Page 1

STACKLINK

10 Stern Avenue, Springfield, NJ 07081

Tel: 973-376-7400 Fax: 973-376-8265

LABLINX

USER MANUAL

Page 2

Contents

CHAPTER 1-Introduction ................................................................................................. 1

Overview .................................................................................................................................... 1

Computer Requirements .......................................................................................................... 2

External Air Requirements ...................................................................................................... 3

Chapter 2-Installation ........................................................................................................ 4

Unpacking the StackLink ......................................................................................................... 4

Parts List .................................................................................................................................... 5

Setting up the StackLink .......................................................................................................... 6

Setting up the TrackLink(s) ..................................................................................................... 6

Setting Up StopLink(s) ............................................................................................................. 7

Connect Power Cord & Communication Cable: .................................................................... 9

Switching AC Line Voltage 110VAC/220VAC ....................................................................... 9

CHAPTER 3-StackLink Software ................................................................................... 10

Brief Description of Software ................................................................................................. 10

How to Install Software .......................................................................................................... 10

Configuring a Workcell .......................................................................................................... 11

Setting Up Plate Parameters .................................................................................................. 13

StackLink Delay (msec) .......................................................................................................... 14

CHAPTER 5-StackLink Components ................................................................................... 15

DriveLink System .................................................................................................................... 15

Stacks ....................................................................................................................................... 15

Power Cord/Communication Cable Connection .................................................................. 15

Power Switch ........................................................................................................................... 15

Optional Components ............................................................................................................. 15

CHAPTER 6-Hardware Specifications ........................................................................... 17

General ..................................................................................................................................... 17

TrackLink ................................................................................................................................ 17

StopLink ................................................................................................................................... 17

Mechanical Description .......................................................................................................... 17

Dimensions ............................................................................................................................... 18

Electrical .................................................................................................................................. 18

Environmental ......................................................................................................................... 18

StackLink User Manual Hudson Robotics, Inc.

i

Page 3

CHAPTER 7-Maintenance .............................................................................................. 19

Maintenance ............................................................................................................................ 19

Cleaning the StackLink .......................................................................................................... 19

Change the Fuse(s) .................................................................................................................. 19

Appendix A: ...................................................................................................................... 21

Hudson's LabLinx Communications and Command Set................................................. 21

Protocol Description ............................................................................................................... 21

StackLink Command Set ........................................................................................................ 23

Error Code Description .......................................................................................................... 30

StackLink User Manual Hudson Robotics, Inc.

ii

Page 4

WARNING

Possible hazardous situation could result in

serious injury.

NOTE

A statement that is cautionary; operating

tip; instrument damage may occur if not

followed.

HINT

Helpful hints and additional information

LIST

List of instructions; parts

Important information

Specifications

! CAUTION

Electrical Hazard

WARNING- -

This product may be used only in the manner described in this manual.

When used other than as specified, the safety protections provided by the

equipment may be impaired.

TABLE OF SYMBOLS:

The following symbols are to alert your attention to important information or

warnings that may present some hazards. These symbols may not appear in the

manual or on the product.

StackLink User Manual Hudson Robotics, Inc.

iii

Page 5

CHAPTER 1-Introduction

Overview

The StackLink (Figure 1) is an automated microplate stacker, which also drives a high

speed, modular and expandable track system that delivers lab ware to multiple laboratory

instruments. A part of LabLinx track system, the StackLink is capable of handling up to

120 (60 x 2 stacks) 96-well, 384-well or 1536-well standard microliter plates.

The StackLink includes Hudson Robotics’ SoftLinx software, which provides an easy-touse interface to coordinate the LabLinx operation with other automated instruments.

Softlinx is written in the Visual Basic for Applications programming language and can

run on Windows Vista, Windows 7. The StackLink can be interfaced with readers,

washers, liquid handlers, labelers, pipettors, etc.

The StackLink is equipped with optional expandable tracks, known as TrackLinks

(Figure 2), as well as up to 8 plate-stop modules called StopLinks (Figure 3). The

StopLink uses proximity sensors in line with quick plate catching “fingers” to stop and

position the microplate in precise locations.

Figure 1

StackLink User Manual Hudson Robotics, Inc.

1

Page 6

Tracklink StopLink

Figure 2 Figure 3

StackLink w/ TrackLink and StopLink options

Figure 4

Computer Requirements

The following are recommended for proper operation of the PlateCrane EX and Softlinx:

Operating System: Windows XP SP3, Windows XP x64, Windows Vista

32, Windows Vista 64, Windows 7 32, Windows 7 64

2.5GHz Quad Core Pentium processor or faster, 4GB RAM or higher, CD-

Rom drive, 2 available USB Ports

3GB MB of free disk space available

.NET Framework 4.0

StackLink User Manual Hudson Robotics, Inc.

2

Page 7

The Computer has the recommended number of working serial ports (You

can Purchase USB-to-serial convertors from Hudson Robotics If NeededPlease contact your local Sales Manager)

Power and communication cables for third party devices being connected

have been verified

External Air Requirements

60 PSI compressed air

StackLink User Manual Hudson Robotics, Inc.

3

Page 8

Chapter 2-Installation

Unpacking the StackLink

WARNING- -

Power switch must be turned OFF during entire installation procedure

DO NOT loosen or tighten any screws or touch parts not specified in the

instructions

Never force any component to fit

The StackLink weighs 30 lbs. and should be handled with care to avoid mishaps

Overview:

1. Remove StackLink from carton (Once you have a firm grasp on the unit gently lift the

unit straight up out of the carton. Make sure that the StackLink is separated from the

shipping foam)

2. Unpack any other accessories (TrackLinks, StopLinks, Alignment Bases) shipped

with the unit.

3. Position the StackLink on the Bench, with the flat side of StackLink facing towards

the end user. Unless limited by installation or layout.

4. Install Stack(s) into stack positions 1 and 2 on the unit. Make sure the stacks are

securely positioned on the unit. The open top section of the stacks should face out

and away from each other. This allows for the end user to remove or add plates easily.

5. Install any TrackLinks included in the system. First, remove the two clamp bars from

the StackLink. Slowly slide the TrackLink into the StackLink, make sure that the

gear on the StackLink and TrackLink align correctly. Then secure the TrackLink by

screwing down the clamp bars back into the StackLink.

6. Position any StopLinks where required by fastening them to the side of the track with

the provided Phillips head screws. Plug the modular plug into the desired port on the

side of the StackLink.

7. Position the plate stops across from the StopLinks and secure them with the provided

Phillip head screws. These plate stops prevent the plate from being pushed off of the

track when the StopLinks close.

8. Connect 1/4 “air line tubing supplying a minimum 60psi of compressed air to the

regulator located on the rear of the instrument.

9. Connect power cord and communication cable to the rear of the StackLink

10. Install Softlinx Software (see Chapter 3)

NOTE:

Please refer to the parts list to verify that all parts are included in the StackLink

carton. If any parts are missing, please contact Hudson Robotics.

StackLink User Manual Hudson Robotics, Inc.

4

Page 9

DO NOT DISCARD the StackLink carton. This carton has been specially

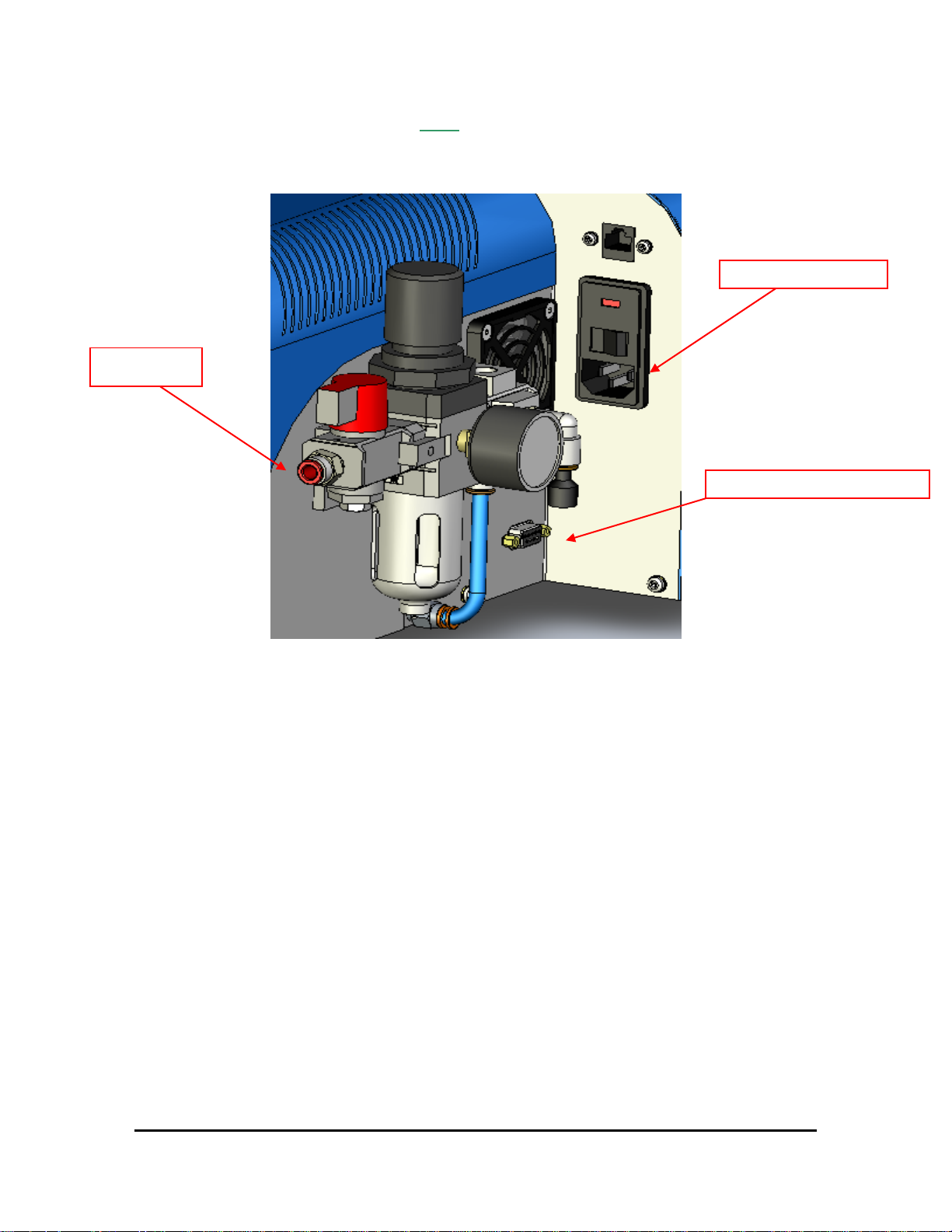

Power Cord Location

Communication Cable location

Air Inlet

created for this product and must be used for any additional shipping of the

instrument to prevent damage.

Figure 5

Parts List

The StackLink carton(s) should include the following:

StackLink

2 Extruded Stacks (double Stacks optional)

Power cord

Communication cable

User Manual (This document)

CD containing Softlinx and interfaces

StopLink(s) (optional)

Modular cord for each StopLink (optional)

Alignment Bases for instrument(s) (optional)

TrackLinks (optional)

TrackLink connection assemblies (for linking multiple tracks) (optional)

Clamp Bars (for securing TrackLinks to StackLink unit)

StackLink User Manual Hudson Robotics, Inc.

5

Page 10

Setting up the StackLink

Remove the StackLink from the carton and carefully remove the protective plastic

covering.

Un-wrap any TrackLinks and/or StopLinks included.

Remove the Stacks from the carton, then remove the stack from the packaging

Install the supplied Stacks on the StackLink securely.

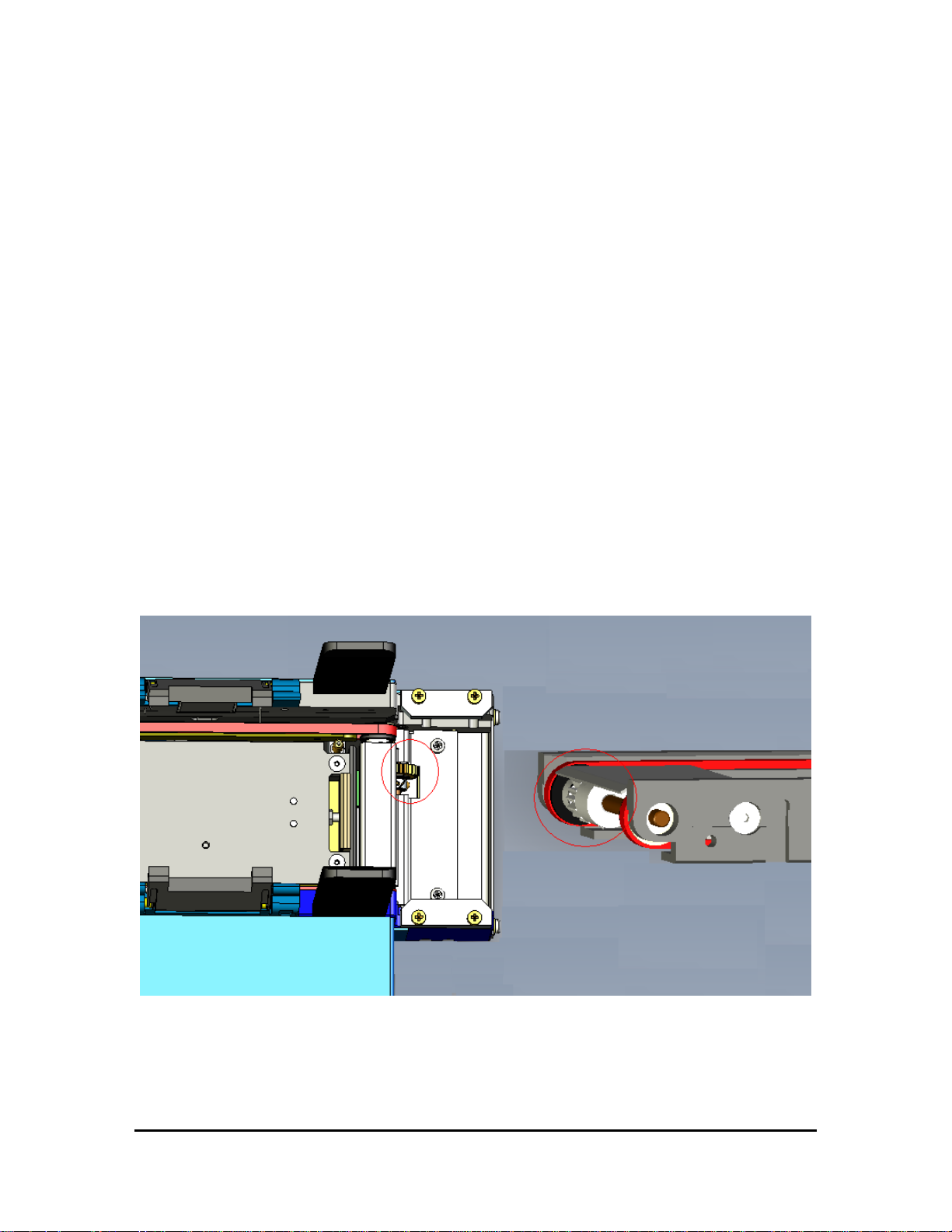

Setting up the TrackLink(s)

Position the TrackLink into either side of the StackLink and insert the track so the

groves match and fit into place (Figure 7).

NOTE: Be sure the TrackLink and StackLink gearing is properly positioned and

aligned for correct operation

Secure the track with the included Clamp Bars (Figure 11). Repeat if connecting

an additional TrackLink if required.

Secure the TrackLink to any instrument nests.

NOTE: Calibration and/or origin adjustments may need to be set for these

instruments. (I.E. PlateCrane positions, Micro10 dispensing origin, etc.)

Figure 7

StackLink User Manual Hudson Robotics, Inc.

6

Page 11

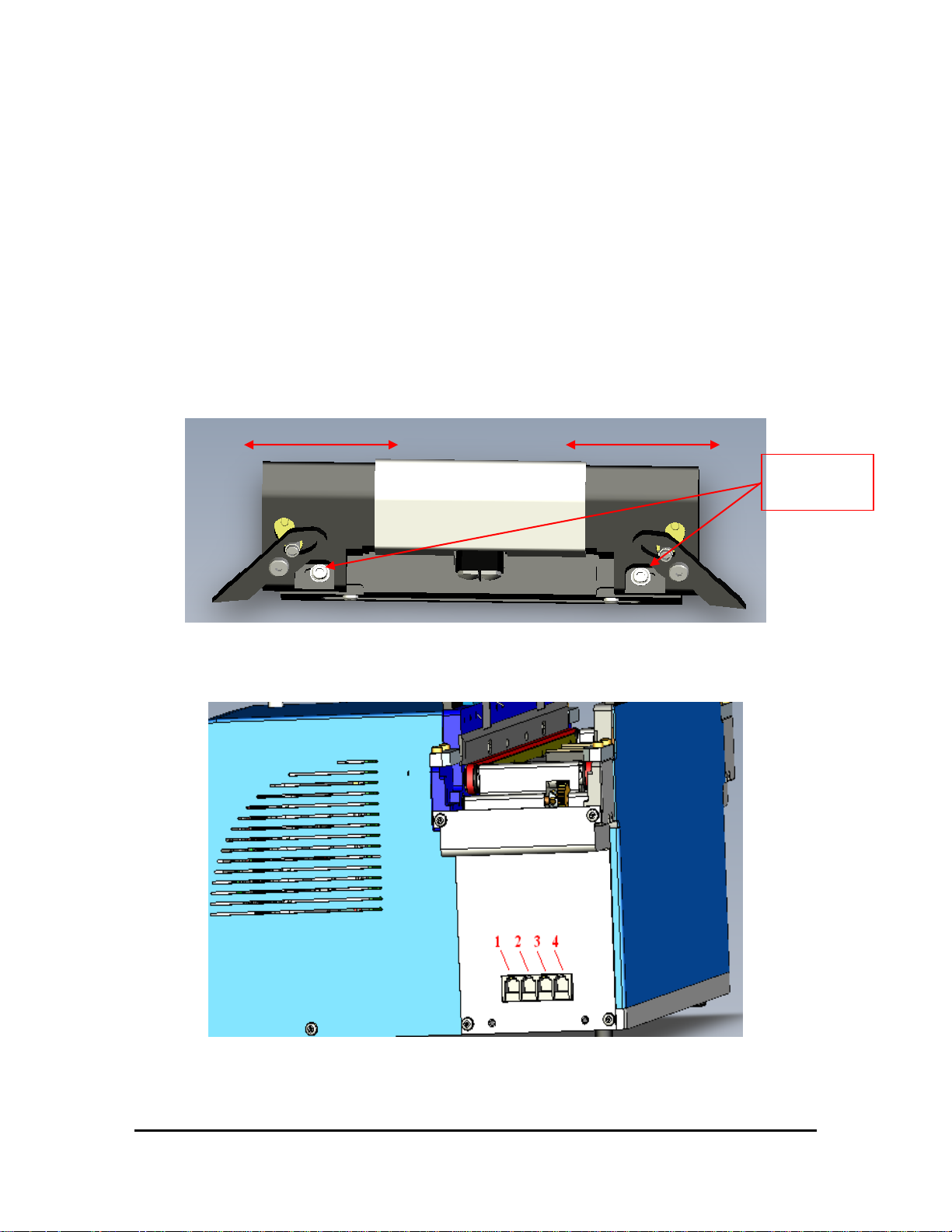

Adjustment

screws

Setting Up StopLink(s)

Position the StopLink in the desired location on the track and secure its position

with the supplied Phillips head screws. (Figure 12)

Connect modular plugs of the black coiled cable into both the StopLink and the

desired port on the side of the StackLink (Figure 9/10).

Adjustments may be needed depending on the size and type of plates used. Place

a plate on the track in front of the StopLink sensor to activate the fingers. Loosen

the 2 hex screws on the StopLink (Figure 8) and adjust the width of the sides so

the plate is secure between the fingers without any movement.

Figure 8

StopLink Positions 1-4

Figure 9

StackLink User Manual Hudson Robotics, Inc.

7

Page 12

Clamp Bars securing tracks

StopLink Positions 7-10

Figure 10

StackLink User Manual Hudson Robotics, Inc.

Figure 11

8

Page 13

Phillips Head

screws positioning

Figure 12

Connect Power Cord & Communication Cable:

Note: Power switch must be turned OFF

Remove power cord and communication cable from StackLink carton.

On the rear side of the base unit housing connect one end of the 9-pin to 9-pin serial cable

(see Figure 7), and attach the other end into COM1 port on Host Computer.

Plug power cable into the StackLink's AC inlet located on rear side of the base unit

housing (see Figure 7).

Note: The communication cable & power cord should be securely plugged into the

StackLink and computer.

Switching AC Line Voltage 110VAC/220VAC

The power supplies installed in the unit are switching power supplies. That means they

are able to handle both 110VAC and 220VAC without any changes to their configuration.

The Run the StackLink on 220VAC perform the following:

Make sure the unit is powered off

Install the power cord that is supplying the 220VAC

Turn on unit

StackLink User Manual Hudson Robotics, Inc.

9

Page 14

CHAPTER 3-StackLink Software

Brief Description of Software

Hudson's standard StackLink application software (SoftLinx) can be found on one (1)

installation CD. This CD can be loaded onto any PC running Microsoft's Windows 98

SE, NT 4.0. w\ service pack 6, 2000, or XP. This software provides a complete set of

utilities to run the StackLink and any instruments purchased by the end user. Hudson’s

LabLinx is an easy-to-use, dynamic scheduling software program for control of

integrated lab automation workcells and systems. LabLinx includes a multitasking core

executable combined with device interfaces that are written in VBA (Visual Basic for

Applications). The user sets up a method using a drag-and-drop icon-based method

editor.

How to Install Software

Turn computer ON. Start Windows, if it's not already running.

Insert CD into CD-ROM drive, and then close the drawer

The CD has an auto run function, so the installation of the software is automatic

If the CD does not auto run, then click on the Start menu

Click the run menu, then type in the location of the CD and Setup.exe

(E:\Setup.exe)

Then click OK to start installation

Follow instructions as prompted to complete the installation.

After installing LabLinx, open it by clicking the shortcut installed on your desktop.

StackLink User Manual Hudson Robotics, Inc.

10

Page 15

Configuring a Workcell

Click on the Configure Workcell icon on the screen.

Click and drag the corresponding icon for each instrument into the workcell and

select the communication port the instrument is assigned to.

Click the Return to Run View icon (same as Configure Workcell) and you will be

prompted to save the workcell you have just created.

StackLink User Manual Hudson Robotics, Inc.

11

Page 16

Click the Setup button under the StackLink icon.

Select each StopLink position(s) with the corresponding side of the TrackLink

you have secured the StopLink to.

StackLink User Manual Hudson Robotics, Inc.

12

Page 17

NOTE: Be sure to match the correct instrument nest name from the pull down

menu or errors will occur when attempting to run methods.

HINT: Clicking on the Test Button will allow you to test the operation of LabLinx

by allowing you to dispense, return, and shift plates.

Setting Up Plate Parameters

Entering correct dimensions for the plates you will be using is used only for the proper

handling of those plates by the PlateCrane EX as it automatically adjusts its positions for

each different plate-type used in every method based solely on the information entered

into that plate’s definition.

While not running a method, the user may click on the ‘Plates’ button located just above

the first configured instrument panel on SoftLinx’ ‘Run’ screen. The following ‘Plate

Setup’ form will be displayed:

Figure 13

StackLink User Manual Hudson Robotics, Inc.

13

Page 18

Click on the ‘Edit Plate’ button to change the parameters of a previously defined plate, or

click on ‘New Plate’ to create a new plate definition. Then, the following form will be

displayed:

Figure 14

HINT: The only parameter value important to the StackLink is:

StackLink Delay (msec)

The delay time (in milliseconds) it takes the Plate Seats to close after the stack

elevator begins to descend.

This is used when using microplates with special extrusions that may interfere

with dispensing.

StackLink User Manual Hudson Robotics, Inc.

14

Page 19

CHAPTER 5-StackLink Components

DriveLink System

The StackLink’s elevator and plate handling components use mostly pneumatic contols to

function. The LabLinx system uses a variety of sensors to feedback the plates

positioning to the unit’s computer controller. The StackLink also uses a powerful bidirectional belt and pulley system driven by a reversible 110 VAC motor to shift plates

along the LabLinx track.

Stacks

The standard StackLink includes two extruded aluminum stacks. Each stack can hold up

to 30 standard-height microliter plates. The stacks are from an aluminum extrusion for

rigidity and precision. The stacks are held in position by plastic guide blocks on the

StackLink. Double stacks are also available to increase plate capacity.

Power Cord/Communication Cable Connection

The power cord plugs into the AC inlet on the rear of the StackLink. Input power is

either 120V or 230V, 50 or 60 Hz. The communication cable is connected from the rear

of the StackLink to the chosen serial port on the computer (usually COM 1).

Power Switch

The power switch is located on the back plate with the power cord and communication

cable (see Figure 5). It has a 0 and 1 engraved on it to show the OFF and ON power

condition of the StackLink. StackLink power is ON when the switch is pressed in the 1

position and PWR LED on the top of the StackLink is illuminated.

Optional Components

The following are additional items available for the StackLink:

Double Stacks -- Expands StackLink capacity of up to 120 microliter plates (4

stacks).

TrackLink (24” & 36”)—Linkable tracks that transport plates to various locations

of the workcell.

StopLink (up to 8) – Modules that catch and release microplates along the

TrackLink path to allow other instruments to access these plates.

StackLink User Manual Hudson Robotics, Inc.

15

Page 20

Instrument alignment bases – Enables the instruments to be locked to the

TrackLink so they will not shift.

DriveLink: A separate instrument that provides the additional power needed to

drive the TrackLink system if additional lengths of track are required.

StackLink User Manual Hudson Robotics, Inc.

16

Page 21

CHAPTER 6-Hardware Specifications

General

Note: Specifications are subject to change without notice.

Plate Capacity: Standard-- Up to 30 plates without lids or 25 plates

with lids.

Additional-- Up to 120 plates without lids or up to 100

plates with lids.

Plate Storage Device: 2 removable stacks (Double Stacks available)

Housing Material: Painted steel covering cast aluminum housing.

Gripper Material: Black anodized aluminum; textured neoprene rubber

inserts.

DriveLink length: 15 inches

TrackLink

Gearing: Guarded power transmitting shaft assembly

Pulley System: 2 - 3/16” wide 1/5 pitch timing belts

Available Lengths: 24” and 36” tracks

Maximum Track Length: 159” (up to 4 -36” tracks) for 1 StackLink

StopLink

Plate Detection: Photoelectric sensor

Stopping Mechanism: 2 plate stop fingers (left & right) operated by rotary

solenoids

Communication: 13” coiled cord (8 pos RJ-12 modular plug)

Mechanical Description

DriveLink Motor: AC reversible motor 110V 60Hz

DriveLink Gearhead: Frame #2, 200 RPM

Elevator Lift: Pneumatic lift cylinder assembly

Plate Gripper: Pneumatic fired gripper pads (10mm bore, 5mm stroke)

Pressurized Air Supply: Regulator with filter and gauge (1/4” air supply fitting)

StackLink User Manual Hudson Robotics, Inc.

17

Page 22

Internal Air Tubing: Parflex Polyurethane tubing 1/16” ID, 1/8” OD

Parflex Polyurethane tubing 2.4mm ID, 4.00mm OD

Stack Present: Proximity switch

Plate Sensor: Type MH photoelectric sensor

Seat Opener: Double rod air cylinder, 10mm x 10mm

Plate Stops: 4 – (pneumatic firing) extruding pins

Dimensions

Height: 26.25” (incl. extruded stack)

Weight: 30 lbs.

Electrical

Power Input: 120V / 230V AC, 50/60 Hz

(Determined by position of fuse holder)

Fuses: For 120V / 230V

One 2A Time Delay, 5mm x 20mm

(.205 in. x .787 in.)

Grounding: Through the power cord, must be properly earth

Grounded

Computer Interface: RS-232 serial cable

Environmental

Operating Temperature: 15 to 40C (59 to 104F)

Operating Humidity: 0 to 85%, no condensation

Storage Temperature: -20 to 65C (-4 to 149F)

Altitude: Up to 2000m

Ventilation Fan requires +2” of free space in front of it

Indoor Use Only

StackLink User Manual Hudson Robotics, Inc.

18

Page 23

CHAPTER 7-Maintenance

Maintenance

WARNING- -

Qualified personnel can perform all maintenance procedures in this

manual. Only Hudson representatives should perform any maintenance

not discussed in this manual.

Gloves should be worn during any cleaning procedure.

Cleaning the StackLink

Note: DO NOT use/spray abrasive cleaners onto the StackLink.

Clean the outside surfaces of StackLink and/or TrackLink using cloth or sponge

dampened with alcohol, water, or mild glass cleaner.

Clean finger pads of gripper with alcohol or other residue-free solvent.

Clean any spills on the StackLink, TrackLink, or StopLink immediately.

Only clean the exterior of the unit. DO NOT remove instrument covers to clean

inside.

Never allow water or fluid to leak inside the StackLink.

Change the Fuse(s)

Fuses burn out occasionally and must be replaced. The following fuses are used with the

StackLink:

Metric: 1 x 2 amp, 5 x 20 mm Time Delay Fuse

WARNING- -

Be sure the power to the StackLink is OFF and the power cord is

unplugged from the instrument or power source before proceeding with

the following instructions.

Turn the StackLink OFF and remove the power cord from the AC inlet on the back

of the unit.

StackLink User Manual Hudson Robotics, Inc.

19

Page 24

Using a small flat head screwdriver, gently pry the fuse holder tray away from its

Location of fuse

holder tray

housing to access the fuses. The Fuse holder door swings down.

Remove the blown fuse. Replace it with the spare fuse.

Slide the fuse holder tray back into the AC inlet until it clicks. Make sure when re-

installing the holder the AC line voltage reads the correct way on the inlet

Reconnect the power cord to the StackLink and reconnect all other cables

previously disconnected.

Verify correct fuse replacement by turning the StackLink switch to ON position--

the light will illuminate immediately.

Figure 15

StackLink User Manual Hudson Robotics, Inc.

20

Page 25

Appendix A:

Hudson's LabLinx Communications and Command Set

Version 1.0

Hudson's LabLinx System is designed to respond to a simplified set of ASCII commands

to allow any user program capable of reading/writing via an RS-232 port or TCP/IP

connection to exercise all the features of the LabLinx Units.

Protocol Description

For RS-232 communication, a single RS-232 port is used to communicate to each

LabLinx device attached to the system.

The RS-232 connection for the LabLinx system operates with the following

communication specifications:

Baud Rate: 38400

Data Bits: 8

Stop Bits: 1

Parity: None

Handshake: None

Device Type: DCE

Connector: 9-pin, female

For TCP/IP communication, each unit must have a unique IP address assigned. This can

be accomplished with the SETIP command. The computer should then connect to this IP

address on TCP port 7.

LabLinx unit commands have the following format:

{command}[{parameter1},{parameter2},…]<13><10>

The {command} portion is the actual command to be executed by the receiving unit.

This may be followed by a comma-separated list of parameters as specified in the

individual command descriptions.

All LabLinx commands are terminated by a carriage return / line feed combination

(ASCII characters 13 and 10). The command is then delivered to the addressed unit,

which parses, validates, and executes the requested command before returning a

response. Commands may be sent to units while they are processing other commands.

Each unit can queue up to 10 commands. The behavior when the queue is overloaded is

StackLink User Manual Hudson Robotics, Inc.

21

Page 26

currently unspecified. There is currently no message indicating that the command queue

has been overloaded.

The following example would send the DISPENSE command, with an argument

indicating to dispense from Stack 1.

DISPENSE 1<13><10>

Command Responses

The controller will echo every byte of the command back to the sender as it is received.

Upon detecting the two bytes <13><10>, the controller will execute the command. Upon

completing execution, the controller will respond in one of two ways:

1. For query commands, where a data response is required, it will return:

{data response}<13><10>

2. For action commands or invalid queries, it will return:

{error code} {error description}<13><10>

If an action is requested, or an error occurs the response will be a 4 digit error code, a

space (ASCII character 32), and a short description of the error that occurred. A response

of “0000 Success" represents a correctly executed command. Other responses will

indicate an error.

As examples:

1. Valid query command:

Command: READINPUT 0,2<13><10>

Echo: READINPUT 0,2<13><10>

Response: 0<13><10> (i.e., input no. 2 is OFF)

2. Valid action command:

Command: CLOSE <13><10>

Echo: CLOSE <13><10>

Response: 0000 Success<13><10> (i.e., action successfully executed)

3. Invalid query command ("WASHER" is an unknown position):

Command: GETPOINT WASHER<13><10>

Echo: GETPOINT WASHER<13><10>

Response: 0002 Invalid Parameter<13><10> (invalid point name)

Note: If any command contains an error, the StackLink sends the response immediately,

otherwise the response is sent at the completion of execution.

StackLink User Manual Hudson Robotics, Inc.

22

Page 27

StackLink Command Set

The StackLink Unit recognizes the following commands:

1. ACKNOWLEDGESEND

The ACKNOWLEDGESEND command is used to indicate that a plate transfer

between two conveyor-based LabLinx units has been completed, and that the

recipient of the command should turn off the conveyor. See the

RECEIVEPLATE and SENDPLATE commands for more information.

Example:

Command: ACKNOWLEDGESEND<13><10>

Response: 0000 Success<13><10>

2. DISPENSE [Stacks]

DISPENSE will cause the StackLink to dispense a plate from the specified stacks.

The Stacks parameter is bit mask indicating the stacks to dispense from. Bit 1

indicates Stack1, bit 2 indicates Stack2. Currently only values from 1-3 are

accepted. Plates under one of the stacks when this command is issued will remain

in place at the completion of the command.

Example:

Command: DISPENSE 2<13><10>

Response: 0000 Success<13><10>

3. GETCONFIG

The GETCONFIG command returns a bit mask indicating the currently available

positions on the StackLink unit. There are 10 possible positions, allowing

configuration values between 0 and 1023. Normally bits 5 and 6 will be active

indicating the presence of Stacks 1 and 2. Other bits may be active depending on

the connected TrackLink and StopLink units. This value is set using the

SETCONFIG command.

Example:

Command: GETCONFIG<13><10>

Response: 112<13><10>

4. GETDISPENSEDELAY

GETDISPENSEDELAY returns the additional time in milliseconds that the plate

seats will be held open when dispensing a plate. This allows the stacker to

StackLink User Manual Hudson Robotics, Inc.

23

Page 28

dispense double-flanged or otherwise oddly shaped plates. This time is set using

the SETDISPENSEDELAY command. This time should be 0 for most plates.

Example:

Command: GETDISPENSEDELAY <13><10>

Response: 0<13><10>

5. GETIP

GETIP returns the current IP address of the unit.

Example:

Command: GETIP<13><10>

Response: 10.1.1.5<13><10>

6. GETMOVETIME

GETMOVETIME returns the current number of seconds the StackLink waits for

labware to arrive at a location before returning a failure to move the labware.

This value is set using the SETMOVETIME command.

Example:

Command: GETMOVETIME<13><10>

Response: 10<13><10>

7. GETPOSNAME {Position Number}

GETPOSNAME returns the name assigned to the indicated position number.

This command allows applications to assign useful names to various StackLink

position numbers. These names are not currently used in any StackLink

commands other than the GETPOSNUM command.

Example:

Command: GETPOSNAME 5<13><10>

Response: Stack1<13><10>

StackLink User Manual Hudson Robotics, Inc.

24

Page 29

8. GETPOSNUM {Position Name}

GETPOSNUM will return the position value associated with the specified

position name.

Example:

Command: GETPOSNUM Stack1<13><10>

Response: 5<13><10>

9. GETSTOPDELAY

GETSTOPDELAY will return the number of milliseconds before the stops will

capture a plate when the plate is placed on the track by another instrument.

Example:

Command: GETSTOPDELAY<13><10>

Response: 300<13><10>

10. LISTPOINTS

The LISTPOINTS command returns a list of the currently available positions and

the names assigned to them. The line “End of List” is returned to indicate the end

of the command.

Example:

Command: LISTPOINTS<13><10>

Response: 5: Stack1<13><10>

6: Stack2<13><10>

7: MyWasher<13><10>

End of List<13><10>

11. MOVEPLATE {Start}, {End}

The MOVEPLATE command moves a plate between the indicated start and end

position numbers. The positions must be available according to the current

configuration. There must be labware in the start position. And the path between

the start and end positions must be clear. If any of these conditions is not met an

appropriate error will be returned.

Example:

Command: MOVEPLATE 5,7<13><10>

Response: 0000 Success<13><10>

StackLink User Manual Hudson Robotics, Inc.

25

Page 30

12. NAMEPOS {Position Number}, {Position Name}

The NAMEPOS command assigns the indicated name to the indicated position

number.

Example:

Command: NAMEPOS 7, MyWasher<13><10>

Response: 0000 Success<13><10>

13. READINPUT {Card Number}, {Input Number}

READINPUT returns the current state of the input located at the indicated I/O

card number and input number. A 0 indicates the input is not active, a 1 indicates

that the input is active.

Example:

Command: READINPUT 0,0<13><10>

Response: 0<13><10>

14. RECEIVEPLATE {Direction}, {End}

The RECEIVEPLATE indicates that the StackLink should activate its conveyor

and begin looking for labware to arrive at the indicated end location. The

direction parameter indicates which direction to turn the conveyor. A 1

designates forward motion, and a 0 indicates reverse motion. The conveyor will

turn off when the labware arrives at the indicated location, or the current move

time has elapsed. See the commands SENDPLATE and

ACKNOWLEDGESEND for more information.

Example:

Command: RECEIVEPLATE 1,6<13><10>

Response: 0000 Success<13><10>

15. RELAYOUT {Card}, {Relay}, {State}

The RELAYOUT command activates the indicated relay on the indicated relay

card. A state of 1 indicates that the relay should close. A 0 indicates that the

relay should open.

Example:

Command: RELAYOUT 1,2,1<13><10>

Response: 0000 Success<13><10>

StackLink User Manual Hudson Robotics, Inc.

26

Page 31

16. RETURN [Stacks]

RETURN will place plates located under the indicated stacks into the stacks. The

Stacks parameter is a bit mask indicating the stacks to return to. Omitting the

Stacks parameter causes the StackLink to return any plates under both stacks.

Plates under stacks not specified in the mask will remain at their current location.

Example:

Command: RETURN 1<13><10>

Response: 0000 Success<13><10>

17. SENDPLATE {Direction}, {Start}

SENDPLATE indicates the StackLink should send the labware located at the start

position off the conveyor in the indicated direction. A 1 indicates forward

motion. A 0 indicates reverse. The conveyor remains active until an

ACKNOWLEDGESEND command is received.

Example:

Command: SENDPLATE 1,5<13><10>

Response: 0000 Success<13><10>

18. SETCONFIG {Configuration}

SETCONFIG sets a bit mask indicating the available positions on the StackLink unit.

There are 10 possible positions allowing values between 0 and 1023.

Example:

Command: SETCONFIG 112<13><10>

Response: 0000 Success<13><10>

19. SETDISPENSEDELAY {Time}

SETDISPENSEDELAY sets the additional time in milliseconds that the plate seats

will be held open when dispensing a plate. This allows the stacker to dispense

double-flanged or otherwise oddly shaped plates. This time should be 0 for most

plates.

Example:

Command: SETDISPENSEDELAY 0<13><10>

Response: 0000 Success<13><10>

StackLink User Manual Hudson Robotics, Inc.

27

Page 32

20. SETIP {IP Address}

SETIP will set the IP address of the unit. This change is immediate and may cause

loss of communication if used during a TCP/IP session.

Example:

Command: SETIP 10.1.1.5

Response: 0000 Success <13><10>

21. SETMOVETIME {Timeout}

SETMOVETIME sets the number of seconds the StackLink waits for a plate to

arrive at its destination before returning an error.

Example:

Command: SETMOVETIME 30<13><10>

Response: 0000 Success<13><10>

22. SETSTOPDELAY {DelayTime}

SETSTOPDELAY sets the amount of time the StackLink will wait before closing the

stops if a plate is placed on the track by another instrument. The DelayTime is in

milliseconds.

Example:

Command: SETSTOPDELAY 300<13><10>

Response: 0000 Success<13><10>

StackLink User Manual Hudson Robotics, Inc.

28

Page 33

23. SHIFT {Direction}, [Positions], [Receive]

The SHIFT command will move plates one position in the indicated direction. A

Direction of 1 indicates forward motion. A Direction of 0 indicates reverse motion.

If the Positions parameter is included, only the plates at the indicated positions will be

shifted. If the Positions parameter is omitted, all plates will be shifted. Issuing a

command to shift the plate located at the end position off of the StackLink will cause

the unit to behave as if a SENDPLATE command had been issued. The StackLink

will shift the indicated plates, and then continue to run the conveyor until an

ACKNOWLEDGESEND command is received. If the Receive parameter is

included, it will indicate whether or not the StackLink should expect to receive a plate

from an adjacent unit. The plate will always be received into the end position of the

StackLink. A Receive value of 1 indicates that a plate is expected. A Receive value

of 0 indicates no plate is expected.

Example:

Command: SHIFT 1,112,1<13><10>

Response: 0000 Success<13><10>

24. VERSION

VERSION returns the unit firmware version.

Example:

Command: VERSION<13><10>

Response: StackLink Unit v0.2<13><10>

25. WRITEOUT {Card}, {Output}, {State}

WRITEOUT changes the state of the indicated output on the indicated I/O card.

A state of 1 indicates the output should be active. A 0 indicates the output should

become inactive.

Example:

Command: WRITEOUT 0,0,1<13><10>

Response: 0000 Success<13><10>

StackLink User Manual Hudson Robotics, Inc.

29

Page 34

Error Code Description

The PlateCrane controller will report one of the following response codes at the

completion of each command:

General Errors:

00 Success

01 Unrecognized Command

02 Invalid Parameter

03 Bad Echo From Unit

StackLink Errors:

0100 Path is blocked.

0101 Nothing to move

0102 Position not available

0103 Failed to move plate

0104

0105

0106 Invalid position name

0107

0108

0109

0110 Elevator Jammed

0111 Elevator Blocked

0112 No Plate Dispensed

0113 Failed to Return Plate

StackLink User Manual Hudson Robotics, Inc.

30

Loading...

Loading...