1

BreathableAirWarning

DISCLAIMER OF WARRANTIES

DANGER!

CALIFORNIA PROPOSITION 65

This productor its power cord may contain chemicals known to the state of

California to causecancerandbirthdefectsor otherreproductiveharm. Wash

handsafterhandling.

In the event the compressor is used for the purpose of breathing air applicaon and proper in-line safety

and alarm equipment is not simultaneously used, exisng warranes are void,and Hulk air force technology

& AIRBASE Industries, LLC disclaims any liability whatsoever for any loss, personal injury or damage.

READ INSTRUCTION MANUAL BEFORE

OPERATING

RISK OF FIRE OR EXPLOSION–DO NOT SPRAY

COMBUSTIBLE/FLAMMABLE LIQUID IN A

CONFINED AREA. SPRAY AREA MUST BE WELL

VENTILATED. DO NOT SMOKE WHILE SPRAYING

OR SPRAY WHERE SPARK OR FLAME IS PRESENT.

ARCING PARTS – KEEP COMPRESSOR AT LEAST

20 FEET AWAY FROM SPRAYING AREA AND ALL

EXPLOSIVE VAPORS.

RISK OF INJURY– DO NOT DIRECT AIR STREAM

AT BODY. USE EYE PROTECTION. COMPRESSOR

STARTS AUTOMATICALLY. MOVING PARTS. DO

NOT TOUCH. KEEP GUARDS IN PLACE.

COMPRESSOR DOES NOT SUPPLY

BREATHABLE AIR.

RISK OF BURSTING– DO NOT ADJUST

REGULATOR TO RESULT IN OUTPUT PRESSURE

GREATER THAN MARKED MAXIMUM PRESSURE

OF ATTACHMENT. IF A REGULATOR HAS NOT

BEEN INSTALLED.

USE ONLY ATTACHMENT RATED AT 200 PSI

ORHIGHER. DO NOT WELD ON OR REPAIR

TANK – REPLACE. DO NOT OPERATE WITHOUT

PROPER ASME SAFETY VALVE IN PLACE.

RISK OF ELECTRICAL SHOCK – HAZARDOUS

VOLTAGE: DISCONNECT FROM POWER SOURCE

BEFORE SERVICING. COMPRESSOR MUST BE

GROUNDED. DO NOT USE GROUNDING

ADAPTORS. DO NOT EXPOSE TO RAIN.

STORE INDOORS.

IF CONNECTED TO A CIRCUIT PROTECTED BY

FUSES, USE TIME-DELAY FUSE MARKED “D”

COMPLIES WITH CCR462 (L)(2).

DO NOT USE BELOW GARAGE FLOOR OR

GRADE LEVEL

DRAIN TANK EVERYDAY TO PREVENT

CORROSIONAND POSSIBLE INJURY DUE TO

TANK DAMAGE

This compressor/pump is NOT equipped and should NOT be used “as is” to supply breathing quality air. For

any applicaon of air for human consumpon, you must fit the air compressor/pump with suitable in-line

safety and alarm equipment. This addional equipment is necessary to properly filter and purify the air to

meet minimal specificaons for Grade D breathing as described in Compressed Gas Associaon Commodity

Specificaon G 7.1 – 1966, OSHA 29 CFR 1910. 134, and/or Canadian Standards Associaons (CSA).

IMPORTANT INFORMATION

LIMITED TOOL WARRANTY

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts for this tool are available at our authorized HULK service centers across USA. For servicing, contact

or return to the retailer where you purchased your product along with your proof of purchase. Please use the 10 digit part numbers

listed in this manual for all part orders where applicable.

2 Year limited warranty on pumps

1 Year limited warranty on parts & labor

HULK

LIMITED WARRANTY

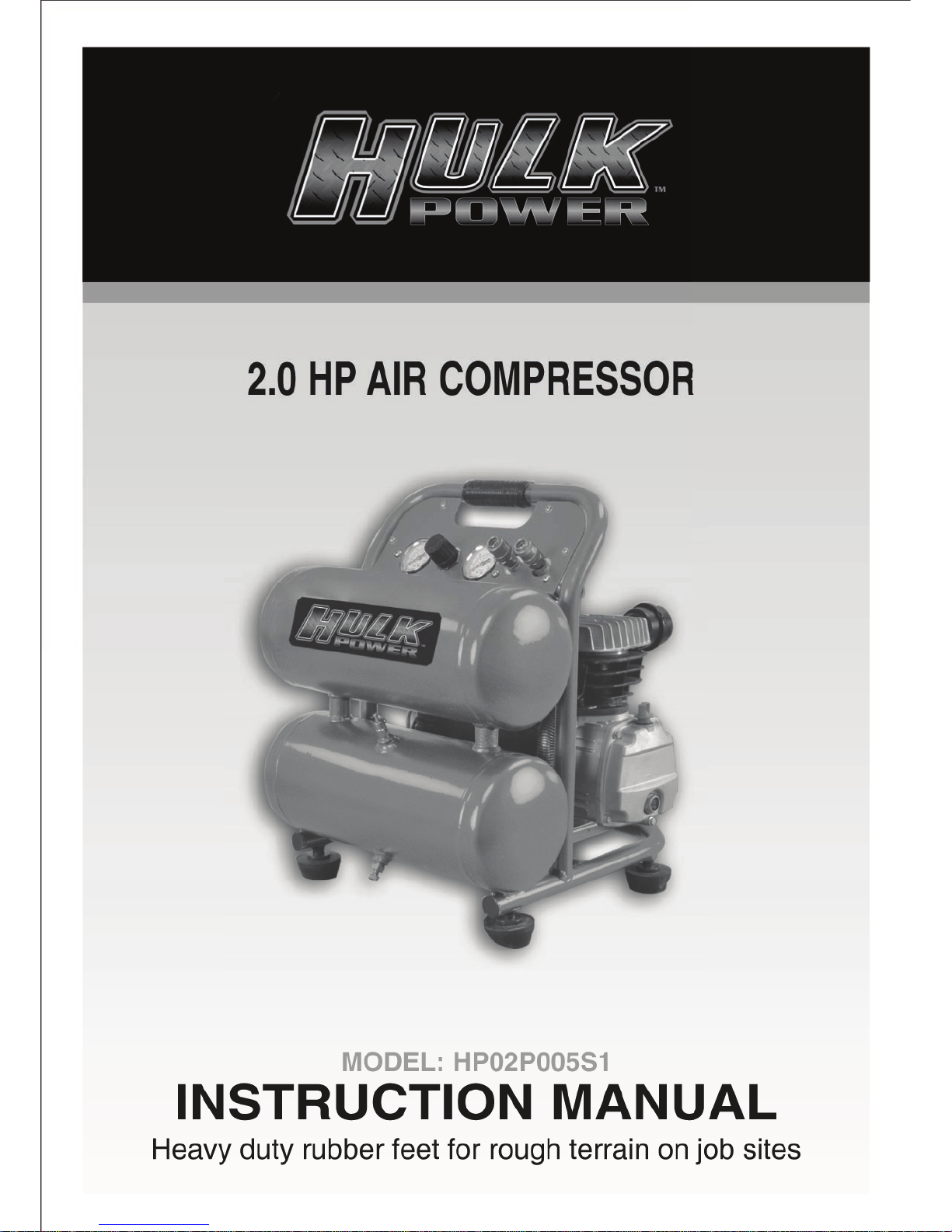

FOR THIS 2.0 HP AIR COMPRESSOR

HULK makes every effort to ensure that this product meets high quality and durability standards. HULK warrants to the original retail

consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free from defects in

materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or

alterations and lack of maintenance. HULK shall not be liable for death, injuries to persons or property or for incidental,

special or consequential damages arising from the use of our products. To take advantage of this warranty, the manufacturer part

must be returned for examination by the retailer. Shipping and handling charges may apply. If a defect is found, HULK will either repair

or replace the product.

2

IMPORTANT SAFETY INSTRUCTIONS

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN

It is normal for electrical contacts within the motor and pressure

switch to spark.

If electrical sparks from the compressor come in contact with

flammable vapors, they may ignite, causing fire or explosion.

Restricting any of the compressor ventilation openings will

cause serious overheating and could cause a fire.

Unattended operation of this compressor could result in

personal injury or property damage.

HOW TO PREVENT

Always operate the compressor in a well ventilated area free of

combustible materials, gasoline or solvent vapors. If spraying

flammable materials, locate the compressor at least 20 feet

away from the spray area. An additional length of hose may be

required.

Store flammable materials in a secure location away from the

compressor.

Never place objects against or on top of the compressor.

Operate compressor in an open area at least 12 inches away

from any wall or obstruction that would restrict the flow or fresh

air to the ventilation openings.

Operate compressor in a clean, dry and well ventilated area.

Do not operate compressor indoors in a confined area.

Always remain in attendance with the compressor when it is

operating.

RISK OF BURSTING

WHAT CAN HAPPEN

1. Failure to properly drain condensed water from the tank,

causing rust and thinning of the steel tank.

2. Modifications or attempted repairs to the tank.

3. Unauthorized modifications to the unloader valve, safety

valve or any other components which control tank pressure.

4. Excessive vibration can weaken the air tank and cause

rupture or explosion.

5. Attachments & Accessories; Exceeding the operating

pressure of air tools can cause them to explode.

HOW TO PREVENT

Drain tank daily or after every use. If the tank develops a leak,

replace tank or get a new air compressor. Never drill into, weld

or make any modifications to the tank or its attachments.

The tank is designed to withstand specific operating pressures.

Never make adjustments or parts substitutions to alter the

factory set operating pressures.

For essential control of air pressure, you must install a

pressure regulator and pressure gauge to the air outlet.

RISK OF BURNS

WHAT CAN HAPPEN

Touching exposed metal such as the compressor head or

outlet tubes, can result in serious burns.

HOW TO PREVENT

Never touch any exposed metal parts on compressor during or

immediately after operation. The compressor will remain hot

several minutes after use.

Do not reach around protective shrouds or attempt

maintenance until the compressor has cooled down

completely.

RISK OF PROPERTY DAMAGE WHEN

TRANSPORTING COMPRESSOR

WHAT CAN HAPPEN

Oil can leak or spill and could result in fire or breathing hazard,

serious injury or death can result. Oil leaks will damage carpet,

paint or other surfaces in vehicules or trailers.

HOW TO PREVENT

Always place compressor on a protective mat when

transporting to protect against damage to vehicle from leaks.

Remove compressor from

vehicles

immediately apon arrival.

3

SPECIFICATIONS & ELECTRICAL INFORMATION

WARNING

ALL ELECTRICAL INSTALLATIONS MUST BE PERFORMED BY A QUALIFIED ELECTRICIAN. FAILURE TO COMPLY MAY

RESULT IN SERIOUS INJURY! ALL ADJUSTMENTS OR REPAIRS MUST BE PERFORMED WITH THE COMPRESSOR

DISCONNECTED FROM THE POWER SOURCE. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY!

POWER SUPPLY

WARNING: YOUR COMPRESSOR MUST BE CONNECTED TO A 110V,

WITH A MINIMUM 15-AMP. BRANCH CIRCUIT. FAILURE TO CONNECT

IN THIS WAY CAN RESULT IN INJURY FROM SHOCK OR FIRE.

GROUNDING

Your compressor must be properly grounded. Not all outlets are properly

grounded. If you are not sure if your outlet is properly grounded, have it

checked by a qualified electrician.

WARNING: IF NOT PROPERLY GROUNDED, THIS COMPRESSOR

CAN CAUSE ELECTRICAL SHOCK, PARTICULARLY WHEN USED IN

DAMP LOCATIONS. TO AVOID SHOCK OR FIRE, IF THE POWER CORD

IS WORN OR DAMAGED IN ANY WAY, HAVE IT REPLACED IMMEDIATELY.

If this compressor should malfunction or breakdown, grounding provides a

path of least resistance for electric current, to reduce the risk of electric

shock. This compressor is equipped with a cord having an grounding

conductor and grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

WARNING: TO MAINTAIN PROPER GROUNDING, DO NOTREMOVE OR

ALTER THE GROUNDING PRONG IN ANY MANNER.

110V OPERATION

As received from the factory, your compressor is ready to run for 110V

operation. This machine is intended for use on a circuit that has an outlet

and a plug which looks like the one illustrated in Fig.1.

WARNING: DO NOT USE A TWO-PRONG ADAPTOR FOR THEY ARE

NOT IN ACCORDANCE WITH LOCAL CODES AND ORDINANCES.

NEVER USE IN USA.

FIGURE 1

LENGTH OF

CONDUCTOR

0-25 FEET

26-50 FEET

51-100 FEET

WIRE SIZES REQUIRED

(AMERICAN WIREGAUGE)

110V LINES

NO.12

NO.12

NO.10

FIGURE 2

EXTENSION CORDS

The use of any extension cord will cause some loss of power. IT

IS RECOMMENDED TO USE A LONGER AIR HOSE INSTEAD

OF AN EXTENSION CORD. If you do not have a choice, use the

table in Fig.2 to determine the minimum wire size

(A.W.G-American Wire Gauge) extension cord. Use only 3-wire

extension cords which have 3-prong grounding type plugs and

3-hole receptacles which accept the tool’s plug.

For circuits that are further away from the electrical circuit box, the

wire size must be increased proportionately in order to deliver

ample voltage to the compressor motor. Refer to Fig.2 for wire

length and size.

PROPERLY GROUNDED OUTLET

CURRENT CARRYING

PRONGS

GROUNDING

PRONG

SPECIFICATIONS

Model ................................................................................................................................................................................HP02P005S1

Voltage............................................................................................................................................................................................110V

Horsepower ................................................................................................................................................................................2.0 HP

Amperage ......................................................................................................................................................................................11.5A

RPM (no load speed) ....................................................................................................................................................................1,720

Phase ....................................................................................................................................................................................................1

Hertz ..............................................................................................................................................................................................60Hz

Operating pressure ..................................................................................................................................................................125 PSI

Tank size ......................................................................................................................................................................2.5 x 2.5 Gallon

4

OPERATION CONTROLS

AIR COMPRESSOR PUMP. To compress air, the piston moves up and down in the cylinder. On the

downstroke, air is drawn in through the intake valves. The exhaust valves remain closed. On the

upstroke of the piston, air is compressed. The intake valves close and compressed air is forced out

through the exhaust valves.

CHECK VALVE (A) FIG.3. When the air compressor is operating, the check valve is “open”,

allowing compressed air to enter the air tank. When the air compressor reaches “Cut-Out” pressure,

the check valve “closes”, allowing air pressure to remain inside the air tank.

ON/AUTO-OFF SWITCH (A) FIG.5. Turn this switch ON by lowering lever downwards to provide

power to the automatic pressure switch and lift to turn compressor OFF.

PRESSURE SWITCH (B) FIG.5. The pressure switch automatically starts the motor when the tank

pressure drops below the factory set “Cut-In” pressure. It also stops the motor when the air tank

pressure reaches the factory set “Cut-Out” pressure.

REGULATOR (B) FIG.6. The air pressure coming from the air tank is controlled by the regulator.

Turn the regulator knob clockwise to increase pressure and counterclockwise to decrease pressure.

To avoid minor readjustment after making a change in the pressure setting, always approach the

desired pressure from a lower pressure. When reducing from a higher to a lower setting, first reduce

the pressure less than that desired, then bring it up to the desired pressure. Depending on the air

requirements of each particular accessory, the outlet regulated air pressure may have to be

adjusted while operating the accessory.

OUTLET PRESSURE GAUGE (C) FIG.6. The outlet pressure gauge indicates the air pressure

available at the outlet side of the regulator. The pressure is controlled by the regulator and is always

less than or equal to the tank pressure.

TANK PRESSURE GAUGE (A) FIG. 6. The tank pressure gauge indicates the reserve air pressure in the

tank.

COOLING SYSTEM. This compressor contains an advanced design cooling system. The cooling

system works when air is being expelled.

DRAIN VALVE (A) FIG. 4. The drain valve is located at the base of the air tank and is used to drain

condensation from the tank to prevent corrosion. Drain tank after each use.

MOTOR THERMAL OVERLOAD PROTECTOR (RESET (A) FIG. 7). The electric motor has an

automatic thermal overload protector. If the motor overheats for any reason, the thermal overload

protector will shut off the motor. The motor must be allowed to cool before restarting. Press the reset

button (A).

PRESSURE RELEASE VALVE. The pressure release valve located on the side of the pressure

switch, is designed to automatically release compressed air from the compressor head and the

outlet tube when the air compressor reaches “Cut-Out” pressure or is shut off. The pressure release

valve allows the motor to restart freely. When the motor stops running, air will be heard escaping

from this valve for a few seconds. No air should be heard leaking when the motor is running, or

continuous leaking after unit reaches “Cut-Out” pressure.

SAFETY VALVE (B) FIG. 4. If the pressure switch does not shut off the air compressor at its

“Cut-Out” pressure setting, the safety valve will protect against high pressure by “popping out” at it’s

factory set pressure (slightly higher than the pressure switch “Cut-Out” setting).

WARNING!: If the safety valve does not work properly, over pressurization may occur, causing air

tank rupture or an explosion. Pull the ring daily on the safety valve to make sure that the safety valve

operates freely. If the valve is stuck or does not operate smoothly, it must be replaced with the same

type of valve before operating again.

FIGURE 3

FIGURE 4

FIGURE 5

FIGURE 6

FIGURE 7

5

BREAK-IN PROCEDURES & OPERATION

LOCATION OF THE AIR COMPRESSOR

ADDITIONAL REGULATORS AND CONTROLS

Since the air tank pressure is usually greater than that which is needed, a regulator is employed to control the air pressure ahead of any

individual driven device. Separate air transformers which combine the function of air regulation, moisture and dirt removal should be used where

applicable.

BREAK-IN PROCEDURES

NOTE: SERIOUS DAMAGE MAY RESULT IF THE FOLLOWING BREAK-IN INSTRUCTIONS ARE NOT CLOSELY FOLLOWED. THIS

PROCEDURE IS REQUIRED BEFORE THE AIR COMPRESSOR CAN BE PUT INTO SERVICE, AFTER REPLACING THE CHECK VALVE,

AND WHEN THE PISTON OR THE CYLINDER SLEEVE IS REPLACED.

A. Fill crankcase with oil as described in “Changing Oil” in the maintenance section on the following page.

B. Set the pressure switch lever to the “OFF” position.

C. Plug the power cord into the correct 110V branch circuit receptacle.

D. Fully open the drain valve (A) Fig. 4, by turning it counterclockwise, to prevent air pressure build-up in the tank.

E. Move the pressure switch lever to “ON/AUTO”. The compressor will start.

F. Run the compressor for 15 minutes. Make sure the drain valve is open and there is no tank pressure build-up by watching the tank pressure

gauge.

G. After 15 minutes, close the drain valve by turning clockwise. The air receiver will fill to “Cut-Out” pressure and the motor will stop. The

compressor is now ready for use.

OPERATING PROCEDURES

Preparation for use:

1. Before attaching an air hose or accessories, make sure the OFF/AUTO lever is set to “OFF” and the air regulator is closed. Once this is done,

you can now attach a hose or an accessory.

WARNING: Too much air pressure causes a hazardous risk of bursting. Check the manufacturer's maximum pressure rating for air tools and

accessories. The regulator outlet pressure must never exceed the maximum pressure rating of the tool being used.

3. Turn the “ON/AUTO-OFF” lever to “ON/AUTO” and allow tank pressure to build. Motor will stop when tank pressure reaches “Cut-Out”

pressure.

4. Open the regulator by turning it clockwise. Adjust the regulator to the correct pressure setting. The compressor is ready for use.

5. Always operate the air compressor in well ventilated areas; free of gasoline or other solvent vapors. Do not operate the compressor near the

spray area.

After Use:

6. Set the “ON/AUTO-OFF” lever to “OFF”.

7. Turn the regulator counterclockwise to set the outlet pressure to zero.

8. Disconnect the air tool or accessory.

9. Pull ring on safety valve (B) Fig. 4, allowing air to bleed from the tank until tank pressure is approximately 20 psi. Release safety valve ring.

10. Drain water from air tank. Turn drain valve (A) Fig. 4, counterclockwise to open.

WARNING!: WATER WILL CONDENSE IN THE AIR TANK. IF NOT DRAINED REGULARLY, WATER WILL CORRODE AND WEAKEN THE

AIR TANK CAUSING A RISK OF AIR TANK RUPTURE.

NOTE: If drain valve is plugged, pull ring on safety valve (B) Fig. 4, and hold until air pressure has been released. The valve can then be removed,

cleaned, and reinstalled.

11. After the water has been completely drained, turn drain valve to close. The air compressor can now be stored.

6

Your compressor comes almost completely assembled. Only the air filter needs to be installed. Operate the air compressor in a dry, clean,

cool, well ventilated area. The air compressor pump and case are designed to allow for proper cooling. Clean or blow off dust or dirt that

collects on the air compressor. A clean air compressor runs cooler and provides longer service. The ventilation openings on your air compressor

are necessary to maintain proper operating temperature. Do not place rags or other containers on or near these openings.

MAINTENANCE & STORAGE

TROUBLE

No start condition

Low pressure

Safety valve releasing

Oil discharge in air

POSSIBLE CAUSE

Fuse blown or circuit breaker tripped

Loose electrical connections

Overheated motor

Air leak in safety valve

Restricted air filter

Defective check valve

Defective pressure switch or improper

adjustment

Improper oil viscosity

Too much oil in crankcase

Compressor overheated

Restricted air filter

CORRECTIVE ACTION

Check voltage or eliminate extension cord or reset

Check wiring connections

Press the reset button or wait for automatic reset

Check valve manually by pulling upwards on ring. If condition

persists replace valve

Clean or replace as necessary

Replace check valve

Check for proper adjustment and if problem persists, replace

pressure switch

TROUBLE SHOOTING

MAINTENANCE

Before doing any maintenance or adjustments to your air compressor,

the following safety precautions should be taken:

- Disconnect electrical power.

- Drain air tank of pressure.

Daily or before each use

1. Check oil level. The oil level should be centered with the red dot

which appears in the oil sight glass (C) Fig.8.

2. Drain condensation from tank.

3. Check for any unusual noise or vibration.

4. Be sure all nuts and bolts are tight.

Monthly

1. Inspect air system for leaks by applying soapy water to all joints.

Tighten those joints if leakage is observed.

250 hours or six months (whichever comes first)

1. Change compressor oil. See following instructions.

2. Replace oil more often if compressor is used near paint spraying

operations or in dusty environments.

CHANGING OIL

To change oil, oil must be drained from the crank case by unscrewing

and removing oil sight glass (C) Fig.8. Drain oil and replace oil sight

glass. To fill the crank case with oil, first unscrew and remove oil

breather cap (A), pour air compressor oil (SAE 10W30 or SAE 10W20

weight non-detergent compressor oil) into crank case oil opening (B)

until the oil level reaches the red dot at the center mark of the oil

sight glass. Secure oil breather cap (A).

KEEP TOOL CLEAN

Periodically blow out all air passages with dry compressed air. Clean all

plastic parts with a soft damp cloth. NEVER use solvents to clean

plastic parts. They could possibly dissolve or otherwise damage the

material.

CAUTION: Wear safety glasses while using compressed air.

FAILURE TO START

Should your compressor fail to start, check to make sure the prongs on

the cord plug are making good contact in the outlet. Also, check for

blown fuses or open circuit breakers in the line.

STORAGE

1. Set the “ON/AUTO-OFF” lever to “OFF”.

2. Turn the regulator counterclockwise to set the outlet pressure to

zero.

3. Remove the air tool or accessory .

4. Pull ring on safety valve (B) Fig. 4, allowing air to bleed from the tank,

until tank pressure is approximately 20psi. Release safety valve ring.

5. Drain water from air tank. Turn drain valve (A) Fig. 4, counterclock-

wise, to open.

NOTE: If drain valve is plugged, pull ring on safety valve (B) Fig. 4, and

hold until air pressure has been released. The valve can then be

removed, cleaned, and reinstalled.

6. After the water has been completely drained, turn drain valve to

close. The air compressor can now be stored.

7. Store the air compressor in a clean and dry location.

FIGURE 7

7

Replace oil with SAE 10W30 or SAE 10W20 non-detergent

compressor oil. Drain crankcase and fill to proper level

Air pressure regulated too high

Replace filter

PARTS DIAGRAM MODEL: HP02P005S1

8

PARTS LIST MODEL: HP02P005S1

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

38

39

40

42

No. Part Number Description Qty

Cap screw

Spring washer

Cylinder head

Air filter

Gasket

Valve assembly

Valve gasket

Cylinder

Piston

Piston ring set (3)

Retaining ring/bore

Piston pin

Connecting rod

Gasket

Cap screw

Spring washer

Crank shaft

Cap screw

Crankcase gasket

Crankcase cover

Flange hd hex. bolt

Oil sight glass

O-ring

Flange hd hex. bolt

Oil breather cap

Crankcase

Oil seal

Ball bearing

Armature

Ball bearing

Field coil

Wave washer

Rear motor housing

Spring washer

Hex. bolt

Fan

Shaft retaining ring

Capacitor

Motor cover

4

4

1

1

1

1

1

1

1

1

2

1

1

1

2

2

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

4

4

1

1

1

1

CS30106090

SW30502060

CH00102001

AF50901020

GA40501020

VA40201000

VG40502020

CY00602001

PI00747001

PI40302000

RR30503120

PP40901002

CR00802001

GA40503020

CS30108020

SW30502080

CS00902001

CS30108011

CG40402000

CC00502001

FB51200006

OS30601000

OR30603000

FB30306021

OB40602000

CR00202000

OS30602001

BB30701003

AR10103200

BB30701001

FC10103201

WW30505000

RM00403001

SW30502052

HB30205192

FA40702000

SR30504140

CA40801070

MC50102000

No. Part Number Description Qty

FB30305012

FB30305022

MB20203002

FB30306021

PS50201001

CO50705001

OR51200002

CN50705000

UN51200001

PC50601000

RH51002003

TF20203000

HS30315011

PA20203001

HS30316001

WA30501051

SW30502051

HN30405001

MA50401010

PG50301012

QC50501005

EL50703001

TP50701006

HO51301000

RF51001000

WA30502080

HB30108020

CV50405000

SV50402024

DV50403000

PR50802311

EP50802301

CW51200000

EL40101010

OP41001040

RC20203003

43

44

45

46

47

49

50

51

52

53

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

F

F

Flange hd hex. bolt

lange hd hex. bolt

Motor bracket

lange hd hex. bolt

Pressure switch

Connector

O-ring

Connector nut

Unloader

Power cord

Rubber handle

Twin tank & frame

Pan head screw

Panel

Pan head screw

Washer

Spring washer

Hex. nut

Manifold

Pressure gauge

Female quick coupler

90° elbow

Threaded plug

Hose

Rubber foot

Washer

Hex. bolt

Check valve assembly

Safety valve

Drain valve

Pressure relief tube

Exhaust pipe assembly

Copper washer

Elbow

Overload protector (reset)

Rubber cap

4

2

1

4

1

1

1

1

1

1

1

1

4

1

2

4

2

2

1

2

2

2

4

1

4

4

4

1

1

1

1

1

2

1

1

2

937-540-1157

Loading...

Loading...