Page 1

1

10/04 P/N 21168202

© COPYRIGHT 2004 by HUFFY SPORTS

Inground System

Owners Manual

Customer Service Center

• N53 W24700 South Corporate Circle • Sussex, WI 53089 • U.S.A.

• 2 People

• Carpenter’s Level

• 15’ Tape Measure

• Shovel & Post Hole

Digger

• Wood Board (scrap)

• Tape

• Sawhorse or

Support Table

• Wedge

•

• Container to Mix

• (2 each) Wrenches and/or Socket Wrenches and

Sockets (Deep-Well Sockets are Recommended).

1/2"

7/16" 9/16" 3/4"

• Optional: Large &

Small Adjustable

Wrenches

1/2" 9/16" 3/4"

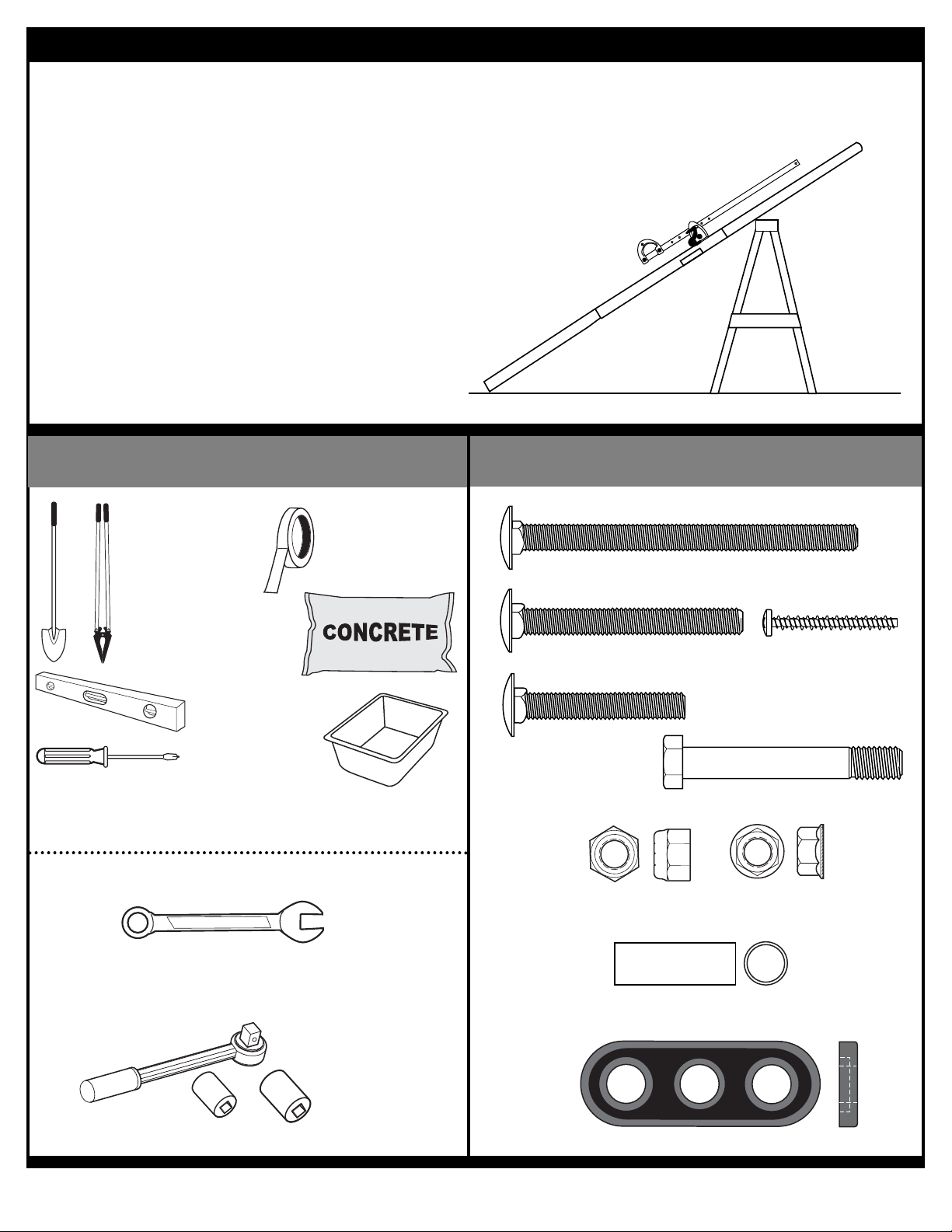

REQUIRED TOOLS AND MATERIALS:

7/16"

• Phillips Screwdriver

• Hammer

• Stepladder 8 ft. (2.4 m)

• Safety Goggles

Toll-Free Customer Service Number for U.S: 1-800-558-5234,

For Canada: 1-800-284-8339,

For Europe: 00 800 555 85234 (Sweden: 009 555 85234),

For Australia: 1-800-632 792

Internet Address: http://www.huffysports.com

READ AND UNDERSTAND

OPERATOR'S MANUAL

BEFORE USING THIS UNIT.

FAILURE TO FOLLOW

OPERATING INSTRUCTIONS

COULD RESULT IN INJURY

OR DAMAGE TO PROPERTY.

WARNING!

• Heavy Duty Tape

Page 2

2

P/N 21168202 10/04

BEFORE YOU START!

To ensure optimal playability of backboard system, a

close tolerance fit between the elevator components

and hardware is required. Test-fit large bolts into large

holes of elevator tubes, backboard brackets, and

triangle plates. Carefully rock them in a circular

motion to ream out any excess paint from holes if

necessary.

Not all items pictured are included with every model.

201251 2/99

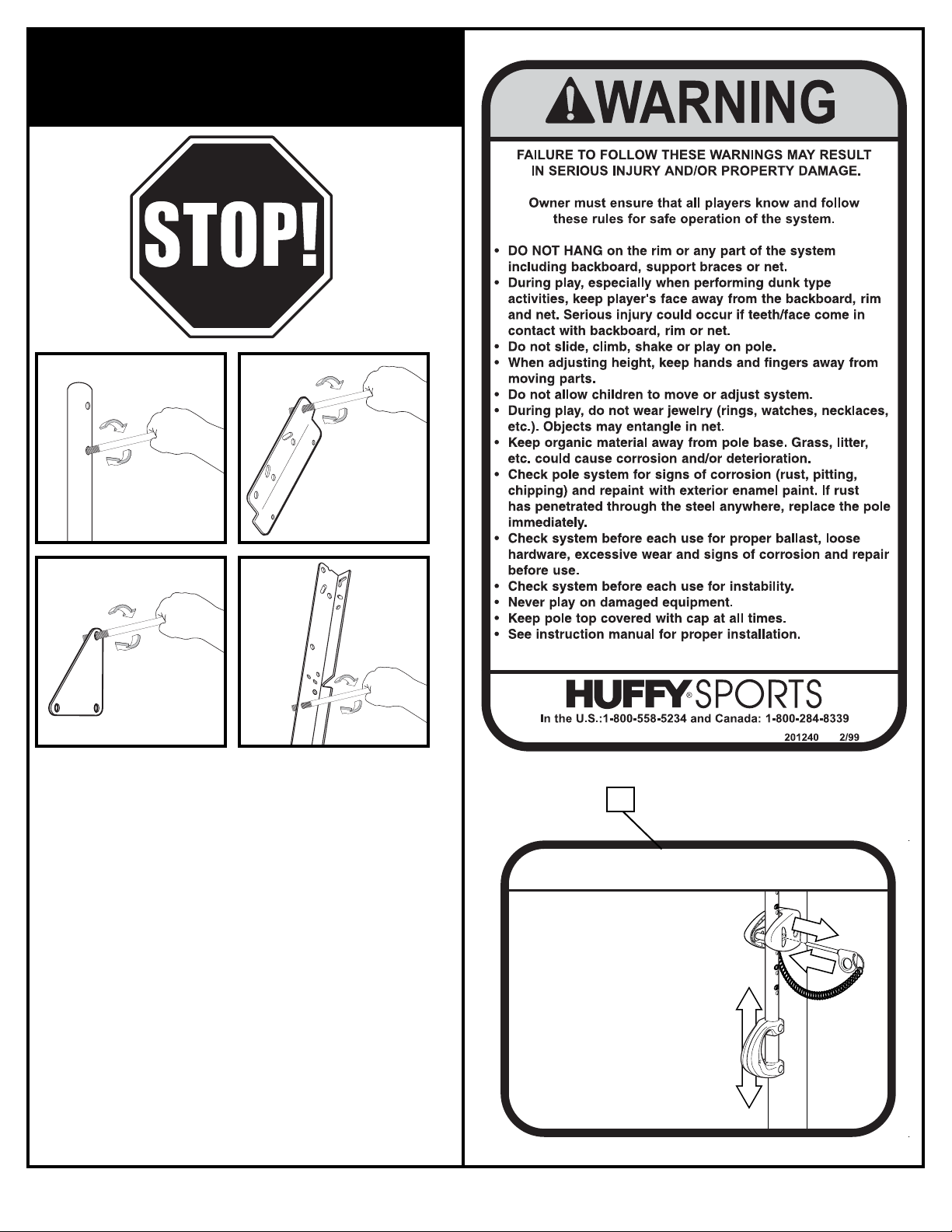

HEIGHT ADJUSTMENT

TO ADJUST BACKBOARD:

1. While holding handle, remove pin.

2. Move elevator up or down to

desired height.

3. Replace pin full length to lock

system at desired height.

35

1

3

2

2

Page 3

10/04 P/N 21168202

3

SAFETY INSTRUCTIONS

Most injuries are caused by misuse and/or not following instructions.

Use caution when using this system.

• If using a ladder during assembly, use extreme caution.

• Two (2) people are reccomended for this operation.

• Seat the pole sections properly. Failure to do so could allow the pole

sections to separate during play.

• Before digging, contact utility company to locate underground power

cables, gas, and water lines. Ensure there are no overhead power lines

within 20 ft. (7 m) radius of pole location.

• Climate, corrosion, excessive use, or misuse could result in system failure.

• If technical assistance is required, contact Huffy Sports.

• Minimum operational height is 6'6" (1.98 m) to the bottom of backboard.

• This equipment is intended for home recreational use only and NOT

excessive competitive play.

• Read and understand the warning label affixed to pole. Label is shown

below

• The life of your basketball pole depends on many conditions. The climate,

placement of the pole, the location of the pole, exposure to corrosives such

as pesticides, herbicides, or salts are all important.

• Adult supervision is recommended when adjusting height.

• Serious injury could occur if teeth/face come in contact with backboard,

net, or rim.

FAILURE TO FOLLOW THESE SAFETY INSTRUCTIONS MAY RESULT IN

SERIOUS INJURY, PROPERTY DAMAGE AND WILL VOID WARRANTY.

Owner must ensure that all players know and follow these rules for safe

operation of the system.

To ensure safety, do not attempt to assemble this system without following

the instructions carefully. Proper and complete assembly, use and

supervision is essential for proper operation and to reduce the risk of

accident or injury. A high probability of serious injury exists if this system is

not installed, maintained, and operated properly. Check entire box and inside

all packing material for parts and/or additional instructional material. Before

beginning assembly, read the instructions and identify parts using the

hardware identifier and part

s list in this document.

Page 4

4

P/N 21168202 10/04

For more information on assembly, placement, proper

use, and maintenance, visit The American Basketball

Council website at http://www.smarthoops.com.

IMPORTANT!

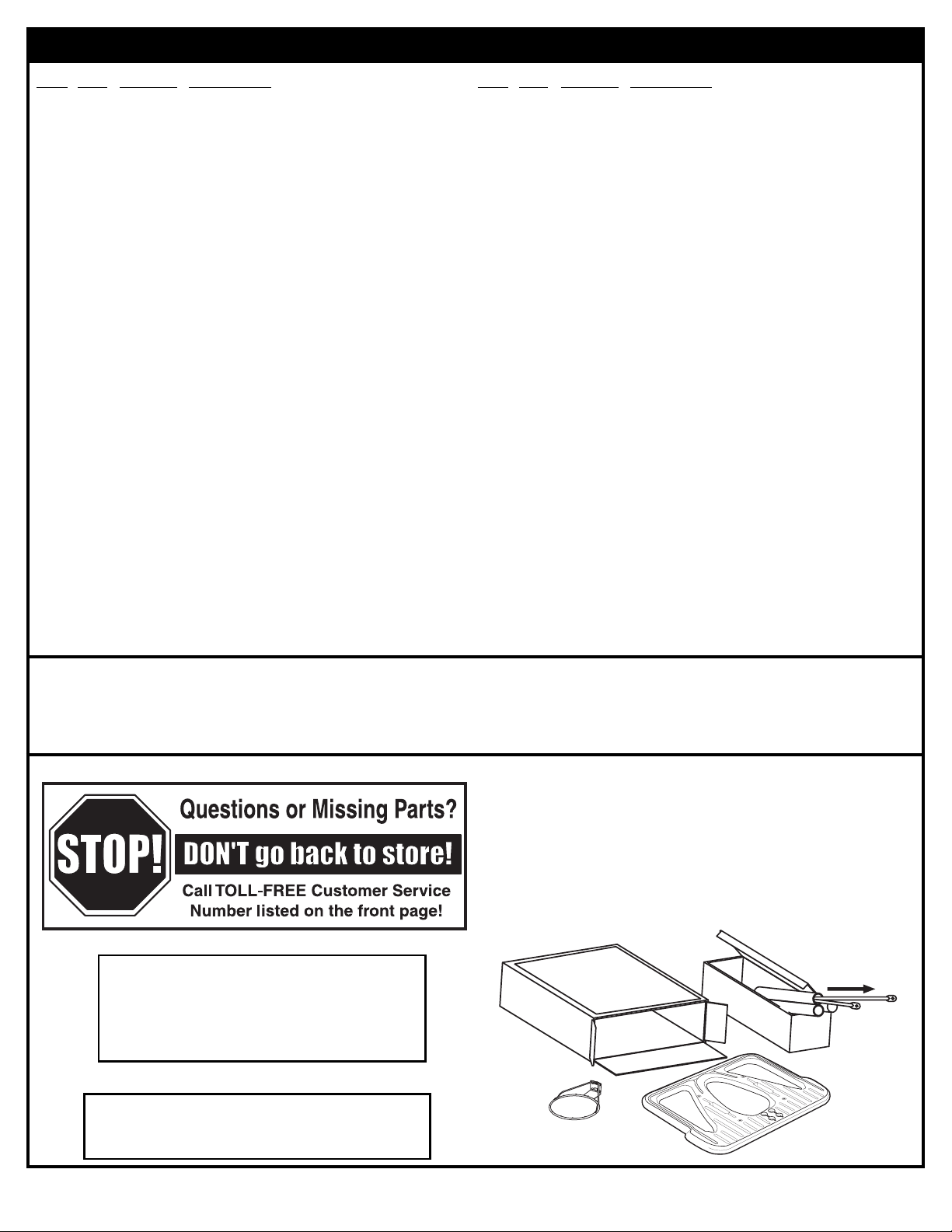

Remove all contents from boxes.

Be sure to check inside pole sections;

hardware and additional parts are

packed inside.

NOTICE TO ASSEMBLERS

ALL Huffy Sports Basketball Systems, including those used for DISPLAYS, MUST be assembled and

ballasted with sand, water or concrete according to the instructions. Failure to follow instructions

could result in SERIOUS INJURY. It is NOT acceptable to devise a makeshift weight system.

WARRANTY CARD:

Please remember to complete your product

registration form either on-line at:

www.huffysports.com or mail-in the

enclosed postcard.

Item Qty.

Part No. Description

1 1 908123 Top Pole Section

2 1 908125 Middle Pole Section

3 1 908124 Bottom Pole Section

4 2 202800 Ground Sleeve

5 1 202801 Ground Sleeve Cap

6 1 204832 Bracket, Pole Mount

7 2 203053 Carriage Bolt, 5/16-18 x 4 Long

8 9* 203100 Hex Flange Nut, 5/16-18

9 3* 206360 Bolt, Hex Head, 3/8-16 x 2-5/8 Long

10 4 203232 Washer, Metal, 3/4” O.D.

11 4 203063 Nut, Nylock, Hex Head, 3/8-16

12 2 204858 Spacer, Biscuit, Plastic

13 2 204857 Spacer, Metal 1/2” O.D. x 1.44 Long

14 2 204859 Cover, Pin Assembly

15 3* 203038 Carriage Bolt, 5/16-18 x 2-3/4 Long

16 1 204850 Pin, Locking

17 1 204853 Lanyard, Black Coil

18 1 908152 Height Adjustment Rod

19 1 204872 Label, Height Indicator

20 2 203103 Carriage Bolt, 5/16-18 x 2 Long

21 1 204803 Screw, Phillips Head

22 4 202862 Spacer, .563 ID x 1.190 Long

23 4 206311 Spacer, .53 I.D. x .65 O.D. x .5 Long

24 6 206340 Lock Nut,1/2-13

25 2 900846 Board Bracket

26 1 207103 Cap,Pole, 3.5" X .75"

27 6 206244 Bolt, Hex Head 1/2-13 x 8 Long

Item

Qty.

Part No. Description

28 2 900183 Elevator Tube, Lower-Long

29 1 204837 Spring

30 2 904807 Elevator Tube, Upper-Short

31 2 201129 Spacer, Metal .402 I.D. x .50 O.D. x 1.8

32 1 Rim

33 12* 201219 Smart Clip

34 1 204281 Net

35 1 201251 Label, Height Adjustment

36 1 203279 Anti-Skid Tape

37 1 204855 Handle, Left

38 1 204856 Handle, Right

39 2 201683 Spacer, Black, 1.5 Long

40 1 206990 Bracket Reinforcement

41 1 900033 Slam Jam Bracket, Black

42 1 203796 Bolt, “Tee” 3/8 - NC x 5 Long

43 1 200318 Bracket Reinforcement, Slam Jam

44 1 203472 Spring, Black

45 1 203470 Washer, Flat 5/8 I.D. x 1-1/2 O.D.

46 1 203795 Nut, Special 3/8-NC

47 4 201611 Bolt, Hex-Flange 5/16-18 x 3" Long

48 1 240017 Bolt, Hex, 1/4-20 x 2-1/4 Long

49 1 240027 Nut, Hex, Nylock, 1/4-20

50 1 903601 Rebar

51 2 204159 Rebar Centering Spacer

52 2 200533 Spacer, Board Mounting, Plastic

53 4 205528 Bolt, Hex Flange, 5/16-18 x 1" Long

54 1 206118 Label, Warning

* YOU MAY HAVE EXTRA PARTS WITH THIS MODEL.

PARTS LIST - See Hardware Identifier

Page 5

10/04 P/N 21168202

5

#8 (9)*

#10 (4)

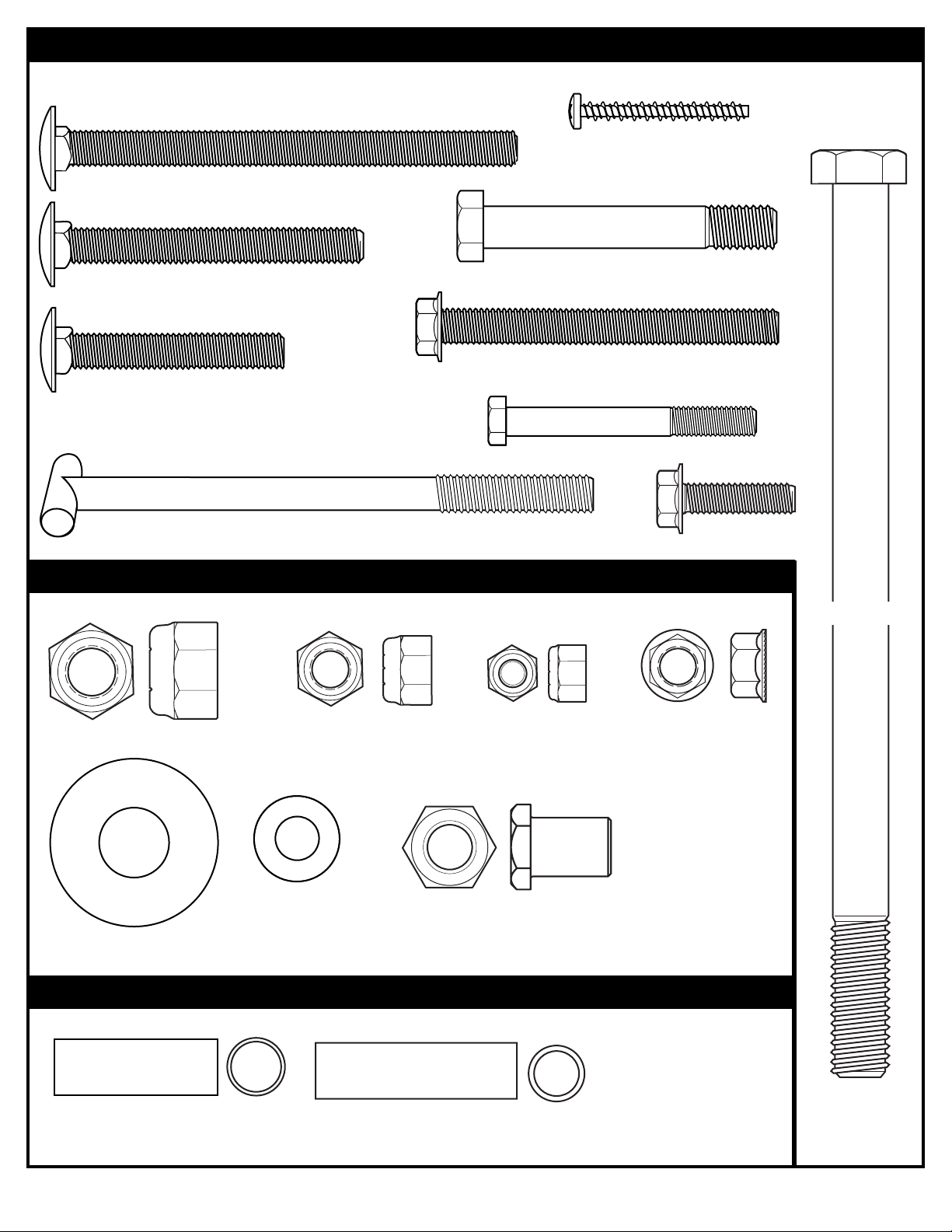

HARDWARE IDENTIFIER (BOLTS & SCREWS)

HARDWARE IDENTIFIER (NUTS & WASHERS)

HARDWARE IDENTIFIER (METAL SPACERS)

#13 (2)

#7 (2)

#11 (4)

#15 (3)*

#20 (2)

#24 (6)

#21 (1)

#31 (2)

#27 (6)

#42 (1)

#46 (1)

#45 (1)

#9 (3)*

* You may have extra parts with this model.

#47 (4)

#48 (1)

#49 (1)

#53 (4)

Page 6

6

P/N 21168202 10/04

#44 (1)

#41 (1)

#43 (1)

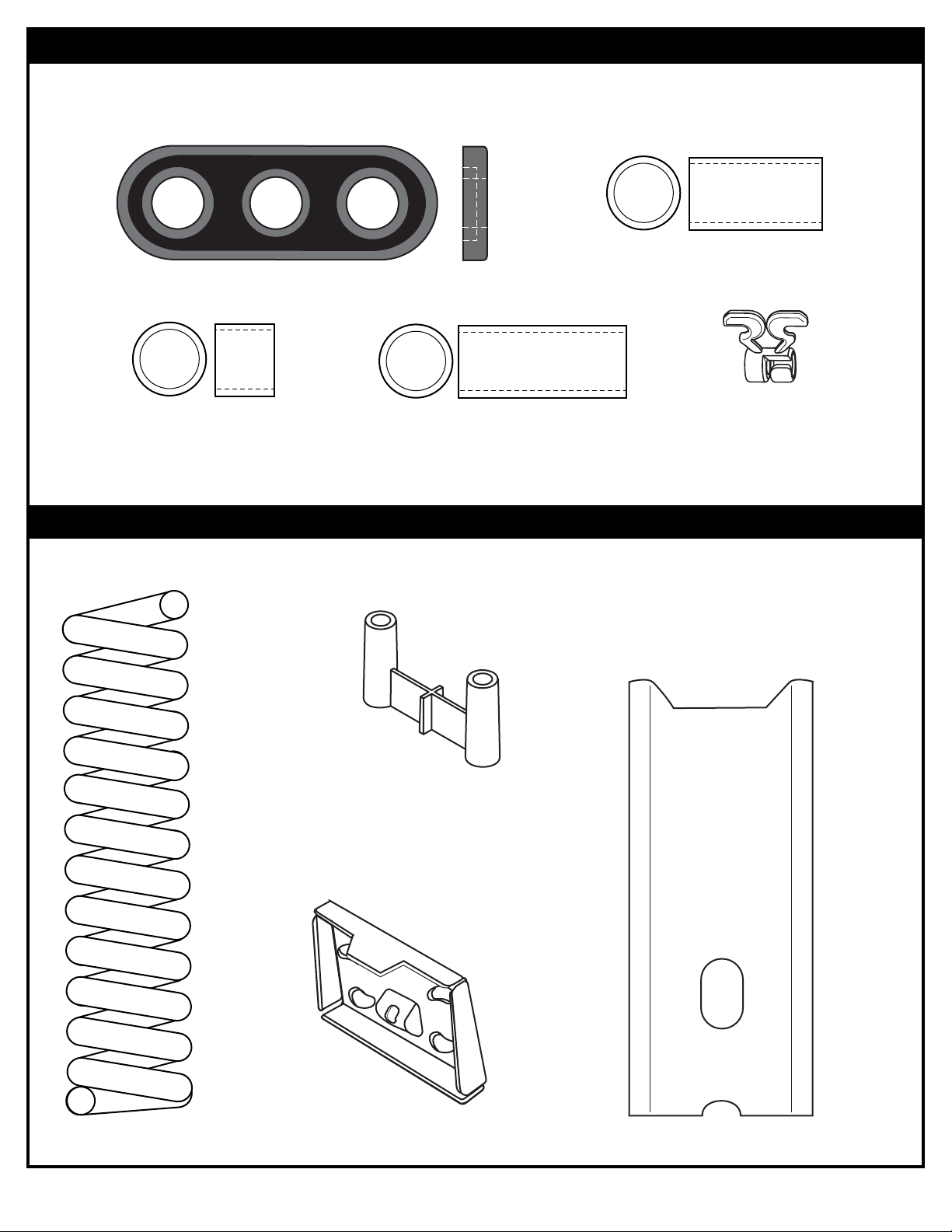

HARDWARE IDENTIFIER (PLASTIC SPACERS & CLIPS)

HARDWARE IDENTIFIER (OTHER)

#23 (4)

#22 (4)

#12 (2)

#39 (2)

#33 (12)*

#52 (2)

Page 7

10/04 P/N 21168202

7

TOOLS REQUIRED FOR THIS SECTION

HARDWARE USED IN THIS SECTION (not actual size)

SECTION A: ASSEMBLE THE POLE

Phillips-Head

Screwdriver

(2) 1/2” and (2) 9/16" Wrenches

9/16”

1/2”

AND/OR

(2) Socket Wrenches and Sockets

Shovel and Post

Hole Digger

Carpenter's Level

Tape

#7

#15

#20

#21

#9

#8

#11

#13

#12

Container to Mix

This is what your system will look like when you’ve

finished this section:

Page 8

8

P/N 21168202 10/04

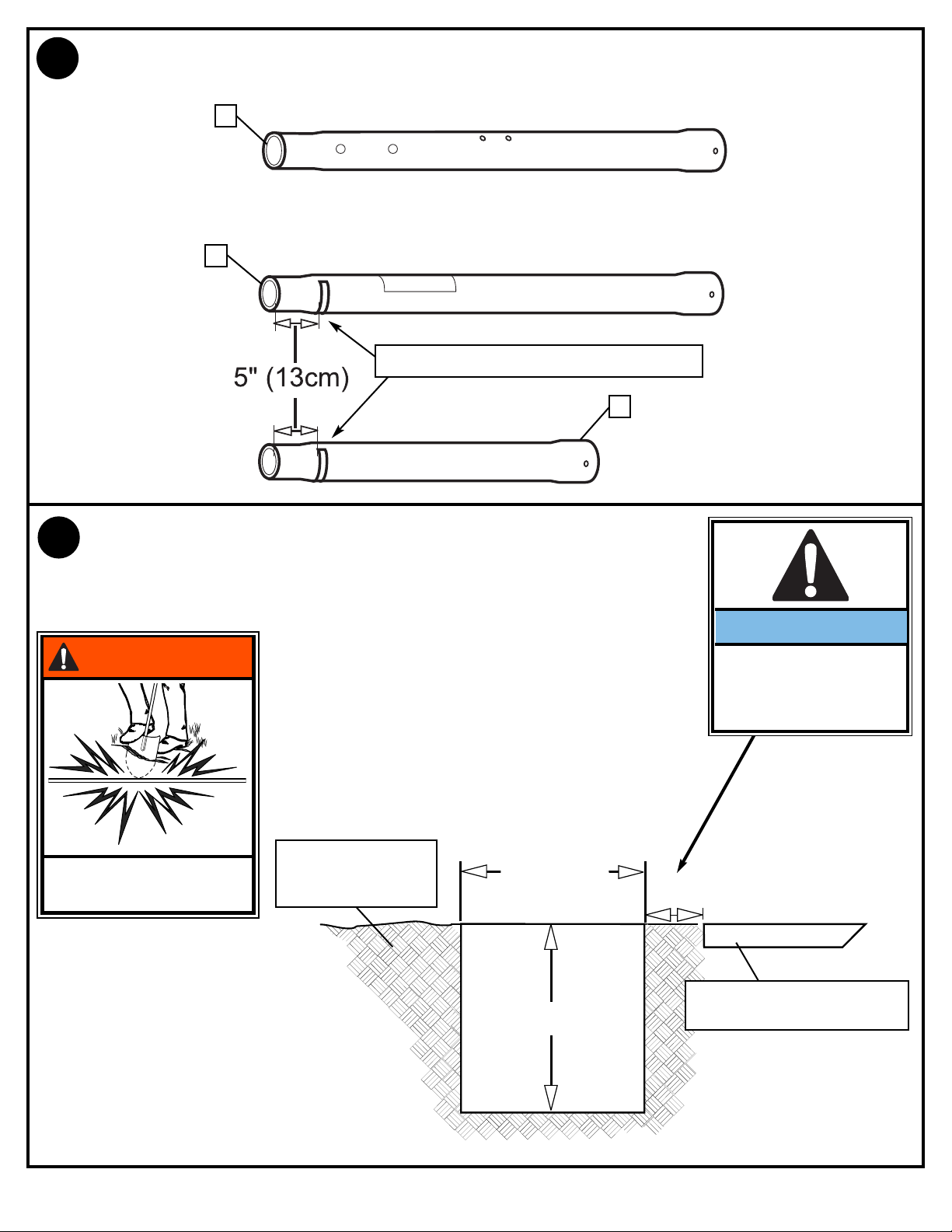

1

TOP

MIDDLE

BOTTOM

2

3

1.

Mark pole sections with tape (not supplied) at indicated distances from ends as shown.

Tape (Not Supplied)

18" (42.7 cm)

6" (15.2 cm)

24" (61 cm)

PLAYING SURFACE

GROUND SURFACE

2.

Ensure ground is level with playing surface, then dig pole hole.

CONTACT UTILITIES

BEFORE DIGGING.

WARNING!

IMPORTANT!:

Maximum distance from

edge of hole to edge of

playing surface 6”

(15.2 cm).

Page 9

10/04 P/N 21168202

9

4.

SIDE VIEW

Fill hole approximately 1/3

full with mixed concrete.

FIG. A

FLANGE

Insert ground sleeve assembly and center

in hole (FIG. A).

Note: Leave 1" below flange exposed

for drainage hill.

5.

IMPORTANT!:

NOTE POSITION OF

FLANGE

IMPORTANT!: CONTINUE ON TO NEXT STEP.

DO NOT

WAIT FOR CONCRETE TO CURE.

PLAYING SURFACE

3.

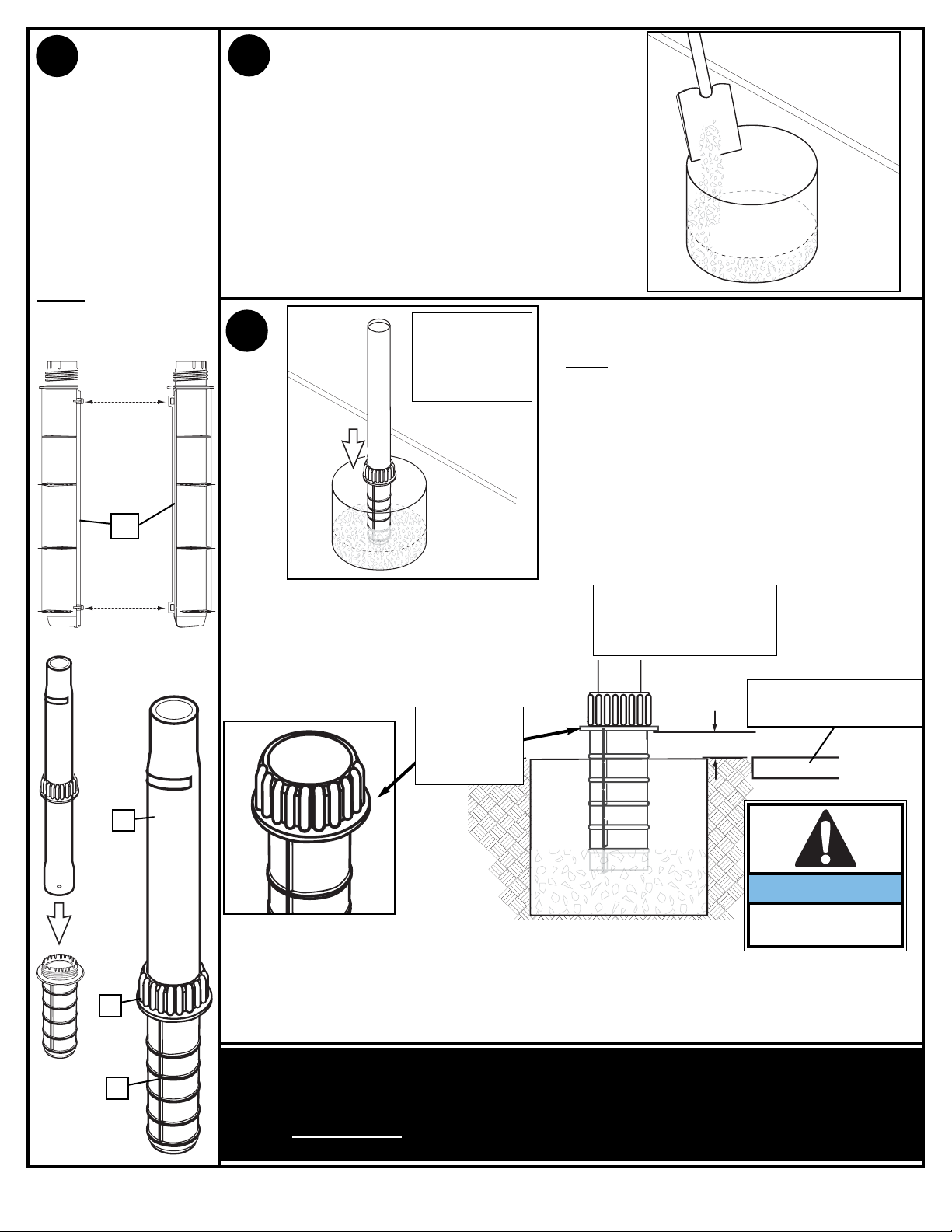

Snap two halves of

ground sleeve (4)

together.

Insert and secure

bottom pole section

(3) into ground sleeve

(4) by tightening

ground sleeve cap (5).

NOTE

: Flared end

goes inside ground

sleeve.

3

5

4

4

1" (2.54 cm)

Page 10

10

P/N 21168202 10/04

4

3

Fill hole completely with concrete.

6.

5

1

7.

Tamp down concrete to release air pockets and build drainage hill. Level pole section in all directions

several times while concrete is curing.

SIDE VIEW

DRAINAGE HILL

IMPORTANT!: CONTINUE ON TO NEXT STEP.

DO NOT

WAIT FOR CONCRETE TO CURE.

IMPORTANT!: W AIT A MINIMUM OF 24 HOURS BEFORE

GOING ON TO NEXT STEP. CONCRETE MUST

CURE.

PLAYING SURFACE

Make a reference mark

here for anti-skid tape.

NOTE A:

Keep flange pushed down

to concrete and leveled.

NOTE B:

1" (2.54 cm)

1" (2.54 cm)

" (2.54 cm)

Page 11

10/04 P/N 21168202

11

Af

ter concrete has cured, remove bottom pole section from ground sleeve (4). Place anti-skid tape (36)

around the bottom area of bottom pole (see note A).

KEEP

GROUND SLEEVE CAP ON BOTTOM POLE.

36

4

8.

5

Place top edge of anti-skid

tape on mark made in

step 7.

NOTE A:

Tape prevents the pole

from rotating during play.

NOTE B:

Page 12

12

P/N 21168202 10/04

1

5

9.

Stack and bounce bottom (3) and middle (2)

pole sections together. Bounce pole sections

together until middle section no longer moves

toward taped reference mark on bottom pole.

2

IMPORTANT 5

Keep on Bottom Pole

3

Wood Scrap

(NOT

SUPPLIED)

10.

Stack upper pole section (1) to bottom and middle

pole assembly and continue bouncing until top pole

(1) no longer moves toward taped reference mark on

middle pole.

IMPORTANT!:

POLE SECTIONS

SHOULD HAVE A

3-1/2" (9 CM)

MINIMUM OVERLAP.

Wood Scrap

(NOT

SUPPLIED)

Taped reference marks

1-1/2"

(3.81 cm)

Tape

5"

(12.7 cm)

Tape

1-1/2"

(3.81 cm)

Tape

5"

(12.7 cm)

Tape

IMPORTANT!:

The warning

label should be

90 degees from

uppermost holes

on top pole (1) see Illustration.

W

ARNING

F

AILU

RE

T

O

FOLLOW

IN

S

E

R

T

IOUS

H

E

SE

I

N

W

J

U

A

R

RNINGS

Y

A

N

D

/O

Owner

MA

R

Y

PR

R

O

E

m

P

SU

u

E

st

RTY

L

T

ensure

DAM

these

A

that

GE.

rules

all

p

la

for

yer

safe

s

•

k

n

DO

operation

ow

NOT

and

fol

HANG

of

l

ow

the

includi

on

sy

the

s

tem

n

g

rim

b

.

ac

•

o

kboar

Du

r

a

r

n

in

y

g

d,

p

play

a

suppor

r

t

of

,

esp

a

the

c

t

tivitie

e

braces

ciall

syst

s

y

e

,

m

w

k

or

ee

h

e

net.

a

p

n

nd

p

per

lay

net.

f

er's

ormin

S

e

fa

r

g

i

c

ous

c

e

d

o

unk

a

ntact

w

i

n

a

jury

y

ty

from

p

w

e

i

co

th

•

u

b

the

D

ld

a

o

c

oc

kboar

bac

n

o

cu

t

kbo

slid

r

d

i

f

,

a

teeth/fa

e

r

r

•

i

,

d,

m

cli

After

rim

o

mb,

r

n

c

ass

e

e

shake

t.

com

e

mb

e

o

l

water

in

y

r

is

p

l

ay

complete

or

on

s

and

b

ase

in

,

and

fill

an

an

s

d/

sta

upright

yste

or

ke

p

m

ol

to

c

e

p

system

o

.

t

h

o

mplete

e

siti

g

r

on

ou

may

l

y

n

without

d.

wi

•

Nev

tip

th

When

ove

e

fill

r

leave

i

r

ng

a

ca

d

justing

b

u

ase

s

sy

in

fin

s

g

tem

with

inju

g

h

ers

eig

r

w

ies.

h

awa

ei

t

gh

or

y

•

t,

mo

from

D

a

o

s

ving

not

mov

system,

allo

ing parts

w

•

c

Du

hi

ke

l

r

dr

in

e

.

p

en

g

hands

play

t

o

mo

,

d

etc

o

a

ve

nd

no

.).

or

t

Obj

wear

a

djus

ec

ts

je

•

t sy

w

S

m

u

e

s

a

lry

rface

t

y

e

m.

en

(

r

in

ta

b

g

ngle

eneath

s,

wat

gra

i

n

c

vel

net.

the

h

e

s,

or

b

a

n

o

se

eck

t

h

mu

e

could

lac

r

s

s

es,

h

t

ar

be

cause

p

s

o

m

b

j

oo

e

•

c

s

th

K

ts

y

ee

s

.

and

tem

P

p

u

org

n

f

t

c

r

o

t

ee

an

u

tip

res

of

i

c

ov

etc

mater

cause

e

.

r

.

c

o

i

u

al

leakag

l

d

awa

c

a

•

use

y

Ch

e

from

a

e

nd

corr

c

k

pole

pol

osion

e

base.

system

chi

and/o

p

G

p

ing

r

r

f

ass,

or

d

et

)

s

and

er

ign

litter

io

penetrated

s

r

r

a

ep

,

o

ti

f

on.

a

corr

int

wit

osion

thr

h

immediatel

e

ough

xt

(rust

e

r

ior

,

th

pi

e

e

t

n

steel

ti

ame

y

ng

•

.

Ch

,

l

an

pa

e

c

ywh

k

in

s

t

.

ys

er

I

f

te

e

rust

,

m

re

har

b

p

has

ef

la

d

ore

c

w

e

ar

p

e

e

ol

,

a

e

e

c

x

h

c

bef

use

e

ss

ore

ive

f

o

r

u

wea

pr

s

e

o

.

per

r

•

a

C

nd

hec

bal

si

l

k

a

gns

s

sys

t

,

l

corr

oos

tem

•

Do

e

osi

b

ef

not

o

or

n

e

and

u

eac

s

e

rep

system

h

cond

use

a

i

r

fo

it

d

ions;

r

urin

in

s

t

g

ab

sys

w

s

i

to

l

i

i

n

t

t

em

y

d

r

a

.

y

g

and

m

e

ay

pos

/

or

ti

it

p

s

ion

a

ove

eve

n

d

and

re

r

f

.

r

ee

P

w

/o

l

ace

e

from

r

at

in

h

•

s

er

an

y

Nev

per

s

t

are

em

s

e

ona

r

a

pl

in

p

ay

l

r

the

ot

pr

on

e

•

o

cte

pe

S

dama

e

d

r

e

ty

from

i

n

a

str

g

nd/o

e

u

d

t

h

ction

equipm

r

e

ov

wi

mainte

e

n

man

rhe

d

e

nt.

a

ual

n

d

ance

w

fo

i

res.

•

r

.

When

pr

oper

mo

insta

v

i

ng

l

lat

s

system,

h

i

ift

on

ing.

and

use

•

Keep

cautio

p

n

ole

to

top

k

•

e

e

Do

p

co

m

n

v

ec

ered

o

t

ha

allo

nism

with

w

water

w

cap

from

eath

at

in

er

all

tank

a

d

t

d

i

mes.

non-t

to

c

om

fr

e

p

o

eze

le

xic

tel

.

anti

During

y

and

•

f

Use

reez

store.

s

e

e

ub

x

,

t

s

-

reme

fr

and

(D

e

e

o

z

or

ing

not

c

S

auti

y

empty

s

use

t

e

o

m

n

sal

i

may

f

ta

p

nk

t

l

.

acing

)

tip

ov

sys

e

r

te

m

m

ore

on

e

asily

slo

p

.

ed

su

r

f

a

c

e

.

In

th

e

U.

S

.:1-8

0

0-55

8

-52

3

4

and

Canad

a:

1

8

00

284

83

3

9

2

012

41

2

/

99

Page 13

10/04 P/N 21168202

13

1

40

7

7

FRONT SIDE

11.

Install pole mount bracket (6) and bracket reinforcement (40) with carriage bolts (7) as shown.

Tighten flange nuts (8) completely.

6

8

FRONT SIDE

Page 14

14

P/N 21168202 10/04

12

6

12

13

13

11

9

10

10

12.

6

8

14

14

17

15

13.

Attach spacers (12, 13) to pole mount bracket (6) with bolts (9), washers (10), and

nuts (11) as shown.

Assemble lanyard (17) to locking pin (16) as shown. Attach covers (14) onto

pole mount bracket (6) with carriage bolt (15) and nut (8) as shown.

DO

NOT OVERTIGHTEN

16

IMPORTANT!:

Tighten just until

washers (10) stop

moving.

Loop end of pin lanyard (17)

over carriage bolt (15) as it

passes through the pole

mount bracket (6) during this

assembly.

IMPORTANT!:

15

17

6

14

8

14

Page 15

10/04 P/N 21168202

15

20

19

38

37

21

18

14.

20

15.

16

Insert handle assembly through pole

mount assembly as shown.

Lock pole assembly in place at the

10’ (3.05 m) mark with pin (16).

Apply logo and height indicator labels (19) to

adjustment rod (18) as shown. Attach handle parts (37,

38) to adjustment rod with screw (21), carriage bolt

(20), and flange nut (8) as shown.

NOTE: Holes in adjustment rod allow for either rear

access or side access.

8

SIDE

ACCESS

Indicator labels

should be applied

as close to holes as

possible to prevent

labels from being

damaged during

height adjustment.

IMPORTANT!:

Page 16

16

P/N 21168202 10/04

SECTION B: ASSEMBLE THE ELEVATOR TUBES TO BACKBOARD

30

Upper Elevator tube

28

Identify elevator tubes (28 & 30).

9/16”

3/4”

1/2”

(2) Wrenches 1/2", (2), 9/16"" and (2) 3/4"

AND/OR

(2) Socket Wrenches and Sockets

#27

#42

#9

#8

#11

#31

#22

#24

#41 (1)

This is what your system will look like when you’ve

finished this section:

TOOLS REQUIRED FOR THIS SECTION

HARDWARE USED IN THIS SECTION (not actual size)

Toward

Pole

Toward

Board

Lower Elevator tube

Toward

Pole

Toward

Board

#47

#31

#53

#52

Page 17

10/04 P/N 21168202

17

48

31

11

9

25

49

Assemble backboard support

brackets (25) using bolts (9 & 48),

spacers (31), and nuts (11 & 49) as

shown.

2.

28

24

22

27

28

25

29

22

Attach lower elevator tubes (28) and counter balance spring (29) to backboard support brackets (25)

using spacers (22), bolt (27), and nut (24) as shown.

1.

Page 18

18

P/N 21168202 10/04

3.

25

53

53

53

52

53

4.

Attach upper elevator tubes (30) to backboard support brackets (25) using spacers (22), bolt (27), and nut

(24) as shown.

42

41

42

41

47

24

27

22

22

30

30

25

52

Place board spacers (52) into board as shown. Bend upper portion of the

board brackets (25) to match holes in backboard as shown. Insert t-bolt (42)

into rim bracket (41). Secure board brackets (25) and rim bracket (41) to

backboard with bolts (53 & 47) and nuts (8). Insert bolts (53) into unused

holes in board

8

52

25

Page 19

10/04 P/N 21168202

19

SECTION C: ATTACH THE BACKBOARD & ELEVATOR ASSEMBLY

TO POLE SYSTEM

3/4”

#27

#46

#24

#45

#23

#39

#44

#43

#33

TOOLS REQUIRED FOR THIS SECTION

HARDWARE USED IN THIS SECTION (not actual size)

Phillips-Head

Screwdriver

(2) 3/4" Wrenches

AND/OR

(2) Socket Wrenches and Sockets

Container to Mix

This is what your system will look like when you’ve

finished this section:

Page 20

20

P/N 21168202 10/04

1.

1

24

30

30

23

23

23

23

24

28

28

2.

Support pole on sawhorse. Attach backboard assembly to top pole section (1).

Install handle assembly to long elevator

tubes (28) using bolt (27), spacers (39),

and nut (24) as shown.

27

27

USE CAUTION; ELEVATOR

ASSEMBLY IS HEAVY.

TWO PEOPLE REQUIRED FOR THIS

PROCEDURE. FAILURE TO

FOLLOW THIS WARNING COULD

RESULT IN SERIOUS INJURY

AND/OR PROPERTY DAMAGE.

WARNING!

27

28

28

24

39

39

Before going on to

next step, set

adjustable system

assembly to the 10’

(3.05 m) setting.

NOTE:

Page 21

10/04 P/N 21168202

21

3.

43

46

45

41

42

Install Slam Jam Rim to Backboard

32

44

42

45

46

A

B

C

D

E

A • Fit rim (32) securely into bracket (41) as shown (Allow "T"-bolt (42) to slip through

center hole in rim (32).

B • Install reinforcement bracket (43) onto “T” bolt (42) as shown.

C • Install spring (44) onto “T” bolt (42) as shown.

D • Install special nut (46) and washer (45) onto “T” bolt (42).

E • Tighten nut (46) until flush with end of “T” bolt (42).

42

42

Page 22

22

P/N 21168202 10/04

4.

24

27

30

30

Insert bolt (27) through left side of short elevator tube (30),

then stretch spring or springs (29) onto bolt (27). Insert bolt

(27) through right side of short elevator tube (30) and secure

with nut (24).

USE EYE PROTECTION

WHEN INSTALLING

SPRINGS.

WARNING!

29

Place rebar with spacers into bottom pole section (3)

as shown.

6.

Assemble rebar centering spacers

(51) near top and bottom of rebar

(50) as shown.

5.

51

50

51

51

50

3

2"

3"

Reinforcement Bar

Page 23

10/04 P/N 21168202

23

Fill pole with concrete approximately 1” (2.54 cm)

below bottom elevator hole as shown.

IMPORTANT!:

WAIT A MINIMUM OF 24 HOURS BEFORE GOING ON TO NEXT STEP.

CONCRETE MUST CURE.

1

8.

IMPORTANT!:

FAILURE TO FILL YOUR

POLE COMPLETELY WITH

CONCRETE AS

DESCRIBED IN THESE

INSTRUCTIONS WILL

VOID ALL WARRANTIES

WRITTEN AND IMPLIED.

IMPORTANT!:

Make sure that

concrete does not

bulge from the end of

pole assembly. Allow

concrete to completely

cure.

50

Heavy-Duty Tape

(Not Included)

Seal hole at the bottom of the bottom pole

with heavy-duty tape (not included) to retain

rebar and concrete inside.

7.

Page 24

24

P/N 21168202 10/04

9.

Install clips.

Insert one “arm” of clip into ram as shown. Twist “body” of clip slightly so that

second “arm” slides over the top of the first “arm” as shown.

Push in direction indicated by arrows.

Push second “arm” back and into ram as shown.

Twist “body” of clip slightly again to spread “arms” of clip.

Clip “arms” must be flat and touching edge to edge as shown, not overlapping.

AA

BB

CC

32

33

USE OF THIS PRODUCT WITHOUT

PROPER INSTALLATION OF SMART

CLIPS

®

, OR WHEN ALL SMART CLIPS

®

ARE NOT PRESENT COULD RESULT IN

BODILY HARM. BE SURE TO FOLLOW

DIRECTIONS CAREFULLY.

WARNING!

CLIP “BODY”

CLIP “ARM”

Page 25

10/04 P/N 21168202

25

Twist net until it snaps into position. Net must be centered through clip.

NET INSTALLATION

10.

32

33

34

Insert net into bottom

of clip as shown.

SIDE VIEW

NET

NET

NET CLIP

NET CLIP

Page 26

26

P/N 21168202 10/04

SECTION D: UPRIGHT, SECURE AND USE POLE SYSTEM

Wedge

Hammer

None

This is what your system will look like when

you’ve finished this section:

TOOLS REQUIRED FOR THIS SECTION

HARDWARE USED IN THIS SECTION (not actual size)

Page 27

10/04 P/N 21168202

27

5

2.

1.

After concrete has cured, remove tape, install pole cap (26), fit pole assembly into sleeve (4).

Use wedge to gently tap cap of ground sleeve (5)

until tight.

4

PLAYING SURFACE

26

USE CAUTION;

ASSEMBLY IS HEAVY.

TWO PEOPLE REQUIRED FOR THIS

PROCEDURE. FAILURE TO FOLLOW

THIS WARNING COULD RESULT IN

SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

WARNING!

Page 28

28

P/N 21168202 10/04

4.

16

B.

A.

C.

3.

A.While holding handle, remove pin (16).

B.Move elevator up or down to desired

height.

C.Replace pin (16) full length to lock

system at desired height.

Apply height adjustment label (35) to front of

pole as shown.

Regulation rim height is 10 feet (3.05 m).

10 ft.

(3.05 m)

201251 2/99

HEIGHT ADJUSTMENT

TO ADJUST BACKBOARD:

1. While holding handle, remove pin.

2. Move elevator up or down to

desired height.

3. Replace pin full length to lock

system at desired height.

35

DO NOT ALLOW CHILDREN TO

ADJUST HEIGHT.

WARNING!

1

3

2

2

Loading...

Loading...