Huebsch ZA3820*A Top-Load Parts Diagram

W138P

Automatic

Washers

Refer to Page 6 for Model Numbers

Service

www.alliancelaundry.com

Part No. 37593R2

November 2016

Table of Contents

Section 1 – Safety Information

Locating an Authorized Servicer ............................4

Section 2 – Introduction

Customer Service ....................................................5

Nameplate Location ................................................5

Model Identification ................................................6

Section 3 – Troubleshooting

1. No Hot Water ...................................................7

2. No Cold Water .................................................7

3. No Warm Water ...............................................8

4. Water Fill Does Not Stop At Proper Level ......8

5. Timer Does Not Advance (Mechanical Tim er

Models Only) ...................................................9

6. Motor Does Not Run ......................................10

7. No Agitation ...................................................10

8. Constant Agitation .........................................11

9. Washer Smokes, Overheats, Cycles On Motor

Thermal Overload Protector, Switch Actuator

Kicks In And Out ...........................................11

10. Slow Spin Or No Spin ....................................12

11. Constant Spin .................................................12

12. Washer Stops In Cycle; Quits After A Couple

Loads; Is Intermittent .....................................13

13. Washer Is Locked Up Or Binding ..................13

14. Outer Tub Does Not Empty ...........................13

15. Excessive Vibration .......................................14

16. Water Leaking From Outer Tub .....................14

17. Troubleshooting Coin Drop ...........................15

Electronic Control Models

18. Error Code Listing .........................................17

19. Cannot Perform Infrared Communication .....19

20. Coins Ignored When Entered .........................20

21. Electronic Control Has No Visible Display ...21

22. No Fill Analysis .............................................22

23. No Motor Run — Agitate Analysis ...............24

24. No Motor Run — Spin Analysis ....................26

25. Overflow Analysis .........................................28

26. Audit Switch Function Analysis ....................30

Section 4 – Grounding

27. Wall Receptacle Polarity Check ....................31

28. Power Cord To Control Hood, Control Hood

To The Control Panel Frame ..........................31

29. Control Hood Wire Harness To Top Left

Rear Corner Gusset Of Cabinet .....................32

30. Wire Harness To Motor .................................32

Section 5 – Service Procedures

31. Control Panel Assembly ................................33

32. Timer Assembly .............................................37

33. Meter Or Timer Case Assembly ....................39

34. Coin Drop .......................................................40

35. Drain Hose Elbow ..........................................45

36. Loading Door .................................................45

37. Front Panel .....................................................47

38. Motor And Mounting Bracket .......................47

39. Idler Lever And Pulley ...................................49

40. Motor Drive Pulley ........................................50

41. Motor Switch .................................................53

42. Agitator ..........................................................54

43. Cabinet Top Assembly ...................................54

44. Cabinet Top Assembly Removal ...................55

45. Agitato r Drive Bell and Seal Kit,

No. 39508P ....................................................56

46. Out-of-Balance Switch Assembly ..................59

47. Mixing Valve Assembly ................................60

48. Outer Tub Cover And Clothes Guard ............61

49. Hub and Seal Kit, No. 495P3 .........................65

50. Outer Tub Assembly ......................................67

51. Drive Pulley and Helix ...................................70

52. Brake Assembly ........... ......... ......... ................72

53. Lower Bearing Housing .................................73

54. Transmission Assembly .................................73

55. Balance Ring ..................................................78

56. Upper Bearing Assembly ...............................78

57. Snubber Pad and Isolator Assembly ..............79

Section 6 – Adjustments

58. Leveling Legs .................................................81

59. Pressure Switch ..............................................82

60. Out-of-Balance Switch ...................................82

61. Belt (Agitate and Spin) ..................................82

62. Idler Spring Tension ......................................83

63. Cleaning Coin Drop .......................................84

Section 7 – Test Procedures

© Copyright 2016, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or tran smitted in any form or by any means withou t

the expressed written consent of the publisher.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

(continued)

1

64. Emerson Motor Switch ..................................87

65. Emerson Motor Windings ..............................88

Section 8 – Cycle Sequence Charts

Timer No. 28716 Cycle Sequence (Long Cycle –

Kingston)................................................................89

Timer No. 31111P Cycle Sequence

(Short Cycle)..........................................................90

Timer No. 34601P Cycle Sequence

(Long Cycle)... .......................................................91

Timer No. 34602 Cycle Sequence

(Long Cycle)... .......................................................92

Section 9 – Internal Wiring of Washer Motor

Switch

.....................................................................93

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 1

• Failur e to install, maintain and/or oper a te this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or

property damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

WARNING

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING” and “DANGER”) followed by spe cifi c ins truct io ns. The se pr eca ut ion s are int end ed fo r the per sona l

safety of the operator, user, servicer and those maintaining the machine.

DANGER

Danger indicates an imminent ly ha zar dous situation that, if not avoided, will caus e se ver e per sona l i njury or death.

WARNING

Warning indicates a hazardous situation that, if not avoided, could cause severe personal injury or death.

CAUTION

Caution indicates a hazardous situat ion that, if not a voided, may cause minor or moderate person al injury or proper ty

damage.

Additional precautionary statements (“IMPO RTANT” a nd “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Section 1 Safety Information

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

W007

WARNING

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

WARNING

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the washer.

Always contact your dealer, distributor, service agent or the manufac turer about any problems or con ditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 2

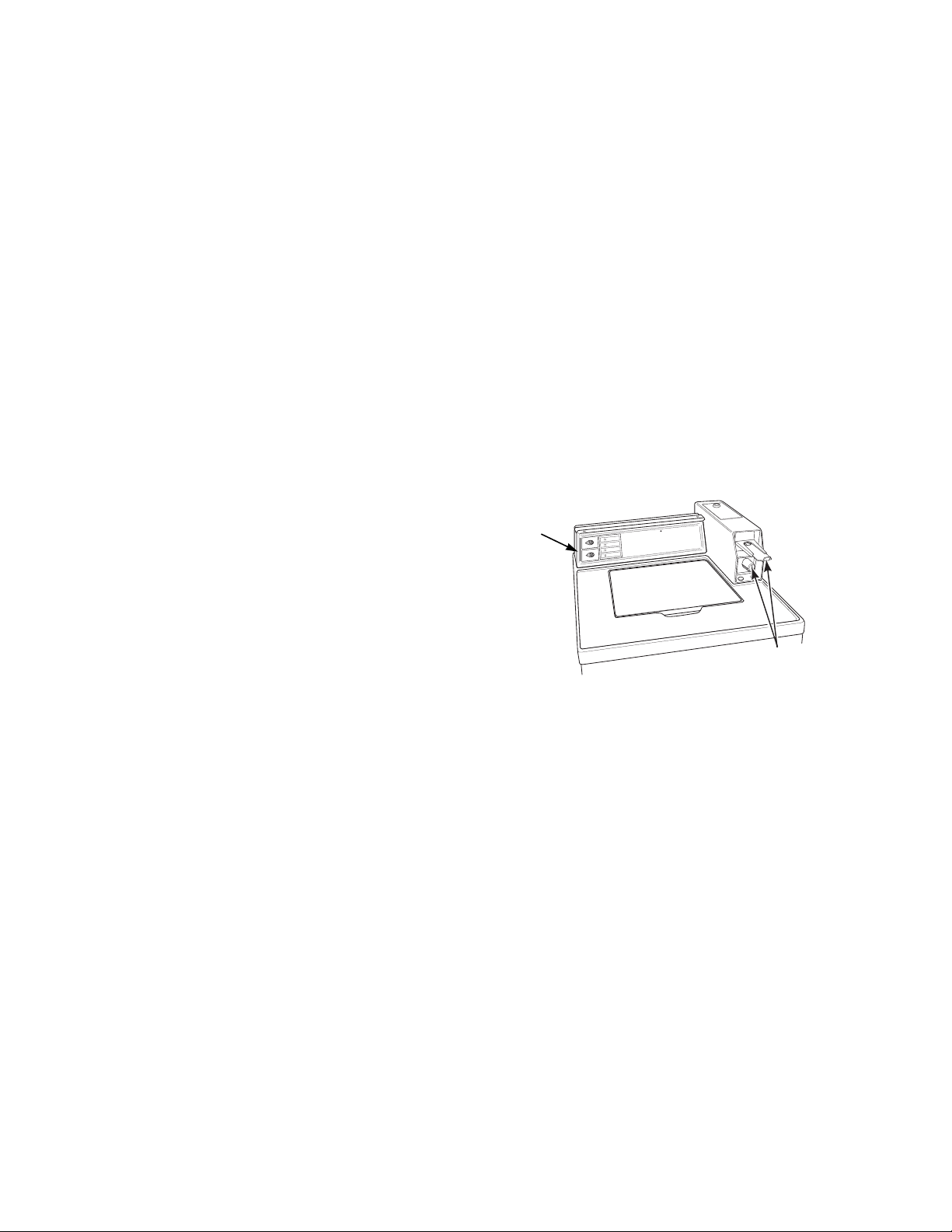

Nameplate

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

Nameplate Location

When calling or wri ting about your p rodu ct, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

IC

R

B

A

F

L

L

A

S

S

E

R

P

T

N

E

N

A

M

R

E

P

D

E

C

N

A

L

A

B

N

U

M

R

A

W

D

A

O

L

D

L

O

C

T

O

H

E

S

U

N

I

E

R

U

T

A

R

E

M

E

T

H

S

A

W

E

S

N

I

R

S

S

E

R

P

.

M

R

E

P

E

T

A

IC

L

E

D

N

I

P

S

L

A

M

R

O

N

R

O

T

C

E

L

E

S

IC

R

B

A

F

NOTE: Coin slide and

coin drawer shown for

illustration purposes

only.

W233SE3A

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Section 2 Introduction

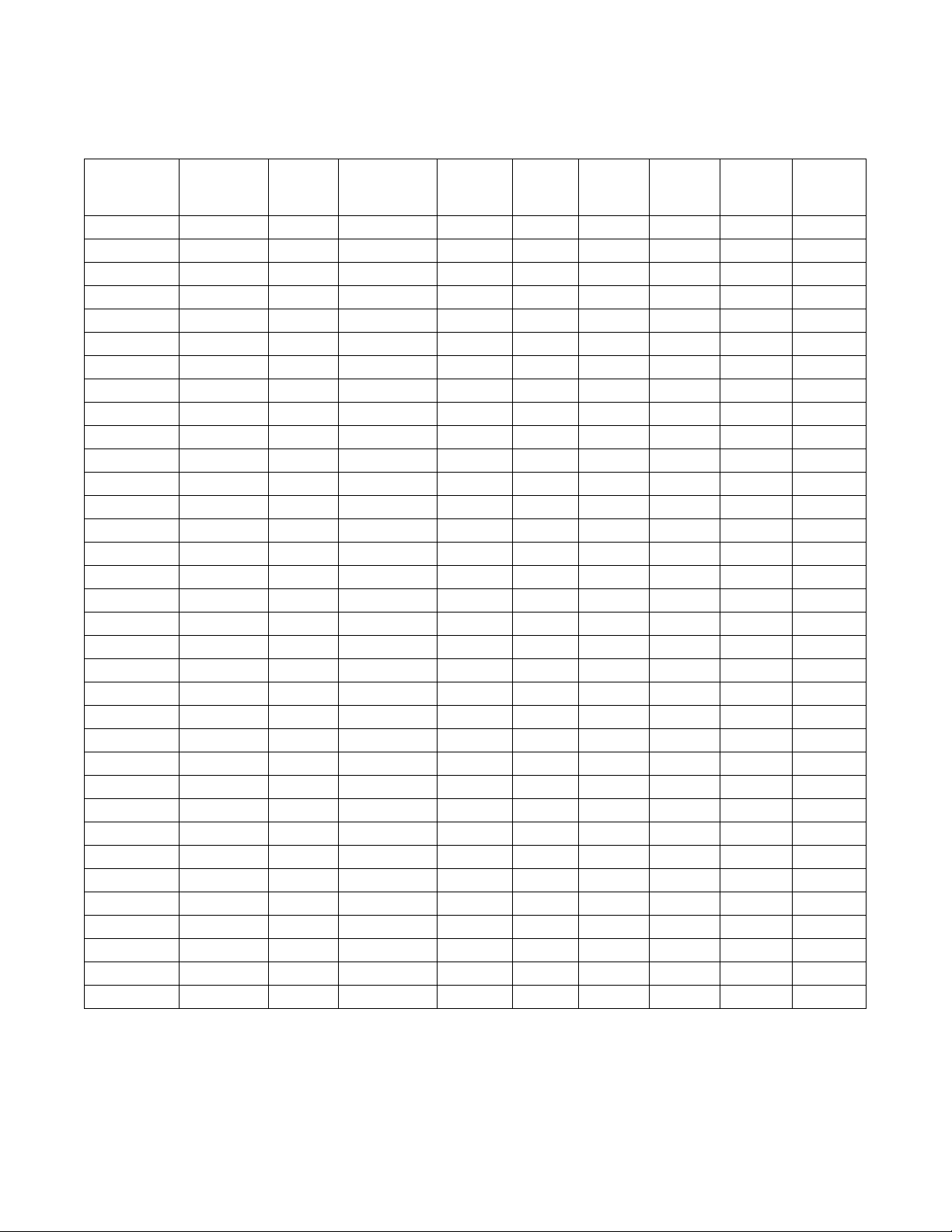

Model Identification

Information in this manual is applicable to these washe r models.

Washer

Model

DWA021*A X XX

EAJ920*A X X X X

EAJ921*A X X X X

EA2011*A X X X

EA2020*A X XX

EA2021*A X XX

EA2110*A X X X

EA2111*A X X X

EA2120*A X X X

EA2121*A X X X

EA2210*A X X X

EA2220*A X X X

EA2221*A X X X

EA2520*A X X X

EA2521*A X X X

EA2610*A X X X X

EA2620*A X X X X

EA2621*A X X X X

EA2710*A X X X X

EA2721*A X X X X

EA2820*A X X X X

EA2821*A X X X X

EA2920*A X X X X

EA2921*A X X X X

EA3820*A X X X X X

EA3821*A X X X X X

EA3920*A X X X X X

EA3921*A X X X X X

JA0110* X X X

ZA2020*A X XX

ZA2110*A X X X

ZA2120*A X X X

ZA3820*A X X X X X

ZA3821*A X X X X X

* Add suffix letter to model number to designate color . L – Almond W – White

Nonmetered

Models

Metered

Models

Computerized

Audit Control

Electronic

Display

Control

Card

Reader

One

Speed

Motor

Two

Speed

Motor

Porcelain

Washtub

Stainless

Steel

Washtub

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Section 3

Troubleshooting

IMPORTANT: Refer to appropriate model wiring diagram for aid in testing washer components.

1. NO HOT WATER

POSSIBLE CAUSE TO CORRECT

Hot water su pply faucet is closed. • Open faucet.

Water supply is cold. • Check water heater.

Kinked hot water inlet hose. • Straighten or replace hose.

Clogged mixing valve screen, or clogged screen in

outer end of inlet hose nearest water supply faucet.

Inoperative hot water mixing valve solenoid. • Test solenoid and replace if inoperative.

Inoperative timer. • Test timer and replace if inoperative.

Inoperative temperature switch. • Test switch and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Clogged pressure hose. • Remove and clean or replace hose.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

• Disconnect hot water inlet hose, and clean or replace

screen.

2. NO COLD WATER

POSSIBLE CAUSE TO CORRECT

Cold water supply faucet is closed. • Open faucet.

Kinked cold water inlet hose. • Straighten or replace hose.

Clogged mixing valve screen, or clogged screen in

outer end of inlet hose nearest water supply faucet.

Inoperative cold water mixing valve solenoid. • Test solenoid and replace if inoperative.

Inoperative timer. • Test timer and replace if inoperative.

Inoperative temperature switch. • Test switch and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Clogged pressure hose. • Remove and clean or replace hose.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

• Disconnect cold water inlet hose, and clean or replace

screen.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

3. NO WARM WATER

POSSIBLE CAUSE TO CORRECT

No hot water. • Refer to Paragraph 1.

No cold water. • Refer to Paragraph 2.

4. WATER FILL DOES NOT STOP AT PROPER LEVEL

POSSIBLE CAUSE TO CORRECT

Inoperative pressure switch. • Test switch and replace if inoperative.

Air leak in pressure hose. • Replace hose.

Sediment on or under mixing valve diaphragm,

defective diaphragm, or armature binding in

• Disassemble and clean mixing valve. Replace if

deteriorated or not easily cleaned.

armature guide.

Broken, weak or missing mixing valve armature

• Disassemble valve and replace spring.

spring.

A siphoning action started in washer will cause

water to be siphoned from washer during cycle due

• Install No. 562P3 Siphon Break Kit. Provide an air gap

around drain hose and drain receptacle.

to end of drain hose being lower th an cabine t top of

washer. Drain hose fits tight in standpipe or drain.

Water in pressure hose. • Blow air through hose to remove water.

Broken, loose, shorte d or incorre ct wiring. • Refer to appropriate wiring diagram.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

5. TIMER DOES NOT ADVANCE (Mechanical Timer Models Only)

POSSIBLE CAUSE TO CORRECT

Timer is designed to pause during fill periods. • Allow completion of fill period.

Inoperative timer. • Test timer, and replace if inoperative.

Loading door is open. • Close loading door. Loading door MUST be closed any

time the washer is set to fill, agitate or spin.

Washer will not fill. • Timer pauses until pressure switch is satisfied.

Timer motor lead wire off timer terminal. • Refer to appropriate wiring diagram and reattach wire.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Timer is design ed to pause when go ing from agi tate

to spin.

Timer is designed to stop if an out-of-balance load

has been encountered while washing clothes load.

Timer is design ed to st op if washe r dri ve motor has

been over loaded and motor thermal overload has

tripped.

• Allow time for timer to go through that step. Refer to

diagram for information on t ime required.

• Open lid and automatically reset out-of-balance switch

when lid is closed.

• Motor thermal protector reset time may vary depending

upon the reason for the washer overload, however, it

should reset within 15 minutes. Check to ensure that

washer was not overloaded with clothes.

Circuit breaker to washer may have tripped,

• Reset circuit breaker.

disconnecting power to washer.

Washer will not fill. • Timer is designed to pause when going from spin into

rinse to allow the washt ub t o st op s pin nin g bef o r e fill i ng.

Make sure that t imer has advanced i nto fill portion of rinse

cycle.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

6. MOTOR DOES NOT RUN

POSSIBLE CAUSE TO CORRECT

Electrical power off, fuse blown or power cord not

plugged in.

• Check laundry room for blown or loose fuse(s) or open

circuit breakers. ( Washer itsel f does not have an electrical

fuse).

Loading door not closed or inoperative switch. • Close door or test switch and replace if inoperative.

Timer improperly set. • Reset timer, or try another cycle.

Inoperative timer. • Test timer and replace if inoperative.

Motor starting functions inoperative. No start; or

• Refer to Section 7 to check start switch and start windings.

motor hums only.

Motor is dead, won’t run. • Refer to Section 7 to check switch and windings.

Motor overload protector has cycle d. • Wait two or three min utes for overload protector t o reset.

If protector cycles repeatedly, refer to Paragraph 9.

Bind in upper or lower motor bearing. • Remove belt and determine if motor shaft will spin.

Replace moto r if shaft is locked up.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Power cord is miswired. • Refer to appr opriate wiri ng diagram for correct wiring.

7. NO AGITATION

POSSIBLE CAUSE TO CORRECT

Inoperative timer. • Test timer and replace if inoperative.

Inoperative action switch. • Test switch and replace if inoperative.

Motor will not run. • Refer to Section 7 to check switch and windings.

Inoperative pressure switch. • Test switch and replace if inoperative.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Broken drive belt. • Replace belt.

Inoperative transmission assembly. • Replace transmission assembly.

Sheared motor pulley roll pin. • Remove drive motor and replace roll pin and any other

damaged parts.

Drive motor overload protector has cycled. • Refer to Paragraph 9.

Bind in pump. • Replace pump.

Loading door is open or door switch is inoperative. • Close door or test switch and replace if inoperative.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

8. CONSTANT AGITATION

POSSIBLE CAUSE TO CORRECT

Inoperative timer. Test timer and replace if inoperative.

Shorted or incorrect wiring. Refer to appropriate wiring diagram.

Inoperative transmission assembly. Repair or replace transmission assembly.

9. WASHER SMOKES, OVERHEATS, CYCLES ON MOTOR THERMAL OVERLOAD PROTECTOR, SWITCH ACTUATOR KICKS IN AND OUT

POSSIBLE CAUSE TO CORRECT

Belt is tacky and does not allow proper slip. Check belt and replace if defective.

Belt tension is too great and does not allow proper

Make sure idler spring is properly connected.

slip.

Inoperative timer. Test timer and replace if inoperative.

Motor switch functions inoperative. Refer to Section 7 to check switch functions.

Bind in water pump. Replace pump.

Brake pads or brake assembly binding. Free binding pads, or replace pads and brake assembly.

Bearings, transmission or motor has locked up and

will not turn.

Check that all these components are able to move freely.

Correct binding component.

Incorrect voltage. Contact local util ity company, or ha ve a qualified ele ctrician

check power supply.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

10. SLOW SPIN OR NO SPIN

POSSIBLE CAUSE TO CORRECT

Inoperative timer. • Test timer and replace if inoperative.

Loading door is open or door safety switch is

inoperative.

• Close loading door, or test switch and replace if

inoperative.

Bind in water pump. • Replace pump.

Broken or worn drive belt. • Replace belt.

Motor will not run. • Refer to “Motor Test” Section 7 to check switch and

windings.

Sheared motor pulley roll pin. • Remove drive motor and appropriately replace roll pin

and any other damaged parts.

Motor overload protector has cycle d. • Wait two or three min utes for overload protector t o reset.

If protector cycles repeatedly, refer to Paragraph 9.

No clearance between brake pads and discs. • Replace pads and brake assembly.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Inoperative transmission assembly. • Repair or replace the transmission assembly.

Lack of idler spring tension. • Adjust motor bracket. Refer to Paragraph 62.

11. CONSTANT SPIN

POSSIBLE CAUSE TO CORRECT

Inoperative timer. Test timer and replace if inoperative.

Washtub does not stop spinning within seven

Replace brake pads and brake assembly.

seconds after loading door is opened.

Excessive wear on brake pads, or missing brake

Replace brake pads and brake assembly.

pads.

Shorted or incorrect wiring. Refer to appropriate wiring diagram.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

12. WASHER STOPS IN CYCLE; QUITS AFTER A COUPLE LOADS; IS INTERMITTENT

POSSIBLE CAUSE TO CORRECT

Belt is tacky and does not allow proper slip. • Check belt and replace if defective.

Belt tension is too great and does not allow proper

• Make sure idler spring is properly c onnected.

slip.

Inoperative timer. • Test timer and replace if inoperative.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Motor overload protector has cycle d. • Wait two or three min utes for overload protector t o reset.

If protector cycles repeatedly, refer to Paragraph 9.

Motor switch functions inoperative. • Refer to Section 7 to check switch functions.

Brake, transmissi on or motor ha s locked up a nd will

• Check that all these components are able to move freely.

not turn.

13. WASHER IS LOCKED UP OR BINDING

POSSIBLE CAUSE TO CORRECT

Excessive belt tension. • Adjust belts.

Bind in upper or lower bearing. • Replace bearing.

Bind in water pump. • Replace pump.

Bind in transmission. • Repair or replace transmission.

Brake pads binding. • Free binding pads, or replace pads.

Incorrect voltage. • Contact local utility company, or have a qualified

electrician check power supply.

14. OUTER TUB DOES NOT EMPTY

POSSIBLE CAUSE TO CORRECT

Kinked drain hose. • Straighten hose.

Drain hose out of clamp in back of cabinet. • Remove washer front panel and install drain hose into

clamp.

Inoperative water pump. • Replace pump.

Obstruction in outer tub outlet hose. • Remove obstruction.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

15. EXCESSIVE VIBRATION

POSSIBLE CAUSE TO CORRECT

Unbalanced load in tub. • Stop washer, redistribute load, then restart washer.

Broken, or disconnected centering spring(s). • Connect or replace centering spring(s).

Washer is not properly leveled. • Adjust leveling legs.

Washer is installed on weak, “spongy”, carpeted or

built-up floor.

• Relocate washer, or support floor to eliminate weak or

“spongy” condition.

Incorrect or loose cabinet screws. • Replace with correct screws or tighten.

Base damaged (washer was dropped). • Replace base assembly.

Balance ring not positioned properly on

• Refer to Paragraph 55.

transmission assembly.

16. WATER LEAKING FROM OUTER TUB

POSSIBLE CAUSE TO CORRECT

Leaking water seal in outer tub. • Replace hub and seal kit assembly. Refer to Paragraph

49.

Hole in outer tub. • Replace outer tub.

Pressure hose or pressure bulb leaking. • Replace pressure hose and/or pressure bulb.

Outer tub cover gasket leaking. • Replace gasket.

Obstruction in drain causi ng water to come over top

• Remove obstruction.

of outer drain tub cover.

Tub-to-pump hose leaking at clamp. • Tighten clamp.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

DRY2B

Additional coins following

path to sensor

Coin Drop

Sensor

Coin in

Coin Slot

17. TROUBLESHOOTING COIN DROP

When coin is placed into coin slot, the coin should roll down drop and be heard dropping into coin vault. If coin

does not fall into coin vault or if coin drop sensor does not register that coin has been entered, follow

troubleshooting instructions on the following page. Refer to Figure 1 for path that coin follows when working

properly.

IMPORTANT: Never use oil to correct coin drop problems. Oil residue will prevent coins from rolling

properly.

IMPORTANT: Do not bend or damage mechanical parts within coin drop.

Figure 1

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Section 3 Troubleshooting

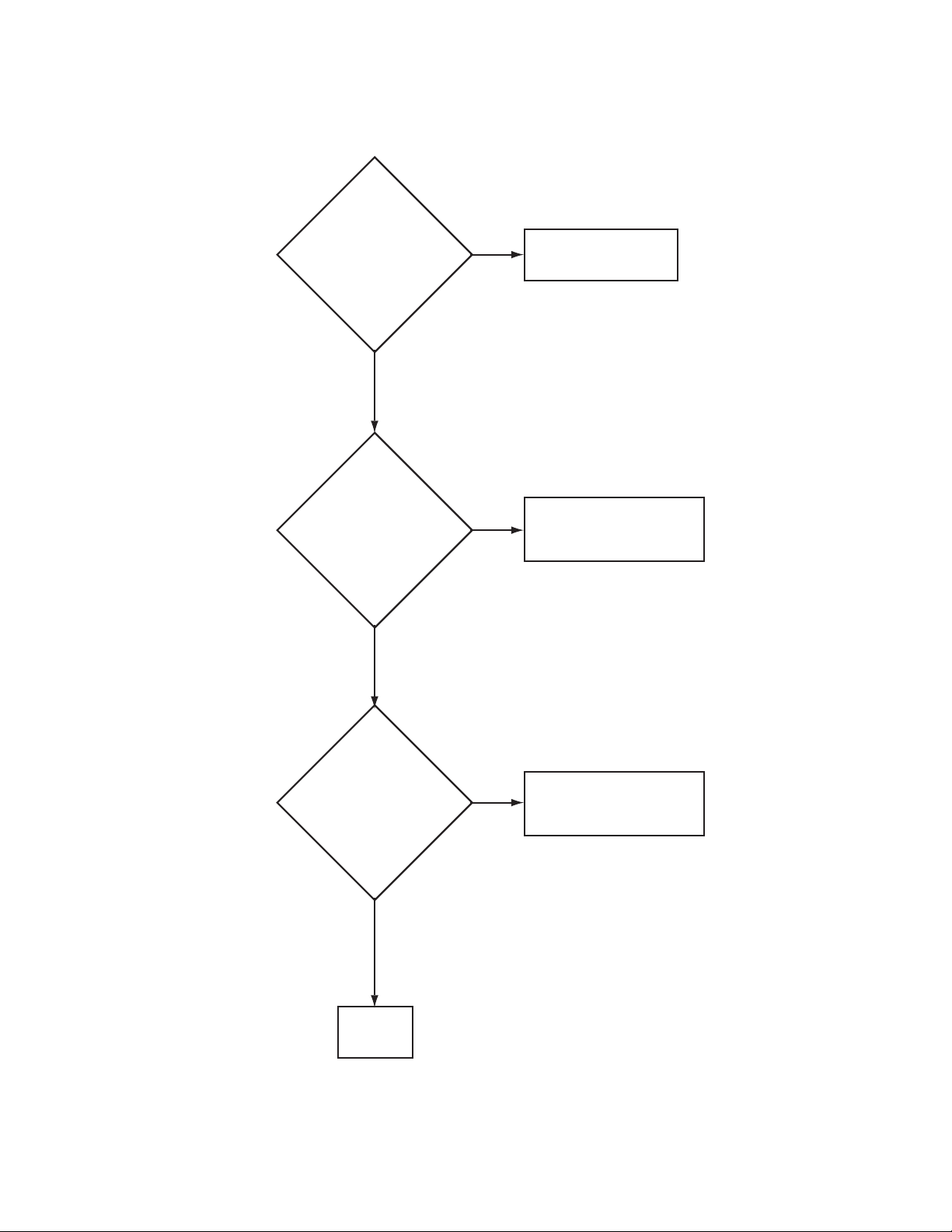

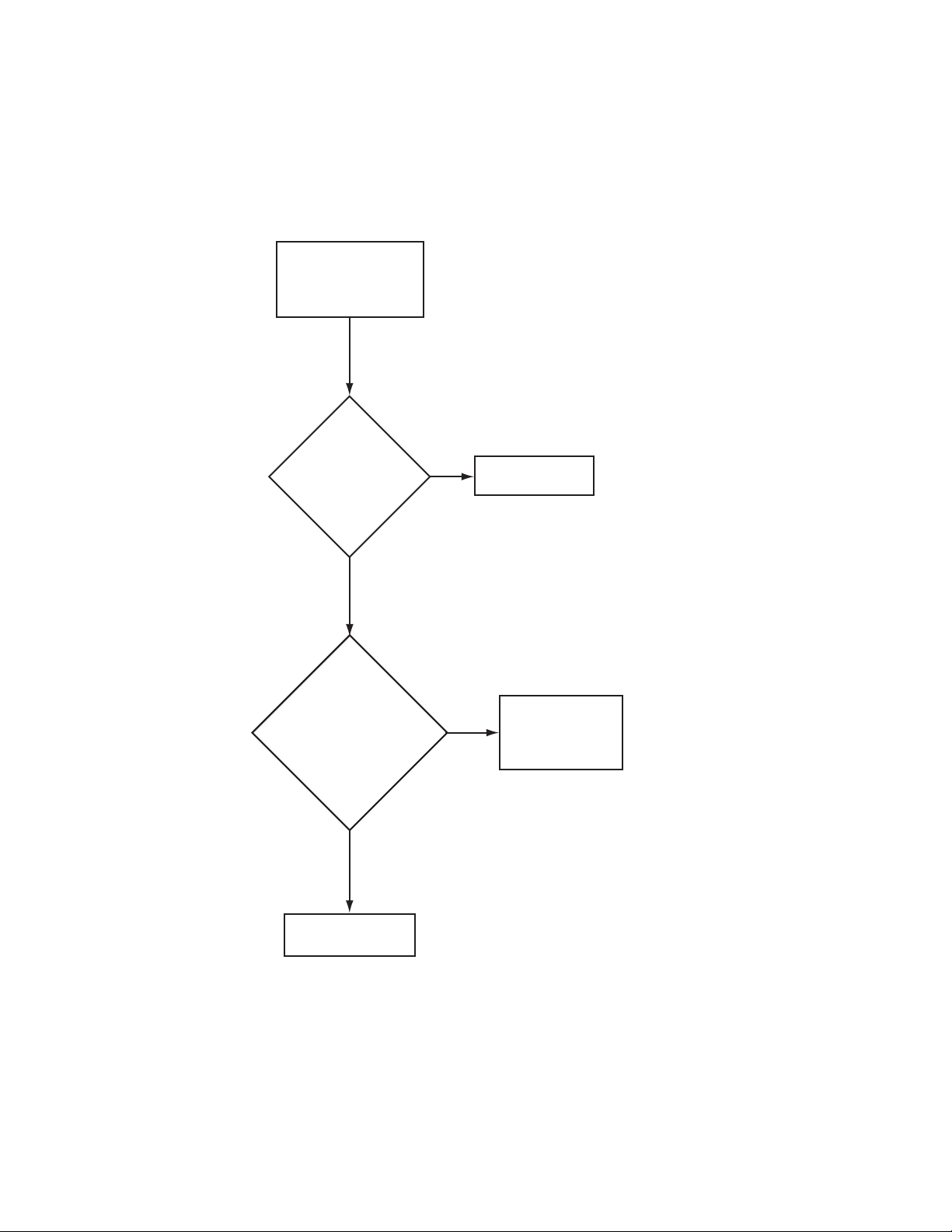

YES

Refer to wiring diagram

for proper connections.

Replace

coin drop

NO

Is proper

electrical power

supplied to coin

drop? (Incorrect

electrical connection may

prevent coins from

registering in

coin drop.)

YES

Refer to Paragraph 63

for instructions on

cleaning drop.

NO

Is coin drop

clean? (Residue

or lint build-up may

prevent coins from

following through

required check

stages of

drop.)

YES

Refer to Installation

Instructions for instructions

on leveling machine.

NO

Is machine

level? (Machines

that aren't level may

prevent coins from

following through

required check

stages

of drop.)

TLW305S

TROUBLESHOOTING COIN DROP

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Troubleshooting

Electronic Control Models

18. ERROR CODE LISTING E:00 General Error

E:01 Proximity Error Micro-wand IIIe is improperly aimed at infrared communicator (angle or

distance): Re-aim Micro-wand IIIe.

E:02 IR Communications

Disconnection

E:05 Invalid Value

Communication

E:07 Inoperative Control Replace electronic control.

E:08 Inoperative Control Replace electronic control.

E:09 Proximity Error Micro-wand IIIe is improperly aimed at infrared communicator (angle or

E:0A Proximity Error Micro-wand IIIe is improperly aimed at infrared communicator (angle or

E:0B IR Communication

Disconnection

E:0C IR Communication

Disconnection

E:0d Pressure Switch Error 1. Check fill and drain hoses for improper installation and kinks.

E:0F IR Communicator

Programmed Off

Micro-wand IIIe prematurely pulled away from electronic control during

infrared communication: Maintain infrared connection between Microwand IIIe and electronic control duri ng commu nic at ion.

Invalid code downloaded from Micro-wand IIIe to electronic control.

distance): Re-aim Micro-wand IIIe.

distance): Re-aim Micro-wand IIIe.

Micro-wand IIIe prematurely pulled away from electronic control during

infrared communication: Maintain infrared connection between Microwand IIIe and electronic control duri ng commu nic at ion.

Micro-wand IIIe prematurely pulled away from electronic control during

infrared communication: Maintain infrared connection between Microwand IIIe and electronic control duri ng commu nic at ion.

2. Check fill electrical circuit: Replace inoperative switches or wires.

Reprogram infrared communicator on.

Err Coin Error 1. Inoperative coin sensor: Run the Coin Drop Diagnostic test.

2. Coin drop obstruction: Check coin drop area and remove any

obstructions.

3. Customer tampering: Evaluate security procedures.

NOTE: Disconnecting power to the unit may clear the error display.

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Section 3 Troubleshooting (Electronic Control Models)

NOTE: If replacing an inoperati ve electronic contr ol due to burnt pin(s) on th e 6-pin wire harness con nector

block, it may be due to damaged terminals in the harness connector. Damaged terminals in the harness

connector will appear burnt or show signs of heat discoloration on the connector block. Replace the control

wire harness with the control to avoid repeated damage.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting (Electronic Control Models)

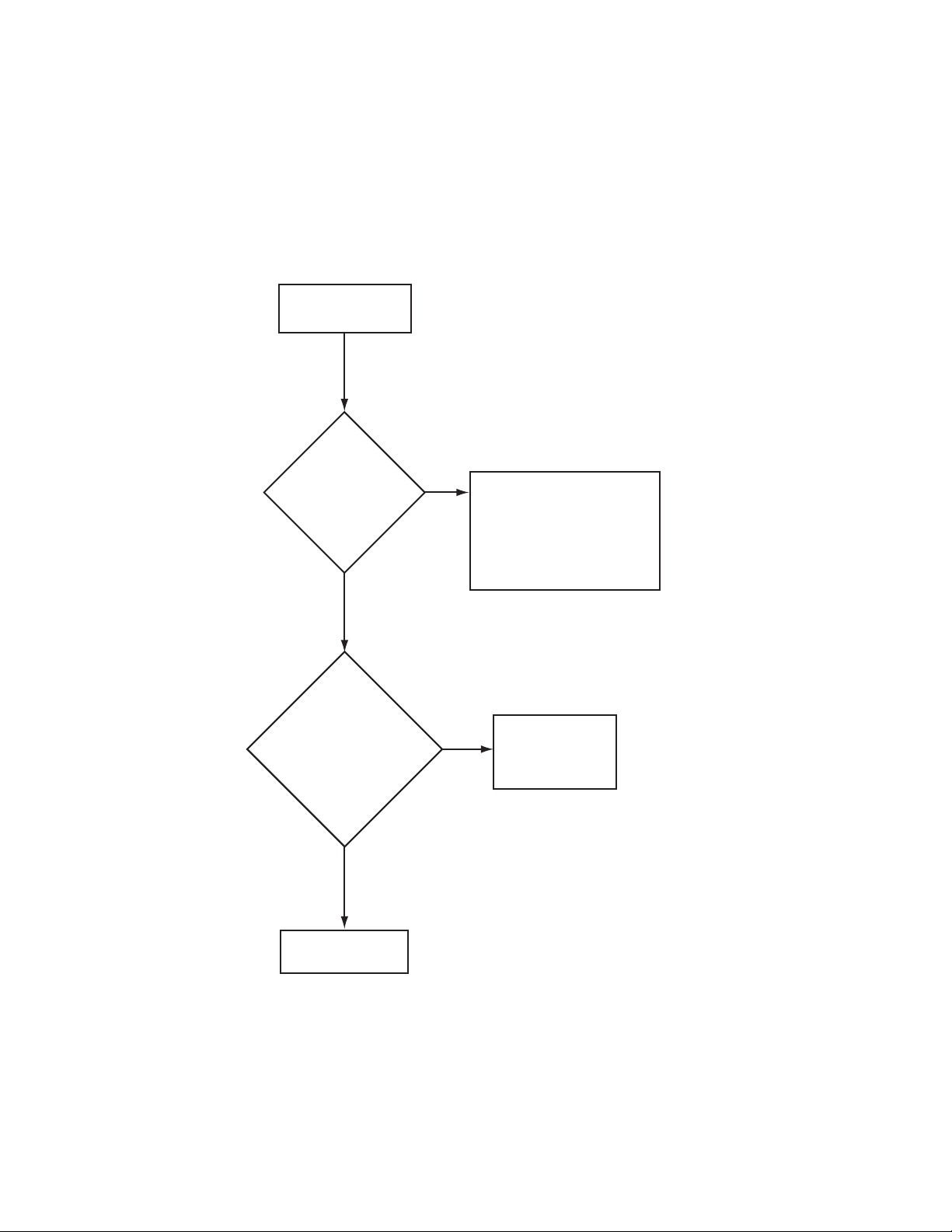

19. CANNOT PERFORM INFRARED COMMUNICATION

Attempt to communicate

with the electronic control

from the Micro-wand.

Is

there any

acknowledgement

of any kind from

the electronic

control?

YES

Does

the electronic

control display

"E:OF" or

"– C–" ?

"E:OF"

Check the following:

– (IR) disabled by manual prog.

– Is the (IR) on the control

covered or blocked?

– If needed, change electronic

control board.

NO NO

"– C–"

Aim Micro-wand

closer and try

again.

Communication

sequence checks

out.

Is

there any

control

response?

YES

Check the following:

– Low battery on Micro-wand.

– Is the (IR) on the control

covered or blocked?

– If needed, replace electronic

control board.

– Is the (IR) cap properly

attached to the Micro-wand?

W367S

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT\

19

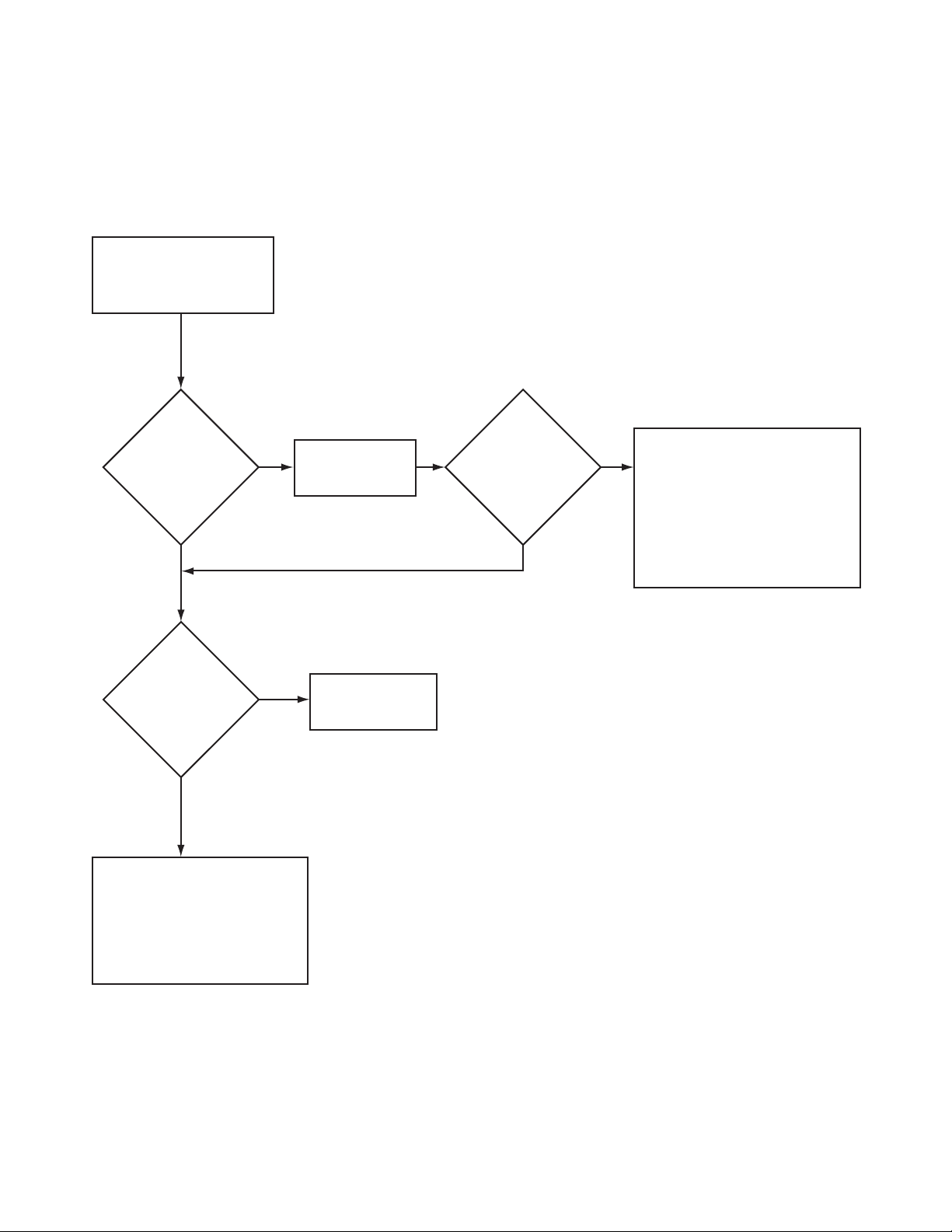

Section 3 Troubleshooting (Electronic Control Models)

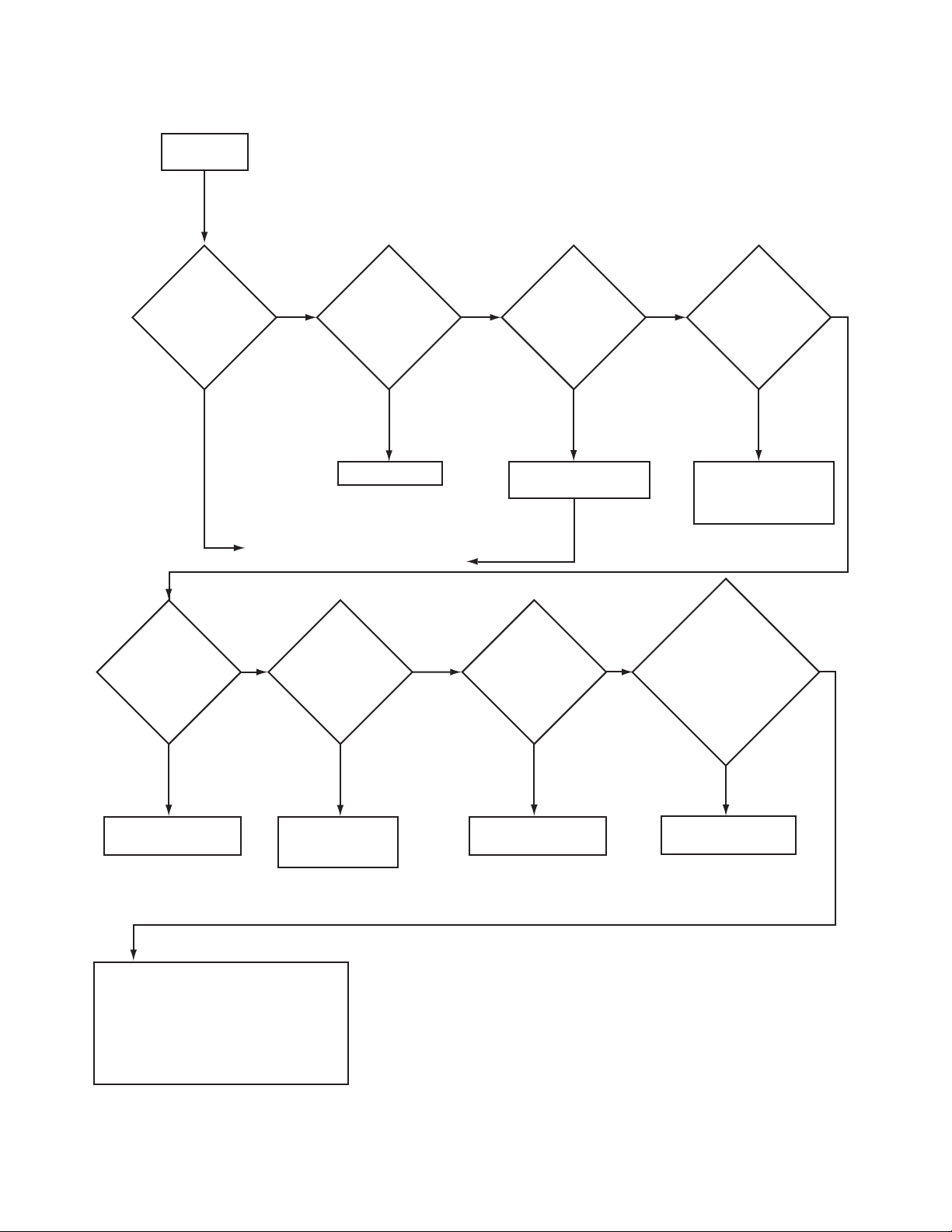

Start coin drop

diagnostic test.

Enter several coins.

Replace

coin drop.

Reconnect and

run test again.

Reconnect and

run test again.

Open

control

panel

Check

coin

drop

Make sure the

control is reset

properly and

prompting for a

vend.

NOTE: In this section, bring the

control out of the diagnostic mode.

Also, make sure the control is not

in a free vend mode.

NOTE: Inspect and test for continuity

the harness between the drop

and electronic control board.

NO

NO NO

Retest again, if not successful

the following is the problem:

– Replace coin drop.

If the problem still exists:

– Replace electronic control.

NO

YES

YES YES YES

Does

the electronic

control display

coin counter

increment

properly?

Is

connection

"H2" firmly seated

in its receptacle

on the

control?

Is

the 3-pin

connector plug

firmly seated in

its receptacle?

Are

wires exiting

the coin drop

optical sensor

cracked or

broken?

W368S

NOTE: For instructions on performing tests,

refer to programming manual.

20. COINS IGNORED WHEN ENTERED

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting (Electronic Control Models)

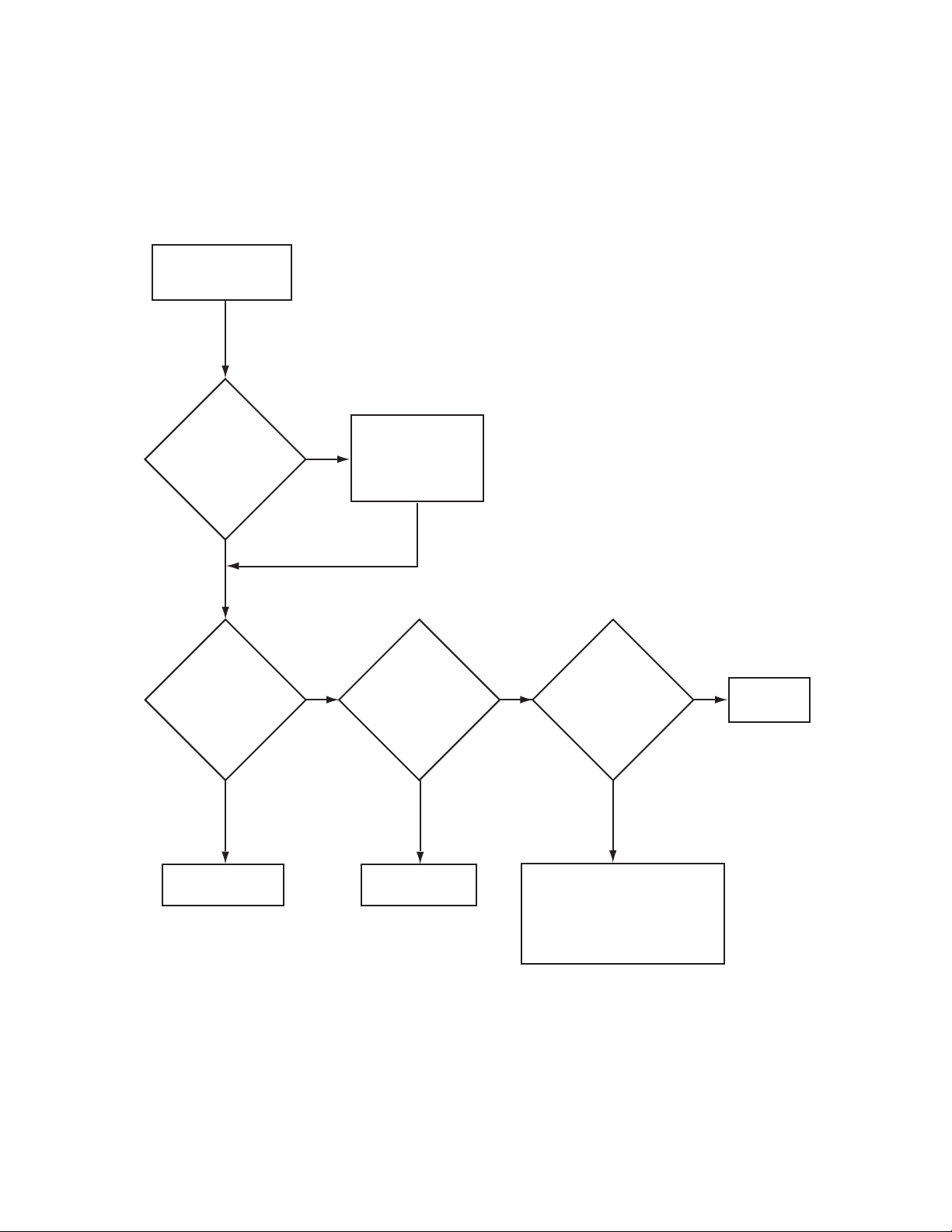

The electronic control has

no LED or VFD functioning

on the control board.

Replace electronic

control.

Open

control

panel

Plug electronic

control unit into

electrical outlet.

YES

YES

Disconnect power and check for

broken, loose, or incorrect wiring from

the electrical outlet to the electronic

control.

NOTE: This voltage check confirms that

main power is present to the control.

NO

NO

Is the

power cord

plugged in?

Is there

voltage at "FS1"

black to "FS2"

white?

W369S

21. ELECTRONIC CONTROL HAS NO VISIBLE DISPLAY

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT\

21

Section 3 Troubleshooting (Electronic Control Models)

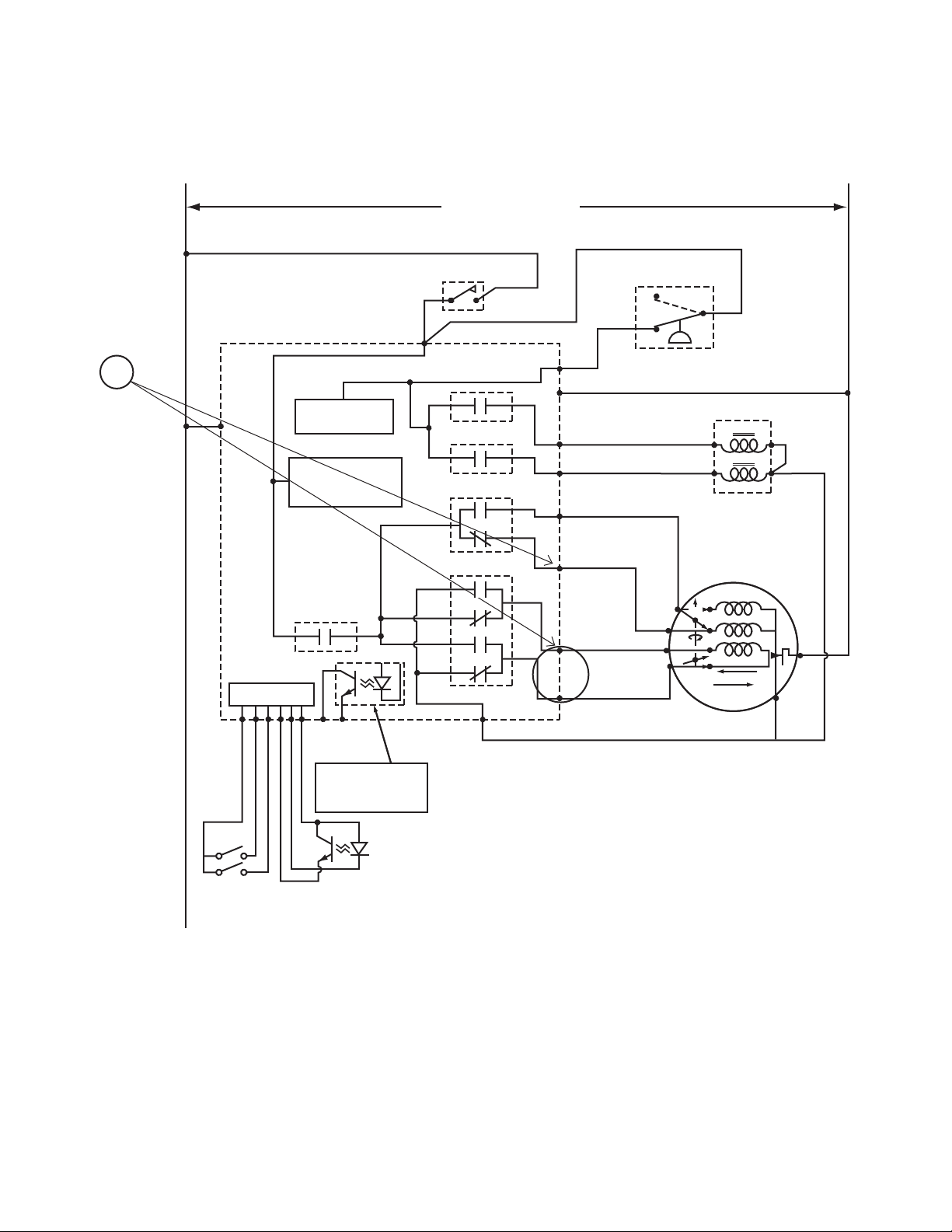

22. NO FILL ANALYSIS

Washer is

not filling.

Is

the display

on?

YES

Are

the water

lines turned

on?

(#) Numbers next to voltage checks

correspond to the locations marked

on the wiring schematic.

Is the

YES YES

coin counter

counting down

as coins are

entered in

the drop?

(1)

Check

voltage at

the lid switch

pnk/blu "COM"

to "H3-3",

is there

voltage?

YES

(2)

Check

voltage at

the pressure

switch "1" PNK/BLU

and to "H3-3",

is there

voltage?

NO

Replace inoperative

wiring.

NONO

Turn on water.

If the problem still exists, refer to

these other troubleshooting guides:

"Electronic control has no visible display",

or "Coins ignored when entered".

(3)

Check

voltage at

YES

the pressure

switch "2" BLU/WHT

and to "H3-3",

is there

voltage?

NO

Replace pressure

switch or

pressure hose.

YES

When checking

voltage to

neutral, check

between source and

"H3-3" since neutral

for mixing values is

through the thermal

protect on the motor.

Replace inoperative

coin drop.

(4)

Check

voltage

at control

"H3-1" to "H3-3",

is there

voltage?

NO

Replace inoperative

wiring.

NO

Open

control

panel

YES

Temps

listed are

determined

by what water

temps have been

selected

NO

After checking for

correct wiring,

replace inoperative

lid switch.

(5)

Voltage

check off

electronic control

board hot - ORG "H5-1"

to "H3-3" cold - GREY,

"H5-4" to "H3-3" warm -

"H5-1" and "H5-4"

to "H3-3",

is there

voltage?

NO

Replace electronic

control board.

YES

On mixing valve check and replace:

– Inlet screens.

– Wiring and connections.

– Replace coils or mixing valve.

– Check thermal protect and wiring

from thermal protect to "H3-3"

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

W370S

37593

Section 3 Troubleshooting (Electronic Control Models)

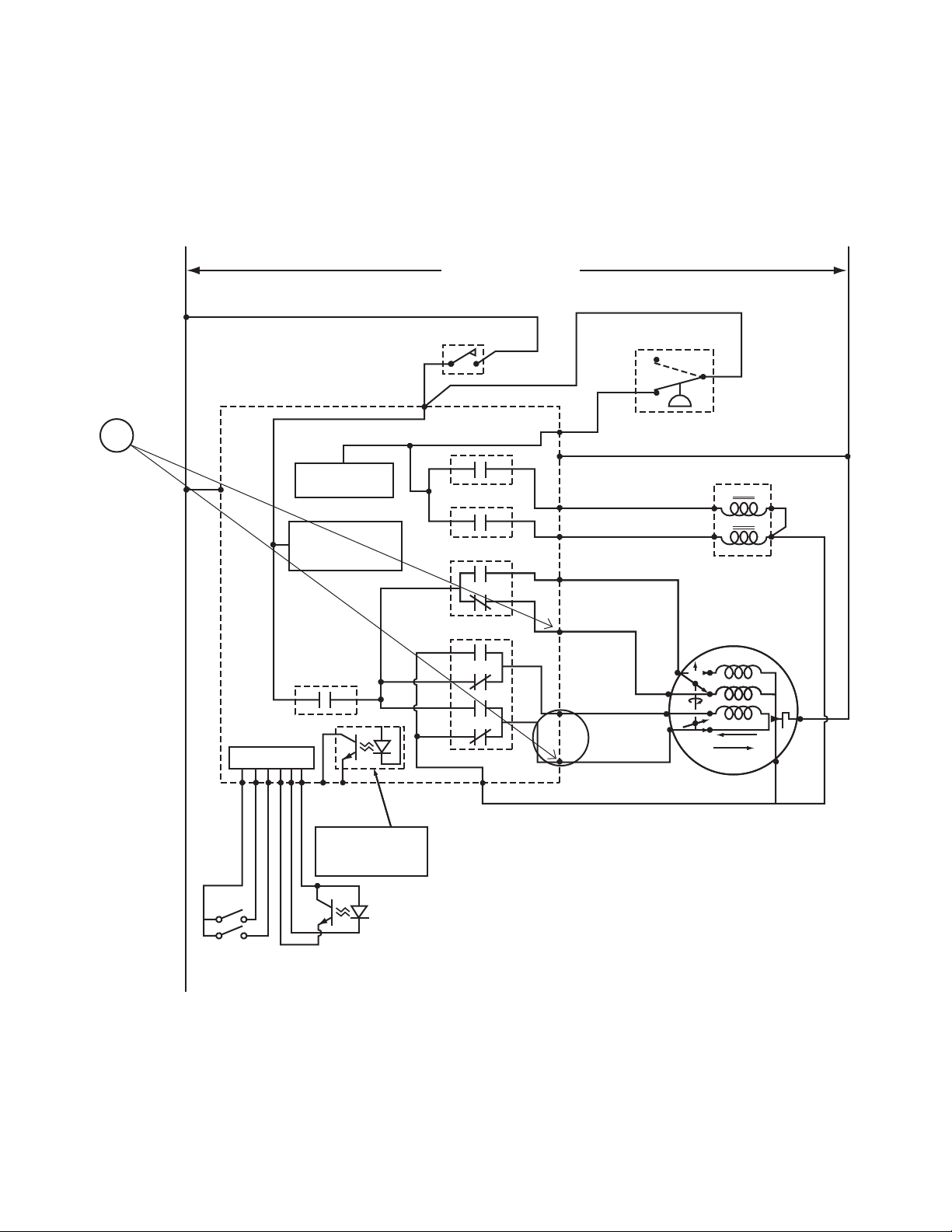

LOW

MOTOR

MOTOR SPEED

HOT

COLD

LID AND UNBALANCE SWITCH

ELECTRONIC CONTROL

SCHEMATIC

COLD

MIXING VALVE

PRESSURE SWITCH

PRESSURE SWITCH

AND

WATER CIRCUIT

LID SWITCH SENSE.

MOTOR DIRECTION

AND CONTROL AND

TIMING CIRCUIT

AVAILABLE OUTPUT

TRANSISTOR IS

"OFF" WHEN MACHINE

IS RUNNING

AUDIT CONTROL

CIRCUIT

H3-2

H6-2

H6-1

H3-3

H3-6

H3-4

K3

K5

K4

K2

K1

FS-2

FS-1

N

H3-1

H3-1

L1

L1

N

H3-5

H5-1

H5-4

MOTOR START/DIRECTION

MOTOR MASTER

SERVICE

DOOR

COIN VAULT

COIN DROP

SENSOR

HIGH

START

AGITATE

SPIN

4

6

1

7

3

3

2

1

8

TP

HOT

120 VOLTS A.C. 60 HZ.

H2-1

H2-2

H2-3

H2-5

H2-6

H2-4

3

1

2

5

4

W371S

NO FILL ANALYSIS

37593

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT\

23

Section 3 Troubleshooting (Electronic Control Models)

23. NO MOTOR RUN — AGITATE ANALYSIS

The wash tub has

been filled and

there is no motor

run for agitate.

washer lid

closed?

Open

control

panel

(1)

voltage at

electronic

control board

BLU "H3-4" to "H3-2"

RED "H3-6" to BRN

"H3-2" is there

voltage?

Is the

Check

YES

(#) Numbers next to voltage checks

correspond to the locations marked

on the wiring schematic.

NOTE: All checks in this flow chart

are based on the assumption a

high speed agitate and spin cycle

have been selected.

NO

YES

Close washer

lid.

After checking

for correct wiring,

refer to Section 7

or Paragraph 6.

24

NO

Replace electronic

control board.

W372S

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting (Electronic Control Models)

NO MOTOR RUN — AGITATE ANALYSIS

L1

L1

ELECTRONIC CONTROL

1

FS-1

L1

L1

AUDIT CONTROL

AUDIT CONTROL

CIRCUIT

CIRCUIT

ELECTRONIC CONTROL

PRESSURE SWITCH

PRESSURE SWITCH

AND

AND

WATER CIRCUIT

WATER CIRCUIT

LID SWITCH SENSE.

LID SWITCH SENSE.

MOTOR DIRECTION

MOTOR DIRECTION

AND CONTROL AND

AND CONTROL AND

TIMING CIRCUIT

TIMING CIRCUIT

MOTOR MASTER

MOTOR MASTER

K4

K4

120 VOLTS A.C. 60 HZ.

LID AND

UNBALANCE SWITCH

H3-1

H3-1

COLD

COLD

HOT

HOT

MOTOR SPEED

MOTOR SPEED

MOTOR START/DIRECTION

MOTOR START/DIRECTION

PRESSURE SWITCH

PRESSURE SWITCH

3

3

2

2

H3-1

N

FS-2

K1

K1

K2

K2

K5

K5

K3

K3

FS-2

H5-4

H5-4

H5-1

H5-1

H3-5

H3-5

H3-4

H3-4

H3-6

H3-6

H3-2

H3-2

1

1

MIXING VALVE

MIXING VALVE

COLD

COLD

HOT

MOTOR

3

7

LOW

HIGH

1

6

START

AGITATE

TP

SPIN

N

N

4

8

37593

H2-4

SERVICE

SERVICE

DOOR

DOOR

COIN VAULT

COIN VAULT

H3-3

H2-6

H2-5

H6-1

H6-1

H2-1

H2-2

H2-3

AVAILABLE OUTPUT

AVAILABLE OUTPUT

"OFF" WHEN MACHINE

"OFF" WHEN MACHINE

H6-2

TRANSISTOR IS

TRANSISTOR IS

IS RUNNING

IS RUNNING

COIN DROP

COIN DROP

SENSOR

SENSOR

H3-3

SCHEMATIC

SCHEMATIC

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT\

W373S

25

Section 3 Troubleshooting (Electronic Control Models)

The washer will

not spin.

Replace electronic

control board.

Open

control

panel

1) Open lid and close

to reset switch.

2) Check lid/unbalance

switch correct wiring.

3) Possible thermal overload

on motor.

NO

NO

YES

YES

Is the

"unbalance"

indicator flashing

on the electronic

control?

(1)

Check

voltage at

electronic control

board

BLU "H3-4" to "H3-6"

BRN "H3-2" to "H3-6",

is there

voltage?

W374S

NOTE: All checks in this flow chart

are based on the assumption a

high speed agitate and spin cycle

have been selected.

(#) Numbers next to voltage checks

correspond to the locations marked

on the wiring schematic.

After checking

for correct wiring,

refer to Section 7

or Paragraph 6.

24. NO MOTOR RUN — SPIN ANALYSIS

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37593

Section 3 Troubleshooting (Electronic Control Models)

NO MOTOR RUN — SPIN ANALYSIS

L1

L1

ELECTRONIC CONTROL

1

FS-1

L1

L1

AUDIT CONTROL

AUDIT CONTROL

CIRCUIT

CIRCUIT

ELECTRONIC CONTROL

PRESSURE SWITCH

PRESSURE SWITCH

AND

AND

WATER CIRCUIT

WATER CIRCUIT

LID SWITCH SENSE.

LID SWITCH SENSE.

MOTOR DIRECTION

MOTOR DIRECTION

AND CONTROL AND

AND CONTROL AND

TIMING CIRCUIT

TIMING CIRCUIT

MOTOR MASTER

MOTOR MASTER

K4

K4

120 VOLTS A.C. 60 HZ.

LID AND

UNBALANCE SWITCH

H3-1

H3-1

COLD

COLD

HOT

HOT

MOTOR SPEED

MOTOR SPEED

MOTOR START/DIRECTION

MOTOR START/DIRECTION

PRESSURE SWITCH

PRESSURE SWITCH

3

3

2

2

H3-1

N

K1

K1

K2

K2

K5

K5

K3

K3

FS-2

H5-4

H5-1

H3-5

H3-5

H3-4

H3-4

H3-6

H3-6

H3-2

H3-2

1

1

MIXING VALVE

MIXING VALVE

COLD

COLD

HOT

MOTOR

MOTOR

LOW

3

3

7

7

1

1

6

6

LOW

HIGH

HIGH

START

START

AGITATE

AGITATE

SPIN

SPIN

TP

TP

N

N

4

8

37593

H2-4

SERVICE

SERVICE

DOOR

DOOR

COIN VAULT

COIN VAULT

H3-3

H2-6

H2-5

H6-1

H6-1

H2-1

H2-2

H2-3

AVAILABLE OUTPUT

AVAILABLE OUTPUT

"OFF" WHEN MACHINE

"OFF" WHEN MACHINE

H6-2

TRANSISTOR IS

TRANSISTOR IS

IS RUNNING

IS RUNNING

COIN DROP

COIN DROP

SENSOR

SENSOR

H3-3

SCHEMATIC

SCHEMATIC

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT\

W375S

27

Loading...

Loading...