The MVP Collection feature allows for test points from multiple parameters (ATP, pH,

Conductivity, etc.) to be grouped together in order to analyze and view data as an interrelated

set to establish trends not previously identified.

ATP Test Points

Note: Test point assignments are alphanumeric and can be up to 25 characters long, however, the

ICON instrument will only display up to 15 characters of the name.

Note: The Warn/Fail threshold limits will automatically populate 2.5 for Warn and 3.0 for Fail,

based on the Zones of Cleanliness. Thresholds can be customized to any zone value between 1.3

and 5.0.

To change the threshold, simply click on the desired cell and change to the applicable correlating

threshold.

Create a new

test point

• From the software’s top menu, select “Test Point Setup”.

• From the table menu, ensure the ATP Test Point tab is highlighted in blue.

• From the left-hand column menu, select “New Test Point”.

Test points will be created in numerical order.

• Click on the “Name” column cell for the applicable test point to assign a name.

• If the reading is less than the Warn limit, the test point result will be reported as a pass.

• If the limit is greater than or equal to the Warn limit but less than the Fail threshold, the

result is a warn.

• If the reading is greater than or equal to the Fail limit, the test point result will be