Page 1

Tuf-Lite

Tuf-Lite II

and

Fans

8000 Series Hub

INSTALLATION MANUAL

Adjustable Pitch Fan Assembly

34’ through 40’ Diameter

Hudson Tuf-Lite® and Tuf-Lite II® fan blades

Hudson Tuf-Lite® (black) fan blades are made from fiberglass reinforced epoxy resin having a very high

strength-to-weight ratio and corrosion resistance (not shown).

Hudson Tuf-Lite II® (blue) fan blades are made from fiberglass reinforced vinyl-ester resin having a very

high strength-to-weight ratio and superior ultra-violet and corrosion resistance. An elastomeric blade/holder

joint cover (not shown) prevents moisture from entering the blade (shown above).

The individually balanced blades can be replaced independently – matched sets are not required.

Installation Manual 8000 Page 1 of 8 January 2004

Page 2

RECOMMENDED TOOLS

z Long T-Handle Allen Wrench Set (3/16” to 3/8”)

z Medium Size Flat Head Screw Driver

z Brass Ball Peen Hammer

z Flat Bastard File

z 240 Grit Sand Paper

z Anti-Seize Lubricant

z WD-40

z 12” Crescent Wrench

INSTALLATION PROCEDURES

ASSEMBLY WITH BUSHING

Clean all mating surfaces between hub, bushing and shaft. If there

is no shoulder on shaft to prevent bushing from sliding down shaft,

slide spacer/sleeve (not provided) on shaft before bushing. Slide

bushing and key onto shaft until flush with end of shaft. Lock W-2

bushing on shaft by tightening set screw in flange with 1/4” Allen

Wrench. (Note: setscrew is not present on all bushings) Line up

key and set hub on bushing. Engage the four (4) 3/4” cap screws in

flange of bushing into hub spool. Using a torque wrench with a

1-1/8” socket, tighten evenly to recommended standard of 250 ft-lb

(dry).

z Shop Towels

z Exact-A-Pitch

z 25 ft. Measuring Tape

z Pencil or Marker

z Open/Box End Wrench Set (1/2” - 1-1/2”)

z Socket Set for 1/2” Drive (1/2” - 1-1/2”)

z Torque Wrench(s) Rated for 0-250 ft-lb.

®

Digital Protractor (P/N 62375)

Torque Value

Cap Screw Socket (ft-lb)

Size Size Lubricated Dry

5/8” NC 15/16” 100 110

3/4” NC 1-1/8” 125 130

1” NC 1-1/2” 150 160

NOTE: Retaining arrangement varies with gear shaft design.

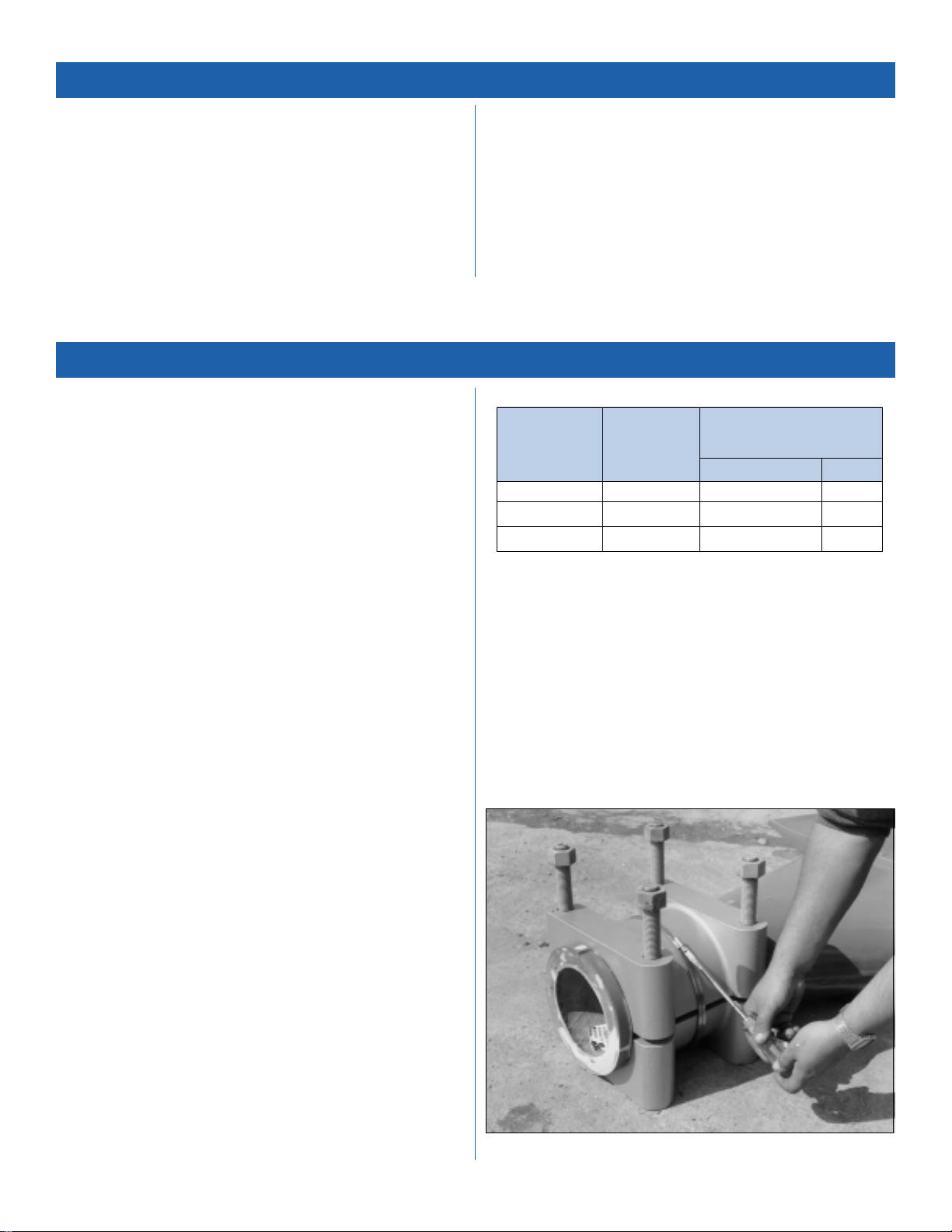

ASSEMBLE BLADE CLAMP ON BLADE NECK

ASSEMBLY WITH STRAIGHT SHAFT

(NO BUSHING)

Clean all mating surfaces between the hub and the shaft. If there is

no shoulder on shaft to prevent hub from sliding down shaft, slide

spacer/sleeve (not provided) on shaft before hub or use a thrust

retainer (optional equipment) on top of hub. Install key in shaft.

Line up key and keyway and set hub on shaft. Tighten two (2) set

screws in hub.

ASSEMBLY WITH TAPERED SHAFT

(NO BUSHING REQUIRED)

Clean all mating surfaces between hub and shaft. Coat all mating

surfaces with an anti-seize or lubricating compound.

Align keyways and install hub. Install retainer plate and cap screw(s)

with lock washer(s). Shaft size determines what size cap screw is

necessary. Using a torque wrench with a socket, evenly tighten cap

screw to recommended standard per table below.

Remove blade clamp studs, lock washers, and blade clamp halves

from hub. Assemble blade clamp halves over groove in blade neck,

with thick leading edge to left and thin trailing edge to right as you

stand at end of blade. Use a band clamp to hold the two blade

clamp halves in position on the blade for installation in the hub

body (See Figure 1).

Figure 1

Installation Manual 8000 Page 2 of 8 January 2004

Page 3

INSTALL BLADE INTO HUB

Hoist the blade into position. (Blade and clamp halves weight about

300 lbs.) Slide blade clamp into blade arm plates and install four

(4) blade studs, eight (8) lockwashers and eight (8) nuts (See

Figure 2). Tighten lightly.

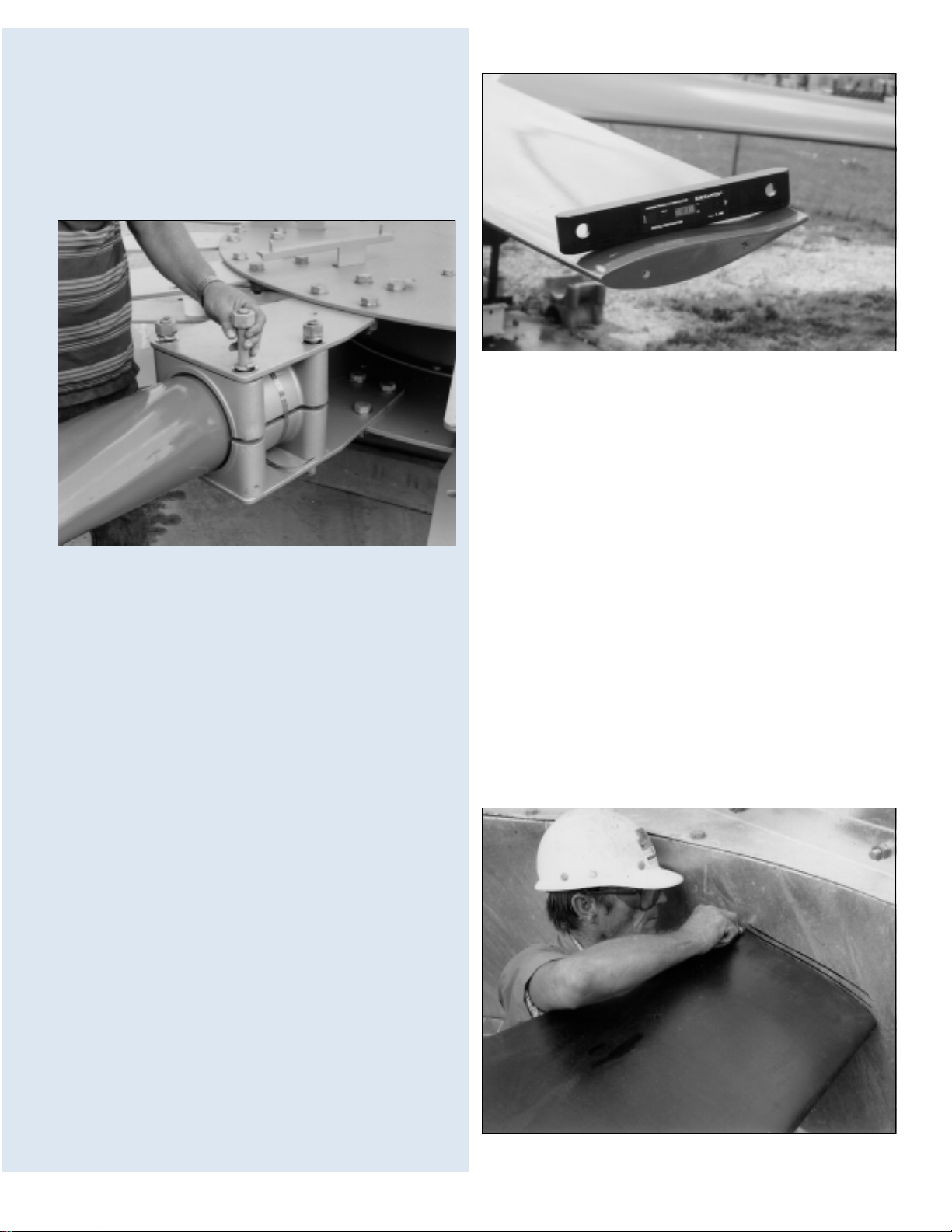

Figure 3

When bolts are tightened, hold a pencil against top end of blade and

mark the level onto a fixed object, such as a pole or the fan ring.

Install remaining blades at same place as first blade, following procedures above. After tightening bolts, mark top end of each blade

in same place first blade was marked. If marks differ by 1-1/2”or

more, adjust blade.

Figure 2

SET PITCH AND TRACK

Use Hudson EXACT-A-PITCH® digital protractor (Shown in Figure 3) or a bubble protractor to set blade pitch. Mount protractor

on a flat bar as a base and place it approximately 1” from tip of blade.

Note pitch on protractor. Rotate fan 360⋅, noting high and low pitch

readings. Locate place where pitch reading is a mid-point between

high and low readings, and set pitch at that point.

Rotate blade in clamp until digital protractor shows specified pitch

angle to within ±0.2⋅. (Fan pitch angle is shown on fan specifica-

tion sheet for design duty.)

After desired pitch angle is set, raise and lower end of fan blade

and find midpoint of blade travel. Hold blade at the midpoint. Pull

blade back so that it sits against blade clamp. Push blade to the

right to remove all slack.

Use torque wrench to tighten clamp bolts to recommended standard of 280 ft-lb (lubricated) or 300 ft-lb (dry). Recheck pitch

setting. Blade must be set within ± 0.2⋅ of desired pitch angle.

Tighten clamp bolts evenly. DO NOT OVER-TORQUE CLAMP

BOLTS.

CHECK TRACK

After fan is installed in fan ring, outline top end of each blade onto

fan ring with a marker. The difference between levels of highest

and lowest outlines should not be more than 1-1/2”. Correct blade

track by loosening clamp bolts and adjusting blade to match track

of other blades. Retighten bolts and recheck track and pitch angle

setting. Retighten blade clamp bolts to recommended standard of

280 ft-lb (lubricated) or 300 ft-lb (dry) torque (See Figure 4).

Figure 4

Installation Manual 8000 Page 3 of 8 January 2004

Page 4

ASSEMBLE SEAL DISC AND MOUNTING

BOLTS

Place seal-disc quarter section on hub, aligning the pear-shaped

opening over one of the eye-bolts (See Figure 6) and drop the

seal-disc quarter section onto the nearest group of seal-disc

bracket stud pairs. Remove adhesive backing on nitrile gasket

section and apply gasket to seal-disc flange surface carefully

such that holes in gasket lineup with the holes in the flange (See

Figure 7). Repeat these operations with the next three seal-disc

quarter sections, ensuring that seal-disc balance match-marks

are aligned.

Figure 7

Make final adjustments to the quarter sections such they mate

properly with each other and all seal-disc bracket studs, install the

fasteners loosely joining each seal-disc section using one flat washer

against the fiberglass surface on each side, one 3/8” hex bolt, lock

washer, and hex nut at each flange hole location (See Figure 8).

Ensure final fit-up of the seal-disc sections, check flatness and

alignment of pear-shape openings with the eye-bolts, and snug all

fasteners. Complete fasteners at each bracket location (two per

bracket) using a 3/8” hex bolt, flat washer, lock washer, and hex nut

(See Figure 9). Snug these fasteners.

Figure 5

Figure 6

Figure 8

Using a measuring tape in several radial locations, double-check

the seal-disc assembly such that it is centrally located on the hub.

Make any final adjustments as necessary to ensure concentricity

and trueness then tighten all fasteners at the flange surfaces and

bracket studs to 15 ft-lbs lubricated or 20 ft-lbs non-lubricated.

Make sure that all other details of fan installation is complete and

be sure to remove all tools, loose parts, and materials from the

completed hub assembly prior to startup.

Installation Manual 8000 Page 4 of 8 January 2004

Page 5

TIP CLEARANCE

Figure 9

Figure 10

NOTE: The purpose of the seal disc is to prevent hot air from

recirculating back down through the hub, increasing efficiency.

Figure 11

OPERATING INSTRUCTIONS

Start fan and check rotation. Viewed from top, fan blades should

rotate clockwise.

Check motor power consumption to be sure fan is pulling desired

load. CAUTION: If positive pitch is set in summer to use all available motor amps (nameplate rating), motor could be

overloaded in winter. Design pitch angles usually do not use all of

the available motor horsepower. This ensures that the motors will

not be overloaded at low winter temperatures.

CHECK TIP CLEARANCE

Rotate fan in position inside fan ring or fan stack to check tip

clearance. Check for spots where fan blade clearance is less

than 3/4” or greater than 1-1/2” from fan ring (See Figure 11). If

necessary adjust fan ring or fan stack by shimming to obtain

proper clearance. Note that different cooling towers may have

different ways to adjust the fan ring or fan stack.

Figure 12

Installation Manual 8000 Page 5 of 8 January 2004

SPACERS

Page 6

PARTS LIST

8000 Series Hub - Adjustable Pitch Fan Assembly (34’ through 40’ Diameter)

PARTS LIST

ITEM DESCRIPTION TYPE PART. NO

Up to 7.44 Diameter Shaft W-2 Hub Assy. No.

Part. No.

1 Hub Plate (2 Per Hub) W-2 Part. No D8126 D8135 D8128 D8129 D8130 D8131 D8132 D8133 D8134

ITEM DESCRIPTION TYPE PART. NO QUANTITY PER ASSEMBLY

2 Hub Spool W-1 65060 1 1 1 1 1 1 1 1 1

3 Bushing W-1 Specify Bore 1 1 1 1 1 1 1 1 1

4 Blade Clamp Half (Epoxy Coated Aluminum) 65018 12 14 16 18 20 22 24 26 28

5 Blade Clamp Stud W/ 2 Nuts 1”-8 x 14 1/2” (Mech. Galv.) 70643 24 28 32 36 40 44 48 52 56

6 1” Flat washer (Mech. Galv.) 57402 48 56 64 72 80 88 96 104 112

7 1” Lock washer (Mech. Galv.) 73742 48 56 64 72 80 88 96 104 112

8 Hub Spool Cap Screw 3/4”-10 x 2 1/2” (316 SS) 57027 16 16 16 16 16 16 16 16 16

9 3/4” Flat washer (316 SS) 73720 16 16 16 16 16 16 16 16 16

10 3/4” Lock washer (316 SS) 73739 16 16 16 16 16 16 16 16 16

11 Blade Arm, Bottom, 44” Long 61650 6 7 8 9 10 11 12 13 14

12 Blade Arm Stiffener, 30 5/16” Long 61660 12 14 16 18 20 22 24 26 28

13 Blade Arm Assy, Top D8127 6 7 8 9 10 11 12 13 14

14 Bolt, HH, 1”-8 x 3” (Mech. Galv.) 59815 48 56 64 72 80 88 96 104 112

15 Bolt, HH, 1”-8 x 2 1/2” (Mech. Galv.) 69927 24 28 32 36 40 44 48 52 56

16 Nut, Heavy Hex, 1”-8NC (Mech. Galv.) 72120 72 84 96 108 120 132 144 156 168

17 1” Flat washer (Mech. Galv.) 57402 144 168 192 216 240 264 288 312 336

18 1” Lock washer (Mech. Galv.) 73742 72 84 96 108 120 132 144 156 168

19 Seal Disc Bracket Weldment B8136 8 8 8 8 8 8 8 8 8

20 Cap Screw, HH, 3/8”-16NC x 3/4” (316 SS) 70033 16 16 16 16 16 16 16 16 16

21 3/8” Lock Washer (316 SS) 73722 16 16 16 16 16 16 16 16 16

22 Seal D isc W asher, 1 /8” Thick, Nitrile 73055 16 16 16 16 16 16 16 16 16

23 Seal Disc Mounting Flat Washer, 3/8” x 1 1/2” OD (316 SS) 60273 16 16 16 16 16 16 16 16 16

24 Seal Disc Mounting Lock Washer, 3/8” (316 SS) 73722 16 16 16 16 16 16 16 16 16

25 Eye Bolt W / Nut 3/4”-10 x 2” (Mech. Galv.) 59547 4 4 4 4 4 4 4 4 4

26 3/4” Flat Washer (Mech. Galv.) 16716 8 8 8 8 8 8 8 8 8

27 3/4” Lock W asher (Mech. Galv.) 73738 4 4 4 4 4 4 4 4 4

28 Pin, Grooved, 1/2” X 1-1/2 ” 74540 4 4 4 4 4 4 4 4 4

29 160” Diameter Seal Disc Kit * D8053 1 1 1 1 1 1 1 1 1

30 Seal Disc Joint Gasket 73047 4 4 4 4 4 4 4 4 4

31 Seal Disc Cap Screw, HH, 3/8”-16NC x 2” (316 SS) 53622 24 24 24 24 24 24 24 24 24

32 Seal Disc Hex Nut, 3/8” (316 SS) 72050 24 24 24 24 24 24 24 24 24

33 Seal Disc Flat Washer 3/8” x 1” OD (316 SS) 73623 48 48 48 48 48 48 48 48 48

34 Seal Disc Lock Washer 3/8” (316 SS) 73722 24 24 24 24 24 24 24 24 24

35

Tuf-Lite II

Tuf-Lite

* Includes all 316 SS hardware (items 22 thru 24 & 30 thru 34) to assembly and mount.

Fan Blade (Blue)

Fan Blade (Black)

(Varies) 6 7 8 9 10 11 12 13 14

(Varies) 6 7 8 9 10 11 12 13 14

6 7 8 9 10 11 12 13 14

8906

8907

8908

D8116

D8117

D8118

NO OF BLADES

8909

8910

D8119

D8120

8911

D8121

8912

D6072

8913

D8123

8914

D8124

Installation Manual 8000 Page 6 of 8 January 2004

Page 7

29

35

7

6

5

13

9

1

1

2

0

2

27

26

25

4

11

15

16

17

18

14

17

18

16

28

12

30

31

32

33

34

8

9

10

2

2

3

2

4

2

2

FAN SHAFT

3

STD. MATERIALS & FINISHES:

1

When Ordering, Specify Fan Diameter, Type and Number of Blades and Shaft Diameter

Blades) of Blades

®

Blades)

®

(Specify “B” for Tuf-Lite

Series 8000 HUB

HUDSON PRODUCTS CORPORATION

Adjustable Pitch Fan Assembly 34’ Thru 40’ Diameter

Fan Model Fan Diameter and Blade Type Number Shaft Diameter

Adjustable Pitch (Specify “H” for Tuf-Lite II

Blades: Fiberglass Reinforced Vinyl Ester Blade Clamps: Epoxy Coated Aluminum (Std)

Hub Spool: Ductile Iron, Zinc Rich Coating Ductile Iron (Optional)

Plates: Steel, Coal Tar Epoxy Fasteners: Steel, Mech. Galvanized & 316 SS

Bushing: Malleable Iron Complete Fan W/316 SS (Optional)

Seal Disc: Fiberglass Reinforced Polyester Complete Fan W/K500 Monel (Optional)

EXAMPLE: APT 40B 10 6 1/2” BORE

Installation Manual 8000 Page 7 of 8 January 2004

Page 8

1307 Soldiers Field Drive

Sugar Land, Texas 77479-4072

Post Office Box 20029

Sugar Land, Texas 7777496-0029

Phone: (281) 275-8100

Fax: (281) 275-8388

1-800-634-9160 (24 Hours)

EMAIL: hudson.products@hudsonproducts.com

http://www.hudsonproducts.com

Hudson, Auto-Variable, Combin-Aire, Exact-A-Pitch, Fin-Fan, Heatflo, Hy-Fin, Split-Flo, Solo Aire, Stac-Flo, Steamflo, Thermflo, Tuf-Edge, Tuf-Lite, and Tuf-Lite II are registered trademarks of Hudson

Products Corporation.

Installation Manual 8000 Page 8 of 8 January 2004

Loading...

Loading...