Page 1

Instruction 871-785 Model 13194

LIMITED WARRANTY

H. D. Hudson Manufacturing Company warrants to the original purchaser only that this product will continue to

function as intended if used in accordance with operating instructions (under NORMAL CONSUMER USE) for

one year. If the product fails to function as intended—DO NOT RETURN IT TO THE STORE—call our CONSUMER

SERVICE HOTLINE AT 1-800-9-SPRAYER (toll free) for fast service. We will, at our option, repair or replace any

non-functioning parts without charge (shipping and handling charges will apply) H. D. Hudson Manufacturing

Company shall have the option of requiring the return of the non-functioning product to the address listed below,

together with the proof of purchase, to establish a claim under this warranty. This warranty does not apply to

damage resulting from accident, misuse, neglect, alterations, operation not in accordance with instructions,

commercial use, or normal wear.

ANY IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR

CONSUMER USE, ARE LIMITED TO THE DURATION SPECIFIED ABOVE. H. D. HUDSON MANUFACTURING

COMPANY’S LIABILITY IS LIMITED SOLELY TO THE REPAIR OR REPLACEMENT OF THE NON-FUNCTIONING

PRODUCT OR PART. H. D. HUDSON MANUFACTURING COMPANY EXCLUDES LIABILITY UNDER THIS WARRANTY

FOR ANY AND ALL INCIDENTAL AND CONSEQUENTIAL LOSS OR DAMAGE.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so these limitations or exclusions may not apply to you. This warranty

gives you specific legal rights and you may have other rights which vary from state to state.

WARNING!

WARNING!!! THIS PRODUCT IS DESIGNED TO APPLY CHEMICALS THAT MAY BE HARMFUL AND COULD

CAUSE SERIOUS PERSONAL INJURY IF INHALED OR BROUGHT INTO CONTACT WITH THE USER. FAILURE TO

READ AND FOLLOW OWNER’S MANUAL INSTRUCTIONS BEFORE USE AND/OR MISUSE OF THIS PRODUCT

COULD RESULT IN EXPLOSIVE FAILURE WITH MAJOR INJURIES.

MAIN FUNCTION

This commercial Bak-Pak® sprayer is comfortable to use and sprays evenly. It’s especially suitable for

the prevention and cure of diseases and insect infestation on crops, blowers, plants and gardens, for the

environmental sanitation of public places, and for the epidemic prevention and sanitation of livestock poultry

sheds.

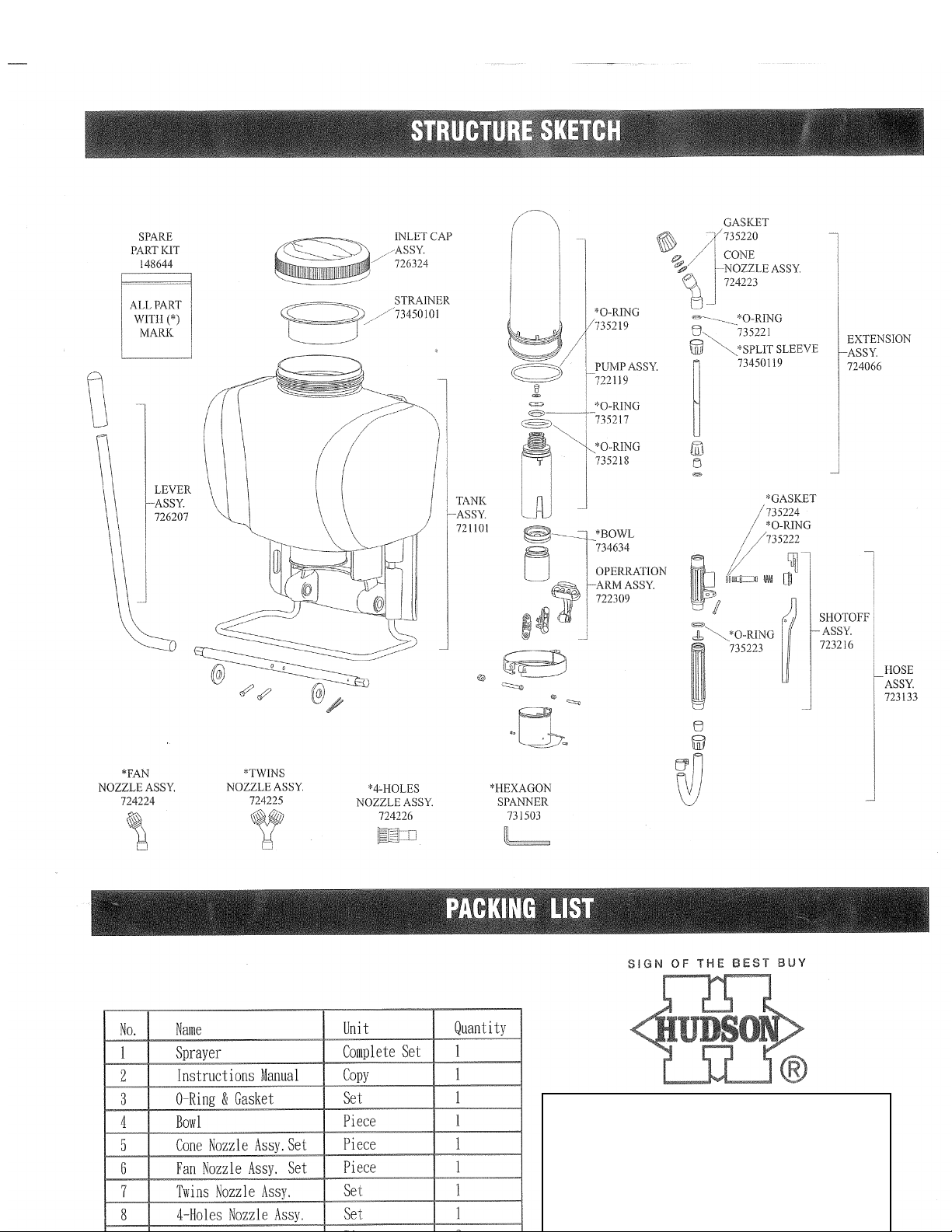

STRUCTURE OF SPRAYER

1. Container to hold liquids 4. Operation arm and components

2. Pump and air chamber 5. Backpack belt system

3. Spraying System (including rubber hose and components, switch, sprayer spindle and head)

Page 2

WORKING PRINCIPLE

Through the swing of the operation arm and components, the pump bowl rises up and down so that the sealing

ball turns on and off, which makes the pressure in the air chamber also rise up and down, impeling the liquid to

get into the chamber. The liquid goes through the spraying system and flows out as spray.

CHARACTERISTICS:

1. The external form is the imitation of the human body’s back curve. The combination of the air chamber and

pump located in the liquid container makes the whole structure compact, safe and leak-resistant.

2. The operation arm uses an action connecting style so that it can be installed on both sides. It’s convenient and

quick in action, and while it is in use, the operation arm does not separate easily-making it easier for the user to

operate the sprayer with the right or left hand.

3. Use the various spray heads for different tasks and to adjust between fine spray and coarse spray patterns.

4. Chosen materials for the sprayer are excellent, resistant to acid, corrosion, and alkalinity. The sprayer is sealed

hermetically and very durable.

OPERATION METHOD

After the sprayer carton is opened, please check to see that all parts conform to the packing list. Then assemble

the sprayer, using the diagram as reference. Before use, please twist off the cap of the container. Fill the liquid

through the filter into the container slowly. Then close the cap tightly and place the sprayer on your back. Swing

the operation arm, after the pressure of the air chamber is boosted. Pinch the switch component to begin spray

operation. It can be point-spray and also can be used as continuous spray.

Choose the different spray head for spraying correctly.

3 types of spray heads are included.

1. Fan style spray head: This sprays evenly, suitable for spraying on medium-height

and short plants. For spraying weed killer, keep the spray head stable and

spray with the direction of any wind.

2. Cone spray head: This can be used for spraying pesticides and insecticides

and to prevent diseases.

3. 4-hole adjustable spray head: Used for spraying tall bushes and fruit trees.

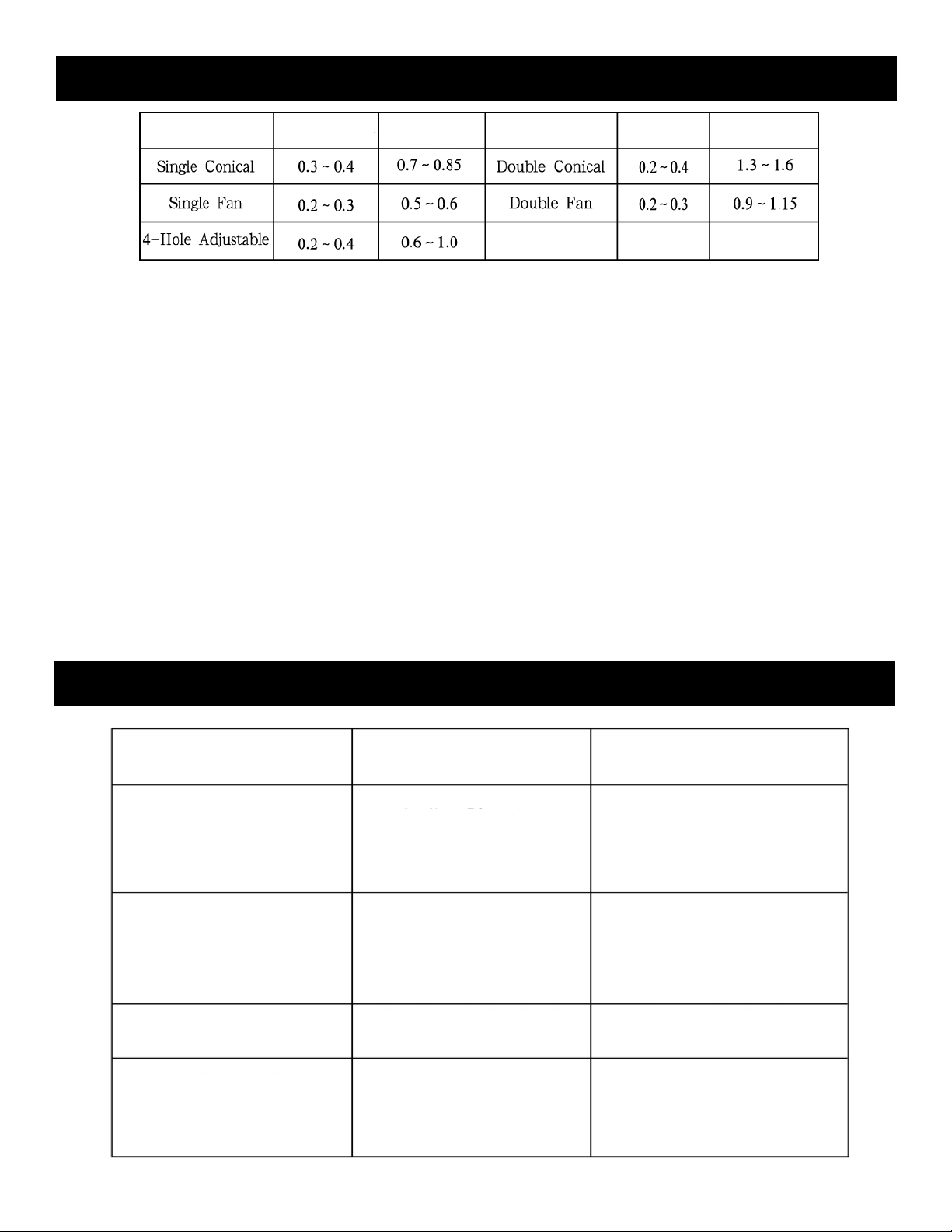

PARAMETERS AND SPRAY-HEAD FLOW RATE

1. Type: Bak-Pak® Sprayer 4. Operation Travel: 60-80mm

2. Container Capacity: 4 gallons, 15 liters 5. Bowl Diameter: 45mm

3. Operation Pressure: 0.3-0.4 MPA 6. Net Weight: 3.2kg

Page 3

IMPORTANT POINTS

Nozzle Type

1. Before turning on the switch, do not swing the operation arm continuously for a long time- this will avoid

damage of the sprayer.

2. While spraying pesticides, the user must wear mask and gloves, to avoid the pesticide directly touching the

skin and damaging the body. Don’t spray pesticide towards the wind. Do not spray pesticides near people,

animals and foodstuff. Don’t operate under high temperature for a long time.

3. While handling the pesticide, please comply with the safety directives seriously.

4. Do not use with strong acid and alkali liquids. Do not use highly-toxic or highly-residual pesticides

on vegetables, melons, gourds, fruits and medicinal herbs. After applying pesticides, according to the

manufacturer’s directions, do not eat vegetables for several days.

5. After spraying, clean the sprayer, to prevent liquids from corroding the sprayer or blocking up the spray head.

Avoid residual pesticide mixed with the next pesticide used. This may cause a chemical reaction and influence

the effect of the pesticide.

Pressure MPA

Flow Rate

L/min.

Nozzle Type

Pressure MPA

Flow Rate

L/min.

6. For extended periods of non-usage or continuous usage for several days, add Vaseline to the seals, o-ring and

moving parts to reduce wear of parts.

TROUBLE SHOOTING

PROBLEM CAUSE SOLUTION

Leakage or

spraying poorly

Pump handle is hard

to move.

Low pressure. Bowl or sealing ball worn. Replace bowl or sealing ball.

Sealing plate is

damaged or loose.

Spray nozzle or filter

blocked.

Replace sealing plate or

tighten.

Rinse filter and nozzle

with water. Add Vaseline

to moving parts.

Pump handle moves too

easily-no pressure.

Seal is missing. Properly position new seal.

Page 4

Page 5

Page 6

Instrucciones 871-785 Modelo 13194

GARANTÍA LIMITADA

H. D. Hudson Manufacturing Company garantiza sólo al comprador original que este producto continuará

funcionando como corresponde si se utiliza de acuerdo a las instrucciones de operación (bajo USO NORMAL POR

CONSUMIDORES) durante un año. Si el producto deja de funcionar como es debido, NO LO REGRESE A LA TIENDA,

llame a nuestra LÍNEA DE SERVICIO AL CLIENTE AL 1-800-9-SPRAYER (gratis) para obtener un servicio rápido. Según

nuestro criterio, repararemos o cambiaremos sin cargo alguno cualquier pieza que no funcione (aplican cargos de

envío y manipulación) Para iniciar un reclamo bajo esta garantía, H. D. Hudson Manufacturing Company se reserva el

derecho de exigir la devolución del producto defectuoso a la dirección incluida más adelante junto con la prueba de

compra. Esta garantía no se aplica a los daños que resulten de accidentes, uso indebido, descuido, modificaciones,

operaciones que no estén de acuerdo con las instrucciones, el uso comercial o el desgaste normal.

TODA GARANTÍA IMPLÍCITA, INCLUIDA LA GARANTÍA IMPLÍCITA DE COMERCIALIZACIÓN Y ADECUACIÓN PARA

EL USO DE LOS CONSUMIDORES, ESTÁ LIMITADA A LA DURACIÓN QUE SE ESPECIFICÓ ANTERIORMENTE. LA

RESPONSABILIDAD DE H. D. HUDSON MANUFACTURING COMPANY SE LIMITA EXCLUSIVAMENTE A LA REPARACIÓN

O EL REEMPLAZO DE LOS PRODUCTOS O PIEZAS QUE NO FUNCIONEN. H. D. HUDSON MANUFACTURING COMPANY

CARECE DE TODA RESPONSABILIDAD BAJO ESTA GARANTÍA EN CUANTO A DAÑOS O PÉRDIDAS, PARCIALES O

TOTALES, INCIDENTALES O CONSECUENTES.

Algunos estados no permiten limitaciones con respecto a la duración de las garantías implícitas, o la exclusión o

limitación de daños incidentales o consecuentes, por lo que es posible que estas limitaciones o exclusiones no se

apliquen a su caso. Esta garantía le otorga derechos legales específicos, y podría gozar de otros derechos que varían

de un estado a otro.

¡ADVERTENCIA!

¡¡ADVERTENCIA!! ESTE PRODUCTO HA SIDO DISEÑADO PARA APLICAR PRODUCTOS QUÍMICOS QUE

PODRÍAN SER DAÑINOS Y PROVOCAR LESIONES PERSONALES GRAVES SI SON INHALADOS O SI ENTRAN

EN CONTACTO CON EL USUARIO. SI NO LEE NI SIGUE LAS INSTRUCCIONES DEL MANUAL DEL PROPIETARIO

ANTES DE SU USO Y/O EL PRODUCTO NO SE UTILIZA CORRECTAMENTE, SE PODRÍA PRODUCIR UNA FALLA

EXPLOSIVA CON LESIONES GRAVES.

FUNCIÓN PRINCIPAL

Este aspersor comercial Bak-Pak® es cómodo para usar y rocía en forma pareja. Es especialmente adecuado

para recuperar cultivos, flores, plantas y jardines de enfermedades e infestación de insectos (o prevenirlos),

desinfectar lugares públicos, evitar epidemias y desinfectar corrales de aves.

ESTRUCTURA DEL ASPERSOR

1. Contenedor de líquidos 4. Brazo y componentes de funcionamiento

2. Bomba y cámara de aire 5. Sistema de cinturón tipo mochila

3. Sistema de rocío (incluye manguera de goma y componentes, interruptor, eje y cabezal del aspersor)

Page 7

PRINCIPIOS DE FUNCIONAMIENTO

Con el movimiento del brazo y los componentes de funcionamiento, el álabe de la bomba sube y baja para

que la esfera de sellado se active y desactive, lo que permite que la presión de la cámara de aire suba y baje,

impulsando el líquido para que entre en la cámara. El líquido pasa por el sistema de rocío y sale pulverizado.

CARACTERÍSTICAS:

1. La forma externa imita la curva de la espalda del cuerpo humano. La combinación de la cámara de aire y la

bomba ubicada en el contenedor de líquido permite que toda la estructura sea compacta, segura y resistente a

las fugas.

2. El brazo de funcionamiento tiene un conector que permite instalarlo en ambos lados. Es conveniente y rápido,

y mientras está en uso, es difícil que el brazo se salga, lo que permite que el usuario pueda usarlo con la mano

derecha o izquierda.

3. Use los distintos cabezales para las diferentes tareas y para ajustar entre patrones de rocío finos y gruesos.

4. Los materiales elegidos para al aspersor son excelentes, resistentes al ácido, la corrosión y la alcalinidad. El

aspersor está sellado herméticamente y es muy durable.

MÉTODO DE FUNCIONAMIENTO

Después de abrir el envase del aspersor, revise que estén todas las piezas que indica la lista del envase. Luego,

arme el aspersor siguiendo las indicaciones del diagrama. Antes de usarlo, desenrosque la tapa del contenedor.

Vierta lentamente el líquido por el filtro en el contenedor. Luego, cierre muy bien la tapa y colóquese el aspersor

en la espalda. Gire el brazo de funcionamiento después de que aumente la presión de la cámara de aire. Apriete

al interruptor para comenzar a rociar. Puede ser un rocío dirigido y también un rocío continuo.

Elija los diferentes cabezales de rocío para rociar correctamente.

Se incluyen tres tipos de cabezales de rocío.

1. Cabezal de rocío tipo abanico: con este cabezal puede rociar en forma pareja y

está indicado para rociar plantas pequeñas o de altura media. Para rociar

herbicidas, mantenga estable el cabezal de rocío y siga la dirección del viento.

2. Cabezal de rocío cónico: se puede utilizar para rociar pesticidas e insecticidas

y prevenir enfermedades.

3. Cabezal de rocío ajustable de cuatro orificios: se utiliza para rociar arbustos

altos y árboles frutales.

PARÁMETROS Y VELOCIDAD DE FLUJO DEL CABEZAL DE ROCÍO

1. Tipo: Aspersor Bak-Pak® 4. Flujo de operación: 60-80mm

2. Capacidad del contenedor: 4 galones, 15 litros 5. Diámetro del álabe: 45mm

3. Presión de funcionamiento: 0,3 a 0,4 MPA 6. Peso neto: 3,2kg

Page 8

PUNTOS IMPORTANTES

Tipo de boquilla:

1. Antes de encender el interruptor, no gire el brazo de funcionamiento en forma continua por períodos largos,

así evitará que se dañe el aspersor.

2. Mientras rocía pesticidas, el usuario debe usar máscara y guantes, para evitar el contacto directo con el

pesticida y lastimar el cuerpo. No rocíe el pesticida hacia el viento. No rocíe el pesticida cerca de personas,

animales ni alimentos. No lo utilice por largos períodos de tiempo bajo altas temperaturas.

3. Cuando manipule el pesticida, cumpla a cabalidad con las indicaciones de seguridad.

4. No utilice con ácidos fuertes ni líquidos alcalinos. No utilice pesticidas altamente tóxicos o altos en residuos

en vegetales, melones, calabazas, frutas ni hierbas medicinales. Después de aplicar los pesticidas, según las

indicaciones del fabricante, no coma los vegetales durantes varios días.

5. Después de rociar, limpie el aspersor, para evitar que los líquidos lo corroan o bloqueen el cabezal de rocío.

Evite mezclar pesticidas residuales con el siguiente pesticida que utilizará. Esto podría provocar una reacción

química y alterar el efecto del pesticida.

MPA de presión

Velocidad de

flujo L/min

Tipo de boquilla:

MPA de presión

Velocidad de

flujo L/min

6. Para períodos de inutilización extendidos o uso continuo por varios días, agregue vaselina en los sellos, el aro

tórico y las piezas movibles para reducir el desgaste de las piezas.

SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA SOLUCIÓN

Fugas o problemas en

el rocío

La palanca de la bomba

está dura.

Baja presión.

La placa de sellado

está dañada o suelta.

La boquilla de rocío o el

filtro está bloqueado.

Álabe o esfera de sellado

gastado.

Cambie la placa de

sellado o apriete.

Enjuague el filtro y

la boquilla con agua.

Agregue vaselina en las

piezas movibles.

Cambie el álabe o la esfera

de sellado.

La palanca de la bomba se

mueve muy rápido, no hay

presión.

Falta el sello.

Coloque el nuevo sello

correctamente.

Page 9

Page 10

Page 11

Instructions 871-785 Modèle 13194

Garantie limitée

H. D. Hudson Manufacturing Company garantit à l’acheteur initial seulement que ce produit fonctionnera comme prévu

s’il est utilisé conformément aux instructions d’utilisation (dans les CONDITIONS NORMALES D’UTILISATION) pendant

une période d’un an. Si le produit ne fonctionne pas comme prévu - NE LE RAMENEZ PAS EN MAGASIN - appelez notre

SERVICE À LA CLIENTÈLE AU 1-800-9-SPRAYER (1-800-977-7293) (sans frais) pour obtenir rapidement du service.

Nous réparerons ou remplacerons gratuitement, à notre choix, toute pièce défectueuse (des frais d’expédition et de

manutention sont applicables).H. D. Hudson Manufacturing Company se réserve le droit de demander le renvoi de tout

produit défectueux à l’adresse ci-dessous, ainsi que la preuve d’achat afin d’établir une réclamation selon les termes

de cette garantie. Cette garantie ne s’applique pas aux dommages résultant d’un accident, d’une mauvaise utilisation,

d’une négligence, de modifications, d’une utilisation non conforme aux instructions, d’une utilisation commerciale ou

de l’usure normale.

TOUTE GARANTIE IMPLICITE, Y COMPRIS LA GARANTIE IMPLICITE DE LA QUALITÉ MARCHANDE ET CELLE D’APTITUDE

À UN USAGE PARTICULIER, SONT LIMITÉES À LA DURÉE SPÉCIFIÉE PLUS HAUT. LA RESPONSABILITÉ DE H. D. HUDSON

MANUFACTURING COMPANY SE LIMITE UNIQUEMENT À LA RÉPARATION OU AU REMPLACEMENT DU PRODUIT OU

DE LA PIÈCE DÉFECTUEUSE. H. D. HUDSON MANUFACTURING COMPANY DÉCLINE TOUTE RESPONSABILITÉ POUR

PERTES ET DOMMAGES FORTUITS ET INDIRECTS ET SECONDAIRES.

Certains États ou provinces ne permettant pas l’imposition de limites de durée d’une garantie implicite, ou ne

permettent pas d’exclure ou de limiter les pertes ou dommages fortuits ou indirects; les présentes restrictions

peuvent donc ne pas vous être applicables. Cette garantie vous confère des droits légaux précis. Il se peut que

vous bénéficiiez d’autres droits, lesquels varieront selon votre État ou votre province de résidence.

MISE EN GARDE!

MISE EN GARDE!!! CE PRODUIT EST CONÇU POUR APPLIQUER DES PRODUITS CHIMIQUES QUI PEUVENT

ÊTRE NOCIFS ET CAUSER DES BLESSURES PERSONNELLES GRAVES S’ILS SONT INHALÉS OU MIS EN

CONTACT AVEC LA PEAU DE L’UTILISATEUR. VOUS DEVEZ LIRE LE MANUEL AVANT D’UTILISER LE PRODUIT

ET VOUS CONFORMER AUX INSTRUCTIONS. UNE MAUVAISE UTILISATION POURRAIT ENTRAÎNER UNE

EXPLOSION OU DES BLESSURES GRAVES.

FONCTION PRINCIPALE

Ce pulvérisateur commercial Bak-PakMD est confortable à utiliser et pulvérise de façon homogène. Il est

particulièrement adapté aux produits de prévention et de soin des maladies, de lutte contre les insectes dans

les récoltes, les fleurs, les plantes et les jardins, aux produits d’assainissement des lieux publics, ainsi qu’aux

produits de prévention et de lutte contre les épizooties des animaux d’élevage et de la volaille.

STRUCTURE DU PULVÉRISATEUR

1. Réservoir pour les liquides Bras mobile et composants 4. Bras mobile et composants

2. Pompe et chambre à air Système de ceinture dorsal 5. Système de ceinture dorsale

3. Système de pulvérisation (avec tuyau en caoutchouc et composants, interrupteur, tige et tête de pulvérisation)

Page 12

PRINCIPE DE FONCTIONEMENT

Grâce au bras mobile et à ses composants, le corps redresseur monte et descend de sorte que la bille de clapet

tourne pour ouvrir ou obturer le passage de l’air, ce qui fait aussi monter et descendre la pression dans la

chambre à air et fait à son tour monter le liquide dans la chambre. Le liquide parcourt le système de pulvérisation

et gicle ensuite.

CARACTERISTIQUES :

1. La forme extérieure imite la courbe du dos. L’assemblage de la chambre à air et de la pompe dans le réservoir

de liquides rend la structure compacte, sécuritaire et résistante aux fuites.

2. Le bras mobile est conçu pour pouvoir être posé d’un côté ou de l’autre du pulvérisateur. Il est facile et

pratique à manipuler et ne se sépare pas facilement du pulvérisateur lors de l’utilisation, ce qui le rend plus facile

à faire fonctionner, que ce soit de la main droite ou de la main gauche.

3. Utilisez les différentes buses pour différentes applications et pour régler les jets fins ou grossiers.

4. Les matériaux choisis pour fabriquer ce pulvérisateur sont de très bonne qualité, résistent aux acides, à la

corrosion et à l’alcalinité. Le pulvérisateur est scellé de façon étanche et très durable.

MÉTHODE DE FONCTIONNEMENT

Après avoir ouvert l’emballage, vérifiez que toutes les pièces correspondent à la liste des pièces. Assemblez

ensuite le pulvérisateur à l’aide du schéma. Avant d’utiliser le pulvérisateur, dévissez le couvercle du réservoir.

Remplissez le réservoir en versant lentement le liquide préparé d’avance à travers le filtre. Fermez ensuite le

couvercle hermétiquement et portez le pulvérisateur sur votre dos. Actionnez le bras mobile, après avoir laissé la

pression de la chambre à air monter. Appuyez sur la poignée de commande pour commencer à pulvériser. Vous

pouvez pulvériser de façon intermittente ou continue.

Choisissez la buse adaptée à l’application.

3 types de buses sont fournis.

1.Buse éventail : Elle pulvérise de façon uniforme et convient pour pulvériser les

plantes de taille petite à moyenne. Pour pulvériser du produit contre les

mauvaises herbes, gardez la buse stable et pulvérisez dans le sens du vent.

2. Buse conique : Vous pouvez l’utiliser pour pulvériser des pesticides et des

insecticides, ainsi que pour les produits de prévention des maladies.

3. Buse réglable à 4 trous : pour pulvériser les gros buissons et les arbres fruitiers.

PARAMÈTRES ET CONTRÔLE DU DÉBIT DE LA BUSE

1. Type : Pulvérisateur Bak-PakMD Portée : 60-80 mm 4. Portée: 60-80mm

2.Capacité du réservoir : 4 gallons,

15 litres Diamètre du corps redresseur : 45 mm 5. Diamètre du corps redresseur: 45mm

3. Pression de travail : 0,3-0,4 MPa Poids net : 3,2 kg 6. Poids net: 3.2kg

Page 13

POINTS IMPORTANTS

Type de buse

1. N’actionnez pas le bras mobile pendant trop longtemps avant d’appuyer sur la commande, ceci pourrait

endommager le pulvérisateur.

2. Lorsque vous pulvérisez des pesticides, portez un masque et des gants, afin d’empêcher le produit d’entrer en

contact avec votre peau et de vous blesser. Ne pulvérisez pas de pesticides contre le vent. Ne pulvérisez pas de

pesticides en direction de personnes, d’animaux ou de nourriture. N’utilisez pas l’appareil pendant de longues

périodes à des températures élevées.

3. Lors de l’entreposage de pesticides, veuillez vous conformer précisément aux directives de sécurité.

4. N’utilisez pas l’appareil avec des acides forts ou des liquides alcalins. N’utilisez pas de pesticides persistants

ou très toxiques sur les légumes, les melons, les courges, les fruits et les herbes médicinales. Après l’application

de pesticides, suivez les recommandations du fabricant et attendez plusieurs jours avant de consommer les

légumes pulvérisés.

5. Nettoyez le pulvérisateur après usage pour empêcher les liquides de corroder le pulvérisateur ou d’obstruer la

buse. Évitez de mélanger un restant de pesticide avec un nouveau pesticide. Ceci pourrait causer une réaction

chimique et avoir des conséquences sur l’efficacité du pesticide.

Pression en MPa

Débit en L/min

Type de buse

Pression en MPa

Débit en L/

min

6. Si vous n’utilisez pas le pulvérisateur pendant de longues périodes ou prévoyez de l’utiliser de façon continue

pendant plusieurs jours, ajoutez de la Vaseline sur les joints d’étanchéité, les joints toriques et les parties

mobiles pour réduire l’usure des pièces.

RÉSOLUTION DE PROBLÈMES

PROBLÈME CAUSE SOLUTION

Fuite ou mauvaise

pulvérisation.

La poignée de la pompe

est difficile à actionner.

Pression basse. Le corps ou la bille de

La plaque d’étanchéité

est endommagée ou mal

serrée.

La buse ou le filtre sont

bloqués.

clapet sont usés.

Replacez ou resserrez-la.

Rincez le filtre et la buse

à l’eau. Ajoutez de la

Vaseline sur les pièces

mobiles.

Remplacez le corps ou la bille

de clapet.

La poignée de la pompe

bouge trop facilement pas de pression.

Il manque le joint

d’étanchéité.

Mettez un nouveau joint bien

en place.

Page 14

Page 15

Loading...

Loading...