Page 1

Hudson Print and Apply

10 Stern Avenue, Springfield, NJ 07081

Tel: 973-376-7400 Fax: 973-376-8265

USER MANUAL

Rev 1.1

Page 2

Table of Contents

CHAPTER 1 - Overview .................................................................................................... 2

A. System Requirements ............................................................................................. 2

B. Environmental Requirements ................................................................................ 2

CHAPTER 2 – Installation ................................................................................................ 3

A. Unpack the Print and Apply .................................................................................. 3

B. Installing Media ................................................................................................... 10

CHAPTER 3 - Calibration ............................................................................................... 12

A. Connection ........................................................................................................... 12

B. Setup Screen ......................................................................................................... 13

C. Label Setup ........................................................................................................... 14

D. Apply Nest Setup .................................................................................................. 18

E. Hardware Setup.................................................................................................... 14

CHAPTER 4 – Operation ................................................................................................ 20

A. Creating Labels .................................................................................................... 20

B. Setup and Testing Apply Profiles ........................................................................ 24

C. SoftLinx Operation .............................................................................................. 26

CHAPTER 5 - Maintenance ............................................................................................ 28

A. Maintenance ......................................................................................................... 28

B. Cleaning the Print and Apply .............................................................................. 28

C. Cleaning the Printer............................................................................................. 28

CHAPTER 6 - Warranty & Service Agreement Terms and Conditions ........................ 29

A. Warranty ............................................................................................................... 29

B. Service Agreements .............................................................................................. 30

Print and Apply User Manual Hudson Robotics, Inc.

i

Page 3

WARNING- -

WARNING

Possible hazardous situation could result in

serious injury.

NOTE

A statement that is cautionary; operating

tip; instrument damage may occur if not

followed.

HINT

Helpful hints and additional information

LIST

List of instructions; parts

Important information

Specifications

! CAUTION

Electrical Hazard

This product may be used only in the manner described in this manual.

When used other than as specified, the safety protections provided by the

equipment may be impaired.

TABLE OF SYMBOLS:

The following symbols are to alert your attention to important information or

warnings that may present some hazards. These symbols may not appear in the

manual or on the product.

Print and Apply User Manual Hudson Robotics, Inc.

ii

Page 4

CHAPTER 1 - Overview

The Print and Apply is an automated Barcode Labeling System. It creates and attaches

printed labels to any SBS-standard microplate or microplate lid. The Print and Apply can

apply labels any of the four sides of a microplate. The Print and Apply’s applicator head

has 35mm of vertical travel which can hit anywhere on a standard microplate. The Print

and Apply has an optional barcode scanner that can be mounted within range of the base,

so you can print and confirm barcodes in one step. For a complete “walk away” system,

the unit can be integrated with a Hudson Robotics PlateCrane EX.

This manual will explain how to setup your Print and Apply to achieve optimal

efficiency. If you have any questions or comments about the contents of this manual,

please contact Hudson Robotics, Inc. at +1-(973) 376-7400. For more information,

please visit our website at http://www.hudsonrobotics.com.

A. System Requirements

The Print and Apply needs the following to optimally run:

32” x 24” benchspace

Clean, dry air with a 1/4” fitting and air line achieving a maintainable 80 psi, 3.0

cfm

120 VAC, 50-60 Hz, 4 amps

PC with Windows XP or Windows 7, with CodeSoft 9.1 or later and SoftLinx V

or later installed.

B. Environmental Requirements

Operating Temperature: 15 to 40C (59 to 104F)

Operating Humidity: 0 to 85%, no condensation

Storage Temperature: -20 to 65C (-4 to 149F)

Altitude: Up to 2000m

Ventilation Fans Require +2” of free space in front of them

Print and Apply User Manual Hudson Robotics, Inc.

2

Page 5

CHAPTER 2 – Installation

A. Unpack the Print and Apply

WARNING- -

Power switch must be turned OFF during entire installation procedure.

DO NOT loosen or tighten any screws or touch parts not specified in the

Never force any component to fit.

The Print and Apply system weighs 50 lbs. and should be handled with

Overview:

instructions.

care to avoid mishaps.

The Print and Apply will arrive in three separate boxes. The Zebra box contains

the printer portion of the system. The Hudson box contains the applicator portion

of the system. The third box contains the alignment base for the printer which

connects the printer to the applicator. Any additional components will be packed

in the Hudson box along with the applicator.

Below are the following steps to unpack the system:

1. Open the third box and remove the alignment base from the box and place

it on the table that will hold the Print and Apply system.

Print and Apply User Manual Hudson Robotics, Inc.

3

Page 6

2. Open the Hudson box and remove the applicator from the box, also

remove any additional components from this box. Place the applicator on

the table next to the alignment base.

3. You will now attach the applicator base to the alignment base. To do so,

you will open the latches on the alignment base (See Figure 3). Then you

will slide the alignment base into the cutout in the applicator base. You

will now move the latches down until they meet the catches. Slowly turn

the latch handles until they close and push the handle down to lock the

latch into location (See Figure 4). Slowly move the alignment base to

make sure that the bases are securely attached.

Figure 3 Figure 4

4. Open the Zebra box and remove the Printer from the box. You will have

to remove the shipping straps from around the printer, before removing the

printer from the box. You will slowly lift the printer out of the box and

install it on the alignment base. You will place the printer on top of the

alignment base and match up the two countersunk holes with the two ball

end leveling feet. The ball end leveling feet will keep the printer secured

onto the alignment base (See Figure 5)

Print and Apply User Manual Hudson Robotics, Inc.

4

Page 7

Figure 5

Printer Leveling Feet

5. Attach all of the cables and accessories as shown in the following pictures,

before turning the unit on.

1- USB Keyboard (optional) 3- Monitor Cable (optional)

2- Communication Cable for Applicator (Attach to computer)

Print and Apply User Manual Hudson Robotics, Inc.

5

Page 8

1- Communication Cable to Rear of Printer

2- Optional Barcode Cable

3- Power Cable for Applicator

4- USB cable for Printer (goes to computer)

Print and Apply User Manual Hudson Robotics, Inc.

6

Page 9

1- Air Pressure Regulator set to 60 PSI w/ ¼” Quick disconnect fitting. User

supplies air input of 80 PSI (5.5 bar) or greater to this unit.

2- Vacuum Lines

Print and Apply User Manual Hudson Robotics, Inc.

7

Page 10

1. 1/8” Air Blast Tubing. (Color may vary.)

Print and Apply User Manual Hudson Robotics, Inc.

8

Page 11

NOTE:

DO NOT DISCARD the Hudson or Zebra Printer box. These cartons have been

specially created for these products and must be used for any additional

shipping of the instruments to prevent damage.

The Print and Apply boxes should include the following:

Print and Apply Applicator

Print and Apply Alignment Base

Zebra Printer

Power cord (s)

Communication cable(s)

Monitor

USB Cable

Keyboard

Mouse

Barcode Scanner (optional)

6ft of 1/4” air tubing

User Manual (This document)

Print and Apply User Manual Hudson Robotics, Inc.

9

Page 12

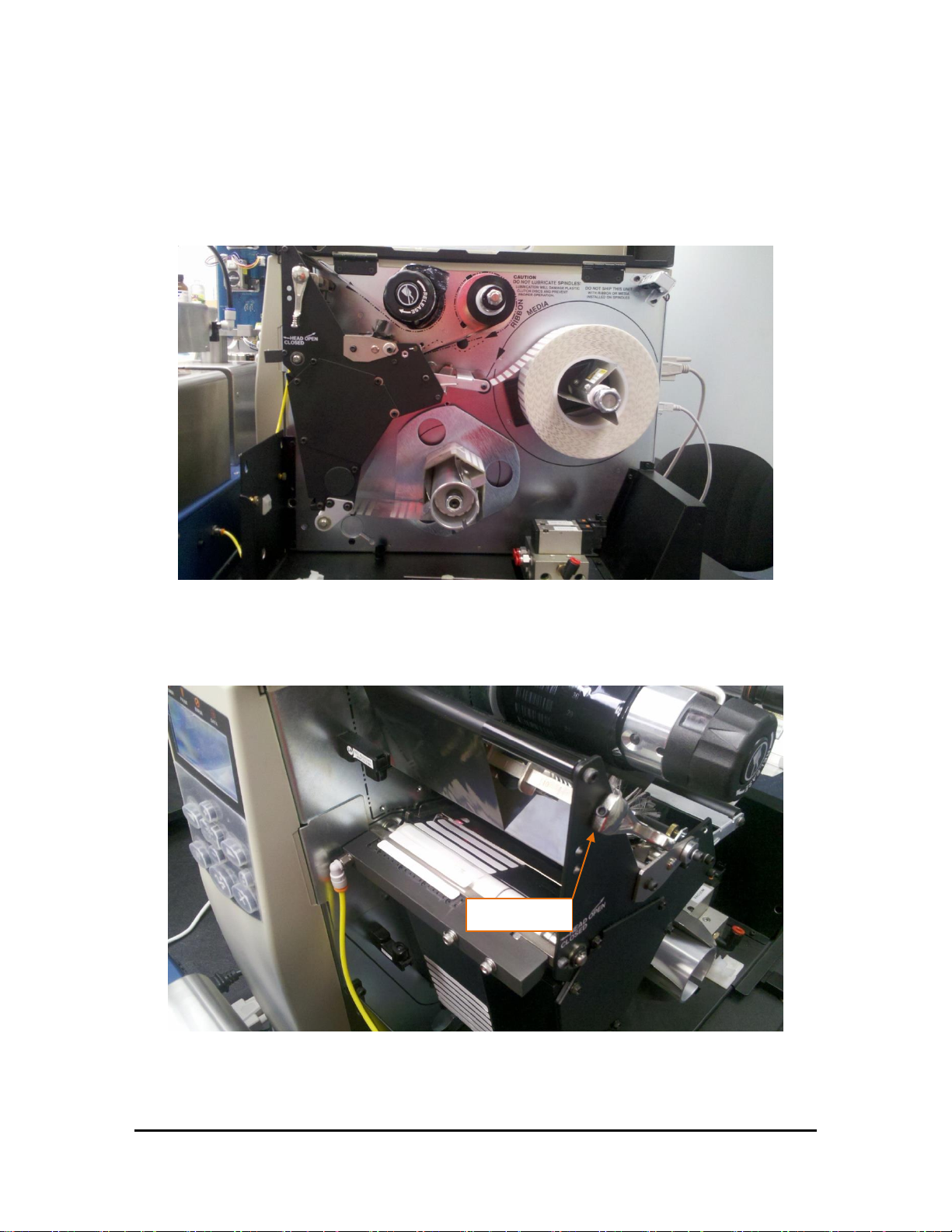

B. Installing Media (Labels)

Print head arm

After the PA1000 is setup correctly the media for the printer must be installed.

1. Open the front cover of the printer. Inside the printer wall is a

schematic of how the media should run through the printer. Use this

as a guide to position the media and print ribbon.

2. The print head must be lifted up so the print ribbon and media can go

through the print head area. To lift up the print head slide the head bar

labeled below counterclockwise until the head pops up.

Print and Apply User Manual Hudson Robotics, Inc.

10

Page 13

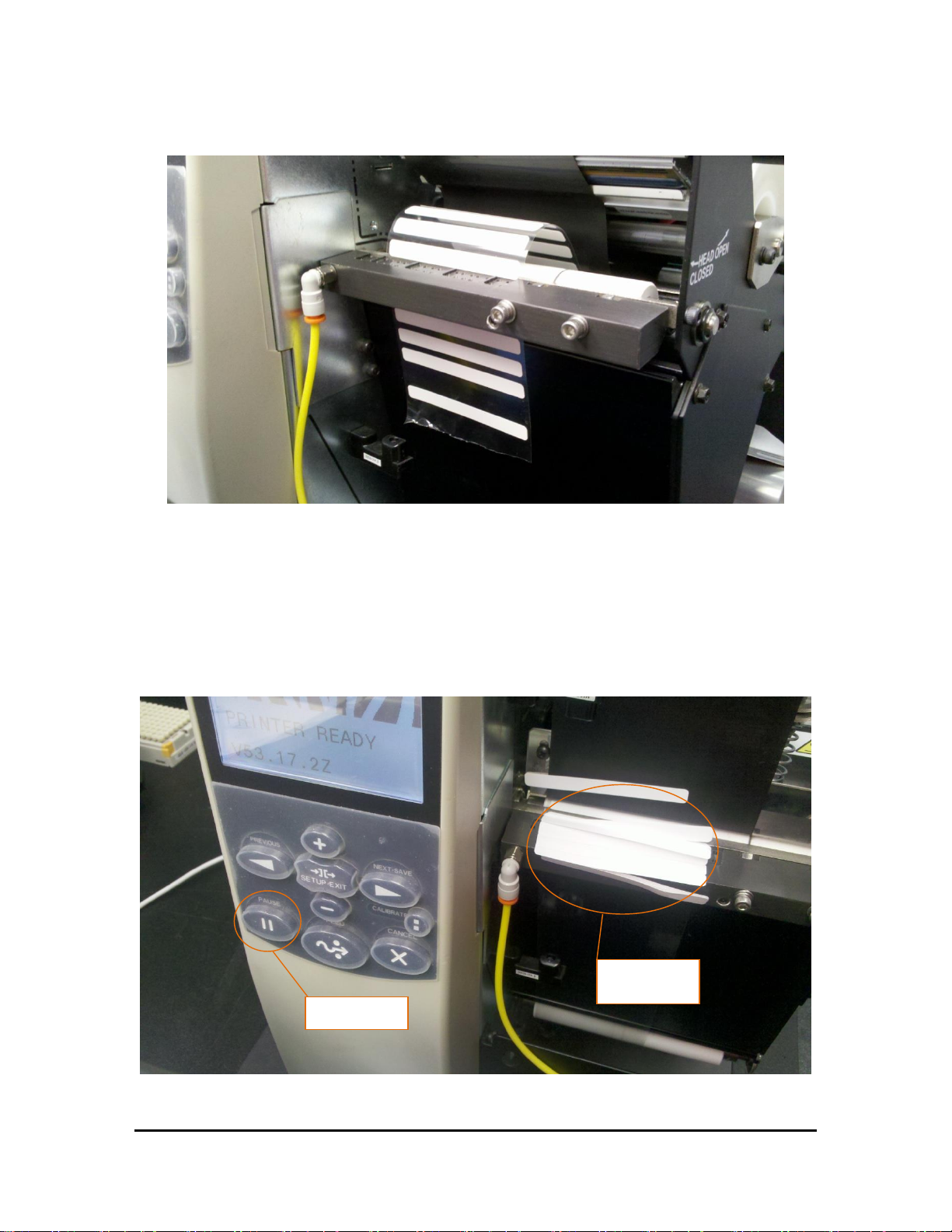

3. Once the media and print ribbon are installed, slide the edge of the

Pause Button

Build up after

calibration

media backing between the air blast and strip bar. Once it is exposed

below the air blast, pull enough media through so it is long enough to

fit around the lower spindle. Tape the media to the lower spindle.

4. Once the media and ribbon are secured to the spindles, the print head

can be lowered back into position and closed. After the print head is

closed, the unit will be in a paused mode. To un-pause the printer,

simply press the pause button. Once the unit is un-paused, or powered

up, it will perform a short calibration requiring a feed of multiple

labels. Remove the built up labels from the air blast before running the

unit.

Print and Apply User Manual Hudson Robotics, Inc.

11

Page 14

CHAPTER 3 - Calibration

The Print and Apply is fully operational through SoftLinx V, with the Print and Apply

interface. Codesoft 9.1 or greater must be installed prior to installing the Print and Apply

interface.

Refer to the SoftLinx V manual for general operation procedures and installation

instructions for interfaces.

A. Connection

The Print and Apply works through an RS232 Serial connection. For computers that do

not have serial ports, a USB to RS232 Serial connection will be required. An Edgeport

USB to Serial converter unit is recommended for all windows operating systems.

The barcode scanner name indicates the barcode scanner interface used by the Print and

Apply. Barcode scanners are included with the Print and Apply, and are named

“MS3204” by default. The Print and Apply interface also requires the MS3204 interface

or other barcode scanner interface to be installed.

Checking the Simulate Applicator box will put the unit in simulate mode. This allows for

software operation of protocols but does not allow the computer to run the unit.

Checking the Simulate Printer box will allow operation of the applicator unit, but the

printer will not print any barcodes via SoftLinx.

Print and Apply User Manual Hudson Robotics, Inc.

12

Page 15

B. Setup Screen

The unit requires setup in 3 steps to ensure successful use:

Label Retrieval Setup: Calibration of how the unit picks up labels, which

includes calibration of the vacuum and airblast, and position of the label

head when retrieving a label.

Apply Nest Setup: Calibration of the rotational nest on the applicator, as

well as the position of the applicator head in relation to the nest when

applying labels.

Apply Profile Setup: Calibration of plate-specific application profiles, to

ensure proper placement of labels during operation. (This is covered in

Chapter 4: Operation)

Setup cannot be run in simulate mode. All functions in setup require the print and apply

unit to be active and connected to the computer.

Print and Apply User Manual Hudson Robotics, Inc.

13

Page 16

C. Hardware Setup

Feed Button

Strip Bar

Prior to Label Setup, the hardware must be configured to pick up labels properly. The

apply head can be controlled from the label retrieval or apply head setup screens.

1. Move the apply head out of the way of the air blast.

2. Press the Feed button on the front of the printer to advance one label to

the tear off position.

3. The label should stop right at the edge of the strip bar as seen below.

4. If the label is not in the correct location, it will have to be adjusted

through the printer’s front panel.

5. To get into the submenus, press the (Setup-Exit) button on the front

panel of the printer.

Print and Apply User Manual Hudson Robotics, Inc.

14

Page 17

6. Press the (Next-Save) button until the tear off setting is displayed,

using the (+) and (–) buttons move the label until it is in the correct

location.

7. Remove that label and press the feed button again 2-3 times to confirm

the proper tear off location.

8. To save the tear off position press the (Setup-Exit) button, this will

send it to the save options, the first option will be Save Permanently,

press the (Next-Save) to accept the save command.

9. After the settings have been saved correctly the printer will

automatically go back to Main screen, where it shows Printer Ready.

*The tear off position may need to be adjusted if the media is removed to clean the

printer or when a new media/ribbon roll is installed.

** Must allow 25 labels to be printed trough the printer when a new roll is installed,

since it needs time to find its natural resting location.

Print and Apply User Manual Hudson Robotics, Inc.

15

Page 18

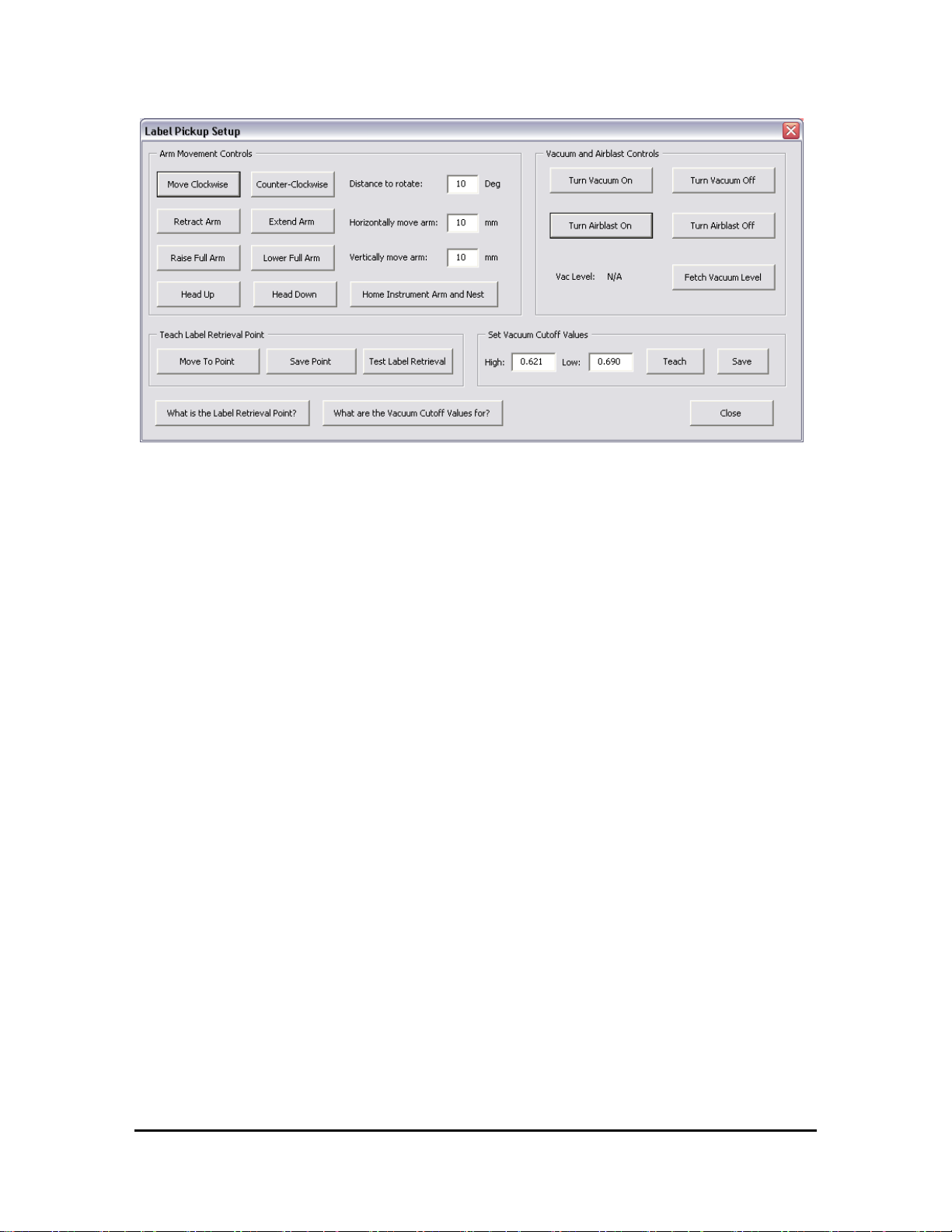

D. Label Setup

To calibrate the unit for label retrieval, the user must obtain vacuum cutoff values and

teach the unit the location of the label retrieval point. The vacuum cutoff values are used

for label detection during operation, and should be taught before teaching the label

retrieval point.

To obtain the correct vacuum cutoff values, the user must obtain a single label from the

printer. Ensure that the air sources are properly attached to the unit at 60 psi. Press the

“Teach” button, and ensure the head is clear of all debris. The unit will turn the vacuum

on, then the airblast on. The unit will then prompt the user to place a label on the head.

Place a label on the head (non-adhesive side), ensuring all holes of the head are covered,

and then press OK. The unit will once again turn the airblast on and off. It will calculate

cutoff values for the unit. Press the “Save” button to retain those values.

The correct location for the label retrieval point is about 0.030” (width of a business card

folded) directly above where the label from the printer is placed after a barcode is printed,

as seen below. The front edge of the tamp head should be aligned with the front edge of

the strip bar, as seen below. It is highly recommended that the applicator head is

completely centered over and parallel to the label that it is picking up. Failing to position

the head parallel to the label at pick up will result in crooked label application.

Print and Apply User Manual Hudson Robotics, Inc.

16

Page 19

0.030” Gap

Front Edge

of tamp head

Front edge

or strip bar

Once the head is over the label, press the “Save Point” button. It is highly recommended

to test label retrieval now. Press the “Test Label Retrieval” button to test how it picks up

a label. If it picks up a label within 2 seconds of its first attempt, it is taught properly.

If the user needs additional assistance in understanding this screen, the user may click on

the two help buttons labeled “What is the Label Retrieval Point?” or “What are the

Vacuum Cutoff Values for?” for additional information during setup.

Print and Apply User Manual Hudson Robotics, Inc.

17

Page 20

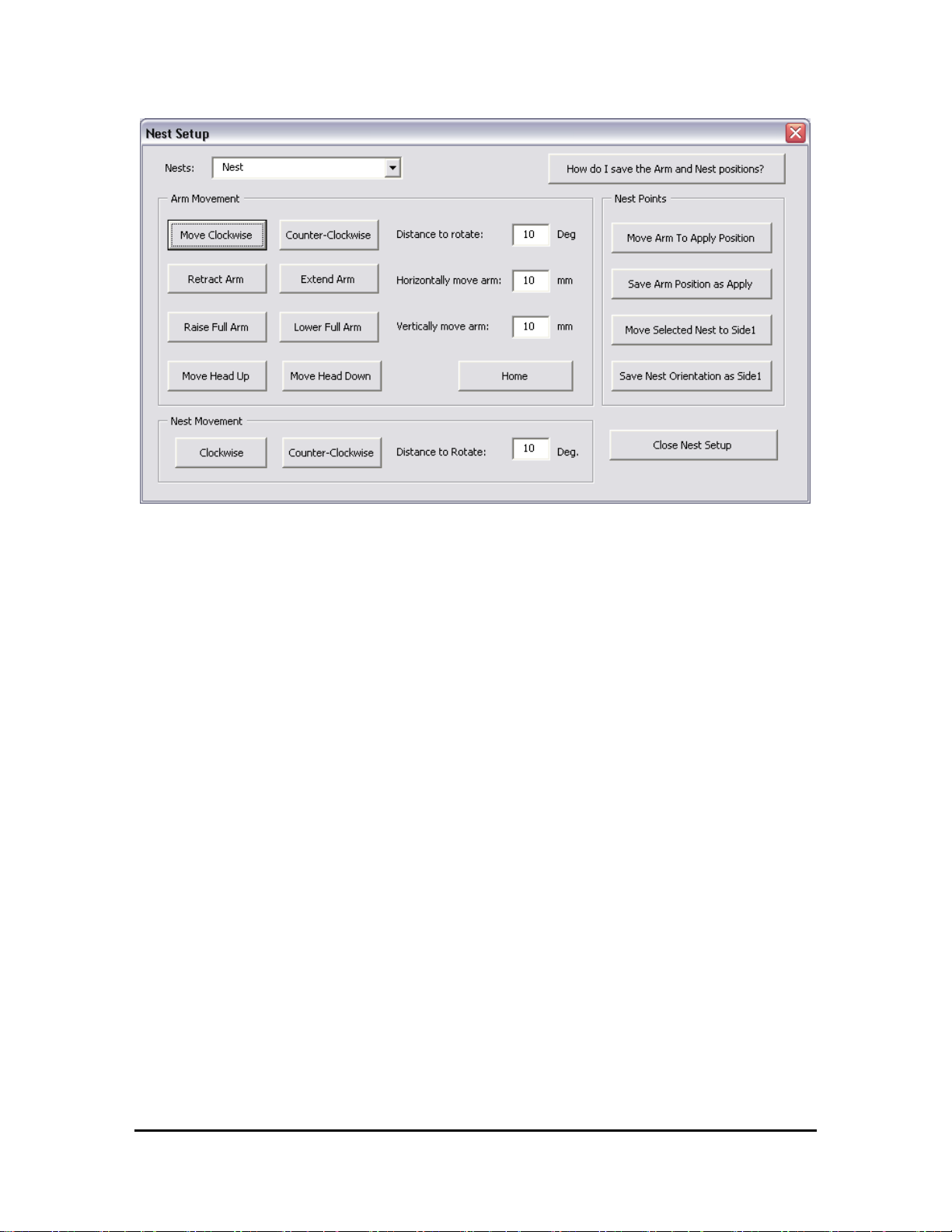

E. Apply Nest Setup

To teach the unit how to apply a label to the selected nest, the user must teach the unit the

orientation of the nest by facing the side labeled “side 1” towards the body of the

applicator. With standard Print and Apply Units, side 1 is the longest side of the nest that

the colored corner, noted as A1, is touching. Other nest types that may be used will have

additional documentation to note which side is A1. The user must also teach the unit how

to face the applicator head towards the selected nest.

The selected nest’s Side 1 should be taught first. Face Side 1 towards the applicator arm.

Place the teach plate into the rotational nest. Retract the arm, put the head up, face the

arm such that it is facing side 1 of the teach plate in the nest. Extend the arm closely to

the teach plate, then in 5mm increments, extend the arm so that it slightly pushes against

the nest and rotates it in the proper position. Retract the arm, and save this position as

Side 1. Press “Save Nest Orientation as Side 1” to do this.

While in this position, remove the teach plate. Move the arm in a position such that the

bottom edge of the head is parallel to and touching the top edge of the rotational nest’s

surface that the plate sits on. Teach this point as the Apply position. Press “Save Arm

Position as Apply” to do this. After pressing this button, return the teach plate to the nest.

The unit will do a calibration procedure to save the point as the apply position, pushing

against all 4 sides of the teach plate.

The user may also click the “How do I save the arm and nest positions?” button for a

graphical explanation of teaching, as shown on the next page.

Print and Apply User Manual Hudson Robotics, Inc.

18

Page 21

Print and Apply User Manual Hudson Robotics, Inc.

19

Page 22

CHAPTER 4 – Operation

A. Creating Labels

Codesoft v.9 is required to create labels. This section also assumes that the Zebra 110Xi4

printer is attached to the computer. Basic labels used with the Print and Apply are 2.5

inches wide by 0.25 inches tall. (63.5mm x 6.35mm) To create the label template, open

Codesoft. Select New Label Document and ensure the label size has a 2.500 in. width and

a 0.2500 in. height.

Print and Apply User Manual Hudson Robotics, Inc.

20

Page 23

To create a barcode, click on the barcode icon on the left toolbar (highlighted in the

picture below) then click on the label itself.

Print and Apply User Manual Hudson Robotics, Inc.

21

Page 24

The barcode type, as well as attached counters can be modified on the screen below.

Select a symbology that is compatible with the barcode scanner. Generally, the Code 39

and Code 128 barcodes are compatible.

Print and Apply User Manual Hudson Robotics, Inc.

22

Page 25

In addition, counter variables are used to automatically increment the barcode during

operation. Please note – both the Shared box and ISO counter box MUST be checked to

allow incrementing barcodes in SoftLinx.

Once the label is set up, the user may print the barcode from Codesoft to ensure proper

printing of the label. See Codesoft documentation or help files for more information.

Print and Apply User Manual Hudson Robotics, Inc.

23

Page 26

B. Setup and Testing Apply Profiles

Apply profiles tell the unit how to apply a label to a specific plate type. The Apply Profile

setup screen is available through the main Setup screen of the Print and Apply interface.

To define an apply profile, the user must specify where to apply a label on each side of a

specific plate, by specifying the apply height on each side. The Apply Height is the

distance between the bottom of the plate and the bottom of the desired location of the

label, in millimeters.

To save the apply profile, enter 4 apply heights for the plate – even if a side would not be

used. Press the “Save Profile” button. The user will be prompted to place the plate into

the nest to allow the unit to calibrate the profile.

Additional graphical help is available by clicking the “How do I do this?” button.

Note: If the user wishes to label a plate when lidded, and a plate without, the user will

have to create two separate apply profiles for that plate – one for plates with lids, one

without. Multiple apply profiles can be made for a single plate type.

Users may also test the profile with labels created from Codesoft.

Print and Apply User Manual Hudson Robotics, Inc.

24

Page 27

Print and Apply User Manual Hudson Robotics, Inc.

25

Page 28

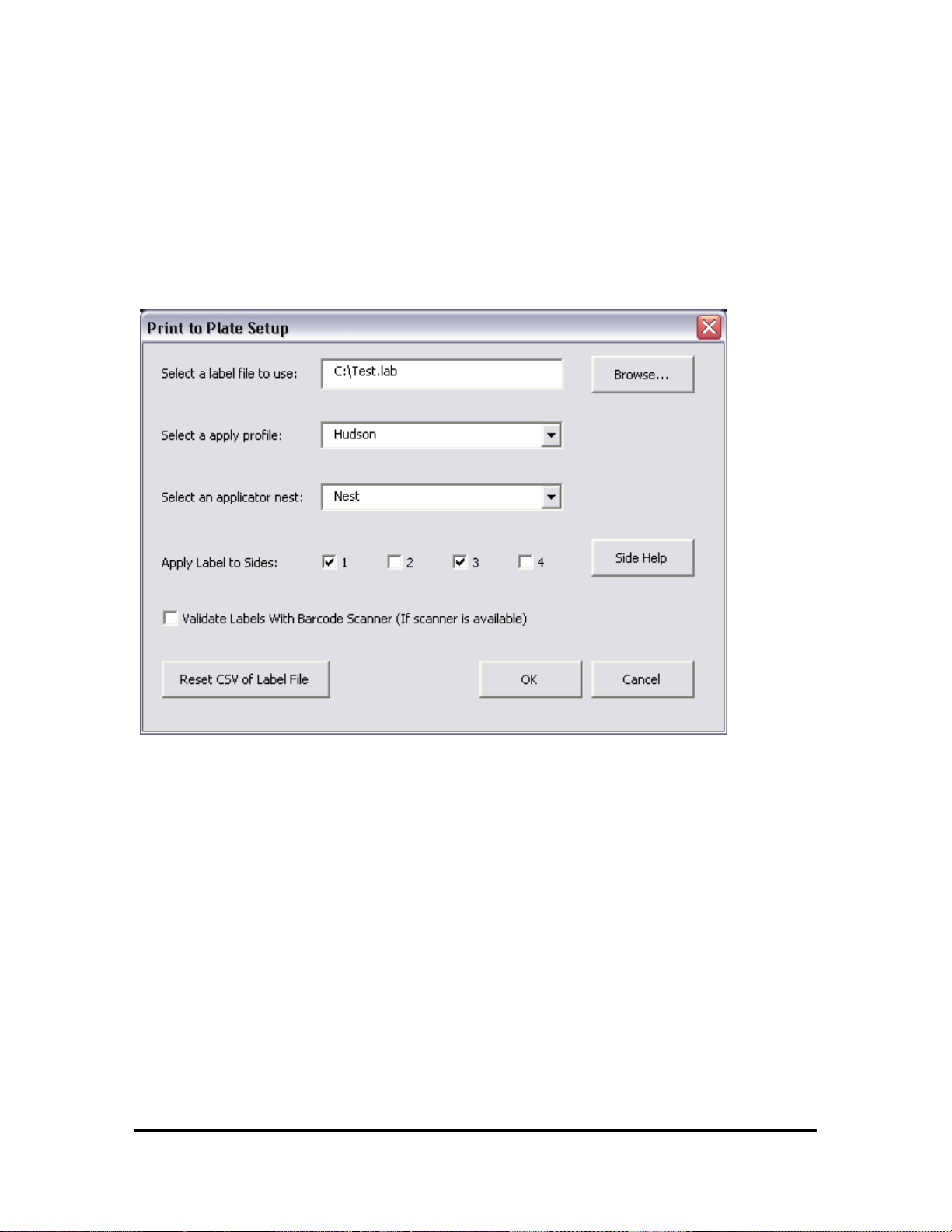

C. SoftLinx Operation

The print and apply interface has two steps available in SoftLinx. The user may re-orient

the rotational nest by selecting the “Move Applicator Nest” step.

The main function of the Print and Apply is accessed by the “Print and Apply Label”

step. This requires a Codesoft Label file and an Apply profile to be available. Previous

sections of the manual note how to create both items required for functioning. Enter the

location of the file, the apply profile for the plate to be used, the rotational nest, the sides

in which the label will be applied, and whether or not a scanner validation is required.

During the execution of a SoftLinx protocol, the Print and Apply’s nest will be moved to

a “Side 2” orientation. It is imperative that the user teaches the plate crane point or other

plate mover positions related to the print and apply in a “Side 2” orientation.

A basic Print and Apply protocol is shown on the next page. This protocol is used to label

multiple plates located in a set of stacks moved by a Hudson PlateCrane.

Print and Apply User Manual Hudson Robotics, Inc.

26

Page 29

Print and Apply User Manual Hudson Robotics, Inc.

27

Page 30

CHAPTER 5 - Maintenance

A. Maintenance

WARNING- -

Qualified personnel can perform all maintenance procedures in this

manual. Only Hudson representatives should perform any maintenance

not discussed in this manual.

Gloves should be worn during any cleaning procedure.

B. Cleaning the Print and Apply

Note: DO NOT use/spray abrasive cleaners onto Print and Apply

applicator.

Clean the outside surfaces of applicator using cloth or sponge dampened with

alcohol or mild glass cleaner.

Clean Applicator head with alcohol or other residue-free solvent.

Clean any spills on Print and Apply immediately.

Only clean the exterior of the unit. DO NOT remove instrument covers to clean

inside.

Never allow water or fluid to leak inside the Print and Apply.

C. Cleaning the Printer

Note: DO NOT use/spray abrasive cleaners onto the Printer.

The printer must be cleaned every time the media is replaced or when

you are having issues printing correctly. You will need to clean the two

white rubber rollers and the print head that are inside the printer. After

cleaning the printer, allow the system to Print and Apply 25 labels to

allow the printer to self-align the new media.

Print and Apply User Manual Hudson Robotics, Inc.

28

Page 31

CHAPTER 6 - Warranty & Service Agreement Terms and Conditions

A. Warranty

a. One-year coverage beginning on the factory ship date on all parts and

labor including return shipping (to the customer) via UPS ground or

equivalent. Warranty is limited to components and software purchased

from or provided by Hudson Robotics, Inc.

b. Technical support by trained personnel via telephone or email during

normal business hours will be provided at no cost (exclusive of telephone

toll charges incurred by the customer) during the warranty period.

c. On-site service will be provided by Hudson Robotics, Inc. during the

warranty period, if provided for in the customer quote for that purchased

product.

d. Factory return service is available for all products, under the following

conditions.

1. The customer is responsible for packing of instrument and

shipping to Hudson. The customer will be notified of nonwarranty repair costs, if any, prior to repair being started.

2. Damage incurred in transit to Hudson including, but not limited to,

damage due to improper packing will be the responsibility of the

customer and / or shipper. The customer is advised to retain the

original packing material, including the cast foam padding, in the

event service is required. Replacement packing materials are

available from Hudson at cost-plus shipping (currently ~$175.00).

3. Hudson will pay return shipping to customer, via UPS ground or

equivalent. Expedited shipping is available at additional cost.

e. Updates to correct performance anomalies shall be provided at no cost

during the warranty period subject to the warranty terms and conditions.

f. Upgrades, which provide additional functionality, may be offered at

reduced costs during the warranty period.

g. Factory repairs must be pre-authorized by Hudson Robotics, Inc. and will

include issuance of a Returned Materials Authorization (RMA) number.

Customer certification of decontamination is required prior to return of

any instrument(s) for factory service (instruments not certified

decontaminated may be refused service and returned at customer’s

expense).

h. While Hudson Robotics, Inc. makes every effort to provide software and

instruments suitable to a wide range of automation tasks, no guarantee is

made as to the suitability of the hardware and/or software provided for a

given application unless so stated in the written purchase agreement.

i. Repair of failures, caused by but not limited, to misuse, fire, flood or other

act of God, chemical or environmental exposure, or repair by persons not

authorized by Hudson Robotics, Inc. may, at the sole discretion of Hudson

Robotics, Inc., be charged at the prevailing hourly service rate (currently

$162.50/hr for Factory Service, $162.50/hr for travel time and $325/hr for

Field Service).

Print and Apply User Manual Hudson Robotics, Inc.

29

Page 32

B. Service Agreements

I. Service Agreements, in one year periods, are available at prevailing rates and

provide the following coverage in addition to the original warranty:

a. One scheduled onsite maintenance service call per year of coverage to

include evaluation and adjustment/repair to meet instrument performance

specifications.

b. Inspection and replacement of marginal components.

c. If previous warranty or service agreement coverage has expired for more

than 30 days pre-inspection and repair of instrument at customers expense

prior to start of service coverage may be required.

d. Pre-inspection may, at the service director’s discretion, be provided in

place of the one scheduled on-site maintenance at no charge beyond that

of the service agreement.

e. Onsite service is priced by travel time to customer from an established

Hudson site.

1. Zone I: Massachusetts, Connecticut, Rhode Island, New Jersey,

New York, Pennsylvania, Delaware, and Maryland.

2. Zone II: All other locations.

f. Payment terms are net thirty (30) days after the date of invoice. Customer

will be invoiced. In case of delayed payment, Hudson Control reserves

the right to decline service.

g. This agreement may be terminated by either party upon default by the

other party of any material obligation under this Agreement which default

continues for thirty (30) days after written notice has been provided by the

non-defaulting party.

II. General Conditions. These apply to all products under warranty or service

agreement.

a. Excluded parts. Covered parts do not include chemicals, reagents, customer

replaceable items, consumables, or other parts listed in the operator's or

instruction manual as customer replaceable parts, sub-assemblies or

accessories. Replacement of these items will be billed at prevailing rates.

b. Hudson Control reserves the right to use repaired parts during the Coverage

Period. For parts that have been replaced, Hudson Control is the sole owner

of these parts and they cannot be sold or repaired by the customer or any third

party.

c. Key operator. Customer shall designate a key operator to a Hudson Control

representative by telephone or email. Such operator shall be qualified to

perform simple adjustments or corrections as requested by a Hudson Control

representative. Failure to perform customer maintenance as specified in the

Instrument Instruction Manual may result at Hudson Control’s option in 1)

cancellation of this Agreement or 2) a service call invoiced by Hudson

Control at its standard rates for service including travel.

Print and Apply User Manual Hudson Robotics, Inc.

30

Page 33

d. Warranty and service coverage does not include the following. Any

service calls made as the result of the below shall be invoiced by Hudson

Control at their standard rates including travel and labor expenses:

1. Damage caused by Customer misuse or operation outside of conditions

prescribed in the Instruction Manual.

2. Damage caused by electrical surges or the use of improper sources,

intervention of a third party, external influences such as fire, water

damage, natural disaster, etc.

3. Relocation of the instrument.

4. Use of chemicals and accessories outside the specifications contained

in the Instruction Manual.

5. Applications related issues.

6. Computer/ Hard drive crashes and failures

e. Safe Working Environment. Customer shall provide the Hudson Control

representative with facilities at Customer's location that comply with the

applicable regulations of the Secretary of Labor promulgated under the

Occupational, Safety and Health Act of 1970.

f. This agreement sets forth the entire agreement and understanding between

Hudson Control and Customer regarding service of the Instruments covered

hereunder. This agreement may be modified only by writing and by

authorized representatives of the parties.

III. Custom Service Packages providing features to meet individual customer

requirements may be arranged. Contact your sales representative or Hudson’s

service director for availability and pricing.

Print and Apply User Manual Hudson Robotics, Inc.

31

Loading...

Loading...