Hudson Boat Owner's Manual

Owners Manual

1930 Mallard Rd.

London, Ontario, Canada

N6H 5M1

519-473-9864

www.hudsonboatworks.com

2

CONTENTS

INTRODUCTION 3

INSURANCE & TRANSPORTATION 4

INSURANCE 4

TRANSPORTATION 4

CAR TOP 5

TRAILERING 6

ASSEMBLY 7

TOOLS 7

PARTS 8

FOOT ASSEMBLY (WITHOUT SHOES AND SHOE PLATE) 8

SEAT ASSEMBLY 9

SLIDES 10

RIGGER (SWEEP) 11

RIGGING 12

FEET 12

RIGGER 15

RIGGER 15

SPREAD (SCULLING) 17

SPAN (SWEEP) 17

HEIGHT 19

PITCH 21

BACKSTAY (SWEEP) 22

SLIDES 23

STEERING (2-/4-X) 24

CLEANING 26

PROTECTION 26

LUBRICATION 27

SALT WATER ROWING 27

STORAGE 28

FAQ’S - RIGGER DIMENSIONS 29

SWEEP 29

SCULLING 30

FAQ’S – CHANGING WHEELS/BEARINGS 31

FAQ’S – REPLACING THE NEW FIN 32

FAQ’S – HOW TO LIFT AND CARRY THE BOATS 34

3

INTRODUCTION

Thank you for choosing Hudson. Your boat is a high performance racing machine, and taking

the time to rig it properly will help you get the most out of it. With minimal preventative

maintenance, your Hudson will give you years of trouble free pleasure. We have designed this

owners manual to cater to all levels, and there are probably one or two things specific to

Hudson Boats that even the most experienced coaches can learn (these are highlighted as tips).

ORIGINAL MANUFACTURING DIMENSIONS AND CODES

4

INSURANCE & TRANSPORTATION

We have chosen to make this the first thing you read, because chances are that before you rig

(assemble) or wash your boat, you will have to move it. Your boat represents a large

investment that can be damaged in transport, on water, and even on the rack. Please refer to

the FAQ How to lift and carry the boat, as the 4-/x/+’s and 8+’s should be lifted by the rigger,

or by the sides of the boat, and not the inspection port.

INSURANCE

Upon delivery your boat becomes your responsibility, and we recommend that you initiate

insurance from the delivery date. Please consult with a broker to find the best coverage for

you. Make sure that it is very clear that what you are insuring is a rowing shell, and that the

broker understands everything that entails. If your broker has no solutions, you may want to

ask other members at your club how they insure their boat.

For our U.S. customers we recommend:

Leonard Insurance Group

1-800-sculler (US only)

610-789-9600

Email: scullerjon@aol.com

For our Ontario customers we recommend:

Petek Insurance Inc.

Lisa Jeffries

1-877-738-3512

TRANSPORTATION

There are two ways to transport your boat; on top of your car, or on a boat trailer. Before we

discuss that, there are a few things you need to do to prepare the boat:

• For the majority of transportation applications the

rigger will be removed from the boat.

• We recommend that the nuts & bolts stay on the boat

to prevent the bolts from scratching other riggers in

transport.

• To ensure long life of the Velcro on the shoes, fasten

them before travel.

• You can use the provided bungee to fix the seat to

the slides (see photo), or you can remove the seat

altogether by sliding it to the stern of the slides and

bumping the bow of the seat with the heel of your

hand (this requires some care in the singles and the

lightweight double to not damage the paint).

• Check that all the slide wing nuts and the feet wing

nuts are tight to prevent them from falling out and

possibly causing damage to other boats.

5

Please note: When packaging a rigger with a backstay for transportation, we recommend that

you loosen the top nut before you rotate the backstay. The port backstay will overtighten the

top nut, and could cause damage when you rotate the backstay in line with the rigger arm.

For all forms of transportation we highly recommend that you check that all ties downs and

racks are secure before you depart. We also recommend that you check the tie downs and

racks at every service stop, as changes in weather, and wind shear may affect the straps. We

also recommend that you remove any tags from the straps. These tags can, and have abraded

the paint over a trip.

Car top

Hudson builds racks for 1x’s and our 2-/x’s which are designed to attach to your cars roof rack

(most factory racks will work, but we recommend aftermarket racks for more security). You

can transport a single with the rigger mounted, just make sure that the rigger: cannot strike

the car in high wind, will not interfere with the operation of your car doors, and does not

protrude beyond the side of the car.

With the hull upside down on the rack, put a strap around the boat and the rack ~4 inches from

the sling. Ensuring that the webbing is flat all the way around, feed the end through the cam

and draw the webbing through until the boat is secure. Then tie both sides of the strap

together, by looping around the other side and creating a knot just below the cam. (see photos

below) For longer trips, or if you are traveling through areas of high wind, we recommend you

tie a safety rope over the boat to the tow mounts at the front of the car. This requires extreme

care, The rope should be tied such that even if it does loosen it cannot get caught in the

wheels of the car. If this happens and the rope is over the bow of the boat, the rope will snap

the bow off. The safety rope should be tight enough to keep the boat from flying off the roof,

but loose enough for the rack to take out the brunt of the road vibrations.

The stern of the boat furthest from your back bumper should have a red flag attached to alert

following drivers. State and Provincial Laws differ, so please consult you M.O.T. or D.O.T. for

rules regarding car topping.

6

Trailering

Trailers are the most common way to move crew and club boats. With a few precautions, you

can make sure that your boat makes it to its destination safely (please note we are providing

information to safely load your boats, refer to you automobile and trailer manufacturer for

safe trailering);

• Load boats to weight the tongue according to the directions of your trailer/tow

• Check that any boats loaded on the trailer will not make contact with the tow vehicle

• Strap the boats down with cam straps (provided with your Hudson), with the cam ~ 2”

• Thread the strap through the cam making sure the webbing lies flat against the hull,

• Test the tightness by trying to move the boat side to side, if it moves draw on the end

• Once it is tight enough so the boat does not slide back and forth, tie the strap off

• Thread the strap back under the rack, and cinch and knot the strap around itself a few

For eights:

Make sure there are three contact points, and make sure the contact points are level, if they

are not use a shim to support the boat. Make sure to securely strap the boat at these three

points.

For Smaller Boats:

Using two contact points, it is ideal if one of these points is the stern most rigger mounting

pad. If the bow does not meet a trailer rack in the cockpit, use a bit of foam to protect the

boat and tie it off on the bow deck, using caution to not overtighten on this end.

vehicle.

in sharp turns, or dips in the road.

above the gunnel, positioned such that it does not make contact with the hull.

and draw on the end of the strap.

of the strap again.

against itself just below the cam. This will prevent the strap coming any looser should

the cam fail.

times.

7

ASSEMBLY

Hudson Boats are designed for simplicity and maximum flexibility in how you choose to set up

your boat.

TOOLS

7/16” wrench - Almost all of your adjustments can be performed using just one tool, the 7/16”

wrench (11mm also works). This is the only tool you need to take your rigger off the boat and

put it back on. Once you have rigged your boat to your specifications, this is the only tool you

should have to carry for your boat.

Tip: Using the box end (closed end) of the wrench lessens the risk of damage to the hull. The

sharp edges of the open end can easily scratch, or damage the hull if it slips. The other safe

option is to use a 7/16” nut driver.

¾” wrench - The only other wrench you’ll need for rigging is a ¾” (19mm will work) for

adjusting the span or spread, and once you‘ve set it, you can forget it.

Tip: While we use a 7/16” and ¾” wrench, the bolt shaft diameter determines the size. For

example the bolt that threads into the top of the pin has a 7/16” hex head, but the shaft

diameter is ¼” (the nut securing the base of the pin has a diameter of ½”). All of the 7/16”

nuts and bolts for Hudson Boats have a thread pitch of 20, which means there are 20 threads

per inch (the ½” nut at the base of the pin has a thread pitch of 13). The other dimension of

the bolt is the length of the shaft, or in other words the total length without the head. So the

proper designation for the bolt that threads in the top of the pin is: ¼” – 20 Hex Head Stainless

Steel X 3/8”.

Flathead Screwdriver or 5/16” (8mm will work) nut driver/wrench- If you have a sweep boat,

you’ll have backstays, and will need a flathead screwdriver (but a dime will do the trick in a

pinch) or a 5/16” (8mm will work) wrench to adjust the hose clamps.

Tape Measure - For measuring heights and span/spread you’ll need a tape measure. Whether

you choose standard or metric, it makes sense to use a tape measure that measures only

standard or metric (so that the lines show on both sides) for optimum accuracy.

Box level - To measure feet and oarlock height accurately and to check lateral pitch, a 48’ box

level serves a dual purpose. If you’re not interested in lateral pitch, a straight edge will do.

Pitch Meter - The blocks that the pins sit in come out of the factory pitched at 0 degrees in

both stern and lateral directions. The pitch meter comes in handy to double check that you’ve

put the pitch bushings in the oarlock properly.

Internal Snap Ring Pliers – You’ll only need these if you want to change the bearings out of your

wheels. (See FAQ’s Changing Wheels and Bearings)

8

End Piece

Toe Bar

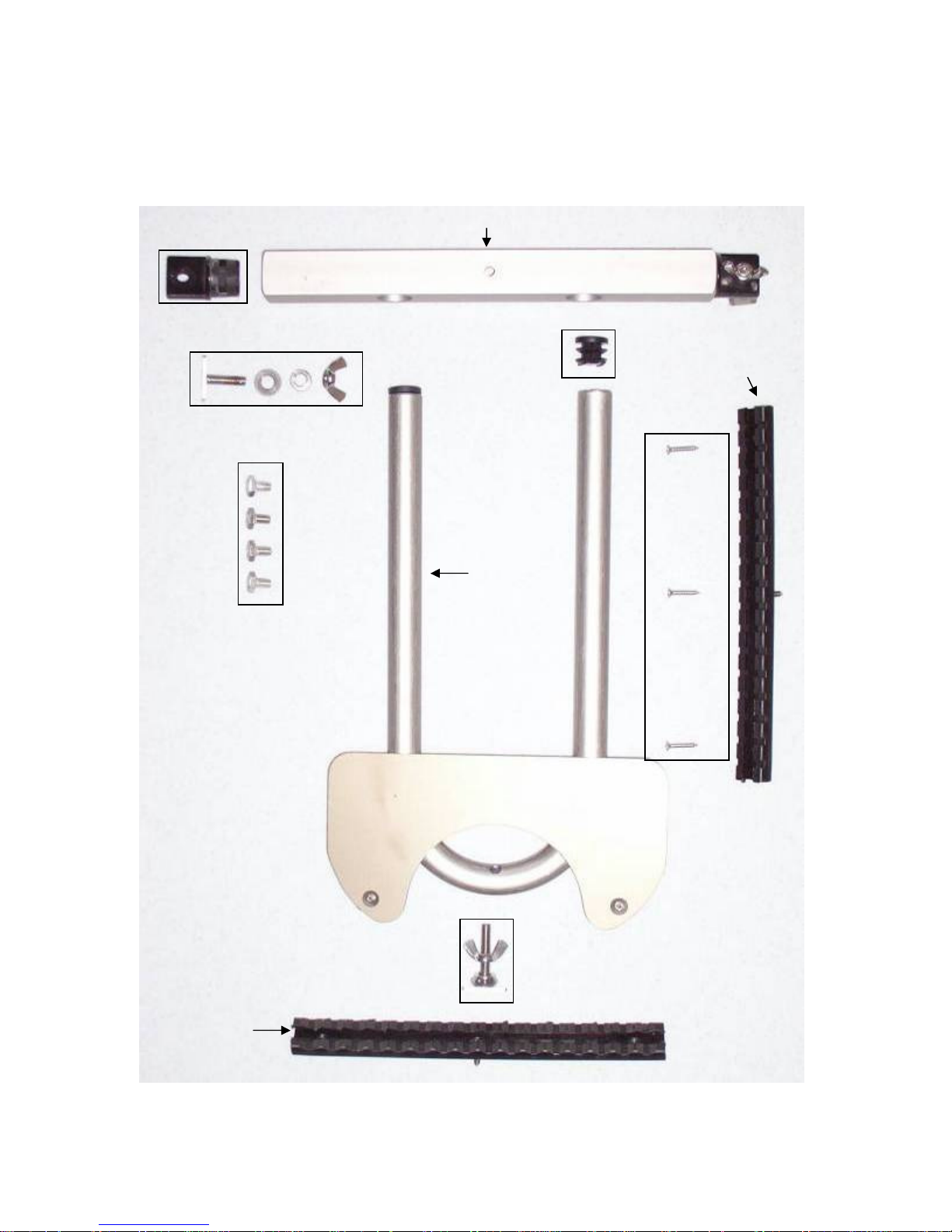

PARTS

Please use this section to help identify the parts referred to in this manual.

Foot assembly (without shoes and shoe Plate)

Foot Stretcher

1” Stretcher Bolt (side), Flat

Washer, Lock Washer and Wing

¼” x ½”

Bolts

(they thread

in the back

of the toe

bar and

shoe plate to

maintain

angle and

height)

Hairpin Plug

Notched

Channel

(side)

Channel

Screws

Hairpin

1 ½” Stretcher Bolt (centre),

Curved Washer, Lock

Washer and Wing Nut

Notched

Channel

(Centre)

9

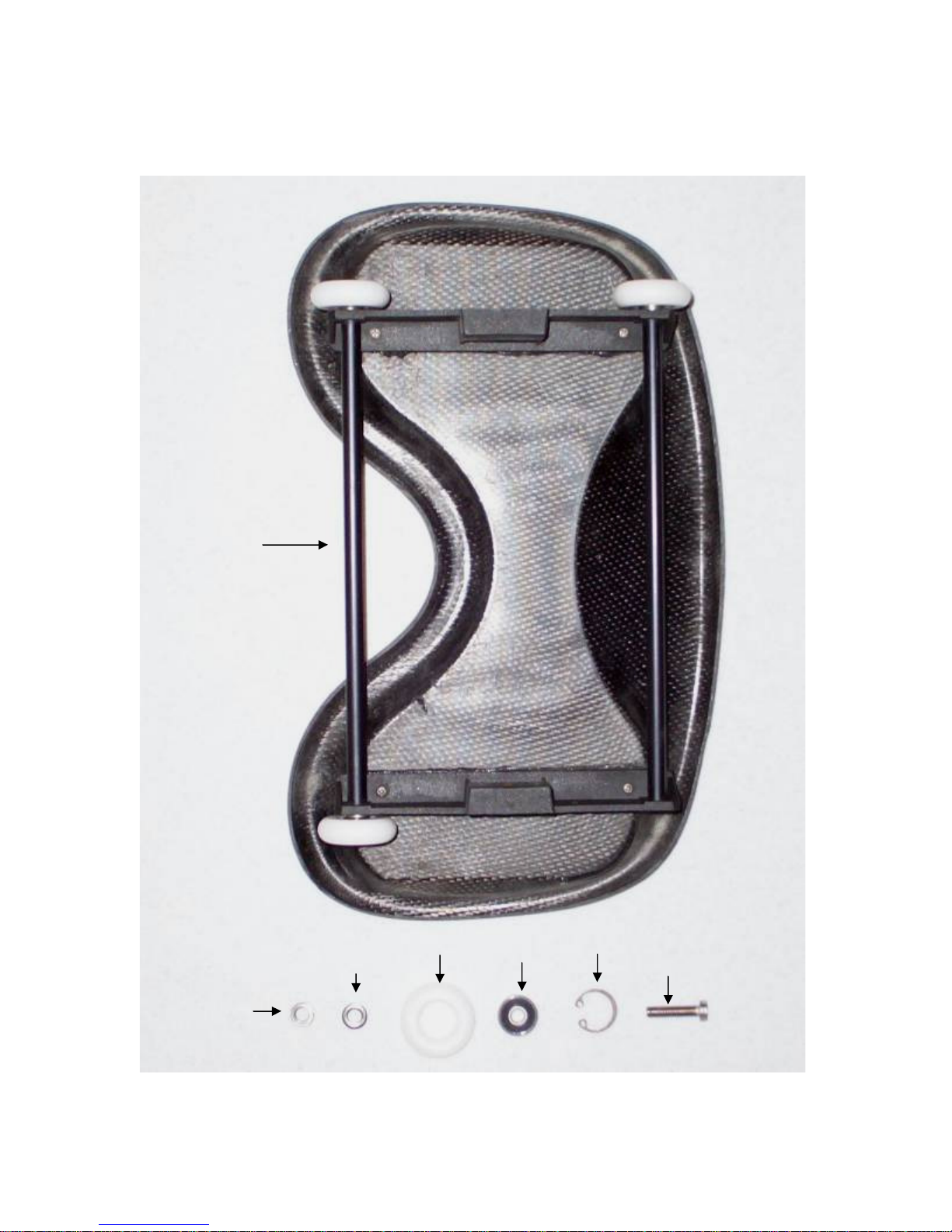

Lock Washer

Bolt

Flat Washer

Seat Assembly

Axle

Furk

Seat Top

Wheel

Bearing

Snap Ring

10

Flat Washer

Slides

Underside of Slide

Slide Bolt

Slide End

Wingnut

Lock Washer

Slide Bolt

Removal

Hole

11

Speed Wa

sher

Sweep Angle Mount

Rigger (Sweep)

¼” x 3/8” Bolt

¼” Lock Washer

¼” Flat Washer

3/8” Backstay

Washer

Oarlock

Sweep

Pin

Pitch Bushing

Height Washer

½” Flat

Washer

½” Lock

Washer

½” Nut

PPiinn

BBlloocckk

Rigger

Shoe

Mount

Loading...

Loading...