Page 1

Copyright by Hukseflux | manual v1627 | www.huksefluxusa.com | info@huksefluxusa.com

USER MANUAL STP01

Soil temperature profile sensor with self-test

Page 2

STP 01 manu al v 162 7 2/ 31

Warning statements

Putting more than 2 Volt across the sensor wiring

can lead to permanent damage to the sensor.

Putting more than 15 Volt across the heater wiring

can lead to permanent damage to the heater.

Do not use “open circuit detection” when measuring

the thermocouple sensor output.

Page 3

STP 01 manu al v 162 7 3/ 31

Contents

Warning statements 2

Contents 3

List of symbols 4

Introduction 5

1 Ordering and checking at delivery 9

1.1 Ordering STP01 9

1.2 Included items 9

1.3 Quick instrument check 9

2 Instrument principle and theory 10

2.1 General soil temperature measurement 10

2.2 STP01 soil temperature measurement 10

2.3 STP01 on-line self-test 11

2.4 Optional thermal conductivity measurement 11

2.5 Conformity testing and traceability 12

2.6 Programming 13

3 Specifications of STP01 14

3.1 Dimensions of STP01 17

4 Standards and recommended practices for use 18

5 Installation of STP01 19

5.1 Site selection and installation 19

5.2 Electrical connection 20

5.3 STP01 diagnostics 22

5.4 Requirements for data acquisition / amplification 23

6 Making a dependable measurement 24

6.1 Uncertainty evaluation 24

6.2 Contributions to the uncertainty budget 24

7 Maintenance and trouble shooting 26

7.1 Recommended maintenance and quality assurance 26

7.2 Trouble shooting 27

8 Appendices 29

8.1 Appendix on cable extension / replacement 29

8.2 EU declaration of conformity 30

Page 4

STP 01 manu al v 162 7 4/ 31

List of symbols

Quantities Symbol Unit

Temperature T °C

Temperature difference ΔT °C, K

Thermal conductivity λ W/(m∙K)

Voltage output U V

Voltage output as a function of heating time U (t) V

Voltage output difference ΔU V

Sensitivity S V/K

Heating power per meter Q W/m

Heater length L m

Time constant τ s

Time t s

Resistance R Ω

Depth of installation x m

Distance from the heater r m

Subscripts

property of a sensor sensor

property of the reference temperature Pt100 reference

property at the (soil) surface surface

property of the surrounding soil soil

property of the heater heater

Page 5

STP 01 manu al v 162 7 5/ 31

Introduction

STP01 accurately measures the temperature profile of the soil at 5 depths close to its

surface. It is used for scientific grade surface energy balance measurements. The sensor

is buried and usually cannot be taken to the laboratory for calibration. The on-line selftest using the incorporated heating wire offers a solution to verify STP01’s measurement

stability.

STP01 soil temperature profile sensor offers an accurate temperature difference

measurement at five measurement locations at 0.02, 0.05, 0.1, 0.2 and 0.5 m below the

soil surface. It also has a well specified and fixed distance between the measurement

locations.

STP01 contains 5 matched thermocouples, at locations A to E, and one reference

temperature sensor (Pt100 type) at location E at 0.5 m depth (see figure 0.2). By having

the reference temperature measurement in the sensor and only measuring differential

thermocouple voltages (relative to the reference at 0.5 m), the uncertainty of the

temperature difference measurement is very low: ± 0.02 °C is attainable. Simple copperconductor signal wire is used in STP01’s cable. As an extra, a heating wire is incorporated

in STP01. Analysis of the temperature change during the heating interval serves as a

self-test.

Soil temperature sensors are preferably left in the soil for as long as possible, so that the

soil properties become representative of natural conditions. Using self-testing, the user

no longer needs to take sensors to the laboratory to verify their stable performance.

The result is a much improved accuracy & quality assurance of the measurement relative

to measurements with conventional sensor types.

Typically every 24 hours, the STP01 heater is switched on to perform a self-test.

When activating the heater for a self-test, this will lead to a local increase in temperature

at the sensors at 0.02, 0.05, 0.1 and 0.2 m depth. The STP01 stability is monitored by

analysis of yearly patterns of this step-response.

The step response of the temperature during the self-test can be used to measure the

soil thermal conductivity at 3 depths; 0.05, 0.1 and 0.2 m. For more background on this

measurement method, see the manual of model TP02 thermal needle. The possibility to

perform this measurement is an experimental option, with an unspecified measurement

accuracy.

STP01 is used for high accuracy, scientific grade measurement of the soil energy

balance, with a high level of data quality assurance. Measurements with STP01 are often

combined with soil thermal conductivity and volumic heat capacity measurements with

sensor model TP01 and measurements with heat flux sensor model HFP01SC.

Page 6

STP 01 manu al v 162 7 6/ 31

STP01 advantages are:

high accuracy, scientific measurement of soil energy balance, with a high level of data

quality assurance

high accuracy K/m temperature gradient measurement by accurate positioning of the

thermocouple joints (± 0.001 m), and accurate temperature difference measurement

(± 0.02 K)

high accuracy and stability of the relative distance between sensors (± 0.0005 m)

thin, 0.6 x 10

-3

m thickness, construction which leaves the soil structure intact

simple copper-core signal wire; no special connectors needed

self-test saves servicing time

Sensors made by Hukseflux are designed for compatibility with the most commonly used

datalogger models. For many models we have example programs and wiring diagrams

available.

Requirements for data acquisition and control are:

for temperature measurement: four millivolt measurements, one Pt100 measurement

for the optional self-test: one heater voltage measurement

for the optional self-test: one relay with 12 VDC nominal output, switching the heater

on and off

Equipped with heavy duty cabling, and potted so that moisture does not penetrate the

sensor, STP01 has proven to be very robust and stable. It survives long-term installation

in soils. For ease of installation with a minimum of disturbance of the local soil, Hukseflux

offers IT01 insertion tool.

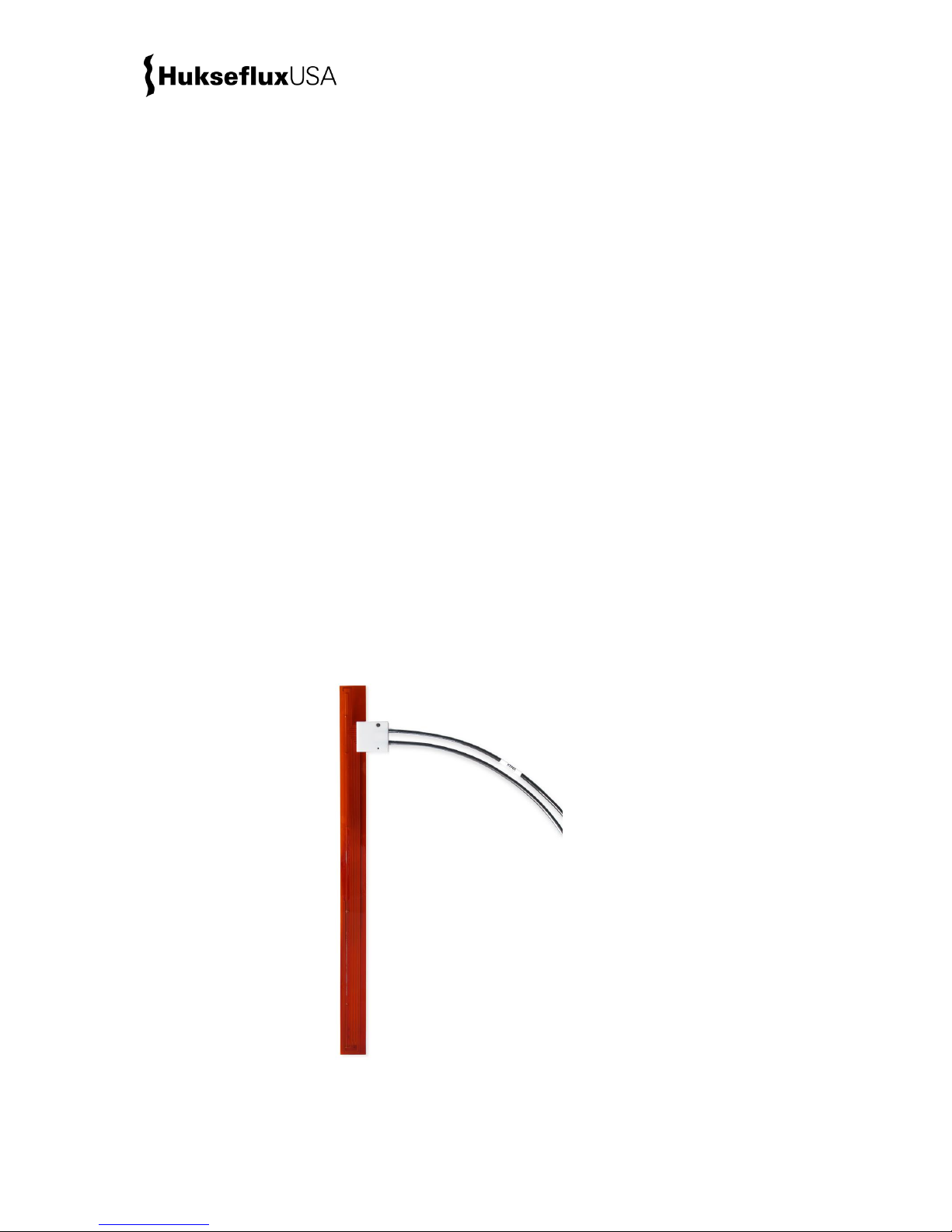

Figure 0.1 STP01. Standard cable length is 5 m.

Page 7

STP 01 manu al v 162 7 7/ 31

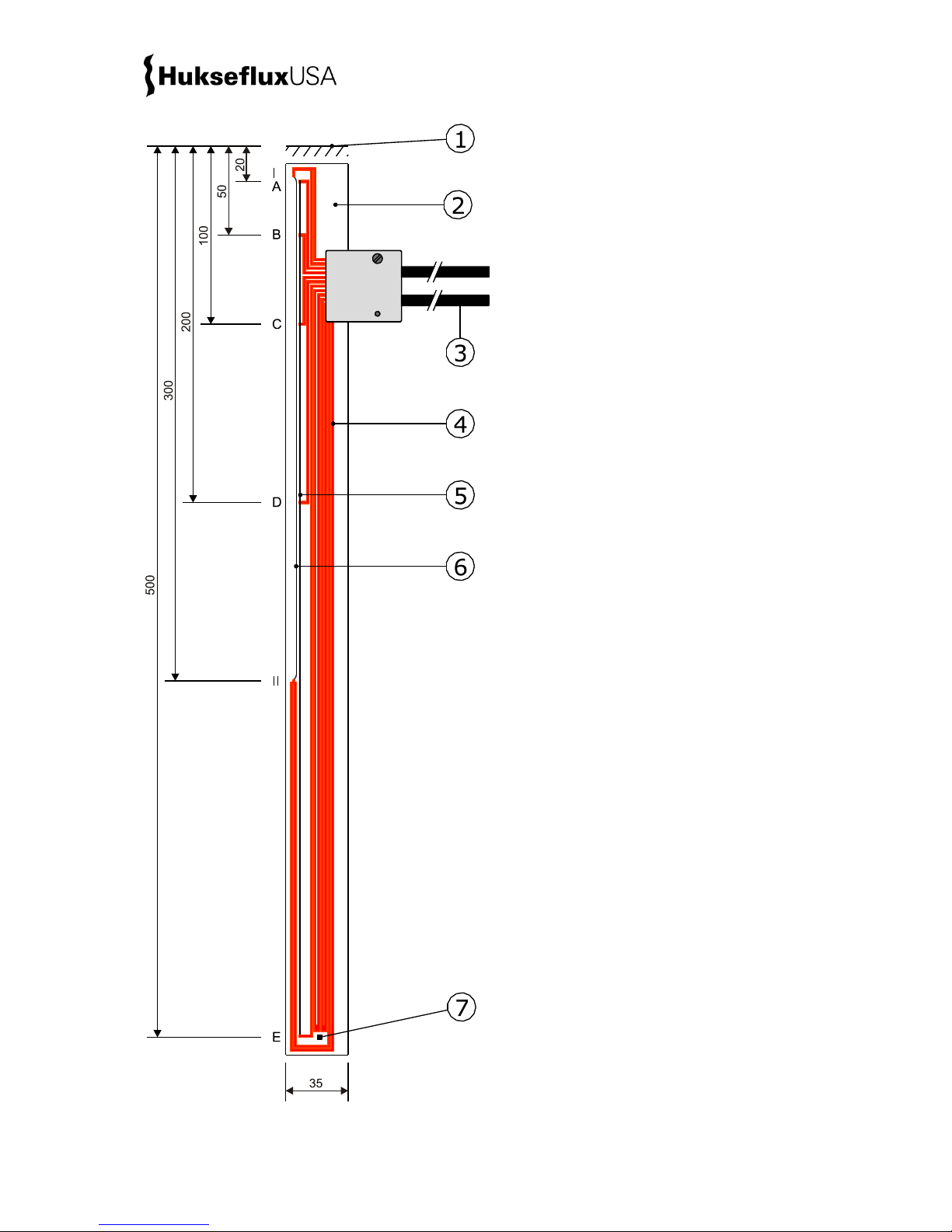

Figure 0.2 STP01 layout and dimensions

1 soil surface

2 sensor foil (0.6 x 10-3 m thickness, 2.5 x 10-3

m at Pt 100)

3 2 x cable 5 m (see options)

4 copper leads

5 T type thermocouple wire

6 CuNi heater wire

7 Pt100 reference temperature sensor (4-wire

connection)

I and II: connection points of the heating wire

(4-wire connection)

A, B, C, D and E: thermocouple type T joints

Dimensions in x 10-3 m

Page 8

STP 01 manu al v 162 7 8/ 31

Options are:

longer cable (2 x), in multiples of 5 m, cable lengths above 20 m in multiples of 10 m

insertion tool IT01

Figure 0.3 IT01 insertion tool is hammered down into the soil. After retracting it leaves

a slit in which STP01 may be inserted.

See also:

model TP01 soil thermal properties sensor

soil heat flux sensors HFP01 and HFP01SC

view our complete product range of surface energy flux measurement products

view our range of pyranometers and net-radiometers

Page 9

STP 01 manu al v 162 7 9/ 31

1 Ordering and checking at delivery

1.1 Ordering STP01

The standard configuration of STP01 is with 2 x 5 metres cable.

Common options are:

longer cable in multiples of 5 m, cable lengths above 20 m in multiples of 10 m.

specify total cable length.

insertion tool IT01

1.2 Included items

Arriving at the customer, the delivery should include:

thermal properties sensor STP01

cable of the length as ordered

product certificate matching the instrument serial number

1.3 Quick instrument check

A quick test of the instrument can be done by connecting it to a multimeter.

1. Check the electrical resistance of the sensor and heater according to the tables in

paragraph 5.3. Use a multimeter at the 50 and 500 Ω range. The typical resistance of the

wiring is 0.4 Ω/m (added value of 2 wires). Infinite resistance indicates a broken circuit;

zero or a lower than 1 Ω resistance indicates a short circuit.

2. Check if the thermocouple sensors react to heat: put the multimeter at its most

sensitive range of DC voltage measurement, typically the 100 x 10-3 VDC range or lower.

Measure between the thermocouple common and the other thermocouple joints. Look at

the reaction when you heat one of the joints.

3. Inspect the sensor foil for any damage.

4. Check the sensor serial number on the cable labels (one at sensor end, one at cable

end of both cables) against the product certificate provided with the sensor.

Page 10

STP 01 manu al v 162 7 10/31

2 Instrument principle and theory

STP01 accurately measures the temperature profile of the soil at 5 depths close to its

surface. A requirement for an accurate measurement is good thermal contact between

soil and sensor. The sensor is buried and usually cannot be taken to the laboratory for

calibration. The on-line self-test using the incorporated heating wire offers a solution to

verify STP01’s measurement stability. The user must incorporate STP01 in his own

measurement and control system. For soil temperature measurement this system should

perform 4 x voltage, and 1 x Pt100 readout. For the self-test you need power supply

switching, and 1 x voltage readout.

Relevant features of TP01 are:

robustness, including a strong cable (essential for permanently installed sensors)

IP protection class: IP67 (essential for outdoor application)

low electrical resistance (low pickup of electrical noise)

2.1 General soil temperature measurement

Usually temperature gradients in the soil are made using separate sensors.

Shortcomings of this method are:

temperature gradients are calculated by taking the difference between inaccurate

measurements. The end result will have a large uncertainty

the relative position is not accurately determined

the sensor construction is often heavy, and conducting a significant amount of heat

Soil temperature and soil thermal properties vary slowly. Usually the data sampling is

done with a 60 s interval and 10 minute averages are stored. You may choose to vary

the data storage interval with depth.

2.2 STP01 soil temperature measurement

STP01 overcomes the traditional shortcomings:

STP01 uses a string of thermocouples type T sharing one and the same CuNi wire and

the same Cu wire (made from the same sheet). We claim that the thermocouples are

“matched”, i.e. have the same properties. The relative accuracy of such matched

thermocouples is better than 0.05 °C.

Determined by the manufacturing process, the relative position of the thermocouple

joints is accurate within ± 0.001 m.

The construction of STP01 consists of plastic foil and relatively thin conductors.

Page 11

STP 01 manu al v 162 7 11/31

A thermocouple type T has an analogue voltage output and a sensitivity of around 40 x

10-6 V/K temperature difference between its two joints. The sensitivity is not a constant

but is a function of T and ΔT.

U = S (T, ΔT) · ΔT (Formula 2.2.1)

In order to measure absolute temperatures at the joints at depth x, the temperature at

one reference joint must be measured. The Pt100 located at 0.5 m depth serves as

“reference temperature”. The thermocouple joint at 0.5 m serves as “reference junction”.

A Pt100 is a standardised type temperature sensitive resistor. It is made of platinum (the

element Pt) and has an electrical resistance of 100 Ω at 0 °C.

T (x) = T

reference

+ U / S (T, ΔT) (Formula 2.2.2)

In commonly used dataloggers it is possible to define the reference temperature T

reference

and the thermocouple type. The datalogger internally calculates absolute temperatures T

(x) using an internal lookup instruction.

2.3 STP01 on-line self-test

The purpose of the self-test is to judge if

the temperature sensors still work, and if so

if they are in good contact with the soil

Typically every 24 hours, the STP01 heater is switched on for 600 s to perform a selftest. When activating the heater for a self-test, this will lead to a local increase in

temperature at the sensors at 0.02, 0.05, 0.1 and 0.2 m depth. The STP01 stability is

monitored by analysis of yearly patterns of this step-response for every depth, corrected

for the heater power. The heater power is, assuming that the resistance is constant,

expressed as U

heater

2

.

U = S · T/U

heater

2

(Formula 2.3.1)

During the self-test, we recommend storing the measured data using a 1 [s] data

storage interval. The time response for one sensor will vary with the soil thermal

conductivity and with the contact between the sensor and the soil. You may look for

yearly patterns.

2.4 Optional thermal conductivity measurement

The step response of the temperature during the self-test can be used to measure the

soil thermal conductivity at 3 depths; 0.05, 0.1 and 0.2 m. For more background on this

measurement method, see the manual of model TP02 thermal needle. The possibility to

perform this measurement is an experimental option, with an unspecified measurement

Page 12

STP 01 manu al v 162 7 12/31

accuracy. The measurement method is based on the thermal needle method. This

requires both a heating wire and a temperature sensor close to the wire. From the

response to a heating step the thermal conductivity of the soil can be calculated.

The method relies on a unique property of a line source: after a short transient period

the temperature rise, T, only depends on heater power, Q, and medium thermal

conductivity, :

T = (Q / 4 ) (ln t + B) (Formula 2.4.1)

With T in K, Q in W/m, in W/(m·K), t the time in s and B a constant. By measuring the

heater power, and tracing the temperature in time is calculated.

The thermal conductivity can be calculated from two measurements at t1 and t2. For

STP01 both t1 and t2 are higher than 200 s, and typically 200 s apart. T is the

temperature difference between the measurements at time t1 and t2, taking t = 0 at the

moment that the heating starts.

= (Q / 4 T) ln(t2 / t1) (Formula 2.4.2)

2.5 Conformity testing and traceability

During manufacturing STP01 has to pass an acceptance test. In the test we verify if the

properties of the thermocouples, Pt100 and heating wire are within specifications. If the

specified sensors are manufactured as required, we consider them traceable to SI. We

rely on their material specifications which we verify by electrical resistance

measurement.

During use, STP01 is buried and usually cannot be taken to the laboratory for calibration.

The on-line self-test using the incorporated heating wire offers a solution to verify

STP01’s measurement stability.

Page 13

STP 01 manu al v 162 7 13/31

2.6 Programming

In case the user writes his own software program for controlling the measurement with

STP01, the program flow in table 2.6.1 may be used.

Table 2.6.1 a summary of a program for control of the measurement with STP01

initialisation

enter sensor and system

information

serial number, upper and lower acceptance limits for T,

U, thermocouple type T, R

heater

every 1 s

measure

measure T

reference

and T (x) for 4

depths

every 600 s

store

store average values

quality checks

acceptance intervals T (x)

every 24 hr

perform self-test

measure U, U

heat,

t

600 s heating interval

heater on

measure U

measure U

heater

at 600 s

heater off

store data

quality checks

acceptance interval

acceptance interval U

heater

acceptance interval U(0) – U(600)

optional

calculate λ at 3 depths

Page 14

STP 01 manu al v 162 7 14/31

3 Specifications of STP01

STP01 measures the temperature profile of the soil at 5 depths close to its surface. It is

designed for long-term monitoring of soils. Good thermal contact between soil and sensor

is required. The on-line self-test, using the incorporated heating wire, offers a solution

for on-site verification of STP01’s functionality and measurement stability. STP01 can

only be used in combination with a suitable measurement and control system. The

possibility to perform a thermal conductivity measurement at 3 depths is an option with

an unspecified measurement accuracy.

Table 3.1 Specifications of STP01 (continued on next page)

STP01 SPECIFICATIONS

Sensor type

soil temperature profile sensor with self-test

Measurand

temperature at 5 depths from 0 to 0.5 m

Rated operating environment

surrounded by soil

Measurand in SI units

temperature in °C

Temperature sensors

matched thermocouples type T

Reference temperature sensor

Pt100, IEC 751:1983 class B

Measurement depths

0.02, 0.05, 0.1, 0.2 and 0.5 m

On-line functionality testing

self-test using the incorporated heater

Measurement range

-30 to +70 °C

Measurand

temperature difference between reference

temperature at 0.5 m and the other measurement

depths

Measurand in SI units

temperature difference in °C

Measurand

temperature gradient

Measurand in SI units

temperature gradient in K/m

Optional non-traceable measurand

thermal conductivity at 3 depths

Measurand in SI units

thermal conductivity in W/(m·K)

Thermocouple type T sensitivity

40 x 10-6 V/K (nominal)

Measurement function / required

programming

thermocouple type T, using a Pt100 as a reference

temperature measurement

Measurement function / required

programming

for the self-test: see the paragraph on this subject

Optional measurement function/ optional

programming

for thermal conductivity measurement: see the

paragraph on this subject

Required readout and control

1 x Pt100

4 x thermocouple type T voltage using the junction at

0.5 m depth as a reference, input resistance > 106 Ω

Expected voltage output

-2 to 2 x 10-3 V (thermocouples)

0 to 15 VDC (heater)

Required uncertainty

10 x 10-6 V at 2 x 10-3 V

0.01 V at 12 V

Optional readout and control

only if the self-test is used

heater: 1 x voltage channel which acts as a current

measurement channel using a current sensing resistor

heater: 1 x switchable 12 VDC, 0.06 A

Rated operating temperature range

-30 to +70 °C

Page 15

STP 01 manu al v 162 7 15/31

Table 3.1 Specifications of STP01 (started on previous page, continued on next page)

Sensor foil surface dimensions

(500 x 35) x 10

-3

m

Sensor foil thickness

0.6 x 10-3 m

2.5 x 10-3 m at Pt100

Connector block dimensions

(40 x 42 x 10) x 10-3 m

Thermocouple sensor resistance range

5 Ω (nominal) + 0.4 Ω/m cable

Standard governing use of the

instrument

not applicable

Standard cable length (2 cables)

5 m (see options)

Wiring

0.15 m wires and shield at cable ends

Cable diameter

2 x 5.5 x 10-3 m

Cable markers

4 x sticker, 1 x at sensor and 1 x cable end, wrapped

around the sensor cables. Both stickers show serial

number and cable 1 / cable 2

IP protection class

IP67

Rated operating relative humidity range

0 to 100 %

Gross weight including 5 m cable

0.7 kg

Net weight including 5 m cable

0.6 kg

Packaging

box of 300 x 210 x 80 mm

HEATER

Heater resistance (nominal)

200 Ω

Heater length

0.28 m

Heater rated power supply

9 to 15 VDC

Heater power supply

12 VDC (nominal)

Power consumption during heating

interval

0.72 W

(heater powered from 12 VDC)

SELF-TEST

Power consumption daily average

0.005 W

(heater powered from 12 VDC, 24 hr interval between

tests)

Interval between self-tests

24 hr

Self-test duration

600 s

INSTALLATION AND USE

Recommended number of sensors

2 per measurement site

Orientation

recommended orientation is with foil surface vertically

oriented (usually this is perpendicular to the soil

surface).

Installation

see recommendations in the product manual

Cable extension

cable extension of STP01 is discouraged: see chapter

on cable extension

Page 16

STP 01 manu al v 162 7 16/31

Table 3.1 Specifications of STP01 (started on previous pages)

CONFORMITY TESTING AND TRACEABILITY

Factory conformity testing

the STP01 functional test compares the electrical

resistance of the produced sensor against the

acceptance interval. This is done for the

thermocouples, Pt100 and heater.

Functional test

STP01 functional test

Calibration traceability

to SI units

Calibration method

by referral to inherent calibration references: type T

thermocouple and Pt 100

Production certificate

included

(confirming result of the functional test)

MEASUREMENT ACCURACY

Uncertainty of the measurement

statements about the overall measurement

uncertainty can only be made on an individual basis.

see the chapter on uncertainty evaluation.

Uncertainty of temperature difference

measurement

1.5 % of measured value plus measurement system

uncertainty in x 10-6 V/40

Uncertainty of reference temperature

measurement

± 0.7 °C plus measurement system uncertainty

Uncertainty of relative position

± 0.001 m

Uncertainty of optional thermal

conductivity measurement

not specified

VERSIONS / OPTIONS

Order code

STP01/cable length in m

Longer cable (2x)

in multiples of 5 m, cable lengths above 20 m in

multiples of 10 m

option code = total cable length

ACCESSORIES

Insertion tool

IT01 insertion tool

Page 17

STP 01 manu al v 162 7 17/31

3.1 Dimensions of STP01

Figure 3.1.1 STP01 soil temperature profile

dimensions in x 10-3 m

(1) soil surface

(2) sensor foil (0.6 x 10-3 m thickness, 2.5 x 10-3 m

at Pt 100)

(3) 2 x cable (standard length 5 m, optionally longer

cable in multiples of 5 m, cable above 20 m in

multiples of 10 m)

(4) copper leads

(5) T type thermocouple wire

(6) CuNi heater wire

(7) Pt100 reference temperature sensor (4-wire

connection)

I and II: connection points of the heating wire (4wire connection)

A, B, C, D and E: thermocouple type T joints

Page 18

STP 01 manu al v 162 7 18/31

4 Standards and recommended practices

for use

STP01 sensors measure temperature as a function of depth in soils, as part of

meteorological surface flux measuring systems. Typically the total measuring system

consists of multiple heat flux- and temperature sensors, often combined with

measurements of air temperature, humidity, solar- or net radiation and wind speed.

There are no standardised operating practices for use of STP01 sensors. The next

chapters contain recommendations of the sensor manufacturer.

Usually this measurement is combined with measurements of the soil heat flux, soil

thermal conductivity and soil heat capacity to estimate the heat flux at the soil surface.

Knowing the heat flux at the soil surface, it is possible to “close the balance" and

estimate the uncertainty of the measurement of the other (convective and evaporative)

fluxes.

Figure 4.1 typical meteorological surface energy balance measurement system with

STP01 installed in the soil

Page 19

STP 01 manu al v 162 7 19/31

5 Installation of STP01

5.1 Site selection and installation

Table 5.1.1 Recommendations for installation of STP01

Location

Preferably install in a large field which is relatively homogeneous and

representative of the area under observation.

Depth

The top of the sensor should be 0.01 m below the soil surface

Orientation

Recommended orientation is with foil surface vertical, (in most cases

that is perpendicular to the soil surface)

Performing a

representative

measurement

At every measurement site we recommend using > 2 sensors at a

distance of > 5 m. This redundancy improves the assessment of the

measurement accuracy.

Installation

There should be no air gaps between sensor and soil.

Use the insertion tool IT01 or a spade (with a flat blade) to make a

vertical cut in the soil.

Make sure the soil around the sensor foil remains intact.

Make sure the sensor and connection block will fit into the cut.

Insert the sensor foil into the cut.

Never run the sensor cable directly to the surface. Bury the sensor cable

horizontally over a distance of at least 1 m, to minimise thermal

conduction through the lead wire. Put the excavated soil back into its

original position after the sensor and cable are installed.

Fixation / strain relief

For mechanical stability and in order to avoid exerting too much force

on the sensor foil, provide sensor cables with additional strain relief, for

example connecting the cable with a tie wrap to one or more metal pins

that are inserted firmly into the soil.

Armoured cable

In some cases cables are equipped with additional armour to avoid

damage by rodents. Make sure the armour does not act as a conductor

of heat or a transport conduit or container of water.

Added heat flux

sensors

Heat flux sensors are typically located closely to the sensor.

Page 20

STP 01 manu al v 162 7 20/31

5.2 Electrical connection

An STP01 must be connected to a measurement and control system, typically a so-called

datalogger. STP01’s thermocouple sensors are passive sensors that do not need any

power. The Pt100 needs a low-power voltage excitation. The heater is powered from 9 to

15 VDC, using a user-supplied relay to switch it on and off.

The 4-wire connections to the heater and Pt100 make it possible to perform a heater and

Pt100 voltage measurement that do not depend on the cable length. In a 4-wire

resistance measurement, two wires carry the heater current, the others are used for the

measurement. No current flows through the latter wires, so that there is no voltage drop

across them, and the true voltage across the resistance is measured.

The thermocouple measurements are independent of cable length. However thermal

voltage offsets may be generated at the points where cables are soldered or connected,

if this is combined with temperature differences between the joints. This is a potential

danger for the accuracy of the temperature (difference) measurement.

Putting more than 2 Volt across the sensor wiring

can lead to permanent damage to the sensor.

Putting more than 15 Volt across the heater wiring

can lead to permanent damage to the heater.

Cables may act as a source of distortion, by picking up capacitive noise. We recommend

keeping the distance between a datalogger or amplifier and the sensor as short as

possible. For cable extension, see the appendix on this subject.

The thermocouple sensor outputs are connected to a differential or single-ended voltage

input.

Page 21

STP 01 manu al v 162 7 21/31

Table 5.2.1 connections of the STP01 cable 1. The cable internally also has pink, yellow

and grey wires, which are not used and not visible when supplied from the factory. The

wires extend 0.15 m from the cable end.

CABLE #

WIRE

FUNCTION

MEASURING SYSTEM

1

Brown

thermocouple 0.5 m (common)

analogue voltage [-] or ground

1

Green

thermocouple 0.2 m

analogue voltage [+]

1

Red

thermocouple 0.1 m

analogue voltage [+]

1

White

thermocouple 0.05 m

analogue voltage [+]

1

Blue

thermocouple 0.02 m

analogue voltage [+]

1

Yellow

not connected

not connected

1

Pink

not connected

not connected

1

Grey

not connected

not connected

1

Black

ground

shield / ground

Table 5.2.2 connections of the STP01 cable 2. The wires extend 0.15 m from the cable end.

CABLE #

WIRE

FUNCTION

MEASURING SYSTEM

2

Yellow

heater measure [+]

analogue voltage [+]

2

Pink

heater power [+]

12 VDC

2

Brown

Pt100 [+]

analogue voltage [+]

2

Blue

Pt100 [+]

excitation [+]

2

Red

Pt100 [-]

analogue voltage [-] or ground

2

Green

Pt100 [-]

excitation ground

2

White

heater measure [-]

analogue voltage [-] or ground

2

Grey

heater power [-]

switched relay to ground

2

Black

ground

shield / ground

Page 22

STP 01 manu al v 162 7 22/31

5.3 STP01 diagnostics

The following tables are use for checking and trouble shooting STP01.

Table 5.3.1 Resistance checks for diagnostics of STP01 cable 1

CABLE #

WIRE

WIRE

RESISTANCE ACCEPTANCE

INTERVAL

1

Brown

Green

2.5 Ω plus 0.4 Ω/m cable (approx.)

1

Brown

Red

3.5 Ω plus 0.4 Ω/m cable (approx.)

1

Brown

White

3.9 Ω plus 0.4 Ω/m cable (approx.)

1

Brown

Blue

4.1 Ω plus 0.4 Ω/m cable (approx.)

Table 5.3.2 Resistance checks for diagnostics of STP01 cable 2

CABLE #

WIRE

WIRE

RESISTANCE ACCEPTANCE

INTERVAL

2

Grey

Pink

190 Ω plus 0.4 Ω/m cable (approx.)

2

White

Yellow

190 Ω plus 0.4 Ω/m cable (approx.)

2

Grey

White

0 Ω plus 0.4 Ω/m cable (approx.)

2

Pink

Yellow

0 Ω plus 0.4 Ω/m cable (approx.)

2

Green

Red

0 Ω plus 0.4 Ω/m cable (approx.)

2

Blue

Brown

0 Ω plus 0.4 Ω/m cable (approx.)

2

Green

Blue

110 Ω plus 0.4 Ω/m cable (approx.)

2

Red

Brown

110 Ω plus 0.4 Ω/m cable (approx.)

Page 23

STP 01 manu al v 162 7 23/31

5.4 Requirements for data acquisition / amplification

The selection and programming of dataloggers is the responsibility of the user. To see if

directions for use with STP01 are available: contact the supplier of the data acquisition

equipment.

Table 5.4.1 Requirements for data acquisition, amplification and control equipment for

STP01 in the standard configuration

Capability to measure small voltage

signals

4 x differential voltage

preferably: 10 x 10-6 V uncertainty

minimum requirement: 20 x 10-6 V uncertainty

(valid for the entire expected temperature range of the

acquisition / amplification equipment)

Input resistance > 106 Ω

Capability to measure the heater

voltage

the heater is powered from 12 VDC

preferably: 0.01 V uncertainty

minimum requirement: 0.1 x 10-3 V uncertainty

Input resistance > 106 Ω

Capability to switch the heater on

and off

a relay must be used. In case you are working from 12 VDC

at 0.06 A (nominal values)

Capability for the data logger or the

software

to store data, and to calculate absolute temperatures from

the reference temperature and thermocouple type T

voltages.

to perform comparison of measurement results against the

acceptance limits

to time and control the self-test

Open circuit detection

(WARNING)

open-circuit detection should not be used, unless this is done

separately from the normal measurement by more than 5

times the sensor response time and with a small current

only. Thermopile sensors are sensitive to the current that is

used during open circuit detection. The current will generate

heat, which is measured and will appear as a temporary

offset.

Page 24

STP 01 manu al v 162 7 24/31

6 Making a dependable measurement

6.1 Uncertainty evaluation

A measurement is called “dependable” if it is reliable, i.e. measuring within required

uncertainty limits for most of the time and if problems, once they occur, can be solved

quickly.

The measurement uncertainty is a function of:

application errors: the measurement conditions and environment in relation to the

sensor properties, the influence of the sensor on the measurand, the

representativeness of the measurement location

It is not possible to give a single estimate for STP01 measurement uncertainty.

Statements about the overall measurement uncertainty can only be made on an

individual basis.

6.2 Contributions to the uncertainty budget

6.2.1 Non- representativeness of the measurement location

The representativeness of the measurement location may be assessed by performing

multiple measurements at various locations in the same area.

6.2.2 measurement uncertainties for the reference temperature measurement

STP01 is equipped with a Pt100 platinum resistance thermometer. It is classified as class

B according to DIN EN 60751. It has a resistance of 100 Ω at a temperature of 0 °C.

To convert resistance in Ω to temperature in °C, one can use the following equation:

with R

Pt100

the resistance in Ω, T the temperature in °C, A and B the Pt100 coefficients

A = 3.908 x 10-3

B = -5.775 x 10

-7

The tolerance values of the temperature are: 0.3 + 0.005 |T|. In the rated temperature

range of STP01, Hukseflux’ interpretation is that the absolute temperature measurement

with the Pt100 has an uncertainty of 0.7 °C, and relative measurements with the Pt100

(Formula 6.2.2.1)

Page 25

STP 01 manu al v 162 7 25/31

an uncertainty of 0.4 °C. Typical added uncertainties due to electronics and in the order

of 0.2 °C for absolute temperature measurement and 0.1 °C for relative temperature

measurements.

6.2.3 Differential measurement with matched thermocouples

Hukseflux estimates that matched thermocouples type T measure temperature

differences with an uncertainty of better than 1.5 % in the -20 to + 70 °C temperature

range. This estimate is based on their linearity specification in that temperature range.

Page 26

STP 01 manu al v 162 7 26/31

7 Maintenance and trouble shooting

7.1 Recommended maintenance and quality assurance

STP01 measures reliably at a low level of maintenance. Unreliable measurement results

are detected by scientific judgement, for example by looking for unreasonably large or

small measured values during the self-test. The preferred way to obtain a reliable

measurement is a regular critical review of the measured data, preferably checking

against other measurements.

Table 7.1.1 Recommended maintenance of STP01. If possible the data analysis should

be done on a daily basis.

MINIMUM RECOMMENDED SOIL TEMPERATURE SENSOR MAINTENANCE

INTERVAL

SUBJECT

ACTION

1

1 day

self-test

at least one self test per day

2

1 week

data analysis

compare measured data to the maximum possible or

maximum expected temperatures and to other measurements

for example from nearby stations or redundant instruments.

Historical seasonal records can be used as a source for

expected values. Look for any patterns and events that

deviate from what is normal or expected. Analyse the

measurement results. Compare to acceptance intervals.

3

6 months

inspection

inspect cable quality, inspect mounting, inspect location of

installation

look for seasonal patterns in measurement data and results of

the self-test

4

2 years

lifetime

assessment

judge if the instrument will be reliable for another 2 years, or

if it should be replaced

Page 27

STP 01 manu al v 162 7 27/31

7.2 Trouble shooting

Table 7.2.1 Trouble shooting for STP01

General

Inspect the quality of installation.

Inspect if the wires are properly attached to the data logger.

Check the condition of the cables.

Inspect the connection of the shields (typically connected at the datalogger side).

Check the datalogger program in particular if the right thermocouple type and

reference temperature are entered.

Check the sensor serial number on the cable labels (one at sensor end, one at

cable end) against the product certificate provided with the sensor.

The sensor

does not give

any signal

A quick test of the instrument can be done by connecting it to a multimeter.

Check the electrical resistance of the sensor and heater according to the tables in

paragraph 5.3. Use a multimeter at the 50 and 500 Ω range. The typical resistance

of the wiring is 0.4 Ω/m (added value of 2 wires). Infinite resistance indicates a

broken circuit; zero or a lower than 1 Ω resistance indicates a short circuit.

Check if the thermocouple sensors react to heat: put the multimeter at its most

sensitive range of DC voltage measurement, typically the 100 x 10-3 VDC range or

lower. Measure between the thermocouple reference at 0.5 m and the other

thermocouple joints. Look at the reaction when you heat one of the joints.

Inspect the sensor foil for any damage.

Check the sensor serial number on the cable labels (one at sensor end, one at

cable end of both cables) against the product certificate provided with the sensor.

The sensor

signal is

unrealistically

high or low

Check the cable condition looking for cable breaks.

Check the data acquisition of the thermocouple sensor measurement by applying a

1 x 10-6 V source to it in the 1 x 10-6 V range. Look at the measurement result.

Check if it is as expected.

Check the Pt100 measurement by replacing it with a 100 Ω resistor with 4 wire

connection. The results should be 0 °C.

Check the data acquisition of the heater voltage measurement by applying a 1 V

source to it. Look at the measurement result. Check if it is as expected.

Check the heater voltage power supply. It should be in the 12 V range.

Check the data acquisition by short circuiting the data acquisition voltage inputs

with a

50 Ω resistor. Look at the measured value. Check if the output is close to 0 V.

The sensor

signal shows

unexpected

variations

Check the presence of strong sources of electromagnetic radiation (radar, radio).

Check the condition and connection of the shield.

Check the condition of the sensor cable.

Check if the cables are is not moving during the measurement.

Page 28

STP 01 manu al v 162 7 28/31

Page 29

STP 01 manu al v 162 7 29/31

8 Appendices

8.1 Appendix on cable extension / replacement

For STP01, Hukseflux discourages extension or replacement of cables because any

connection involving conductors of different composition may cause thermal offsets. This

applies to soldered and clamped connections and also to connectors. Thermal offsets are

usually in the microvolt range and are generated by temperature differences between the

2 joints in one sensor loop. They can be avoided by locating connections in environments

that are in thermal equilibrium, and by locating connections physically close to one

another. Thermal offsets cause errors when they interfere with small thermocouple

voltages. STP01 is equipped with two cables. Keep the distance between data logger or

amplifier and sensor as short as possible. Cables may act as a source of distortion by

picking up capacitive noise. In an electrically “quiet” environment the STP01 cable may be

extended without problem to 100 metres. If done properly, the sensor signals, although

small, will not significantly degrade because the sensor resistance is very low (which

results in good immunity to external sources) and because there is no current flowing (so

no resistive losses). Cable and connection specifications are summarised below.

Table 8.1.1 Preferred specifications for cable extension of STP01

Cable

8-wire, shielded, with copper conductor

Extension sealing

make sure any connections are sealed against humidity ingress

Conductor resistance

< 0.2 /m

Outer diameter

5.5 x 10-3 m

Length

cables should be kept as short as possible, in any case the total cable

length should be less than 100 m

Outer mantle

with specifications for outdoor use

(for good stability in outdoor applications)

Connection

for STP01 we discourage cable extension or replacement.

if cable extension is needed, use high quality gold-plated and metal

shielded connectors.

If connectors cannot be used, solder the new cable conductors and shield

to those of the original sensor cable, and make a waterproof connection

using heat-shrink tubing with hot-melt adhesive, or use gold plated

waterproof connectors. Always connect the shield.

Make sure the soldered connections are thermally protected and as much

as possible in thermal equilibrium. This may be achieved by using a

heavy metal mantle.

Page 30

STP 01 manu al v 162 7 30/31

8.2 EU declaration of conformity

We, Hukseflux Thermal Sensors B.V.

Delftechpark 31

2628 XJ Delft

The Netherlands

in accordance with the requirements of the following directive:

2014/30/EU The Electromagnetic Compatibility Directive

hereby declare under our sole responsibility that:

Product model: STP01

Product type: Soil temperature profile sensor

has been designed to comply and is in conformity with the relevant sections and

applicable requirements of the following standards:

Emission: EN 61326-1 (2006)

Immunity: EN 61326-1 (2006)

Emission: EN 61000-3-2 (2006)

Emission: EN 61000-3-3 (1995) + A1 (2001) + A2 (2005)

Report: 08C01340RPT01, 06 January 2009

Eric HOEKSEMA

Director

Delft

September 08, 2015

Page 31

© 2016, Hukseflux Thermal Sensors B.V.

www.hukseflux.com

Hukseflux Thermal Sensors B.V. reserves the right to change specifications without notice.

Loading...

Loading...