Page 1

Operator’s Manual & Parts List

Manufactured and Engineered

for by

solo

®

®

MODEL 93425 and 93475

IF YOU HAVE ANY QUESTIONS OR CONCERNS, OR ARE

MISSING PARTS, DO NOT RETURN SPRAYER TO THE STORE!

93425

Piston

93475

Diaphragm

PLEASE CALL OUR CONSUMER

HOTLINE AT 1-800-9-SPRAYER

(1-800-977-7293)

Visit us on the Internet: www.hdhudson.com

E-mail: ladybug@hdhudson.com

Instruction 871-931 Model 93425 and 93475

maintenance tip: Cap gasket is prelubricated for improved sealing.Occasional lubrication is recommended.

SAFETY PRECAUTIONS:

1. Before using sprayer with chemicals, fill sprayer with fresh water to assure that you have it properly assembled; pressurize and

practice spraying. Also, check for any leaks at this time. When thoroughly familiar with the sprayer operation, follow normal operating

procedures.

2. Ensure all pressure in the sprayer is relieved by locking the shut-off valve in the open position.

3. Avoid contact with chemicals.

4. Always wear rubber gloves, safety goggles and appropriate protective clothing.

5. Work in a well ventilated area.

6. Individuals should be trained in the proper use of this sprayer, chemical handling procedures, and first aid/emergency

care. Where training is not available, individuals should study and follow the procedures detailed in this manual.

WARNING:

Chemicals can be harmful to individuals and the environment if improperly used. In addition, some chemicals are caustic, corrosive or

poisonous and should be avoided. Read warnings and chemical manufacturers’ instructions. Hudson high density polyethylene sprayers

are fitted with Viton

exercised to ensure that sprayer components are clean, functioning properly, and in a good state of repair before and during use. If

in doubt about a particular chemical, check with the manufacturer. If you suspect or observe indications that the material may be

unsafe in a Hudson sprayer...STOP. DO NOT USE OR APPLY CHEMICAL. ALWAYS WEAR RUBBER GLOVES, GOGGLES, AND APPROPRIATE PROTECTIVE

CLOTHING!

Read and follow operating instructions.•

Do not fill with, use, or spray flammable materials.•

Do not modify sprayer.•

Never spray in the direction of humans, animals or property which might be injured or damaged by spray formula.•

Do not use disinfectants, solvents or impregnating agents unless first tested to ensure they are not harmful to the environment or •

sprayer.

Do not use liquids with a temperature above 110°F (43°C).•

Wear appropriate protective clothing to prevent contact with chemical agents.•

Rinse and clean sprayer thoroughly after using. Disposal of contaminated rinse should be in accordance with applicable ordinances. •

Observe the precautionary instructions of the chemical manufacturer.

DO NOT USE ANY ACID (INCLUDING CITRUS) OR CAUSTIC • CHEMICALS (INCLUDING BLEACH).

Remember that a sprayer with liquid is a significant amount of weight (8 lbs. per gallon). Use caution when bending, leaning or •

walking. Bend at the knees rather than the waist.

During sprayer operation, the pressure cylinder (#4400240) contains compressed air and liquid. Compressed air and liquid under •

pressure are inherently dangerous. Before making adjustments on sprayers fitted with a pressure regulating valve body (#4074323)

or control knob (#4074344) located on the pressure cylinder or any other repair or inspection of any sprayer, be sure to relieve

pressure through the shut-off valve and wand.

® seals which are resistant to a wide variety of agricultural and household chemicals; however, care should be

STOP!

If you are missing parts, instructions or have questions, DO NOT take this unit back to the store.

Call 1-800-9SPRAYER. Hudson will send the missing parts/information to you promptly.

Page 2

A

B

D

1. Nozzle

2. Retaining Nut

3. Nozzle Body

Screw Cap

➔

➔

Wand

C

F

F

4. Filter with Gasket

5. Elbow

Gauge Mount

E

O-Ring

Shut-Off

➔

Install Wand

➔

➔

➔

E

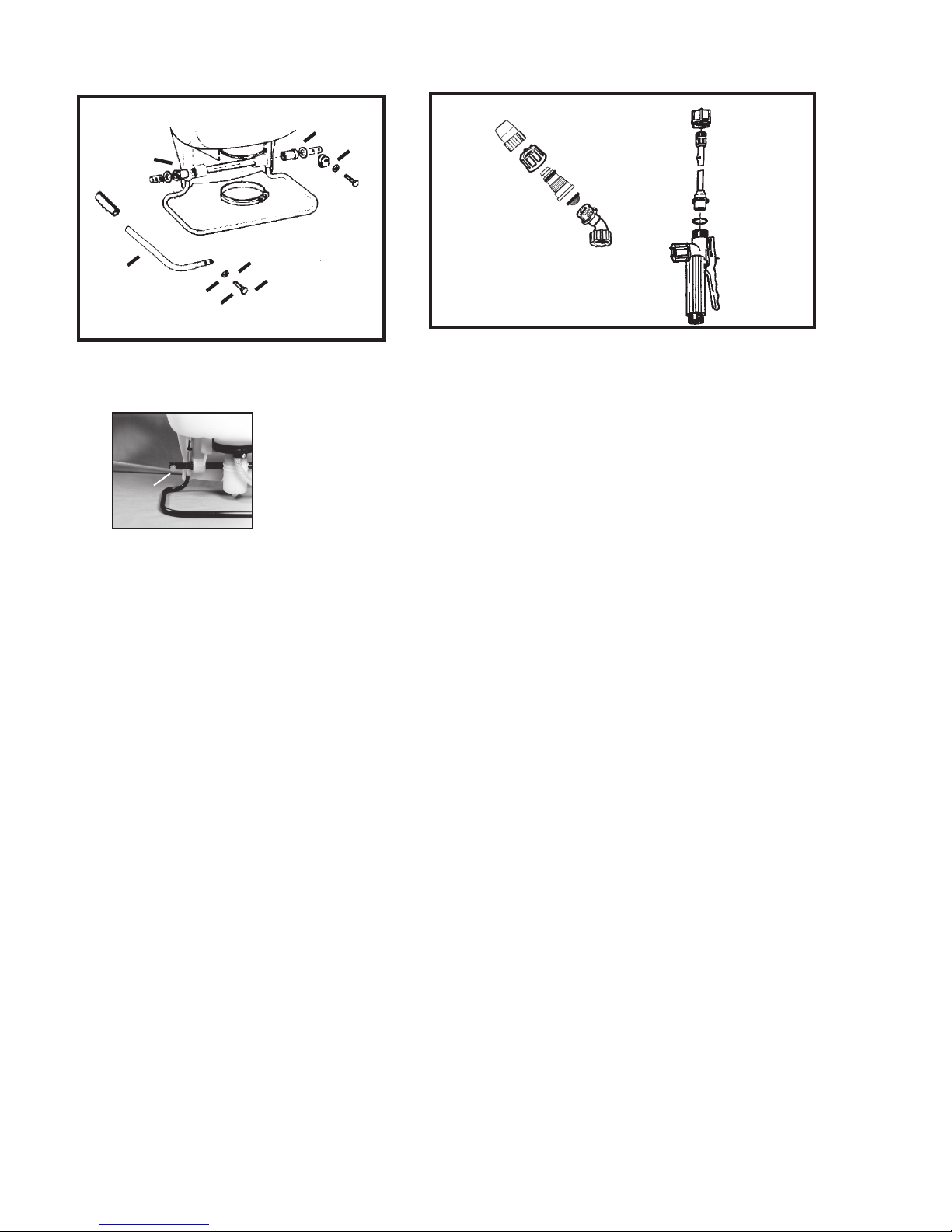

Removing plastic adjustable nozzle

Unscrew the nozzle cap (1) from the nozzle body (3). This

is best accomplished while the retaining nut (2) is fastened

tightly to the elbow (5). Next, unscrew the retaining nut (2).

A

pump leveR installation: All hardware necessary for pump lever installation is

included with the sprayer. The pump lever (C) should be installed as follows: place lever

handle (C) onto the shaft (A). Align bolt holes and install the two bolts (E) and washers

(F); then tighten. To install pump lever on the opposite side, remove the stop plate (D) and

washer, install the pump lever as above. The stop plate (D) should be mounted on the inner bolt hole with the

closed end of the stop plate pointing downward on the opposite side of the pump shaft.

Push the nozzle body (3) out of the retaining nut (2). The filter

with gasket (4) will come out with the body. To reinstall the

nozzle, reverse the above instructions.

assembly instRuctions foR Wand

1. Insert wand into shut-off valve as shown.

2. Tighten the screw cap clockwise onto the shut-off valve.

sHouldeR stRap installation:

The top of the shoulder straps are pre-attached to the sprayer by means of a buckle. The lower end of the straps

are attached by fastening the strap hooks to the metal frame between where frame exits the plastic tank and makes

a bend.

filling:

Mix the spray formula and the proper volume of water in a separate container. Pour the mix through the filter

basket in the tank opening. This keeps debris from entering sprayer. Add 2 or 3 gallons of spray formula mix. Pump

the sprayer handle to prime the pump and fill the pressure cylinder. The volume of liquid in formula mix tank will

appear to decrease as the pressure cylinder is filled. Liquid will flow through the top of the pressure regulator

when the cylinder is completely full. Add the remaining formula mix to the tank. Remember that it’s not necessary

to completely fill the sprayer tank each time. Mix only the amount needed to get the job done.

Always read and follow manufacturer’s instructions printed on the product label. This can save money and help

prevent crop and environmental damage.

2

Page 3

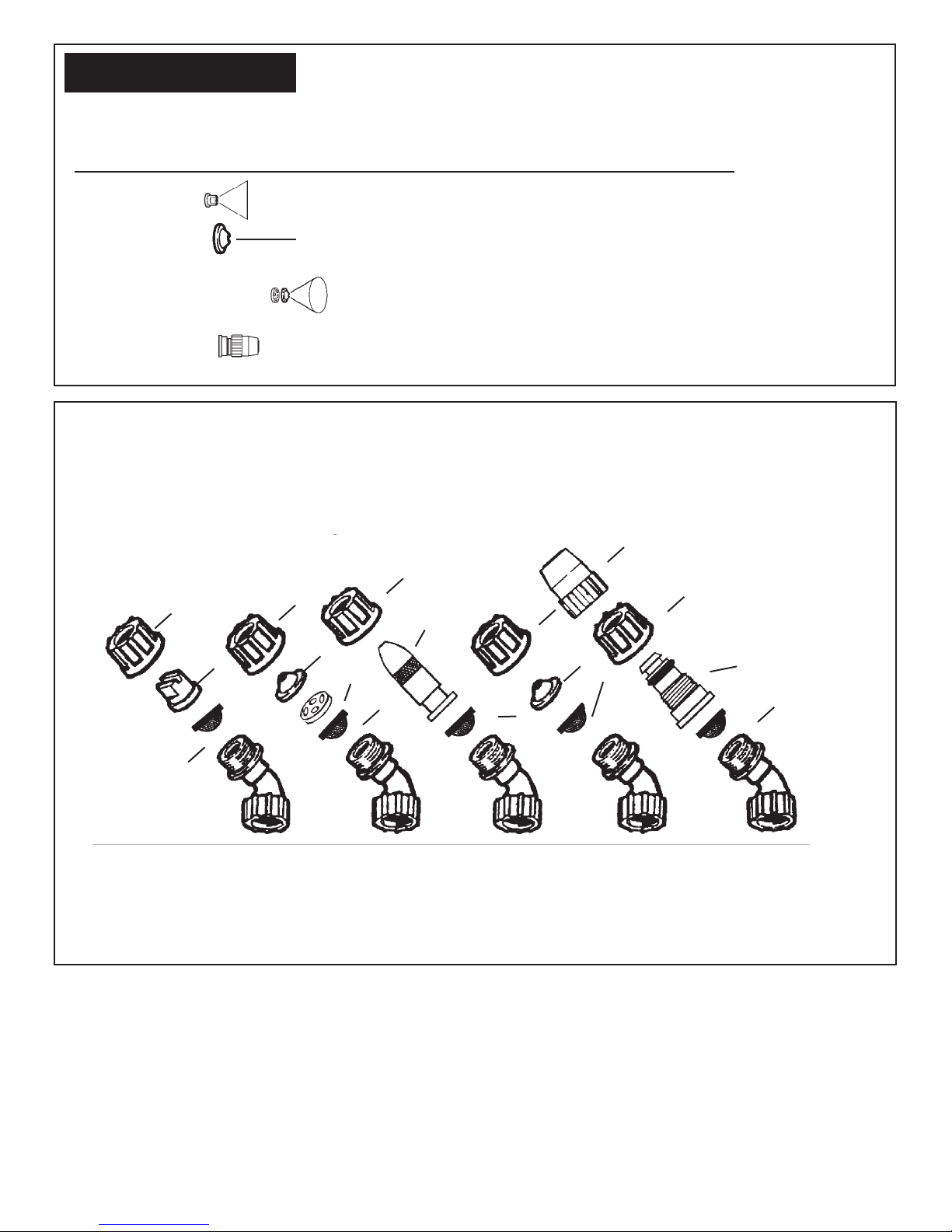

opeRating featuRes:

Nozzles - Your Hudson sprayer is supplied with nozzle arrangements to provide a variety of spray patterns.

Item Application Part #

Flat spray nozzle Row treatment 4074263

Jet stream nozzle Spot & longer range 4074755

Jet stream nozzle and Shrubs and bushes 4074755

Swirl plate = hollow cone 4074756

Plastic adjustable Spot, shrubs & bushes 4900527

nozzle

spRay tip assembly

1. Flat spray nozzle

2. Filter

3. Jet cap

4. Swirl plate

5. Nozzle cap

6. Nozzle body

7. Brass adj. nozzle*

8. Nozzle retaining nut

8

1

8

8

7*

3

4

2

8

2

5

8

3

2

6

2

2

Flat spray Hollow

*Brass adjustable nozzle is not a standard item on all Hudson sprayers.

Spray tips should be assembled as above for desired spray pattern.

spRaying:

Prime the pump with rapid pump strokes. When you feel very firm resistance, the pressure chamber is filling with liquid.

With repeated piston strokes, the air in the pressure chamber is slowly compressed. By pressing the hand lever, the valve

opens, and liquid is forced through the nozzle. The shut-off valve has a retaining clip which keeps the valve in the “OPEN”

position for continuous operation. Pump using the end of the pump handle, as it is less fatiguing. The volume of liquid

delivered varies with the working pressure which should be as high as needed to ensure an adequate spray pattern for each individual

application.

NOTE: Should the pressure drop very quickly, drain the tank completely and pump without liquid. By this procedure, the air chamber is

refilled with the required volume of air. It is advisable to pump the tank completely empty from time to time.

cone spray

3

Brass

adjustable

nozzle*

Jet stream Plastic

adjustable

nozzle

Page 4

Wettable poWdeRs:

Avoid use in piston pump sprayer model 93425! The

Hudson model 93475 sprayer with a diaphragm pump

are generally resistant to abrasive materials and are

recommended for this purpose. Note: If you use a wettable

powder in your 93425 sprayer, be sure it is thoroughly

mixed in the formula solution. Immediately after use, be

sure to remove the piston, clean and lubricate the Viton®

collar with petroleum jelly. Thorough flushing of sprayer

will extend the life of its working parts. If you use wettable

powders in the piston pump sprayer, be sure to inspect

regularly for seepage around the piston and repair

accordingly.

cleaning:

• After spraying, clean the tank thoroughly. If some

spray liquid is left inside, drain tank completely.

• Pumpingcausesairtobetakeninandtheremaining

liquid to be discharged. Pump until liquid and air are

coming out through the nozzle.

• Refilltankwithafewquartsofcleanwaterandpump

the water out as explained above (if necessary,

repeat this procedure several times).

• If the shut-off valve is removed, the pump can be

flushed quickly. Improper spray distribution is the

result of a clogged nozzle, which is easily removed

and cleaned.

• Soapandwatermayalsobeusedtocleantank.

• Do not use aggressive cleaning agents or

abrasives.

• Follow the recommendations of the chemical

manufacturer for disposal of waste water and

chemicals.

• Activated charcoal in liquid or other form may be

used to absorb chemicals in tanks or spills.

NOTE: When cleaning the sprayer after working with

hormone weedkillers, follow the instructions of the

herbicide producers. Neutralize with activated

charcoal. (Example: add 0.35 oz./1 g. of activated

charcoal to 1.7 pint/1 liter of water and leave this

detergent in the tank and the lines approximately

for 24 hours.) This is very important if other

chemicals should be sprayed as the residues of the

herbicide may damage susceptible plants. Cleaning after

application of products containing carbolineum, if they

are not water soluble, should be done with a 5% soda lye

having a temperature of 104°F (40°C). Rinse with plenty

of clean water.

maintenance and stoRage tips:

To protect the piston, cylinder and Viton® collar, a fine

mesh, stainless steel screen is located on the pressure

cylinder inlet.

If you find that your sprayer

will not empty the formula

tank, check for a clogged inlet

screen (2). The inlet screen is

located at the bottom of the

pressure cylinder on the side

that faces your back.

One indication that it needs

cleaning is that when you let

go of the pump handle, it

“springs” to the down position.

The screen can be cleaned

with a small bristle brush or

a discarded toothbrush. See

diagram for location of

screen.

• After operation, the sprayer should be storedaway

from direct sunlight to prevent UV damage.

• After removing the pump or when mounting a new

Viton® collar, treat both the collar and the piston with

water-resistant grease.*

• Before winter,drain all liquid in tank, lines and air

chamber. (See “Cleaning.”) Leave shut-off valve

locked in the “open” position.

• Forservice,visitourwebsitewww.hdhudson.comto

locate your nearest Hudson dealer. Always insist on

original Hudson spare parts.

• Regularly inspect hose, wand, pump, tank and

shut-off valve for wear, damage or leaks. Repair

promptly.

• Occasionallylubricatecapgasket.*

Avoid excessive wear by:

1) Regular lubrication of Viton® collar, cylinder and

piston with water resistant grease.*

2) Prompt and thorough cleaning and flushing of

sprayer. Soap and water work well.

1. Pressure Cylinder

2. Inlet Screen

3. Cylinder Support

1

2

3

WARNING!!! THIS PRODUCT IS DESIGNED TO APPLY CHEMICALS THAT MAY BE HARMFUL AND COULD

CAUSE SERIOUS PERSONAL INJURY IF INHALED OR BROUGHT INTO CONTACT WITH THE USER. FAILURE TO

READ AND FOLLOW OWNER’S MANUAL INSTRUCTIONS BEFORE USE AND/OR MISUSE OF THIS PRODUCT

COULD RESULT IN EXPLOSIVE FAILURE WITH MAJOR INJURIES.

WARNING!

4

Page 5

LIMITED WARRANTY

H. D. Hudson Manufacturing Company warrants to the original purchaser only that this product will continue to

function as intended if used in accordance with operating instructions (under NORMAL CONSUMER USE) for

one year. If the product fails to function as intended—DO NOT RETURN IT TO THE STORE—call our CONSUMER

SERVICE HOTLINE AT 1-800-9-SPRAYER (toll free) for fast service. We will, at our option, repair or replace any

non-functioning parts without charge (shipping and handling charges will apply) H. D. Hudson Manufacturing

Company shall have the option of requiring the return of the non-functioning product to the address listed below,

together with the proof of purchase, to establish a claim under this warranty. This warranty does not apply to

damage resulting from accident, misuse, neglect, alterations, operation not in accordance with instructions,

commercial use, or normal wear.

ANY IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR

CONSUMER USE, ARE LIMITED TO THE DURATION SPECIFIED ABOVE. H. D. HUDSON MANUFACTURING

COMPANY’S LIABILITY IS LIMITED SOLELY TO THE REPAIR OR REPLACEMENT OF THE NON-FUNCTIONING

PRODUCT OR PART. H. D. HUDSON MANUFACTURING COMPANY EXCLUDES LIABILITY UNDER THIS WARRANTY

FOR ANY AND ALL INCIDENTAL AND CONSEQUENTIAL LOSS OR DAMAGE.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so these limitations or exclusions may not apply to you. This warranty

gives you specific legal rights and you may have other rights which vary from state to state.

IF YOU HAVE QUESTIONS OR CONCERNS: PLEASE CALL OUR CONSUMER HOTLINE AT 1-800-9-SPRAYER.

(1-800-977-7293)

genuine seRvice paRts:

Order them from your dealer or call 1-800-9-SPRAYER (1-800-977-7293).

A

A. 0610402K Shut-off valve repair kit

Includes O-rings, plunger, spring and retaining cap

B. 4900170N 28" universal wand assembly

Includes 28” unbreakable poly wand for hard-to-reach places, adjustable and flat fan nozzle

for multiple spraying tasks, professional shut-off valve with lock-on/lock-off features.

C. 0610408P Sprayer elbow & nozzle assortment

Includes elbow, retaining nut, swirl plate, jet cap, filter screen, flat spray nozzles, no-drip

check valve and O-rings.

D. 0610410P Brass adjustable nozzle kit

Includes retaining nut, O-ring, brass nozzle body and nozzle tip

E. 0610406K Diaphragm pump repair kit

Includes replacement diaphragm, pressure cylinder O-ring, valve plates, seal plug with spring,

and O-rings for valve assembly.

F. 0610407K Piston pump repair kit

Includes Viton collar, pressure cylinder O-ring, valve plates, seal plug with spring, and

O-rings for pump cylinder.

B

In the best interest of continued technological progress, we reserve the right to change design and configuration of

any product without prior or other notice. Therefore, please note that text and illustrations of this manual are not to

be considered binding and do not constitute a basis for legal or other claims.

C D E F

5

Page 6

spaRe paRts list

38

107

108

Deluxe models only

109

110

113

ECS Model

DLX

Only

PLEASE NOTE THAT REPLACEMENT PARTS ARE SOLD AS KITS AND NOT INDIVIDUALLY.

(SEE PAGE 5 FOR KIT LISTINGS) PLEASE CALL OUR CUSTOMER CARE LINE AT 1-800-9SPRAYER.

6

Page 7

INSTALLATION INSTRUCTIONS

PISTON PUMP REPAIR KIT ( # 0610407-K)

Tools needed for kit installation: 6mm Allen Head Wrench, Flat Screwdriver, 11mm Wrench or Cresent Wrench, Long Nose

Pliers, Hammer, 13mm Socket or Wrench, T-25 Torx Screwdriver, Grease or Petroleum Jelly, 2X4 Piece of wood 18” long

1. Using a 13mm socket wrench

remove the handle bolts, and set

aside. Lay unit on its back with pump

assembly facing you. See figure 1.

Loosen hose clamp (E). Pull off sprayer

hose. Caution: There may be liquid

inside the hose and pressure cylinder

even when the tank is empty. Wear

protective gloves. Next, remove the

nut and bolt from protective cap, and

remove cap (C). Loosen stop plate (A)

but do not remove. Rotate the pump

shaft to access the two lever bolts in

the center (B). Using a 6mm allen head

wrench, remove them. Pull the piston

(F) out of the piston cylinder (D).

2. To remove the piston cylinder

assembly, turn the cylinder counter

clockwise when viewing from the

bottom. Figure 2. Caution: The piston

cylinder has sharp edges.

3. Check the inside of the piston and

cylinder for scratches. If the piston or

cylinder are scratched, replace. Figure

3.

4. To remove connecting rods from

the piston and lever, insert a flat

tip screwdriver between the two

connecting rods and twist. Figure 4.

5. With the new piston, place the two

connecting rods over the studs on the

inside of the piston. Place the lever

studs into the connecting rods and

snap together with your fingers. Figure

5.

6. To replace the Viton® collar, push

it off the top of the piston with your

thumb. Figure 6. Install the new collar

on the piston onto the form fitted sides.

C

E

D

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

B

A

8. If necessary remove the pressure

cylinder by unscrewing the pressure

F

regulator control, if equipped. Remove

the large clamp at the bottom of the

cylinder. Use a block of wood and hit

forcefully with a hammer, driving the

assembly through the bottom of the

tank. Figure 9.

9. Next, assemble the piston cylinder.

First grease the O-ring on the piston

cylinder, being careful not to get any

on the valve plate, and then place

the piston cylinder into the pressure

cylinder. Screw the piston cylinder

clockwise until it is tight and the

bottom O-ring is no longer seen. Figure

10. When properly seated the notch on

the piston cylinder (G) will line up with

the indent on the pressure cylinder (H).

Figure 11.

10. Apply a light coat of grease to the

inside of the piston cylinder wall and

on the Viton® collar, and then re-install

the piston into the piston cylinder.

Figure 12. To insert the piston, tilt at

a slight angle with the leading edge

of the Viton® collar placed over the

slot. When seated, install the 6mm

Allen Head bolts through lever base

into shaft. Replace the protective cap

and tighten the nut and bolt. Reinstall

the handle. Re-tighten the stop plate,

making sure the bolt goes through the

rear hole. Replace the hose and black

hose clamp making sure it is firmly

secured. Re-tighten the stop plate,

making sure the bolt goes through the

rear hole. Replace the hose and black

hose clamp making sure it is firmly

secured.

Figure 8.

Figure 9.

Figure 10.

G

Figure 11.

Figure 12.

H

7. Remove the valve plate and

O-rings from the outside of the piston

cylinder. Install the new valve plate

and the two O-rings making sure the

O-rings seat in the grooves. Finally,

inside the piston cylinder you will find

a second valve plate. Using needle

nose pliers, pull out the red or orange

pin and remove the valve plate. Figure

7. Install a new valve plate and firmly

reseat the retaining pin using needle

nose pliers. Figure 8.

Figure 6.

Figure 7.

NOTE: Always wear rubber gloves, safety goggles and appropriate

protective clothing when repairing a sprayer. Work in a well-ventilated

area. Prior to repair, flush unit with water by filling, then spraying the

water into an appropriate container or area. Ensure that all pressure is

released by locking the shut-off valve in the open position. Once a repair is

completed, fill the unit with clean water, pressurize, and check for leaks. If

the sprayer leaks, DO NOT USE. Repair leaks and recheck.

7

Page 8

INSTALLATION INSTRUCTIONS

Diaphragm Pump Repair Kit ( # 0610406-K)

Tools needed for kit installation: 6mm Allen Head Wrench, Flat Screwdriver, 11mm Wrench or Cresent Wrench, Long Nose

Pliers, Hammer, 13mm Socket or Wrench, T-25 Torx Screwdriver, Grease or Petroleum Jelly, 2X4 Piece of wood 18” long

1. Using a 13mm socket wrench,

remove handle bolts and loosen the

stop plate (A) and remove the two

allen head screws (B) that hold the

connecting pieces to the pump rod.

Figure 1.

2. With unit laying on its back with

pump assembly facing you, remove the

pump rod (C). Loosen hose clamp and

remove pressure hose (D). Next, loosen

the clamp at the base of the sprayer (E).

Figure 2.

3. Push the pressure cylinder

approximately 1" out of the bottom of

the tank. Then turn the pump assy. 180

degrees. Note: Wooden block may be

used to tap the pump assembly through

bottom of tank. Remove pressure

regulating valve, if equipped before

removal of cylinder.

4. Next remove the 12 torx screws that

hold the flange in place. The flange

and diaphragm can then be removed.

Figure 3. Note: For clarity the pressure

cylinder is shown removed from the

tank.

5. To replace the diaphragm, remove

the connecting rod retaining screw (G)

from the plunger and lever (F). Replace

the diaphragm and reassemble. See

Figure 4.

6. The valve assy. (H) is removed using

a locally made tool. Remove red valve

plate retaining pin using needle nose

pliers, then insert tool into slots. See

Figure 5. Use a screwdriver to rotate

tool counter clockwise.

7. Once the valve assembly is removed,

the valve plates and O-rings can be

replaced. The bottom valve plate is

secured into place with a red retaining

pin. Push pin into place using needle

nose pliers. Figure 6.

8. The pump housing (I) is separated

from the pressure cylinder (J) by pulling

it off. Figure 7. The O-ring can then be

replaced.

Figure 1

Figure 2

Figure 3

G

Figure 4

Figure 5

Figure 6

J

Figure 7

9. When reassembling the pump housing

to the pressure cylinder, be sure the

square tab on the pump housing (K) is

K

L

aligned in the notch. See arrows (L)

on the pressure cylinder in Figure 8. Be

careful not to pinch or nick the O-ring.

Note: Grease O-rings for re-assembly. Screw

Figure 8

the valve assembly into the cylinder.

10. Place diaphragm assembly (O) onto

the pump housing (M). Place the flange

(N) over the diaphragm. Reinstall the 12

M

N

O

torx screws around the outside diameter

of the flange. Figure 9.

11. Push pressure cylinder into the

Figure 9

tank being careful not to pinch the large

O-ring (P).

Note: Wooden block may also be used

for installation of the pressure cylinder.

P

12. Tighten pump clamp securely

F

(E). Install pump rod (C). Reinstall the

connecting pieces and allen head screws

Figure 10

(B). Reinstall the stop plate (A) making

sure that the bolt goes through the rear

hole. Reinstall the hose and hose clamp

making sure it is firmly secured (D).

H

Figure 11

I

NOTE: Always wear rubber gloves, safety goggles and appropriate

protective clothing when repairing a sprayer. Work in a well-ventilated

area. Prior to repair, flush unit with water by filling, then spraying the

water into an appropriate container or area. Ensure that all pressure is

released by locking the shut-off valve in the open position. Once a repair is

completed, fill the unit with clean water, pressurize, and check for leaks. If

the sprayer leaks, DO NOT USE. Repair leaks and recheck.

8

Loading...

Loading...