Page 1

12.09

product manual

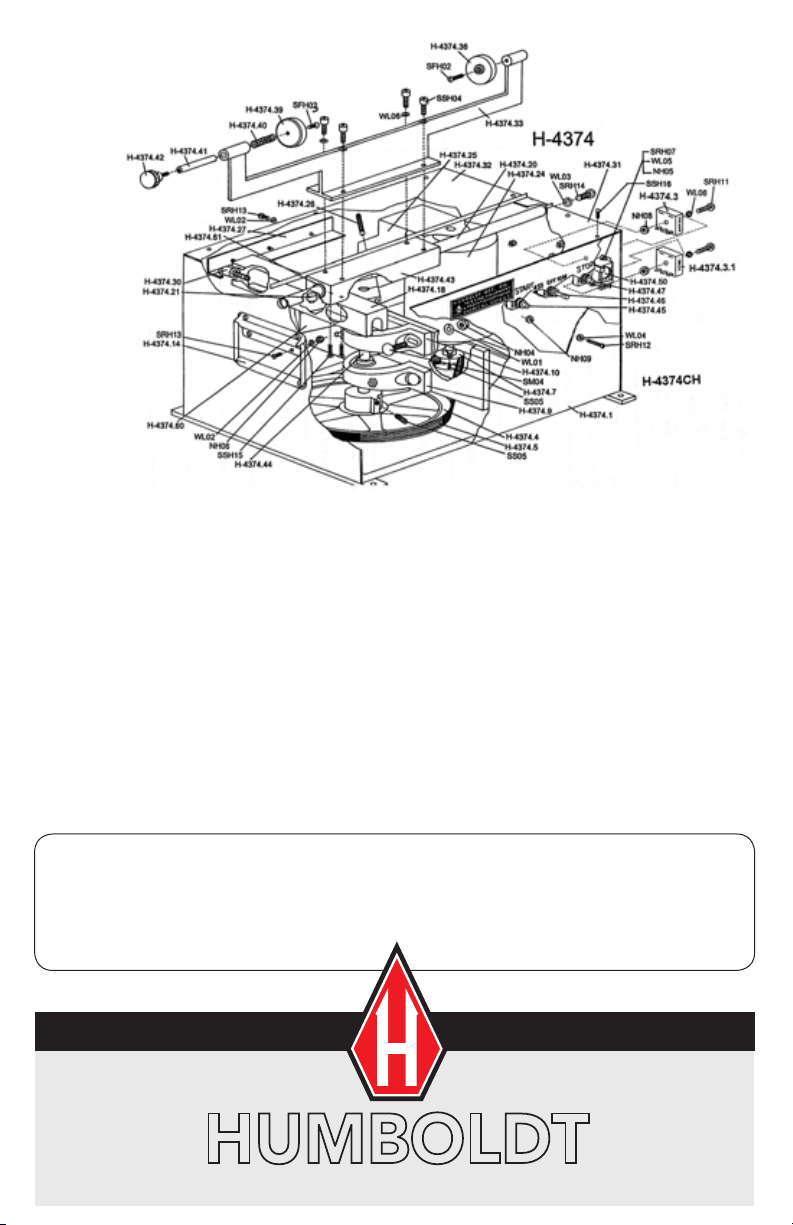

H-4374 & H-4374.5F

Sand Equivalent Shaker

Page 2

Introduction

The motorized sand equivalent shaker features two separate electronic

timers (one preset at 45 seconds and the other preset at 10 minutes) to

increase accuracy and ease of operation compared to a spring-type timer.

It is recommended for samples in the laboratory.

The consistent, repeatable oscillation of the apparatus eliminates operatorcaused variations.

The equipment meets specifications for the following tests:

ASTM D2419

AASHTO T176

California Test Method 217

General Information

Your Sand Equivalent Shaker was thoroughly inspected before it was shipped

and should be ready to operate as soon as you have completed the set-up

procedure. Notify Humboldt Mfg. Co. or your local agent and file a claim with

any carriers involved if you find any damage to the machine.

Physical Specification:

Shipping weight: 125 lbs. (56.7kg)

Overall height: 24” (61 cm)

Base dimension: 12” x 24” (31 x 61 cm)

Power Supply:

115V, 60Hz, 6.8amps, 1 phase (H-4374)

230V, 50Hz, 3.6amps, 1 phase (H-4374.5F)

Check that your machine has the correct voltage for your

local supply.

Power Cord: Your Sand Equivalent Shaker is fitted with a molded vinyl

grounding plug. The core is made of three conductors (USA color

coding).

Green Ground (Earth)

White Cold (Neutral)

Black Hot (Live)

(Note: The molded vinyl plug is removed on the H-4374.5F)

Initial Installation

Remove the packing list and verify that parts have been received. Remove the

wood support packaging from underneath the motor. The unit is complete

assembled and ready for use. Place the machine where it is to be used in

the laboratory or field and mount it securely to a firm and level base. Plug or

connect to the electric power indicated.

Page 3

Operation

Control Panel:

The controls are situated on the front, right hand side of the machine base.

Preset Travel and Speed:

The shaker has a throw of 8 ± 0.04” and operates at 175 ± 2 cycles per

minute.

Method:

Prepare the sample to be tested according to the governing agency

standard(s). Place the clear plastic cylinder containing the test sample and

rubber stopper in position on the slide assembly of the shaker. The end with

the spring loaded holder fits over the cork (rubber stopper) in the open end

of the clear cylinder.

Select the time period appropriate for the test, either 45 seconds or 10

minutes using the center toggle switch. Then press the start push-button

switch to begin the test. The test will end at the end of the elapsed time

selected, or by the operator pressing the pushbutton stop switch any time

during the test.

Maintenance

First unplug the machine from its power receptacle or source. Normal routine

maintenance consists of lubrication at several key locations. In addition, worn

components should be suspected if there is any unusual sound or action of the

machine.

Lubricate as follows:

A. The slide assembly should be lubricated once a month with

approximately three (3) drops of household oil on each end of the main

slide bar.

B. Two (2) grease fittings should be greased once a year with automotive

type grease. These are accessible from under the machine through the

fly-wheel.

C. The cam action guide, H-4374.18 and the two outside slide bars,

H-4374.27 can be greased by smearing a film of grease on each one.

Accessories

In addition to the Sand Equivalent Shaker, Humboldt Mfg. Co. also has available

a complete Sand Equivalent Test Set that includes four graduated cylinders,

siphon assembly, weighted foot assembly, wide mouth funnel, 3 oz. measuring

can and standard stock solution. Consult the Humboldt catalog for this and for

ordering accessories separately.

Page 4

Warranty

Humboldt Mfg. Co. warrants its products to be free from defects in material or

workmanship. The exclusive remedy for this warranty is Humboldt Mfg. Co.,

factory replacement of any part or parts of such product, for the warranty of this

product please refer to Humboldt Mfg. Co. catalog on Terms and Conditions

of Sale. The purchaser is responsible for the transportation charges. Humboldt

Mfg. Co. shall not be responsible under this warranty if the goods have been

improperly maintained, installed, operated or the goods have been altered or

modified so as to adversely affect the operation, use performance or durability

or so as to change their intended use. The Humboldt Mfg. Co. liability under

the warranty contained in this clause is limited to the repair or replacement of

defective goods and making good, defective workmanship.

Humboldt Mfg. Co.

875 Tollgate Road

Elgin, Illinois 60123 U.S.A.

Testing Equipment for

HUMBOLDT

www.humboldtmfg.com

U.S.A. Toll Free: 1.800.544.7220

Voice: 1.708.456.6300

Fax: 1.708.456.0137

Email: hmc@humboldtmfg.com

Construction Materials

Loading...

Loading...