Hudson 480-490, 480, 490 Service Manual

This manual provided by

HET Club member

Drew Meyer

I

FOREWORD

ORGANIZATION

Much has been written and spoken about the proper operation of a service department and the factors

which make such an operation profitable and successful.

Some of these operating factors, tried and proven by successful dealers, will bear repetition frequently.

We all know them but are prone to overlook and even disregard them unless they are occasionally called to our

attention.

Some of the more important factors are:

1. Shop Appearance

2. Proper Service Equipment

3. Personnel - Proper dress

Neat appearance

APPEARANCE IS IMPORTANT

Customers are inclined to judge the quality of your work by the appearance of your shop. In looking over

your operation from an appearance standpoint, the first thing to check is identification. The Hudson Service

sign is designed to identify your place of business as an authorized Hudson service station and will not only

create confidence in the minds of the owners but will guide transient owners and new customers to your door.

Next in order is an inspection of the service department and shop. Is it as clean and attractive as soap and

water and paint can make it? Hot water, cleaning compound, and a few gallons of paint will work wonders in

the appearance of a service department and will return their cost many times in increased customer satisfaction

and comfort.

An accumulation of junk and broken and discarded parts and tools is an eyesore in any shop. An easily

accessable junk box outside the building, near an alley for easy unloading, is the best answer. Make each

member of the service staff responsible for removing his own junk parts. Remember - - - - - - first impressions

are lasting.

EQUIPMENT

Adequate equipment provides the means for good service men to perform first class service work at a

minimum of cost. Car owners, thru costly experience with poorly equipped shops, have become tool and

equipment conscious. Therefore, proper tools and equipment are a strict necessity. We must show our

customers that we have the equipment by proper arrangement and display.

II

INTRODUCTION

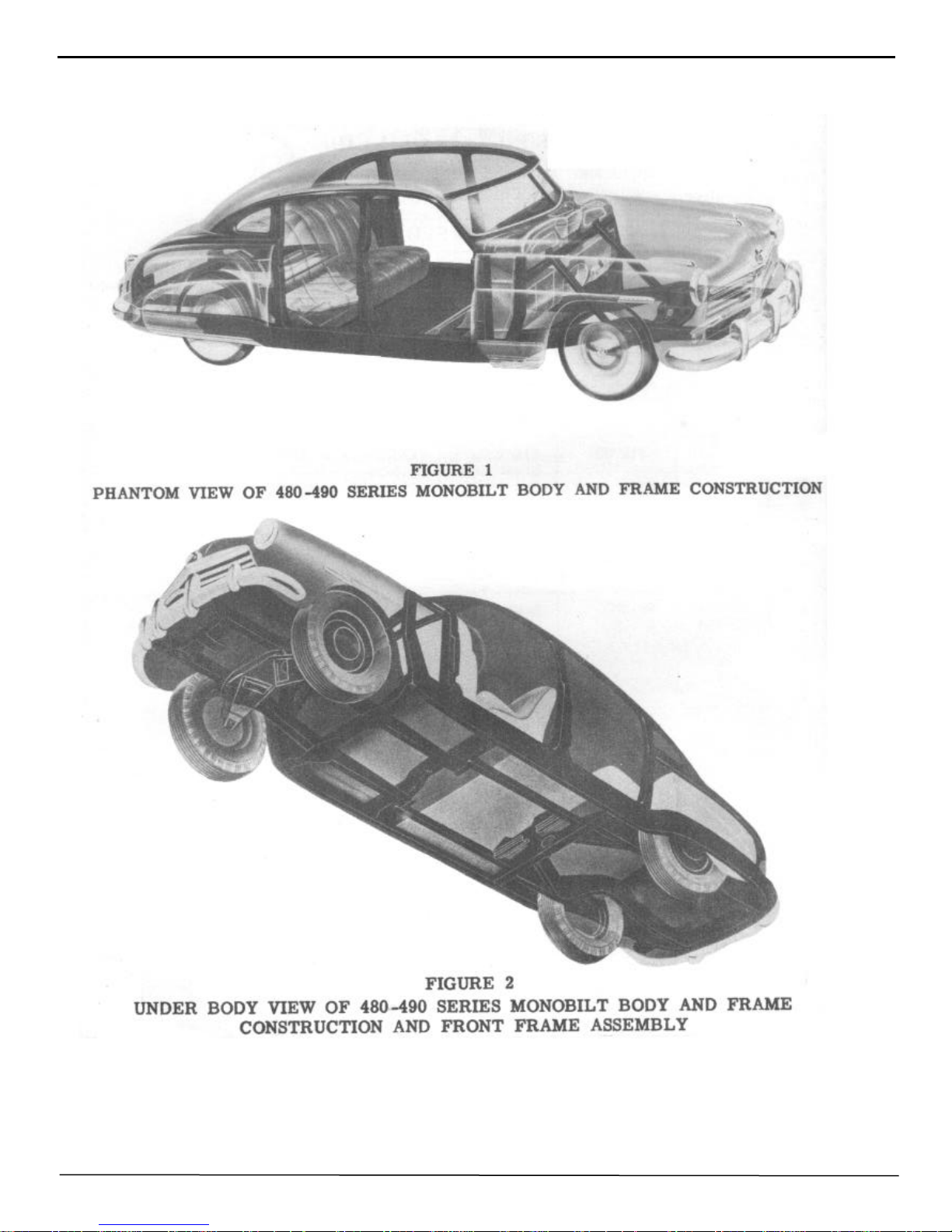

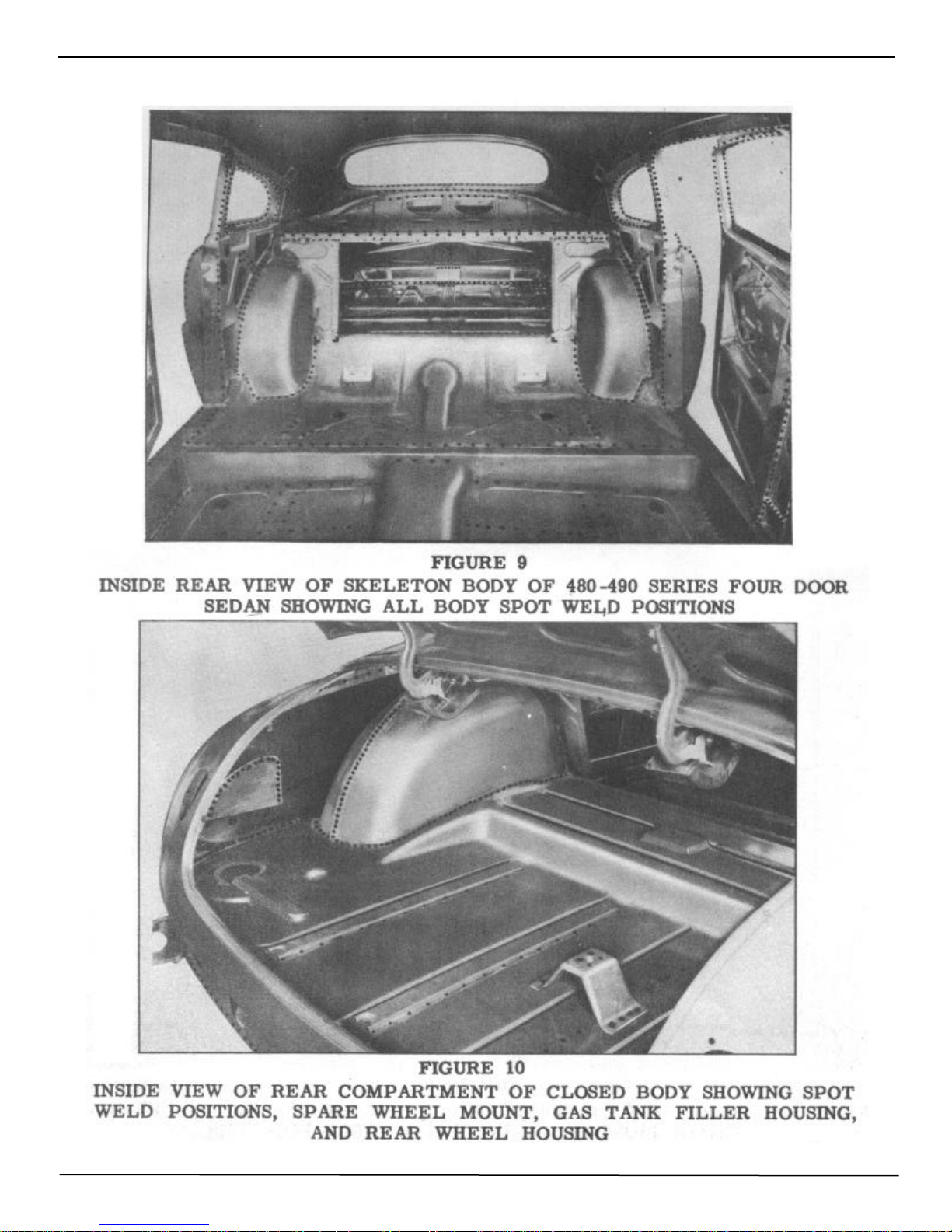

The series 480 and 490 Hudson is built of a completely new principal and design, and is not just another

motor car. The "Monobilt" body and frame construction differs greatly from the conventional motor car

employing separate body and frame units. Naturally being so totally different, a new approach to the repair of

body damage is necessary. These differences, however, do not make the repair job more difficult or more

costly to complete. In many instances the time required on a specific operation is less than that required on

previous models.

Once you are completely familiar with the Monobilt body and frame construction of the 480 and 490

series Hudson, when you have learned the placement of all of the various parts and assemblies and how they

fit together to make the rugged and sturdy Monobuilt all steel unit, then you will go about each job with

complete confidence.

The information contained in this body manual is to be used as a guide for servicing the 480-490 series

Hudson.

The manual has been divided into four parts:

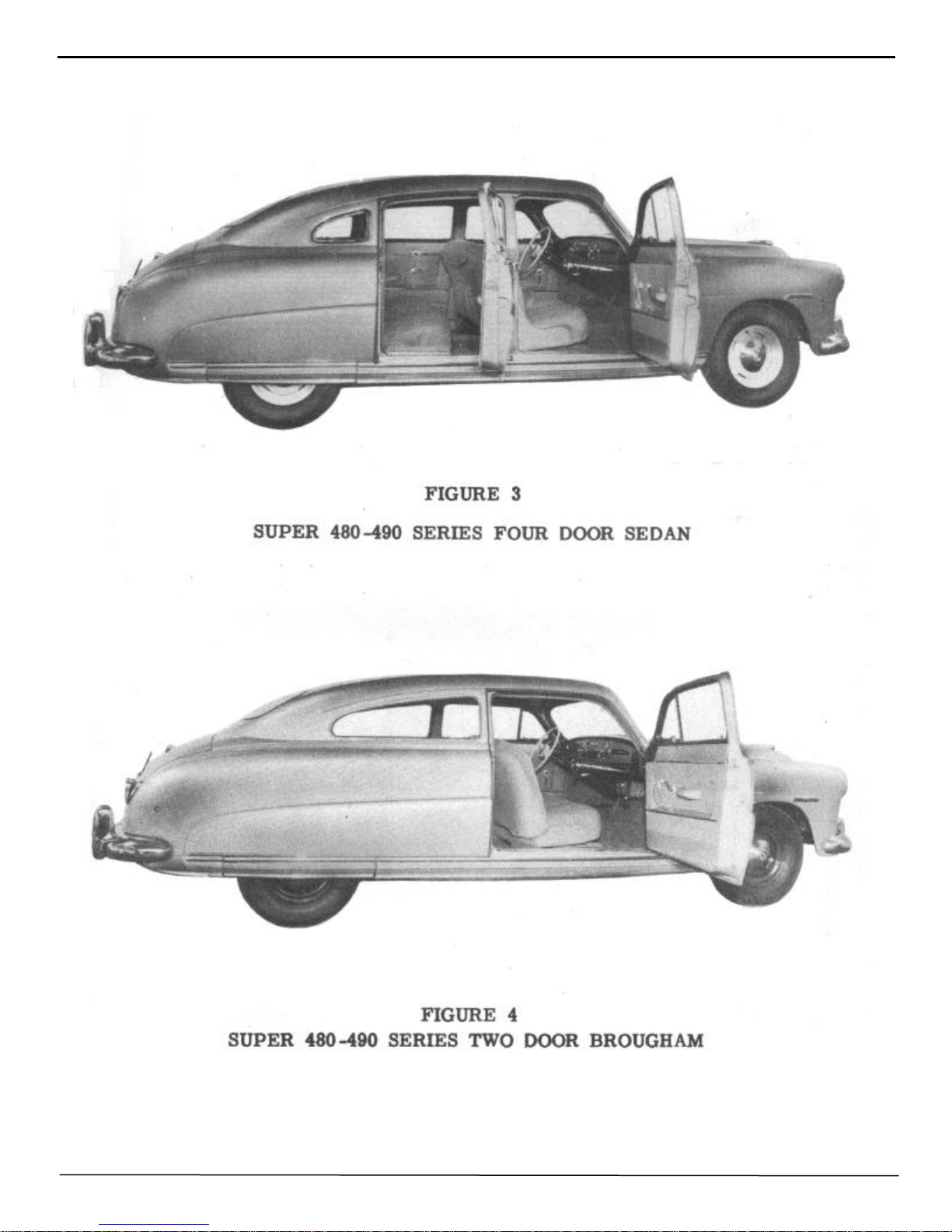

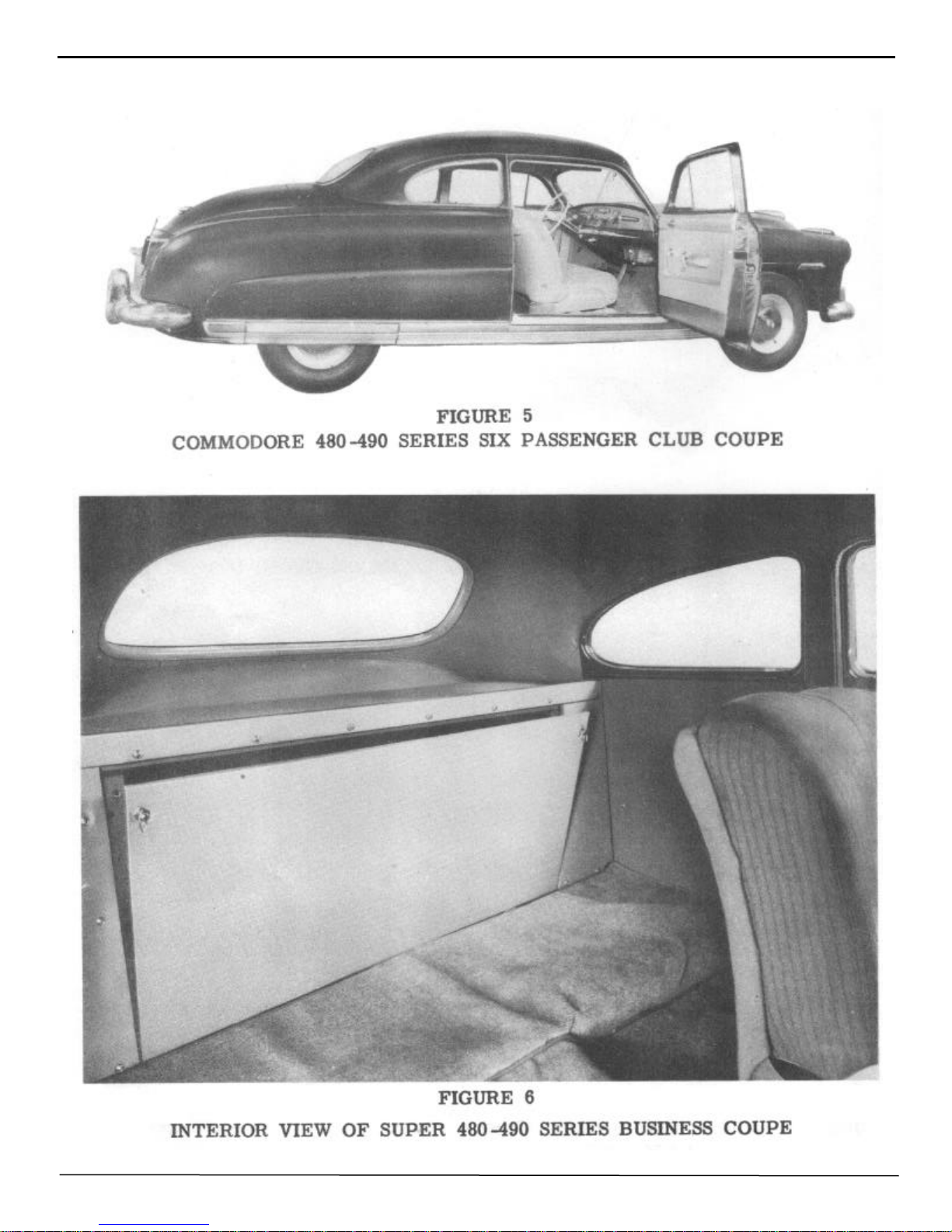

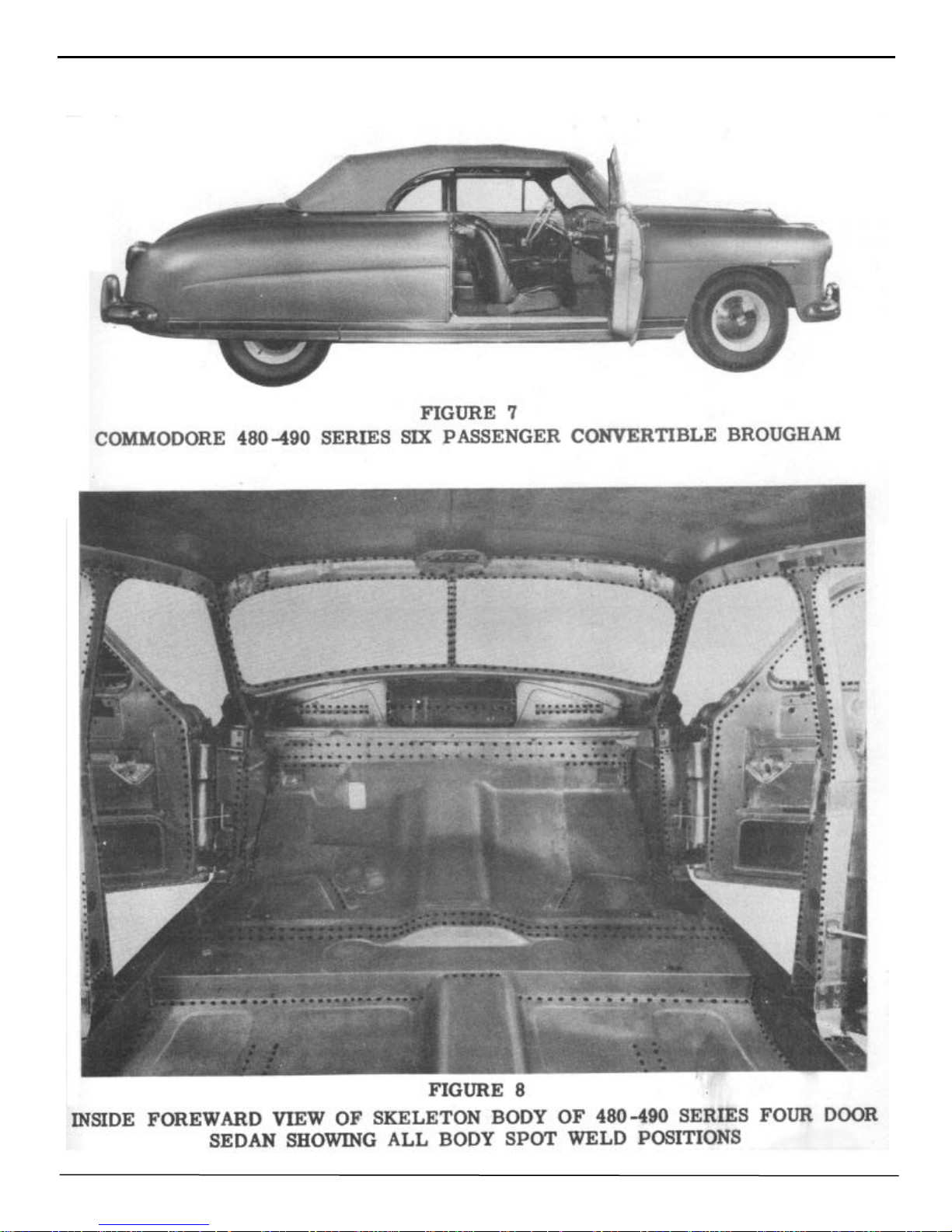

Part one - includes technical information, model designations, body paint color code, estimating and

ordering of repair parts, car serial number identification, and trim material color chart. Illustrated in this

section are the various body types, positions of body welds and top panel soldering.

Part two - includes removal and installation of sheet metal parts: viz., fenders, rocker panels, hood, grille,

rear compartment; also interior hardware, trim, instruments, headlining, door locks, handles, and regulators;

and front wheel alignment.

Part three - includes body repair and metal finishing, consisting of tool application, bumping, dinging,

solder filling, shrinking, fender welding, filing, sanding, and removing minor dents. Part three also includes

body alignment checking, door repairs, and door alignment.

Part four - comprises the convertible 480-490 series, consisting of complete information on repairs of

hydraulic and electrical units, removal and installation of component assemblies and parts, top adjustments,

and trouble shooting.

Illustrations and pages of this manual are numbered consecutively.

An alphabetical index is placed in the front of the manual for easy reference.

A thorough study of the operations and necessary tools and equipment will enable the Hudson Service

dealer to perform reliable service at reasonable cost.

INDEX

III

Adjustment, door striker

folding top

hood

radio

weather control

door window

windshield wiper arms

top control rod

Alignment, body

door

frame

front wheel

rear curtain, convertible

Battery gravity

Bleeding the hydraulic system

Body aligning

Body repair

Breaker, circuit

Brazing

Bumping

Camber

Caster

Cigar lighter

Circuit breaker

Circuit breaker- check, convertible

Cleaning upholstery

Clock

Coil spring sag

Cold shrinking

Construction, body

Color guide

Colors, body

Convertible brougham

Curtain, rear

Cylinder, door lock

Cylinder, hydraulic

Cylinder, solenoid

Dimensions

Dinging

Door aligning

Door lock cylinder

glass front

glass rear

lock

outside handle

remote control

striker plate adjustment

striker plate

trim panel

ventilator wing

ventilator wing regulator

window regulator front

window regulator rear

Page

27,60

74

23

38

40

88

36

74

48,62-64

58

60-61

1,41-43

85

90

94

62

47

32,41,88,91

54

47-54

1,41-43

1,41-42

33

32,41,88,91

91

44

34

43

53,55

50

9,25

3-5

13,67-96

84-86

27,83

69,74-78

77,92-93

2

52,53

58

27,83

31,77

31,77

27,29,83

28-82

30,83

27-60

27

28,31,81,82

30,78

30

28

29

Door lock lubrication

Door straightening

Door trim panel - Convertible .

Door window regulator hydraulic

convertible

cylinder

Elastic metal

Electrical system checks - convertible

Fender, front

rear

Fender and grille side support

Fender stone guard and panel - front

Fender tie panel

Filing

Finish, care of

Fluid, hydraulic

Fluid pressure

Flux

Forging welds

Frame alignment

Front suspension

Fuel gauge

Fuses

Glass, door

quarter window

rear window

windshield

Grille, radiator

radio speaker

Ground, cylinder solenoid . . .

pump motor

Gauge, fuel

rear curtain

temperature

Handle, door

Headlining

Heat shrinking

Hood

Hood adjustment

lock upper support

lock lower support

Hydraulic pump prime

Hydraulic system check - convertible

Hydro-Lectric Motor and pump assy

Hydro-Lectric, service

system

Ignition switch

Instruments

Instrument panel

Insulation

Jacks, body

Lamps

Lock, door

Page

83

59

81

75-77

77

77

47

91

20

19

23

20

24

52,53,57

45

76,90-91, 94

70,76,93

54

57

60

1,41-43

35

41

31,77

31,32

32

26

22

37

77,93

70,71,72

35

85

35

28,82

24-27

53,55

23

23

23

23

94

93

70,72

90

67-96

32

32

32

65

49,51-52

2,33,34

27,29,83

Window operating switches-convertible

IV

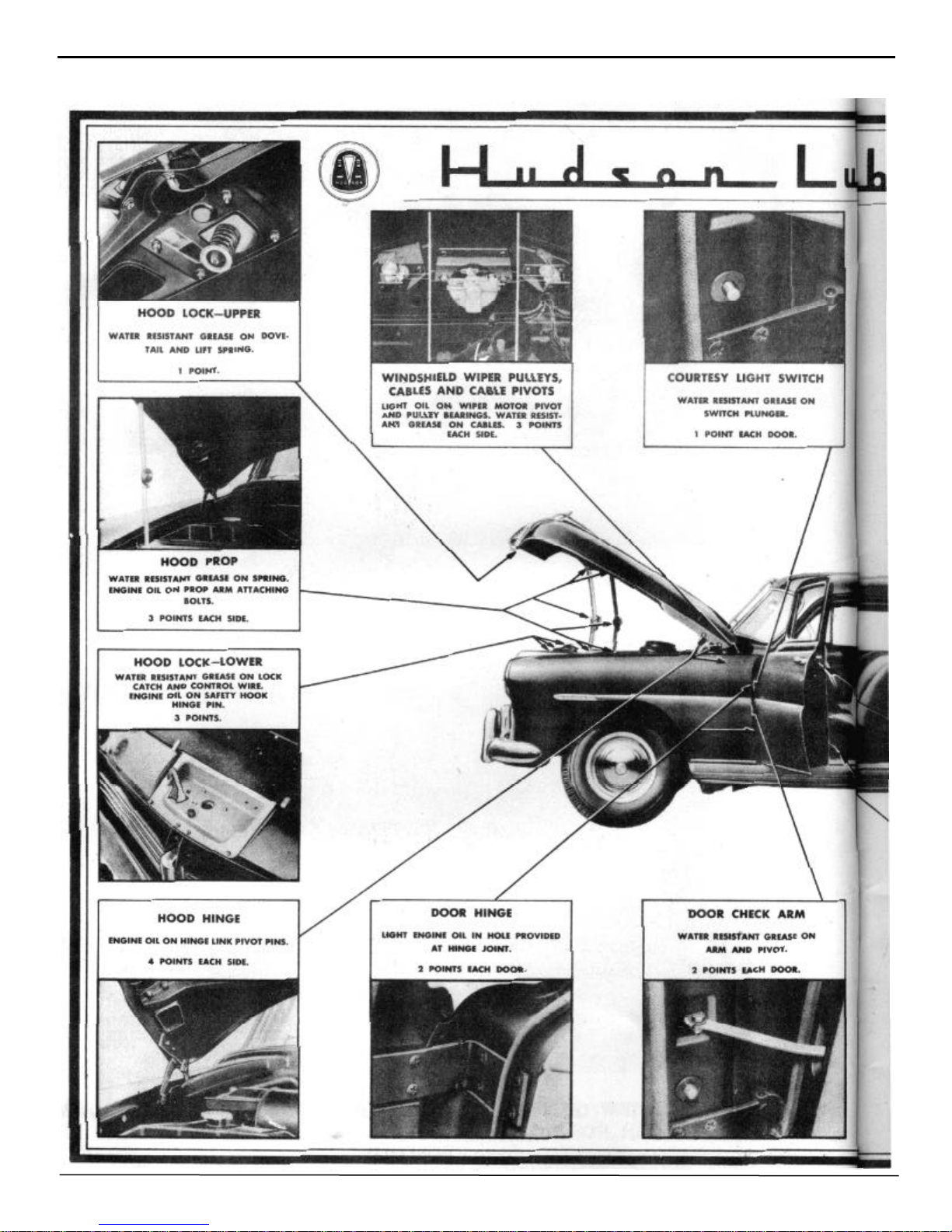

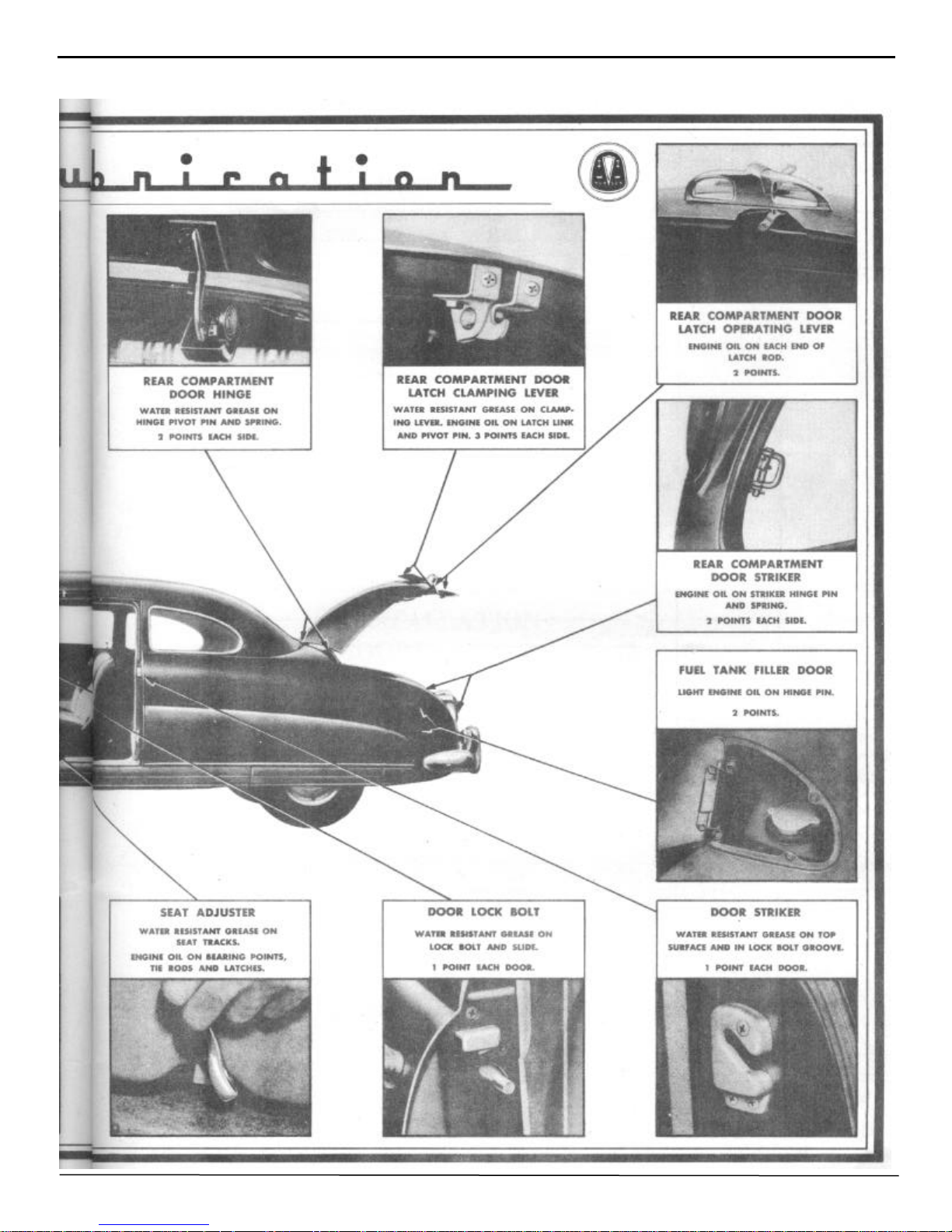

Lubrication, body

hydraulic cylinder

lock

Metal finishing

Model designations

Monobuilt body

Motor, pump

Motor solenoid switch check-convertible

Normalizing

Paddle, solder

Paint

Paint - care of finish

Panel, instrument

switch

trim

Parts, repair

Pivot pin inclination

Pulley adjustment

Pump hydraulic

Quarter trim panel

Quarter window

trim panel

window regulator

Quarter window - convertible

Quenching

Radiator

Radiator grille baffle (upper) .

front splash guard and moulding

grille center bar (upper)

Radiator splash guard moulding

Radiator "U" channel

Radio

Radio - installation

automatic tuning

Rear window

Refilling the hydraulic system convertible

Remote control, door

Regulator, door wing

front door

hydraulic

quarter window

rear door

Resealing

Reservoir, fluid

Rheostat, lamp

Riding height and coil spring sag

Roof bows

Roughing

Sanding

Sealing

Seat cushion front and rear

back, front and rear

Serial numbers

Shrinking - cold

hot

Solder filling

Speedometer

Page

16

75, 77

83

47-58

1

II, 10

68, 69,70-72, 90

92

64

9, 54

3-6,45

45

32,34,37

34

28,31,81,82

6, 19

42

36

70,72,90,94

82

31

31

32, 79

79

54,56

22

22

22

22

23

22

36, 39

36

38

32

94

30, 83

30, 78

28

69,75-78,86,88

32,79

29

64

70,71,90-91

33

43

9, 25

48, 58

53,58

65

82

82

1,6

55

55

52,53,54

34

Spindle pin inclination

Splash guard

Spot weld positions

Springs, front

rear

window regulator

Starter switch

Stone guard

Striker, door

Switch, ignition

light

motor solenoid

starter

top operating

window operating

Technical Information

Temperature gauge

Tie rods

Tools - application of

Tools - body

clip removing

headlining

switch removing

Toe-in

Toe-out

Top adjustment

Top control rod

Top covering installation

Top, folding

Top operating cylinder

Top operating switch check

Top operating valve and switch

Torch soldering

Tramming

Trim material

Trim panels

Trouble shooting

Upholstery cleaning

Upholstery material

Valve, cylinder solenoid

pressure relief

top operating

Weather control

Wedge, hydraulic

Welding

Wheel bearings

Window adjustment

Window lift switch-check-convertible

Window regulator solenoid check

Windshield

Windshield wiper

Windshield wiper control

wiper cable tension

Wing, door ventilator

Wiring

Page

1, 41-42

22, 23

13-15

2 43

2

69, 75, 76

32

20

27, 60

32

32

68, 69, 70, 92

32

72, 73, 90, 91-92

69, 79-81, 88, 91

1

35

1

50

49

78

25

80, 81, 91

1, 41, 43

43

86 87

73, 74, 91

84

68, 70-75, 84, 16

74, 75

91

72, 73, 74, 93

52, 53, 54

62

7

28, 31, 81, 82

95-96

44

7

77, 92-93

70 93

68, 72, 73, 90, 93

39, 41

49

53, 54, 57

1

88 89

91

79, 80

92

26

33

33

36

30, 79

88, 89, 90, 91, 93

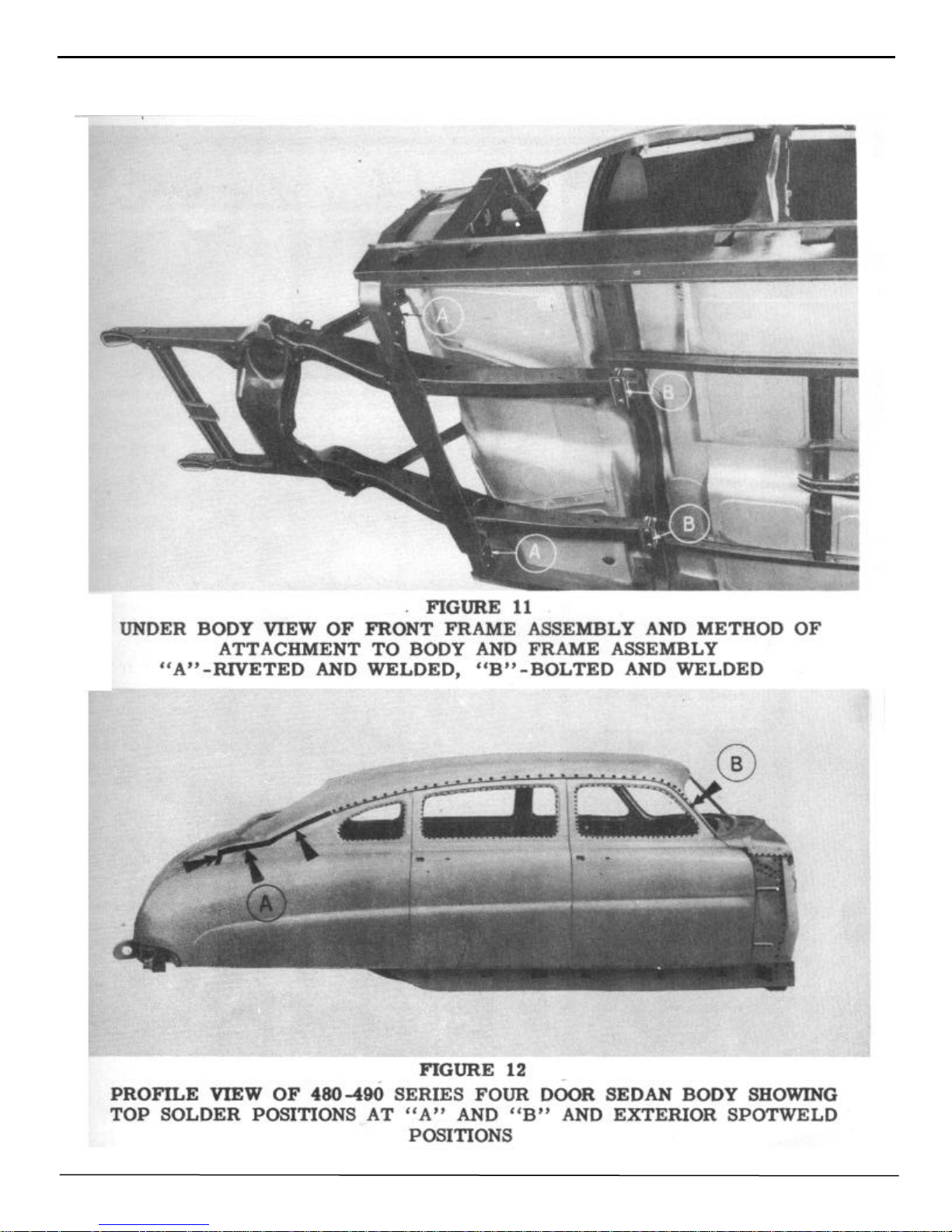

BODY MANUAL 1

NOTE: Caster must not vary

more than ½ between sides

Tie Rod End Adjustment (As

seen from right side of car

):

MODEL DESIGNATIONS AND SERIAL NUMBERS

The new Hudson models are produced in the Super and Commodore Series and carry the following designations:

Hudson Super Six Series - Model 481 - 491

BODY TYPES

Brougham

4 Door Sedan

3 Passenger Coupe

Club Coupe

Convertible Brougham

4 Door Sedan

Club Coupe

4 Door Sedan

Club Coupe

4 Door Sedan

Club Coupe

Convertible Brougham

STARTING SERIAL NO’S

481101 - 491101 and up

Hudson Commodore Six Series - Model 482 - 492

482101 - 492101 and up

Hudson Super Eight Series - Model 483 - 493

483101 - 493101 and up

Hudson Commodore Eight Series - Model 484 - 494

484101 - 494101 and up

The car serial number, which is also the engine number, is stamped on a metal plate attached to the right front

door hinge pillar post. In the car numbering system, the first three digits of the serial number indicate the series and

model while the remaining digits represent the actual car number. As the cars leave the production line, they are

numbered in consecutive order, regardless of series or model. As an example, the car built after serial number

491999 would be numbered 4911000 instead of 492000. Code letters or numbers indicating the car paint color

option are stamped on the upper hinge of the right front door.

TECHNICAL INFORMATION

FRONT SUSPENSION SIX CYLINDER EIGHT CYLINDER

Type

Camber

Caster

Toe-in

Spindle pin inclination

Spindle pin thrust bearing

Wheel Bearing - Type

End Play

Tie Rod End (Type)

Number of Tie Rods

Independent Coil Springing

1/2° to 1-1/2°

1/2º to 1-1/2°

0" to 1/16"

3° - 36'

Ball

Adjustable tapered roller

.001 to .003

Plain Bearing

2

Independent Coil Springing

1/2º to 1-1/2º

1/2º to 1-1/2 ° sides

0" to 1/16"

3° - 36'

Ball

Adjustable tapered roller

.001 to .003

Plain Bearing

2

To lengthen

To shorten

Turn clockwise

Turn counter-clockwise

Turn clockwise

Turn counter-clockwise

2 BODY MANUAL

FRONT SPRINGS SIX CYLINDER EIGHT CYLINDER

Type

Free Height

Height under curb weight

REAR SPRINGS

Type

Covers

Length and Width

Number leaves

Shackles

Lubricant-Shackles and Leaves

Headlight (Sealed Beam Type)

Hood Light

Parking Light with Direction

Indicator

Tail and Stop Light

License Light

Dome Light-Front

Rear Quarter Lights (2)

Clock

Speedometer

Instrument Cluster

Direction Indicator

Ignition Lock

Courtesy Lights

Fog Light (Sealed Beam)

Spot Light Sealed Beam)

Parking Light

Generator and Oil Indicator

Radio

Headlight Beam Indicator

Coil

16-5/16"

9-9/16"

Semi-elliptic

Covered

Uncovered

Metal

54" - 1-3/4"

8

Silent "U" Threaded

Viscous chassis lube

LAMP BULBS

No.

4030

55

1154

1154

63

87

81

55

55

55

55

55

87

4015-A

4535

63

55

55

55

C. P.

Sealed

2

21-3

21-3

3

15

6

2

2

2

2

2

15

Sealed

Sealed

3

2

2

2

Coil

16-5/16"

9-9/16"

Semi-elliptic

Covered

Uncovered

Metal

54" - 1-3/4"

8

Silent "U" Threaded

Viscous chassis lube

Base

Sealed

Single

Double

Double

Single

Single

Single

Single

Single

Single

Single

Single

Single

Sealed

Sealed

Single

Single

Single

Single

DIMENSIONS (6 Passenger 4 Door Sedan)

Wheel Base

Overall Length

(Including Bumpers and Guards)

Overall Width (Including Fenders)

Tread

Front

Rear

Road Clearance

Front

Rear

Overall Height-Road to Roof

SIX CYLINDER EIGHT CYLINDER

124"

207-1/2"

77"

58-1/2"

55-1/2"

8"

8"

60"

124"

207-1/2"

77"

58-1/2"

55-1/2"

8"

8"

60"

BODY MANUAL 3

1948 HUDSON BODY COLORS

Standard Single Body Colors Option Special Two-Tone Combinations Option

Banner Blue

Jockey Blue

Gallant Gray

Quartermaster Gray

Piedmont Green

Savoy Green

Maroon-Deep

Ruby Red*

Navahoe Bronze

Harness Tan

Ebony Black

* Ruby red is a special body color and is listed above only to complete the two-tone combination

with maroon-deep.

B

M

RR

G

Q

N

H

K

Upper Body Color

J

P

S

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

SPECIAL SINGLE BODY COLORS

JB

QG

SP

RM

HN

Body Colors Option Option on Models

Ruby Red*

Platinum

RR

CC

481-P - 482 - 483 - 484 Broughams

Sedans, Bus. Coupes, Club Coupes, and

481-P - 482 - 484 Convertible Brougham

ORDERING PAINT OR PAINTED PARTS

When ordering paint or painted parts, special care should be exercised in listing the paint option code and the

paint color or colors. This information is valuable, especially when the automobile has a two-tone color

combination. Always use the charts furnished herein and be sure that every repair order including paints has the

complete, detailed information.

Hudson body colors are pure virgin lacquers. For the maintenance and protection of these high quality finishes

refer to Page 45 of this manual under the heading "Paint - care of finish."

4 BODY MANUAL

CHART No. 1

1949 HUDSON BODY COLORS

Standard Single Body Colors Option Special Two-Tone Combinations Option

Brigantine Blue**

Jersey Blue

Glowing Gray

Queenstown Gray

Piedmont Green**

Savoy Green**

Nomad Bronze**

Holster Tan**

Maroon - Deep**

Ruby Red*

Ebony Black

* Ruby red is a special body color and is listed above only to complete the two-tone combination

with maroon-deep.

**Not available on convertible brougham.

M

RR

G

Q

N

H

K

B

J

P

S

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

SPECIAL SINGLE BODY COLORS

Body Colors Option Option on Models

JB**

KG

SP**

HN**

RM**

Ruby Red*

Platinum

*Refer to Page 5 for 1949 body color option information.

RR

CC

491-P - 492 - 493 - 494 Broughams

Sedans, Bus. Coupes, Club Coupes, and

491-P - 492 - 494 Convertible Brougham

CHART No. 2

1949 HUDSON BODY COLORS

Standard Single Body Colors Option Special Two-Tone Combinations Option

Pacemaker Green Opalescent

Sierra Green Opalescent

Naples Tan Opalescent

Hardwood Tan Opalescent

Gull Gray Opalescent

Quebec Gray Opalescent

Burgundy Maroon Opalescent

Radiant Red Opalescent*

Brazilian Blue Opalescent

Jet Blue Opalescent

Ebony Black

8

10

7

3

2

9

6

16

1

4

5

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

Upper Body Color

Lower Body Color

14

11

13

15

12

SPECIAL SINGLE BODY COLORS

Body Color Option Option on Models

BODY MANUAL 5

Radiant Red Opalescent

Gray Gold (light) Opalescent

16

17

491P - 492 - 493 - 494 Broughams, Sedans,

Bus. Coupes, Club Coupes, and 492-P 492 - 494 Convertible Brougham.

1949 BODY COLOR OPTION INFORMATION

It will be noted that the 490 Series Hudson has two methods of paint option identification. On approximately the first 100,000

490 Series cars an ALPHABETICAL paint option was stamped into the right hand front door upper hinge, body half. (See 1949

Body Color Chart No. 1)

Body color Chart No.2 lists the new body colors and the NUMERICAL options used on the 490 Series Hudson after

approximately the first 100,000 cars. This numerical paint option is also stamped into the body half of the right hand front door

upper hinge.

EXAMPLE: (Chart No. 1)

Single Body Color Option

Brigantine Blue

Jersey Blue

Two-Tone Combination

B

J

Brigantine Blue

Jersey Blue JB

Option

Either brigantine blue or jersey blue may be used as an all over body color in which case a single "B" or "J" will

be stamped into the right hand front door upper hinge. When both brigantine blue and jersey blue are used together as a two-tone combination, the letters "JB" will be stamped into the right hand front door upper hinge.

EXAMPLE: (Chart No. 2)

Single Body Color Option

Pacemaker Green Opalescent

Sierra Green Opalescent

The application of the numerical option colors is handled in the same manner as is the alphabetical

options outlined above.

8

10

Two-Tone Combination

Pacemaker Green Opalescent

Sierra Green Opalescent 14

Option

6 BODY MANUAL

jobs, or lose money on them if you do get them. A successful future for your business depends upon the correctness

In the event a new NUMERICAL body color is used in two-tone combination with an old ALPHABETICAL

body color, the option stamping will appear as below:

Brazilian Blue Opalescent (New) 1

Jersey Blue (Old) J

This will be the only occasion when both SINGLE body color options used in two- tone combinations will appear stamped in the right hand front door upper hinge.

ESTIMATING AND ORDERING OF REPAIR PARTS

Like any other automobile repair operation, the damaged body must have a preliminary survey to determine the

over all extent of the damage. When the survey has been completed, the answer to three vital questions will be necessary before work can begin.

Can you repair the damage?

How much will it cost?

How soon can it be ready?

The accuracy of your answers to these vital questions determines whether or not your shop gets the repair job

and whether or not you make any profit on the job if you do get it. Guessing won't do----that way you lose repair

with which you answer those three important questions.

The service departments of all Hudson distributors and dealers are supplied with current service parts catalogues

from which a listing, by PROPER NAME and PART NUMBER, of the parts required can be formulated.

From this list, which includes the proper car IDENTIFICATION NUMBER taken from the car serial number

plate, the Hudson parts manager will be able to arrive at an estimate of the cost of the job, from which a definite decision can be made before ordering the necessary parts.

To be certain that the proper repair parts are received with the least possible delay, it is important that the following car identification be included with each repair order.

CAR SERIAL NUMBER PAINT CODE MARKINGS *

*The paint color code is the alphabetical stamping on the right hand front door upper hinge, body half.

By supplying this information you are enabling those who make up the repair parts order to include the correct

parts. Thus delays, such as would be encountered upon the receipt of the wrong parts, are eliminated, and considerable time is saved.

BODY MANUAL 7

DESCRIPTION OF PARTS

The correct description of the parts as they are listed in the service parts catalogue is all-important, as is the location of the part on the automobile.

For example fenders, doors, windshield glass, and rocker panels should be referred to as left or right, front or

rear.

ORDERING TRIM MATERIAL

The following chart on the Hudson upholstery options in relation to paint options will prove helpful when the

need arises to order upholstery material.

The paint option chart is also included and will serve to clarify the alphabetical paint code stamping on the upper

hinge of the right hand front door and as a cross reference guide when ordering upholstery materials. See Page 4.

CHART No. 3

Use This Chart In Conjunction With Chart No. 1, Paint Option Codes

1948 COMMODORE SERIES UPHOLSTERY OPTIONS

Option Model Upholstery Color Standard with Body Colors

W-1

W-2

482-484

482-484

Tan Broadcloth

Gray Broadcloth

H,K,M,N,P,RR,S,HN,SP,RM

B,CC,G,J,K,Q,JB,QG

1949 COMMODORE SERIES - EXCEPT CONVERTIBLES

W-1

W-2

W-3

W-4

492-494

492-494

492-494

492-494

Tan Broadcloth

Gray Broadcloth

Brown Cloth and

Maroon Leather Trim

Gray Cloth and

Maroon Leather Trim

H,M,N,P,RR,S,HN,SP, and RM

B,CC,G,J,K,Q,JB, and QG

(Optional)

(Optional)

CONVERTIBLE BROUGHAM UPHOLSTERY

Models Color

491, 492, 494 Maroon Leather antique grain is standard

Models Color

481, 491, 483, 493 Bedford Cord cloth, Blue-Green shade, is

SUPER SERIES UPHOLSTERY

standard

8 BODY MANUAL

CHART No. 4

Use this chart in conjunction with chart No. 2, 1949 "Paint Option Codes"

COMMODORE SERIES - EXCEPT CONVERTIBLES

Option Model Upholstery Color Standard with Body Colors

W-1

W-2

492-494

492-494

Tan Cloth Trim

Gray Cloth Trim

CONVERTIBLE BROUGHAM UPHOLSTERY

Models Models

491-492-494 Maroon full leather trim is standard.

Brown cloth and maroon leather

combination trim - optional.

Gray cloth and maroon leather

combination trim - optional.

SUPER SERIES - EXCEPT CONVERTIBLES

Model Color

491, 492, 494 Gray cloth trim is standard

Gray leather trim - optional

M-6, RM-15, RR-16 and CC-17

H-3, N-7, HN-11, P-8, S-10, SP14

B-1, G-2, J-4, Q-9, JB-12, QG-13

and K-5

LEATHER TRIM

ALL BROUGHAMS, SEDANS, BUSINESS COUPES, AND CLUB COUPES

Material Color

Russet Leather Trim

Gray Leather Trim

Maroon Leather Trim

Hudson upholstery materials are of the finest broadcloth and Bedford Cord available, however, this fact does not

create immunity to spots and stains. For details on the removal of spots and stains, please refer to Page 44 of this

manual under the heading "General Information on Appearance."

Standard with body colors S-10, P-8, SP-14, H-3, HN-11,

M-6, RR-16, RM-15, and CC-17.

Optional with body colors B-1, G-2, J-4, Q-9, JB-12,

QG-13, and K-5

Standard with body colors B-1, G-2, J-4, Q-9, JB-12,

QG-13, and K-13. Optional with S-10, P-8, SP-14, H-3,

HN-11, M-6, RR-16, RM 15, and CC-17

Optional

CHART No. 5

BODY MANUAL 9

Bow

No.

1

2

3

4

5

6

1

2

3

4

5

6

Part

Number

Up to and

Including

Serial No.

ROOF BOW COLOR

Color

GUIDE

Part

Number

4 DOOR SEDAN

210761

210762

210763

210764

210765

210766

*Except car numbers 115221 thru 115722 inclusive

483115172

"

"

"

"

"

Black

Light Gray

Tan

Light Blue

Dark Red

Pink

216220

216221

216222

215223

216224

216225

2 DOOR BROUGHAM

210761

210768

210769

210774

210775

210776

4912700

"

"

"

"

"

Black

Light Gray

Tan

Light Blue

Dark Red

Pink

216220

215226

216227

216228

216229

216230

Serial No.

and upward Color

48311517*

"

"

"

"

"

4912701

"

"

"

"

"

Black

Light Green

Yellow

Light Red

Dark Green

Dark Brown

Black

Light Gray

Cream

Light Blue

Dark Red

Pink

COUPE AND CLUB COUPE

1

2

3

4

5

6

210751

210768

210769

212954

212955

212956

4912700

"

"

"

"

"

Black

Light Gray

Tan

Silver

Gold

Dark Gray

216220

216226

210769

216231

215232

212956

4912701

"

491127

4912701

"

4912701

Black

Light Gray

Silver

Gold

Gold

10 BODY MANUAL

BODY MANUAL 11

12 BODY MANUAL

BODY MANUAL 13

14 BODY MANUAL

BODY MANUAL 15

16 BODY MANUAL

Figure 13

BODY MANUAL 17

18 BODY MANUAL

REFERENCE

Source of

Information

Date Subject

BODY MANUAL 19

REMOVAL AND CARE OF

PARTS

With most damaged bodies, there are parts that

have to be removed to facilitate the repair of the

damaged sections. These parts, whether they are

damaged or not, should be kept in some suitable

container or storage bin to prevent further damage

and eliminate the possibility of parts becoming lost.

Where severe body damage is encountered, it is

best to remove body trim parts, all of which are

easily removed, and store them in a clean, dry

place. By approaching the actual repair job in this

manner, more freedom and better visibility during

the repair operation is possible. Considerable time.

and patience, too, is thus saved in the aligning

operation and in the effective placing of body jacks.

With the body trim parts safely stored out of the

way, the possibility of burning, tearing, or soiling

of upholstered parts is negligible.

8. Remove rear bumper extension at side of fender.

9. Pry off fender panel lower moulding.

10. Remove the two self tapping screws attaching rear

fender panel and moulding retainers to the rocker panel.

11. Remove the 7 bolts and nuts attaching the fender

panel and moulding retainers to the rocker panel.

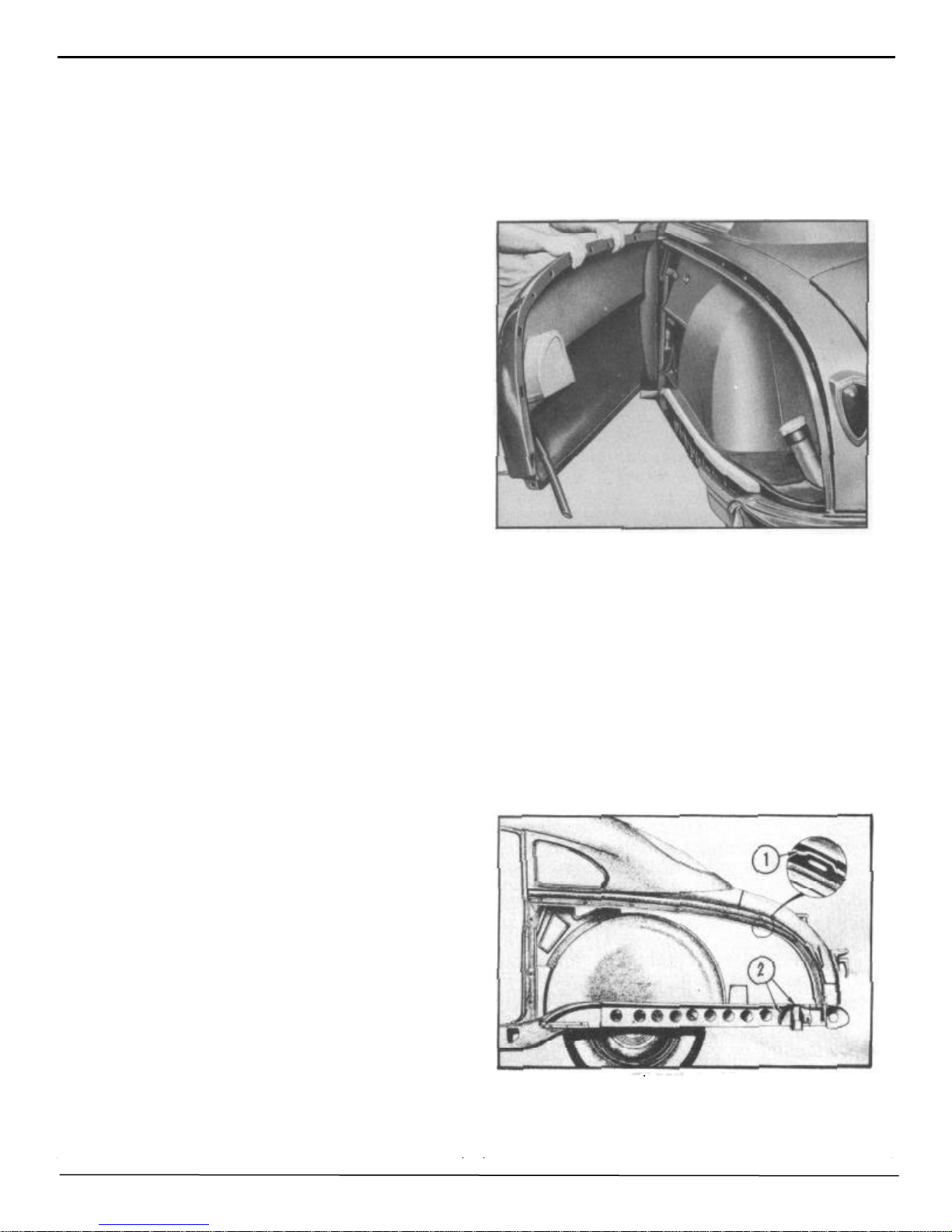

12. Lift off rear fender. See Figure 14.

REMOVAL & INSTALLATION

PROCEDURES

REAR FENDER

REMOVAL:

1, Remove rear wheel cover and rod assembly.

2. Remove rear seat cushion and remove the end

section of the rear seat back from same side from

whlch fender is to be removed.

3. Remove rear quarter window garnish moulding

and the valance reveal moulding.

4. Remove rear quarter inside trim panel.

5. Remove 3 Phillips head screws and two self

tapping screws at door pillar post.

NOTE: On Broughams and Coupes it is necessary to remove the rear quarter window to

allow removal of the three fender attaching

screws located behind the glass. See "Quarter

Window Glass Removal," Page No. 31.

FIGURE 14

INSTALLATION:

NOTE: Before installing rear fender apply a bead of

Permagum No. 576, Part No. 175356 Sealer, starting

from base of rear door hinge pillar and crossing

quarter panel flange to frame at rear and to area at

2 as shown in Figure 15. Care must be taken to

assure that the bead of sealer is unbroken and does

not cross any fender attaching bolt holes.

6. Remove the spare tire from rear compartment to

permit better accessibility.

7. Remove 7 screws inside rear compartment

which fasten fender to rear quarter panel.

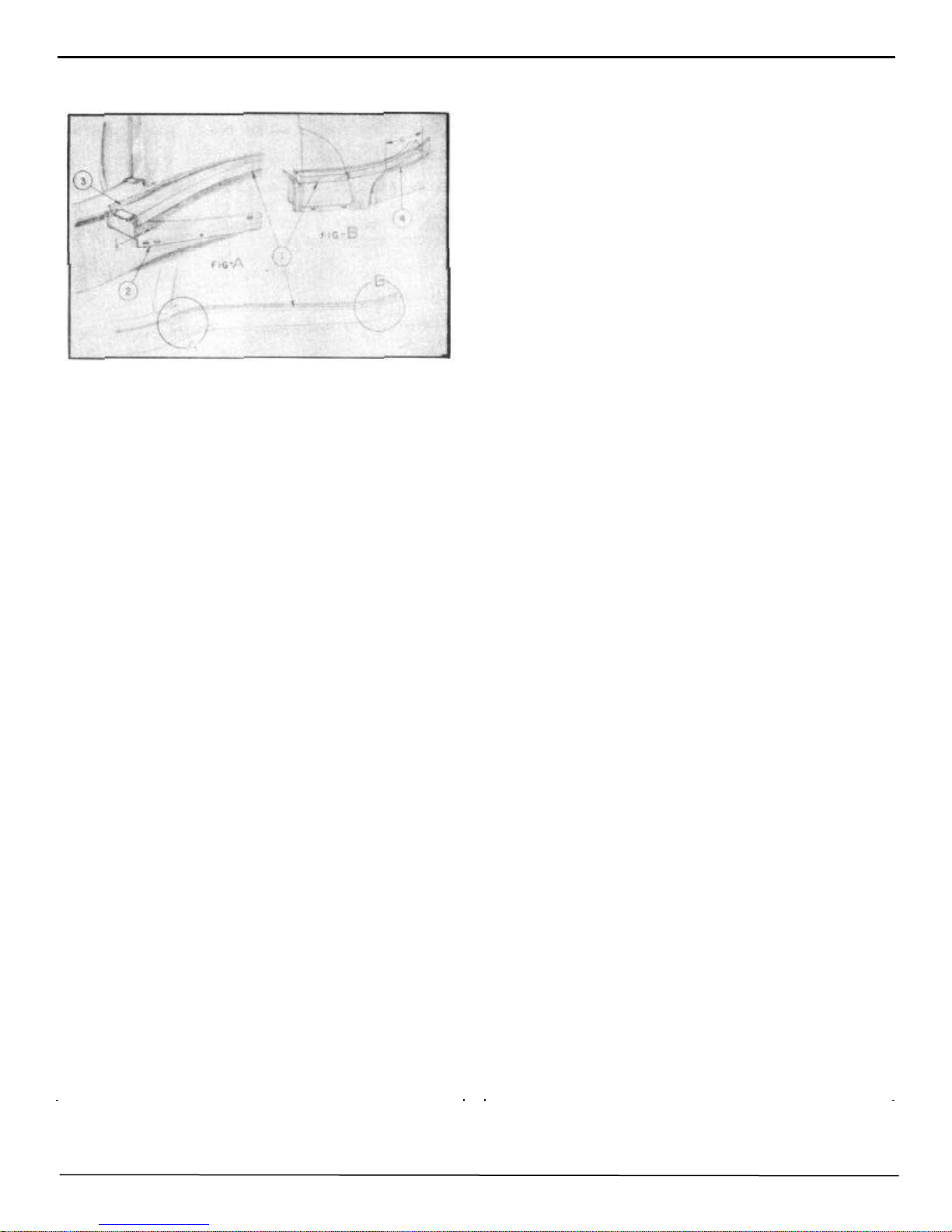

FIGURE 15

1. Align fender at door hinge pillar and install attaching

screws. DO NOT TIGHTEN.

20 BODY MANUAL

2. Attach all upper bolts at quarter panel flange before

attaching fender to rocker panel. DO NOT TIGHTEN.

FIGURE 16

3. Install rear fender seal flush with frame flange,

raising the front end 1/8" to interfere with rocker panel

filler, Figure 16, No. 1 and No. 2. Cement seal tightly

and allow approximately 6" from the end of the seal to

remain loose until the fender is completely installed,

No. 4, Figure 16. Then cement seal securely to frame

flange, No. 3, and fender. TIGHTEN ALL ATTACHING BOLTS AND SCREWS SECURELY.

FRONT FENDER

9. Remove moulding and 4 self-tapping screws

attaching fender and moulding clips to front rocker

panel.

10. Remove kick pad in the front seat compartment

at the dash panel.

11. Remove the screw attaching the door opening

belt weatherstrip to fender and front cowl panel.

12. Remove the 4 bolts from behind the kick pad

which attach the fender to the dash panel and front

hinge pillar.

13. Lift off front fender.

14. Remove all trim and useable parts from damaged

fender and install on new fender.

INSTALLATION :

1. With help of an assistant, align fender at cowl

panel and attach screws at kick panel opening and

front door hinge pillar.

2. Attach fender to radiator baffle side shield, fender

side dust shield, and radiator splash guard.

3. Reverse procedure of removal on balance of installation.

NOTE: Reseal fender at cowl panel and at belt

moulding with dolphinite sealer No. 2465,

REMOVAL:

1. Raise hood and disconnect headlight wires at junction block on radiator support.

2. Remove headlight rim (3 Phillips head screws) and

remove the headlight housing (4 screws).

3. Remove the attaching bolts from the fender and side

dust shield.

4. Remove two bolts attaching fender tie panel and

hood lock lower support to fender.

5. Remove the upper hood prop bolt and allow hood

prop to be removed with fender side dust shield. Support hood during this operation.

6. Raise car and remove front wheel.

7. Remove 3 bolts attaching fender to radiator baffle

side shield.

8. Remove 3 bolts attaching fender to lower radiator

splash guard.

NOTE: Front fender front extension is spot welded

to the fender and will have to be removed with the

fender.

Part No. 175367. If necessary to replace the weatherstrip, proceed as follows:

A. Apply a coating of rubber cement to the surfaces

of the front pillar face and the belt weatherstrip.

B. Press weatherstrip into position then insert and

tighten attaching screws.

FRONT FENDER STONE GUARD

AND PANEL ASSEMBLY

REMOVAL:

1. Remove 4 bolts attaching stone guard and panel

to front quarter dash panel under the fender, 2 bolts

under rubber pad, and one located to the left of hood

hinge.

2. Remove 3 Phillips head screws and speed nuts at

dust shield extension rubber shield.

3. Remove the panel and stone guard.

INSTALLATION:

Reverse procedure of removal.

BODY MANUAL 21

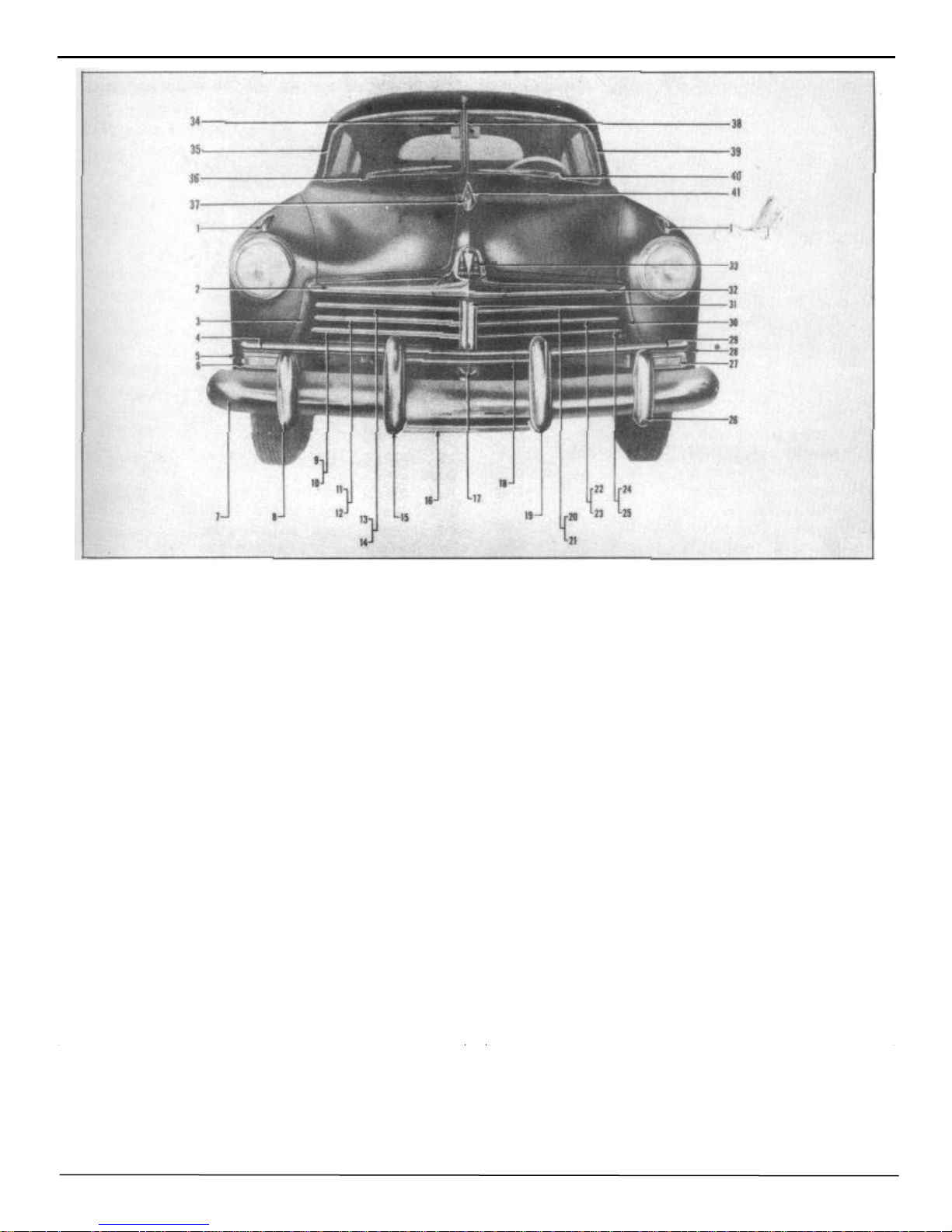

1. Front fender ornament.

2. Hood louver (R.H.)

3. Radiator grille baffle side support (R.H.)

4. Front splash guard moulding

5. Front fender extension assembly (front R.H.)

6. Parking light assembly

7. Front bumper impact bar

8. Front bumper guard (outer R.H.)

9. Radiator grille moulding (lower R.H.)

10. Radiator grille baffle (lower R.H.

11. Radiator grille moulding ( center R. H.)

12. Radiator grille baffle (center R.H. )

13. Radiator grille moulding (upper R.H.)

14. Radiator grille baffle (upper R.H.)

15. Front bumper guard assembly (inner R.H.

16. Front bumper license guard (lower)

17. Radiator grille center bar (lower)

18. Front bumper license guard (upper)

19. Front bumper guard assembly (inner L.H.)

20. Radiator grille moulding (upper L.H.)

21. Radiator grille baffle (upper L.H.)

FIGURE 17

22. Radiator grille moulding (center L.H.)

23. Radiator grille baffle (center L.H.

24. Radiator grille moulding (lower L.H.)

25. Radiator grille baffle (lower L.H.)

26. Front bumper guard (outer L.H.)

27. Parking light assembly

28. Front fender extension assembly (front L.H.)

29. Front splash guard moulding

30. Radiator grille baffle side support (L. H.)

31. Radiator grille center bar

32. Hood louver (L.H.)

33. Hood front ornament assembly

34. Center windshield reveal moulding ( R. H.)

35. Windshield reveal moulding (R.H.)

36. Pulley housing and cable assembly ( R. H.)

37. Hood crest assembly

38. Center windshield reveal moulding

(L. H.)

39. Windshield reveal moulding (L.H.

40. Pulley housing and cable assembly (L.H.)

41. Hood crest ornament.

22 BODY MANUAL

RADIATOR

REMOVAL:

1. Drain radiator and disconnect hoses.

2. Remove two sheet metal screws attaching deflector shield

to fender tie panel.

3. Remove headlight wiring from retaining clips at the front

of radiator.

4. Remove 4 hex head bolts attaching radiator to "U" channel

and remove radiator.

INSTALLATION:

Reverse procedure of removal.

RADIATOR "U" CHANNEL WITH

RADIATOR REMOVED

REMOVAL:

1. Remove headlight junction blocks; leave wires attached.

2. Remove two attaching bolts (each side) from radiator

mounting channel to fender.

3. Remove attaching bolts from mounting channel to fender

tie panel.

4. Remove the bolt attaching the bottom of mounting channel

to frame front cross-member. Remove channel from car.

INSTALLATION:

Reverse procedure of removal.

separately.

1. Remove complete front bumper assembly.

2. Remove three bolts at each side attaching splash

guard to radiator grille panel.

3. Remove bolt at grille lower center bar and the bolt

attaching center plate to right and left hand splash guard.

4. Slide splash guard out.

INSTALLATION:

Reverse procedure of removal.

RADIATOR FRONT SPLASH

GUARD AND MOULDING

REMOVAL:

1. Remove front bumper center grille guard.

2. Remove one bolt (each side) attaching front splash

guard (center) to front fender and lower splash guard.

3. Remove two brass nuts and clips (each side) under

fender attaching fender to splash guard moulding.

4. Remove bolt attaching splash guard to grille lower

center bar and remove splash guard.

INSTALLATION:

RADIATOR GRILLE BAFFLE

(UPPER)

(Right or Left)

REMOVAL:

1. Remove center support bar moulding.

2. Remove screw at front and rear of center bar.

3. Remove one screw from under fender and one screw at

grille baffle side supports. Remove baffle from car.

INSTALLATION:

Reverse procedure of removal.

RADIATOR SPLASH GUARD

(Right or Left)

REMOVAL:

NOTE: The splash guard consists of two pieces joined at

center support. Either right or left side may be removed

Reverse procedure of removal.

RADIATOR GRILLE CENTER BAR

(UPPER)

REMOVAL:

1. Remove two screws and remove the center bar

support moulding.

2. Remove bolts attaching grille baffles to center bar.

3. Remove two bolts attaching center bar to fender tie

panel and to front splash guard.

4. Remove center support and splash guard center plate.

Remove bar from car.

INSTALLATION:

Reverse procedure of removal.

FENDER AND GRILLE SIDE

SUPPORT

(Right or Left Hand)

REMOVAL:

1. Remove the screws attaching the radiator grille baffles

to side and center support. Remove baffles.

2. Remove five bolts under fender attaching the side

panel to fender.

3. Remove the three bolts, nuts, and shakeproof washers

attaching the side support to the radiator mounting channel.

4. Remove three bolts, nuts, and shake- proof washers

attaching the side support to the lower front splash guard.

5. Remove the front splash guard and moulding and

remove the side support from the car.

BODY MANUAL 23

INSTALLATION:

Reverse procedure of removal.

RADIATOR SPLASH GUARD

REMOVAL:

1. Remove two brass nuts and clips (each side) under

fender attaching moulding to front fender lower extension.

2. Pry off moulding with a screwdriver. Use care if

moulding is to be used again.

INSTALLATION:

Snap moulding into place and attach to fender in reverse

procedure of removal.

ENGINE HOOD

REMOVAL:

FIGURE 18

HOOD ADJUSTMENT

1. Loosen the two bolts, ( 9 and 10), which attach the hood

hinge to the cowl just enough to allow for backward or

forward movement.

2. Loosen screws (7 and 8) attaching hinge arm to hood,

(each side).

NOTE: Forward and backward adjustments and up

and down adjustments can now be made at the rear of

the hood. Up or down adjustments at the front of the

hood can be made by raising or lowering the three

rubber bumpers mounted on the front fender tie panel

and adjusting the spring retainer bolt mounted on the

hood lock upper support.

3. After all adjustments have been made, tighten all bolts

and lock nuts securely.

HOOD LOCK UPPER SUPPORT

1. Raise and place prop under front of hood (1), Figure

18.

2. Remove two hood prop bolts ( 2), (one on each side).

Hood props ( 3) remain attached to fender side dust

shields ( 11).

3. Remove the two hood hinge bolts, (7 and 8), from each

side at rear of hood.

4. With a helper, remove hood from car.

INSTALLATION:

Reverse procedure of removal and adjust at hood hinge

bolts.

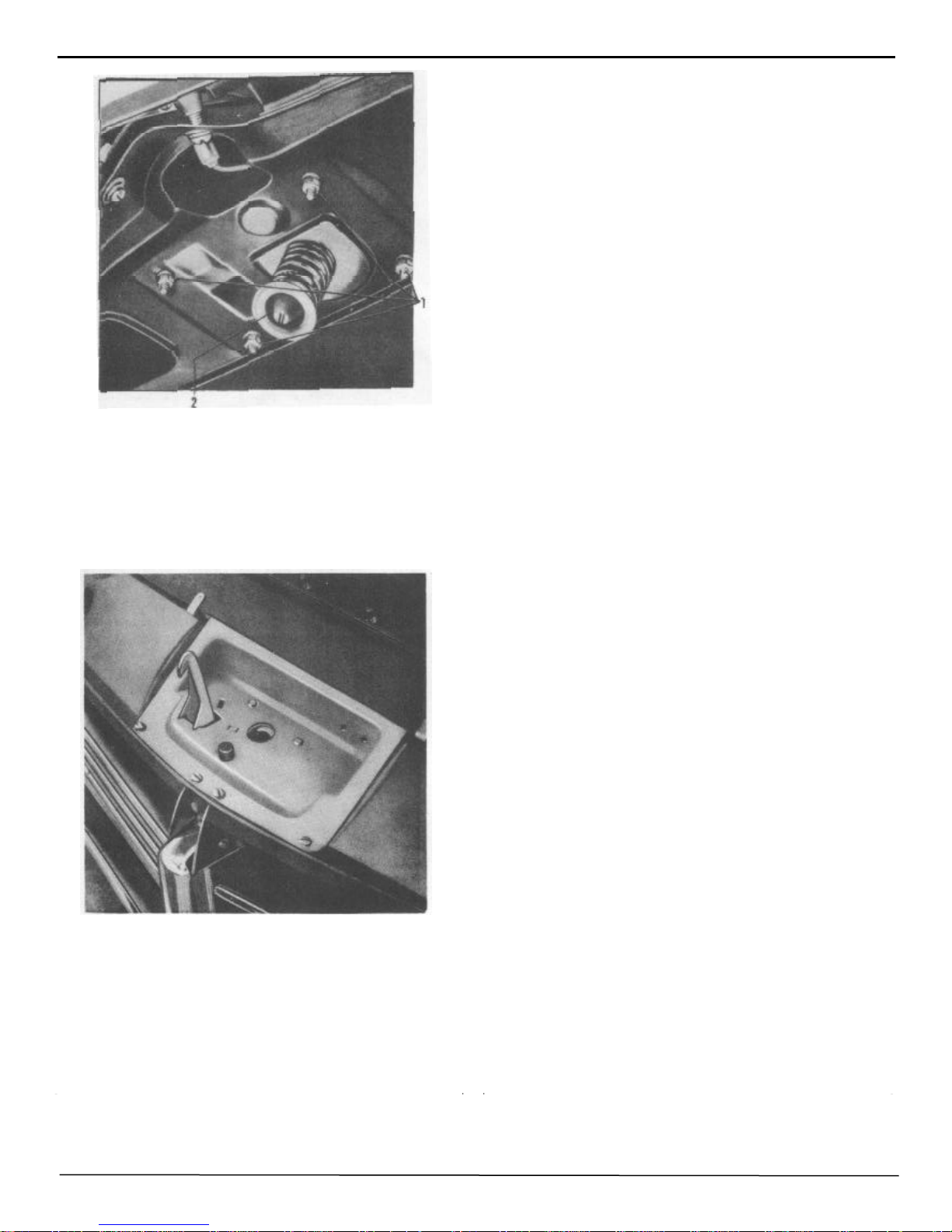

REMOVAL:

1. With a screwdriver remove the spring retainer bolt (2)

from the attaching nut and remove retainer and spring,

Figure 19.

2. Remove the four attaching nuts and washers ( 1) from

lock support plate. 3. Remove the two sheet metal screws

from bracket at rear of assembly and slide assembly to one

side and remove.

INSTALLATION:

Reverse procedure of removal. Adjust locking spring by

turning slotted retainer assembly to left or right.

24 BODY MANUAL

FIGURE 19

HOOD LOCK LOWER SUPPORT

FENDER TIE PANEL AND HOOD

LOCK LOWER SUPPORT

REMOVAL:

1. Raise hood and disconnect hood lock control wire.

2. Remove two bolts (each side) attaching fender tie

panel and hood lock support to fender bracket.

3. Remove two bolts attaching the fender tie panel and

hood lock support to radiator mounting channel.

4. Remove two bolts attaching fender tie panel to the

front fender skirt.

5. Removing one bolt attaching hood lock support to

radiator grille center support and remove the support

assembly from the car.

INSTALLATION:

Reverse procedure of removal.

REMOVAL:

1. Disconnect flood lock control wire.

2. Remove 4 bolts attaching hood lock lower support to

fender tie panel and remove lower support from car.

FIGURE 20

INSTALLATION:

Reverse procedure of removal. Lock hood control wire

securely and apply water resistant grease to hood lock

release catch.

HEADLINING

Preparatory to headlining removal, remove the following trim parts:

A Sun visors

B Rear view mirror

C Front dome lamp lens assembly

D Upper and lower windshield garnish moulding

E Windshield inside center trim bar

F Windshield retainers

G Windshield glass

H Rear seat cushion, back rests, and center arm rest

I Rear window

J Rear package shelf

K Rear quarter window garnish mouldings

L Rear dome lamp lens assembly

NOTE: HANDS MUST BE CLEAN AT ALL

TIMES WHEN WORKING ON THE INTERIOR

TRIM OF A BODY.

REMOVAL:

1. Remove upholsterer's tacks from around rear window

opening and rear quarter window openings and the

cardboard tacking strips at the extreme rear edge of the

headlining on the package shelf. Pull headlining loose

from cement.

Loading...

Loading...