Page 1

RapidWash

User Manual

Rev 1.2

10 Stern Avenue, Springfield, NJ 07081

Tel: 973-376-7400 ♦ Fax: 973-376-8265

Page 2

Index

Section 1 - Setup ................................................................................................................. 3

1.1- Tubing and Connections .......................................................................................... 3

1.2 - Bottles .................................................................................................................... 4

1.2- RapidWash Select Manifold .................................................................................... 5

1.4 - Trough ................................................................... Error! Bookmark not defined.

Section 2 - Operation of RapidWash through the Touch Screen Controller ...................... 7

2.1 - Key Pad Functions .................................................................................................. 7

2.2 - Wash ....................................................................................................................... 8

2.3 - Prime ..................................................................................................................... 12

2.4 - Auto Prime ............................................................................................................ 13

2.5 - Maintenance Mode ............................................................................................... 14

2.6 – Change Settings ................................................................................................... 17

Section 3 - Maintenance of the RapidWash Manifold ...................................................... 23

3.1 - Removal and Installation of the Manifold ............................................................ 23

3.2 - Disassembly of the Manifold ................................................................................ 25

3.3 - Cleaning ................................................................................................................ 25

Section 4 - Hardware Specifications ................................................................................. 26

Section 4.1 - General..................................................................................................... 26

Section 4.2 - Mechanical Description: .......................................................................... 26

Section 4.3 - Materials: ................................................................................................. 26

Section 4.3 - Dimensions: ............................................................................................. 27

Section 4.4 - Electrical: ................................................................................................. 27

Section 4.5 - Environmental: ........................................................................................ 27

2

Page 3

Section 1 - Setup

1 4

5

6

7

8 9

2

3

1.1- Tubing and Connections

Rear Panel

Figure 1

1- Touch Screen Display Connection

2- RS-232 Communication Connection

3- AC Inlet For Power Cable

4- Liquid 1 Level Sensor

Position around Liquid 1 bottle close to bottom (See Figure 2)

5- Liquid 2 Level Sensor

Position around Liquid 2 bottle close to bottom (See Figure 2)

6- Waste Level Sensor

Position around Waste bottle close to top (See Figure 3)

7- Vac Control

Output for remote control for external vacuum

8- Air In

From air source 40-70 PSI to rear of Rapid Wash, this for the

internal pressure regulator and optional plate gripper

9- Pressure source for Liquid 1 and 2

1/4" OD tube connected between Liquid 1/ liquid 2 bottles and rear

of RapidWash (See Picture 2)

3

Page 4

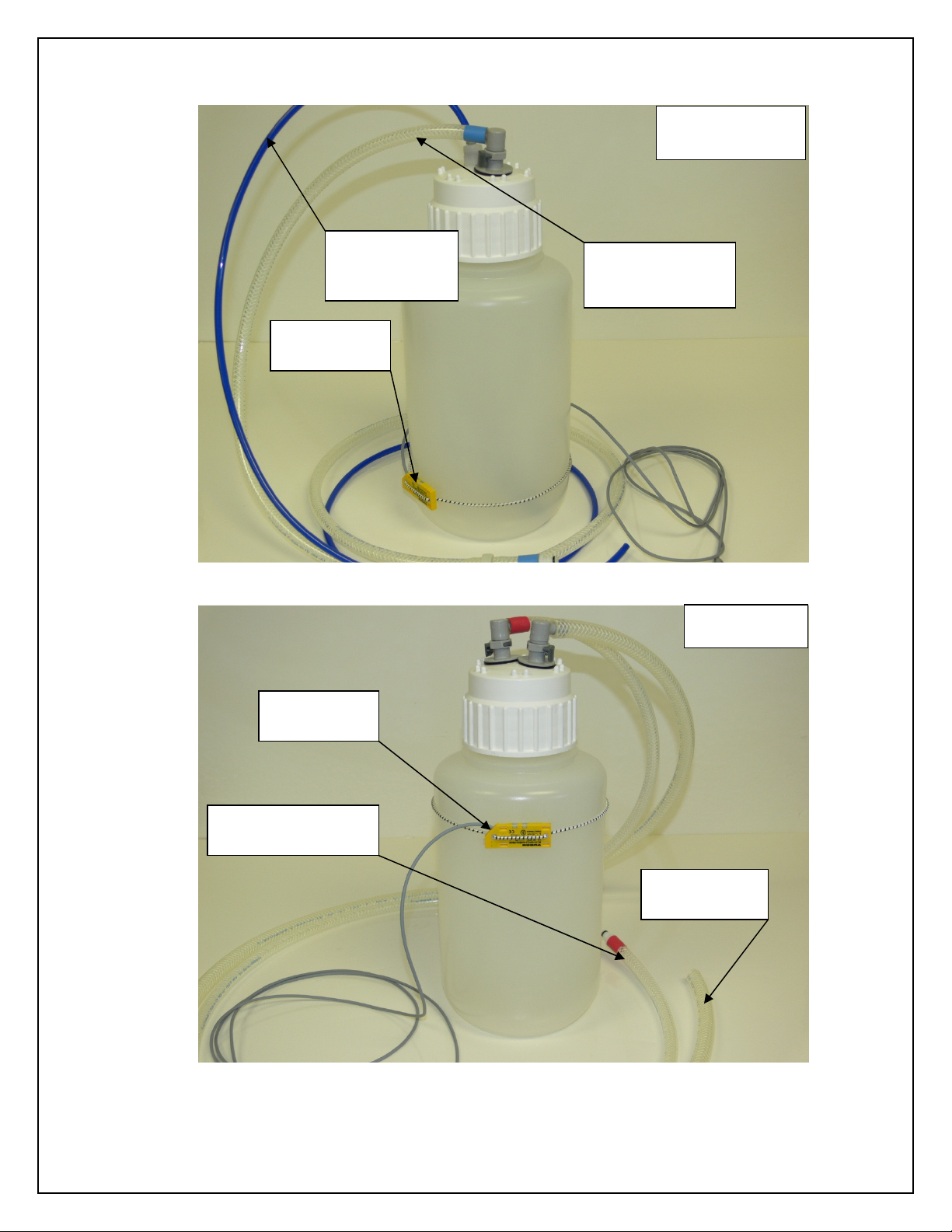

Dispense Bottle

Select Manifold

Liquid 1 and 2

Tubing for

Liquid 1 or 2

Pressure source

Liquid Level

Sensor location

Tubing to Liquid 1

or Liquid 2 Port on

Figure 2

Waste Bottle

Tubing For Waste Port

on Select Manifold

1.2 - Bottles

Liquid 1

Waste Level

Sensor location

Tubing to

Vacuum Source

Figure 3

4

Page 5

• Pressure In- From 12psi pressure source (#9 from figure 1) from

the rear of the RapidWash to top of bottle (1/4” blue tubing-See

Figure 2)

• Level Sensor - positioned near bottom of bottle (See Figure 2)

• Liquid Out - From bottle to side port of RapidWash Select

Manifold (See Figure 4)

Liquid 2

• Pressure In- From 12psi pressure source (#9 from figure 1) from

the rear of the RapidWash to top of bottle (1/4” blue tubing-See

Figure 2)

• Level Sensor - positioned near bottom of bottle (See Figure 2)

• Liquid Out - From bottle to side port of RapidWash Select

Manifold (See Figure 4)

Waste

• Vacuum In - From vacuum source to top of bottle (See Figure 3)

• Liquid In - From side port of RapidWash Select Manifold to top

of bottle (See Figure 4)

• Level Sensor - positioned near top of bottle (See Figure 3)

Note: The Level Sensors for source liquids and waste are identical. Only their

positioning on the bottles must be different, as described above.

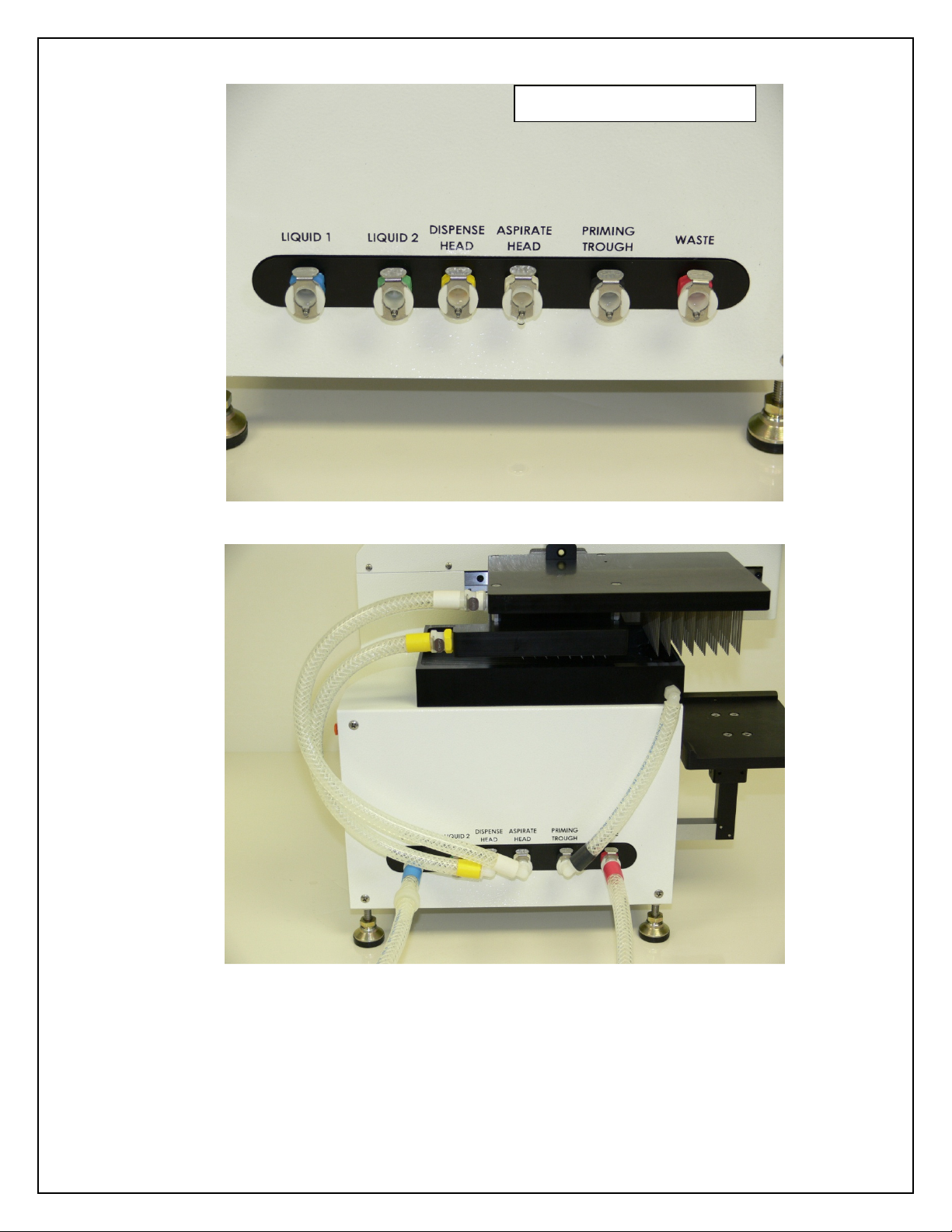

1.2- RapidWash Select Manifold

All Liquid tubing is attached to the Select manifold on the side left side of the

RapidWash (Figure 4). All the ports on the Select Manifold are color coded, so the

matching color fitting should be plugged into the appropriate port. The Color Coding is

as followed.

Blue – Liquid 1 Bottle

Green – Liquid 2 Bottle

Yellow – Dispense Head

White – Aspirate Head

Black – Priming Trough Waste

Red – Waste Bottle

When all the tubing is installed on the RapidWash it should look like the Layout in

Figure 5

5

Page 6

RapidWash Select Manifold

Figure 4

6

Figure 5

Page 7

Section 2 - Operation of RapidWash through the Touch Screen

Controller

2.1 - Key Pad Functions

Wash – Up to 20 Wash programs can be created and stored

Prime - Pumps either liquid 1 or 2 through the dispense manifold

Auto-Prime - Allows the dispense path to be primed on a time interval

Maintenance Mode - Tools for cleaning dispense and aspirate paths

Change Settings – Define parameters for operation such as plate locations

Figure 7

7

Page 8

2.2 - Wash

The RapidWash can support up to 20 dispense programs. Press the Next or Prev

key (Figure 8) on the Touch Panel to select the program number you would like to

setup.

Figure 8

Wells – Select the well pattern of the plate used in this program by pressing the

appropriate screen button (Figure 8)

Plate Height – Enter the height of the plate used in this program, in mm above the

base of the plate nest (see also Figure 9)

New – This will add a new Aspirate, Dispense, or Delay step in your Wash

Program (see also Figure 10)

Move Up – Allows you to move the position of the highlighted line up one line

in the program.

Move Dn – Allows you to move the position of the highlighted line down one line

in the program.

8

Page 9

Aspirate – Allows selection of:

Depth - The distance in mm traveled down into the plate wells, measured

from the top of the plate.

Speed - % of full speed travel during the aspirate step (Figure 11).

Figure 9

Figure 10

9

Page 10

Figure 11

Dispense – Select the liquid number (1 or 2) and the desired volume, in uL

(Figure 12). Note: If the liquid (1 or 2) being dispensed has not been

primed into the dispense head, the RapidWash will automatically

perform a priming step prior to the first dispense step in the Wash

Program being run. Subsequently, if only that liquid is dispensed in

that Wash Program, the remaining dispense steps will execute without

another priming action.

Figure 12

Delay – Entered as seconds. During a delay the plate is moved away from the

manifold and the washer will not aspirate or dispense until the delay is

over (Figure 13).

10

Page 11

Figure 13

Example of Wash Program (Figure 14)

Figure 14

All program values and steps are automatically saved to that program, as they appear on

the screen in Figure 14.

11

Page 12

2.3 - Prime

The Prime feature allows you to select the liquid number and the total volume (in

uL) dispensed through the dispense manifold. Priming occurs at the priming

trough. During the prime process the trough will self empty to the waste bottle

(Figure 15).

Volume – This is the total volume that will be primed through the system.

Liquid – This allows you to select the fluid source for the prime

Figure 15

12

Page 13

2.4 - Auto Prime

Auto Prime performs exactly like the Prime feature but will run automatically at

the user determined interval (Figure 16)

Volume – This is the total volume that will be primed through the system.

Liquid – This allows you to select the fluid source for the prime

Time – This is the interval in seconds; a time of 0 deactivates this feature

Figure 16

13

Page 14

2.5 - Maintenance Mode

The features in this section are used to clean and maintain the performance of the

dispense and aspirate manifolds (Figure 17).

Figure 17

Cleaning Procedure – This feature is used to flush the dispense manifold, it can

be helpful when attempting to remove debris from the dispense manifold. During

the cleaning procedure wash solution is dispensed out of the dispense manifold

into a user supplied trough and aspirated back though the dispense manifold to

waste.

A user-supplied trough is required for this procedure. It is placed in the plate nest

prior to starting the procedure. Clear lids for SBS pipette tip boxes work well and

allow you to see the cleaning cycle during operation.

If a clean, non-system wash solution is desired, the user-supplied trough can be

filled with the desired solution prior to the wash step. The control parameters are

as follows (Figure 18)

14

Page 15

Figure 18

Plate Height - Operates as described previously

Cycles - The number of times the cleaning process will be performed

Volume - This is the volume dispensed through the system: because the fluid path

could be empty after your first cycle you should pay close attention to

this volume to avoid under or over dispensing into your wash plate

Liquid 1, Liquid 2 - Operates as described previously

Soak Delay - Number of seconds the dispense manifold will soak in the dispensed

liquid

Drain Time - The number of seconds the Dispense manifold will aspirate to waste

Empty Manifold – This feature is used to pull vacuum on the aspirate manifold.

The unit does not move and only turns on the vacuum. This feature is typically

used when cleaning the manifold. The manifold does not need to be mounted

on the unit. On the run screen enter time in seconds and press “Run”.

Empty Trough – This feature is used to pull vacuum on the priming trough. The

unit does not move and only turns on the vacuum to the trough. This feature is

used to clear excess fluid from the trough. On the run screen enter time in

seconds and press “Run”.

Dispense Liquid – This feature is used to dispense liquid from unit. The unit does

not move, does not turn on any vacuum, and only dispenses liquid at the current

location. This feature is used to quickly test dispensing functionality. The net

volume dispensed from the unit is exactly as defined in the step, it is not defined

15

Page 16

by the number of wells (i.e. a volume of 9600 would lead to 9.6 mL dispensed

across a 96 well plate or 100 uL in every well). If run without the manifold

attached, volume dispensed will not match what is defined due to a different flow

rate without the head. On the run screen enter volume in uL and press “Run”.

Manual Move – This feature is used to jog the dispense head (Y Axis) IN or OUT,

jog the plate nest (Z Axis) UP or DOWN, and OPEN/CLOSE the plate gripper on

track-based units. Three settings are available for the distance of each jog

movement: 0.1mm, 1mm or 10mm.

16

Page 17

2.6 – Change Settings

This Section allows you to modify all the performance settings of the RapidWash

(Figure 19)

Settings Tab:

Aspirate Shift- This is the distance that the RapidWash will use above and in the

plate wells to begin the aspirate step. +mm is above the top of the Plate and –mm

is aspirate begins in the plate.

Dispense Shift- This is the distance that the RapidWash will use above and in the

plate wells to begin the dispense step. +mm is above the top of the Plate and –mm

is aspirate begins in the plate.

Travel Shift- This is the distance that the RapidWash will travel above the Plate

when the manifold moves between Aspirate, Dispense, and Prime Positions. +mm

is above the plate

Teaching Plate- This is the plate height of the microtiter plate that is used on the

calibration procedures (a standard 96 shallow well SBS Plate is usually between

13.5mm-14.0mm).

Dwell Time- This is the delay time the aspirate head stays in the plate after it stops

at the defined depth location. This setting is set in seconds default is 0.5 seconds.

Prime Volume- This is the amount of fluid in uL the RapidWash primes when the

unit switches it liquid path during a wash program.

Figure 19

17

Page 18

Initialize on Powerup- This will allow the RapidWash to automatically home

when the unit is turned on. The default setting is auto initialize is set to on.

Set Dispense Pressure- This option has been removed (12/10/2013).

Calibration tab:

This screen allows you to recalibrate the positions saved in the RapidWash

(Figure 20).

Figure 20

Prime Position- This is the saved position of the dispense manifold when it

primes the RapidWash (Figure 21).

18

Page 19

Figure 21

Aspirate Origin- This is the saved position of the aspirate manifold when the

RapidWash begins to aspirate. This position is calibrated with a 96 well teaching

plate. The position should be taught where each set of tips are centered in each

well of the plate (Figure 22).

Figure 22

19

Page 20

Dispense Origin- This is the saved position of the dispense manifold when the

RapidWash begins to dispense. This position is calibrated with a 96 well teaching

plate. The position should be taught where each set of tips are centered in each

well of the plate (Figure 23).

Figure 23

Track/Nest Height- This Position should only be modified when the unit is used

with a TrackLink on our Lablinx system. This is the beginning position of the

nest, default is 0. When used with a track the position is taught just below the

bottom the track (Figure 26).

The image cannot be displayed. Your co mputer may not hav e enough memory to open the image, or the image may have been co rrupted. Restart your computer, and then open the file again. If the red x still appears, you may have to delete the image and then insert it again.

Figure 24

Grip Position- This position is only used when a nest with a gripper is attached to

the RapidWash. This is used for through track-based washing only. This is the

Position at which a plate is gripped by the nest before the washing procedure.

This Position is usually taught +5mm above the track (Figure 25)

20

Page 21

The image cannot be displayed. Your co mputer may not hav e enough memory to open the image, or the image may have been co rrupted. Restart your computer, and then open the file again. If the red x still appears, you may have to delete the image and then insert it again.

Figure 25

Plate Origin- This is the starting position (origin) of the aspirate tips relative to

the teaching plate. To teach this position move the Aspirate head out until the

front set of tips are aligned with the teaching plate. Then move the nest up until

the aspirate tips touch the top of the teaching plate (Figure 26).

Figure 26

21

Page 22

Calibration tab:

The validation setting turn on/off various checks that the unit can perform prior to

executing programs and priming. Validation checks occur only on the resources

needed for a particular operation (i.e. If liquid 1 is the only fluid being used, the

unit will not validate liquid 2). It is strongly recommended that the validation

checks are not disabled.

- Check Waste Level: Checks if the sensor on the waste bottle is activated.

This may be deactivated for an in-house vacuum and waste management

system.

- Check Liquid 1 Level: Checks if the sensor on liquid bottle 1 detects fluid.

- Check Liquid 2 Level: Checks if the sensor on liquid bottle 2 detects fluid.

- Check Dispense Pressure: Checks if there is pressure for dispensing. This

may be deactivated for motion testing or demo purposes and will run without

dispensing fluid.

- Min Aspirate Vacuum: Checks if there is vacuum supplied to the unit.

WARNING: Disabling this check can lead to flooding!

22

Page 23

Section 3 - Maintenance of the RapidWash Manifold

3.1 - Removal and Installation of the Manifold

The RapidWash is shipped without the manifold assembly attached to the unit.

The manifold assembly is shipped with a shipping bracket to protect the tips. This

shipping bracket must be removed before the Manifold assembly can be installed onto the

RapidWash. The Manifold assembly has a quick disconnect fitting that holds the

Manifold (Figure 27).

Manifold Quick

Disconnect Fitting

Figure 27

The side of the manifold has two locating holes that allow the manifold to slide onto the

two locating pins on the manifold mount (Figure 28).

23

Page 24

Figure 28

Slide the manifold onto the locating pins and continue to slide the manifold towards the

mount until it locks into place (Figure 29).

To remove the manifold press the Steel release tab on the top of the quick disconnect,

then slowly slide the manifold off the locating pins on the manifold mount (Figure 29).

Figure 29

24

Page 25

3.2 - Disassembly of the Manifold

Remove the flat head screws that hold the aspirate and dispense manifolds

together. If desired, the standoffs may be removed from the dispense manifold

(Figure 30)

3.3 - Cleaning

All of the pump parts may be cleaned in an ultrasonic cleaner with a dilute

detergent solution. The parts must be thoroughly rinsed prior to reassembly.

Figure 30

25

Page 26

Section 4 - Hardware Specifications

Section 4.1 - General

NOTE: Specifications are subject to change without notice.

RapidWash:

• Plate Format: 96, 384 well plates in shallow, medium or

deep well-formatted SBS plate.

• Housing Material: Painted steel covering anodized cast

aluminum housing

• Plate Nest Material Acetal Copolymer

• Number of Axes Two (Y and Z axes)

Section 4.2 - Mechanical Description:

• Y-axis: Integrated stepper motor/stepper controller

with encoder. This is a belt driven axis with

pulley

• Y-axis: Stepper motor linear actuators with 250

count encoder. Actuator has integrated 1/2”

pitch Leadscrew. Controlled by separate

stepper controller with encoder option.

• Y-axis Travel Distance: 211mm hard stop to hard stop

• Y-axis Stepper Motor 1000 encoder steps per revolution linear

actuator. +/- 0.026mm resolution,

approximately ½ second for entire travel

distance.

• Z-axis: Stepper motor linear actuator. Actuator has

integrated 9.74mm pitch Leadscrew.

Controlled by separate stepper controller.

• Z-axis Travel Distance: 75mm hard stop to hard stop

• Z-axis Stepper Motor: 200 steps per revolution linear actuator.

+/- 0.006mm resolution, approximately ½

second for entire travel distance.

Section 4.3 - Materials:

• Housing Material: Stainless steel covering anodized aluminum

frame.

• Reservoir Material: Polypropylene

• Valve Material: PTFE

• Tubing Material: Acetal fittings on Tygothane Polyurethane

Tubing

26

Page 27

Manifold:

• Manifold Material: Acetal Copolymer

• Sealing O-rings Viton

• Fixed tip Material: Stainless Steel

Section 4.3 - Dimensions:

• 12.34”H X 11.11”W X 14.98”D

• Weight – 10LBS

Section 4.4 - Electrical:

• Power Input: 120VAC/240VAC, 50/60Hz

• Fuses: Two 2A time delay, 5mm x 20mm fuse

• Grounding: Through the power cord, must be properly

• Computer Interface: RS-232 straight through serial cable

Section 4.5 - Environmental:

• Operating Temperature: 15° to 40°C (59° to 104°F)

• Operating Humidity: 0 to 85%, no condensation

• Storage Temperature: -20° to 65°C (-4° to 149°F)

• Altitude: Up to 2000m

Section 4.6 - Pneumatic:

• Air Supply: 40 – 80psi; 1 SCFM

• Vacuum: -25 in. Hg (min); 1.2 SCFM

earth grounded

27

Loading...

Loading...