human care FloorLine LTC Service Manual

FloorLine LTC

Service Manual / Servicemanual

Part no: 90600-90603, 90606-90609

22

www.humancaregroup.com

Content/Innehåll

Service Manual (ENG) 2

1. Product Description 2

2. Maintenance 3

3. How to fit and remove 6

Human Care beds are designed & manufactured

to provide many years of safe operation and

use, when operated in accordance with these

instructions.

This Service manual is valid for beds with part

no: 90600 = class 2, 90601 = class 2, 90602 =

class 2, 90603 = class 2, 90604 = class 2, 90605

= class 2, 90606 = class 1, 90607 = class 1,

90608 = class 2,90609 = class 2

WARNING!

Service work contained in this manual should

only be undertaken by Human Care trained

and authorised service agents. Only Human

Care supplied parts should be used. Failure

to comply with the above two items will

void warranty and could result in further

unnecessary damage to the bed and possible

extreme safety hazard to the person occupying

the bed and/or caring staff.

Service Manual (ENG)

PURPOSE

This document will be made available to Human

Care staff, distributors, agents and authorised

Human Care service providers. It is not for

publication or distribution to the public or

clients who may use the information to allow

other companies or individuals to repair or

modify Human Care products.

This document and its contents are intended

to be used in the performance of service on

Human Care produced products, i.e. FloorLine

LTC range series products. This document

also serves as a reference for office and sales

staff in the performance of their duties, i.e.

collecting service call information to facilitate

the expedient diagnosis of any problems and

problem solutions.

This document should be read in conjunction

with Human Care’s Operating and Assembly

Guides, Instruction Manuals and Spare Parts

Catalogues. This document is copyright to

Human Care Beds and must not be reproduced

in any form without written permission of

Human Care.

1. Product Description

ENG

Servicemanual (SV) 8

Produktbeskrivning 8

1. Underhåll 8

2. Montering och demontering 12

Spare part list/Reservdelslista 14

www.humancaregroup.com

3

2. Maintenance

ENG

Operators of hospital beds are obligated

to keep medical products in a safe state

throughout their entire service life. This also

includes regularly carrying out expert, Human

Care authorised maintenance and safety

checks.

As a result of improper operation as well as

long-time use, damage, defects, and signs of

wear may occur. Such defects can present

hazards if not promptly recognised and

eliminated.

If damage or a malfunction is suspected,

the bed must be withdrawn from service

immediately until repairs have been carried

out or the defective parts have been replaced.

Human Care suggests regular inspections by

users see checklist.

As a guideline, it is recommended that regular

preventative maintenance occurs and an annual

inspection be carried out on all Human Care

Beds.

Contact Human Care for information on the

Safety and Condition Audit program. Human

Care recommends regular user checks.

Maintenance Checklist – Explanatory

Notes

VISUAL CHECKS

• Handset Cable – Check for cracks in plastic

insulation, check for breaks in casing, cable

holder and plugs.

• Mains Cable – as above

• Handset – Check that all functions work

and ensure there is no damage to casing or

faceplate.

• Chassis – Check the bed frame for bent or

corroded pieces; ensure that all bolts and

screws are tight.

• Head & Foot Covers – Check ABS covers

have no cracks and are secured tightly.

• Castors – Check that each wheel will turn,

test the brake and directional locking.

Ensure that each castor is tightly secured.

• Paintwork/Corrosion – Ensure all metal parts

have no flaking paint or signs of rust.

• Bed Extension (If Fitted) – Check that this has

been installed correctly and all bolt s are tight.

• Accessories correctly fitted – Check that

all accessories fitted to the bed have been

correctly installed and that all the bolts are

tight.

• Serial No. Label – Each bed has its own Serial

Number and the label is found on the rail

running underneath the mattress platform.

Check that this in place.

MECHANICAL CHECKS

• Bed to maximum low/high measurements –

Check the height of the mattress platform

(at all 4 corners) to ensure that they agree

with the correct specifications for this

product.

• Platform level – Measure from mattress

platform to the floor at each corner and

ensure that each measurement is the same

• Kneebreak Maximum up/down – Operate

kneebreak to fullest height and check for any

damage.

• Backrest Maximum up/down – Operate

backrest to fullest height and check for any

damage.

• Trendelenburg Maximum forward & reverse

– Operate Trendelenburg to fullest height

• Quiet smooth Hi/Lo Function – Operate bed

up and down checking that it is quiet and

goes smoothly up and down.

• End covers and fittings – Check all covers are

fitted correctly and secured to frame of bed.

• Castors tight and lockable – check castor

fixing bolts are tight, check directional castor

(green tab) x 1 and locking castors x 3 for

correct function.

• Hilo drive mechanism – Check raise/lower

actuators for excess noise or slow operation.

44

www.humancaregroup.com

Check nylon bushes for wear or damage.

• Side Rails – Check condition of side rails and

brackets if fitted, ensure that the screws are

tight.

• All bolts, screws, fasteners must be checked

regularly before putting the beds into

service and between patients/residents.

STRUCTURAL

• Visible distortion of frame – Check frame for

bent or cracked metal parts.

• Visible serious client damage – Check for

damage caused by bed lifters etc. and report

to client.

• Structural Fractures – Check for cracks or

tears in steel frame

• Hinges/mounts not bent – Check all the

hinges on platform, actuator fixing points

and platform fixing points for damage.

ELECTRICAL

• Battery backup working/condition (if fitted)

– Disconnect mains cable from power point

and operate bed.

• Handset buttons all working – Check all

functions on handset.

• Cables secure and in good condition – Check

that all cables are secured correctly, not

hanging loose.

• All Actuators secured & working – Check for

excessive noise, vibration or cracks in casing.

REPLACEMENT PARTS

In order to maintain operational safety and

the right to claim under warranty, only original

Human Care replacement parts may be used!

Please quote part numbers for each item as per

the Human Care Spare Parts Catalogue.

2. Maintenance

ENG

ELECTRICAL COMPONENTS

The corresponding replacement parts can be

obtained from Human Care. When ordering

please specify – TYPE & ITEM. The necessary

details are found on the type plate (as shown

below) on each electrical component.

Safety information on replacing electrical

components

This is a Class 2 electrical product.

CAUTION! Before commencing any work

on electrical equipment, always unplug

the mains cable from the electrical socket.

battery

backup

Handset

Actuators

Mains

Any work and/or repairs to the electrical

equipment may only be carried out by service

engineers, qualified technicians or authorised

electricians in compliance with all the relevant

country of use safety standards.

All electrical drive system components

(actuators, handset, and control box) are

maintenance-free and must not be opened.

In the event of a malfunction, the

corresponding component must always be

replaced in full.

www.humancaregroup.com

5

2. Maintenance

ENG

When replacing individual components,

always ensure that the plugs, outfitted with

undamaged O-rings (seals), are inserted into

the control unit as far as possible. Only then

can reliable sealing and perfect operation be

guaranteed.

The component plugs are connected to the

corresponding port in control box. To prevent

the plugs from inadvertently disconnecting,

they are secured with a locking device. When

necessary, this device can be carefully lifted off

using a screwdriver. The locking device must

always be properly refastened.

Checked OK Not ok Description of fault

Visual check of the electrical components

Handset cable Damage, routing

Mains cable Damage, routing

Visual check of the mechanical components

Mattress Platform is parallel to

floor (ie level)

Damage

Bolts, fasteners, screws Check & tighten regularly

Chassis Damage, deformations

Check for rust or corrosion. Damage

Castors Damage

Bed Extension Damage

Performance check of the electrical components

Backrest Adjustment, secure

retention

Platform Hi/Lo Adjustment, secure

retention

Battery Backup ( if fitted) Check fully charged &

operational

Accessories (eg: Self Help Pole,

side rails)

Fastening, damage

Signature of the Inspector: Name of Inspector:

Inspection result: Date:

66

www.humancaregroup.com

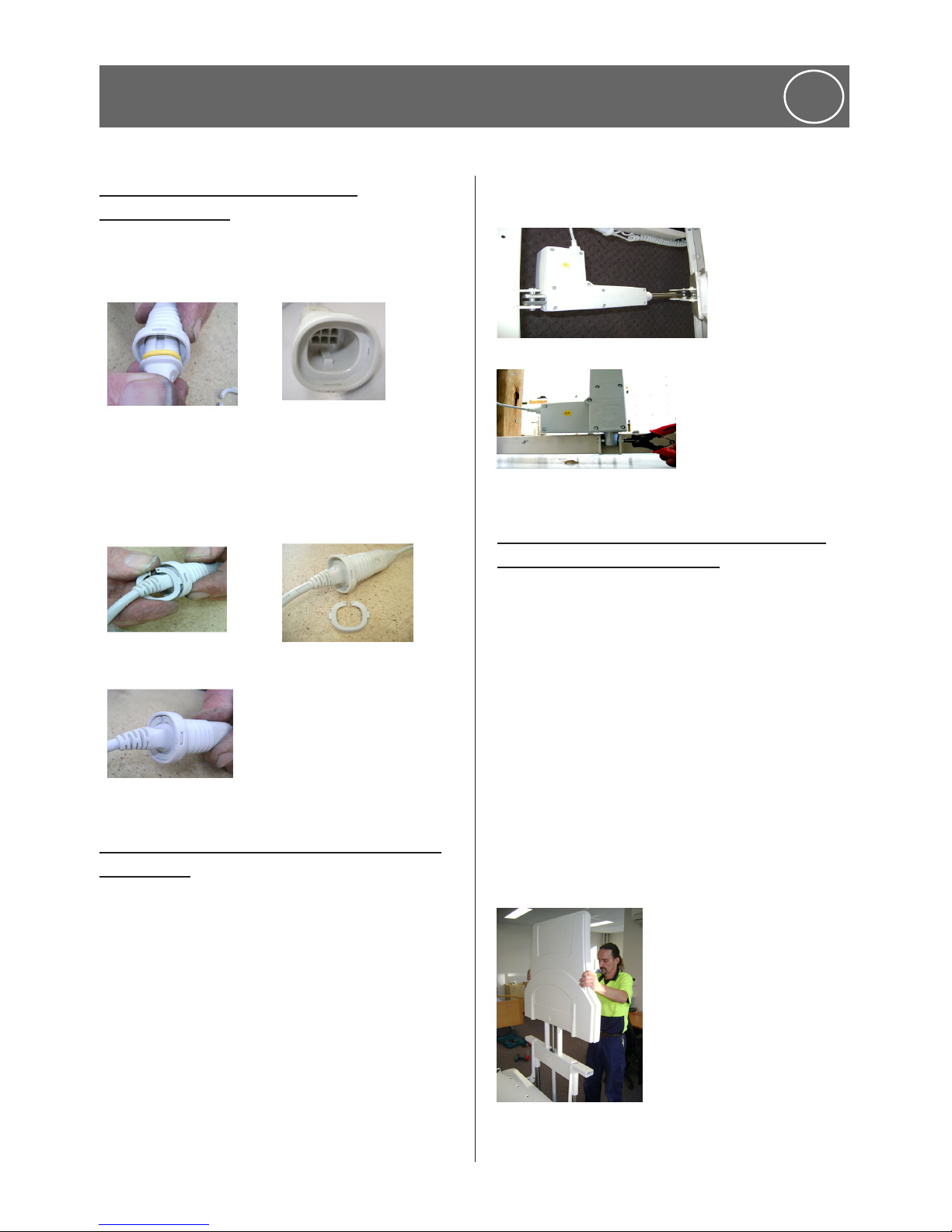

How to fit a mini fit plug when

assembling bed

Pic 1. Lightly lubricate seal on the plug and

insert firmly into the socket ensuring that the

key and keyways are aligned (Pic 2.)

Pic 1. O ring seal

Pic 2 keyway

Pic 3. Fit the plastic circlip using a small flat

blade screwdriver and ensure that the two

locking tabs lock into the slots of the socket.

Pic 3

Pic 4 Locking

Pic 5 Locking slot

How to remove an Actuator –Kneebreak

& Backrest

Raise bed to a comfortable working height.

Remove minifit plug using a small flat blade

screwdriver to release the plastic circlip locking

tabs and separate the male and female mini fit

plug (see pic 1 below)

Remove actuator circlip washer and pin at the

bottom of the actuator only while supporting

the weight of the actuator (with chocks) remove

circlip washer and pin from the other end.

Reverse these steps to replace or install an

actuator.

pic 1

Pic 2

How to remove main bed lift actuators

(Hi/Lo) Head and foot end.

• Pic 1 Remove plastic inner cover by lifting up

and out (not fastened).

• Pic 2 Lower pedestal end onto two blocks

of timber (not supplied) approximately 500600mm in length.

• Remove P clips (cable retainers) with a

Phillips head screw driver.

• Pic 3 Remove circlip and pin from base of

actuator anchor point

• Remove circlip and pin from top of actuator

anchor point.

• Reverse these steps to install or replace an

actuator.

Pic 1

3. How to fit and remove

ENG

Loading...

Loading...