Page 1

HM-9110_9111_0414

product manual

HM-9110, HM-9111

Asphalt Permeameter

Page 2

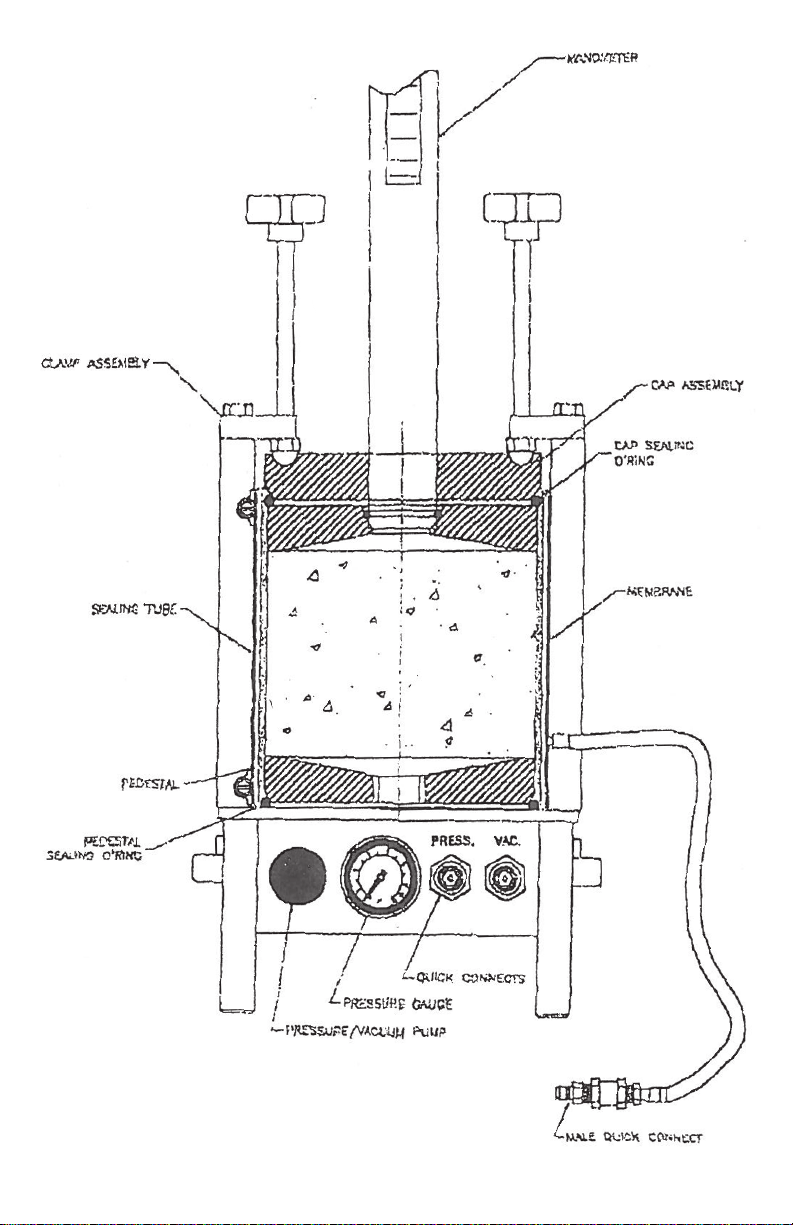

These Asphalt Permeameters are compact, self-contained, easy-to-use units,

which can be used in the lab or in the field. They are used to test the permeability of a compacted asphalt paving mixture by using the falling-head method to

determine hydraulic conductivity of saturated 4" and 6" samples. These Permeameters comply with ASTM Provisional Standard PS 129 and Florida FM 5-565.

Both permeameters include a 500cc manometer with 15ft of .25" OD water line,

built-in hand pump and a pressure gauge.

Directions for Use—(see ASTM Provisional PS-129·01 for procedure)

Position the two rear legs on an angle (45 degrees)and tighten the bolts. Attach

the outflow pipe to the brass ball valve and tighten. The out flow pipe will then

be positioned two inches (2.0") over the bottom of the sample pedestal.

Attach the two upright rods to the permeameter base by threading through the

base and installing the nut from the bottom on each rod and tightening.

The piston on the front panel is used for drawing a vacuum on the membrane in

order to position the membrane cylinder over the sample. Attach the tube from

the cylinder to the VACUUM quick connect on the front panel and working the

hand pump back and forth you will notice the membrane being pulled against

the side wall of the container. This will allow you to place the container over the

sample and pedestal. You will then position the top cap assembly into the container and over the sample. Note the two dished out pockets in the top cap are

to be aligned with the nylon acorn nuts on the hold down clamp. The hold down

clamp is then positioned to upright rods and the nuts tightened.

The two clamping screws on the clamp assembly are screwed down evenly until

the large o'rings on the pedestal and top cap are expanded against the side wall

of the latex membrane in the container.

The manometer tube is then placed through the clamp assembly and into the

top cap. Please note there is an o'ring in the top cap. It may require extra effort

(pushing down the manometer) to seat it properly through the o'ring. A lubricant

is sometimes recommended on the end of the manometer tube.

The container tubing is then removed from the VACUUM quick connect on the

front panel and attached to the PRESSURE quick connect. The membrane can

then be pressurized using the hand pump. Keep in mind the gauge on the front

panel is for reading positive pressure only. Please note the latex membrane is

susceptible to damage and will leak if not cared for properly.

Page 3

Page 4

Humboldt Mfg. Co.

875 Tollgate Road

Elgin, Illinois 60123 U.S.A.

U.S.A. Toll Free: 1.800.544.7220

Voice: 1.708.456.6300

Fax: 1.708.456.0137

Email: hmc@humboldtmfg.com

Testing Equipment for

HUMBOLDT

www.humboldtmfg.com

Construction Materials

Loading...

Loading...