Page 1

800.765.SAWS • WWW.HUD-SON.COM

OSCAR 121 & OSCAR 328 SAWMILL OWNERS MANUAL

FOR THE WORK YOU DO.

FOR THE WORK YOU DO.

FOREST EQUIPMENT

Page 2

A NOTE FROM HUD-SON

Thank you for your purchase of a sawmill from Hud-Son Forest Equipment. We are

pleased that you chose us as your supplier of your forestry equipment.

Hud-Son Forest Equipment has been in the forestry business since 1965 and prides itself

on developing new and innovative products for the forestry business.

Our product line is always transforming so please check us out on the web at www.hudson.com for the up and coming developments we are making.

Should you have any questions with the setup of your mill or have any technical questions

please feel free to contact our onsite technician Monday - Friday, 8 to 4:30 and Saturdays

from 8 to noon eastern time at 1-800-765-7297. We are always available to our customers

for any questions or concerns they may have about their equipment.

CONTENTS

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . .A note from Hud-Son

3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Introduction

4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Safety

7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Set Up

7 . . . . . . . . . . . . . . . . . . . . . . . . . .Welded Track Assembly

15 . . . . . . . . . . . . . . . . . . . . . . . . . . .Care & Maintenance

18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Parts & Warranty

21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Transport

22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Trouble Shooting

24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Parts List

26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sawmill Drawings

2

Page 3

INTRODUCTION

Purchaser Agreement

By accepting the delivery of your sawmill by Hud-Son Forest Equipment you

agree that you will not modify your mill from it’s original assembly. This

will VOID any warranty from Hud-Son Forest Equipment.

Dealer: ________________________________________

Phone Number: _________________________

Address: ___________________________________________

___________________________________________________

Purchase Date: ______________________

Model: ___________________________________________

Serial Number: _________________________________________________

This manual is filled with the latest information and specifications at the time of publication. We have the right to make changes as they are needed. Any of the changes in our

product may cause a variation between the illustrations and explanations in the manual

and the item that you have purchased.

3

Please fill out the information for quick reference:

DISPUTES

All disputes, claims and causes of action arising out of the delivery, use, or warranty

claims for personal injury and or property

damage must:

1. Claimant must provide a written notice

of the claim or dispute to the company (at the

address below) at least 30 days after the claim

arose prior to commencement of any action;

2. Company has 60 days to make a decision

on the claim and will provide a written

response to claimant;

3. No action may be commenced until after

the company has provided its decision on the

claim;

4. All claims against the company for any

cause related to delivery, design defects,

repairs, use of the equipment or warranty shall

be filed in Supreme Court, Oneida County,

State of New York. The parties may file for

Arbitration in Oneida County New York after

consent by both parties.

5. Construction and interpretation of this

agreement and any and all claims shall be subject to the Laws of the State of New York.

6: The address for submission of claims is:

Hud-Son Forest Equipment

PO Box 345

8201 State Route 12

Barneveld, NY 13304

7. Notices under this agreement must be in

writing and sent by certified or registered mail;

Page 4

4

2 - Keep all body parts and foreign objects away from all moving parts. Do not reach into

the machine while it is still operating. (Be Sure The Machine Is OFF.)

3 - Do not attempt to override any safety features on the machine.

4 - Inspect the machine before every use for wear, damage, and that it’s functioning correctly. If the machine has been damaged or is not running correctly, DO NOT attempt to

operate the machine. Repair or replace all parts when necessary.

5 - Do not wear loose clothing or jewelry while operating or servicing the machine.

6 - All replacement parts should be of the same specifications as the original parts on your

Hud-Son machine.

7 - All guards and covers must be in place befor

e operating the machine.

8 - Before starting the machine be sure that it is set up properly.

9 - DO NOT operate or service any machinery while under the influence of drugs or alcohol, while tired or if you are unable to control your movements.

10 - All worn or damaged decals should be replaced.

11 - Any modifications to the machine requires written approval from Hud-Son Forest

Equipment.

12 - The sawmill should only be used when it is on level stable ground.

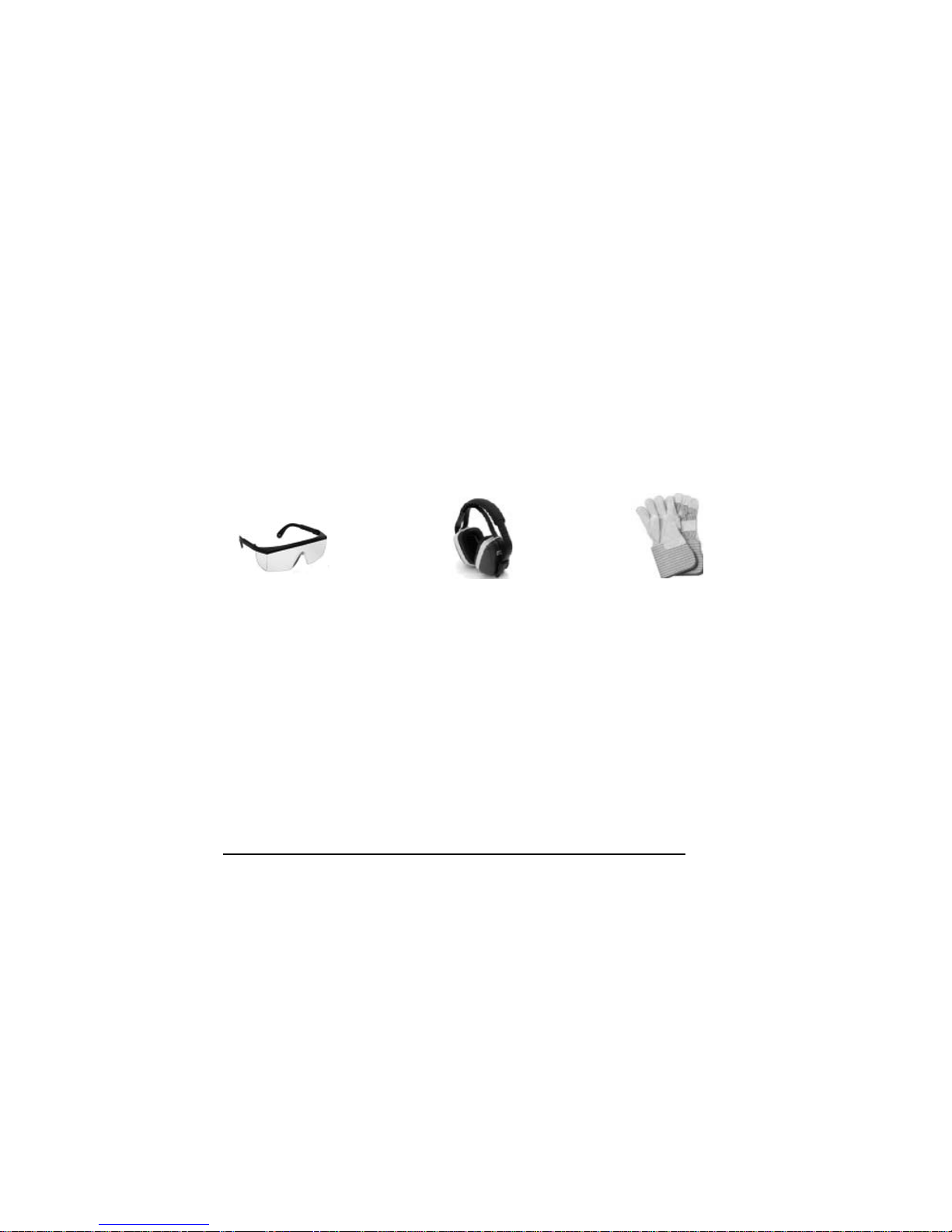

Safety Guidelines

The reason for the safety section is to inform the operators and maintenance personnel,

the precautions that should be taken while operating or servicing the Hud-Son Mills.

Please use good judgement and keep safety in mind when operating Hud-Son machinery.

Please read and follow ALLthe instructions in this manual before operating the Hud-Son

Mill safely at all times. These instructions were produced for your benefit. Your ability

to understand and follow the instructions is essential for the safe operation of this product. Always call your servicing dealer if you are in doubt before operation of any kind.

General Safety Procedures

1 - Always wear safety glasses, ear protection, and gloves while operating or servicing the

machine.

Page 5

5

The safety rules are made for the benefit of the persons operating and servicing the

machine, to prevent injury to oneself or others. Please review all setup and operating

procedures before attempting to run the machine, whether covered in this manual

or not, to ensure the safest operation of this product.

Hud-Son Forest Equipment is not liable for damage to property or personal injury due to

the failure of any person and/or operator to follow the instructions and recommendations

set forth in this manual or any other instructions or recommendations contained in other

literature issued by other vendor manuals in the owner's kit.

Product Safety Decals

The decals below are used on the Hud-Son Saw Mills to identify warnings and prohibited actions. It is very important that you understand the meaning of the decals for your

safety and the safety of others. Decals are to be replaced if worn or illegible.

CAUTION - Be EXTRA careful around

these areas, unsafe practices may cause

personnel injury or damage.

DANGER - Be careful around any rotating parts, they may cause personnel injury

or damage.

DANGER - Be sure to be very cautious

and alert, these areas may cause personnel

injury or damage.

CAUTION - Operating equipment without guards may cause personnel injury or

damage.

BLADE LUBE TANK - Be sure to use

the correct lubrication, if incorrect lube is

used it may cause personnel injury or

damage.

NOTICE - Please remember to send in

warranty card and information.

CAUTION - All debris need to be

removed from machine before transporting, failure to do so may cause personnel

injury or damage.

Page 6

Receiving and Unit Inspection

1 - Upon receiving your unit do a walk around and visual inspection of the unit. Make

note of any damage and contact us immediately with any issue you may have. Note: All

equipment is assembled, tested and inspected before shipping. Damage can occur during

transit, which could cause the unit to not operate correctly.

Unpacking Unit

1 - Flat bed trailer delivery: remove straps or chains securing the unit.

2 - Remove lag screws and strapping that secures the machine to the skid.

1 - Check oil and fuel levels

2 - Check blade lubrication and

hydraulic levels (if applicable)

2-A - Check blade lubrication and

hydraulic levels.

DO NOT USE: petroleum products,

petroleum based products, flammable

products, a vegetable oil based product.

The above products mixed with water or

straight will cause damage to your mill.

The fluid will be slippery between the

blade and wheel belting causing blade to

come off.

DO USE: In The Summer Months tap

water. If there is a problem with pitch build

up on the blade, add 1 oz. of dish soap or

pinesol to 1 gallon of tap water. This will

help keep the blade clean and less heat.

In the Winter Months water will freeze

in the lube tank. Use regular windshield

washer fluid (usually blue in color) If there

is a pitch build up problem add the 1 oz. of

dish soap or pinesol.

Adjustment: Before starting the engine,

adjust the flow of lube to the blade by

adjusting the flow shut off valve so there is

a constant drip. If more lube is necessary,

continue to adjust the valve until the

desired flow is acquired.

3 - Be sure the blade is sharp and tight

4 - Be sure all levers and switches are in

the neutral/center position before starting

the engine (if applicable)

5 - Be sure all persons are clear of the

equipment

6 - Make sure the unit is level and stable.

Moving the Unit

(Forklift is needed for track units)

1 - Machine needs to be lifted at the lift point, see picture

for points.

a. Use a safety devise for lifting to avoid any

damage/injury.

2 - Move unit to operator's site, lower unit and remove

unit from forks.

Before operating the Hud-Son Saw Mill

the following procedures need to be performed:

Start Engine Procedure

1 - Summer Use: Be sure to let the unit idle for at least 5 minutes before any use.

2 - Winter Use: Be sure to let the unit idle for at least 15 minutes before any use.

3 - If the unit has been sitting for a period of time, allow the unit to run long enough to

have the oil do a complete circulation before use.

6

Page 7

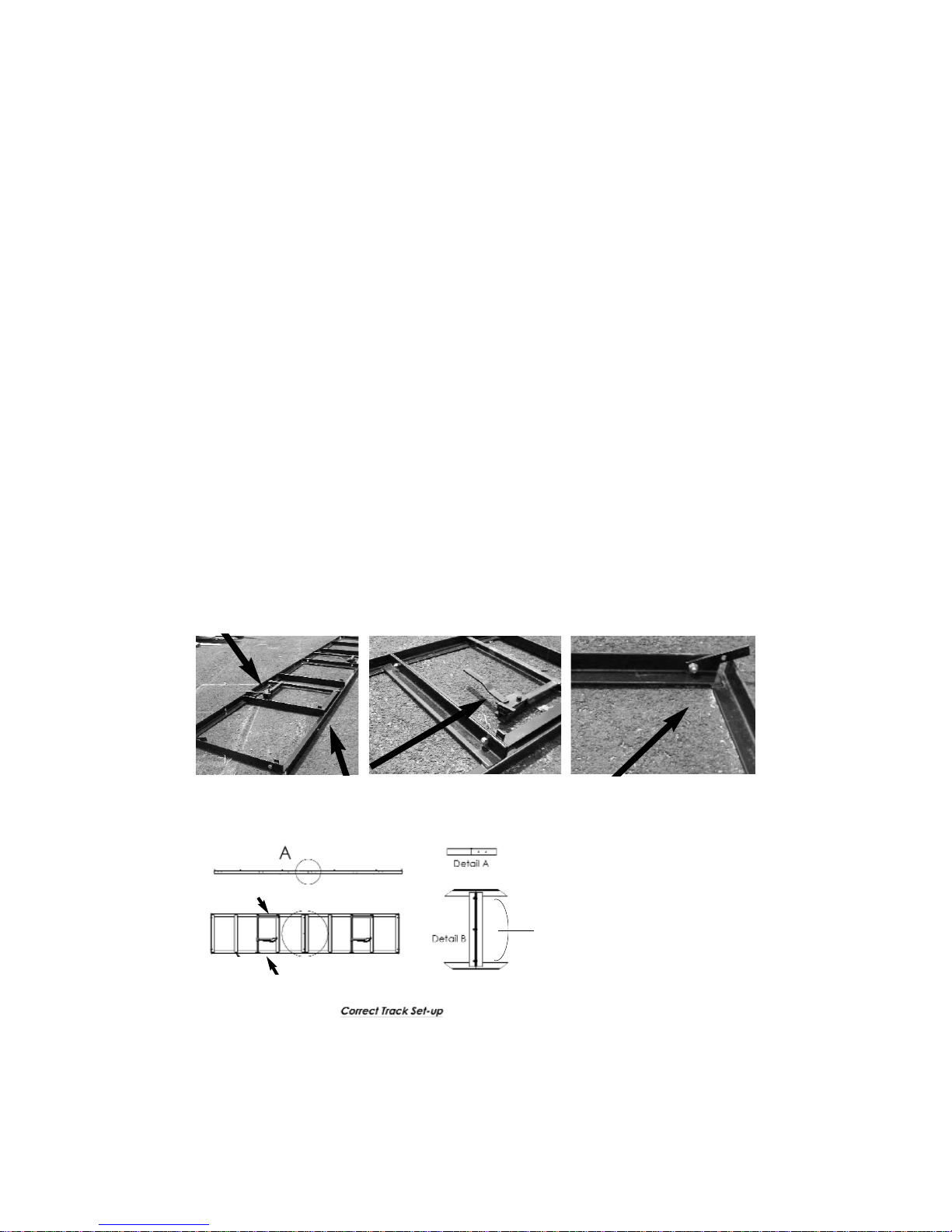

Steps for Setting-Up the Hud-Son Saw Mill

A. Machine Set-Up (ground track unit)

a) For best results and easier set-up, the mill location should be level and free of

obstructions.

b) Alevel cement pad is the best option, but square timbers also work well. You will

need to support the track at each joint and under each cross member.

c) You will need to be sure that the mill is level from front to back and side to side.

The better the mill is supported the better the mill work.

d) There should be a 4 ft. clear work area around the entire mill.

B. Welded Track Assembly

a) Dogs needs to facing in the same direction, the moveable dogs need to be on the

same side of the track which is on the operator's side of the mill head.

b) There are additional holes in the track so that the dogs can be moved to different

positions.

c) The tracks are bolted together using bolt and nuts. The Oscar 18 and 228 mills will

have 2 bolt/nuts: the Oscar 230/236 and 52 mills will have 3 bolts/nuts. Line up the tracks

so that the center holes align. Using the provided bolts put them through the holes and

finger tighten the nuts. Adjust the track height so that the 2 pieces of track meet flush

and level. Work one side then the other, once level has been achieved, check the track to

see if it aligns vertically. If the track is not aligned correctly use a hammer to tap it into

position. Once this is accomplished tighten the bolts securely.

Bolted together Track

Flush & Level

Track on level ground, free of

obstructions

Moveable dogs on one side

Track Stops

Squaring Pin

Operator’s Side

d) The track comes with four

track stop tabs. They consist of

the track stop tab bolt and nut.

Place the tracks stops in the four

end corners of on the inside of

the track. Place them on the

inside of the track secure them

into place with the bolt and nut.

The track stop tabs are placed at

an angle over the track to prevent

any further travel of the mill

head.

Bolts

Set-Up and Operation

Moveable Log Dog

7

Page 8

8

e) To saw a board accurately, the track needs to be straight and flat. To obtain

this, use a string tied tight from end to end or a level. If the track/trailer has a crown or

dip, you will not be able to saw a straight board.

Correct Track

Incorrect

Dipped Track

C. Machine Set-Up (trailer unit) 20' or 24' Torsion Axle Trailers, (230, 236, 56, Farm

Boss, H360))

a) Set-up area should be relatively level and clear of debris. The head will need to roll

down the track so be sure the area is free of obstructions.

b) Lower the trailer jack and raise the jack until the coupler is free of the hitch. Once

this is done remove the unit from the vehicle. Using the "T" handles, loosen the bolts and

lower the front 2 legs.

c) Do the same to lower back 2 legs, and level the trailer.

d) Lower the center 2 legs last, the track should already be level.

e) On the 121/328 models, you will need to unbolt the head from the track. The travel bolts are located behind your guide arms at the base of the mill head.

f) Once the head is unbolted from travel position, roll it down the track to be sure it is

level. If your head rolls on its own you will need to adjust your leveling legs. Return the

head to the center of the trailer and re-bolt or raise the center legs to lock head into place.

Once the head is secure you can reset the leveling legs.

**Always secure the head before re-leveling the trailer***

g) Once the trailer is level, the head should not roll on its own. If your trailer is not level,

it will not saw your boards correctly. Refer to previous instructions for proper set-up.

Correct

trailer set

up. All legs

are level;

head should

not move on

its own.

D. Setting Head on Track (If Applicable) Ground Models

Once your track is level, you are ready to set the head on the track. Once again, be

sure the area is still free and clear of obstructions. You will want the head to roll

freely down the track.

a) Install the head with operator's side on the same side as the moveable dog. The

discharge side is the side with the squaring pins.

b) Raise the head 3 inches and roll from one end to the other. The head should roll

Legs are

locked into

place,

head will

not move.

Page 9

9

smoothly along the track. If the head "thumps" when it passes over the track joint, check

to make sure the tracks are level. Re-level the track and try rolling the head again. Also

be sure to watch the track as you roll the head, if the track moves, you will need to support the track in that area.

c) Set the guide bracket so that the back bearing is on the same plane as the blade, so

that if the blade were to wander back it would hit the back bearing evenly across the middle of the roller. If the bearing needs to be adjusted up or down, loosen the bolt that holds

it to the guide bracket and space it in either direction using the washers that are on either

side of the bearing.

d) Once the bearing is set, position the guide bracket so that the bearing is spaced 1/8"

behind the back of the blade. Once the bearing is in position, tighten the bolt on the top

of the guide bracket into place. Be sure guide is 90

o

to the blade.

e) The guide shoes are to be set using a sheet of paper to gauge the spacing. Place the

paper between the shoe and the blade, slide the shoe so that it is pinching the paper, and

tighten the bolt so that the shoe is set in place. Do the same on the bottom of the blade.

Note that you do not want the shoes to be pinching the blade so hard that they are prohibiting blade travel.

f) Make sure that all nuts and bolts are tightened firmly.

ALWAYS WEAR GLOVES AND EYE PROTECTION

WHEN OPERA

TING SA

WMILL

Squaring arm on right, adjustable dog on left.

Correct head placement; Operators side is on side

with the scale stick.

Pictured is a close-up of the guide

It shows all the bolts and bearings that

can possibly be adjusted. Note how the

teeth are outside of the guide.

Set-Up and Operation

E. Tensioning the Blade on all Models

NEVER tension your blade with the engine running. Your mill is shipped to you without any tension on the blade. If there is tension left on the blade for a period of time,

it can cause flat spots in the belt.

Page 10

10

This will cause the blade to fall off the wheel. Always remember to de-tension your

blade when you are done sawing for the day.

a) a) To tension or loosen the blade, see figure below.

b) Turn the adjusting bolt or stud, clockwise until 30-35 pounds of torque is achieved.

The recommended tool for this is a torque wrench. By hand, rotate blade 3-4 full revolutions; this centers the blade on the wheels.

c) With gloves on, pull up on the blade at the center guard. Allow for no more than a

¼" movement up or down on the blade.

d) Blade guides must not be so tight they cause the blade to heat up. If this occurs readjust guides.

e) Perform a simple test call the "Flutter" test. Put the guards on and then run the

engine at full RPM's (be sure the blade is not in a cut during this test) and watch the blade

under the blade guard. The blade must run straight, if it does not, shut the engine down

and apply more tension. Keep in mind that over tensioning will also cause the blade to

flutter. You should have attained proper tension around 30-35 pounds.

f) A tensioned blade should come off the bottom of the band wheel and run straight

across to the other band wheel, so there is NO sag in the blade between the two wheels.

Tension nut for

smaller units

(121/328)

F Setting Logs

Once the track is set, the head is in place and the blade is tensioned correctly, you are

almost ready to cut.

a) Place the log determined by the mills size, on the center of the track. Using the log

dogs secure the log to the track. Be sure to dog the log high enough (1/2" way up the log)

to ensure the log does not move. If the log is too big for the log dog to hold in place, but

your sawmill head still rolls unobstructed use the "Cheater" to hold it. (For use on the

121/328 only).

Cheater

Squaring Arm and Adjustable Dog

Page 11

11

G. Getting Ready to Cut

Now is the time to debark or clean your log. This can be achieved by the simple chainsaw attachment, called a Log Debarker (available through Hud-Son Forest Equipment

Inc.) or you can pressure wash or use whatever method available to remove any mud

or bark from the logs. By debarking and cleaning your log it will extend the life of your

blade.

a) Adjust the Hud-Son guides so that they are slightly (no more than 2 inches) wider than

the maximum width of the log.

(Note: as you cut slabs, boards or squares you may need to adjust the guide to ensure

the best performance and quality cuts)

b) Find the top of the log with the blade. Remember, that you may have cheaters in

place so be sure these are clear when making the first cut. You will be removing the top

potion of the log. (top slab)

c) On the manual lift models, crank your head down to the desired height and click up

one notch to set the head. Make sure your blade will clear your dog assembly.

d) Start your engine, let it idle for at least 5 minutes. (Refer to the engine manual for

proper engine maintenance)

e) With the engine in idle position, increase the throttle to start the blade. Sawing

should always be done with the engine in full throttle.

f) Gently push the saw head through the log, pushing on the head frame. If the engine

starts to labor, you are going to fast, slow down. Go slow through burls and knots as the

engine may bog down through these parts of a log.

g) When you are at the end of the log, power down the engine, crank the head up so

that will clear the log and roll back to the front of the log. For ease of operation, put the

slabs on the operator's side of the mill, this way you will not have to dig through sawdust

for your lumber.

h) You now have a flat surface on top of your log, remove the cheaters (if applicable),

you will no longer need them, as long as the log dogs will hold the log in place.

i) Set your log dog assembly so that they are standing in the track. Turn the cut side

of the log, using a cant hook, ¼ of a turn. The flat side must be flush against the squaring

pin to assure a square cant.

j) Adjust the log dog at an angle to the track so that the blade can pass over the top,

but so that the dogs are effective in securing the log.

Debark the log.

Guide location

- log width

Page 12

k) Once again, increase the engine throttle to start the blade, and saw another slab.

You will repeat step (I) until your log is squared into a cant. You may now saw your

dimensional lumber.

l) Steps (I-K) may not be applicable if a cant is not desired.

Adjustable dog, set at an angle so that log can be

sawed without interference.

Place flat side, flush against squaring pin to

ensure a square cant.

H. Cutting Dimensional Lumber

You can cut down to a 1" thick bottom board. To achieve this you will use the moveable side of the dog and the short squaring pins welded in the track.

a) You will need to determine the size lumber that can be cut and how many, then using

the scale start sawing your lumber. Lower the blade to desired thickness and saw your

board. Repeat this process unit all lumber is cut.

b) You may need to turn your cant to make the desired lumber.

I. Replacing the Blade

No matter how well you care for your blade, they will dull after time and need to be

changed. Longevity of your blade depends on how well you maintain it.

a) The engine needs to be stopped, turned off and the key removed, this ensures that

the engine can not be accidentally turned back on. On engines with manual start, you will

need to remove the spark plug wire prior to servicing. On electric motors a lockout/tagout

should be used.

b) Loosen and remove wing nuts so you can remove the outside and center guards on

all models.

c) Loosen band blade tensioner bolt until adjusting bolt is flush with threaded plate.

d) With a gloved hand, put hand on the top of the band blade and push down. (Use

extreme CAUTION, dull blades are still sharp and may be hot).

e) Remove band blade from both band wheels and take out of carriage.

f) Inspect new or sharpened blade, be sure blade teeth are facing in correct direction.

Teeth should always point away from the operator. (Towards discharge chute). Be sure

to wipe blade clean of all oily substance prior to installing. Aclean, dry rag or cloth works

best.

g) Starting from your stationary wheel set the blade on the wheel then thread though

your guides. Work the blade over the tensioning wheel until the blade is set.

h) Lightly tension the blade to remove the slack, and then turn the wheel in the direction of travel (towards the operator) 3-4 rotations to be sure the blade is tracking properly on the wheel.

12

Page 13

13

i) Once the new blade is tracking properly, replace the guards and re-tension the blade

as previously stated.

J. End of Processing Lumber

a) Completely decrease engine throttle and turn engine switch, red one, to off position.

b) The blade will continue to turn automatically and will coast to a stop.

c) If you are done sawing for the day, de-tension the blade, so that you do not have flat

spots. Lower the mill head so that the lift cable has slack.

K. Blade Maintenance

Longevity of band blades depends on how well they are cared for. Using a lube tank,

Log Debarker, band blade sharpener, tooth setter, all will help keep your blade in top

condition. Be sure to clean your logs by using a pressure washer or debarker to keep

them free of mud and debris. Refer to 2A on page 6

L. Blade suggestions

a) Never force a dull blade, this will result in overheating of the blade and result in

wavy lumber.

b) Overuse of a blade jeopardizes the ability of the saw blade to be re-sharpened.

c) A new blade may stretch after cutting and may have to be re-tensioned to assure

quality lumber.

d) De-tension the band blade after each day of cutting.

e) Never operate the mill without the guards in place.

The Hud-Son Forest Equipment, Inc sawmill comes with a band blade and we have an

excellent re-sharpening program for your band blade.

M. Adjusting Sawmill Guides

a) Purpose of the Guides

• Superior Hud-Son guide design. Supports on the top, bottom and back of the

blade, where can the blade go? This guide design limits the chance of blade wander.

• The lower blade holds the blade up and decreases the chance of "diving". Most

companies only use a top support.

• The closer to the log the guides are to the log the better support the blade has

as it cuts.

b) Adjusting the guides

• Tools that will be needed:

1) 17 mm wrench

2) 17 mm socket

3) 9/16" wrench

4) 3/16" Allen wrench

Page 14

14

• All guides are aligned and set at the factory, but occasionally they get moved

out of adjustment in shipping or after a period of usage. It is important that they be

checked often for proper alignment and adjusted correctly.

• To adjust your guides correctly you must first tension the blade properly as previously described. A tensioned blade should come off the bottom of the band wheel and

run straight across to the other, so there is NO sag between the two wheels.

c) Now that the blade is tight, slightly loosen the Allen head that holds the guide shoes,

so that they slide up and down freely. Now loosen the bolt that fastens the aluminum

guide bracket to the guide rod, so that the guide bracket can be moved in, out and it can

be rotated in either direction.

d) Set the guide bracket so that the back bearing is on the same plane as the blade, so

that if the blade were to wander back it would hit the back bearing evenly across the middle of the roller. If the bearing needs to be adjusted up or down, loosen the bolt that holds

it to the guide bracket and space it in either direction using the washers that are on either

side of the bearings.

e) Once the bearing is set, position the guide bracket so that the bearing is 1/8" behind

the back of the blade. Once the bearing is in position, tighten the bolt on top of the guide

bracket in to place. Be sure the guide is 90 to the blade.

f.) The guide shoes are to be set using a sheet of paper to gauge the spacing. Place the

paper between the shoe and the blade, slide the shoe so that it is pitching the paper and

tighten the bolt so that the shoe is set in place. Do the same on the bottom of the blade.

Note that you do not want the shoe to be pitching the blade so hard that it is prohibiting

blade travel

g) Make sure that all nuts and bolts are tightened firmly.

N. Using the Lumber Scale

a) All Hud-Son sawmills are equipped with a Lumber Scale. The scale is used to make

the dimensioning process simple. The scale incorporates 4 separate scales with the blade

kerf factored in for each increment.

Scale Resulting Thickness

4/4 1”

5/4 1 - 1/4”

6/4 1 - 1/2”

8/4 2”

Note:

The 1" standard ruler does NOT account for kerf. When using this scale be sure to

plan on kerf. 1" increments will result in approximately a 7/8" end result, depending

on what blade is being used.

Page 15

15

Actual Blade Height

Used For Scaling

Inch Scale

8/4 Scale Row = 2”

Lumber

6/4 Scale Row =

1 - 1/2” Lumber

5/4 Scale Row =

1 - 1/4” Lumber

4/4 Scale Row

= 1” Lumber

Care and Maintenance

Hud-Son Saw Mills require a certain amount of care and maintenance, so that it may

continue to perform at its best. If you are not confident in your ability to perform the

maintenance that is required, please look into having a professional come in and perform the work for you.

Page 16

16

Cleaning your Saw Mill

Using an air hose, blow off all loose debris that builds around the unit.

Use extreme caution when cleaning the mechanism.

Never use flammable or combustible materials to clean the mill.

Be in a well ventilated area. Always wear protective equipment to

prevent injury.

Use proper procedure to dispose of waste materials.

Wipe down the idler and pulley wheels using an air hose, brush or rag.

Clean and inspect blade guides.

Preventative Maintenance

For electrical engine follow the correct Lockout/Tagout procedures.

Check for correct blade tension guaranteeing that 30-35 pounds of torque is

on tensioning bolt/nut.

Check blade tracking, a 1 - ¼" blade should be centered on band wheels.

Check bearing, idler and pulley wheels for wear. Sighs of wear are:

Excessive heat

Squeaking sounds

Looseness

Grease idler, pulley wheels and bearings.

Grease blade tensioner shaft.

Grease the lift tubes.

Check all belts for wear and to make sure the belt tension is "taut".

Belt should have no more than ½" deflection.

Looseness

Grease idler, pulley wheels and bearings.

Grease blade tensioner shaft.

Grease the lift tubes.

Check all belts for wear and to make sure the belt tension is "taut".

Belt should have no more than ½" deflection.

Page 17

17

MAINTENANCE SCHEDULE CHART

Service Recommendations for Hud-Son Sawmills

Service Item

Daily

40

Hours

See

Manual

Check Engine Oil Level

Check/Clean Engine Air Filter

Check Hydraulic Oil Level (fill 1” from top) if applicable

Clean Unit of Bark, Saw Dust, and other Debris

Lubricate Grease Fittings and Oil Points (see Diagram for locations)

Check Tire Pressure - Upon transport (if applicable)

Check Cylinders and Seals for Leakage

Check Feed Chains for tension (if applicable)

Clean Battery Connections

Check Wiring and Connections for Corrosion and Decay

Lubricate Chains (if applicable)

Check Blade Sharpness

Fuel - fill as needed

Blade Lubricant - fill as needed -

Refer to 2A on page 6

Check hoses/gauges for damage, cracks, leakage (chaffing, dry rot, cracks,

replace hoses if applicable)

* Change engine oil after 8

hours of operation on a new

engine (break -in period)

CAUTION!

Maintenance Procedures requiring special training or

tools should be performed by a trained technician.

A routine inspection of the entire machine is encouraged. Check to see if all fittings are

tight and secure. Make sure all nut are tightened. Check to see any damage that may need

to be repaired before and further damage occurs. Routinely checking the equipment and

proper maintenance will help in keeping the Hud-Son Saw Mill running to the best of its

ability.

Page 18

Parts and Warranty

Mill Replacement Parts

Out sourced components will be warranted by the respective company for a period equal

to the warranty in place at the time of shipping, as shown below from date of purchase.

Description

Part Number

Warranty

Gasoline Engine

6.5 HP, 8.0 HP, 16 HP,

18 HP, 21 HP, 23 HP, 31 HP

Up to 2 Years

See Briggs & Stratton

Manual

Electric Engine

131549

1 Year - call Hud-Son

and ask for warranty

department.

1.5” Pillow Block

Bearing, 1” Pillow

Block Bearing

UCP 208-24

UCP 205-16

6 Years

Drive Belt

Oscar 121/328 - B77,

Oscar 230/236/FB/H360 - B85,

52, B92

1 Year - Call

your servicing

Hud-Son Dealer.

Rubber Wheel Belting

16” Wheel B49,

19” Wheel - B56.5

1 Year Defect

Urethane Wheel Belting

16” Wheel HF 49, 19” Wheel - HF

56.5 - 25” Wheel - HF 77

1 Year Defect

Not Melted

1 Year Defect

Sk 1 - 1/2

1 Year

Drive Belt Tensioner

(Idler Pulley)

Oscar121/328 - Idler Pulley

1 Year

Guide Assembly,

Left/Right (see break-

down for parts list)

976-001

30 Days

Call

your servicing

Hud-Son Dealer.

Scale Sticker

24” Scale Sticker

Scale decal

36” & 48” Scale Sticker -

Scale Decal 36 & 48

1 Year

Site Glass Assembly

DH-1006 1 Year

Cable Lift Kit Assembly

Oscar 121/328, Oscar 230/236,

Oscar 52,

Farm Boss/H360

1 Year

Band Blade

Oscar 121/328 - WM 132, (132”x.035x11/4”)Oscar 230 - WM 160, (160”x.035x1-1/4”)

Oscar 236/FB/H360 - WM 167, (167”x.042x1-

1/4”)Farm Boss w/25” band wheels - WM 189,

(189”x.042x1-1/4”) - Oscar 52 - WM 221,

(221”x.0542x1-1/2”)

Breakage &

Re-sharpening -

Call Wood-Mizer, Inc.

at 1-800-244-4600

18

Page 19

19

Part Picture

Description

Part Number

Warranty

Winch

Oscar 121/328/230

DBL800A - (hand crank)

Oscar 236/52/FB/H360 -

ATV2500 - (you will need your

serial # for warranty)

1 Year - call your servicing

Hud-Son Dealer.

Winch Switch

C7755- 236/FB

H2HG/H360

Oscar 52

1 Year - call your servicing

Hud-Son Dealer.

Winch Solenoid

C7700 - 236/FB

H2HG/H360

Oscar 52

1 Year - call your servicing

Hud-Son Dealer.

Clutch

4075P007 - Oscar 121/328

Oscar 230/236/FB/H360 160021- Oscar 52 180021

(double pulley)

30 Days- Call your servicing

Hud-Son Dealer.

Band Wheel

16” - 1B160DSK

19” - 1B184SK

25” - 1B250SK

1 Year - call your servicing

Hud-Son Dealer.

Log Dog Only

Log Dog (121/328)-976-027

Dog Only (230/236)-976-028

2 Years - call your servicing

Hud-Son Dealer.

Track Wheel

w/Replacement Bearing

976-019 - Trolly

2 Years - call your servicing

Hud-Son Dealer.

Replacement Bearing for

Track Wheel

6203-2RS

2 Years - call your servicing

Hud-Son Dealer

Pulley for Lift Cable 976-004 - Cable - Pulley

1 Year - call your servicing

Hud-Son Dealer.

Lift Cable Cable

Cheater

O18-003 - Oscar 121 -

Cheater

O228 - 003 - Oscar 328 -

Cheater

2 Years - call your servicing

Hud-Son Dealer.

Guide Pins

DH-1098 - Oscar121/328

Oscar 230/236/FB/H360

Oscar 52

2 Years - call your servicing

Hud-Son Dealer.

Low Handle Kit Oscar 230/236 - DH 7009

2 Years - call your servicing

Hud-Son Dealer.

Page 20

20

Bolt for Track Wheel 976-026 - Trolly-Bolt

2 Years - call your

servicing Hud-Son Dealer.

Track Sections

1 Year - call your servicing

Hud-Son Dealer.

Axles (Trailer Models)

1 Year - call your servicing

Hud-Son Dealer.

Hydraulic Motors, Pumps,

Valves, Hose & Fittings

1 Year - call your servicing

Hud-Son Dealer.

Sprockets & Chain

90 Days - Call Hud-Son

and ask for the warranty

department

Parts and Warranty

Parts and Warranty

Warranty:

Warranty registration cards must be completed and returned to Hud-Son Forest

Equipment, Inc. within 30 days of purchase. Failure to do will void the warranty!!

Warranty claims must be registered with the Dealer/Distributor, and defective parts must

be returned to the Dealer/Distributor at the owner's expense. The Dealer/Distributor will

assume cost of the shipping one way in regards to any warranty claim. Freight is standard

UPS ground. Any expedited services are at an additional charge and will be paid in full

before shipping at the owner's expense. The shipping of warranty/parts out of the continental USA, will not be covered under warranty. The labor charge out of the continental

USA is also not covered under warranty.

All mills have a 2 year warranty against manufactures defects.

Excluding the H360, and Oscar 52, they have a 1 year warranty.

Warranty Claim Procedure

All warranty claims that are done in the field will be handled as follows:

1 - Customer will call the Dealer/Distributor and acknowledge the problem.

2 - If the problem can be solved in the field, new parts will be shipped, invoiced and paid

for. A credit will be given once the old parts are returned, if covered by warranty.

3 - If requested, parts to be replaced must be returned, at owner's expense within 30-days

to receive credit.

4 - If the problem is deemed to severe to be fixed in the field by the customer, then the

customer must bring the saw mill, at the owner's expense, to the closest Hud-Son

Dealer/Distributor for repair. If the Dealer/Distributor is not qualified to make the

repairs, then the equipment must be returned to Hud-Son Forest Equipment, Inc at the customer's expense.

5 - If the problem is deemed not to be a warranty problem, an invoice will follow for the

Page 21

21

parts that were replaced, as well as an invoice for any time spent on the mill by Hud-Son

Forest Equipment, Inc staff and/or Dealer/Distributor staff.

6 - Any modification to the band mill that is performed by any personnel other than HudSon Forest Equipment, Inc direct staff voids the warranty.

7 - Any parts that are replaced without the discretion of the Dealer/Distributor voids the

warranty on the part the customer is replacing and no reimbursement will be made.

8 - Parts purchased by the customer from an outside source, without prior approval from

Hud-Son Forest Equipment, Inc will NOT be reimbursed.

ALWAYS CALLYOUR SERVICING DEALER FIRST!!

Dealers/Distributors carry parts and are very knowledgeable with the inner workings of

your sawmill. Remember that modifying your mill or using parts that are Not Hud-Son

Forest Equipment Inc approved, can void your warranty.

CE Approved Models: European Mills

Warranty on Parts ONLY!! No warranty on labor or shipping.

Warranty/Service Information:

Please contact our warranty department with any issues or to reorder parts,

at 315-896-4316 or 1-800-765-7297. Hours of operation are M-F 8:00 - 4:30 est.

IF NOT IN THE CONTINENTAL USA - HUD-SON DOES NOT PAY

FREIGHT OR SHIPPING ON WARRANTY OR LABOR.

Follow all the steps to safely transport the Hud-Son Saw Mill Trailer Model

1 - Lock head into travel position.

2 - Raise extension legs and lock in upright positions.

3 - Raise rear legs of frame and pin in raised position.

4 - Raise jack to desired height, remove pin and rotate to horizontal position, hook hitch

to vehicle. Plug in lights and brakes. Hook-up safety chains and break-away switch. (If

applicable)

5 - Lift front legs and lock in transport position.

6 - Be sure to clean unit of all loose debris, including all bark, sawdust and dirt.

Transport Instructions

Page 22

Trouble Shooting

Problem Cause Solution

Blade is Diving/Rising

Dull Blade

RPM’s Not High Enough

Blade Not Tensioned Properly

Sawing Soft Pitch Wood

(Pitch Build-Up in Blade Gullets)

Sharpen or Replace Blade

Saw at Full Throttle

Check Torque on Tensioning Bolt

(Perform “Flutter” Test)

Use Lubricant on Blade

PETROLEUM PRODUCTS, MINERALOIL

OR VEGETABLE OILSHOULD NOT BE

USED ON OUR MILLS

Saw Tree from the Top to the Bottom

(small end to wide end)

Slow Down Reset Teeth to Proper Set

Mill Sawing Hard

RPM’s Not High Enough on Engine

Belt is Slipping

Sawing Hardwood

Dull Blade

Bark or Sawdust Build-up on Wheels or

Track

Always Saw at Full Throttle

Adjust Belt Tension

Slow Down your Sawing Speed

Sharpen or Replace Blade

Clean Wheels and Track

Clutch Slipping Debris and/or Oil can cause slippage

Clean out clutch bell

Inspect/repair springs and shoes

Engine Powers Down

(Loosing RPM’s)

Pushing the Mill too Fast

Dirty Air Filter

Dull Blade

Slow Down your Sawing Speed

Clean/Change

Sharpen/Replace Blade

Mill not Sawing Square

Over Dogged

Track Not Level & Square

Cables are Out of Line

Guides are Out of Adjustment

Not Putting Flatside of Cant Flush with

Squaring Post on the First Turn

Bad Trolley Bearing

Loosen Dog Pressure

Level Track

Re-adjust Cables

Re-Adjust Blade Guides

Put Cant on Flatside, Flush with

Squaring Post

Replace Trolley Wheel

Log Moves When Dogged

Over Dogged, too Much Pressure on

Dogs

Loosen Dog Pressure

New Blade Will Not Cut Blade Could Be Turned Inside Out

Turn the Blade So That the Teeth are

Pointing to the Discharge Direction

Boards have Fine or Large

Lines in them Every Several

Inches in a Repeating Pattern

A Tooth in the Blade is Out of Set Reset Tooth in Blade

22

Page 23

Oscar 121 Mill Assembly

34

1

16

3

17

2

31

35

19

24

7

9

11

12

46

45

21

13

18

41

10

48

22

14

23

8

42

32

6

29

5

10

15

20

22

14

10

26

22

37

4

36

24

43

14

47

25

1

44

39

38

27

40

13

28

33

ITEMS NOT SHOW ON MODEL

Part No

Description

Qty

1

1

4

1

45504

45504

45112

07-302

5/32” Lift cable - 56”

5/32” Lift Cable - 86”

Cable Clamps

1/4” Fuel Line 56”

Decals

23

30

Page 24

24

Item No. Part No. Description Qty

1 10542-02299

KEYWAY

1/4" X 1/4" X 2"

3

2 17155 HCS 7/16 - 20 X 1 Z5 1

3 1133624 SPLIT L/W 5/16" Z 1

4 110120300 HCS 1/4 - 20 x 1/2 Z5 1

5 11343-00644 NY 1/2 X 1 1/4 X .062 7

6 12057 HCS 3/8 - 16 X 1 P5 5

7 13060 HCS 1/4 - 20 X 1 Z5 4

8 13112 HCS 3/8 - 16 X 2.25 Z5 1

9 33006 USS F/W 5/16 Z 14

10 33086 SAE F/W 1/2" Z 17

11 33620 L/W 5/16 Z 7

12 36303 FHN 5/16" - 18 P5 7

13 36305 FHN 3/8 - 16 P5 7

14 36310 FHN 1/2" - 13 Z5 11

15 37341 FLNG LK 3/8 - 16 Z 3

16 4075P007

CLUTCH PULLEY .75

1AB 2.50

1

17 410-803 HRUSH WASHER 1

18 75051

2.5 GALLON LUBE

TANK

1

19 1132037

HWH 10 X 3/4"

TEKS3 - SELF-TAP

1

20 1133012 USS 1/2 F/W Z 6

21 1133082 SAE 3/8 F/W Z 4

22 1133626 1/2" SPLIT L/W Z 10

23 1137024 NYLOCK 3/8 - 16 Z 1

24 110120344 HCS 3/8 - 16 X 1 Z5 5

Oscar 121 Mill Parts List

Oscar 121

Page 25

25

25 110120384 HCS 1/2 - 13 X 2 1/2 Z5 4

26 110120390 HCS 1/2 - 13 X 4 Z5 4

27 976-001-L GUIDE ASSEMBL Y 1

28 976-001-R GUIDE ASSEMBLY 1

29 976-004

CABLE PULLEY -

00158

4

30 976-006 EYE BOLT - L3 2

31 976-009

SHOULDER BOLT FOR

00158 PULLEY

1

32 976-010

SHOULDER BOLT - 3/8

X 2.5

2

33 B-77 V-BELT 1

34 BS-8 10HP ENGINE 1

35 DH-1006

SITE GLASS

ASSEMBLY

1

36 DH-1007 LUBE HOSE BRACKET 1

37 DH-1078

SHEAVE ASSEMBLY

W/BELTING

1

38 DH-1098 GUIDE PIN ASSEMBLY 2

39 DH-1099 SHEAVE W/RED PAINT 1

40 DH-2523

18/228 CENTER GUARD

"HUD-SON"

1

41 F1406 TANK STRAP 1

42 FA3002SB0002

3" FLAT BELT IDLER

W/BUSHING

1

43 O18,O228--004-01 GUIDE SLIDE BAR 1

44 O18,O228-004-04

PILLOW BLOCK KEY

SHAFT

2

45 O18,O228-006

18/228 GUARD

ASSEMBLY

2

46 O18-001 OSCAR 121 CAGE ASSEMBLY 1

47 O18-002

OSCAR 121 HEAD

ASSEMBLY

1

48 UCP208-24-Q PILLOW BLOCK 4

49 WM132

132" BAND BLADE:

18/228

1

Page 26

26

Oscar 121 Cage Assembly

Oscar 121 Cage Parts List

O18-001

Item No. Part No. Description Qty.

1 33078 SAE F/W 1/4 Z 2

2 1133006 F/W USS 5/16 Z 6

3 1133620 SPLIT 5/16 L/W Z 3

4 1136304 FHN 5/16 - 18 Z5 3

5 1136306 3/8 - 16 FHN Z5 4

6 1136316 3/4 - 10 FHN Z5 4

7 110120325 HCS 5/16 - 18 X 1 14 Z5 3

8 976-013 WINCH 1

9 DH-1064 MILLS - WINCH PLATE ASSEMBLY 1

10 DH-1065 PULLEY BRACKET ASSEMBLY 1

11 DH-1071 TRACK WHEEL ASSEMBLY 4

12 O18-001-00-1 OSCAR 121 CAGE WELDMENT 1

13 O18-001-04 OSCAR 18 LIFT TUBE 2

14 O18.O228-003-01 GUSSETT - 1 3/4" X 1/4" FLAT 1

15 SS-0012 1 1/2" Angle Bracket w/Hole 12

16 SS-0013 1 1/2" BRACKET NO HOLE 4

7

3

2

4

13

1

6

12

11

5

16

15

9

14

10

8

Page 27

27

Part No. D/13

Ruler 24” Scale Inch

ruler not shown

Head Assembly

Oscar 121

O18-002

Item No. Part No. Description Qty.

1 12105 HCS 3/8 - 16 X 1 P5 2

2 33086 SAE F/W 1/2" Z 1

3 36305 FHN 3/8 - 16 P5 2

4 36410 FHN 1/2" - 13 YZ8 1

5 11343-00204 TAP BOLT- GR 1/2 X 5 1

6 60108 Curt ZERK 3/16" - GREASE FITTING 2

7 DH-2223 TENSION PLATE 1

8 DH-2223 TENSION BLOCK PLATE 1

9 O18,O228-002-00-2 SLIDE TUBE ASSEMBLY 2

10 O18,O228-002-00-4 BELTADJUSTER BRACKET ASSY 1

11 O18,O228-002-00-5 GUARD BRACKETASSEMBLY 2

12 O18,O228-002-00-7 SLIDE TUBE ASSY 1

13 O18,O228-002-00-8 LONG GUIDE POCKET 1

14 O18,O228-005-00-1 LUBE TANK BRACKET 1

15 O18-002-00-1 O121 HEAD SUB-ASSY 1

16 O18-002-00-3 SCALE STICK 1

17 O228-005 MOTOR BRACKET ASSEMBLY 1

18 SS-0012 1 1/2" Angle Bracket w/Hole 2

19 SS-0014 3" X 1 1/2" ANGLE BRACKET W/HOLE 2

Head Parts List Oscar 121

17

16

12

14

13

3

18

6

8

2

5

15

4

7

10

11

19

1

Page 28

28

Track Assembly

Oscar 121

7

8

3

10

4

6

2

5

9

O18-005

Track Parts List Oscar 121

Item No. Part Number Description Qty.

1

1136302

FHN 1/2 - 20 Z5 2

2

1136310

FHN 1/2 - 13 Z5 6

3 110120304 HCS 1/4 - 20 X 1 Z5

2

4 110120380 HCS 1/2 - 13 X 1 1/2 Z5 6

5 976-027 SMALL LOG DOG 2

6 DH-0939 TRACK STOP BRACKET 4

7 DOUBLE HEADED NAIL DOUBLE HEADED NAIL - 2 1/2” 4

8 O18-003 LOG SUPPORT 2

9 O18-005-00-1W OSCAR 121 TRACK WELDMENT 2

10 O18-005-00-2 OSCAR 121 J-BAR WELDMENT 2

Page 29

29

Trailer Assembly

Oscar 121

Item No. Part No. Description Qty

1 0091060 COUPLER 1

2 1133012 USS 1/2 F/W Z 2

3 1136310 FHN 1/2 - 13 Z5 2

4 110120384 HCS 1/2 - 13 X 2 1/2 Z5 2

5 3S140 TRAILER TIRE 2

6 4-150-02-00 4 1/2” HUB 2

7 O18-005 OSCAR 121 TRACK ASSEMBLY 1

8 O18-006-00-1 OSCAR 121 TRAILER FRAME WELDMENT 1

O18-006

Trailer Parts List Oscar 121

3

2

4

6

5

8

1

7

Page 30

30

Oscar 328 Mill Assembly

31

7

18

20

1

13

14

3

2

32

29

5

27

12

42

10

34

24

45

11

41

9

19

40

4

33

8

39

21

28

11

17

44

38

24

15

41

19

26

25

37

30

46

10

Items Not Shown in Model

Part No Description Qty.

45504 5/32" Lift Cable - 56" 1

45504 5/32" Lift Cable - 86" 1

45112 Cable Clamps 4

07-302 1/4” Fuel Line 56” 1

DECALS

Page 31

31

Item No. Part No. Description Qty.

1 10542-02299 KEYWAY1/4" X 1/4" X 2" 1

2 17155 HCS 7/16 - 20 X 1 Z5 1

3 1133624 SPLIT L/W 5/16" Z 1

4 110120300 HCS 1/4 - 20 x 1/2 Z5 1

5 11343-00644 NY 1/2 X 1 1/4 X .062 6

6 12057 HCS 3/8 - 16 X 1 P5 2

7 13060 HCS 1/4 - 20 X 1 Z5 4

8 13112 HCS 3/8 - 16 X 2.25 Z5 1

9 33086 SAE F/W 1/2" Z 19

10 36305 FHN 3/8 - 16 P5 7

11 36310 FHN 1/2" - 13 Z5 12

12 37341 FLNG LK 3/8 - 16 Z 3

13 4075P007

CLUTCH PULLEY .75 1AB

2.50

1

14 410-803 THRUSH WASHER 1

15 75051 2.5 GALLON LUBE TANK 1

16 1132037

HWH 10 X 3/4" TEKS3 -

SELF-TAP

1

17 1133012 USS 1/2 F/W Z 6

18 1133620 SPLIT 5/16 L/W Z 4

19 1133626 1/2" SPLIT L/W Z 8

20 1136304 FHN 5/16 - 18 Z5 4

21 1137024 NYLOCK 3/8 - 16 Z 1

22 110120344 HCS 3/8 - 16 X 1 Z5 1

23 110120384 HCS 1/2 - 13 X 2 1/2 Z5 4

OSCAR 328

Trailer Parts List Oscar 328

Page 32

32

Item No. Part No. Description Qty.

24 110120384 HCS 1/2 - 13 X 4 Z5 4

25 976-001-L GUIDE ASSEMBL Y 1

26 976-001-R GUIDE ASSEMBLY 1

27 976-004

CABLE PULLEY -

00158

3

28 976-006 EYE BOLT - L3 2

29 976-010

SHOULDER BOLT

- 3/8 X 2.5

3

30 B-77 V-BELT 1

31 BS-8 10HP ENGINE 1

32 DH-1006

SITE GLASS ASSEM-

BLY

1

33 DH-1007 LUBE HOSE BRACKET 1

34 DH-1078

SHEAVE ASSEMBLY

W/BELTING

1

35 DH-1098 GUIDE PIN ASSEMBLY 2

36 DH-1099 SHEAVE W/RED PAINT 1

37 DH-2523

18/228 CENTER GUARD

"HUD-SON"

1

38 F1406 TANK STRAP 1

39 FA3002SB0002

3" FLAT BELT IDLER

W/BUSHING

1

40 O18,O228--004-01 GUIDE SLIDE BAR 1

41 O18,O228-004-04

PILLOW BLOCK KEY

SHAFT

2

42 O18,O228-006

18/228 GUARD ASSEM-

BLY

2

43 O228-001 328 CAGE ASSEMBLY 1

44 O228-002 O328 HEAD ASSEMBLY 1

45 UCP208-24-Q PILLOW BLOCK 4

46 WM132

132" BAND BLADE:

18/228

1

Page 33

33

Oscar 328 Cage

Assembly

Cage Parts List

Oscar 328

Item No Part No Description Qty

1 1133006 F/W USS 5/16 Z 6

2 1133620 SPLIT 5/16 L/W Z 3

3 1136304 FHN 5/16 - 18 Z5 3

4 1136306 3/8 - 16 FHN Z5 4

5 1136316 3/4 - 10 FHN Z5 4

6 110120325 HCS 5/16 - 18 X 1 14 Z5 3

7 110120344 HCS 3/8 - 16 X 1 Z5 2

8 976-013 WINCH 1

9 DH-1064 MILLS - WINCH PLATE ASSEMBLY 1

10 DH-1065 PULLEY BRACKET ASSEMBLY 1

11 DH-1071 TRACK WHEEL ASSEMBLY 4

12 O18.O228-003-01 GUSSETT - 1 3/4" X 1/4" FLAT 1

13 O228-001-00-1 OSCAR 328 FRAME WELDMENT 1

14 O228-001-04 LIFT TUBE STOP 2

15 O228-001-05 LIFT TUBE 2

16 SS-0012 1 1/2" Angle Bracket w/Hole 10

17 SS-0013 1 1/2" BRACKET NO HOLE 2

18 SS-00A1 8 3/8" BRACE 8

O228-001

18

5

13

11

7 4

14

17

16

3

9

8

6

1

2

10

12

15

Page 34

34

Oscar 328 Head

Assembly

Part No. D/13 - Ruler 24”

Scale Inch ruler not shown

Head Parts List Oscar 328

O228-002

Item No Part No Description Qty

1 33086 SAE F/W 1/2" Z 1

2 36305 FHN 3/8 - 16 P5 2

3 144583 TAP BOLT - GR 1/2 - 13 X 4.5" 1

4 1136310 FHN 1/2 - 13 Z5 1

5 110120344 HCS 3/8 - 16 X 1 Z5 2

6 60108 Curt ZERK 3/16" - GREASE FITTING 2

7 DH-2223 TENSION PLATE 1

8 O18,0228-002-00-6 TENSION BLOCK PLATE 1

9 O18,O228-002-00-2 SLIDE TUBE ASSEMBLY 2

10 O18,O228-002-00-4 BELTADJUSTER BRACKET ASSY 1

11 O18,O228-002-00-5 GUARD BRACKET ASSEMBLY 2

12 O18,O228-002-00-7 SLIDE TUBE ASSY 1

13 O18,O228-002-00-8 LONG GUIDE POCKET 1

14 O18,O228-005-00-1 LUBE TANK BRACKET 1

15 O228-002-00-1 O328 HEAD SUB-ASSY 1

16 O228-002-00-5 O228 SCALE STICK ASSEMBLY 1

17 O228-005 MOTOR BRACKET ASSEMBLY 1

18 SS-0012 1 1/2" Angle Bracket w/Hole 2

19 SS-0014 3" X 1 1/2" ANGLE BRACKET W/HOLE 2

13

18

16

17

12

2

8

9

6

19

3

1

4

7

3

11

15

5

14

Page 35

35

Track Assembly Oscar 328

O228-003A

Track Parts List Oscar 328

Item

No.

Part No. Description Qty.

1 1136302 FHN 1/4 - 20 Z5 2

2 1136310 FHN 1/2 - 13 Z5 6

3 110120304 HCS 1/4 - 20 X 1 Z5 2

4 110120380 HCS 1/2 - 13 X 1 1/2 Z5 6

5 976-027 SMALL LOG DOG 2

6 DH-0939 TRACK STOP BRACKET 4

7 O228-003-00-1 O228 TRACK WELDMENT 2

8 O228-003-00-2 J-BAR 2

9 O228-003-00-3 LOG SUPPORT 2

10 Not applicable Nails (Not Shown) 4

2

6

8

1

3

5

9

7

4

Page 36

36

Trailer Assembly Oscar 328

Item No. Part No. Description Qty

1 0091060- Coupler COUPLER 1

2 1133012 USS 1/2 F/W Z 2

3 1136310 FHN 1/2 - 13 Z5 2

4 110120384 HCS 1/2 - 13 X 2 1/2 Z5 2

5 3S140 TRAILER TIRE 2

6 4-150-02-00 4 1/2" HUB 2

7 O228-003 A TRACK ASSEMBLY 1

8 O228-004-00-1

OSCAR 328 TRAILER FRAME

WELDMENT

1

O228-004

Trailer Parts List Oscar 328

7

6

5

8

1

4

2

3

Page 37

37

Item No. Part No. Description Qty.

1 6200-2RS 6200-2RS BEARING 1

2 976-001-SW SMALL WASHER 2

3 976-001-01 GUIDE MAIN BODY 1

4 976-001-02 GUIDE BRACKET 1

5 976-001-03 SHORT GUIDE BRACKET 1

6 976-001-04 O18-001-04 1

7 976-001-06 GUIDE WASHER 5

8 976-001-AB GUIDE - ALAN BOLT 1

9 976-001-B GUIDE BOLT 1

10 976-001-BOLT-1 BOLT 1

11 976-001-LN GUIDE - LOCK WASHER 2

12 976-001-RB GUIDE -LOCK WASHER 1

13 976-001-SCREW GUIDE -SCREW 2

14 976-001-SPW GUIDE - SPLIT WASHER 1

15 CP20-10A O18-0001-05 2

976-001-R

Guide Assembly Parts List

Item

No.

Part No. Description Qty.

1 976-019

TW3 TRACK

WHEEL

1

2 976-026 SHOULDER BOLT 1

3

11343-

00592

F/W 3/4 X 1 X 1/8 Z 2

4 1133092 SAE F/W 3/4" Z 1

5 1168060 C-CLIP 1

6 6203-2RS BEARING - 3/4" ID 1

DH-1071

Track Wheel Assembly Parts List

1

3

2

1

1

4

5

8

1

15

7

2

9

13

4

10

11

3

12

14

Page 38

38

Site Glass Assembly Parts List

Item No. Part No. Description Qty.

1 38655 HCS 10MM - 1.5 X 25 8.8 Z 2

2 90702 M10 - 1.5 FLANGE NUT ZP 2

3 1137406 LK 8 - 2 4

4 SS-0029 SIGHT GLASS BRACKET 1

5 UG-001 SITE GLASS 1

DH-1006

Item No. Part No. Description Qty

1 976-027-1 HANDLE 1

2 976-027-10 GRAB SPACER 1

3 976-027-2 PIVOT ROD 1

4 976-027-3 REAR POCKET 1

5 976-027-4 MAIN SUPPORT 1

6 976-027-5 PLATE 2

7 976-027-6 FRONT POST 1

8 976-027-7 ROCKER PIN 1

9 976-027-8 SPACER 1

10 976-027-9 GRAB 1

976-027

Small Log Dog Parts List

Small Dog

2

3

4

5

1

10

6

2

7

8

3

9

1

5

4

Page 39

39

DH-1078

Item No Part No Description Qty

1 1B160SK

16” Sheave

w/Red Paint

1

2 4999410 Belting Crown Top 1

3 SKS 1.5

Q Bushing for

Sheaves

1

4 SKS 1.5-B Bolt 3

5 Not Applicable Lock Washer 1

Sheave Assembly Parts List

w/Belting for

Oscar 121 & 328

3

1

4

5

2

Clutch Breakdown

Parts List for

Oscar 121 & 328

Item No Part No Description Qty

1 11061199 DRUMS 1

2

J-1416

ALT # 03000015

BEARING 1

3 11301005 HUB 1

4 02400066 WASHER 1

5 01900004 SNAPRING 1

6 01200153 SHOE 2

7 0100012 SPRING 2

3

2

1

6

5

4

7

Page 40

800.765.SAWS • WWW.HUD-SON.COM

800.765.SAWS • WWW.HUD-SON.COM

Thank you for choosing

We have an onsite technician available to answer any questions

Monday - Friday 8 to 4:30 and Saturday from 8 to noon. 315-896-7297.

Hud-Son Forest Equipment, Inc.

8201 State Rt. 12, PO Box 345 Barneveld, NY 13304

Fax: 315.896.2627 • e-mail: info@hud-son.com

FOREST EQUIPMENT

Loading...

Loading...