Page 1

Page 2

Page 3

Page 4

Page 5

2

ENGINE SECTION

(6 Cylinder)

ENGINE IDENTIFICATION

The engine number is located on the upper left

hand forward portion of the cylinder block on

the "Hornet" and "Wasp" Series.

The engine number on the "Rambler" Series is

located on a machined surface on the right side

of the engine block just above the exhaust pipe.

Letter Identification, Size of Bore, Main Bearings and

Connecting Rod Bearings

In the machining of cylinder .blocks and

crankshafts, it is sometimes necessary to

machine the cylinder bores to .010" oversize,

and the crankshaft main bearing journals or

crank pins to 0.10" undersize.

These engines are marked with a three letter

code. The code is stamped adjacent to the

engine number. The letters are decoded as

follows:

First Letter Size of Bore

Second Letter Size of Main Bearings

Third Letter Size of Connecting Rod

Bearings

Letter "A" Standard

Letter "B" .010" Undersize

Letter "C" .010" Oversize

Engines (after Number F-2814 or M-3616) that

are not marked are standard in all respects.

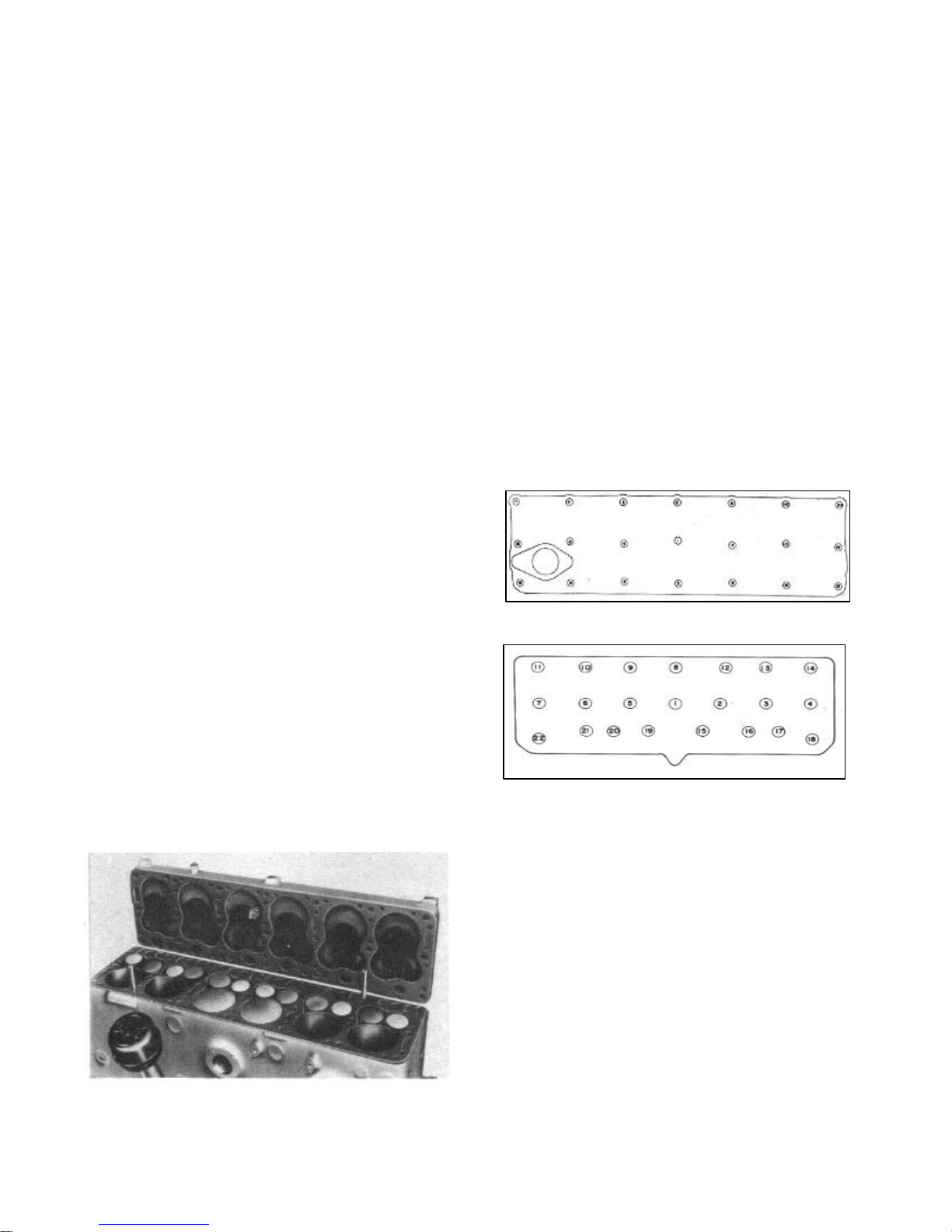

CYLINDER HEAD AND GASKET

Whenever a cylinder head is removed, inspect

the mating surfaces on the cylinder head and

block for cleanliness and squareness with a

straight edge.

Coat the gasket with a non-hardening gasket

paste and locate the gasket on the cylinder

block. A pair of guide pins, size 3" x 1/2"-13

"Hornet" and 3" x 7/16"-14 "Wasp" Series, will

aid in the installation of the cylinder head

(Fig. 1).

Series, and the studs on "Rambler" Series, as

they connect to water passages in the cylinder

head.

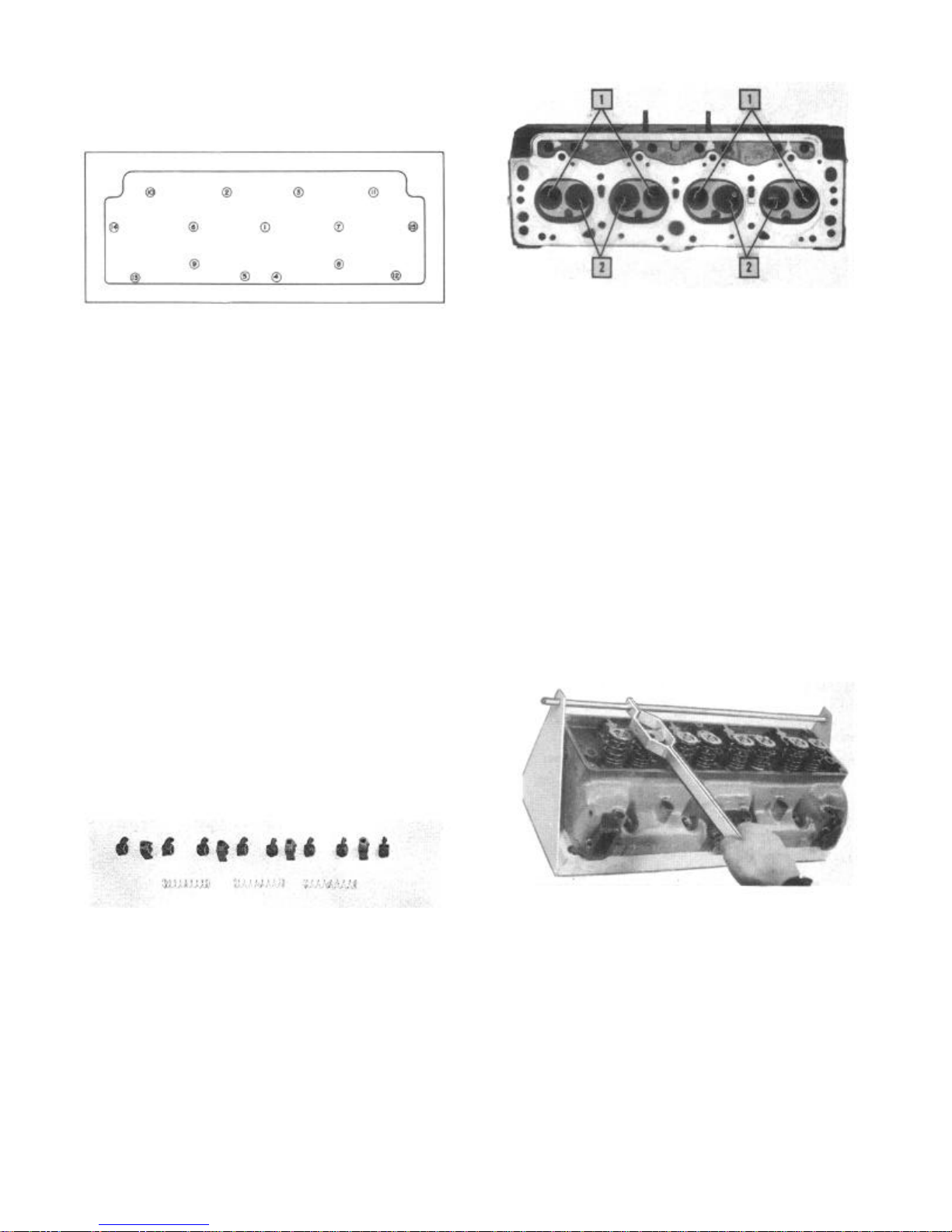

Tighten the cap screws or stud nuts with a

torque wrench in a uniform manner, following

the sequence shown in Figures 2 and 3.

The "Hornet" Series, with aluminum cylinder

head, cap screws should be drawn up to 75-80

foot pounds of torque with engine at room

temperature.

The "Wasp" Series, with cast iron cylinder

head, cap screws are drawn up to 60-65 foot

pounds of torque with engine at normal operating temperature. With aluminum cylinder head,

tighten to 60-65 foot pounds of torque with

engine at room temperature.

Tighten the "Rambler" Series stud nuts to

57-60 foot pounds torque with engine at normal

operating temperature.

FIGURE 2—"Hornet" and "Wasp" Series

Cylinder Head Tightening Sequence

FIGURE 3—Cylinder Head Tightening

Sequence "Rambler" Series

VALVES

Valve Springs

Whenever valve springs are removed, they should

be tested according to the specifications

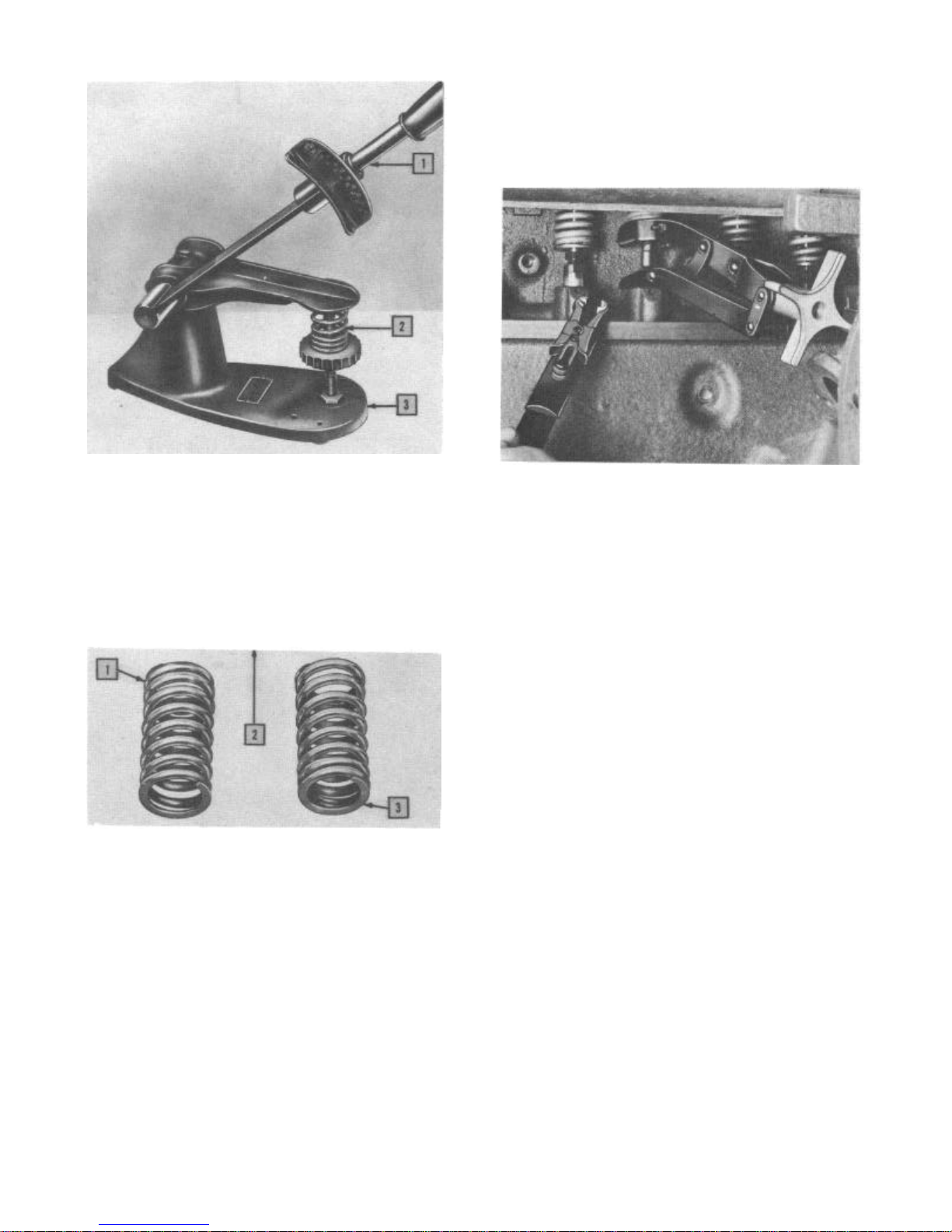

listed below, using a valve spring tester (Fig.

4). Any spring not within the specifications

should be replaced.

FIGURE 1—Guide Pin Installation to Install

Cylinder Head

Be sure that a sealing compound is used on all

cylinder head cap screws, "Hornet" and "Wasp"

Valve Spring Specifications

Series "Hornet" "Wasp" "Rambler"

Valve Spring

Approximate

Free Height 2-1/2" 2-3/16" 2-5/32"

Valve Spring

Pressure

Valve Closed 73-81 Lbs. 40-48 Lbs. 37-41 Lbs.

@ 2-1/2" @ 1-61/64" @ 1-3/4"

Valve Open 153-165 Lbs. 16-124 Lbs. 75-82 Lbs.

@ 1-27/32" @ 1-19/32" @ 1-7/16"

Page 6

1. Torque Wrench

2. Valve Spring Tester

3. Valve Spring

ENGINE 6 CYLINDER

engine supports and loosening the rear supports. The engine may then be moved slightly

upward and to the left.

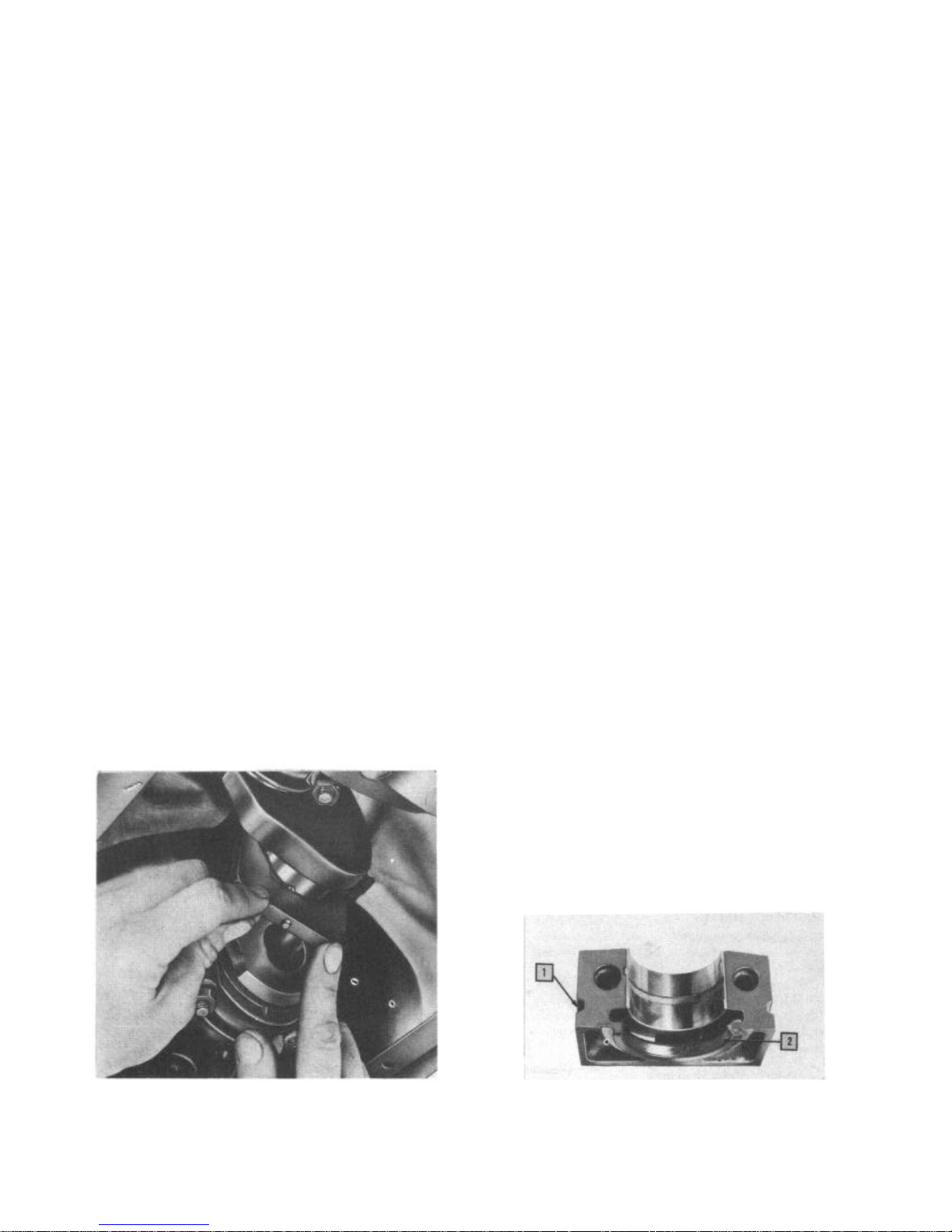

To assist in the installation of valve

locks, Tool J-1953 can be used on the "Hornet"

and "Wasp" Series (Fig. 6).

FIGURE 6—Valve Lock Installation "Hornet"

3

and "Wasp" Series

FIGURE 4—Valve Spring Tester

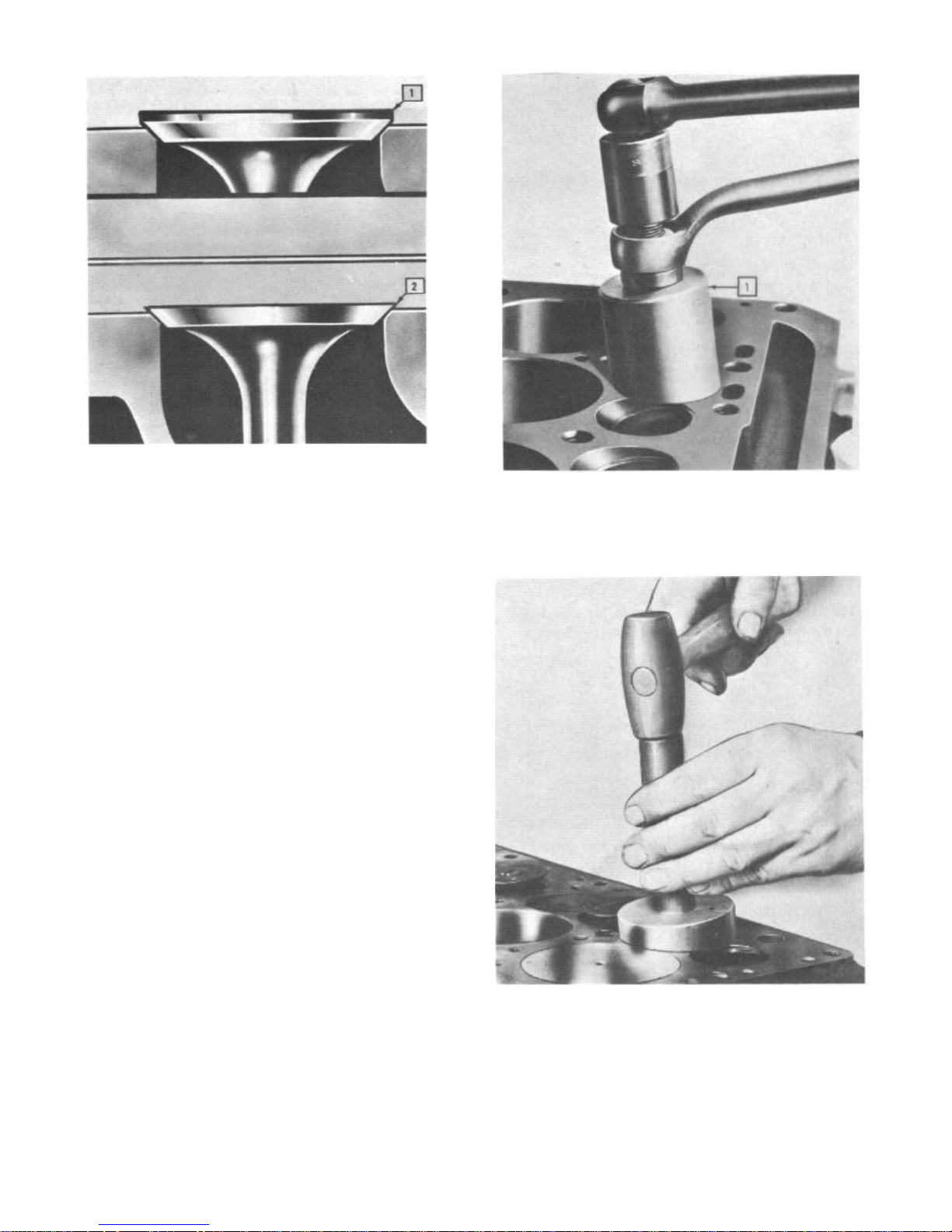

Valve Spring Position

The valve springs are installed with the closed

coils toward the head of the valve as shown in

Figure 5.

1. Correct Position, Closed Coils Up

2. Arrow Points to the Valve Seat

3. Incorrect Position, Closed Coils Down

FIGURE 5—Correct Position of the

Valve Spring

Valve Spring and Valve Removal

The valve springs and valves can be removed

after the manifolds (where necessary), cylinder

heads, and valve covers are removed.

"Hornet" 6 and "Wasp" Twin-H-Power

To remove the intake and exhaust manifolds as

an assembly with the carburetors, required

additional clearance can be obtained by removing the 5/8" nut from the top of the front

"Wasp" Hi-Torque 6

Clearance permits removal of the manifolds

without movement of the engine.

"Rambler" Series

Exhaust pipe mounted to side of engine need

not be removed.

Valve Spring Compressor J-4487 ("C" Type) will

facilitate valve spring removal and replacement on the "Rambler" Series.

Valve Adjustment

After removing the intake and exhaust manifold

assembly and valve covers, the valves on the

"Hornet" and "Wasp" can be adjusted to a cold

setting clearance of .010" "go"-.011" "no-go"

on the intake valves and .014" "go"-.015"

"no-go" on the exhaust valves.

The "Rambler" valves are adjusted without

removal of the exhaust pipe to a cold setting

clearance of .016" intake valves and .018"

exhaust valves.

Valve Refacing

It is important when refacing valves that just

enough material be ground off to clean up the

face.

The valve should be replaced if there is less

than approximately 1/16" material, "Hornet"

and "Wasp" Series and 1/3

2" "Rambler" Series, left on outer diameter of

the valve head known as the valve head margin.

A heavy margin aids in the dissipation of heat

and helps avoid valve warpage (Fig. 7).

The "Hornet" Series intake and exhaust valve

seat and face angle is ground to 45°.

Page 7

6

TECHNICAL SERVICE MANUAL

1. Correct Valve Refacing

2. Incorrect Valve Refacing

FIGURE 7—Correct Valve Refacing

1. Valve Guide Removing Tool J-2814

The "Wasp" Series intake valve seat and

face angle is 45°. The exhaust valve seat and

face angle is 46°.

The "Rambler" Series intake and exhaust

valve face angle is 44°. The valve seat angle

is 45°.

Valve Guides

"Hornet" Series valve stem to guide clearance

is .0015"-.003" Intake, .002"-.004" Exhaust;

"Wasp" Series .001"-.003" Intake, .002".004" Exhaust; "Rambler" Series .0018".0033" Intake and Exhaust.

Replace the guides when these clearances are

exceeded. Check valve stem diameters to

determine whether or not proper stem to guide

clearance exists.

Stem diameters are:

Intake

Exhaust

“Hornet”

.3412”-.3422”

.3402”-.3412”

The valve guides can be removed through

the valve seat opening with a puller.

"Rambler" Series Tool J-2814, illustrated in

Figure 8, can also be adapted to the "Hornet"

and "Wasp" Series by using the spacers from

their respective guide installing tools.

The "Hornet" Series valve guides are

installed with Tool J-883-A (Pilot J-883-8

or 9) to insure that the guides are driven

to the correct depth of 1-3/32 for the

exhaust guides, 1-7/16" intake guides, from

the top of the guide to the top face of the

block (Fig. 9).

“Wasp”

.3412”-.3422”

3402”-.3412”

“Rambler”

.3407”-.3412

.3407”-.3412

FIGURE 8—Removing Valve Guides

"Rambler" Series

FIGURE 9—Installing Valve Guides

The "Wasp" Series valve guides are installed with Tool J-883-A (Pilot J-883-101.

The guides are inserted to a depth of 1%9"

from the top of the guide to the top face of

block.

Use Tool J-1429-A to install the "Rambler"

Page 8

ENGINE 6 CYLINDER

Series valve guides. Drive the guides flush

with the opening of the guide bore in the

block.

Valve Timing

Valve timing is determined by the relation

between the sprocket on the camshaft and the

sprocket on the crankshaft.

"Hornet" and "Wasp" Series

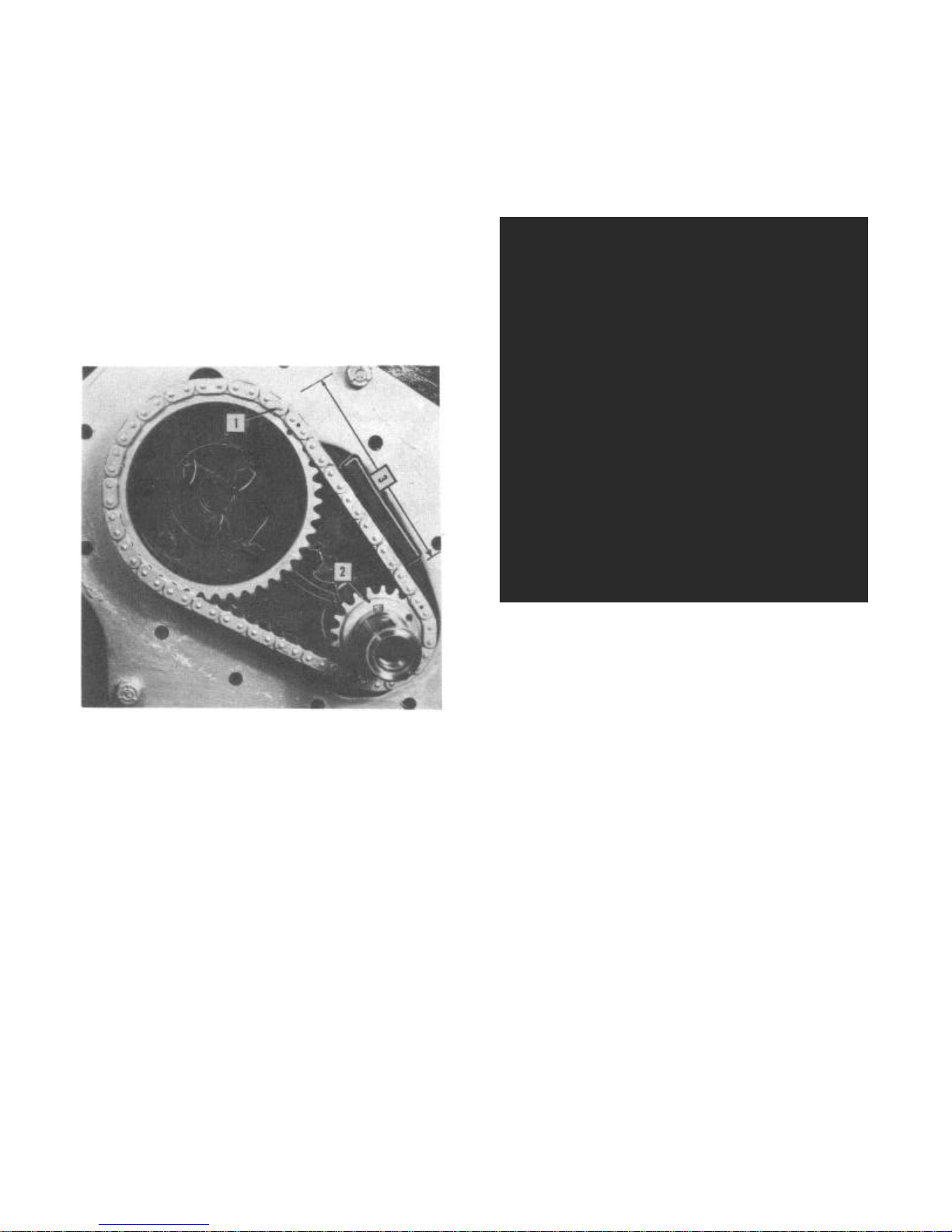

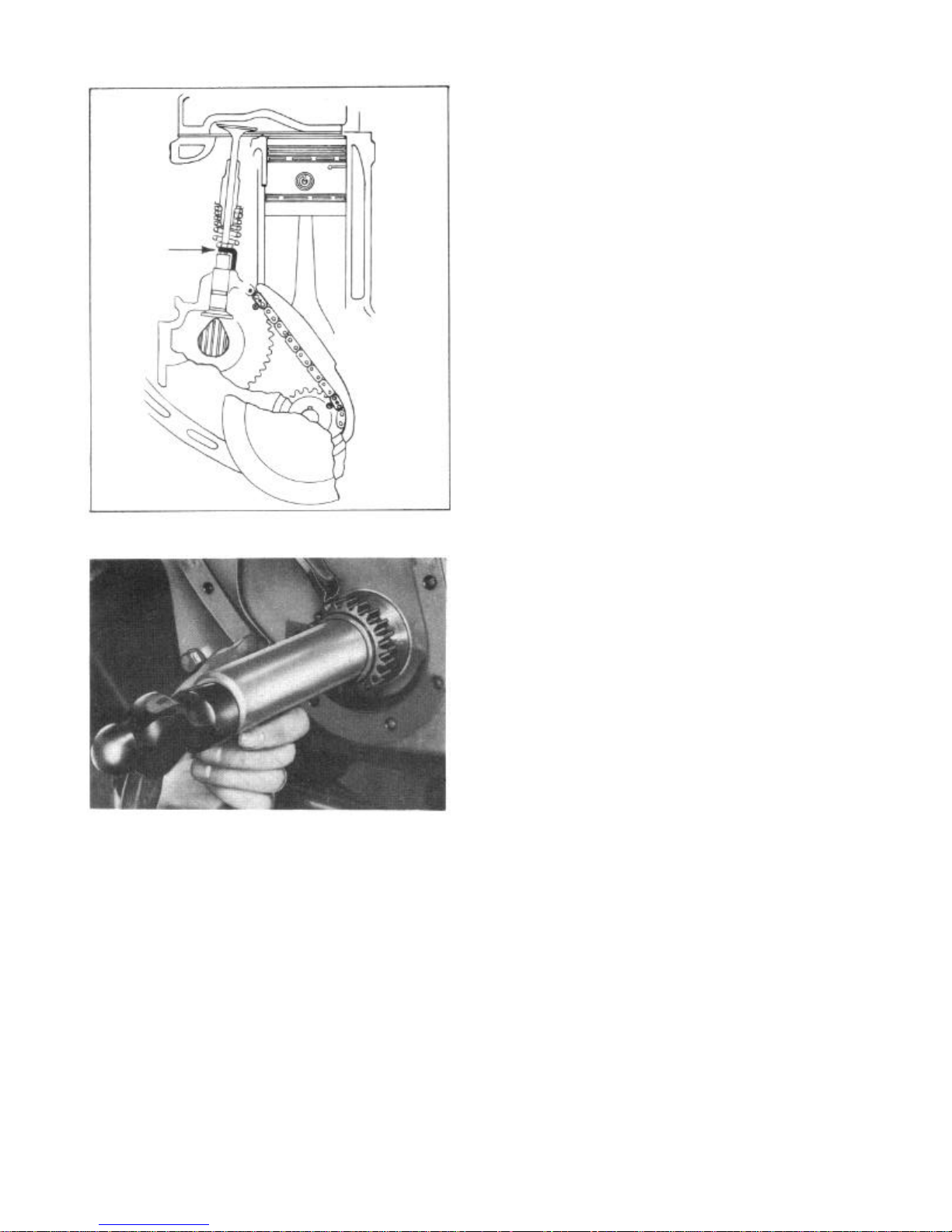

When installing timing assembly, line up the

marked teeth on the sprockets with the marked

links on the chain. Correct installation will

result in locating 7 links or 14 pins between

marks on sprockets as illustrated in Figure 10.

5

mark on the inner timing mark radius (5.06"

flywheel radius).

This distance should be 21/4" plus or minus 1/s"

for valve lash errors. One tooth off timing on

crankshaft sprocket will affect this dimension

by plus or minus 1-31/64". One tooth off on

camshaft sprocket will affect this dimension by

plus or minus 13/16".

1. Marked Tooth on Camshaft Sprocket

2. Marked Tooth on Crankshaft Sprocket

3. 7 Links or 14 Pins

FIGURE 10—Correct Timing Chain Installation

"Hornet" and "Wasp" Series

"Hornet" Series

Valve timing can be checked without dismantling the engine.

With the engine at room temperature,

locate No. 1 piston at U.D.C. exhaust stroke.

Install a dial indicator on No. 1 cylinder

exhaust valve head through spark plug opening. Crank engine slowly until dial indicator

indicates valve has seated.

Place a chalk mark on the flywheel,

through the ignition timing mark opening in

line with the lower ledge of opening.

Crank engine backwards to expose both the

chalk mark and U.D.C. mark on flywheel. (This

is only possible if timing is correct or

early.) With a pair of dividers, measure the

distance between the U.D.C. mark and chalk

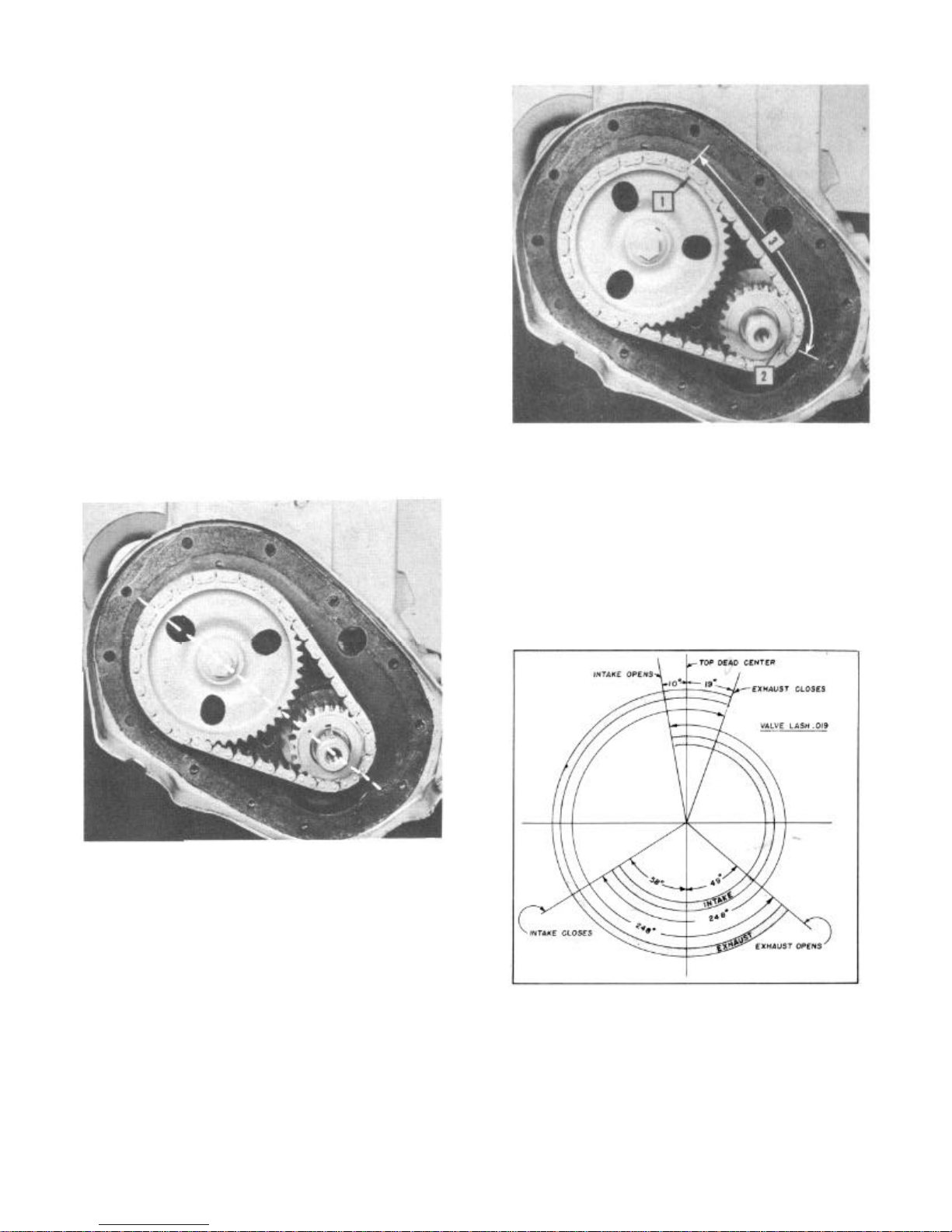

FIGURE 11—Valve Timing Diagram

"Hornet" Series

"Wasp" Series

To check valve timing on the "Wasp" Series,

crank engine until No. 1 piston is at T.D.C.

exhaust stroke.

Install a dial indicator on No. 1 cylinder

exhaust valve head through spark plug opening.

Crank engine slowly until dial indicator indicates valve has seated.

Place a chalk mark on outer edge of vibration

damper below pointer.

Measure distance from chalk mark back to U.D.C.

No. 1 mark with steel scale located around

circumference of damper. This distance should be

approximately 13/4" (with cold valve lash .015")

plus or minus 1/8" for valve lash errors. If the

camshaft sprocket is off one tooth, it will

affect the dimension by plus or minus 1%2". If

the crankshaft sprocket is off one tooth, the

dimension will be affected by plus or minus

13/16".

"Rambler" Series

When installing timing assembly, line up the

marked teeth adjacent to each other on a center

line drawn through the center of the camshaft

and the center of the crankshaft (Fig. 13).

Before installing the timing chain cover, check

the correct installation of the timing chain;

locate the marked tooth of the camshaft sprocket

Page 9

6

TECHNICAL SERVICE MANUAL

1. Marked Tooth on the Camshaft Sprocket

2. Marked Tooth on the Crankshaft Sprocket

3. 91/2 Links or 19 Pins

FIGURE 12—Valve Timing Diagram

"Wasp" Series

FIGURE 14—Correct Timing Chain Installation

"Rambler" Series

FIGURE 13—Place Marked Teeth on Center

Line When Installing Sprockets and Chain

"Rambler" Series

at approximately the one o'clock position.

This should place the marked tooth of the

crankshaft sprocket where it begins to mesh

with the chain (Fig. 14). Count the number

of links between the marked teeth of both

sprockets. There should be 91/2 links or 19

pins.

Valve timing may be inspected by locating

the No. 6 piston on T.D.C. in firing

position. Then set valves on the No. 1

cylinder to .003" clearance. Slowly rock the

crankshaft back and forth.

If the timing is set properly, the

exhaust valve should open before the D.C.

mark on the vibration damper lines up with

the pointer. Note this distance. The intake

valve should open an equal distance after the

D.C. mark passes the pointer.

FIGURE 15—Valve Timing Diagram

"Rambler" Series

TIMING CHAIN COVER

"Hornet" and "Wasp" Series

The timing chain cover oil seal is a leather

chevron design, spring loaded, to contact the

seal surface of the vibration damper under

Page 10

ENGINE 6 CYLINDER

7

pressure.

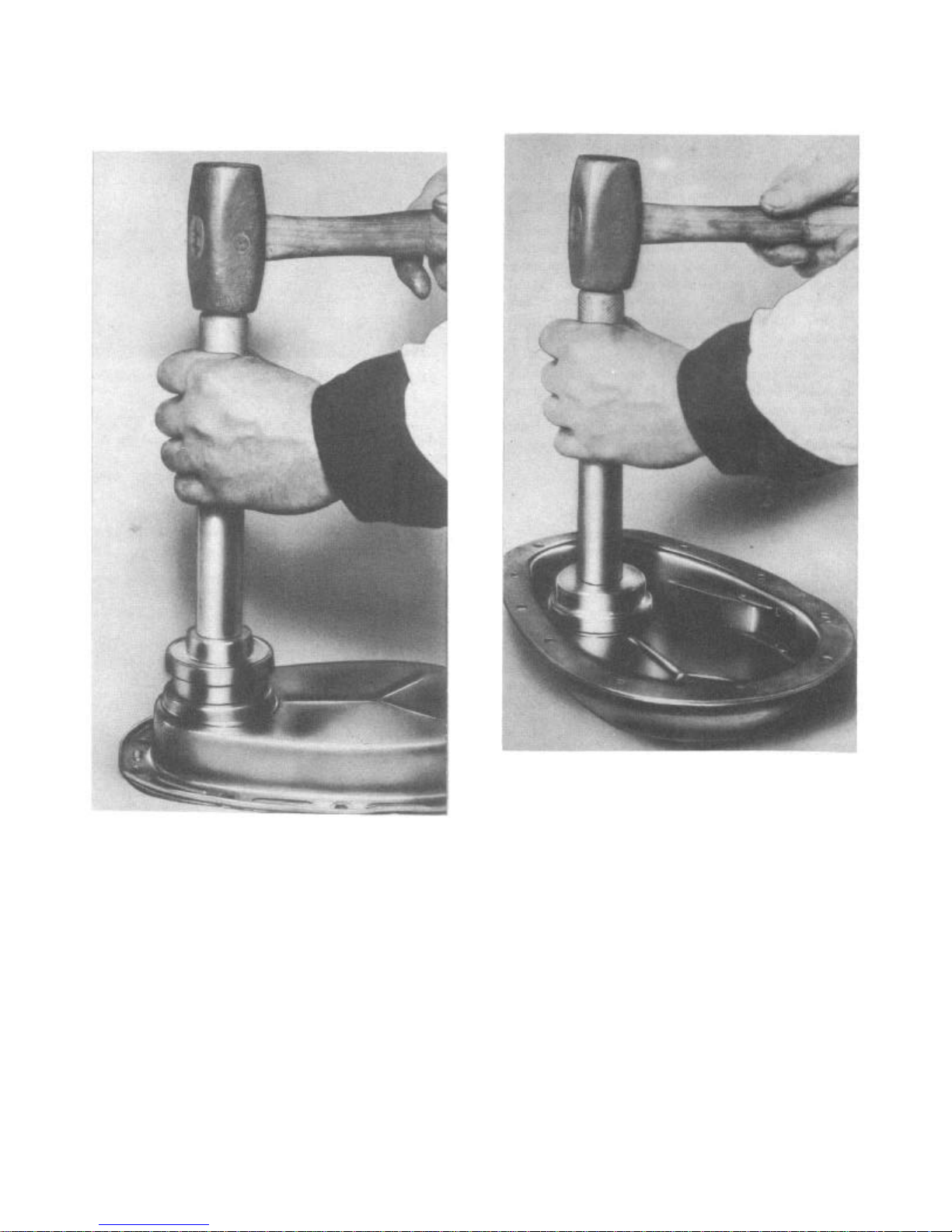

Tool J-2776 is used to remove and install

the timing chain cover oil seal (Figs. 16 and

17):

lip of leather is in good condition and

not curled over.

FIGURE 16—Removing Timing Chain Cover

Oil Seal—"Hornet" and "Wasp" Series

Insert the collar so that slot in collar

engages depression in cover. Support the

cover when driving out the seal with the

straight side of the driver.

NOTE: The tool head is reversible on the

handle. The side with the tapered pilot

is used for installing the seal and the

large size for removal. Before installing

a new oil seal, apply a coating of white

or red lead in the well of the timing

cover. Install the oil seal in cover

using tapered pilot side of tool (Fig.

17). With J-872-5, handle screw in

opposite end of tool, and with an arbor

press or soft hammer, press the seal

tightly into place. After seal is installed, recheck to make certain that the

FIGURE 17— Installing Timing Chain Cover Oil

Seal—"Hornet" and "Wasp" Series

"Rambler" Series

The timing chain cover is provided with a

felt seal to prevent the leakage of oil

around the front crankshaft pulley hub. To

prevent damage to this seal, it is important

that the cover be properly aligned when

installing the vibration damper. This is

accomplished by leaving the cover to block

screws loose until the vibration damper has

been partially installed. Then tighten the

cover screws.

At time of installation of a new seal,

the rubber section of the seal must be

installed to the rear of the cover.

The oil seal installed in the timing

chain cover is replaced by driving the old

one out from the rear and installing a new

seal and retainer from the front.

An oil slinger is used inside the timing

chain cover.

Page 11

8

The slinger is held in place by the crankshaft

sprocket and vibration damper.

TECHNICAL SERVICE MANUAL

CAMSHAFT AND BEARINGS

The camshaft is supported by four steel

shelled, babbitt lined bearings which have

been pressed into the block and line reamed.

The camshaft bearings are step bored being

larger at the front bearing than at the rear

to permit easy removal and installation of the

camshaft. All camshaft bearings are lubricated under pressure through drilled passages

in the cylinder block.

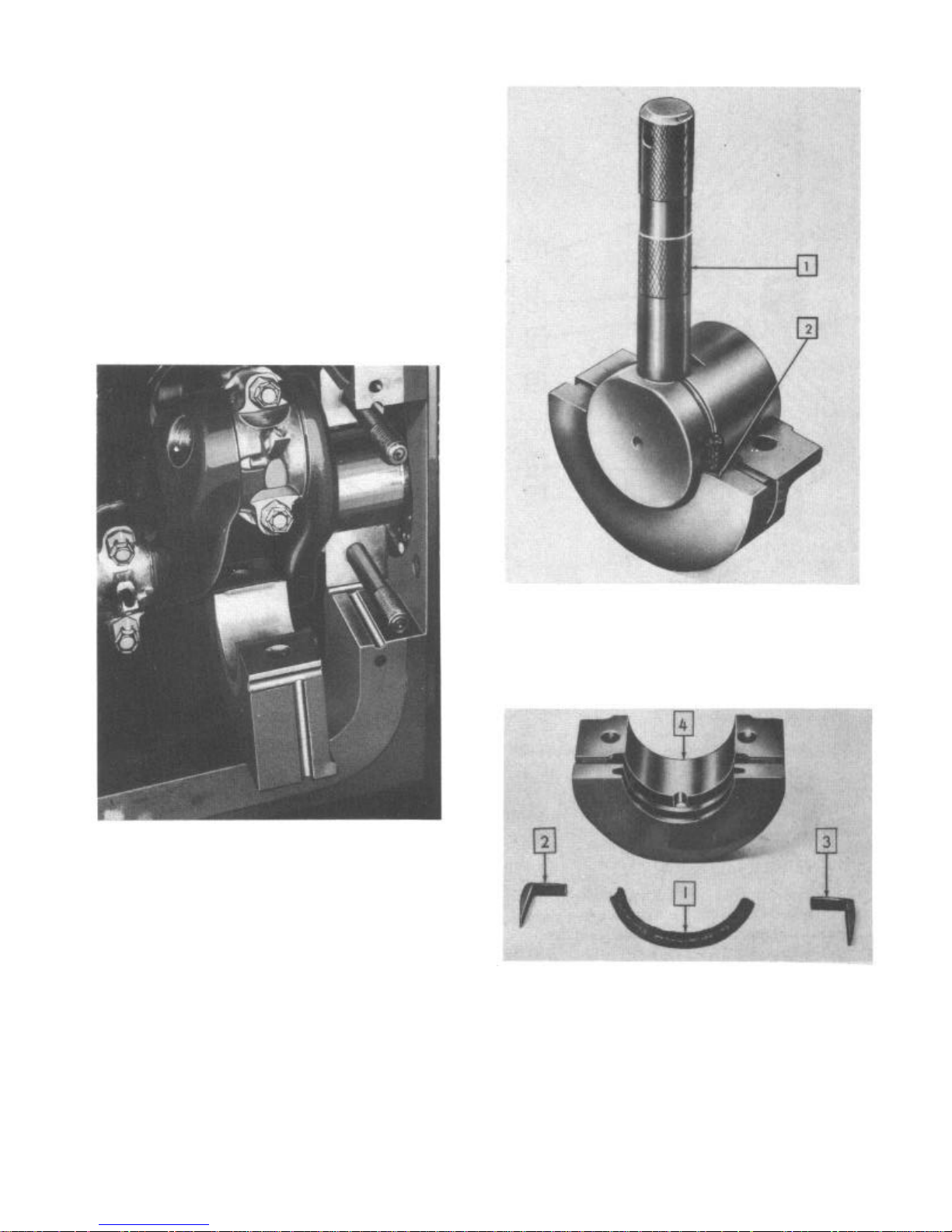

To simplify camshaft removal on the "Hornet"

and "Wasp" Series, remove the radiator core

and grille assemblies and intake exhaust

manifold. Then raise the front of the engine

slightly.

On cars equipped with air conditioning and all

"Rambler" Series, the engine should be

removed for camshaft removal.

The engines should also be removed from the

car if camshaft bearing replacement and/or

line reaming is contemplated.

Camshaft Bearing Oil Clearances

"Hornet" .0015"-.002"

"Wasp" .0005"-.0015"

"Rambler" .001"-.002"

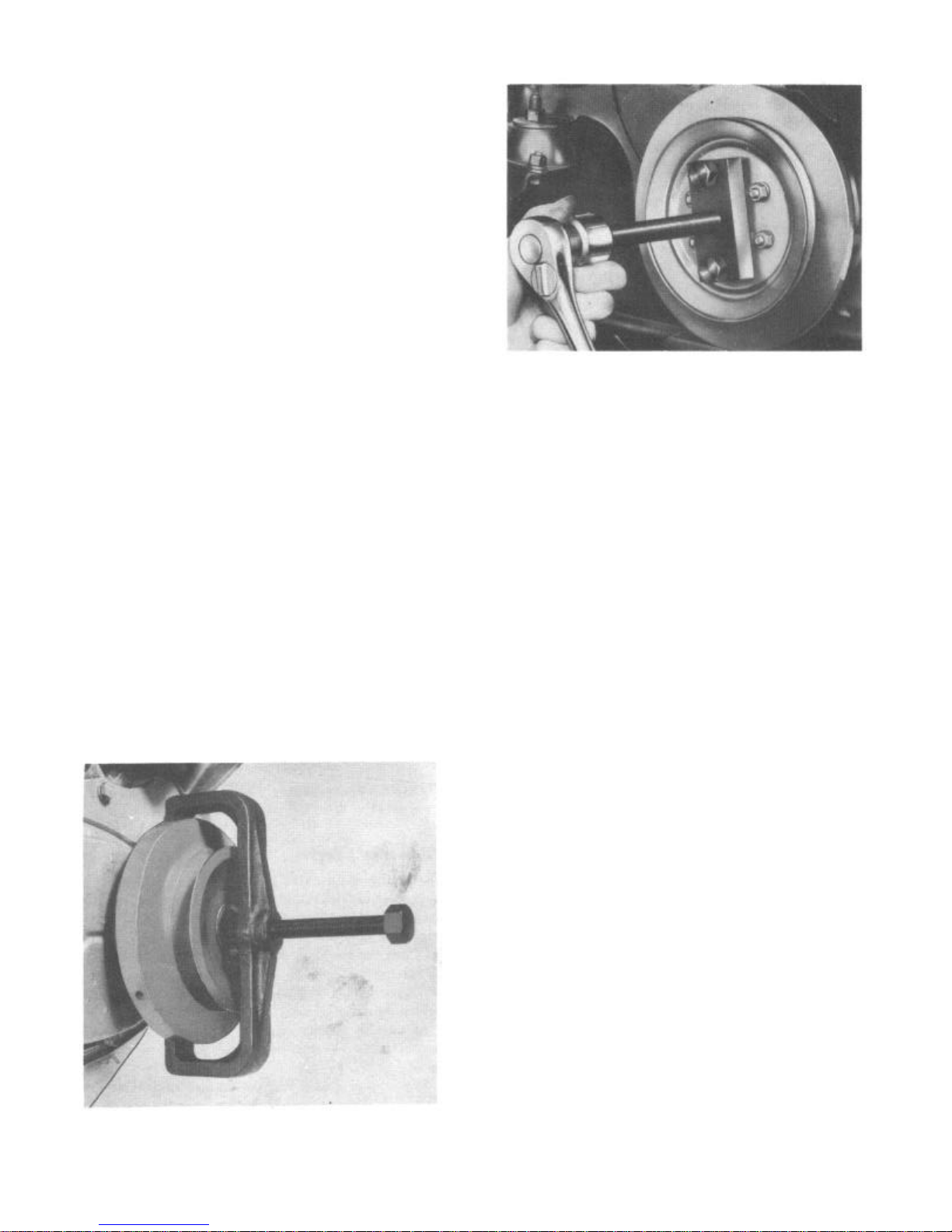

FIGURE 19—Removing Vibration Damper

Assembly "Wasp" Series

Locate engine with timing assembly lined

up as shown in Figure 10.

Remove timing chain cover and cut safety

wire from camshaft sprocket mounting bolts.

Remove camshaft sprocket and chain assembly.

Use Puller 1-471 to remove crankshaft

sprocket (Fig. 20) if a gear change is to be

made.

Camshaft Removal

"Hornet" and "Wasp" Series

Remove the radiator, radiator grille, fan

assembly, and intake and exhaust manifolds.

Pull the vibration damper pulley assembly

after removing retaining cap screw. Use

Puller J-676-C for the "Hornet" Series (Fig.

18) and J-5371 "Wasp" Series (Fig. 19).

FIGURE 20—Removing Crankshaft Sprocket

Remove valve side covers and raise valves

and springs sufficiently to install tools

1-1612-3-A tappet holders (Fig. 21). Remove

oil spout on the "Wasp" Series and spout and

chain silencer on the "Hornet" Series.

Remove camshaft thrust plate.

Remove camshaft.

To reinstall the crankshaft sprocket, if

removed, use Driver J-5369 (Fig. 22):

FIGURE 18—Removing Vibration Damper

Assembly "Hornet" Series

"Rambler" Series

Remove engine from the car. Remove fan

assembly and cylinder head. Remove valve

tappet covers and vibration damper. Remove

valves and valve springs;

Page 12

ENGINE 6 CYLINDER

End Play: .003"-.005" "Hornet" and "Wasp"

Series .004"-.006" "Rambler" Series

The camshaft end play can be checked with a

feeler gauge between the rear of the camshaft

sprocket and the front surface of the

camshaft thrust plate. A dial indicator can

also be used for checking the end play of the

camshaft.

PISTONS

"Hornet" and "Wasp" Series

The pistons are aluminum alloy cam ground

with taper ground skirt.

Ring grooves are provided for four piston

rings, two compression and two oil control

rings. One oil control ring is installed

below the piston pin while two compression

rings and one oil control ring are above the

pin. The rings are positioned and retained

in a limited working area by pins installed

in the piston ring grooves.

"Rambler" Series

9

FIGURE 21—Tool J-1612-3A Tappet Holders

FIGURE 22—Installing Crankshaft Sprocket

"Hornet" and "Wasp" Series

retain tappets with wire.

Remove timing chain cover and oil slinger.

Position engine with timing marks on a

center line (Fig. 12). Remove camshaft

sprocket retaining screw. Remove timing

chain and sprockets. The sprockets can be

pryed off of the shafts.

Remove camshaft thrust plate and camshaft.

Camshaft End Play

The camshaft end play is obtained between

the front surface on the camshaft bearing

and the camshaft thrust plate. When excessive end play occurs, a change in thrust

plate will restore the correct end play.

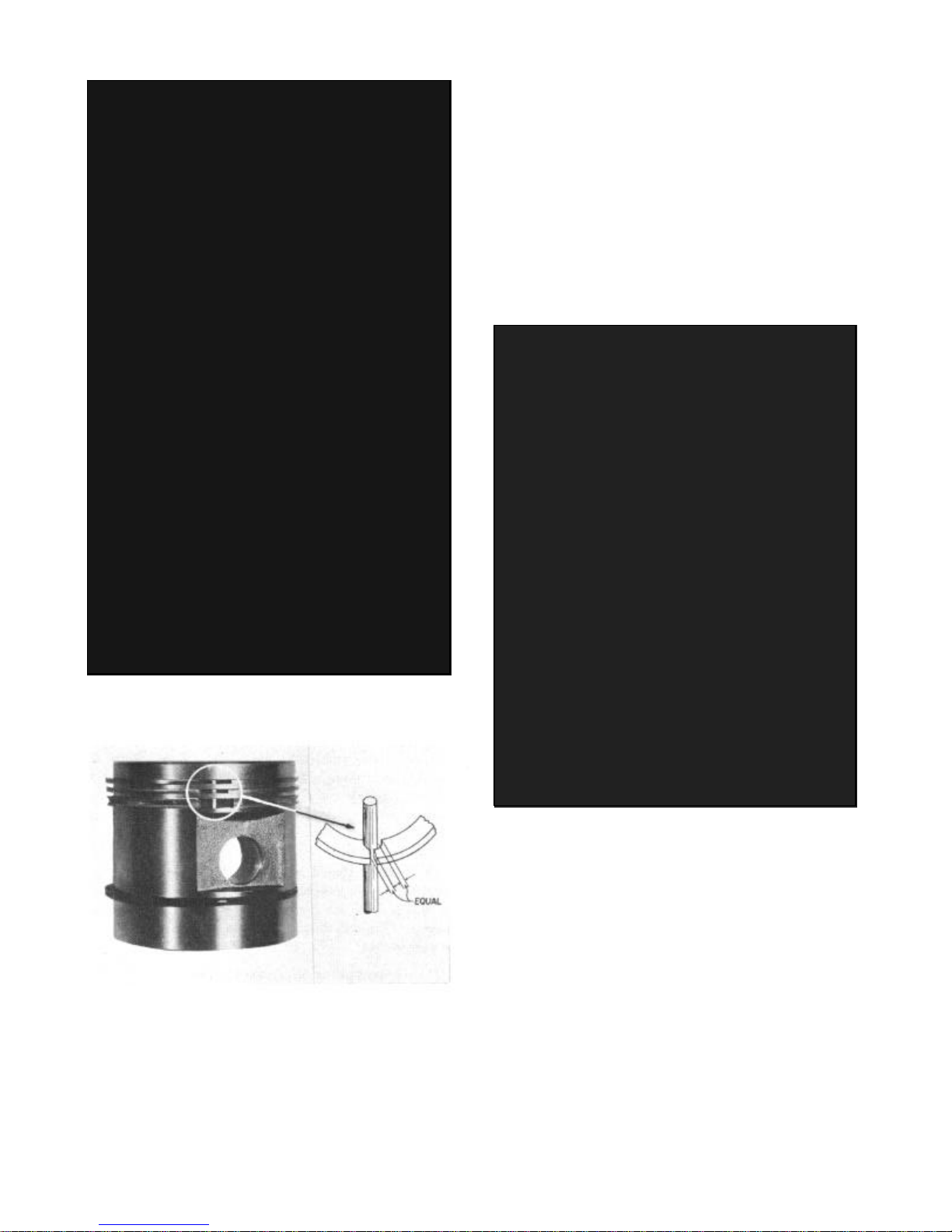

The pistons are aluminum alloy cam ground

having a larger diameter measured at right

angles to the piston pin hole and taper

ground skirt. A steel strut for structural

strength and to control expansion is located

in the pin boss structure.

Ring grooves are provided for four rings

above the piston pin, two compression and two

oil control rings. The piston pin is off-set

from the center axis toward the thrust side

of the cylinder.

To insure proper installation of off-set pin,

a notch is cast in top of piston. Piston must

be installed in the engine with the notch

toward the front.

Piston Removal

Piston removal is accomplished from the top

of the engine. However, before removing the

pistons, the ring ridges in the cylinder

bores must be removed. Failure to remove the

ridge at the top of the cylinder bore will

very often result in piston ring breakage and

damage to the piston groove land. If cylinder

taper exceeds .009", bore must be trued up

and oversize pistons and rings used.

Fitting Pistons

"Hornet" and "Wasp" Series

The pistons are fitted by the use of a spring

scale and feeler tape for a clearance of

.002" under a three to four pound pull.

(Parts must be clean, dry, and at room

temperature.)

"Rambler" Series

The piston is fitted so that each piston will

support its own weight in any portion of the

cylinder with all parts clean and dry. Piston

Page 13

10

TECHNICAL SERVICE MANUAL

to bore clearance is .0006" to .0012".

PISTON RINGS

The pistons are fitted with four piston

rings, two compression and two oil control

rings.

A chrome plated upper ring is used to resist

corrosion.

Before assembling the rings to the piston,

carbon must be cleaned from all ring grooves.

The oil drain holes in the oil ring grooves

must be cleared. Care must be exercised not

to remove metal from the grooves, since that

will change their depth, nor from the lands,

since that will change the ring groove

clearance and destroy ring to land seating.

Checking Ring Groove Clearance

Side groove clearance is measured with a

feeler gauge. Roll the rings around the

piston in the grooves in which they operate.

Check for freedom all the way around.

The groove clearances are listed below by

ring number with the top ring as number one.

Ring Number 1 2 3 4

"Hornet" .002"-.004" .002"-.004" ,001"-.003" ..001"-.003"

"Wasp" .002"-.004" .002"-.004" .001"-.003" .001"-.003"

"Rambler" .002"-.004" .002"-.004" .002"-.004" .002"-.004"

Rings must be installed on pistons with a

ring installation tool to prevent distortion

and ring breakage.

Detailed instructions in service ring packages must be followed.

"Hornet" and "Wasp" Series

Four piston rings are used; three rings are

located above the piston pin and one below

the pin. The rings are pinned in place to

prevent movement (Figs. 23 and 24).

Checking Ring Gap Clearance

Piston ring gap clearance is measured in the

bottom of the cylinder near the end of the

ring travel area. To square the ring in the

bore for checking gap clearance, place the

ring in the bore. Then, with an inverted

piston, push the ring down near the lower end

of the ring travel area. When other than

standard ring sizes are used, rings should

be individually fitted to their respective

bores.

The ring gaps for fitting rings are listed below:

"Hornet" .006"-.014"

"Wasp" .004"-.009"

"Rambler" .010"-.020"

Piston Ring Installation

Removal of glaze from the cylinder wall for

quicker ring seating can be accomplished by

various methods. If the expanding flexible

type hone is used, do not use more than 10

strokes (each stroke down and return) to

recondition a cylinder wall.

Successful ring installation depends upon

cleanliness in handling parts and while

honing the cylinder walls. The engine bearings and lubrication system must be protected

from abrasives.

Rigid type hones are not to be used to

remove cylinder glaze as there is always a

slight amount of taper in cylinder walls

after the engine has been in service.

FIGURE 23—Ring Arrangement

"Hornet" Series

The rings are notched on the inner diameter

at the gap slot. The width of the notch is

.125". Approximately .075" is at one end of

the ring and .050" at the other end. This

off-setting of the notch enables a single pin

pressed in from the top of the piston to

locate the three top rings without having the

gaps on adjacent rings aligned (Fig. 25).

Page 14

ENGINE 6 CYLINDER

CAUTION: Because of the backlash clearance requirement, it is suggested that

no ring be filed to fit a bore size

smaller than the ring size.

"Rambler" Series

The two compression and two oil control rings

are located above the piston pin. The

compression rings are of the "twist" design

with an inner groove installed to the top of

piston. A conventional oil control ring is

used in the third ring groove.

11

FIGURE 24—Ring Arrangement

"Wasp" Series

FIGURE 25—Pinning of Piston Rings "Hornet"

and "Wasp" Series

The end gap is equal to the backlash of the

ring notch on pin. Therefore, if the ends of

a ring are filed to obtain the correct ring

end gap, the notch has to be filed enough to

provide the backlash in equal amount.

1. Inner Groove Up

2. Oil Control Ring

3. Oil Control Ring "U" Flex

FIGURE 26—Ring Installation

"Rambler" Series

The "U" flex oil control ring used in the

lower oil control ring groove, as original

equipment, differs from all other rings. The

normal free diameter of this ring is 1/8" to

3/1_6" larger than the bore diameter in which

it is installed. Installation is outlined in

Figures 27, 28, 29, and 30.

Before installing piston in engine,

arrange ring gaps 180° apart, being sure no

gap is over the piston pin.

Service Ring Sets

For service ring replacement, follow detailed instructions enclosed in the ring

package.

Page 15

12

TECHNICAL SERVICE MANUAL

FIGURE 27—Step 1—Place "U" Flex Ring in

Bottom of Oil Ring Groove. Lubricate all

Rings and Piston Skirt with a Light

Grade Engine Oil. Butt Ends of

"U" Flex Ring Together

FIGURE 28—Step 2—Keep Ends of "U" Flex

Ring Butted Together and Place Compressor

Over Piston, Either a Constricting Band

or Split Sleeve Type Compressor

can be Used

FIGURE 30—Step 4—Make Sure Compressor

Rests Squarely on Top of Block, and

Push or Tap Piston into Cylinder

CAUTION: If Piston Does not Enter

Cylinder without Excessive Force, Remove Piston Assembly and Examine Rings

for Ring Interference.

PISTON PINS

"Hornet" and "Wasp" Series

Full floating type piston pins are used. They

are retained in the piston by two circular

lock rings, one at each end of the pin. The

piston pin fit in the connecting rod bushing

is a hand push fit at room temperature (70°).

The piston pin fit in the piston is a

hand push fit in a heated piston. Heat piston

in water or electric furnace to 200°F.

The piston pin bushings are steel back

bronze. To remove and replace, press out old

bushing, using burnisher block tool J-2950

and remover J-2948 for the "Hornet" Series,

and J-2951 and J-2948 "Wasp" Series. Install

new bushing with same tools making sure oil

holes in bushing and rod are in alignment.

Burnish bushing with block J-2950 and burnisher J-2791 "Hornet" Series, and J-2951 and

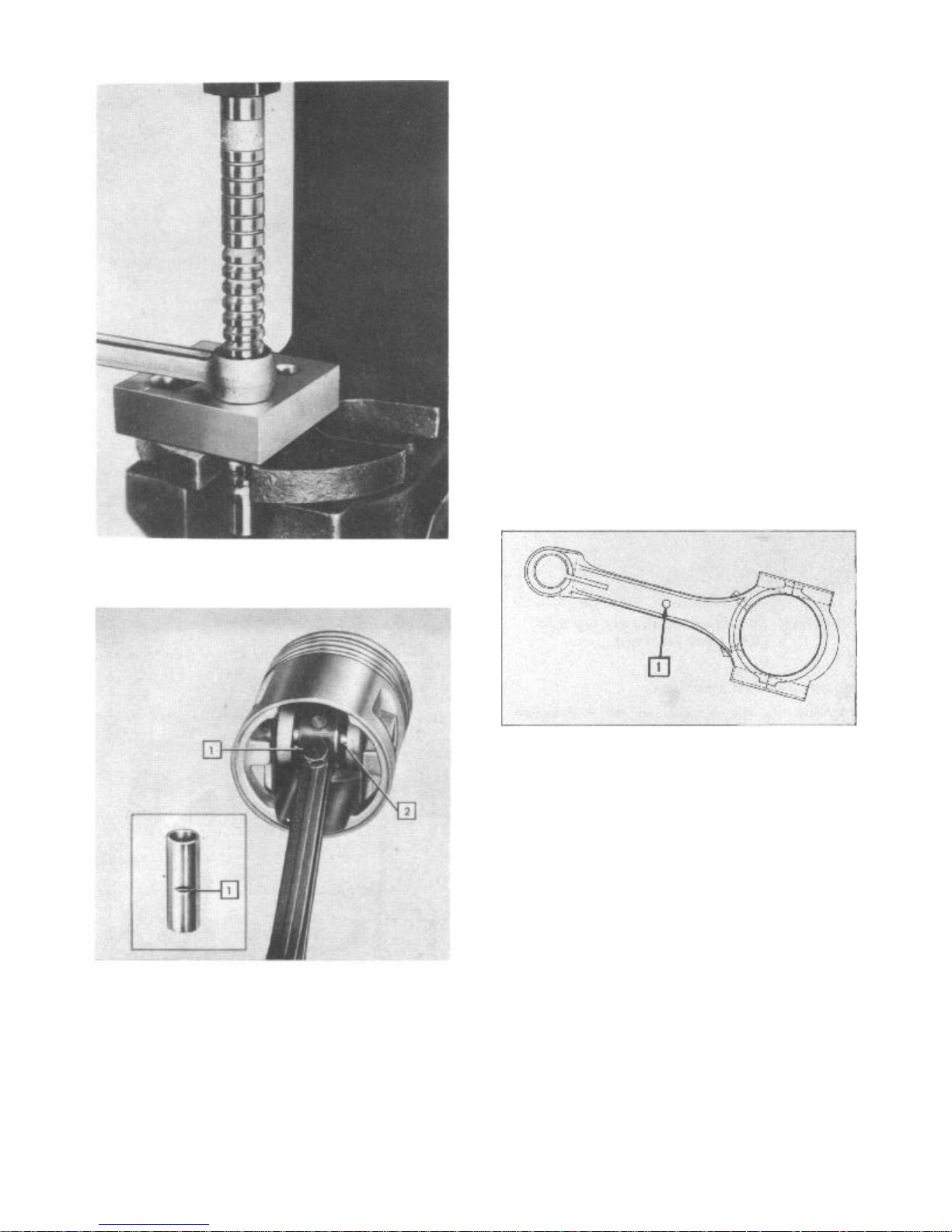

J-2949 "Wasp" Series (Fig. 31).

The bushing should be reamed .0003"

larger than its matching pin diameter. Check

the fit by holding the piston with the

connecting rod in a horizontal position. The

rod should just turn on the pin under its own

weight.

FIGURE 29—Step 3—Tighten Ring Compressor

if Band Type is Used. If Sleeve Type is Used,

BE SURE THAT IT IS NOT PULLED

HIGHER THAN THE TOP OF THE

PISTON. However, it Should be

Drawn up High Enough to

Cover all of the Rings

The standard piston pin dimensions are:

“Hornet”

“Wasp”

Length

2.942" — 2.932"

2.4375" + or

—.005"

Diameter

.9687" — .96845"

.7499" + .000"

—.00025"

"Rambler" Series

The piston pin is locked in place in the

connecting rod by means of a locking bolt

(Fig. 32).

To fit the piston pin, hone the connecting rod to fit the pin. Then hone the piston

to allow a thumb press

Page 16

ENGINE 6 CYLINDER

Tighten piston pin clamp screw to 18-22

foot pounds torque.

CONNECTING RODS

"Hornet" and "Wasp" Series

The connecting rods have oil squirt holes to

provide cylinder wall lubrication, at low and

idle speed, to the thrust side of the

cylinders. An oil hole on the top of the rod

supplies lubrication to the piston pins.

When installing connecting rods, the

squirt hole is toward the camshaft side

(thrust side) of the engine.

The cylinder location numbers are stamped

on the connecting rod and caps during initial

assembly.

"Rambler" Series

Two oil squirt holes are provided in the

upper rod cap section for cylinder wall

lubrication at low and idle speeds.

The notch on the top perimeter of the

piston and the identification boss on the

connecting rod (Fig. 33) must be installed

to the front of the engine.

13

FIGURE 31—Burnishing Connecting Rod

Bushing "Hornet" and "Wasp" Series

1. Locking Bolt and Notch

2. Piston Pin

FIGURE 32— Piston Pin "Rambler" Series

fit or .0002" maximum loose fit in piston at

room temperature (70°F.).

The standard piston pin dimensions are:

Length 2.755", Diameter .8598"-.8595".

1. Identification Boss

FIGURE 33—Connecting Rod Identification

Boss "Rambler" Series

The connecting rods are stamped by cylinder number location during initial assembly.

Always assemble the rods and caps with the

cylinder location numbers on the same side.

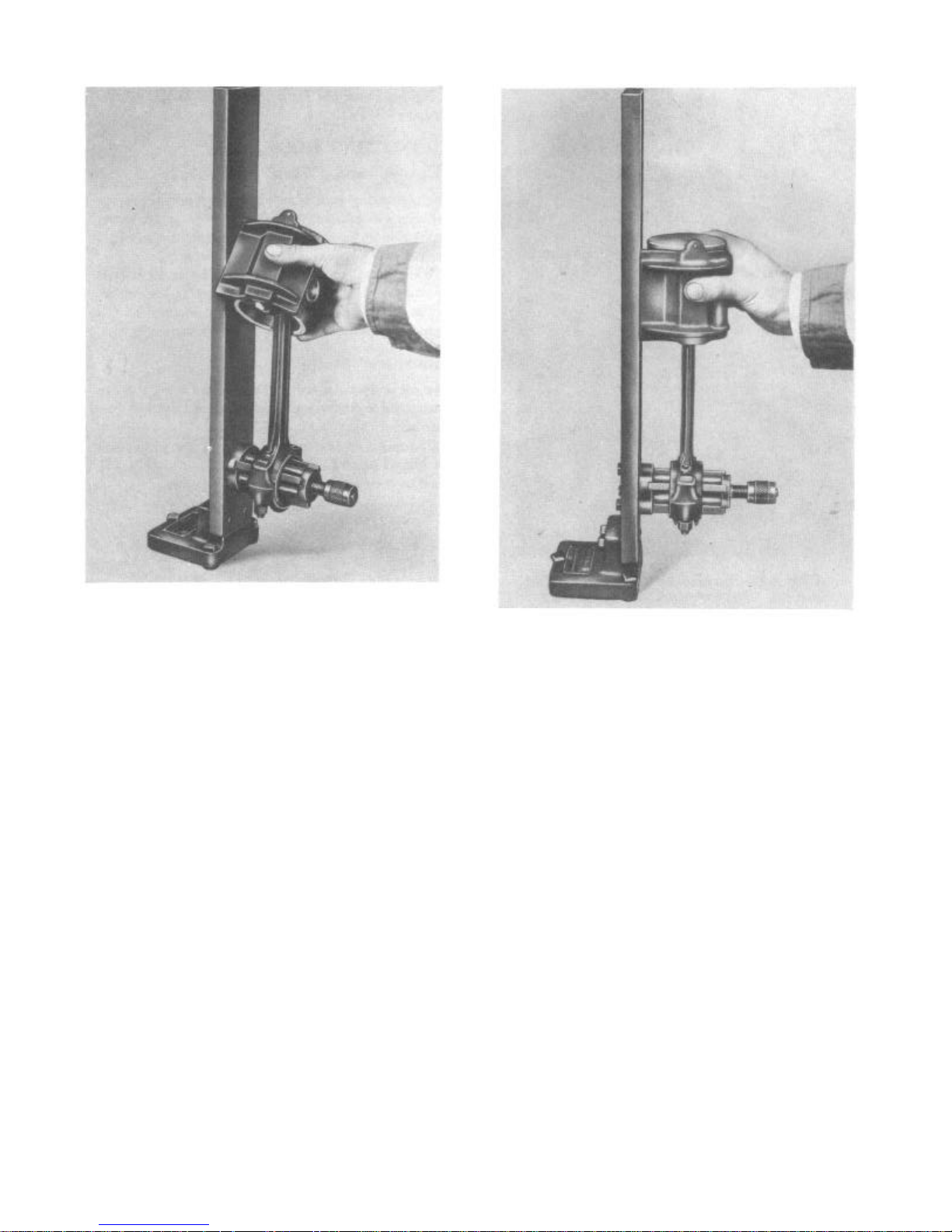

Connecting Rod Alignment

Whenever new rings are installed or new

piston pins are replaced, it is necessary to

align the connecting rods and pistons, as

assemblies, to insure true operation in the

cylinder bore.

Misaligned rods will cause uneven piston

and ring wear which will result in oil

consumption and noise. The connecting rod

should be inspected for a twisted or bent

condition (Figs. 34 and 35).

Always bend beyond the true alignment

position and then bend back to straighten so

the stresses and strains in the rod material

are relieved. If the stresses are not

relieved, the rod will not hold its alignment

after installation in the engine.

Page 17

14

TECHNICAL SERVICE MANUAL

FIGURE 34—Checking Connecting Rod

Alignment for Twist

Connecting Rod Bearings

The connecting rod bearings are the steel

backed babbitt lined precision type. They are

installed as pairs in connecting rod and cap.

CAUTION: Never file a connecting rod or

cap to adjust bearing clearance.

If the bearing clearance is excessive,

the correct connecting rod undersize bearing

set must be installed. The correct connecting

rod bearing clearance is .0005" to .0015"

"Hornet" and "Wasp" Series and .001" to

.0015" on "Rambler" Series.

To determine the amount of bearing

clearance, use a piece of Plastigage in the

bearing cap as shown in Figure 36. Then

tighten the cap to the torque specification

to compress the gauge.

Remove the bearing cap and calibrate the

width of the Plastigage with the scale

furnished as shown in Figure 37.

Connecting Rod Bearing Caps

FIGURE 35—Checking Connecting Rod

Alignment for Bend

It is important that the connecting rod cap

bolt nuts be drawn up to the correct tension.

Tighten to:

"Hornet" 40-45 Ft. Lbs.

"Wasp" 40-50 Ft. Lbs.

"Rambler" 27-30 Ft. Lbs.

FIGURE 36—Plastigage in Place in the

Bearing Cap

Page 18

ENGINE 6 CYLINDER

FIGURE 37—Measure the Width of the

Plastigage Scale

Reduce torque 15 per cent if threads are

oily

The notches on the lower and upper rod

caps should be to the same side of engine

with the squirt hole on upper cap to camshaft

side of engine on the "Hornet" and "Wasp"

Series.

The cylinder numbers are to the camshaft

side of the engine and the identification

mark (Fig. 33) to the front of engine on the

"Rambler" Series.

Connecting rod side clearance:

"Hornet" and "Wasp" .007" — .013"

"Rambler" .005" — .015"

CRANKSHAFT

"Hornet" and "Wasp" Series

The crankshaft is supported by four main

bearings with the end thrust taken at the No.

3 bearing position.

The crankshaft, flywheel, and vibration

damper are balanced as individual units.

Complete engine assemblies are then balanced

with all reciprocating parts in motion.

Replacement of vibration damper or flywheel

can be accomplished without rebalancing the

complete assembly.

15

caps should never be filed.

When either half of a bearing requires

replacement, a complete set should be installed. To replace the upper half of a

bearing, remove the bearing cap of the

bearing to be replaced. Then loosen all of

the other bearing caps and insert a small pin

in the crankshaft oil hole. The head of the

pin should be large enough so that it will

not fall into the oil hole, yet thinner than

the thickness of the bearing (Fig. 38).

FIGURE 38—Removing Main Bearing Insert

With the pin in place, rotate the shaft so

that the upper half of the bearing will

rotate in the direction of the locating

tongue on the bearing.

Tool J-2955 will greatly facilitate front and

rear bearing cap removal on the "Hornet" and

"Wasp" Series (Fig. 39).

CAUTION: Care must be exercised on

removal of the front main bearing cap

because if the front engine end plate

gasket is damaged, a replacement requires the removal and replacement of

timing assembly and front engine end

plate.

"Rambler" Series

The crankshaft is supported by four main

bearings with the end thrust taken at the

front main bearing location.

The component parts of the crankshaft

assembly are individually balanced; then

rebalanced as an assembly.

Replacement of vibration damper or flywheel can be accomplished without rebalancing

the complete assembly.

Crankshaft. Main Bearings

Main bearings are of the precision type

having a steel back with a babbitt lining.

The bearings are not adjustable. Shims should

never be used and the bearing

FIGURE 39— Removing Front Min Bearing

Cap with Tool J-2955 "Hornet" and

"Wasp" Series

Page 19

Crankshaft Main Bearing Clearance

The standard clearance of .0005" to .0015"

on the "Hornet" and "Wasp' Series and .001"

to .0015" "Rambler" Series can be accurately

checked by the use of Plastigage.

NOTE: When checking bearing clearance

with the engine in such a position

that the bearing caps support the

weight of the crankshaft and flywheel, keep all main bearing caps

tight except the one being checked.

Support the weight o f the crankshaft

with a jack.

Remove the bearing cap and wipe the oil

from the bearing insert.

Place a piece of Plastigage across the

full width of the bearing insert (Fig. 36).

Reinstall the bearing cap and tighten

75-80 foot pounds torque (dry) on the

"Hornet" and "Wasp" Series and 66-70 foot

pounds torque (dry) on the "Rambler" Series.

Then remove the bearing cap and with the

graduated scale, which is printed on the

plastigage envelope, measure the width of the

flattened plastigage at its widest point

(Fig. 37). The number within the graduation

indicates the clearance in thousandths of an

inch. Install the proper size bearing liners

(inserts) to bring the clearance to standard.

Before installing crankshaft or main bearing

inserts, the journals must be inspected for

condition and dimensions.

Main Bearing Journals

Main journals can be measured without removing the crankshaft from the engine block.

There are various gauges for this use, one

of which is shown in Figure 40.

Then release the plunger so that it is up

against the journal and lock the adjusting

screw in position. Remove the gauge carefully

and double the micrometer reading across the

pin and anvil in the center of the

"V". This reading is the diameter of the

journal.

Always check the journal at both ends for

taper. Then rotate the shaft 90° and measure

for out-of round. The out-of-round and taper

limit is to be held to .001".

Main Journal

Series Diameter

"Hornet" 2.4988"-2.4998"

"Wasp" 2.4988"-2.4998"

"Rambler" 2.4791"-2.4798"

Connecting Rod Bearing or

Series Crankpin Diameter

"Hornet" 2.1244"-2.1254"

"Wasp" 1.937" -1.938"

"Rambler" 2.0948"-2.0955"

Main bearing caps are recessed into the

engine block and line reamed. Therefore, it

is not practical to replace them in the field.

Crankshaft End Play

The "Hornet" and "Wasp" Series end thrust of

.003" to .009" is taken at the No. 3 main

bearing. The "Rambler" Series end thrust of

.003" to .008" is taken at the flanged front

main bearing.

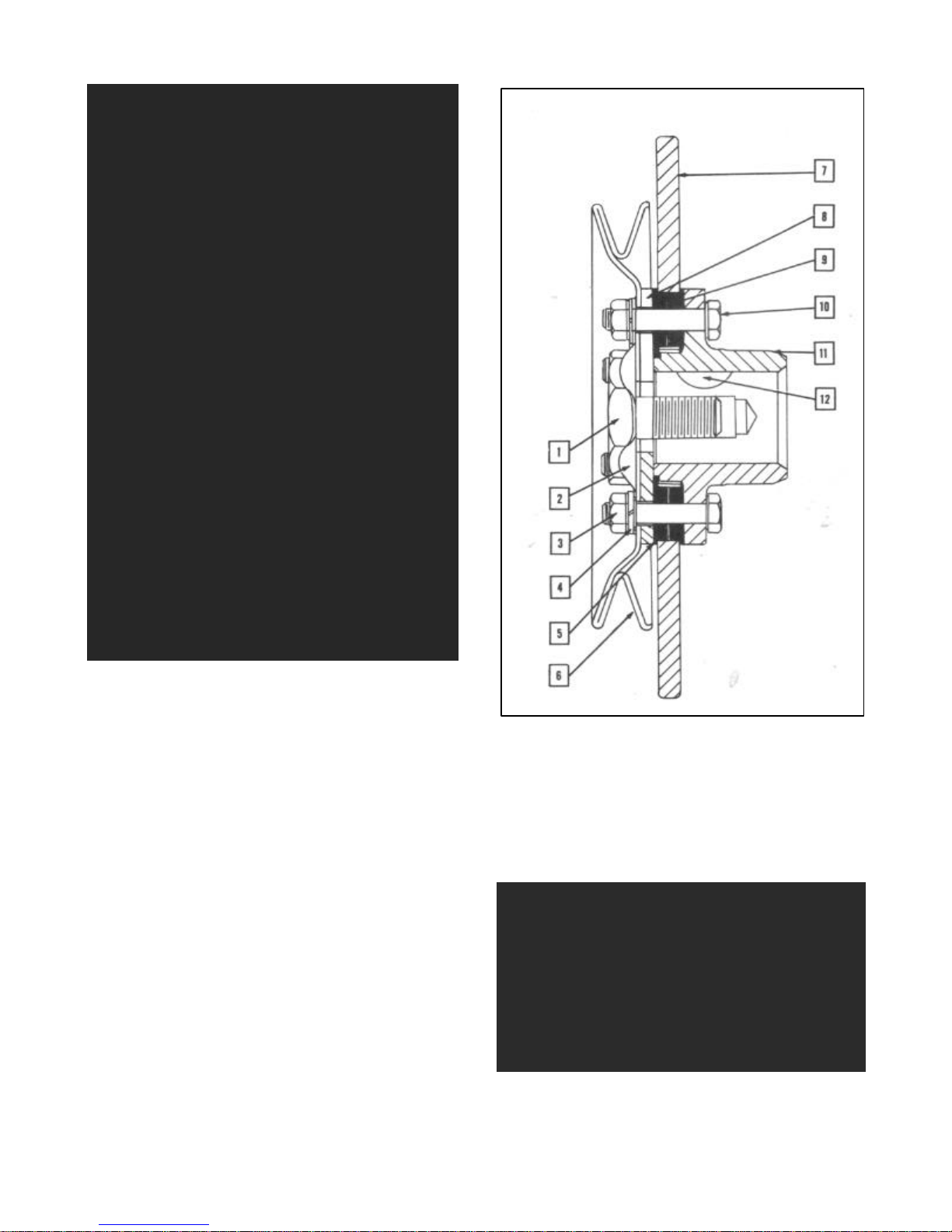

MAIN BEARING OIL SEALS

"Hornet" and "Wasp" Series

The rear main bearing oil seal is a metal

backed neoprene lined seal made in two

identical halves. The upper half can be

removed without removing the crankshaft by

removing the rear main bearing cap and

applying pressure against the metal part of

the seal with a 1/4" brass rod. At the same

time, rotate the flywheel to assist in

removing the seal.

At time of installation of the seals, coat

the groove of the seal with non-hardening

sealer.

FIGURE 40—Measuring Main Bearing Journal

To operate this gauge, remove the main

bearing cap and place the gauge against the

crankshaft journal

1. Packing Groove

2. Oil Seal

FIGURE 41—Rear Main Bearing Oil Seal

"Hornet" and "Wasp" Series

Page 20

ENGINE 6 CYLINDER

After the rear main bearing cap is replaced,

cotton waste must be driven into the vertical

packing holes to seal the side of the cap. A

punch smaller in diameter than the vertical

holes and at least 4" long will facilitate

the packing of the cotton waste. Enough

packing must protrude to seal between the pan

gasket and bearing cap.

The front main bearing cap has both a

horizontal and a vertical seal to prevent

external oil leakage. This packing seals from

leakage between the engine front end plate

gasket and the bearing cap. The vertical

grooves are packed before the horizontal

grooves (Fig. 42).

17

FIGURE 42— Front Bearing Cap Oil Seal

Groove Locations "Hornet" and

"Wasp" Series

"Rambler" Series

A hemp packing and "L" shaped neoprene rubber

type rear main bearing oil seals are used. A

special tool J-1610 is required to install

the hemp packing (Fig. 43) . To properly

replace upper hemp packing, the crankshaft

must be removed.

VIBRATION DAMPER

"Hornet" Series

The vibration damper (Fig. 45) on the "Hornet"

Series has two punch marks for alignment to

maintain proper balance when the damper is

disassembled for replacement of rubber discs.

2. Point at which Packing is Cut Flush

1. Oil Seal Installing Tool J-1610

FIGURE 43—Installing Hemp Packing Oil Seal

in Rear Main Bearing Cap "Rambler"

Series

1. Hemp Packing

2. Cap Side Seal

3. Cap Side Seal

4. Main Bearing Cap

FIGURE 44— Rear Main Bearing Cap and Seals

"Rambler" Series

Pulley Remover J-676-C and Replacer J-483

will facilitate removal and replacement

operations (Fig. 18).

Page 21

18

TECHNICAL SERVICE MANUAL

1. Outer Member 5. Spacer

2. Rubber Discs 6. Oil Seal

3. Inner Member 7. Retainer Plate

4. Damper Cap Screw

FIGURE 45—Vibration Damper "Hornet"

Series

Tighten damper cap screw to 100-120 foot

pounds torque.

"Wasp" Series

The vibration damper has an off-set screw

location to insure proper reassembly for

balance in the event disassembly was made to

replace rubber cushions.

Pulley Remover J-5371 and Replacer J-5369

will facilitate removal and replacement

operations (Fig. 19)

Tighten damper cap screw to 80-90 foot

pounds torque.

"Rambler" Series

The vibration damper is not adjustable. The

screws that retain the rubber are drawn up

to a point where the shoulders will limit the

tension of the rubber blocks (Fig. 47).

1. Damper Cap Screw 8. Damper Cover Plate

2. Cap Screw Lock 9. Rear Damper Cushion

3. Nut 10. Pulley to Damper

4. Lockwasher Screw

5. Front Damper Cushion 11. Hub

6. Damper Pulley 12. Key

7. Damper

FIGURE 46— Vibration Damper "Wasp" Series

FIGURE 47—Vibration Damper "Rambler"

Series

Tighten damper cap screw to 100-110 foot

pounds torque

Page 22

ENGINE 6 CYLINDER

19

STARTER RING GEAR

With the exception of the flywheel, as used

with the automatic transmission, which is a

steel stamping, the starter ring gear can be

replaced by placing the flywheel in an arbor

press with steel blocks equally spaced around

the gear and pressing the flywheel through,

or the ring gear can be broken with a chisel.

To install the new starter ring gear, first

heat it to expand the inside diameter so that

it can be pressed over the flywheel.

SHAFT PILOT BEARING

The pilot bearing for the shaft is located

at the center of the rear end of the

crankshaft. This is an oil impregnated bronze

bearing. It is pressed into the end of the

crankshaft. This bearing does not require any

lubrication after assembly. When assembled

in service, it is advisable to place a small

amount of high melting point grease on the

end of the shaft as it is installed into the

bearing. Bearings being installed must be of

the correct size for the series and type of

transmission.

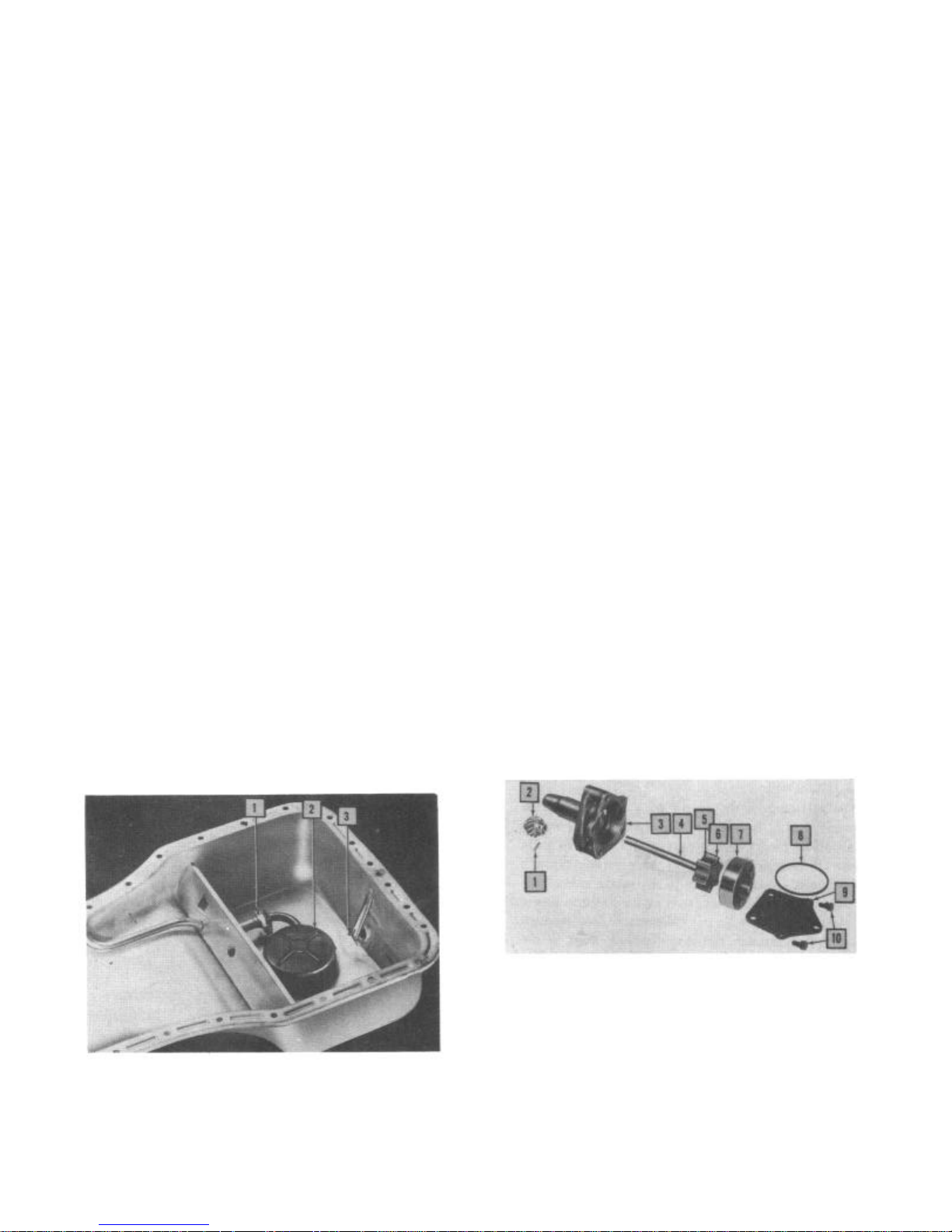

LUBRICATION SYSTEM

The lubrication system is of the full

pressure type with all vital moving parts

receiving lubrication under pressure except

the piston pins.

"Hornet" and "Wasp" Series

The pressure is supplied by a positive

displacement rotor type oil pump mounted on

the right lower side of cylinder block and

driven from a gear cut on the camshaft.

The oil is drawn through the floating oil

intake screen (Fig. 48) to the intake side

of the oil pump.

Oil under pressure passes the plunger of

the oil relief valve assembly and fills the

main horizontal oil gallery from which it is

directed through drilled passages to lubricate the camshaft bearings, tappet assembly,

main and connecting rod bearings, cylinder

walls, and timing assembly.

Piston pins are lubricated by oil "throwoff" from rotating parts and wiping action

of piston rings.

Before removing the oil pump, position the

engine crankshaft so that No. 1 cylinder

piston is at T.D.C. exhaust stroke and No. 6

cylinder piston is at T.D.C. on compression

stroke.

Upon disassembly of the oil pump, remove

the oil pump cover and use a brass drift to

mark an indexing point of one lobe and notch

on rotor and internal gear or outer rotor to

insure relationship for reassembly.

Measure the clearance between a lobe and

notch opposite the reference mark. This

clearance should be .010" or less. If more

than .010", replace both rotors and shaft.

Place a straight edge across the pump body

between the screw holes. Use a feeler gauge

to measure the clearance between the top of

the rotors and the straight edge. This

clearance should be .004" or less. If the

clearance is greater than this limit, the

pump body must be replaced.

With the outer rotor pressed against one

side of the pump body, measure the clearance

between this rotor and the body on the

opposite side. If this clearance is more than

.008", replace the pump body.

The pump cover plate must be smooth and

not worn from the rotors. Place a straight

edge across the cover. If a .002" feeler can

be inserted between the cover and the

straight edge, the cover is worn and must be

replaced.

1. Swivel Connectlon

2. Intake Screen

3. Drain Plug Outlet

FIGURE 48— Oil Intake Screen Assembly

"Hornet" and "Wasp" Series

1. Oil Pump Drive Gear Pin

2. Oil Pump Drive Gear

3. Oil Pump Body

4. Oil Pump Shaft

5. Oil Pump Inner Rotor

6. Inner Oil Pump Rotor Lobe

7. Outer Oil Pump Rotor

8. Oil Pump Cover Gasket

9. Oil Pump Cover

10. Oil Pump Cover Screws

FIGURE 49—Oil Pump Assembly "Hornet"

and "Wasp" Series.

Page 23

20

TECHNICAL SERVICE MANUAL

In the event the engine crankshaft was not

moved, replacement of the oil pump presents

no problem. However, if the crankshaft was

moved, the following procedure can be used

to insure basic distributor timing location

inasmuch as the distributor is driven by the

oil pump shaft.

Crank the engine until the No. 1 cylinder

piston is on T.D.C. exhaust stroke and No. 6

is on T.D.C. in firing position.

Install Aligning Tool J-2794 so that the

guide pin indexes with the distributor

mounting screw hole (Fig. 50).

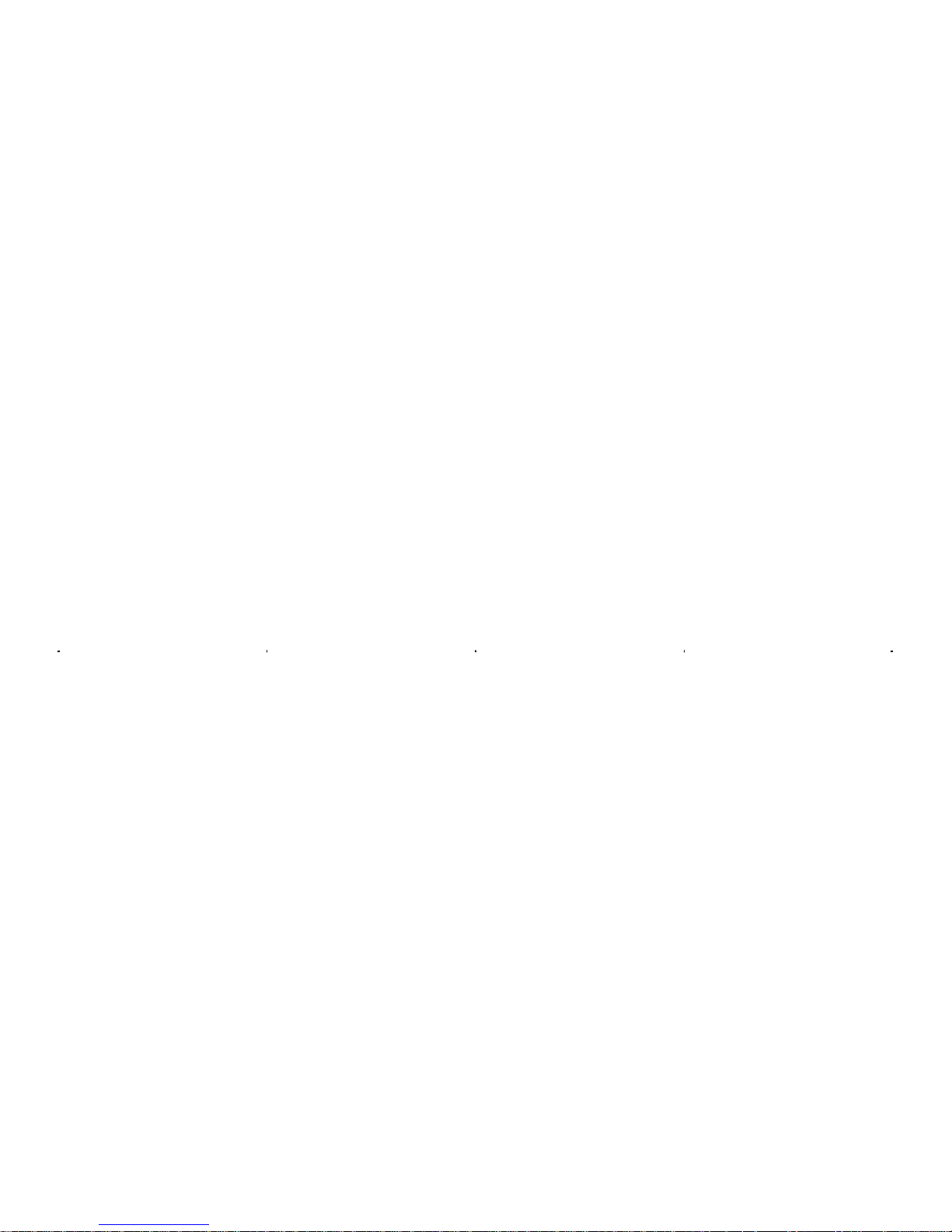

1. Screen and Retainer 9. Idle Gear

2. Bolt 10. Key

3. Inlet Tube Gasket 11. Oil Pump Drive Shaft

4. Bolts 12. Oil Pump Idle Shaft

5. Cap Screws 13. Oil Pump Body

6. Oil Pump Cover 14. Oil Pump Drive Gear Pin

7. Gasket 15. Thrust Washer

8. Drive Gear (In Pump) 16. Oil Pump Drive Gear

FIGURE 51— Oil Pump "Rambler" Series

FIGURE 50—Oil Pump Shaft Aligning Tool

Install the oil pump, indexing the slot

in the pump shaft with the tang on aligning

tool, and push out the tool.

Install distributor with rotor aligned

with terminal in distributor cap which leads

to No. 6 cylinder spark plug.

"Rambler" Series

The oil pump is mounted on the right hand

side of the cylinder block. It is of the

positive displacement gear type.

The oil pump is driven off of a gear cut

on the camshaft and in turn drives the

distributor by means of an off-set tang which

is part of the oil pump main shaft. Oil is

drawn from the oil pan reservoir through a

fixed inlet screen assembly to the intake

side of the oil pump. The oil is discharged

under pressure past a relief valve in the

main oil gallery and then through holes

drilled through the main bearing webs to the

crankshaft and camshaft main bearing locations. The crankshaft drillings provide

lubrication from the main bearings to the

connecting rod bearings. The front camshaft

bearing permits oil to flow onto the timing

gear and chain assembly.

The valve tappets and piston pins are

lubricated by crankshaft oil "throw-off" and

vapors.

CAUTION: Always maintain a tight

connection between the oil pump inlet

flange and oil inlet hole located on

the right side at the bottom of the

cylinder block

The position of the oil pump drive gear

keyway should be noted before removal of oil

pump. Installing in the same location will

prevent disturbance of distributor timing.

In the event the crankshaft has been moved,

crank the engine until No. 1 cylinder is at

T.D.C. in firing position. The keyway will

be located at approximately the three-thirty

o'clock position, viewed from the lower

section of the pump body.

Oil Pressure Relief Valve

The oil pressure relief valve consists of a

plunger, spring, and retainer.

The valve is located on the left side of

the cylinder block on the "Hornet" and "Wasp"

Series and the right side of the cylinder

block on the "Rambler" Serieas.

The oil pressure relief valve is not

adjustable. A setting of 40 P.S.I. for the

"Hornet" and "Wasp" Series and 50-58 P.S.I.

for the "Rambler" Series is built into the

tension of the spring.

1. Housing Plug 3. Spring

2. Gasket 4. Plunger

FIGURE 52— Oil Pressure Relief Valve

"Rambler" Series

Page 24

ENGINE 6 CYLINDER

ENGINE SPECIFICATIONS

21

Series

Type

No. Cylinders

Bore

Stroke

Compression Ratio

(Standard)

(Optional)

Piston Displacement

Compression Pressure

at Cranking Speed

Horsepower

Twin Carburetor

Engine Lubrication

Series

Stem Diameter

Intake

Exhaust

"Hornet"

L-Head

6

3-13/16"

41/2"

7.5:1

308 Cu. In.

100 P.S.I. Min.

160 @

3800 R.P.M.

170 @

4000 R.P.M.

Pressure

VALVE SPECIFICATIONS

"Hornet"

.3412"-.3422"

.3402"-.3412"

"Wasp"

L-Head

6

3"

43/4"

7.5:1

8.0:1

202 Cu. In.

100 P.S.I. Min.

115 @

4000 R.P.M.

126 @

4000 R.P.M.

Pressure

"Wasp"

.3412"-.3422"

.3402"-.3412"

"Rambler"

L-Head

6

3W'

41/4"

7.32:1

195.6 Cu. In.

120 P.S.I.

90 @

3800 R.P.M.

Pressure

"Rambler"

.3407"-.3412"

.3407"-.3412"

Stem to Guide Clearance

Intake

Exhaust

Head Diameter

Intake

Exhaust

Seat Angle

Intake

Exhaust

Valve Face Angle

Intake

Exhaust

Valve Spring Free Height

Valve Spring Pressure

Valve Open

Valve Closed

Spring Retainer Lock

.0015"-.003"

.002"-.004"

1.831"

1.556"

45°

45°

45°

45°

2-1/2"

153-165 Lbs.

@ 1-27/32

73-81 Lbs.

@ 23/16"

Split Two Piece

.001"-.003"

.002"-.004"

1.495"-1.505"

1.390"-1.400"

45°

46°

45°

46°

2-1/2"

116-124 Lbs.

@ 1-13/32"

40-48 Lbs.

@ 1-61/64"

Split Two Piece

.0018"-.0033"

.0018"-.0033"

1.594"

1.343"

45°

45°

44º

44°

2-1/2"

75-82 Lbs.

@ 17/16"

37-41 Lbs.

@ 1-3/4"

Single Horseshoe

Tappet Clearance

Cold Setting

Intake

Exhaust

.010" "Go"

.011" "No-go"

.014" "Go"

.015" "No-go"

.010" "Go"

.011" "No-go"

.014" "Go"

.015" "No-go"

.016"

.018"

Page 25

22

TECHNICAL SERVICE MANUAL

OIL SYSTEMS

Series

Oil Pump Type

Normal Oil Pressure

Oil Pressure Release

Engine Oil Refill

Capacity

Series

Bearing Type

No. of Main Bearings

Main Bearing Clearance

Diameter

Shaft End Play

End Thrust Taken By

Bearing Cap

Adjustment

"Hornet"

Rotor

40 P.S.I. @

30 M.P.H.

40 P.S.I.

7 Qts.

CRANKSHAFT AND BEARINGS

"Hornet"

Replaceable

4

.0005"-.0015"

24988"-2.4998"

.003"-.009"

No. 3 Main Bearing

75-80 Ft. Lbs.

(Dry)

"Wasp"

Rotor

40 P.S.I. @

30 M.P.H.

40 P.S.I.

5 Qts.

7

"Wasp"

Replaceable

4

.0005"-.0015"

2.4988"-2.4998"

.003"-.009"

No. 3 Main Bearing

75-80 Ft. Lbs.

(Dry

"Rambler"

Gear

30 P.S.I. @

20 M.P.H.

12 P.S.I. Min.

@ 600 Engine R.P.M.

50-58 P.S.I.

4 Qts.

"Rambler"

Replaceable

4

.001"-.0015"

2.4791"-2.4798"

.003"-.008"

Front Main Bearing

66-70 Ft. Lbs.

(Dry)

Series

No. Rings Per

Piston

End Gap

(Except "U"

Flex Ring)

Compression Ring Side

Clearance in Ring

Groove

Oil Ring Side Clearance

in Ring Groove

Series

Bearing Type

Bearing Clearance

Crankpin Diameter

Bearing End Play

Bearing

PRODUCTION PISTON RINGS

"Hornet"

4

.006"-.014"

.002"-.004"

.001"-.003"

"Wasp"

.004"-.009"

.002"-.004"

.001"-.003"

CONNECTING ROD AND BEARING

"Hornet"

Replaceable

.0005"-.0015"

2.1244"-2.1254"

.007"-.013"

40-45 Ft. Lbs.

(Dry)

"Wasp"

Replaceable

.0005"-.0015"

1.937"-1.938"

.007"-.013"

40-50 Ft. Lbs.

4

(Dry)

"Rambler"

4

.010"-.020"

.002"-.004"

.002"-.004"

"Rambler"

Replaceable

.001"-.0015"

2.0948"-2.0955"

.005"-.015"

27-30 Ft. Lbs.

(Dry)

Page 26

ENGINE 6 CYLINDER

TUNE-UP DATA

23

Series

"Hornet"

"Wasp"

"Rambler"

Engine Idle Speed—Transmission in Neutral, Air

Conditioning on.

"Hornet" and "Wasp" 540-560 R.P.M. (Standard

Transmission)

575 R.P.M. (Overdrive

Transmission)

490-510 R.P.M. (Hydra Matic)

"Rambler" 500-550 R.P.M. (Standard

and Overdrive)

475 R.P.M. (Hydra Matic)

500 R.P.M. (With

Air Conditioning on)

Compression Pressure at Cranking Speed —

"Hornet" and "Wasp" 100 P.S.I. Minimum

"Rambler" 120 P.S.I.

Spark Advance (See Electrical Section—Distributor)

Firing Order-1, 5, 3, 6, 2, 4

Plug

Gap

.032"

.032"

.030"

Int. Exh.

.10" "Go"

.11" "No-go"

.010 "Go"

.11" "No-go"

.016"

Tappet Clr. Cold

.14" "Go"

.15" "No-go"

.14" "Go"

.15" "No-go"

.018"

Distributor

Point Gap

.020"

.020"

.018"-.024"

Positive Battery Terminal Grounded

Coil—Secondary Terminal Tower, Negative Polarity

Breaker Point Spring Tension—

"Hornet" and "Wasp" 17-20 Ounces

"Rambler" 17-21 Ounces

Spark Plugs"Hornet"—Champion H-11 Torque 25 Ft. Lbs.

(Aluminum Head)

"Wasp"—Champion H-10 Torque 30 Ft. Lbs.

(Cast Iron)

25 Ft. Lbs. (Aluminum Head)

"Rambler"—Auto-Lite A-7 Torque 30 Ft. Lbs.

(Cast Iron)

Cylinder Head—Nut or Cap Screws Torque Specifications—

"Hornet"-75-80 (Cold)

"Wasp"-60-65 (Operating Temperatures) Cast

Iron (Cold) Aluminum

"Rambler"-57-60 (Operating Temperature)

Dwel

Angle

38º

38º

31º-37º

Igniton Timing

T.D.C.

at Idle Speed

T.D.C.

at Idle Speed

4° A.T.D.C.

at Idle Speed

Description

Cylinder Head

Exhaust Pipe Clamp Nut

Exhaust Manifold

Intake Manifold

Oil Pan Bolt

Timing Chain Cover

Piston Pin Clamp Screw

Connecting Rod Cap Nuts

Crankshaft Main Bearing

Cap Screws

Vibration Damper

Retaining Screw

Flywheel Retaining Cap

Screw or Nuts

Camshaft Sprocket Screw

*Aluminum cylinder heads are tightened at room temperature (70° F.).

ENGINE TORQUE TIGHTENING CHART

(Foot Pounds Dry)

"Hornet"

*75-80

20-35

12-15

15-20

15-20

40-45

75-80

100-120

40-45

20-30

"Wasp"

*60-65

20-30

12-15

15-20

15-20

40-50

75-80

80-90

40-45

20-30

"Rambler"

57-60

10-15

15-20

15-20

18-22

27-30

66-70

65-70

100-110

50-55

Page 27

24

TECHNICAL SERVICE MANUAL

TECHNICAL SERVICE LETTER REFERENCE

Date Letter No. Subject Changes of informatin on Page. No.

Page 28

Page 29

2

ENGINE SECTION

V-8

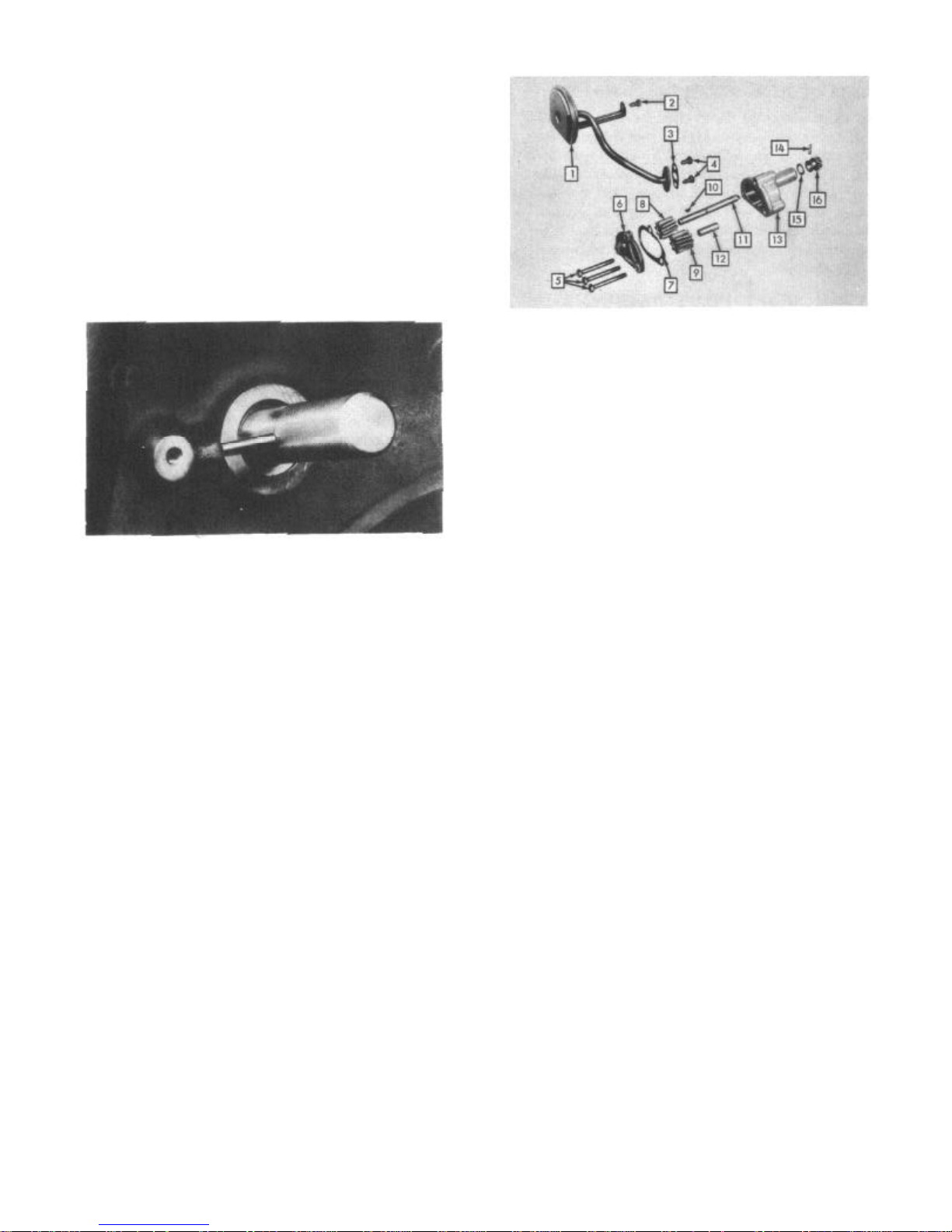

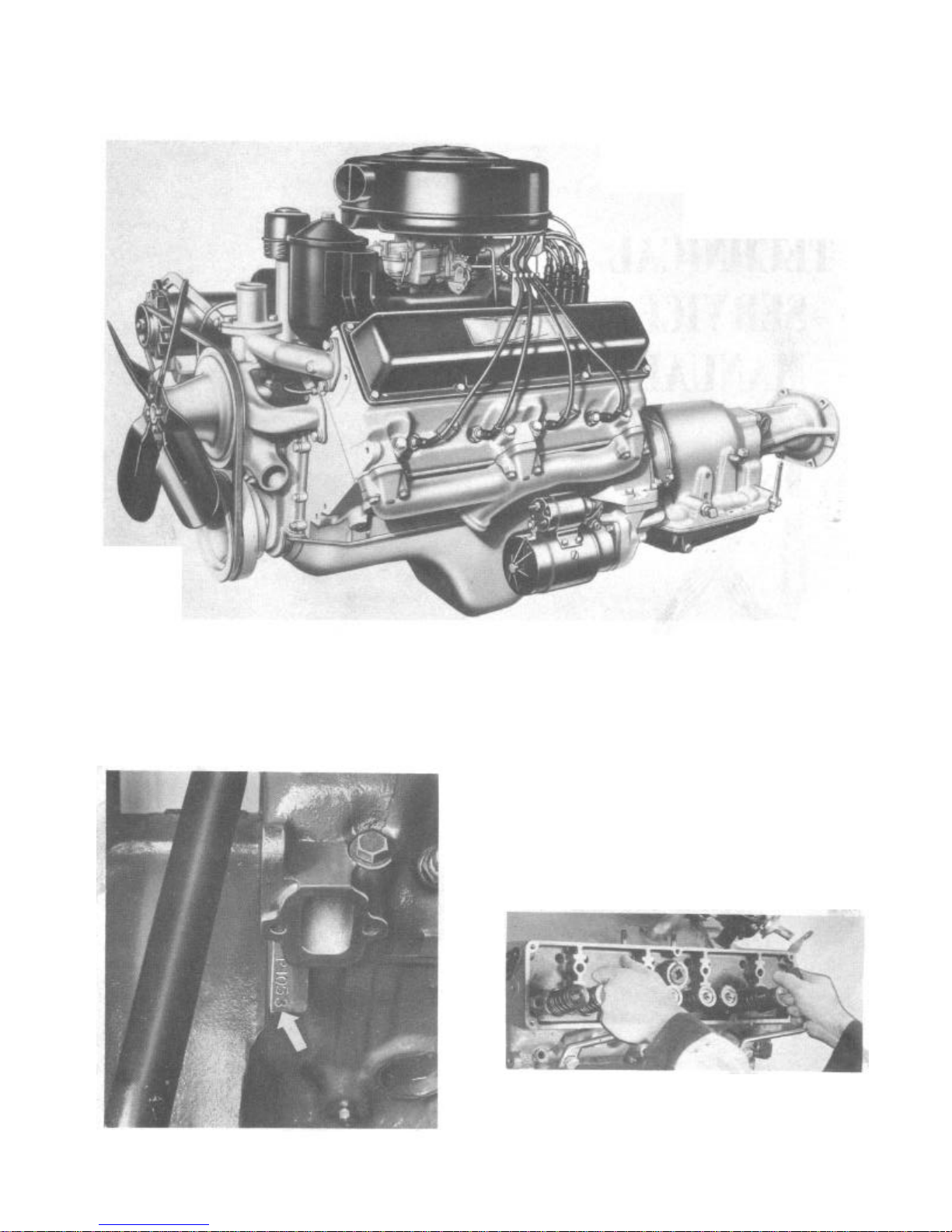

FIGURE 1—V-8 Engine Assembly

ENGINE IDENTIFICATION

The engine number is located at the right

rear upper corner of the cylinder block below

the rear exhaust manifold port (Fig. 2)

FIGURE 2—Engine Number Location

CYLINDER HEAD AND GASKET

After thoroughly cleaning the top surface of

the block and the bottom surface of the

cylinder head, inspect each for smooth and

flat surfaces with a straight edge.

The cylinder block surface has two sleeve

locating dowels to assist in lining up and

holding position of cylinder head and gasket

during installation or removal.

Coat the gasket with a non-hardening

gasket paste. For convenience in removing and

installing the cylinder head, use Tool J-4159

(Fig. 3).

FIGURE 3—Removing or Installing Cylinder

Heads with Tool I-4159

After installing the push rods, rocker arm

assembly, and cylinder head cap screws, tighten

them evenly.

Page 30

ENGINE V-8

Then retighten to 55 to 60 foot pounds with

torque wrench following the sequence outlined

in Figure 4.

3

FIGURE 4—Torque Tightening Sequence

55-60 Ft. Lbs.

ROCKER ARM AND SHAFT ASSEMBLY

The rocker arm shaft assembly is secured to

the cylinder head with four long cylinder

head and rocker arm shaft retaining cap

screws. The rocker arm shafts axe hollow,

plugged at each end, serving as oil galleries

for rocker arm, push rod end, and valve stem

lubrication.

The oil pressure supply for the left hand

bank rocker arm assembly is taken from the

left main oil gallery at the front camshaft

bearing. The oil under pressure through

connecting passages in cylinder block and

cylinder head enters around the undercut stem

area of. the front rocker arm shaft mounting

cap screw upward into the rocker arm shaft.

The right bank rocker arm assembly lubrication pressure is taken from the vertical

oil gallery passages at the rear camshaft

bearing oil passage through the cylinder head

and block to the rear rocker arm shaft

retaining cap screw.

Two different rocker arms are used to

accommodate the angle from the rocker arm

shaft support to the valve stems. However,

the rocker arm shaft assemblies are interchangeable from cylinder bank to cylinder

bank.

1. Exhaust Valves

2. Intake Valves

FIGURE 6—Valve Arrangement

Intake or Exhaust Valve Spring:

Valve Closed 78-86 Lbs. @ 1-3/4"

Valve Open 158-172 Lbs. @ 1-3/8"

Valve springs are installed with the

inactive (closed) coils against the cylinder

head.

The valve spring retainer serves the dual

purpose of holding the valve and spring

together and providing a valve stem oil seal.

The seal is moulded onto the retainer. At

valve service periods, the valve spring

retainers should be replaced to insure good

oil control at this point.

Tool J-5988 will facilitate removal of the

valves from the cylinder head (Fig. 7). The

half conical shaped valve locks can be

removed after compressing the spring.

FIGURE 5—Valve Rocker Arm Assembly

VALVES

Figure 6 illustrates the valve arrangement.

Valve Springs

Whenever valve springs are removed, they

should be tested according to the specifications listed below. Use valve spring tester

and replace all springs not within specifications.

FIGURE 7—Removing Valves from

Cylinder Head

Valve Stem to Guide Clearance

Valve guides are cast integrally with the

cylinder head. The valves are replaced with

oversize stem valves when excessive stem to

guide clearance develops (Fig. 8). For

service, valves with oversize stems are

supplied in .003", .010", .020', and .030".

A special set of valve guide reamers

(J-6042) are available to fit the various

size valves to their guide.

Page 31

4

TECHNICAL SERVICE MANUAL

FIGURE 8—Checking Valve Stem to Guide

Clearance Limits—.004" Intake,

.005" Exhaust

Valve Refacing

The intake valves are faced to a 30° angle

and the exhaust valves to a 45° angle. Valves

may be refaced until remaining margin is down

to 1/32"; then the valve must be replaced.

The valve stem tip when worn can be

resurfaced and rechamfered. However, never

remove more than .010".

Valve Seat Refacing

Grind the valve seats to the following

specifications:

FIGURE 9—Checking Valve Seat Runout

under pressure flows into the body through

the check valve assembly maintaining the

tappet fully charged. This cycle of operation

occurs when tappet leaks off some oil during

the normal valve opening events. Opening

movement of the cam lobe causes tappet body

movement, closing the check valve and transmitting "zero-lash" movement of the push rod

to open the cylinder valve.

The valve tappets should be cleaned and

serviced at time of engine overhaul or

whenever excessive noise exists.

Seat Angle

Intake Valve 30°

Exhaust Valve 45°

Seat Width

Intake Valve 3/64"

Exhaust Valve 5/64"

Narrowing stones should be used to obtain

the proper seat widths when required.

Control seat runout to a maximum of .002"

(Fig. 9).

Valve Tappets and Push Rods

11222

The hydraulic valve tappet consists of a

body, plunger, plunger return spring, check

valve assembly, push rod socket, and lock

ring (Fig. 10).

The tappet operates in a guide bore which

has an oil passage drilled into the adjoining

main oil galleries.

When the tappet is on the heel of the cam

lobe, the plunger return spring indexes an

oil hole undercut in the plunger with the oil

supply admitted through the tappet body. Oil

FIGURE 10— Valve Push Rod and Tappet

Page 32

ENGINE V-8

When removing the tappets, they must be

kept in an order that will insure replacement

in their respective operating bores in the

engine because they are select fitted to that

bore. Keep each tappet component group by

itself as all detail components are select

fitted to one another in manufacturing. Only

complete tappet assemblies are supplied for

service replacement.

The tappet assembly should be cleaned in

a solvent to remove all varnish or leaded

deposits. After cleaning, the tappet must be

"leak-down" tested to insure its "zero-lash"

operating ability. Kerosene should be used

for this test. Test the tappet by filling the

body with kerosene and then install the

plunger return spring, plunger assembly, and

push rod socket. Leave out snap ring for

test. Insert the tappet in tappet test tool

J-5978, and check it for "leak-down" by

squeezing the handles together (Fig. 11) .

5

FIGURE 11— Checking Hydraulic Tappet

"Leak-Down"

If the tappet leaks down rapidly or

collapses immediately, it must be rechecked

and/or replaced with a complete new tappet

assembly. The normal tappet will take approximately 10 seconds or more to "leak- down"

with kerosene. After testing tappets, they

should be prelubricated and assembled in the

engine without an oil charge. They will

normally charge themselves in 3 to 8 minutes

of engine operation.

Tappet Noise

A loud clicking noise is usually the result

of the plunger stuck down below its operating

position or a check valve held open. A light

clicking noise is usually the result of

excessive "leak-down" caused by wear or

slight leakage at the check valve and its

seat.

An intermittent noise at tappet is the

result of dirt or chips stopping the check

valve or a lack of oil flow into the body

because of dirt. A general tappet noise is

in most cases due to a lack of oil volume or

pressure.

The normal tappet plunger operating range

is .140" to .170".

Valve Timing

The correct valve timing is established by

the relation between the sprocket on the

camshaft and the sprocket on the crankshaft.

FIGURE 12—Properly Installed Timing

Assembly

To obtain the correct valve timing, index

the "0" marks on camshaft and crankshaft

sprockets on a line drawn vertically through

the center line of each shaft (Fig. 12) . To

check the assembly, rotate the crankshaft

until the timing mark on camshaft sprocket

is on a horizontal line at either the 3 or 9

o'clock position. Count the number of links

or pins on the timing chain between timing

marks. You should have 101/2 links and/or 21

pins between timing marks. Each' link contains two pins.

To make an external check of valve

timing, remove the cylinder head covers and

spark plugs. Crank the engine until No. 6

cylinder piston in right bank is on T.D.C.

on compression stroke. This places No. 1

cylinder piston on T.D.C. on the exhaust

stroke valve overlap position. Rotate the

crankshaft counterclockwise. 90°.

Install a dial indicator on the number

one intake valve rocker arm push rod end

(Fig. 13). Crank the engine slowly in

direction of rotation (clockwise) until the

dial indicator indicates push rod movement.

The hydraulic lifter should be fully charged

for this check.

At the time the dial indicator moves, the

ignition timing mark on the vibration damper

should align with the 14° (approx.) position

on the degree quadrant section of the timing

assembly cover. If more than 1/2” variance

Page 33

6

TECHNICAL SERVICE MANUAL

FIGURE 13—Installation of Dial Indicator

for External Valve Timing Check

in either direction is evident, remove the

timing chain cover and inspect timing chain

installation. Replace timing chain if over

chain deflection exists.

TIMING CHAIN COVER

The timing chain cover is a die casting

incorporating an oil seal at the vibration

damper hub.

To remove the timing chain cover, first

remove the oil filter pressure line, water

pump and manifold, fuel pump assembly, and

vibration damper.

The oil seal can be pryed out of the cover

and a new one installed with seal installing

tool J-5983 (Fig. 14).

To prevent damage to this seal, it is

important that the cover be properly aligned

when installing the vibration damper. This

is accomplished by leaving the cover to block

screws loose until the vibration damper has

been partially installed. Then tighten the

cover screws.

An oil slinger is used inside the timing

chain cover. The slinger is held in place by

the crankshaft sprocket, and the vibration

damper hub.

CAMSHAFT AND BEARINGS

The camshaft is supported by five steel

shelled, babbitt lined bearings which have

been pressed into the block and line reamed.

The camshaft bearings are step bored, being

larger at the front bearing than at the rear,

to permit easy removal and installation of

the camshaft. All camshaft bearings are

lubricated under pressure.

The oil for lubrication is supplied through

connecting drilled passages from the intermediate main bearing locations and from the

main oil galleries to the front and rear

camshaft bearing locations.

Camshaft End Play

The camshaft end thrust is controlled by the

front surface of the camshaft bearing and the

rear surface of the thrust plate, and the

rear hub surface of the camshaft sprocket and

the front surface of the thrust plate.

The end play tolerance is .004" to .006".

Camshaft Removal

Remove cylinder head covers, ignition plug

wires, rocker arm assemblies, intake manifold, and carburetor. Remove water pump and

water distribution manifold. Remove upper

oil breather and tappet assembly cover.

Remove inner oil baffle cover. Remove push

rods, keeping them in their relative operational positions. Remove hydraulic tappets

and keep in relative operational positions.

Remove fuel pump, vibration damper, and

timing chain cover. Crank engine until timing

marks line up on a vertical line with shaft

centers (Fig. 12).

Remove oil shedder, fuel pump eccentric,

crankshaft sprocket, camshaft sprocket, and

timing chain assembly (Figs. 15 and 16).

Timing sprockets can be pryed off with ease.

Remove the camshaft retainer and thrust plate

and the end thrust spacer (Figs. 17 and 18).

FIGURE 14— Installation of Timing Chain

Cover Seal

PISTONS

Slipper type, tapered skirt, cam ground,

pistons are used. They are of aluminum alloy,

steel reinforced for controlled expansion.

Page 34

ENGINE V-8

FIGURE 15—Timing Chain Cover Oil Shedder

7

The ring belt area provides for three piston

rings, two compression and one oil control

ring above the piston pin.

The pistons are removed from the top of

cylinder bore after removing ring ridge.

The piston pin boss is "offset" from the

piston center line to place it nearer the

thrust side of the cylinder. To insure proper

installation of the piston in the bore, a

notch is cast in the piston top, and letters

"F" cast in the pin boss structure at the

front (Fig. 19).

FIGURE 16— Fuel Pump Drive Eccentric

FIGURE 17— Camshaft Retainer and Thrust

Plate

FIGURE 18— Camshaft End Thrust Spacer

1. Notch and "F" letter to Front of Engine

FIGURE 19— Correct Piston Position

The piston to bore clearances are .021" to

.027" at top land, .001" to .0015" top of

skirt, and .000" to .0015" bottom of skirt

(Fig. 20).

PISTON PINS

Full floating type piston pins are mounted

in a split bronze bushing at the connecting

rod upper end and retained by lock rings in

piston pin bosses. Prior to fitting a new

piston pin, the bronze connecting rod bushing

is pressed into place and burnished with

components of tool J-6055 (Fig. 21). Be sure

oil hole in bushing lines up with oil hole

drilled in rod.

The burnishing operation is required to

prevent the bushing from turning in the rod

end while honing or reaming to fit piston

pin.

The piston pin should be a palm press fit

in rod bushing at room temperature and a palm

press fit in a piston heated in water to

about 200°F. When pin is properly fitted to

rod, rod will fall by its own weight when

located in a horizontal position and held by

the piston pin.

Page 35

8

ENGINE V-8

FIGURE 20— Measuring Clearance at Bottom

of Piston Skirt

PISTON RINGS

A three ring piston is used. The two

compression and one oil control rings are

located above the piston pin boss.

Before assembling the rings to the piston,

carbon must be cleaned from all ring grooves.

The oil drain holes in the oil ring grooves

must be cleared with the proper size drill.

Care must be exercised not to remove metal

from the grooves, since that will change

their depth, nor from the lands, since that

will change the ring groove clearance and

destroy ring to land seating.

Checking Ring Groove Clearance

Side clearance between land and piston ring

should be .0015" to .005". Roll the ring

around the groove in which it is to operate.

It must fit freely at all points.

Checking Ring Gap Clearance

Piston ring gap or joint clearance is

measured in the bottom of the cylinder near

the end of the ring travel area. To square

the ring in the bore for checking joint

clearance, place the ring in the bore. Then

with an inverted piston, push the ring down

near the lower end of the ring travel area.

FIGURE 21— Burnishing Piston Pin Bushing

When other than standard ring sizes are used,

rings should be individually fitted to their

respective bores for a gap clearance of .010"

to .018".

Piston Ring Installation

Removal of glaze from the cylinder wall for

quicker ring seating can be accomplished by

various methods. Where an expanding type hone

is used, do not use more than ten strokes

(each stroke down and return) to recondition

a cylinder wall.

Successful ring installation depends upon

cleanliness in handling parts and while

honing the cylinder walls. The engine bearings and lubrication system must be protected

from abrasives.

Rigid type hones are not to be used to

remove cylinder glaze as there is always a

slight amount of taper in cylinder walls

after the engine has been in service.

Rings must be installed on the pistons

with a ring installing tool to prevent

distortion and ring breakage.

For service ring replacement, follow the

detailed instructions enclosed in the ring

package.

Prior to installing the piston and connecting rod assembly into engine, the piston

ring gaps are to be

Page 36

ENGINE V-8

FIGURE 22

-

PISTON RING GAP LOCATION

9

arranged so that the gap for the oil ring

expander is to the outside of the block and

oil ring gap is toward the inside of the

block. The gaps on the compression rings as

shown in Figure 22 are 120° apart. Do not

locate a ring gap over the piston pin boss.

CONNECTING RODS

Connecting rods are the "I" beam drop forged

steel type. The connecting rods are stamped

with the cylinder numbers in which they are

assembled. The numbers are opposite the

squirt holes and toward the outside of the

banks in which they are located.

The squirt holes from connecting rods in

one bank lubricate the cylinders in the

opposite bank.

The connecting rod squirt holes are

located in the parting surface of the bearing

cap (Fig. 23).

The cylinders are numbered 1, 3, 5, 7 in

the left bank of engine from front to rear,

and even numbers 2, 4, 6, 8 in the right

bank, front to rear as viewed from driver's

seat.

Two connecting rods are mounted, side by

side, on each crankpin. The side clearance

is .003" to .011" Fig. 24).

FIGURE 23— Connecting Rod Squirt Hole

Location

FIGURE 24— Checking Connecting Rod

Side Clearance

Page 37

10

TECHNICAL SERVICE MANUAL

CRANKSHAFT

The crankshaft is a precision steel cast shaft

having five main journals, four crankpins, and

provided with an oil stinger at rear journal

inboard of the rear oil seal.

The component parts of the crankshaft assembly are individually balanced, and then the

complete engine assembly is balanced as a unit.

Replacement of crankshaft, flywheel, or vibration damper can be accomplished without rebalancing the complete assembly.

Main Bearing Journals

Main bearing journals can be measured without

removing the crankshaft from the engine block.

Various gauges are available for this purpose.

Always check both ends of the journal to note

the taper. Then rotate the shaft 90° and measure

for out of round.

The main bearing diameter is 2.500" and

should not taper or be out of round more than

.002".

FIGURE 25—Piston and Connecting Rod

Assembly

Connecting Rod Alignment

Whenever new rings are installed or new

piston pins are replaced, it is necessary to

align the connecting rods and pistons as

assemblies to insure true operation in the

cylinder bore.

Misaligned rods will cause uneven piston

and ring wear which will result in oil

consumption. The connecting rod should be

inspected for a twisted or bent condition.

Connecting Rod Bearings

The connecting rod bearings are the steelbacked, babbitt lined precision type. They

are installed as pairs in the connecting rod

and cap.

CAUTION: Never file a connecting rod

or cap to adjust bearing clearance.

To determine the amount of bearing clearance, use a piece of Plastigage in the

bearing cap. Then tighten the cap to torque

specifications to compress the gauge. Remove

the bearing cap and calibrate the width of

the Plastigage with the scale furnished.

If the bearing clearance is excessive, the

correct undersize bearing insert (pair)

should be installed in the connecting rod.

The correct connecting rod bearing clearance

is .0005" to .0025".