Page 1

Tuf-Lite

®

and

Tuf-Lite II® Fans

5000 Series Hub

INSTALLATION MANUAL

Adjustable Pitch Fan Assembly

22’ thru 30’ Diameter

Hudson Tuf-Lite® and Tuf-Lite II® fan blades

Hudson Tuf-Lite® (black) fan blades are made from fiberglass reinforced epoxy resin having a very high

strength-to-weight ratio and corrosion resistance (not shown).

Hudson Tuf-Lite II® (white, prev. blue***) fan blades are made from fiberglass reinforced vinyl-ester resin

having a very high strength-to-weight ratio and superior ultra-violet and corrosion resistance. An elastomeric

blade/holder joint cover (not shown) prevents moisture from entering the blade (shown above).

The individually balanced blades can be replaced independently – matched sets are not required.

Installation Manual 5000 Page 1 of 8 April 2010

Page 2

RECOMMENDED TOOLS

l Long T-Handle Allen Wrench Set (3/16” to 3/8”)

l Medium Size Flat Head Screw Driver

l Brass Ball Peen Hammer

l Flat Bastard File

l 240 Grit Sand Paper

l Anti-Seize Lubricant

l WD-40

l 12” Crescent Wrench

INSTALLATION PROCEDURES

ASSEMBLY WITH BUSHING

Clean all mating surfaces between hub, bushing and shaft. All

grease and lubricant should be removed, leaving the mating surfaces dry.

If there is no shoulder on shaft to prevent bushing from sliding

down shaft, slide spacer/sleeve (not provided) on shaft before bushing or use a thrust retainer (optional equipment) on top of hub.

Slide bushing and key onto shaft until flush with end of shaft. The

shaft size determines the bushing type (R2, S2, or U1). Lock bushing on shaft by tightening the set screw in flange with an Allen

Wrench. Line up key and set hub on bushing. Engage the three (3)

cap screws in flange of bushing into hub spool, using a torque

wrench with a socket, and tighten evenly. Use the following table

to determine the proper tools and torque values.

l Shop Towels

l Exact-A-Pitch

l 25 ft. Measuring Tape

l Pencil or Marker

l Open/Box End Wrench Set (1/2” - 1-1/2”)

l Socket Set for 1/2” Drive (1/2” - 1-1/2”)

l Torque Wrench(s) Rated for 0-200 ft-lb.

®

Digital Protractor (P/N 62375)

ASSEMBLY WITH STRAIGHT SHAFT

(NO BUSHING)

Clean all mating surfaces between the hub and the shaft. If there is

no shoulder on shaft to prevent hub from sliding down shaft, slide

spacer/sleeve (not provided) on shaft before hub or use a thrust

retainer (optional equipment) on top of hub. Install key in shaft.

Line up key and keyway and set hub on shaft. Tighten set screw(s)

in hub.

ASSEMBLY WITH TAPERED SHAFT

(NO BUSHING REQUIRED)

Clean all mating surfaces between the hub and shaft.

Allen Cap Torque

Bushing Wrench Screw Socket (ft-lb)

Size Size Size Size Dry

R2 3/16” 3/8” 9/16” 29

S2 3/16” 1/2” 3/4” 70

U1 3/16” 5/8” 15/16” 140

Align keyways and install hub. Install retainer plate and cap

screw(s) with lock washer(s). Shaft size determines what size cap

screw is necessary. Using a torque wrench with a socket, evenly

tighten cap screw to recommended standard per table below.

Torque Value

Cap Screw Socket (ft-lb)

Size Size Lubricated Dry

5/8” NC 15/16” 100 110

3/4” NC 1-1/8” 125 130

1” NC 1-1/2” 150 160

NOTE: Retaining arrangement varies with gear shaft design.

Installation Manual 5000 Page 2 of 8 April 2010

Page 3

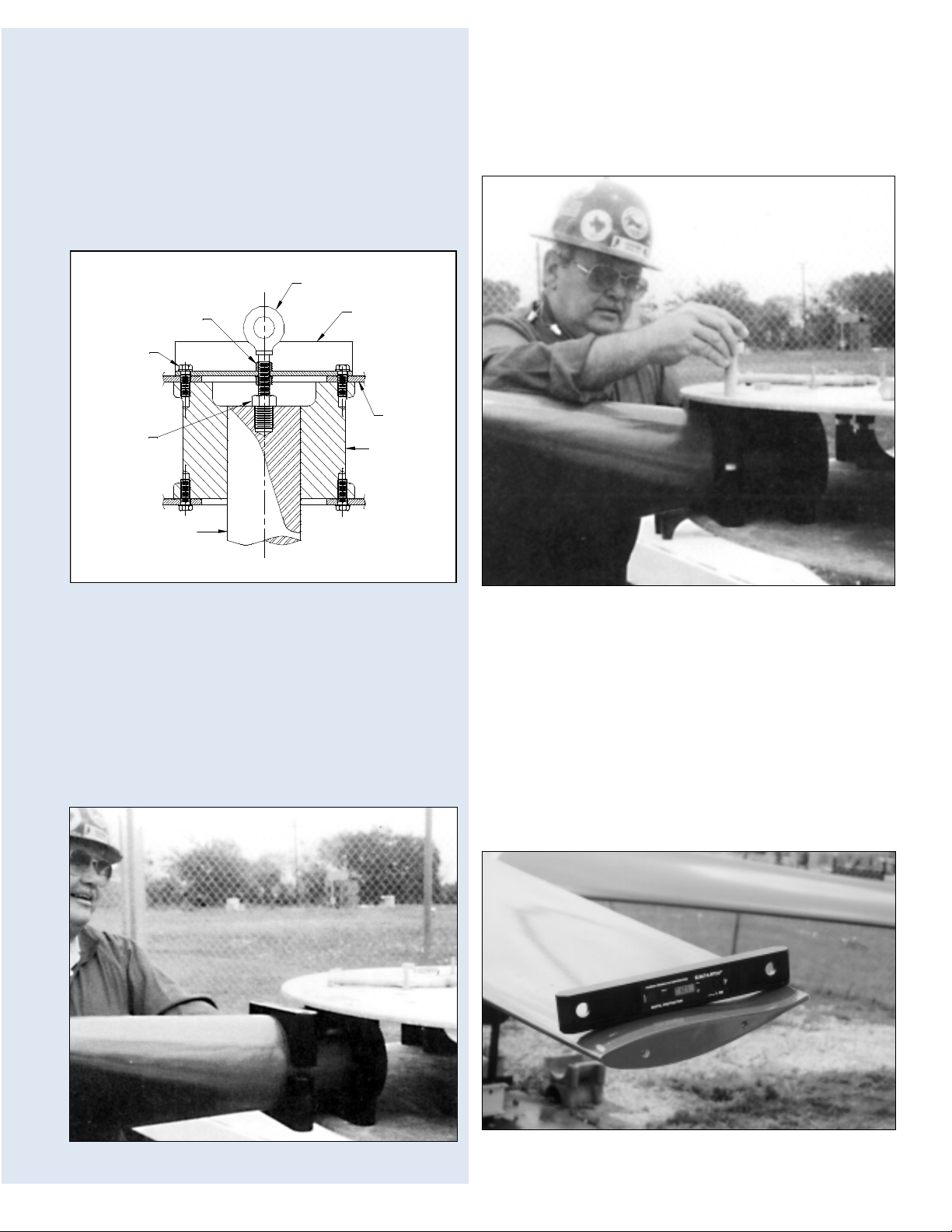

THRUST RETAINER (optional equipment)

EYE BOLT

JAM N UT

THRU ST R ETAIN ER

CHAN NEL W/ NU T

HUB P LATE

HUB S POOL

HUB SPO OL

BOLT

CUST OME R

PROVI DED

BOLT

FAN S HAFT

Install proper load bolt (not provided) into top of fan shaft and

tighten (See Figure 1). Install thrust retainer channel on top

hub plate using existing hub spool cap screws. Torque cap screws

to 60-65 ft-lb. Install thrust retainer eyebolt and jam nut. Hand

tighten eyebolt. Tighten jam nut securely against top of thrust

retainer channel.

Install clamp bolts through hub plates and blade clamp, putting bolt

heads on top, lock washers and nuts on bottom. Tighten lightly (See

Figure 3).

Figure 1

BLADE INSTALLATION

Remove blade clamp bolts, nuts, lock washers, and blade clamp

halves from hub. Assemble blade clamp halves over groove in

blade neck, and install into hub (See Figure 2). The thick leading edge will be to your left and thin trailing edge will be to

your right as you stand at end of blade.

Figure 3

SET PITCH AND TRACK

Use Hudson EXACT-A-PITCH® digital protractor (See

Figure 4) or a bubble protractor to set blade pitch. Mount

protractor on a flat bar as a base and place it approximately 1”

from tip of blade. Note pitch on protractor. Rotate fan 360°,

noting high and low pitch readings. Locate place where pitch

reading is at mid-point between high and low readings, and set

pitch at that point.

Figure 2

Installation Manual 5000 Page 3 of 8 April 2010

Figure 4

Page 4

Rotate blade in clamp until digital protractor shows specified

pitch angle to within +/-0.2°. Fan pitch angle is shown on fan

specification sheet for design duty. After desired pitch angle is set,

raise and lower end of fan blade and find midpoint of blade travel.

Hold blade at the midpoint. Pull blade outward so that the blade

neck flange rests against the back of the blade clamps. Push blade

to the right to remove all slack.

SEAL DISC ASSEMBLY & INSTALLATION

Install self adhesive rubber gaskets on both flanges of one seal

disc half. Bolt two halves of seal disc together, using 3/8” NC

bolts, flat washer, lock washer, and nut. Torque to 15 ft-lb

(lubricated) and 20 ft-lb (dry).

Use torque wrench to tighten clamp bolts to 100 ft-lb (lubricated) or 125 ft-lb (dry). Recheck pitch setting. Blade must be

set within +/-0.2° of desired pitch angle. Tighten clamp bolts

evenly. DO NOT OVER-TORQUE CLAMP BOLTS.

When bolts are tightened, hold a pencil against top end of blade

and mark the level onto a fixed object, such as a pole or the

fan ring.

Install remaining blades at same place as first blade, following

the instructions above. After tightening bolts, mark top end of

each blade in same place first blade was marked. If marks differ

by 1” or more, adjust blade.

CHECK TRACK

After fan is installed in fan stack cylinder ring, outline top side

of each blade onto fan stack cylinder ring with a marker (See

Figure 5). The difference between levels of highest and lowest

outlines should not be more than 1”. Correct blade track by

loosening clamp bolts and adjusting blade to match track of other

blades. Retighten bolts and recheck track and pitch angle setting. Retighten blade clamp bolts to recommended standard of

100 ft-lb (lubricated) or 125 ft-lb (dry) torque.

Install 3/8” NC bolts at six (6) places on top hub plate (See

Figure 6). Threaded portion of bolts must be pointing up to

mount seal disc. Install lock washer, nut, and flat washer on

each bolt. Tighten 3/8” NC nuts to 15 ft-lb (lubricated) and 20

ft-lb (dry).

NOTE: 22B & 24B fans pitched above 10½ and 26B - 30B fans

pitched above 19½ require a different mounting arrangement.

Refer to instructions included with seal disc for details.

Locate the six (6) mounting holes in seal disc and install over

the six (6) bolts pointing up on upper hub plate. If difficulty is

encountered, loosen bolts on seal flanges until seal disc can be

mounted, then retighten to 15 ft-lb (lubricated) or 20 ft-lb (dry).

NOTE: The purpose of the seal disc is to prevent hot air from

recirculating back down through the hub, increasing efficiency.

Figure 6

Figure 5

Installation Manual 5000 Page 4 of 8 April 2010

Page 5

After mounting, install flat washer, lock washer, and 3/8” NC

nuts. Tighten to 15 ft-lb (lubricated) or 20 ft-lb (dry).

(See Figure 7)

Note: Refer to instructions included with seal disc for further

details.

Figure 7

OPERATING INSTRUCTIONS

Start fan and check rotation. Viewed from top (discharge), fan

blades should rotate clockwise.

Check motor power consumption to be sure fan is pulling desired

load. CAUTION: If positive pitch is set in summer to use all

available motor amps (nameplate rating), motor could be overloaded in winter.

available motor horsepower. This ensures that the motors will not

be overloaded at low winter temperatures.

Design pitch angles usually do not use all of the

CHECKING TIP CLEARANCE

Rotate fan in position inside fan stack to check tip clearance

(See Figure 8). The recommended tip clearance is between

1” and 1 1/2 ”. Check for spots where fan blade clearance is

not within the recommended tolerance. If necessary adjust fan

stack by shimming to obtain proper clearance.

Figure 8

Installation Manual 5000 Page 5 of 8 April 2010

Page 6

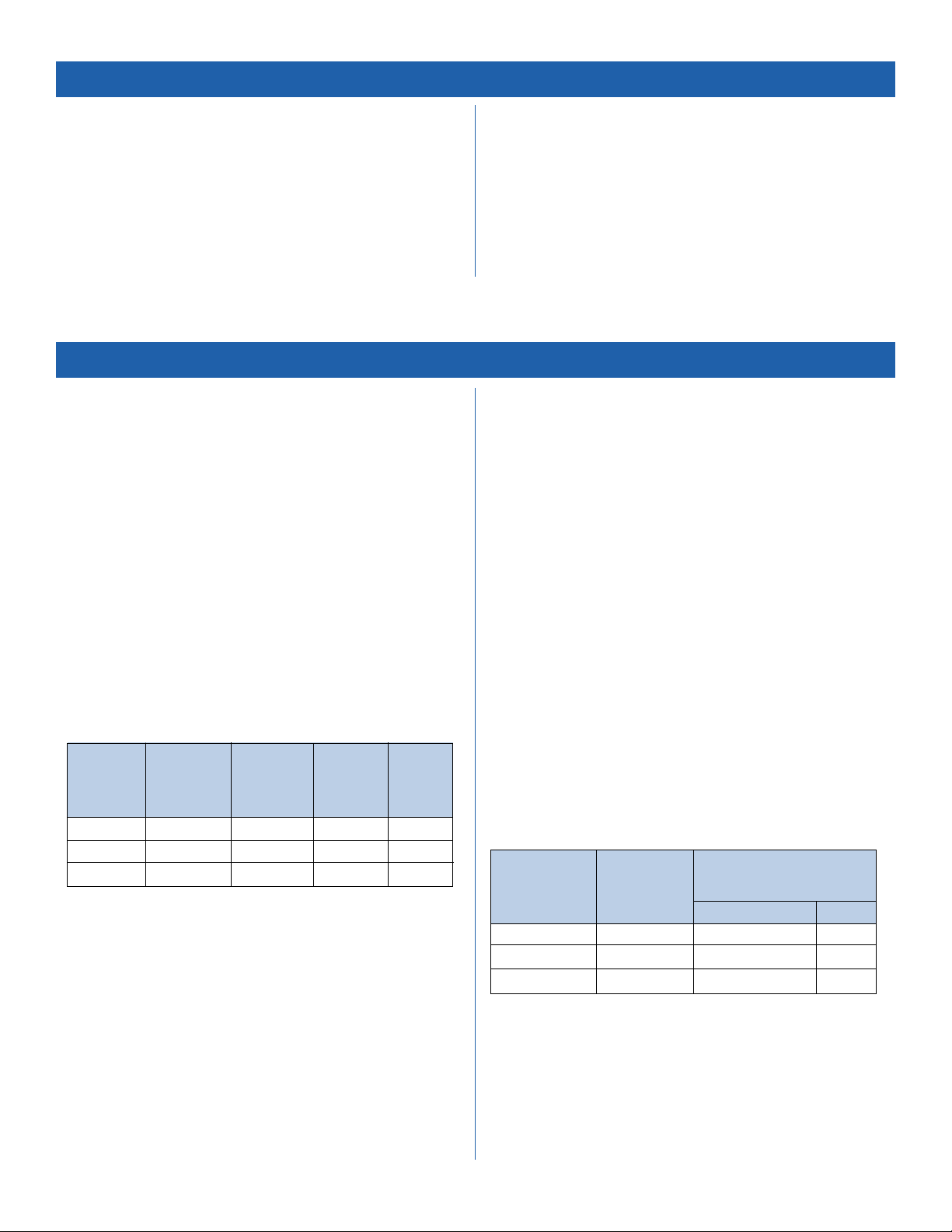

HUDSON PRODUCTS CORPORATION

Adjustable Pitch Fan Assembly 22’ thru 30’ Diameter

Series 5000 HUB

PARTS LIST

5208

H5420

5308

H5320

5808

H5620

C5282

C5283

NO. OF BLADES

5210

5209

H5440

H5420

5309

H5330

5809

H5630

61514

61523

5310

H5340

5810

H5640

61515

61524

5212

5211

H5460

H5450

5311

H5350

5811

H5650

61516

61525

5312

H5360

5812

H5660

C5282

C5283

ITEM DESCRIPTION TYPE PART. NO

Up to 3 .62” Diameter S haft

3.68” Diameter thru 4.19” Diameter Shaft

4.25” Diameter thru 5.50” Diameter Shaft

1 Hub Plate

(2 Per Hub)

ITEM DESCRIPTION TYPE PART. NO QUANTITY PER ASSEMBLY

2 Hub S pool R-2

3 Bushing R-2

4 Blade Clamp Half, Powder Epoxy Coated Die Cast Alum. (Standard)

Option 1: Powder Epoxy Coated Ductile Iron**

Option 2: C oal Tar Epoxy Coated Ductile Iron**

5 Blade Clamp Bolt W/ Nut 3/4”-10 x 10” (Mech. Galv.) 79299 24 28 32 36 40 44 48

6 3/4” Lock washer (Mech. Galv.) 73738 24 28 32 36 40 44 48

7 Hub Spool Cap Screw 5/8”-11 x 1 1/2”(316 SS) 72402 16 16 16 16 16 16 16

8 5/8” Lock washer (316 SS) 73731 16 16 16 16 16 16 16

9 Pin, Grooved, 1/2” X 1-1/2 ” 74540 4 4 4 4 4 4 4

10 76” Diameter Seal Disc Kit * (22B-24B)

88” Diameter Seal Disc Kit * (26B-30B and 22H-30H)

11

Tuf-Lite II® Blade (W hite) ***

Tuf-Lite® Blade (Black)

* Includes all hardware (316 SS) to assembly and mount.

** Recommended on concrete and round towers, or corrosive environments. Contact Hudson for pricing.

*** Blade color was blue prior to March 2006.

R-2

S-2

U-1

R-2 & S-2

U-1

S-2

U-1

S-2

U-1

Hub Assy. No.

Part. No.

Hub Assy. No.

Pat No .

Hub Assy. No.

Part No.

Part. No .

Part No.

65050

65055

65058

Specify Bore 1 1 1 1 1 1 1

D5131

65013

65013C

81122

81126

(Varies)

(Varies)

6 7 8 9 10 11 12

5207

5206

H5410

H5400

5307

5306

H5310

H5300

5807

5806

H5610

H5600

C5282

61512

C5283

61521

1 1 1 1 1 1 1

12 14 16 18 20 22 24

1 1 1 1 1 1 1

6 7 8 9 10 11 12

STANDARD MATERIALS & FINISHES

Blades: Fiberglass reinforced vinyl ester or epoxy

Hub Spool: Ductile Iron, Zinc Rich Coating

Plates: Galvanized Steel, Coal Tar Epoxy

Bushing: Malleable Iron

Seal Disc: Fiberglass Reinforced Polyester

Blade Clamps:

Powder Epoxy Coated Die Cast Alum (Standard)

Powder Epoxy Coated Ductile Iron (Option 1)

Coal Tar Epoxy Coated Ductile Iron (Option 2)

Fasteners:

Steel, Mech. Galvanized & 316 SS Opt.

Complete Fan W/316 SS (Option 1)

Complete Fan W/K500 Monel (Option 2)

WHEN ORDERING, SPECIFY FAN DIAMETER, TYPE & NUMBER OF BLADES & SHAFT DIAMETER

EXAMPLE:

APT

Fan Model

Adjustable Pitch

Fan Diameter & Blade Type

(Specify “H” for Tuf-Lite II® Blades)

(Specify “B” for Tuf-Lite® Blades)

Installation Manual 5000 Page 6 of 8 April 2010

28H

8

Number

of Blades

3 1/2” BORE

Shaft Diameter

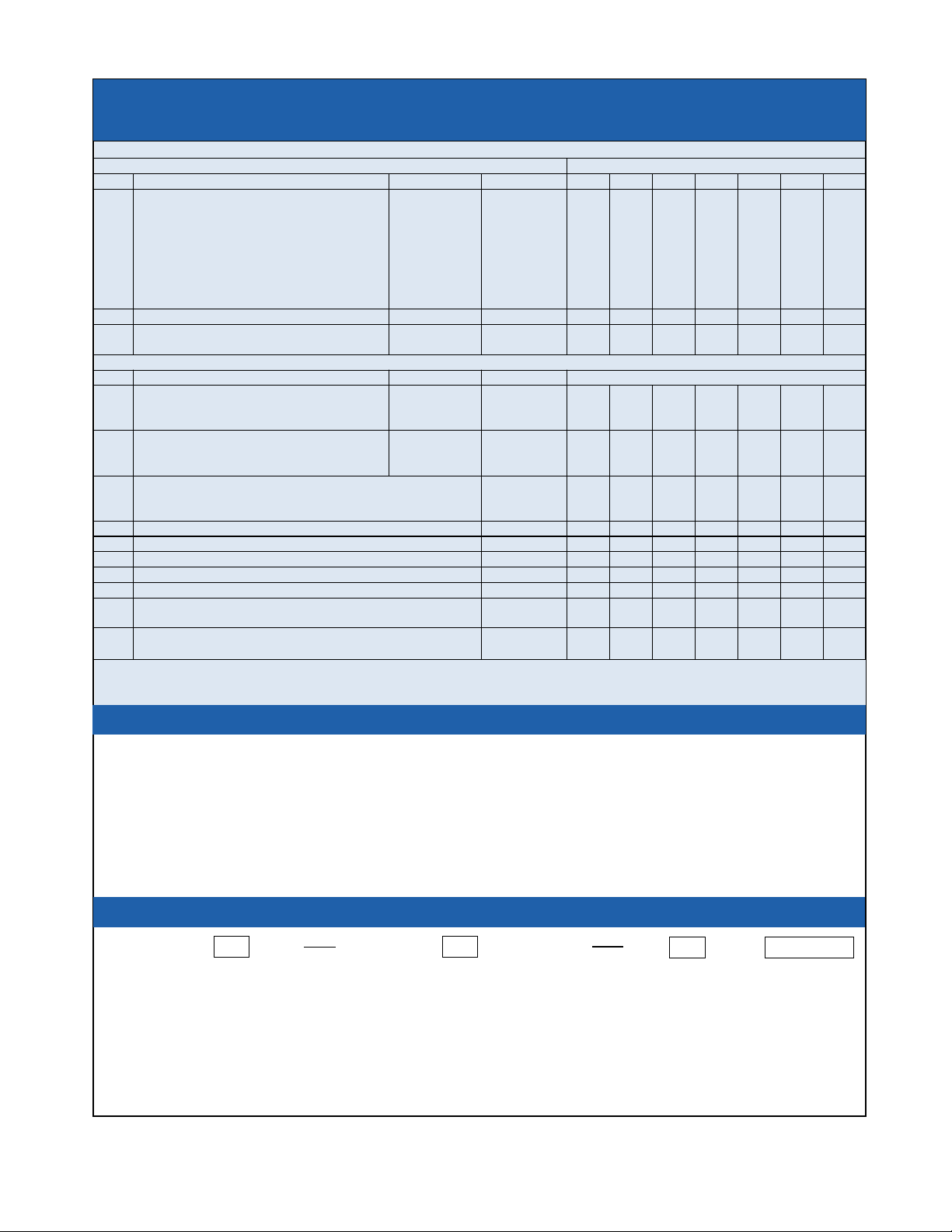

Page 7

10

11

HUB MODEL NO. & SERIAL NO.

9

®

BALANCE. (TUF-LITE II BLADES ONLY)

AND FINAL MOMENT

DATE OF MANUFACTURE

SERIAL NO.

BLADE MODEL NO.

3

8

6

7

5

1

2

4

FURNISHED WITH BUSHING

KEY, SET SCREW & CAP SCREWS

Series 5000 HUB

HUDSON PRODUCTS CORPORATION

Adjustable Pitch Fan Assembly 22’ thru 30’ Diameter

Installation Manual 5000 Page 7 of 8 April 2010

Page 8

1307 Soldiers Field Drive

Sugar Land, Texas 77479-4072

P. O. Box 20029

Sugar Land, Texas 77496-0029

Phone: 281-275-8100

Fax: 281-275-8388

1-800-634-9160 (24 Hours)

EMAIL: hudsonproducts@hudsonproducts.com

http://www.hudsonproducts.com

Hudson, Auto-Variable, Combin-Aire, Exact-A-Pitch, Fin-Fan, Heatflo, Hy-Fin, Split-Flo, Solo Aire, Stac-Flo, Steamflo, Thermflo, Tuf-Edge, Tuf-Lite, Tuf-Lite II,

Hudson Products Corporation.

©2003 Hudson Products Corp. All Rights Reserved.

Installation Manual 5000 Page 8 of 8 April 2010

and

Tuf-Lite III

are registered trademarks of

Loading...

Loading...