Page 1

FOR ALL 1/8

OFF-ROAD

& TRUGGY

®

Page 2

2

CONTENTS

Introduction 3

Equipment and Tools 4

Set-up System Components 4

Tools and Equipment 5

Assembling and Installing the Set-up Stands 7

Assembling the Set-up Stands 7

Assembling the Set-up Board 8

Installing the Set-up Stands 8

Overview of Car Set-up 9

Downstops 10

Effects of Downstop Adjustment 10

Measuring Downstops 10

Adjusting Downstops 11

Ride Height 12

Effects of Ride Height Adjustment 12

Measuring Ride Height 12

Adjusting Ride Height 13

Camber 14

Effects of Camber Adjustment 14

Measuring Camber 14

Adjusting Camber 16

Track-width 14

Effects of Track-width Adjustment 16

Measuring Track-width 16

Adjusting Track-width 17

Caster 18

Effects of Caster Adjustment 18

Measuring Front Caster 18

Adjusting Front Caster 19

Toe 20

Effects of Toe Adjustment 20

Measuring Toe 20

Adjusting Toe 21

Steering 22

Ackermann 22

Servo Saver Preload 23

Bump Steer 23

Roll Center 24

Front Roll Center 24

Rear Roll Center 25

Shock Absorbers 26

Shock Damping 26

Shock Pistons 26

Shock Oil 27

Shock Springs 27

Shock Mounting Position 28

Shock Preload 28

Kick-up (Front) 29

Effects of Front Kick-up Adjustment 29

Adjusting Front Kick-up 29

Anti-squat (Rear) 30

Effects of Rear Anti-squat Adjustment 30

Adjusting Rear Anti-squat 30

Wheelbase 31

Effects of Wheelbase Adjustment 31

Adjusting Wheelbase 31

Anti-roll Bars 32

Effects of Anti-roll Bar Adjustment 32

Adjusting Anti-roll Bars 32

Rear Wing 33

Effects of Rear Wing Adjustment 33

Adjusting the Rear Wing 33

Clutch 34

Clutch Springs 34

Clutch Shoe Orientation 34

Differentials 35

Differential Oil 35

Differential Gears 36

Optional Differentials (XRAY Active Diff™) 36

Gearing 37

Primary Drive Ratio 37

Gear Mesh Adjustment 37

Wheels, Tires and Inserts 37

Recommended Chemicals for Off-road Cars 39

Page 3

3

INTRODUCTION

Top-competition off-road cars/truggies are precision racing machines that feature multiple

adjustments that allow you to set up for any track condition. Most modern off-road cars/

truggies include innovative set-up features that allow you to change adjustments quickly

to achieve a full range of adjustment.

The HUDY Off-road Set-up Book describes how to adjust your off-road car/truggy to suit

your driving style. For each individual set-up area, we describe the effects of changing

the adjustment and how to make the adjustment.

When setting up the car/truggy it is very impor tant that the car sits on an ultra-fl at surface.

We strongly recommend using high-quality HUDY professional set-up tools – including

an ultra-fl at set-up board and marking decal – for every set-up adjustment.

The Basic Set-Up Sheet for your vehicle is always a very good overall starting point. After

rebuilding the chassis, or in case you become lost with your set-up, always return to the

basic starting set-up. If you choose to experiment with set-up, make small adjustments

one at a time, and see if you fi nd any improvement with each adjustment. We strongly

advise you to record and keep track of your set-up changes, record which set-ups work

best at different racetracks under various conditions.

If you own an XRAY model racing car then you can use blank XRAY Set-Up Sheets to

record your data and set-ups or use the unique Virtual Online Database set-up sheets at

www.teamxray.com where you can upload and share your set-up sheets or search for

other set-up sheets posted by factory team drivers or search particular set-up for your

track. The XRAY Virtual Online Database features thousands of set-up sheets and is the

world’s most unique set-up sheet source for your reference.

IMPORTANT!

The adjustment possibilities and methods of adjustment shown in this HUDY Off-road

Set-up Book are particular to the XRAY XB808 1/8 off-road nitro buggy. The general

theory behind the adjustments applies to all off-road vehicles, though the manner in

which the measurements and adjustments are made may differ on other vehicles. Some

of the off-road cars may not have possibility for some adjustments or may require use of

some other optional parts to be able to per form some of the set-up adjustments. Always

refer to the original manufacturer’s documentation for explicit instructions on how to

make set-up adjustments.

Page 4

4

EQUIPMENT AND TOOLS

When setting up, operating and maintaining your off-road car or truggy, we strongly

recommend using high-quality professional HUDY set-up equipment and tools.

SET-UP SYSTEM COMPONENTS

#108805 Exclusive Alu Set-Up System

For All 1/8 Off-road Cars & Truggies

•

CNC-machined alu. and acrylic components

• fully ball-bearing equipped

• precision engraving

• directly measures camber, camber rise,

caster, toe, steering throw symmetry

• easy one-screw assembly/disassembly

#107703 Droop Gauge Support Blocks

• CNC-machined high-grade aluminum

• precision engraving

• supports chassis when checking

downstops

• extra-high 30mm blocks for 1/8 off-road

cars & truggies

• used with 107717 Droop Gauge

#107717 Droop Gauge

• CNC-machined high-grade aluminum

• precision engraving

• measures downstops for off-road

vehicles when used 107703 Droop

Gauge Support Blocks

#108202 Set-Up Board

• exceptionally fl at, warp-resistant

surface

• lightweight, easy to carry

• provides perfectly fl at reference surface

for chassis set-up

• must be used for any set-up

adjustments

#108212 Set-Up Board Decal

• self-adhesive set-up decal for 108202

Set-Up Board

• accurate, clear markings for adjustment

of 1/8 Off-road cars & truggies

• tough, smooth, liquid-resistant plastic

surface

• used for track width adjustment and

checking

#108860 Alu Nuts for Set-up System

• CNC-machined alu nuts for quick &

easy attachment of set-up system plates

to wheel axles

#108841 Truggy Upside Measure Plate

• CNC-machined upside measure plate

(toe plate) for setting up 1/8 truggies

• made of high-quality, tough acrylic

plastic

• precision engraved markings for instant,

reliable readings

• used for the adjustment of: camber &

camber rise, caster, front and rear toe,

steering throw symmetry

• must be used with the #108805 Set-up

System

Page 5

5

TOOLS & EQUIPMENT

Turnbuckle Wrenches

• precision turnbuckle wrenches designed

exclusively by HUDY from special selfdeveloped, world-renown HUDY Spring

Steel™ to ensure maximum strength,

durability, and long life

• additionally hardened to provide

unmatched life span

• wrench head shape is hand-ground on

a precision grinding machine to ensure

a very precise shape to a snug fi t on the

turnbuckle

•

the fork end of the tool is additionally

ground fl at to keep the tool shape as thin as

possible for very easy access in restricted

areas

• available in 3 sizes: 3mm (#181030),

4mm (#181040), and 5mm (#181050)

HUDY Tools

• Allen 1.5 / 2.0 / 2.5mm

(HUDY #111549 / #112049 / #112549)

• Phillips 5.0mm

(HUDY #165049)

• Socket 5.0 / 5.5mm

(HUDY #170058 / #170059)

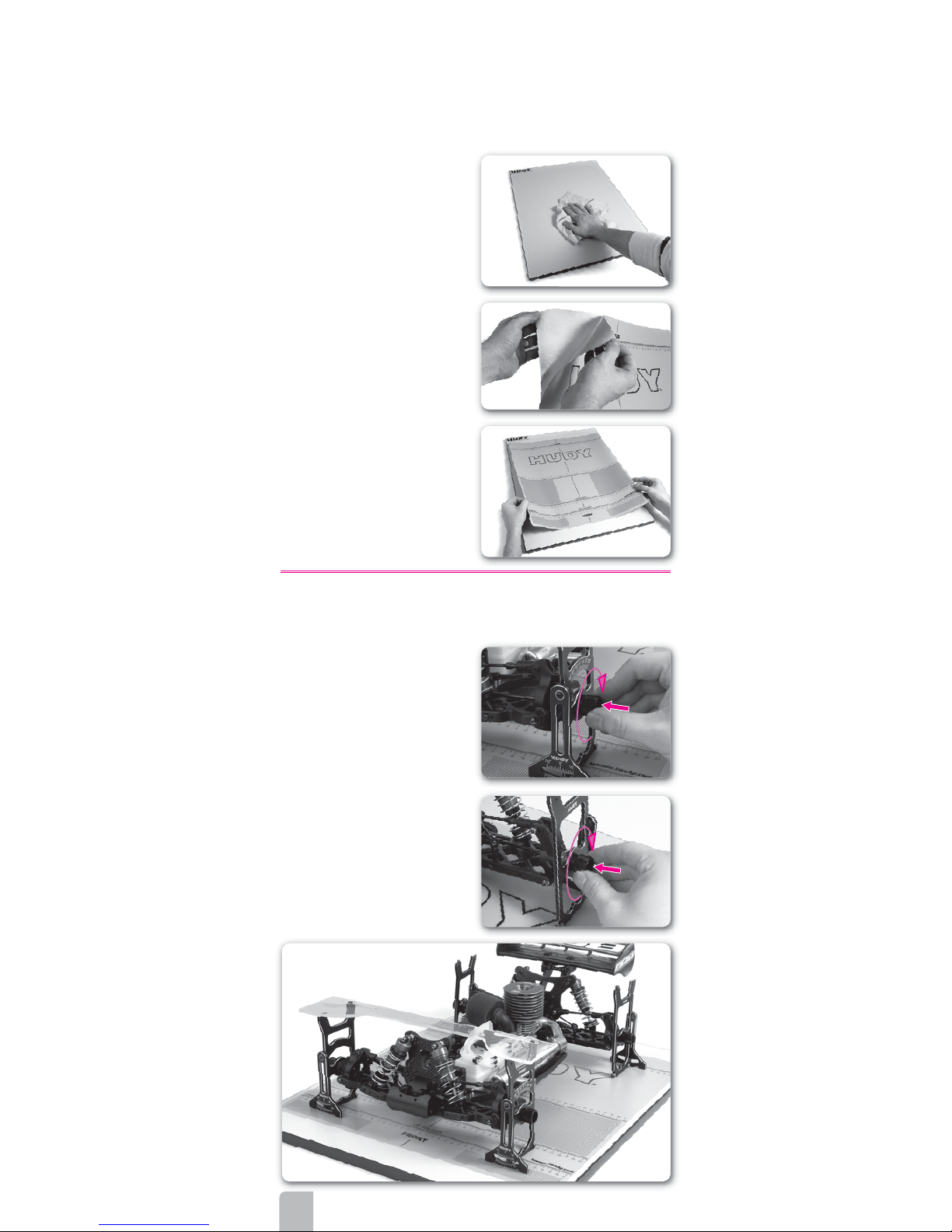

#182010 Flywheel Tool

• CNC-machined professional Flywheel

Tool off-road and on-road nitro vehicle

clutches

• fl ywheel holder holds all modern RC nitro

car fl ywheels with 2-to-4 pin designs,

allowing you to loosen or tighten the

fl ywheel nut very comfortably and

easily.

• use with 107581 Wrench-Glowplug /

Clutchnut to hold and loosen/tighten

fl ywheel nuts quickly & easily

• other features (including clutch gap

measurement, XCA-style clutchbell

holder) for use with on-road XCA-style

clutches

#107570 Wheel Nut Tool

• CNC-machined hardcoated tool for easy

loosening/tightening 17mm wheel nuts

on 1/8 off-road cars and truggies

• oversized handle gives superior torque

• robust design, machined from one piece

• hard anodized for extra-long lifespan

#107581 Wrench-Glowplug / Clutchnut

• unique, highly-useful combination tool

for nitro racing includes the following:

• 10mm socket wrench for Centax type

fl ywheel nut

• 8mm socket wrench for glowplug

• 5mm hex bit for suspension pivotballs

• extended 8mm glowplug wrench reaches

glowplug even in deep cylinder heads

• made of world-renowned HUDY

Spring Steel™ for highest strength and

durability

• lightweight, perfect-fi t tool

• laser-engraved for easy tool

identifi cation

Page 6

6

#107610 Exhaust Spring/Caster Clip Remover

• designed to easily and quickly remove

caster clips and exhaust springs

• tip from specially hardened steel

• very light non-slip duraluminum handle

• very durable, long life

#107600 Reamer For Lexan Bodies

• professional-quality reamer cuts perfect

holes 0-18mm diameter

• exclusive design by HUDY

• very light non-slip duraluminum handle

• special CAD-designed cutting head, handground on specially-modifi ed production

machinery

• perfect & comfor table cutting and use

Arm Reamer

• designed specifi cally for RC use, this

arm reamer precisely resizes plastic

holes without creating excessive slop,

allowing you to build a perfect free-moving

suspension

• comfortable molded handle

• quick & easy to use

• available for different size pins: 3.5mm

pins (#107632), 3.0mm pins (#107633),

4.0mm pins (#107634).

#106000 Drive Pin Replacement Tool

• compact, rugged multi-use tool set for

replacing 3mm drive pins in drive shafts

• heavy-duty construction for long life

• replacement pin sets available separately:

3x14 (#106050)

3x12 (#106051)

3x10 (#106052)

#104140 HUDY Engine Break-In Bench

• the ultimate tool for easy, safe, and

professional break-in of your .12/.15/.21

engine

• suits all bump-start SG crank engines

• allows for a controlled break-in process that

reduces wear & tear on engine components

and increases performance, reliability, and

longevity

• constructed of top-quality components of

tough aluminum and spring steel

• comes partially assembled from the factory

Page 7

7

ASSEMBLING AND INSTALLING THE SET-UP STANDS

When you are measuring and adjusting track-width, camber & camber rise, caster,

toe, steering throw symmetry, and tweak, you will need to assemble and install the

set-up stands.

When you are measuring downstops and ride height, you do not need to use the set-up

stands.

ASSEMBLING THE SET-UP STANDS

The set-up stands of the Exclusive Alu. Set-Up System For All 1/8 Off-road Cars &

Truggies must be assembled in order for you to use them. These stands were designed

for quick and easy “one screw” assembly and disassembly

The set-up stands consist of the

following pieces:

• alloy side plates front (2)

• alloy side plates rear (2)

• alloy camber gauges (4)

• acrylic toe gauge (1)

➊ Attach a camber gauge to a side plate

using a screw through the ball-bearing at

the top of the camber gauge.

➋ Using a 2.0mm Allen wrench, tighten

the screw until snug.

➌ Make sure the stand operates freely

without binding.

Page 8

8

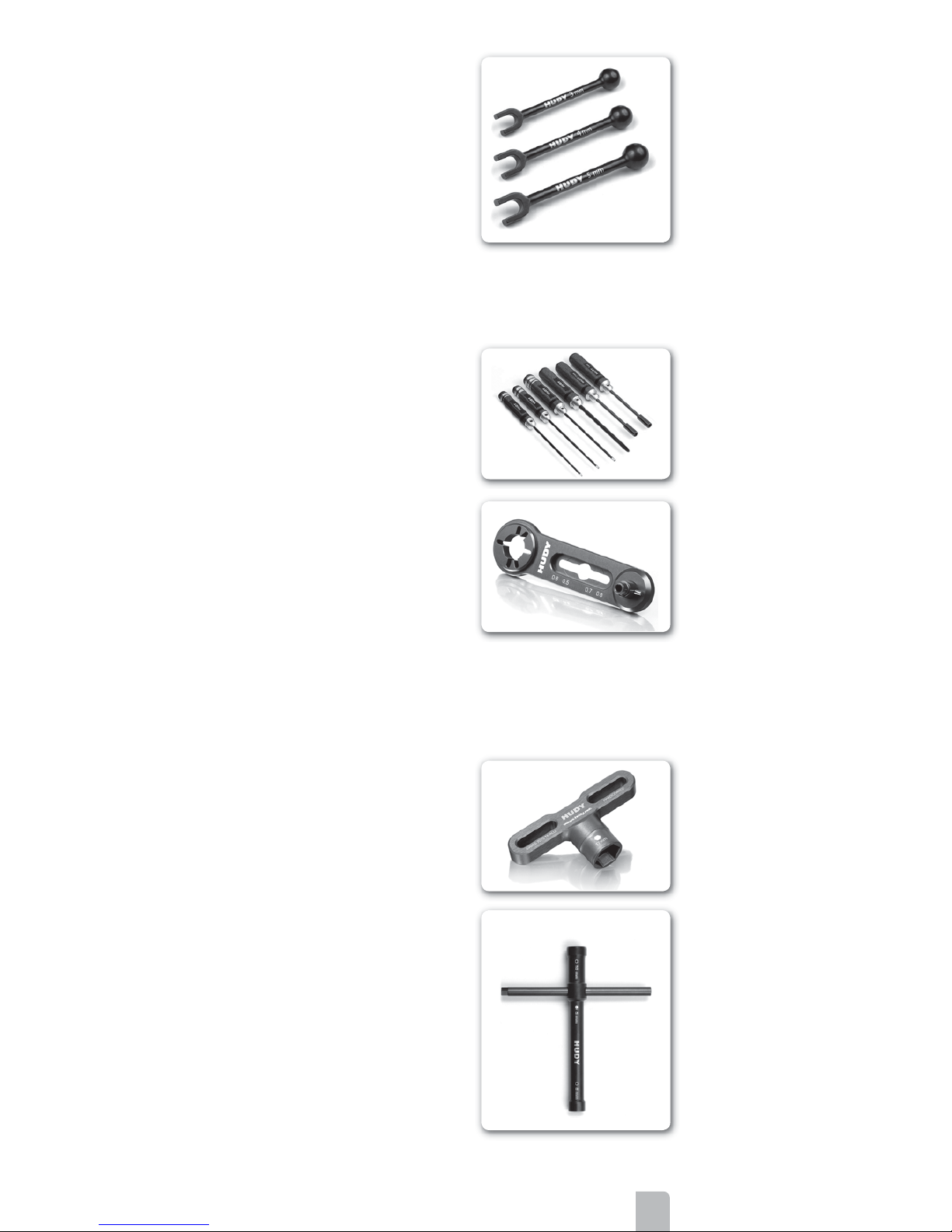

➋

Remove the paper from the rear of the

decal, exposing the adhesive backing.

➌ Center the decal on the board, and

then press the entire decal fi rmly onto the

board.

➍ Rub the decal until it is fl at and

completely adhered to the board.

INSTALLING THE SET-UP STANDS

After you have assembled the four set-up stands, mount them to your car as follows.

➊ Remove the wheels from the car. In

place of the wheels, mount a set-up stand

on each of the four axles. In front use side

plates with scale, while in rear use side

plates without scale (only with HUDY logo).

➋ The camber gauge of each stand

should face outward so it is easy to read.

The camber gauge of the front stand

should face forward, while the camber

gauge of the rear stand should face

rearward.

➌ Place the car (with the mounted set-up

stands) on the set-up board.

FRONT

REAR

ASSEMBLING THE SET-UP BOARD

The completed set-up board consists of the Set-Up Board and the Set-Up Board Decal.

IMPORTANT:

You should always use only the HUDY set-up board when setting up your car with the

HUDY All-In-One Set-Up Solution. This exceptionally fl at, warp-free board will ensure

accurate, precise measurements.

➊ Clean the board with a soft cloth to

remove any debris or contaminants.

Page 9

9

OVERVIEW OF CAR SET-UP

When setting up your off-road car/truggy, we recommend setting it up in the order

indicated in the table below. The order of the settings has been determined as the most

logical to set up your car/truggy properly and easily. Also, certain settings must be

made before others, as changing one setting will impact another setting.

The table below also lists the set-up components to be used to measure or adjust a

particular setting.

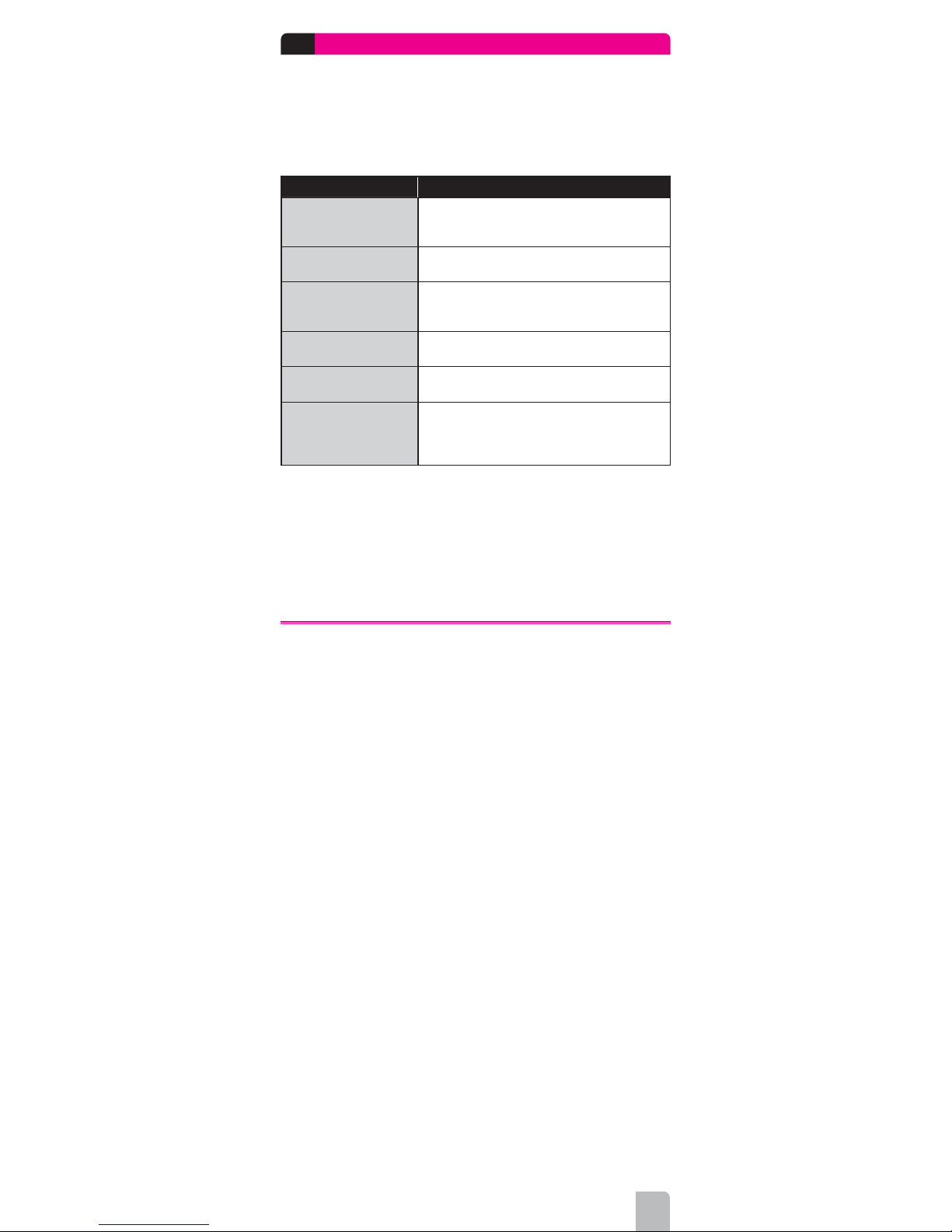

TO MEASURE OR ADJUST USE

Downstops

•

Flat set-up board

• Droop gauge support blocks

• Droop gauge

Ride height

• Flat set-up board

• Droop gauge

Camber

• Flat set-up board

• Droop gauge support blocks

• Assembled set-up stands

Track-width

• Flat set-up board

• Board decal

Caster

• Flat set-up board

• Assembled set-up stands

Toe

• Flat set-up board

• Droop gauge support blocks

• Assembled set-up stands

• Toe gauge

There are several types of suspensions used on RC cars, including pivotball and C-hub

suspensions. Each suspension type has its own way of making adjustments for

downstops, camber, caster, toe, etc. For detailed information on adjusting the settings on

your car, refer to the appropriate set-up manuals for your car.

When setting up your off-road car/truggy, you should always prepare it so it is ready to

run, though without the body. This means you should install all electronics, batteries, and

fi ll the fuel tank (nitro only).

Page 10

10

1.1 DOWNSTOPS

Downstops limit how far the suspension arms travel downward, which determines how

far upward the chassis rises. This affects the car’s handling (due to effects on camber

and roll-center) and the ability of the tires to “follow” the track. The effects may change

with the type of track and/or amount of grip available. Downstops are a very sensitive

adjustment, since they alter weight transfer, and all aspects of chassis performance are

affected: braking, acceleration, jumping, traction and rough track handling.

More suspension travel (lower downstop value) makes the car more responsive but less

stable; it is also typically better on a bumpy track or on a track with slow corners. This

allows the chassis to “pitch” rearward or forward more under acceleration or braking

(respectively), which results in more weight transfer.

Less suspension travel (higher downstop value) makes the car more stable and is

typically better on a smooth track. This prevents the chassis from “pitching” rearward

or forward too much under acceleration or braking (respectively), which results in less

weight transfer.

It is very important to have the same downstop settings on the left and right sides

of the car.

EFFECTS OF DOWNSTOP ADJUSTMENT

FRONT DOWNSTOPS

Higher downstop value

(arm is higher

, less

travel)

• Decreases front chassis upward travel on-throttle

• Less rearward weight transfer

• Better on smooth tracks

• More on-power steering

• More responsive in direction change

Lower downstop value

(arm is lower, more

travel)

• Increases upward chassis travel on-throttle

• More rearward weight transfer

• Increases rear traction on corner exit

• Better on bumpy tracks

REAR DOWNSTOPS

Higher downstop value

(arm is higher

, less

travel)

•

Decreases rear chassis upward travel off-throttle or

under braking

• Less forward weight transfer

• Better on smooth tracks

Lower downstop value

(arm is lower, more

travel)

• Increases rear chassis upward travel off-throttle or

under braking

• Less stable under braking

• Increases steering on corner entry

• Better on bumpy tracks

• More turn-in

MEASURING DOWNSTOPS

INITIAL STEPS SET-UP COMPONENTS

Prepare the car as follows Use the following set-up components

• Shocks: Attach the shocks

• Anti-roll bars: Attach the anti-roll bars

• Wheels: Remove the wheels

• Droop Gauge Support Blocks #107703

• Droop Gauge #107717

• Set-up Board #108202

Page 11

11

➊ Place the droop blocks on the fl at set-

up board, and then place the fl at part of

the chassis (not the angled part) on the

blocks. Make sure the chassis is solidly

mounted on the support blocks so it does

not move.

➋ Lift and drop the suspension arms so

that they settle in their lowest positions.

➌ Using the droop gauge, measure the

downstop values at the front and rear of

the car.

FRONT DOWNSTOPS:

Measure the front downstop values under

the round part of the front wheel axles. DO

NOT measure under the hex part.

The values shown on the droop gauge

indicate how many millimeters the

suspension drops below the level of the

chassis.

REAR DOWNSTOPS:

Measure the rear downstop values under

the round part of the rear wheel axles. DO

NOT measure under the hex part.

The values shown on the droop gauge

indicate how many millimeters the

suspension drops below the level of the

chassis.

ADJUSTING DOWNSTOPS

FRONT DOWNSTOPS

Increase

Turn IN (or OUT) the front downstop screw

(depending on the car design) so the front

lower arm raises up slightly.

Decrease

Turn OUT (or IN) the front downstop screw

(depending on the car design) so the front

lower arm drops slightly.

REAR DOWNSTOPS

Increase

Turn IN (or OUT) the rear downstop screw

(depending on the car design) so the rear

lower arm raises up slightly.

Decrease

Turn OUT (or IN) the rear downstop screw

(depending on the car design) so the rear

lower arm drops slightly.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 12

12

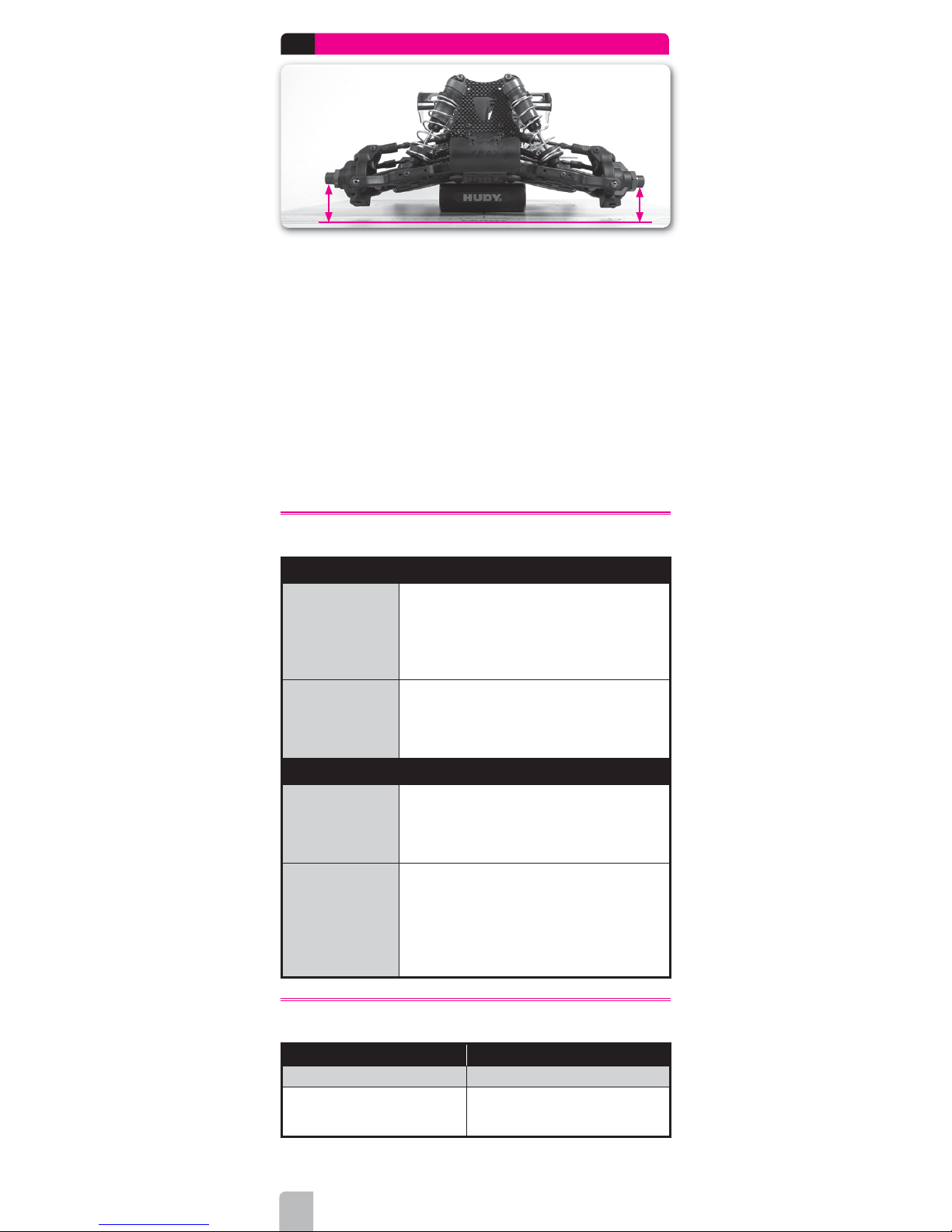

1.2

RIDE HEIGHT

front ride height rear ride height

Ride height is the height of the chassis in relation to the surface it is sitting on, with the car

ready to r

un. Ride height affects the car’s traction since it alters the car’s center of gravity

and roll center. Differences in ride height alter the car’s attitude (angle of the chassis)

which in an off-road vehicle can effect how it jumps and lands. Because of changes in

suspension geometry and ground clearance, there are negative consequences to altering

ride height too much.

Ride height is measured with the wheels on the car, and the car ready-to-run. Use the

shock preload collars or clips to raise and lower the ride height.

EFFECTS OF RIDE HEIGHT ADJUSTMENT

Decreasing ride height

• Increases overall stability

• Better on smooth tracks

Increasing ride height

• Decreases overall stability

• Better on bumpy tracks (prevents bottoming)

Front higher than rear

• Increases weight transfer to the rear on-power

• Increases stability

• Decreases steering

Front lower than rear

• Increases weight transfer to front off-power

• Increases steering

• Decreases rear traction

• May cause car to nosedive off jumps

MEASURING RIDE HEIGHT

INITIAL STEPS SET-UP COMPONENTS

Prepare the car as follows

Use the following set-up components

• Shocks: Attach all shocks

• Anti-roll bars: Attach all anti-roll bars

• Wheels: Attach all wheels. Both left and

right wheels at the front or rear should be

the same diameter

• Flat Set-up Board #108202

• Droop Gauge #107717

➊ Place the car on the set-up board.

➋ Lift the front of the car and let it fall back

to the set-up board by itself.

➌ Using the droop gauge, measure the

ride height value at the front of the car.

Page 13

13

➍ Lift the rear of the car and let it fall back

to the set-up board by itself.

➎ Using the droop gauge, measure the

ride height value at the rear of the car.

FRONT RIDE HEIGHT

Place the droop gauge under the front of the chassis (under the FLAT part of the chassis,

not the angled part) and measure the difference between the set-up board and the bottom

of the chassis.

The 0 mark on the droop gauge is equal to 30mm ride height. A negative value on the

droop gauge is lower than the 30mm reference height. For example, if the chassis is at

-3mm on the droop gauge, your ride height is 30-3mm = 27mm.

REAR RIDE HEIGHT

Place the droop gauge under the rear of the chassis (under the FLAT part of the chassis)

and measure the difference between the set-up board and the bottom of the chassis.

The 0 mark on the droop gauge is equal to 30mm ride height. A negative value on the

droop gauge is lower than the 30mm reference height. For example, if the chassis is at

-3mm on the droop gauge, your ride height is 30-3mm = 27mm.

ADJUSTING RIDE HEIGHT

Adjust ride height using spring preload only; DO NOT adjust ride height using downstop

screws.

Your car may use threaded spring preload collars or preload spacers.

Preload setting Threaded preload collar Preload spacers

Increase

TIGHTEN collar so it moves DOWN

the shock body

Use THICKER spacers

above the spring

Decrease

L

OOSEN collar so it moves UP the

shock body

Use THINNER spacers

above spring

FRONT RIDE HEIGHT

Increase

INCREASE preload on both FRONT springs

EQUALLY.

Decrease

DECREASE preload on both FRONT

springs EQUALLY.

REAR RIDE HEIGHT

Increase

INCREASE preload on both REAR springs

EQUALLY.

Decrease

DECREASE preload on both REAR springs

EQUALLY.

Page 14

14

1.3

CAMBER

-

+

r

c

a

m

b

e

Camber is the angle of a wheel to the surface on which the car is resting (with wheels and

shock absorbers mounted).

• Zero degrees (0°) of camber means that the wheel is perpendicular to the reference

surface.

• Negative camber means that the top of the wheel is leaning inwards towards the

centerline of the car.

• Positive camber means that the top of the wheel is leaning outwards from the centerline

of the car.

Camber affects the car’s side traction. Generally more negative (inward) camber means

increased grip since the side-traction of the wheel increases. Adjust front camber so that

the front tires wear fl at. Adjust rear camber so that the rear tires wear slightly conical to

the inside.

The amount of front camber required to maintain the maximum contact patch also depends

on the amount of caster. Higher caster angles (more inclined) require less negative camber,

while lower caster angles (more upright) require more negative camber.

EFFECTS OF CAMBER ADJUSTMENT

FRONT CAMBER

More negative (more inclined)

• More steering

Less negative (less inclined)

• Less steering

REAR CAMBER

More negative (more inclined)

• Decreases rear traction entering and in corners

Less negative (less inclined)

• Increases rear traction entering and in corners up

to a point

• If the shock is too vertical and traction is lost, the

traction will be lost very abruptly and the car will

be hard to control

MEASURING CAMBER

INITIAL STEPS SET-UP COMPONENTS

Prepare the car as follows Use the following set-up components

• Shocks: Attach all shocks

• Anti-roll bars: Detach all anti-roll bars

• Wheels: Remove all wheels

• Flat Set-up Board #108202

• Assembled Set-up Stands #108805

• Droop Gauge Support Blocks #107703

➊ Assemble the set-up stands.

➋ Mount the set-up stands on the axles.

➌ Place the droop blocks on the fl at set-up

board, and then place the fl at part of the

car chassis (not the angled part) on the

blocks.

Page 15

15

➍

Push on the car so the chassis rests fl at

atop both droop blocks at front and rear.

➎ Read the camber setting from the

camber gauge of each of the four set-up

stands.

Each graduated mark indicates a 1° camber

value. You should be able to set camber

with a resolution of 0.5°.

ADJUSTING CAMBER

FRONT CAMBER

Increase (more –ve)

SHORTEN the front upper camber link.

Decrease (less –ve)

LENGTHEN the front upper camber link.

FRONT CAMBER

Increase (more –ve)

SHORTEN the rear upper camber link.

Decrease (less –ve)

LENGTHEN the rear upper camber link

NOTE:

Changing the front camber will affect front toe. After setting the camber you must readjust the toe and then re-check the camber settings again. It may take a few repetitions

of these steps to ensure that both camber and toe are set to the desired values.

REAR CAMBER

Page 16

16

1.4

TRACK-WIDTH

Track-width is the distance between the outside edges of the wheels, front or rear, and it

affects the car’s handling and steering response. It is important that front or rear trackwidth is adjusted symmetrically, meaning that the left and right wheels (at one end of the

car) must be the same distance from the centerline of the chassis.

EFFECTS OF TRACK-WIDTH ADJUSTMENT

FRONT TRACK-WIDTH

Wider

• Decreases

front grip

• Increases understeer

• Slower steering response

• Use to avoid traction rolling

Narrower

• Increases front grip

• Decreases understeer

• Faster steering response

REAR TRACK-WIDTH

Wider

•

Increases rear grip at corner entry

• Increases high-speed on-throttle steering

• Use to avoid traction rolling

Narrower

• Increases grip at corner exit

• Increases high-speed understeer

MEASURING TRACK-WIDTH

INITIAL STEPS SET-UP COMPONENTS

Prepare the car as follows Use the following set-up components

• Shocks: Attach all shocks

•

Wheels: Attach all wheels. Both left and

right wheels at the front or rear should

have the same offset

• Flat Set-up Board #108202

• Board Decal #108212

➊ Place the car on the set-up board.

➋ Align the center of the car with the

centerline on the set-up board decal. Make

sure both front and rear are centered on the

decal.

front track-width rear track-width

Page 17

17

➌

Make sure the front wheels rest on

the front track-width graduation marks.

The amount of toe-in/toe-out has direct

infl uence on the track width so make sure

to measure at the part where the car is

widest.

➍ Make sure the rear wheels rest on the

rear track-width graduation marks.

FRONT TRACK-WIDTH

Look where the outer edge of each front wheels lie on the front track-width graduation

marks. Use a straight-edge against the wheel if necessary to see what the measurement

is.

The measurement represents the distance from the car’s centerline to the outer edge of

each wheel.

For example, on a 308mm wide buggy car, the measurement should be close to

154mm (½ the track-width) for each wheel.

REAR TRACK-WIDTH

Look where the outer edge of each rear wheels lie on the front track-width graduation

marks. Use a straight-edge against the wheel if necessary to see what the measurement

is.

The measurement represents the distance from the car’s centerline to the outer edge of

each wheel.

For example, on a 306mm wide buggy car, the measurement should be close to

153mm (½ the track-width) for each wheel.

ADJUSTING TRACK-WIDTH

Different cars may use different methods for track-width adjustment.

C-HUB SUSPENSION

Normally you cannot adjust the trackwidth of a car with C-hub suspension due

to the design of the suspension system.

The suspension arms and other parts are

designed to give you the correct trackwidth automatically. Optional off-set wheel

axles may be offered to adjust trackwidth.

PIVOTBALL SUSPENSION

Cars with adjustable pivotball-style suspension can change track-width by adjusting the

pivotballs into or out of the suspension arms.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 18

18

1.6

CASTER

c

a

s

t

e

r

Caster describes the angle of the front steering block with respect to a line perpendicular

to the ground. The primary purpose of having caster is to have a self-centering steering

system. Caster angle affects on- and off-power steering, as it tilts the chassis more or

less depending on how much caster is applied.

For the purpose of RC cars, it is generally recommended that you use a steeper caster

angle (more vertical) on slippery, inconsistent and rough surfaces, and use a shallower

caster angle (more inclined) on smooth, high-grip surfaces.

CAMBER vs. CASTER

Camber is all about contact patch – keeping as much tire on the ground as possible.

Camber and caster are related in that caster can afford an amount of EFFECTIVE CAMBER

change when the front wheels are turned in a corner.

Caster has the effect of progressively leaning the front tires into the direction of the

corner. The more the caster angle is laid-back, the greater the effective camber change

when the wheels are turned. This happens because the tops of the wheels BOTH TILT

towards the inside of the corner; the wheels “dig in” more, counteracting the centrifugal

forces pushing the car to the outside.

Compare that to the static camber of the wheels, which is adjusted with the car sitting

on a level surface and the wheels pointed straight ahead. Static camber adjustments

primarily affect the outside wheels, since these are the wheels that bear the majority of

the load during cornering.

Hence, the amount of front camber required to maintain maximum tire contact largely

depends on the amount of caster. A steeper caster angle requires more camber, while a

shallower caster angle requires less camber.

TOTAL CASTER ANGLE

Total caster angle also depends on the front kick-up angle.

To determine the total caster angle, combine the kick-up angle + C-hub caster angle.

Example: 10° front kick-up + 10° caster in C-hub = 20° total caster

EFFECTS OF CASTER ADJUSTMENT

Less caster angle

(more vertical)

• Decreases straight-line stability

• Increases off-power steering at corner entry

• Increases suspension effi ciency

More caster angle

(more inclined)

• Increases straight-line stability

• Decreases off-power steering at corner entry

• Makes the car more stable through bumpy track conditions

MEASURING FRONT CASTER

INITIAL STEPS SET-UP COMPONENTS

Prepare the car as follows Use the following set-up components

• Shocks: Attach all shocks

• Wheels: Remove all wheels

• Flat Set-up Board #108202

• Assembled Set-up Stands #108805

Page 19

19

➊ Assemble the set-up stands.

➋ Mount the set-up stands on the axles.

➌ Place the car on the set-up board.

➍ Read the caster angle from the side of

the front set-up stands.

Read the caster angle on the side plates

between the imaginary line that goes from

the top pivot point to the bottom pivot

point. Each graduated mark indicates a 2°

camber value. You should be able to set

camber with a resolution of 1°.

ADJUSTING FRONT CASTER

There are several different ways to adjust

caster on a car with C-hub suspension,

depending on the design of the car:

• Non-adjustable C-hubs (for example,

XB808): change to C-hubs of different

caster values

• Adjustable C-hubs (for example,

XB8EC): change the C-hub eccentric

pin holder.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 20

20

1.6

TOE

t

o

e

i

n

t

o

e

o

u

t

0

t

o

e

i

n

0

Toe is the angle of the wheels when looked at from above the car. Toe is used to stabilize

the car at the expense of traction, as it introduces friction and therefore some slip in the

tires.

• When the wheels are parallel with the centerline of the car, toe is 0° (neutral).

• When the wheels are closed towards the front, this is called toe-in (positive value).

• When the wheels are open towards the front, this is called toe-out (negative value).

Front wheels can have either toe-in or toe-out.

Rear wheels should always have toe-in; they should never have toe-out.

Toe may be adjustable at either end of a suspension arm:

• Inboard toe (if available) is typically adjusted by altering the angle of the suspension

arm’s inner pivot pin. Inboard toe adjustment is not available on all vehicles.

• Outboard toe (if available) may be adjusted in two ways: at the front by adjusting the

lengths of the steering rods; at the rear by altering the angle of the suspension arms

inner mounting pin (or other method)

EFFECTS OF TOE ADJUSTMENT

FRONT TOE

Increasing (more toe-in)

• Makes car easier to drive

Decreasing

(less toe-in, or more

toe-out)

• Decreases understeer

• Increases steering at corner entry

• Faster steering response

• Less stable under acceleration

• Makes car more diffi cult to drive

REAR TOE

Increasing (more toe-in)

• Increases understeer

• More stable exiting on-power at corner exit and braking

• Less chance of losing rear traction

• Decreases top speed

Decreasing (less toe-in)

• Less stable at on-power corner exit and braking

• More chance of losing rear traction

• Increases top speed

MEASURING TOE

INITIAL STEPS SET-UP COMPONENTS:

Prepare the car as follows: Use the following set-up components:

• Shocks: Attach all shocks

• Wheels: Remove all wheels

• Flat Set-up Board #108202

• Assembled Set-up Stands #108805

• Toe Gauge (for Truggy #108841)

• Droop Gauge Support Blocks #107703

When using the acrylic toe gauge, the toe gauge does not fi t over the pins on the set-up

stands so that the toe gauge is in one position. The toe gauge is designed to slide over

the pins from one side to the other, depending on which wheel you are measuring (left or

right). Follow the instructions carefully.

Page 21

21

➊ Assemble the set-up stands.

➋ Mount the set-up stands on the axles.

➌ Place the droop blocks on the fl at set-up

board, and then place the fl at part of the

car chassis (not the angled part) on the

blocks.

➍ Push on the car so the chassis sits fl at

atop both droop gauges at front and rear.

➎ Place the toe plate atop the stands and

measure the toe value.

FRONT TOE

Set the toe gauge atop the front set-up

stands. The pins at the top of the stands

fi t in the machined slots in the toe gauge.

Set the steering trim on your servo &

transmitter so that the front wheels point

directly forward. Set the steering in the

neutral position using the transmitter.

Turn on the car & transmitter when setting

front toe so the front wheels point straight

ahead.

Push on the car so the chassis sits fl at atop

both droop gauges at front and rear.

To read the toe value of the left front wheel,

push the toe gauge to the right until the pin

on the top edge of the left set-up stand

hits the edge of the slot in the toe gauge.

Now read the toe value on the toe gauge.

The black line on the top edge of the stand

points to a toe value engraved in the toe

gauge. Each graduated mark indicates a

1° toe value. You should be able to set toe

with a resolution of 0.5°.

To read the toe value of the right front

wheel, push the toe gauge to the left until

the pin on the top edge of the right set-up

stand hits the edge of the slot in the toe

gauge. Read the measurement.

REAR TOE

Set the toe gauge atop the rear set-up

stands. The pins at the top of the stands fi t

in the machined slots in the toe gauge.

Push on the car so the chassis sits fl at atop

both droop gauges at front and rear.

To read the toe value of the left rear wheel,

push the toe gauge to the right until the pin

on the top edge of the left set-up stand

hits the edge of the slot in the toe gauge.

Now read the toe value on the toe gauge.

The black line on the top edge of the stand

points to a toe value engraved in the toe

gauge. Each graduated mark indicates a

1° toe value. You should be able to set toe

with a resolution of 0.5°.

To read the toe value of the right rear wheel,

push the toe gauge to the left until the pin

on the top edge of the right set-up stand

hits the edge of the slot in the toe gauge.

Read the measurement.

ADJUSTING TOE

FRONT TOE

Increase (more front toe-in)

LENGTHEN both front steering rods

EQUALLY.

Decrease (less front toe-in)

SHORTEN both front steering rods

EQUALLY

REAR TOE

Refer to your car‘s instruction manual for

more information about changing rear toe in.

Different cars use different methods to adjust

rear toe-in usually changing toe-in blocks.

Refer to your car’s instruction manual for

more information.

NOTE:

Changing the front camber will affect front toe. After setting the camber you must readjust the toe and then re-check the camber settings again. It may take a few repetitions

of these steps to ensure that both camber and toe are set to the desired values.

Page 22

22

1.7

STEERING

Steering systems may be adjustable for Ackermann angle, servo saver preload, and

bump steer.

ACKERMANN

1.7.1

Ackermann controls the difference in steering arcs between the front inside and outside

wheels; the inside wheel always has a tighter arc in any corner. The amount of grip

provided by the tires, in relation to the steering arc and speed of the car, create an amount

of measurement called a “slip angle” for each wheel. For some tires you need a greater

difference in slip angles between the inner and outer wheel and for some you need less.

The servo saver on off-road cars & truggies forces the inside wheel to increase its turning

angle at a greater rate than the outside wheel, as the servo turns either way from center.

The rate of the increase, called Ackermann effect, can be changed by the angle of the

steering rods connecting the steering plate. The straighter the rods are in relation to each

other, the more Ackermann effect will be applied to the inside wheel

EFFECTS OF ACKERMANN ADJUSTMENT

STEERING ROD INNER MOUNTING

POSITION

CHARACTERISTICS

Forward holes (sharper angle)

• Smoothens out steering response

• Car reacts smoothly

• Better suited to smooth fl owing tracks with

high speed corners

Rearward holes (shallower angle)

• Quickens initial steering response

• Car reacts faster to steering input

• Better suited to small, tight tracks

ADJUSTING ACKERMANN

Adjust the Ackermann angle by moving the inside ends of the steering rods into different

holes in the steering plate.

IMPORTANT!

After adjusting the Ackermann, recheck that your front toe setting is still correct.

steering

Page 23

23

SERVO SAVER PRELOAD

1.7.2

On cars equipped with an adjustable steering servo server, you may adjust the spring

preload to alter the steering characteristics.

EFFECTS OF SERVO SAVER PRELOAD

SERVO SAVER SPRING PRELOAD CHARACTERISTICS

Softer

• Less steering

• Better suited to standard servos

Stiffer

• More steering with a quicker reaction

• Better suited to high torque metal-geared servos

ADJUSTING SERVO SAVER PRELOAD

Adjust the preload of the central servo saver by adjusting the tension on the spring with

the threaded collar.

• To make the preload SOFTER, loosen the

collar so the spring is not compressed

as much.

• To make the preload STIFFER, tighten the

collar so the spring is compress more.

preload

BUMP STEER

1.7.3

Bump steer is a front suspension tuning option commonly used in off-road RC racing to

change steering characteristics over rough and loose terrain. Bump steer occurs when a

car’s front toe angle changes as the suspension compresses or rebounds, which affects

how parallel the front wheels are.

EFFECTS OF BUMP STEER

More bump steer

(wheels more parallel under

compression)

• Increases steering in mid-corner

• Steering may become “twitchy”

• Easier to control on smooth tracks

Less bump steer

(wheels open more under

compression)

• Decreases steering in mid-corner

• Smoother steering response

• Better on rough or bumpy tracks

ADJUSTING BUMP STEER

Bump steer is adjusted differently on every

car. Please refer to the car’s documentation

to determine how to make adjustments.

The following table describes how to adjust

bump steer on an XRAY XB808, using

shims below the steering plate (between

the steering rod inner ends and the bottom

of the steering plate).

More bump steer

• Fewer/thinner shims below steering plate

• Steering rod becomes more angled (away from horizontal)

Less bump steer

• More/thicker shims below steering plate*

• Steering rod becomes more horizontal

* Remember that you can add more shims to get less bump steer, but only up to a certain

point (when the steering rods become horizontal). If you continue to add more shims

the steering rod will become more angled the other way (as the inner end moves further

away from the steering plate), and you will start to get more bump steer again.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 24

24

ROLL CENTER

1.8

A “roll center” is a theoretical point around which the chassis rolls, and is determined

by the design of the suspension. Front and rear suspensions normally have different roll

centers. The “roll axis” is the imaginary line between the front and rear roll centers. The

amount that a chassis rolls in a corner depends on the position of the roll axis relative

to the car’s center-of-gravity (CG). The closer the roll axis is to the center of gravity, the

less the chassis will roll in a corner. A lower roll center will generally produce more grip

due to the chassis rolling, and the outer wheel “digging in” more. Roll-centers have an

immediate effect on a car’s handling, whereas anti-roll bars, shocks and springs require

the car to roll before they produce an effect.

Roll center is determined by the car’s suspension geometry. Each end of the car has its

own roll center, determined by the suspension geometry at that end of the car.

Depending on the car, front and rear roll center may be adjusted by raising or lowering a

variety of different pivot points of the suspension arms & blocks, such as the following:

• inner upper pin/link

• outer upper pin/link

• inner lower pin

• outer lower pin

For information on adjusting roll center on cars with other adjustment possibilities

(for example, outer lower pins) please refer to the manufacturer’s original detailed

documentation.

FRONT ROLL CENTER

1.8.1

Typically on off-road cars (such as the XRAY XB808) front roll center is adjusted using

the front upper camber link inner mounting position on the front shock tower. Those

same holes on the front shock tower may also be used to adjust camber rise. For more

information, see the section on Camber & Camber Rise.

For information on adjusting front roll center on cars with other adjustment possibilities

(for example, the outer lower pin) please refer to the manufacturer’s original detailed

documentation.

EFFECTS OF FRONT ROLL CENTER ADJUSTMENT

FRONT UPPER CAMBER LINK SHOCKTOWER

EFFECT ON FRONT ROLL CENTER

Upper holes (lower roll center)

• Increases steering into corner

• Car is more responsive

Lower holes (higher roll center)

• Decreases steering into corner

• Car is less responsive

• Use in high-grip conditions

ADJUSTING FRONT ROLL CENTER

Front roll center is typically adjusted by

changing where the inner end of the front

upper camber link attaches to the front

shock tower.

IMPORTANT!

Make equal adjustments on both left and right sides of the car. Recheck front camber

after adjusting front roll center.

Page 25

25

REAR ROLL CENTER

1.8.2

Typically on off-road cars (such as the XRAY XB808) rear roll center is adjusted using

the rear upper camber link inner mounting position on the rear shock tower. Those

same holes on the rear shock tower may also be used to adjust camber rise. For more

information, see the section on Camber & Camber Rise.

For information on adjusting rear roll center on cars with other adjustment possibilities

(for example, the outer lower pin) please refer to the manufacturer’s original detailed

documentation.

EFFECTS OF REAR ROLL CENTER ADJUSTMENT

REAR ROLL CENTER CHARACTERISTICS

Higher

•

Increases on-power traction

• Use to avoid traction rolling at corner entry

• Use under low-traction conditions

Lower

• Decreases rear traction into corner

• Increases steering into corner

• Use to avoid traction rolling mid-corner and corner exit

REAR UPPER CAMBER LINK LENGTH

CHARACTERISTICS

Shorter link (outer hole on tower and/

or inner hole on hub)

• Increases steering and decreases

stability into corner

• Increases on-power traction slightly

Longer link (inner hole on tower and/or

outer hole on hub)

• Decreases rear camber gain

• Increases stability

• Slows down the car‘s responsiveness

REAR UPPER CAMBER LINK SHOCKTOWER

EFFECT ON REAR ROLL CENTER

Upper holes

• Lower rear roll center

Lower holes

• Higher rear roll center

ADJUSTING REAR ROLL CENTER

Use the mounting positions of the rear upper camber link to adjust rear roll center.

Inner mounting position:

• The inner end of the rear upper camber

link can be attached to the rear shock

tower in several different positions.

Outer mounting position:

• The outer end of the rear upper camber

link can be attached to the rear hub in

one of several positions.

IMPORTANT!

Make equal adjustments on both left and right sides of the car. Recheck rear camber after

adjusting rear roll center.

Page 26

26

SHOCK ABSORBERS

1.9

Shock absorbers, or shocks, are the

suspension components that allow the

wheels to keep as much contact as possible

with the track surface. All off-road cars

& truggies have fully-independent front

and rear suspension, meaning that the

suspension at each corner of the car (front

left, front right, rear left, rear right) moves

and may be adjusted independently of the

others. As such, there is a shock absorber

at each corner of the car. Damping,

mounting position, spring tension, and

spring preload are all characteristics that

determine how the shock performs.

SHOCK DAMPING

1.9.1

Shock damping manages the resistance of the shock to movement, as the internal shock

piston moves through the shock oil when the shock compresses and rebounds. Damping

mainly has an effect on how the car behaves on bumps and jumps, and how it reacts

initially to steering, braking, and acceleration.

Damping only comes into play when the suspension is moving (either vertical wheel or

chassis movement or due to chassis roll), and loses its effect when the suspension has

reached a stable position. Without damping, the shock springs would cause the shock to

“pogo” or “bounce” (compressing and rebounding) until it stabilized.

When the shock is compressing or rebounding, the shock oil resists the movement of the

piston through it. The amount of resistance is affected by several factors:

• Viscosity (thickness) of the shock oil

• Restriction of oil fl ow through the piston (affected by the number of holes in the piston

and the hole diameter)

• Velocity (speed) of the piston

Damping is affected by both shock oil and shock piston settings; getting the optimum

shock damping typically requires a lot of “hands on” experience.

EFFECTS OF SHOCK DAMPING

The effects of damping are often diffi cult to distinguish since there is an adjustment

where grip is optimum. When you get away from the optimum damping setting, either

softer or harder, the car will always lose grip.

The table below describes the handling effects by changing damping on one end of the

car; the starting point is always the ideal “optimum.”

ADJUSTING WITH...

EFFECT

SHOCK

OIL

PISTON

HOLES

Front Shocks

Softer

Damping

Thinner

More holes/

Larger holes

• Increases steering on low grip surface

• Slower steering response

• Decreases initial steering at corner entry

• Increases oversteer at corner exit/under

acceleration

Harder

Damping

Thicker

Less holes /

Smaller holes

• Faster steering response

• Decreases steering on low grip

• Increases initial steering at corner entry

• Increases understeer at corner exit/under

acceleration

Rear Shocks

Softer

Damping

Thinner

More holes/

Larger holes

• Increases rear grip at corner exit/under

acceleration

Harder

Damping

Thicker

Less holes /

Smaller holes

• Decreases rear grip at corner exit/under

acceleration

SHOCK PISTONS

Typically, shock pistons are provided with

different sizes of the holes. The sizes or

number of holes affect shock damping by

altering the fl ow of oil through the holes.

• More holes or larger holes give softer

damping

• Fewer holes or smaller holes give harder

damping

Page 27

27

Different size holes also produce an effect known as “pack” which affects how quickly

the shocks respond.

• Smaller holes increase the pack of the shock, which is better suited to big-jump tracks

where you will often land on the fl at surface & not the down ramp side of the jump.

It slows things on compression and rebound, and is not well suited to very bumpy

tracks.

• Larger holes decrease the pack of the shock, which is better suited to bumpy tracks

and jump sections where you land on the down ramp side of the jump. Compression

and rebound are faster.

IMPORTANT!

Both front shocks should use the same pistons; both rear shocks should use the same

pistons. However, front & rear shock pairs may use different pistons.

SHOCK OIL

Shock oil is rated with a “viscosity” number that indicates the thickness of the oil, which

determines how much the oil resists fl owing and how much it resists the shock piston

moving through it. Shock oil with a higher viscosity (for example, 1000 cSt) is thicker

than shock oil with a lower viscosity (for example, 500 cSt).

We recommend using only highest-grade XRAY Silicone Oil, which is available in

numerous viscosities. XRAY Silicone Shock Oil is specially formulated to be temperatureresistant and low-foaming for use in XRAY shocks. To be able to compare your setup with

other XRAY drivers, we advise using only XRAY Silicone Shock Oil.

Note that typically you should use piston hole sizes to suit the track conditions rather

than alter the oil viscosity.

IMPORTANT!

Both front shocks should use the same oil; both rear shocks should use the same oil.

However, front & rear shock pairs may use different pistons.

XRAY PREMIUM SILICONE OIL

# 359210 100 cSt # 359245 450 cSt

# 359215 150 cSt # 359250 500 cSt

# 359220 200 cSt # 359260 600 cSt

# 359225 250 cSt # 359270 700 cSt

# 359230 300 cSt # 359280 800 cSt

# 359235 350 cSt # 359290 900 cSt

# 359240 400 cSt # 359301 1 000 cSt

SHOCK SPRINGS

Spring tension determines how much

the spring resists compression, which is

commonly referred to as the “hardness”

of the spring. Different spring tensions

determine how much of the car’s weight is

transferred to the wheel relative to the other

shocks. Spring tension also infl uences the

speed at which a shock rebounds after

compression.

Spring tension is usually rated in a “spring

weight” ; higher spring weights are stiffer,

while lower spring weights are softer.

IMPORTANT!

Both front shocks should use the same springs; both rear shocks should use the same

springs. However, front & rear shock pairs may use different springs.

EFFECTS OF SHOCK SPRING REPLACEMENT

SHOCK SPRING CHARACTERISTICS

Softer

• More chassis roll

• More traction

• Better on bumpy tracks

• Increases chance of bottoming out when landing

Stiffer

• Less chassis roll

• Less traction

• More responsive

• Better on smooth tracks

• Decreases chance of bottoming out when landing

Page 28

28

SHOCK MOUNTING POSITION

1.9.3

You can change the shock mounting

position by leaning the shocks at different

angles, and also moving the shock closer

or further from the centerline of the car.

EFFECTS OF SHOCK MOUNTING POSITION ADJUSTMENT

SHOCK POSITION CHARACTERISTICS

More inclined

(moving in on tower

and/or moving out on

lower arm)

• Softer initial damping

• More progressive damping

• More lateral (side) traction

• Makes the handling more ”forgiving”

• May be better on high-bite tracks, since it slows

down the handling and makes it easier to driver

Less inclined (moving

out on tower and/or

moving in on lower arm)

• Harder damping

• Less lateral (side) traction

• Makes the car more responsive

• Usually better suited on technical tracks

SHOCK UPPER POSITION (SHOCK TOWER)

Front Shock

Tower

Outer holes

• Faster steering

• Better on bumps and jumps

Inner holes

• Easier to drive

• More side bite

• Slower initial steering

Rear Shock

Tower

Outer holes

• Less mid corner grip

• More traction into corner

• Squares up better on exit

Inner holes

• More steering into corner

• More mid corner grip

SHOCK LOWER POSITION (ARM)

Front Arm

Outer holes

• Increases stability

• Easier to drive

• Bigger turn radius

Inner holes

• Faster steering

• Better for bumps and jumps

Rear Arm

Outer holes

• More stability

• More lateral grip in turns

Inner holes

• Better for bumps and jumps

• Less side bite

• More exit traction

ADJUSTING SHOCK MOUNTING POSITION

Adjust shock position by moving the shock top and bottom mounts to different locations

on the shock towers and lower arms.

SHOCK PRELOAD

1.9.4

Shock preload affects the ride height of the car. For more information, see the section

on Ride Height.

EFFECTS OF SHOCK PRELOAD ADJUSTMENT

SHOCK PRELOAD CHARACTERISTICS

Less preload (thinner/less

spacers)

• Lower ride height

• May give higher corner speed on high bite tracks

• Better suited to smooth tracks

More preload (thicker/more

spacers)

• Higher ride height

• Less prone to bottoming out

• Better suited to rough tracks

Page 29

29

ADJUSTING SHOCK PRELOAD

Adjust the front and rear shock spring

preload by using preload clips of various

thicknesses above the shock springs, or

by adjusting the height of threaded preload

adjustment collars.

Initial set front preload so that the front

and drive shafts are level, and initially set

rear preload so that the rear lower arms

are level. You can then adjust front and/

or rear preload to suit track conditions &

requirements.

IMPORTANT!

Both front shocks should have the same preload; both rear shocks should have the same

preload. However, front & rear shock pairs may use different preload.

KICK-UP (FRONT)

1.10

Front kick-up is the angle of the front lower

suspension arm when viewed from the

side of the car. With kick-up the front of

the arm is higher than the rear of the arm.

Kick-up may be built into the design of the

chassis plate (bend upwards at the front)

or it may be accomplished by altering the

angle of the front lower inner pivot pins.

Front kick-up is used to adjust the amount

of weight transfer to the front when the car

is off-throttle or under braking.

EFFECTS OF FRONT KICK-UP ADJUSTMENT

FRONT KICK-UP

ANGLE

CHARACTERISTICS

More kick-up

• More weight transfer to the front of the chassis off-throttle or

under braking

• Chassis compresses or drops more off-throttle or under

braking

• Handling is improved on bumpy tracks

• Decreased steering response

Less kick-up

• Less weight transfer to the front of the chassis off-throttle or

under braking

• Chassis compresses or drops less off-throttle or under

braking

• Handling is improved on smooth tracks

• Increased steering response

ADJUSTING FRONT KICK-UP

Some vehicles (like the XB808) have fi xed

front kick-up, though optional parts may

be available to allow adjustment. When

front kick-up is adjustable, it is typically

adjusted via adjustable holders for the front

lower inner pivot pin.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 30

30

ANTI-SQUAT (REAR)

1.11

Rear anti-squat is the angle of the rear

lower suspension arm when viewed from

the side of the car. With anti-squat the

back of the arm is lower than the front of

the arm.

Rear anti-squat is used as a tuning aid

primarily when a car needs to run a soft

rear spring but also has a tendency for the

rear end to squat down too much under

acceleration. An added benefi t of rear antisquat is quicker initial acceleration at the

start of a race. In order to prevent 100% of the car’s weight transfer force from being

exerted onto the soft rear springs, anti-squat is used to allow a certain percentage of the

weight transfer to be absorbed by the rear lower arm motion.

EFFECTS OF REAR ANTI-SQUAT ADJUSTMENT

REAR ANTI-SQUAT ANGLE CHARACTERISTICS

Less anti-squat (fl atter arm)

• Increases rear traction off-power

• Decreases rear traction on-power

• Better on a bumpy track

More anti-squat (leaning more

backwards)

• Increases rear traction during acceleration

• Decreases rear traction off-power

• Better on smooth high grip tracks

ADJUSTING REAR ANTI-SQUAT

Some vehicles (like the XB808) have fi xed

rear anti-squat, though optional parts may

be available to allow adjustment. When

rear anti-squat is adjustable, it is typically

adjusted via eccentric holders for the rear

lower inner pivot pin.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 31

31

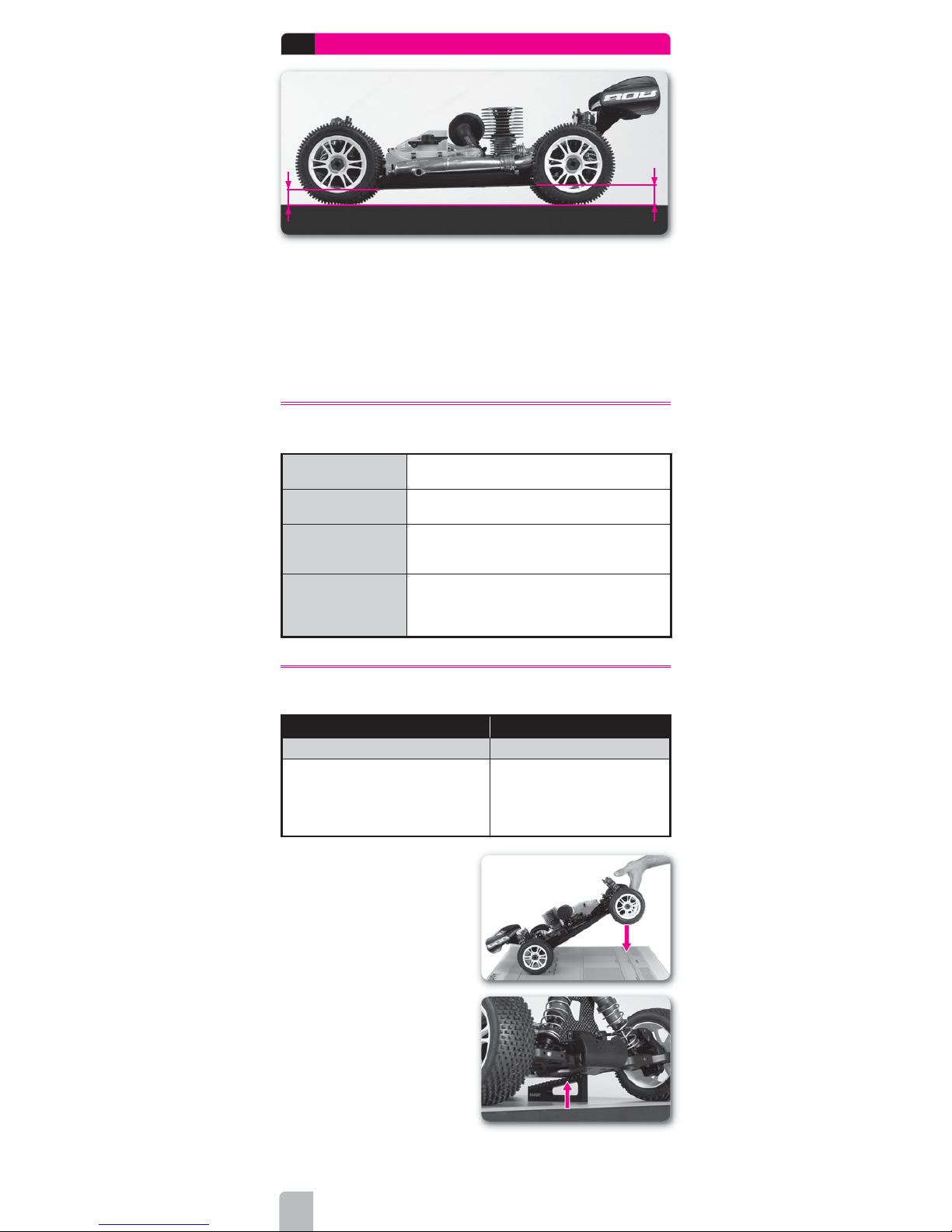

WHEELBASE

1.12

wheelbase

Wheelbase refers to the horizontal distance between the front and rear axles. Changes

to wheelbase can have a dramatic effect on the handling of your car

, since it readjusts

the distribution of weight on the wheels, which adjusts traction. Not all RC cars have the

option to adjust the wheelbase.

By adjusting the wheelbase at one end of the car, you affect the traction at that end of

the car. For example, by shortening the wheelbase at the rear of the car, you place more

weight over the rear wheels (resulting in more rear traction).

EFFECTS OF WHEELBASE ADJUSTMENT

WHEELBASE CHARACTERISTICS

Shorter wheelbase

(less spacers in

front of rear upright)

• Increases rearward weight transfer during acceleration

• Increases on-power traction

• Quicker off-power steering into corners

• Slight tendency to push on-power at corner exit

• Increases steering response

• Better on tighter, more technical tracks

Longer wheelbase

(more spacers in

front of rear upright)

• Decreases off-power steering into sharp corners

• Increases stability

• Slower initial steering reaction (off-power)

• Improves on-power steering at corner exit

• Better handling over bumps and ruts

• Better on more open tracks with high-speed corners

ADJUSTING WHEELBASE

Depending on the car, wheelbase may be

adjusted by using shims in the following

locations:

• Front and rear lower inner pivot pins,

ahead of & behind the front and rear

lower suspension arms

• Rear lower outer pivot pins, ahead of &

behind the rear uprights

Insert the appropriate shims on the pins

ahead of the arm (front) / upright (rear),

and insert the proper shims behind to

remove any slack.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 32

32

ANTI-ROLL BARS

1.13

Anti-roll bars are used to adjust the car’s side (lateral) grip. They can also be used in

conjunction with a softer spring rate to handle bumpy tracks more effi ciently without

excessive chassis roll at mid-corner. Anti-roll bars resist chassis roll and by doing so

transfer wheel load from the inside wheel to the outside wheel. The stiffer the anti-roll

bar, the more load is transferred. However, as the outside wheel is not able to convert the

extra wheel load into extra grip, the sum of the grip of both wheels is actually reduced.

This changes the balance of the car to the axle at the other end of the car; increasing the

stiffness of an anti-roll bar on one particular axle (front or rear) decreases the side grip of

that axle and increases the side grip of the axle at the other end of the car.

The overall traction of a car cannot be

changed, but it can be balanced by

distributing wheel loads. Anti-roll bars are

a very useful tool to change the balance

of the car. Chassis stiffness plays a very

important role in the effectiveness of

anti-roll bars, and a stiffer chassis makes

the car more responsive to anti-roll bar

changes.

The front anti-roll bar affects mainly off-power steering at corner entry.

The rear anti-roll bar affects mainly on-power steering and stability in mid-corner and at

corner exit.

EFFECTS OF ANTI-ROLL BAR ADJUSTMENT

ANTI-ROLL BAR STIFFNESS CHARACTERISTICS

FRONT

Softer (thinner wire)

• Increases front chassis roll

• Increases front traction

• Decreases rear traction

• Increases off-power steering (may cause oversteer)

Stiffer (thicker wire)

•

Decreases front chassis roll

• Decreases front traction

• Decreases off-power steering at corner entry

(increases understeer)

• Quicker steering response

REAR

Softer (thinner wire)

•

Increases rear chassis roll

• Increases rear traction

• Decreases front traction

• Decreases on-power steering (increases understeer)

Stiffer (thicker wire)

• Decreases rear chassis roll

• Decreases rear traction

• Increases front traction

• Increases on-power steering (may cause oversteer)

• Quicker steering response in high speed chicanes

ADJUSTING ANTI-ROLL BARS

Adjust the stiffness of the front or rear anti-roll bar by using a thinner or thicker wire.

Page 33

33

REAR WING

1.14

The angle and position of the rear wing

affects stability at various speeds,

increases or decreases rear traction, and

also affects car attitude when jumping.

EFFECTS OF REAR WING ADJUSTMENT

WING POSITION/ANGLE CHARACTERISTICS

Higher

• Increases stability at higher speeds

Lower

• Increases stability at lower speeds

Forward

• Decreases rear traction

Rearward

• Increases rear traction

Flatter angle

• Level jumping or nose-diving

Steeper angle

• Increases traction at higher speeds

• Less nose-diving

ADJUSTING THE REAR WING

Adjust the position and angle of the rear

wing using the different mounting position

on the wing supports. You can also add

shims between the rear bulkhead and the

rear wing posts to move the wing further

rearward.

IMPORTANT!

Make equal adjustments on both left and right sides of the car.

Page 34

34

CLUTCH

2.0

A properly set up clutch will have a dramatic

impact on the performance and drivability

of your off-road car. It is important to

note that there are many factors that may

affect engine and clutch performance,

including engine tuning, proper clutch

assembly, clutch shimming, spring rate,

and shoe orientation can all affect clutch

performance.

CLUTCH SPRINGS

2.0.1

Clutch springs affect the engagement point of the clutch.

EFFECTS OF CLUTCH SPRING STIFFNESS

CLUTCH SPRINGS CHARACTERISTICS

Thinner (softer)

• Clutch engages earlier at lower RPM

• More gradual acceleration

• Easier to drive but not as aggressive

• Easier to drive on low-grip tracks

Thicker (stiffer)

• Clutch engages later at higher RPM

• More sudden acceleration

• Car is more aggressive

• Engine will perform better on high-grip tracks

ADJUSTING CLUTCH SPRINGS

Adjust the engagement characteristics

of the clutch by using different clutch

springs.

CLUTCH SHOE ORIENTATION

2.0.2

The orientation of the clutch shoes affects how aggressively the clutch engages.

EFFECTS OF CLUTCH SHOE ORIENTATION

CLUTCH SHOE ORIENTATION CHARACTERISTICS

Trailing shoes

• Clutch engages more smoothly

• More ideal for slick track conditions

Leading shoes

• Clutch engages more aggressively

• More ideal on high-traction tracks

ADJUSTING CLUTCH SHOE ORIENTATION

Adjust the engagement characteristics of the clutch by changing the orientation of the

clutch shoes on the fl ywheel pins.

Trailing shoes

Leading shoes

Page 35

35

DIFFERENTIALS

2.1

Off-road cars typically feature sealed gear

differentials at the front, center, and rear.

The characteristics of the differentials may

be adjusted by using thinner or thicker

differential oils inside their cases. Optional

differentials – such as the XRAY Active

Diff™ – may also be used to replace the

standard front differential.

DIFFERENTIAL OIL

2.1.1

You can adjust the characteristics of the differentials by using thinner or thicker silicone

oil within their cases.

• Changing the oil in the front differential affects overall steering response.

• Changing the oil in the center differential affects the front-to-rear drive.

• Changing the oil in the rear differential affects cornering traction and overall steering.

We recommend using only highest-grade XRAY Silicone Oil, which is available in

numerous viscosities. XRAY Silicone Oil is specially formulated to be temperatureresistant and low-foaming for use in XRAY differentials. To be able to compare your setup

with other XRAY drivers, we advise using only XRAY Silicone Oil.

XRAY PREMIUM SILICONE OIL

# 359301 1 000 cSt # 359340 40 000 cSt

# 359302 2 000 cSt # 359350 50 000 cSt

# 359303 3 000 cSt # 359360 60 000 cSt

# 359305 5 000 cSt # 359380 80 000 cSt

# 359307 7 000 cSt # 359392 100 000 cSt

# 359310 10 000 cSt # 359394 150 000 cSt

# 359320 20 000 cSt # 359396 200 000 cSt

# 359330 30 000 cSt # 359398 300 000 cSt

EFFECTS OF DIFFERENTIAL OIL REPLACEMENT

DIFF

OIL

THICKNESS

CHARACTERISTICS

Front

Thinner

• Increases steering into corners (off-power)

• If oil is too thin the steering may become inconsistent,

especially it can lose forward traction (and steering)

during acceleration out of corners

Thicker

• Increases stability into corners during braking

• Increases steering on-power at corner exit

Center

Thinner

• Front wheels unload more during acceleration

• Decreases on-power steering (reduces oversteer)

• Easier to drive on rough tracks

• If a high-power engine is used you could waste too

much power and sometime “cook” the oil in the center

differential because it “overloads”

• More off-power steering

Thicker

• More all-wheel drive effect

• Better acceleration

• Increases on-power steering (reduces understeer)

• Better suited on high-bite, smooth tracks

• Car can be more nervous to drive especially if a high

power engine is used - you might need to be smooth on

the throttle

Rear

Thinner

• Increases cornering traction

• Increases steering into corner

Thicker

• Decreases rear traction while cornering

• Reduces wheelspin

Page 36

36

DIFFERENTIAL GEARS

2.1.2

Another tuning option for the differentials is

to change the outer crown or spur gears to

tailor the car to your driving style or track

conditions. Note that overdrive changes

are only done in the front.

EFFECTS OF DIFFERENTIAL GEAR REPLACEMENT

GEAR WHEN TO USE

FRONT

Larger front gear

(more teeth)

• Using a larger front gear is NOT recommended

Standard

• Standard gear works well on most tracks and conditions

Smaller front gear

(less teeth)

• Recommended for slippery tracks

• Gain more overall steering and makes car easier to drive

• Rear end follows the car around

CENTER

Larger center gear

(more teeth)

• Increases acceleration

• Decreases top speed

• Use on smaller track to get more punch

• Use with a larger clutchbell to get more overall torque

while maintaining the same gear ratio

Standard

• Standard gear works well on most tracks and conditions

Smaller center gear

(less teeth)

• Decreases acceleration, but smoother

• Increases top speed

REAR

Larger rear gear

(more teeth)

• Recommended for slippery tracks

• Underdrives the rear end with the same effect as a

smaller front gear

Standard

• Standard gear works well on most tracks and conditions

Smaller rear gear

(less teeth)

• Using a smaller rear gear is NOT recommended

OPTIONAL DIFFERENTIALS (XRAY ACTIVE DIFF™)

2.1.3

The XRAY Active Differential™ is a highperformance, adjustable front gear

differential for XRAY 1/8 nitro off-road cars

& truggies. It vastly improves the car’s

speed and handling characteristics. The

special design of the internal components

– using different angled segments – allows

the diff gears to engage on-power to

increase the forward traction and stability

to the buggy, making it faster and easier

to drive.

• High-performance adjustable front Active Differential for improved speed & handling

• Designed for XB8-based models

• Fully-adjustable on- and off-power performance using different internal segments and

gears

• Improves diff action and increases traction

• Easy and consistent steering

SEGMENT

AVAILABLE

WHEN TO USE

The standard 90° segment provides

a very good balance of performance

between on- and off-power. On-power

the diff becomes hard after a brief

delay. Off-power the diff becomes

free after a brief delay.

Recommended for high grip

and/or bumpy tracks.

The optional 120° segment gives

more immediate response both onand off-power. On-power the diff

becomes very hard immediately (no

delay). Off-power the diff becomes

free immediately (no delay).

Recommended for slippery

and/or flat tracks.

Page 37

37

ACTION

EFFECT

Off-power Action

Off-power the Active Diff works the same way as standard front

differential, so adjustment is made by using different viscosities

of silicone oil to get the desired off power steering. The softer

the oil, the more off-power steering but the car will be more

aggressive.

On-power Action

The main advantage of the Active Diff is readily apparent when onpower. The diff becomes harder and more locked when throttle is

applied, giving a lot of forward traction and stability to the car.

GEAR

WHEN TO USE

Standard / Larger

Gear

Standard / larger gear recommended for tracks with good grip

Optional / Smaller

Gear

Optional / smaller gear recommended for slippery tracks.

Increases stability but introduces slight amount of on-power

understeer

GEARING

2.2

Proper gearing is one of the most essential

tuning options required to maximize the

performance potential of your car.

PRIMARY DRIVE RATIO

2.2.1

Most modern off-road cars & truggies (including the XRAY XB808) feature a single-speed

transmission, so gearing is adjusted by changing the pinion gear (on the clutchbell)

and the spur gear (on the central differential)… also known as the “primary drive ratio

(PDR).” It is very important to establish the best gear ratio for each track environment,

engine/chassis setup and driving style.

• Smaller pinion / larger spur = high gearing (long/tall) = faster acceleration but

lower top speed

• Larger pinion / smaller spur = low gearing (short) = slower acceleration but higher