Page 1

IF YOU HAVE ANY QUESTIONS OR CONCERNS, OR ARE MISSING PARTS

DO NOT RETURN SPRAYER TO THE STORE!

PLEASE CALL OUR CONSUMER HOTLINE AT 1-800-9-SPRAYER

Visit us on the Internet: www.hdhudson.com

e-mail: ladybug@hdhudson.com

Instruction 871-786 Model 13854

LIMITED WARRANTY

H. D. Hudson Manufacturing Company warrants to the original purchaser only that this product will continue to

function as intended if used in accordance with operating instructions (under NORMAL CONSUMER USE) for

one year . If the product fails to function as intended—DO NOT RETURN IT TO THE STORE—call our CONSUMER

SERVICE HOTLINE AT 1-800-9-SPRAYER (toll free) for fast service. We will, at our option, repair or replace any

non-functioning parts without charge (shipping and handling charges will apply) H. D. Hudson Manufacturing

Company shall have the option of requiring the return of the non-functioning product to the address listed below

together with the proof of purchase to establish a claim under this warranty. This warranty does not apply to

damage resulting from accident, misuse, neglect, alterations, operation not in accordance with instructions,

commercial use, or normal wear.

ANY IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR

CONSUMER USE, ARE LIMITED TO THE DURATION SPECIFIED ABOVE. H. D. HUDSON MANUFACTURING

COMPANY’S LIABILITY IS LIMITED SOLELY TO THE REPAIR OR REPLACEMENT OF THE NON-FUNCTIONING

PRODUCT OR PART. H. D. HUDSON MANUFACTURING COMPANY EXCLUDES LIABILITY UNDER THIS WARRANTY

FOR ANY AND ALL INCIDENTAL AND CONSEQUENTIAL LOSS OR DAMAGE.

(1-800-977-7293)

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so these limitations or exclusions may not apply to you. This warranty

gives you specific legal rights and you may have other rights which vary from state to state.

IF YOU HAVE QUESTIONS OR CONCERNS: PLEASE CALL OUR CONSUMER HOTLINE AT 1-800-9-SPRAYER.

(1-800-977-7293)

WARNING!

WARNING!!! THIS PRODUCT IS DESIGNED TO APPLY CHEMICALS THAT MAY BE HARMFUL AND COULD

CAUSE SERIOUS PERSONAL INJURY IF INHALED OR BROUGHT INTO CONTACT WITH THE USER. FAILURE TO

READ AND FOLLOW OWNER’S MANUAL INSTRUCTIONS BEFORE USE AND/OR MISUSE OF THIS PRODUCT

COULD RESULT IN EXPLOSIVE FAILURE WITH MAJOR INJURIES.

MAIN FUNCTION

This Neverpump™ Bak-Pak® sprayer is a highly-efficient sprayer, suitable for controlling pests in crops, flowers

and gardens, epidemic controlling of livestock and poultry houses, and sanitation of public places. Powered by

a 12V/10Ah battery, this sprayer saves labor time and attains 3 to 4 times more efficiency than a manual sprayer.

This sprayer can be operated continuously for up to 10 hours and spray 110 gallons of liquid after one full

charging-which consumes only 0.3 kwh of electricity.

Structure: This sprayer consists of a sprayer, base, battery, mini-pump, charger, spraying system, rubber tubes,

switch, spraying rod, nozzle and strap.

STRUCTURE OF SPRAYER

Page 2

FEATURES

1. Smooth and streamline appearance. The sprayer is ergonomically designed to conform to the human back,

making it easy to carry.

2. The sprayer comes with a mini-diaphragm pump which is compact in size, light-weight, creates high pressure

and has an extended service life. It features a pressure protection switch to prevent over-pressurization.

3. Triple screens prevent foreign matter or particles from clogging the nozzle. The screen is uniquely designed to

allow easy dismantling and cleaning.

4. This sprayer has an under-voltage alert circuit. An alarm will sound when the voltage of the battery decreases

to 10.5 Volts. This will protect the battery. The supplied charging socket can be used as a 12 Volt power supply in

addition to a charging unit.

5. Special charger features intelligent three section charging (constant current/constant voltage/maintenance)

and short-circuit/over current/inverse-connection protection. The indicator lamps of charger: RED-charging;

GREEN-charged/stand-by.

OPERATION

Be sure to charge the battery sufficiently prior to operation. Fill the sprayer with prepared liquid through the

screen and close the sprayer cover. Turn on the power switch and grip the switch handle to start spraying. Either

instant or continuous spraying is allowed.

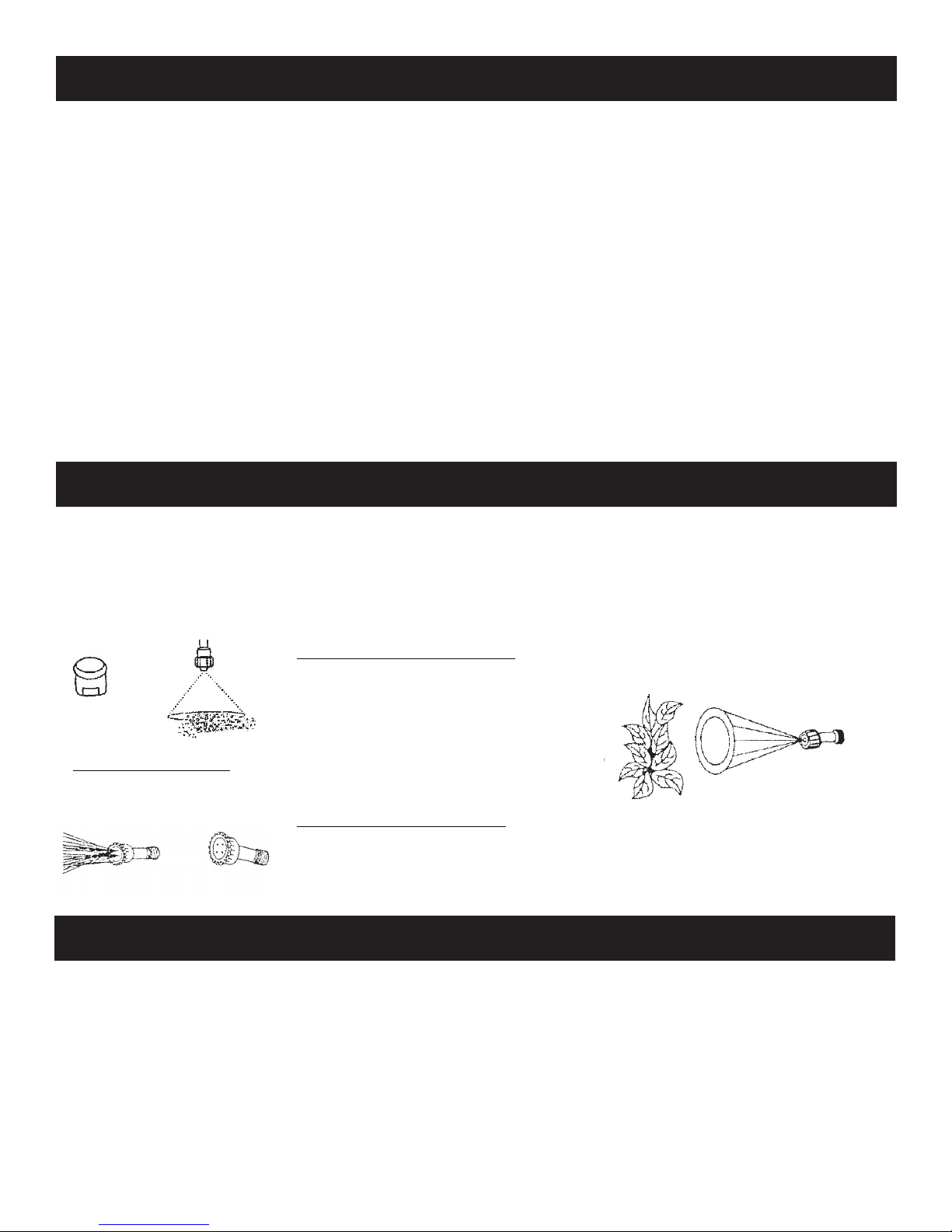

Three kinds of nozzles are supplied for your spraying needs.

1. Fixed Conical Pattern Nozzle: This nozzles sprays uniform mist on target.

Designed for spraying pesticides. Follow the wind and move in a parallel manner

one side while spraying.

2. Misting Cone Nozzle: Best for controlling of pests. Follow the wind

and move in a cross manner on one side while spraying.

3. Four-hole adjustable nozzle: Best for spraying of high plants and fruit trees.

However, it may result in significant loss of pesticide, since it covers a wider area.

PARAMETERS AND SPRAY-HEAD FLOW RATE

1. Type: Neverpump® Bak-Pak® Sprayer 4. Size: 40 x190 x 555mm

2. Pump: mini-diaphragm 5. Capacity: 15 liters

3. Charger: Input AC100-240v 6. Net Weight: 7.4kg

50/60hz, Output DC12v 2a

7. Battery: 12v10ah (fully enclosed, maintenance free)

Max. Pressure: 0.4-0.45Mpa

Page 3

POINTS FOR ATTENTION

Adjustable Cone Nozzle

Fixed Conical Pattern Nozzle

1. The battery has been charged before being delivered. However, it will self-discharge in the course of

transportation and storage. Additional charging before initial use is required.

2. Try your best to avoid operating the sprayer without water in it. This may damage the diaphraghm. Never place

the sprayer upside down. Otherwise, the battery may be damaged.

3. In case a noise is heard from inside the sprayer, or poor atomization occurs after long periods of use, the

sprayer may have a low battery voltage and requires charging. Connect the plug to an electrical outlet without

removing the battery from the sprayer. A charging time of at least 8 hours is required. The charger should be

placed in a dry, well-ventilated safe place.

4. Trial spraying with clean water is necessary for initial use-to make sure neither leakage or poor atomization

occurs.

5. There are a few points the user should remember while spraying. Wear a mask and gloves to protect skin

and to avoid direct contact with pesticides or harmful liquids. Never spray pesticides against the wind or spray

towards humans, animals or food. Never operate for extended periods of time under high temperatures. Strict

compliance with safety instructions of pesticides is required. Never operate with strong acids, strong bases or

flammable liquids. Never use high-resistent and very toxic pesticides for pest controlling purposes on vegetables,

fruit trees, and plants.

6. For short-term use, charging is not usually required. For long-term storage, regular full discharging and

recharging are required, with an interval of 2 weeks, a month, or two months, to ensure the service life of

the battery.

7. Don’t operate sprayer in temperatures exceeding 100 degrees or lower than 35 degrees.

8. After use for half a year, you should dismantle the base and check whether the screws are loose.

If they are loose, please tighten them. Also, be sure to switch off power before storage.

9. It is strictly prohibited to keep this sprayer near fire or expose base to water or immerse the sprayer in the

water to clean or to fill it with water. Unauthorized removal of the charger’s housing is prohibited.

Page 4

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

The motor fails to start

after being powered on.

Abnormal sound heard

in the motor.

Leakage occurs to the

bottom of the base.

Poor atomization.

STRUCTURE SKETCH PARTS LIST

• The power cable has come off

• The battery needs recharging

• The power switch has been damaged

• The fastening screws for the pump

are loose

• The inlet and outlet tubes of pump

break or are loose at the connection

• The spraying hole was clogged

• Spraying hole and o-ring worn

• Seal is upside down

• Filter screen was clogged

• Leakage occurred to tubes at joints

• Battery short of power

• Air remained in the pump

• Dismantle the base to connect

the cables soundly.

• Charging

• Replace the switch

Tighten the screws.

• Dismantle the base and tighten

the tube clamps.

• Remove foreign matter

• Replace o-rings

• Correct by reversing

• Clean with clear water

• Tighten screws

• Alarm maybe out of order, replace

it, charge.

• Remove the nozzle or extension

rod to discharge the air

Conical mist o-ring

Loading...

Loading...