Page 1

Page 2

Page 3

FOREWORD

The following product information will provide Hudson Service Information for the "Hornet"

V-8 Series when used in conjunction with the 1955 and 1956 Technical Service Manuals and

the 1956 "Hornet" Special V-8 Supplement.

This product information should be kept in a convenient location together with the Service

Manuals so that complete information will be available for prompt model and series reference.

1

AMERICAN MOTORS CORPORATION

NAP56-5501 LITHOGRAPHED IN U.S.A.

AUTOMOTIVE TECHNICAL SERVICE

3280 South Clement Avenue

Milwaukee 7, Wisconsin

Page 4

2

Page 5

ENGINE

(V-8)

3

For service procedures and general description of the

V-8 engine, refer to the 1956 Special V-8 Technical .

Service Manual Supplement.

ENGINE SPECIFICATIONS

Type

Bore

Stroke

Displacement

Compression Ratio

Carburetor

Brake Horsepower

Torque

Taxable Horsepower

Fuel

The engines are similar in design varying only

dimensionally effecting increase in horsepower

90° V-8 O.H.V.

4"

314"

327 Cu. In-

9.00:1

WCFB-Four Barrel

255 @ 4700 R.P-M.

345 Lbs. Ft. @ 2600 R-P.M.

51.2

Premium (95.9 Octane Research)

VALVES

Intake Valve Lift

Intake Valve Stem

Standard Diameter

Intake Valve Face Angle

Intake Valve Seat Angle

Intake Valve Seat Width

Intake Valve Spring Tension

Valve Closed

Valve Open

Intake Valve Stem to

Guide Clearance

Valve Guide I.D.

Exhaust Valve Lift

Exhaust Valve Stem

Standard Diameter

Exhaust Valve Face Angle

Exhaust Valve Seat Angle

Exhaust Valve Seat Width

Exhaust Valve Spring Tension

Valve Closed

Valve Open

.375"

.3412"-.3417"

29°

30°

.078"-.093"

85-91 Lbs. @ 1-13/16"

150-160 Lbs. @ 1-7/16"

-0013"-.0028"

.3430"--3440"

.375"

.3407"--3412"

44°

45°

.093"--104"

85-91 Lbs- ((4 1-13/16"

150-160 Lbs. (a) 1-7/16"

Page 6

4 ENGINE (V-8)

Exhaust Valve Stem to

Guide Clearance

Exhaust Guide I.D.

Valve Timing

Intake

Opens

Closes

PISTONS AND RINGS

Piston to Bore Clearance

Top Land

Skirt Top

Skirt Bottom

Piston Ring Gap Clearance

Top

Center

Bottom (Steel Rail I

.0018"-.0033"

.3430”-.3440"

12° 30' B.T.D.C. 244°

51° 30' A.B.D.C. Duration

.028"-.032"

.0009"-.0025"

.0009"-.0015"

.010"-.020"

.010"-.020"

.015"-.055"

Piston Ring Side Clearance

Top

Center

Bottom

Piston Pin to Connecting Rod

Piston Pin to Piston

CRANKSHAFT AND BEARINGS

Main Bearing Diameter

Main Bearing Clearance

Main Bearing Cap Torque

(Except Rear)

Main Bearing Cap Torque

(Rear Only)

Crankshaft End Play

Crankshaft End Thrust

Connecting Rod Bearing Diameter

Connecting Rod Bearing Clearance

Connecting Rod Cap Torque

Connecting Rod Side Clearance

.002"-.006"

.002"-.006"

.0001"-.0079"

Press Fit

Palm Press Fit in Piston at Room

Temperature

2.4983"-2.4990"

.0006"-.0032"

80-85 Ft. Lbs.

50-55 Ft. Lbs.

.003"-.007"

Front Main Bearing

2.2483"-2.2490"

.0007"-.0028"

46-50 Ft. Lbs.(oiled)

.004"-.012"

Camshaft End Play

Camshaft Bearing Clearance

CAMSHAFT

.003"-.006"

.001"-.003"

Page 7

ENGINE (V-8)

OIL SYSTEM

5

Oil Pump Type

Normal Oil Pressure

Oil Pressure Release

Engine Oil Refill Capacity

TUNE-UP DATA

Compression Pressure

Cranking Speed

(Throttle Wide Open)

Engine Idle R.P.M.

Standard and Overdrive

Hydra-Matic—In Neutral

With Air Conditioning

NOTE: When equipped with air condi-

tioning, adjust idle with air conditioning unit "ON".

Gear

10 Lbs. Min. Vii; 600 R.P.M.

55-60 Lbs.

5 Qts.

140 P.S.I. Min. 0) 315 R.P.M.

550

425

475

Ignition Timing

(Vibration Damped 1

Distributor Point Gap

Dwell or Cam Angle

Breaker Point Tension

Rotor Rotation

Spark Plugs

Auto-Lite

Champion

Gap

Torque

Cylinder Head Torque

Firing Order

5° B.T.D.C.

(10° B.T.D.C. optional with

Automatic Transmission or

where local fuel octane per-

mits)

.016"

28º-32º

19-23 Ozs.

Left Hand

AL-7

H-10

.035"

30 Ft. Lbs.

60-65 Ft. Lbs.

1, 8, 4, 3, 6, 5, 7, 2

Page 8

6

ELECTRICAL

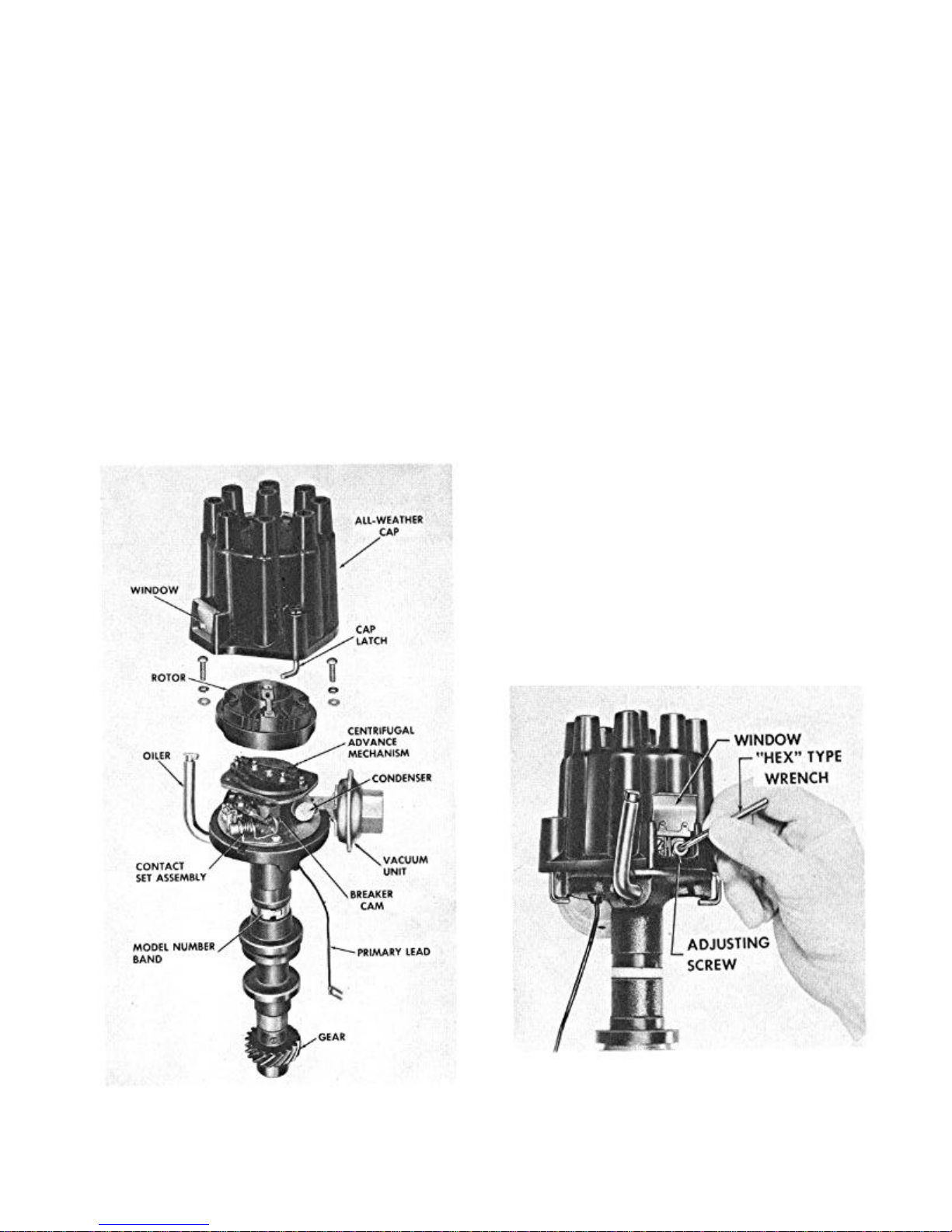

DISTRIBUTOR (DELCO-REMY)

Model 1110887

(External Adjustment Type)

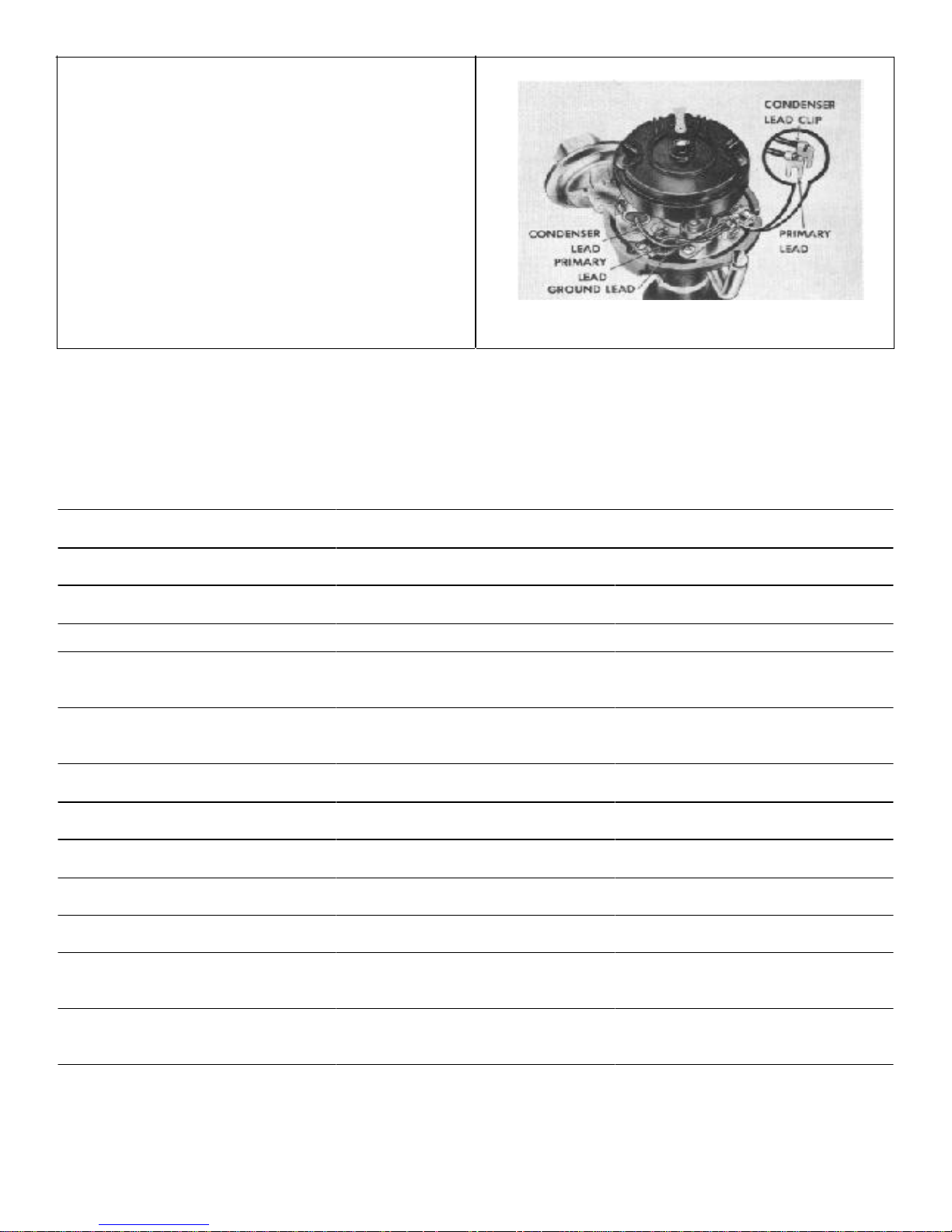

The external adjustment type distributor illustrated in Figure

1 is a 12 volt, 8 cylinder unit. The cap has a window for

adjusting dwell angle while the cap is in amounted position.

The circuit breaker plate is located below the centrifugal

advance mechanism and uses the outer diameter of the main

shaft bushing for its bearing surface. The movable plate is

held into position by a retainer clip in the upper shaft bushing.

The molded rotor serves as a cover for the centrifugal advance

mechanism. The vacuum control unit is mounted under the

movable breaker plate to the distributor housing. The contact

set is attached to the movable breaker plate. The service

replacement contact set has the BREAKER LEVER SPRING

TENSION AND POINT ALIGNMENT prefactory adjusted

and is serviced as one complete assembly. Only the point

opening ( dwell angle I requires adjusting after replacement.

Under part throttle operation, the intake manifold vacuum is

sufficient to actuate the vacuum control diaphragm and cause

the movable plate to move, thus advancing the spark and

increasing fuel economy. During acceleration or when the

engine is pulling heavy, the vacuum is not sufficient to actuate the diaphragm and the movable plate is held in the retarded position by a calibrated return spring which bears

against the vacuum diaphragm.

The centrifugal advance mechanism consists of an automatic cam actuated by two centrifugal weights controlled by

springs. As the speed of the distributor shaft increases with

engine speed, the weights are thrown outward against the pull

of the springs. This advances the cam causing the contact

points to open earlier and thus advancing the spark.

Lubrication

The hinge cap oiler should be filled with SAE 20 oil at each

vehicle lubrication period. When replacing the contact set

assembly, add a trace of Ball Bearing Lubricant to the breaker

cam. No other lubrication is required. The movable breaker

plate is lubricated by oil from the upper shaft bushing. In

addition to lubrication, the distributor requires periodic inspection of the cap and rotor, wiring, breaker points, and

timing.

Adjustment of Dwell Angle on the Car

With the engine running at idle, the dwell is adjusted by first

raising the window provided in the cap and inserting a "Hex"

type wrench into the head of the adjusting screw as shown in

Figure 2.

FIGURE 1—Distributor Assembly

Figure 2—Adjusting Point Spacing (Dwell)

Page 9

ELECTRICAL

7

Preferred Method:

Turn the adjusting screw until the specified dwell is obtained

as measured by a dwell meter. (See specifications.)

Alternate Method:

Turn the adjusting screw in (clockwise) until the engine

begins to misfire, then give the wrench one-half turn in the

opposite direction (counterclockwise) thus giving the approximate dwell angle required.

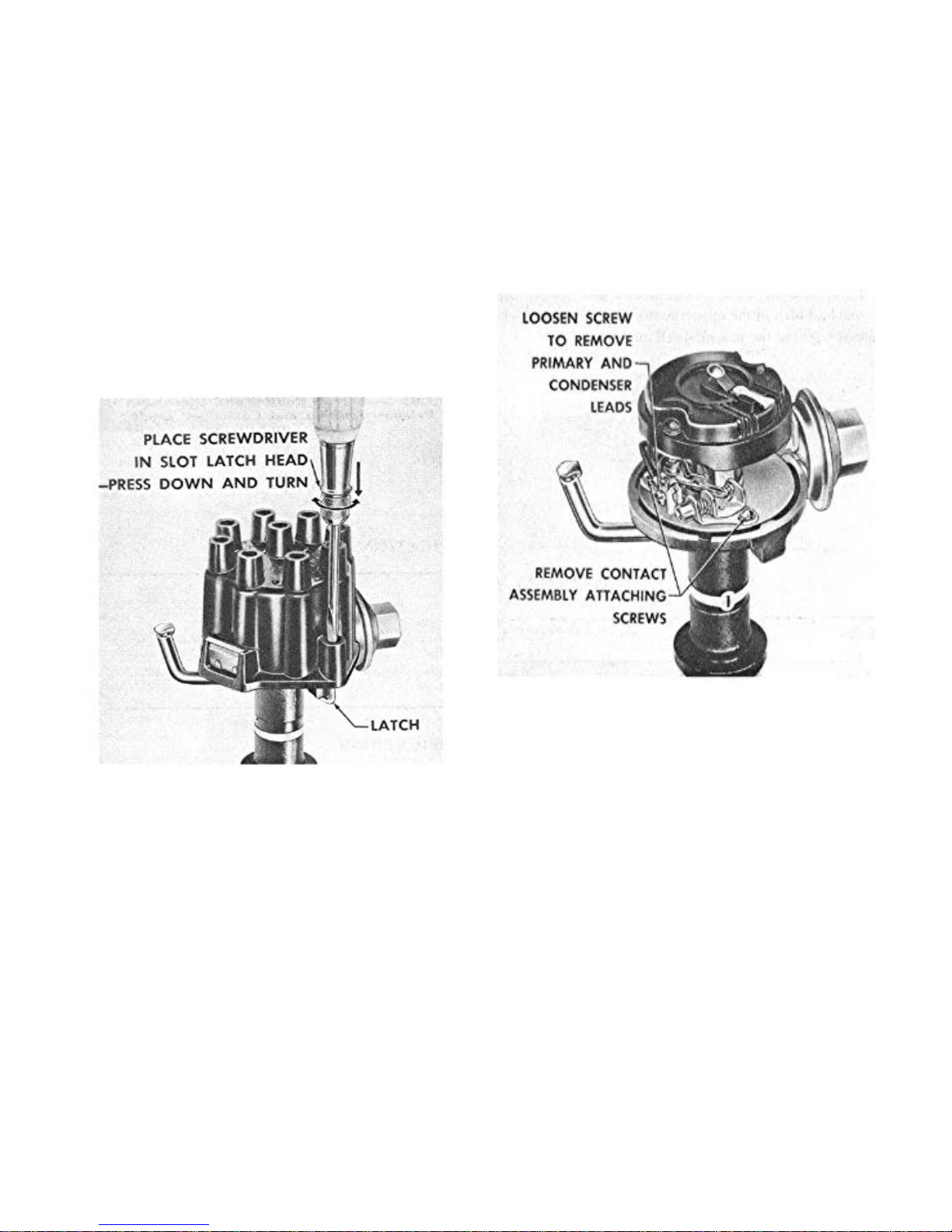

Removal of Distributor Cap

The cap is removed as shown in Figure 3. Place screw driver

in slot head of the hatch, press down and turn 1/4 of a turn in

either direction.

Insulation Resistance (or Leakage, Series Resistance, Breakdown Test, and Capacity (mfd.).

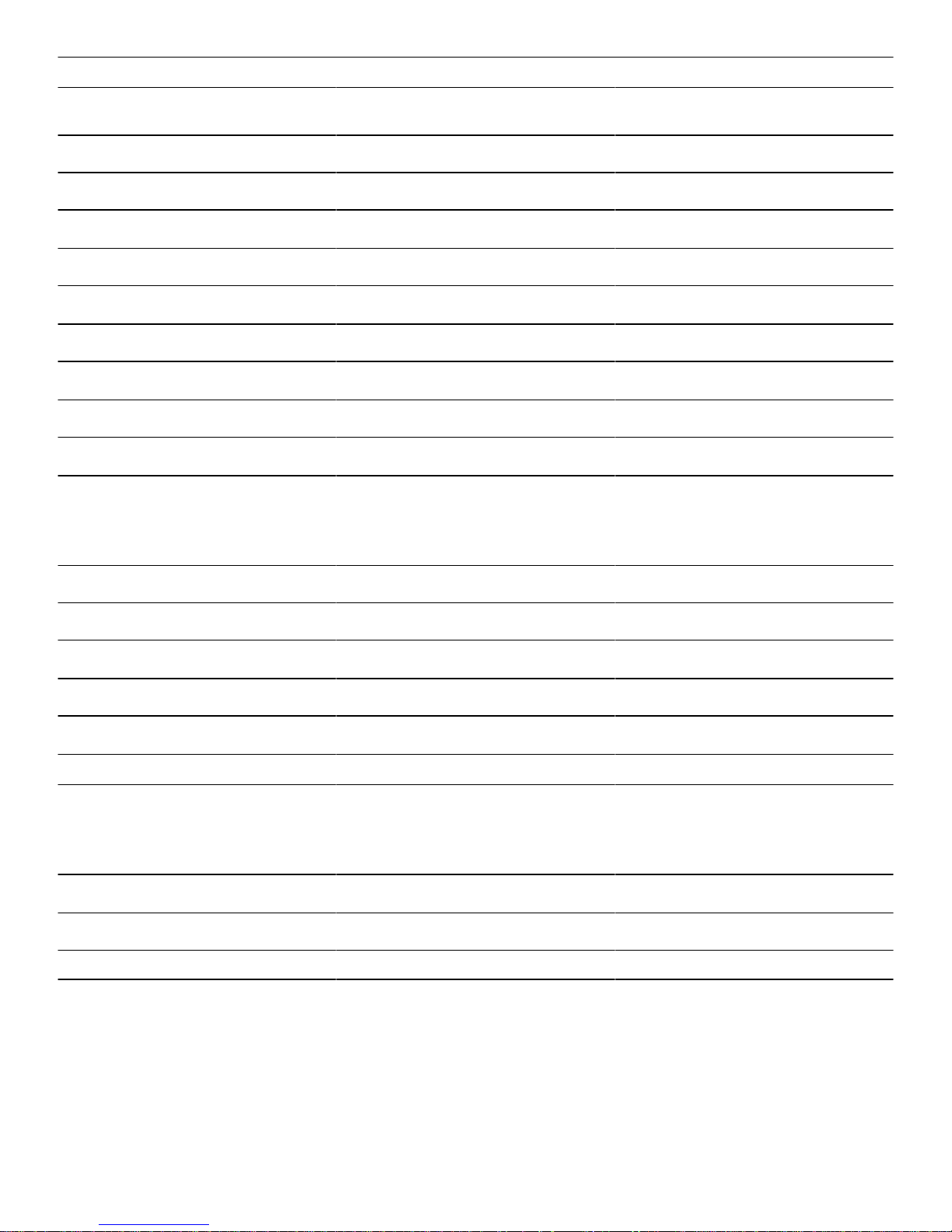

Replacing Distributor Contact Set

The contact point set is replaced as one complete assembly

(Fig. 4). The BREAKER LEVER SPRING TENSION and

POINT ALIGNMENT on the service replacement contact

set are factory adjusted. Only the POINT OPENING requires

adjusting after replacement.

FIGURE 3—Distributor Cap Removal

Distributor Inspection and Checking

With the distributor removed from the vehicle, it is advisable

to place the distributor in a distributor testing machine or

synchroscope. When mounting distributor in tester, first

secure the gear in the drive mechanism, then push distributor

housing down toward the gear to take up end play between

the gear and housing, and finally secure the housing in the

tester. Test the distributor for variation of spark, correct

centrifugal and vacuum advance, and condition of contacts.

This test will give valuable information on the distributor

condition and indicate parts replacement which may be necessary.

When checking the distributor condenser, it should be

checked with a reliable make of condenser tester. The condenser should be checked for the following properties.

FIGURE 4—Removing Distributor Contact Set

Replacement of contact set is as follows:

Remove the two attaching screws (Fig. 4) which hold the

base of contact set assembly in place.

Remove the condenser lead and primary lead from the nylon

insulated connection by turning screw (Fig. 4) in contact set.

Replacement is the reverse of removal.

CAUTION: At time of assembly, make sure the

condenser lead and primary lead are located as in,

Figure 5.

Leads must be properly located to eliminate lead interference between cap, weight base, and breaker advance plate.

Add a trace of Ball Bearing Lubricant to the breaker cam.

Adjusting Distributor Dwell Angle

Either of the following methods can be used to adjust the

dwell angle to the proper setting off the vehicle:

Screw Adjustment Method—Distributor Mounted in

Distributor testing Machine

Connect the dwell meter to the distributor primary lead.

Page 10

8 ELECTRICAL

Turn the adjusting screw to set the dwell angle to the proper

setting of degrees (Fig. 2). (See Test Specifications.)

Screw Adjustment Method Distributor Mounted in a

Vise

Connect a testing lamp to the primary lead.

Rotate the shaft until one of the circuit breaker cam lobes is

under the center of the rubbing block of the breaker lever.

Turn the adjusting screw (clockwise) as shown in Figure 2

until the lamp lights, then give the wrench one-half turn in

the opposite direction (counterclockwise) giving the proper

dwell angle.

Figure 5—Correct Routing and Attachment of

Primary Ignition and Condeser Leads

BATTERY SPECIFICTIONS

Make Auto-lite

Model 11-HS-60

Rating 60 Ampere Hours

No. of Plates (Each Cell) 11

GENERATOR SPECIFICATIONS

With

Air Conditioning

Make \Delco-Remy \Delco-Remy

Model 1102070 1102018

Type Shunt Shunt

Rotation CW. @ Drive End CW. @ Drive End

Brush Spring Tension 28 Oz. 28 Oz.

Withoout

Air Conditioning

Field Current 1.69-1.79 Amperes

Cold Output 35 Amperes @ 14.0

@ 12 Volts, 80°F.

Volts, 2510 R.P.M.

1.48-1.62 Amperes @

12 Volts, 80°F.

30 Amperes @ 14.0

Volts, 2210 R.P.M.

Page 11

ELECTRICAL

VOLTAGE AND CURRENT REGULATION

9

With

Air Conditioning

Make Delco-Remy Delco-Remy

Model 1119168 1119003

Cutout Relay Closing Voltage 11.8-13.5 11.8-13.5

Air Gap .020" .020"

Point Gap .020" .020"

Voltage Regulator Volts 13.8-14.8 13.8-14.8

Air Gap .075" .075"

Current Regulator Amperes 32-37 27-33

Air Gap .075" .075"

Without

Air Conditioning

STARTING MOTOR SPECIFICATIONS

Make Delco-Remy

Model 1107648

Brush Spring Tension 35 Oz. Min.

No Load Test Amperage Draw 75 Maximum

Volts 10.3

R.P.M. 6900

SOLENOID SWITCH

Model 1119760

Hold-in Winding 18-20 Amperes at 10 Volts

Both Windings 72-76 Amperes at 10 Volts

Page 12

10 ELECTRICAL

DISTRIBUTOR SPECIFICATIONS

Make Delco-Remy

Model 1110887

Rotation L.H. CCW.

Point Opening .016"

Cam Angle 28°-32° (Set to 30° )

Breaker Lever Tension 19-23 Ozs.

Condenser Capacity .18-.23 Mfd.

Centrifugal Advance

(Engine Degrees and R.P.M.)

Start

Intermediate

Intermediate

Maximum

0-4°

15-19°

24-28°

34-38°

700 R.P.M.

1550 R.P.M.

2600 R.P.M.

3800 R.P.M.

Vacuum Control

(Engine Degrees and Inches

Mercury)

Start

Full Advance

Maximum Engine Degrees

1116117 Delco-Remy

5"-7"

14.25-15.75

20°

SPARK PLUG SPECIFICAITONS

Make Auto-lite Champion

Model AL-7 H-10

Thread 14 M.M. 14 M.M.

Gap .035" .035"

Torque 30 Ft. Lbs. 30 Ft. Lbs.

Page 13

Trade Number

and

Candle Power

ELECTRICAL

BULB CHART

American Motors

Part Number Location

11

57

2 C.P.

57

2 C.P.

1488

2 C.P.

67

2 C.P.

89

6 C.P.

1034

32 & 4 C.P.

1073

32 C.P.

5400

50 & 40W

127934 Glove Box and

Hood Ornament Emblem

127934 Instrument Illumination

Clock

Head Lamp Beam Indicator

Directional Signal Indicator

Generator Charge Indicator

Oil Pressure Signal

3145931 Selector Lever Indicator

Light

142450 License

142452 Dome and Courtesy Light

454645 Tail, Stop, and Direction

Part and Direction

454646 Back-Up

456796 Head Light

Page 14

12

FUEL———CARBURETION

CARTER MODEL WCFB-2593-S FOUR-BARREL CARBURETOR

The Carter Model WCFB carburetor is basically two (2)

dual carburetors contained in one assembly. The section

containing the metering rods, accelerating pump and

choke is termed the primary side of the carburetor, the

other section, the secondary side. It has five (5) conventional circuits. They are:

2—Float Circuits

1—Low Speed Circuit

2—High Speed Circuits

1—Pump Circuit

1—Climatic ® Control (Choke) Circuit

FLOAT CIRCUITS

The purpose of the float circuits is to maintain an adequate

supply of fuel at the proper level in the bowls for use by

the low speed, high speed, pump and choke circuits. Primary and secondary bowls are separated by a partition.

The fuel line connection is on the primary side. Fuel is

supplied to the primary and secondary intake needles and

seats through a passage in the bowl cover. There are two

fine mesh strainer screens in the bowl cover. They are

located at the fuel inlet and at the secondary intake needle

seat.

The bowls are vented to the inside of the air horn by

vertical vent tubes and to atmosphere by drilled passages

in the air horn. Bowl vents are calibrated to provide proper

air pressure above the fuel at all times. The bowl cover

gasket seals the fuel bowl, idle and vacuum passages. To

assure a positive seal, always Use a new bowl cover gasket

when reassembling. An air leak at this point can result in

a performance or economy complaint.

A connecting passage along the outside of the body

effects a balance of the fuel levels and air pressures between the two bowls.

FIGURE 1—Float Circuit

Fuel enters the idle wells through the metering rod jets

on the primary side of the carburetor. No idle system is

used in the secondary side of the carburetor.

The low speed jets measure the amount of fuel for idle

and early part throttle operation. The air by-pass, economizers, and idle air bleeds are carefully calibrated and

serve to break up the liquid fuel and mix it with air as it

moves through the passages to the idle ports and idle

adjustment screw ports. Turning the idle adjustment

screws toward their seats reduces the quantity of fuel

mixture supplied by the idle circuit.

The idle ports are slot shaped. As the throttle valves are

opened more of the idle ports are uncovered allowing a

greater quantity of the fuel and air mixture to enter the

carburetor bores. The secondary throttle valves remain

seated at idle.

FIGURE 2—Low Speed Circuit

Throttle Bore Vapor Vent Passages

Under certain conditions of high, under-hood temperature,

fuel vapor forms in the throttle bores when the engine is

not operating. This vapor accumulation may retard hot

engine starting until sufficient air is drawn into the carburetor to mix with the vapor to form a combustile mixture.

The throttle bore vapor vent passages vent the bores

above the throttle valves to cavities in the underside of the

carburetor flange. Air is admitted to these cavities through

openings in the flange gasket. The air supplied by these

vent passages, when mixed with the accumulated vapor,

forms a more combustible mixture. This improves hot

engine starting.

LOW SPEED CIRCUITS

Fuel for idle and early part throttle operation is metered

through the low speed circuit.

HIGH SPEED CIRCUITS

Fuel for part throttle and full throttle operation is

Page 15

FUEL—CARBURETION

13

supplied through the high speed circuits. Main discharge

nozzles are permanently installed and must not be removed in service.

Primary Side

The position of the metering rods in the metering rod jets

control the amount of fuel flowing in the high speed circuit

of the primary side of the carburetor. The position of the

metering rods is dual controlled; mechanically by movement of the throttle, and by manifold vacuum applied to

the vacuum piston on the vacumeter link.

Mechanical Metering Rod Action

During part throttle operation, manifold vacuum pulls the

vacumeter piston, link and metering rod assembly down,

holding the vacumeter link against the metering rod countershaft arm. Movement of the metering rods will then be

controlled by the metering rod countershaft arm which is

connected to the throttle shaft. This is true at all times that

the vacuum under the piston is strong enough to overcome

the tension of the vacumeter spring.

Vacuum Metering Rod Action

Under any operating conditions (acceleration, hill climbing, etc.), when the tension of the vacumeter spring overcomes the pull of vacuum under the piston, the metering

rods will move toward their wide-open throttle or power

position.

Secondary Side

Fuel for the high speed circuit of the secondary side is

metered at the main metering jets (no metering rods used).

Throttle valves in the secondary side of the carburetor

remain closed until the primary throttle valves have been

opened a predetermined amount. They arrive at wide open

throttle position at the same time as the primary throttle.

This is accomplished by linkage between the throttle levers.

The second set of counterweighted off-set throttle

valves mounted above the secondary throttle valves are

called "auxiliary throttle valves." Air velocity through the

carburetor controls the position of the auxiliary throttle

valves. When the accelerator is fully depressed, only the

primary high-speed circuit will function until there is

sufficient air velocity to overcome the weight of the counterweight on the auxiliary throttle lever and open the

auxiliary throttle valves. When this occurs, fuel will also

be supplied through the secondary highspeed circuit.

The secondary throttle valves are locked closed during

choke operation, to insure faster cold engine starting and

good "warm-up" performance.

Anti-Percolator

To prevent vapor bubbles in the nozzle passages and low

speed wells from forcing fuel out of the nozzles, antipercolator passages and calibrated plugs and bushings are

used. Their purpose is to vent the vapors and relieve the

pressure before it is sufficient to push the fuel out of the

nozzles and into the intake manifold. Anti-percolator

plugs and bushings are permanently installed and must not

be removed in service.

FIGURE 3—High Speed Circuit Metering Rods

FIGURE 4—High Speed and Anti-Percolator

Circuits

PUMP CIRCUIT

The pump circuit is located only in the primary side of the

carburetor.

Page 16

14 FUEL—CARBURETION

The accelerating pump circuit provides the measured

amount of fuel necessary to insure smooth engine operation during acceleration at speeds below approximately 30

MPH.

tends to pull the choke valve open. The choke valve

assumes a position where tension of the thermostatic coil

is balanced by the pull of vacuum on the piston and air

velocity on the off-set choke valve.

When the throttle is closed, the pump plunger moves

upward in its cylinder and fuel is drawn into the pump

cylinder through the inlet passage. The discharge needle is

seated at this time to prevent air being drawn into the

cylinder. When the throttle is opened, the pump plunger

moves downward forcing fuel out through the discharge

passage, past the discharge needle, and out of the pump

jets. When the plunger moves downward, the inlet valve is

closed preventing fuel from being forced back into the

bowl.

If the throttle is opened suddenly, the pump spring will

be compressed by the plunger shaft telescoping, resulting

in a smoother pump discharge of longer duration.

At speeds above approximately 30 MPH, pump discharge is no longer necessary to insure smooth acceleration. When the throttle valves are opened a predetermined

amount, the pump plunger bottoms in the pump cylinder

eliminating pump discharge.

FIGURE 5—Accelerating Pump Circuit

CHOKE CIRCUIT

The Climatic ® control circuit provides a correct mixture

necessary for quick cold engine starting and warm-up.

When the engine is cold, tension of the thermostatic coil

holds the choke valve closed. When the engine is started,

air velocity against the off-set choke valve causes the

valve to open slightly against the thermostatic coil tension.

Intake manifold vacuum applied to the choke piston also

FIGURE 6—Choke Circuit

FIGURE 7—Choke Housing Assembly

When the engine starts, slots located in the sides of the

choke piston cylinder are uncovered allowing intake man-

ifold vacuum to draw air heated by the exhaust manifold,

through the Climatic ® control housing. The flow of warm

air heats the thermostatic coil and causes it to lose some of

its tension. The thermostatic coil loses its tension gradu-

ally until the choke valve reaches wide open position.

When the engine is accelerated during the warm- up peri-

od, the corresponding drop in manifold vacuum allows the

thermostatic coil to momentarily close the

Page 17

FUEL—CARBURETION

15

choke, providing a richer mixture.

During the warm-up period, it is necessary to provide a

fast idle speed to prevent engine stalling. This is accomplished by a fast idle cam which is rotated by a connector

rod attached to the choke shaft. The fast idle cam prevents

the primary throttle valves from returning to a normal

warm engine idle position while the Climatic ® control is

in operation.

During the starting period if the engine becomes flooded, the choke valve can be partially opened manually. This

can be accomplished by depressing the accelerator pedal

to the floor and engaging the starter. The projection on the

throttle lever (unloader) will rotate the fast idle cam and in

turn partially open the choke valve.

OVERHAUL AND ADJUSTING

Flooding, stumbling on acceleration, and other performance complaints in many cases are attributable to dirt,

water, or other contaminants in the carburetor. Therefore,

when removing a carburetor for inspection, do not drain

the fuel bowl. The contents of the carburetor may be

examined for evidence of contamination.

Whenever the carburetor is removed, use care when

handling to prevent damage to the throttle valves. The

lower edge of the throttle valves extend beyond the base of

the carburetor when in the open position.

Figure 8 illustrates the locations and relative lengths of

the air horn attaching screws.

The float needles and seats must not be interchanged,

therefore, group the needles and seats with their respective

float assemblies.

The accelerator pump discharge check needle is located

in the passage below the pump jet cluster and may be

removed by inverting the carburetor.

The primary metering rod jets have larger openings than

the secondary jets. Therefore, do not mix. the jets.

When cleaning the carburetor, follow the instructions

for the cleaning solution being used.

Do not use drills or wire to clean jets or ports, this may

result in inadvertent enlarging the openings or ports, af-

fecting carburetor performance.

ASSEMBLY PROCEDURE

Assembling Throttle Flange

Install primary and secondary throttle shafts.

Assemble throttle valves on shafts with trade mark (C)

toward idle ports on primary valves and away from center

of carburetor on secondary valves when viewed from the

bottom. (Use Oval head screws on secondary valves.)

Install idle mixture adjusting screws and springs finger

tight, then loosen one turn.

NOTE: Do not tighten mixture screws tighter than

finger tight.

Assemble secondary throttle return spring and throttle

lever on secondary throttle shaft. Install and tighten retain-

ing washer and screw.

Wind the return spring 11/2 turns and hook over secondary

throttle lever.

FIGURE 8—Location and Lengths of Air Horn

Attaching Screws

Carefully remove the air horn assembly with the gasket

and attaching parts. If the gasket sticks to the body casting,

the floats may become bent.

FIGURE 9—Assembling Secondary Throttle

Lever and Spring

Install primary shaft wave washer, inner throttle shaft

arm, and throttle shaft dog. Hook flex spring on outer

throttle lever and throttle shaft dog and install outer lever

on primary shaft. Install washer and screw.

Install primary to secondary connector rod using a flat

washer on each side of the levers and retain with pin

springs.

Page 18

16 FUEL—CARBURETION

Install auxiliary throttle shaft and auxiliary throttle

valves.

Using a new gasket, assemble the throttle flange on the

carburetor body. Assemble while holding auxiliary throttle

valves closed.

CAUTION: Tighten the screws indicated in Figure

13 securely to prevent leakage between the body

and throttle flange.

FIGURE 10—Primary Throttle Shaft Arm

and Lever Assembly

Assemble fast idle cam and spring assembly and lower

choke lever placing the assembly on the attaching screw.

FIGURE 11—Fast Idle Cam and Spring

Assembly

Place the secondary lockout lever against boss and

install the fast idle cam assembly in position on the boss.

The levers must operate freely.

FIGURE 13—Location of Body to Flange

Screws-

Assembling Carburetor Body

Install the primary metering rod jets, (jets with the large

holes) in the accelerator pump side of the carburetor. Then

install the secondary main jets.

Install the two low speed jets in the primary side of the

body.

The steel pump inlet ball check and retainer is installed

in the bottom of the accelerator pump cylinder. A 5A6" six

point socket assists pressing into place.

Install pump passage screw plug and gasket.

The brass pump discharge check needle is installed

point down in the passage below the pump discharge jet

cluster.

Install the accelerator pump discharge cluster gasket

and cluster assembly.

Inspect vacumeter spring. The vacumeter spring affects

both economy and performance. If it appears damaged or

distorted, replace. If there is any doubt, compare it with a

new one. Place the spring in vacumeter bore.

Install lower pump spring in pump cylinder.

FIGURE 12—Secondary Lockout and Fast

Idle Cam Assembled

Assembling Air Horn

Using a new gasket, install the primary needle and seat;

then install secondary needle and seat assembly.

Page 19

FUEL—CARBURETION

NOTE: Intake needles and seats are carefully

matched during manufacture. Do not use the primary needle in the secondary seat or vice versa. To

avoid unnecessary bending, both floats should be

reinstalled in their original positions and then

adjusted.

Setting the floats to, specifications assures an adequate

supply of fuel in the bowls for all operating conditions.

Float adjustments must be made with the bowl cover

gaskets removed and should be checked vertically

(specified distance between bowl cover and bottom of

floats) and laterally (sides of floats should just clear the

arms of gauge) . Correct lateral adjustment is important. If

the floats are misaligned, they may bind or drag against the

inner walls of the bowl.

LATERAL ADJUSTMENT—Place primary float

gauge T-109-232 and secondary float gauge T-109-222

under center of float with notched end of gauge fitted over

edges of casting. Sides of floats must just clear vertical

uprights of gauge. Adjust by bending arms.

FIGURE 14—Float Gauge in Position

VERTICAL ADJUSTMENT—Check with gauge in

position. Floats must just clear the horizontal part of the

gauge. There must be 1/8" between top of floats and air

horn for .primary and 3/16" for secondary floats. Adjust by

bending at center section of float arms.

FLOAT DROP ADJUSTMENT—Hold air horn assembly in normal upright position and measure between the

top center of floats to air horn. It must be /8" for primary

and 11/16" for secondary floats. Adjust by bending tabs on

float brackets.

Remove float assemblies and install new air horn gasket.

Assemble vacumeter link and vacumeter piston with lip

on link toward air horn.

Insert accelerator pump plunger shaft in air horn and

17

FIGURE 15—Checking Float Drop

retain with link and pump arm assembly.

Reassemble floats.

Install air horn assembly on carburetor body. Be sure

vacumeter piston and pump plunger are properly aligned.

Do not bend float arms while assembling. Refer to Figure

8 for correct location of different length screws.

Insert metering rods, catching spring loop with lower

end before inserting. Start rods in jets; then twist eye of rod

to engage vacumeter link assembly.

Install countershaft return spring on countershaft.

The pump countershaft is inserted into the pump operating

arm and metering rod arm. Be sure metering rod arm is in

slot of vacumeter link.

Install idle vapor vent lever and screw; then tighten

pump arm screw.

Place washer on lower end of throttle connector rod.

Install rod into throttle lever while holding lever in closed

position and retain with spring and retainer.

Wind countershaft return spring one-half turn.

Install throttle connector rod in pump countershaft lever

and retain with pin spring.

Install choke housing onto air horn using a new gasket.

Assemble choke piston on link and install shaft and

piston, assembly through air horn while guiding piston in

cylinder.

Place choke valve in position on choke shaft in air horn

so that (C) is visible from the top. Center the valve and

tighten screws. Be sure valve or shaft does not bind and

valve opens freely of its own weight.

Position baffle plate on choke housing.

Install choke coil housing gasket on piston housing with

index mark on plastic housing at the bottom and retain

with three screws and retainers. Leave coil housing in this

position while making other adjustments.

Install choke operating levers on shaft. Tighten screw

only enough to permit lever to be moved.

The choke connector rod is installed in operating lever

and choke lower lever. Retain lower end with pin spring.

Install strainer plug, gasket, and strainer in primary side

and strainer plug and gasket on secondary side.

Page 20

18 FUEL—CARBURETION

ADJUSTMENTS

Float Adjustment

Float adjustment is performed during assembly. "Refer to

Assembling Air Horn."

Pump Adjustment

Back out idle speed screw, hold choke in wide open

position, then close throttle valves tight in bores of carburetor.

Flat on top of pump arm must be parallel with dust

cover gasket surface.

Bend throttle connector rod at lower angle to obtain

adjustment.

FIGURE 16—Accelerator Pump Adjustment

Metering Rod Adjustment

With throttle valves seated, press down on vacumeter link

until metering rods are bottomed.

Holding rods down with throttle valves seated, rotate

metering rod arm until it contacts lip on vacumeter link.

Tighten metering rod arm clamp screw.

Vapor Vent Adjustment

Lubricate countershaft with oil and install dust cover and

gasket.

With choke valve held in wide open position and throttle valves seated, there should be I/32" between lower edge

of bowl vapor vent valve and dust cover. To adjust, remove dust cover and bend vapor vent arm.

Rotate choke coil housing in direction opposite arrow

until index mark on coil housing is aligned with center

index on piston housing. Tighten retaining screws.

With choke lever clamp screw loose, hold choke valve

closed.

Figure 17—Meteromg Rpd Adkist,em

Figure 18—Vapor Vent Adjustment

Place wire gauge T-109.189 .023" on boss. Rotate choke

lever on shaft until tang on fast idle cam contacts wire gauge

Page 21

FUEL—CARBURETION

19

FIGURE 19—Fast Idle Cam Clearance

Adjustment

Hold choke valve tightly closed.

Adjust fast idle screw on primary throttle shaft arm to

obtain .023" (T-109-189) opening between the edge of the

throttle valve and the bore of the carburetor (side opposite

idle port). The fast idle speed lug must be on high step of

cam while making this adjustment.

Unloader Adjustment

With throttle wide open, there should be %2" (T-109126)

clearance between upper edge of choke valve and side of

air horn. Adjust by bending unloader projection on throttle

lever.

Secondary Throttle Lever Adjustment

Block choke valve open to unlock secondary throttle

valves.

Place 11/;4" gauge (T-109-166) between upper edge of

primary throttle valve and bore (next to idle port) and

adjust secondary operating rod (use bending tool T-109-

213) until secondary throttle valves just start to open.

Page 22

20 FUEL—CARBURETION

There should be .008" to .013" clearance (Gauge T-109-

200) between the primary and secondary throttle positive

closing shoes with throttle valves closed. Adjust by bending primary shoe (Figs. 22 and 23).

FIGURE 23—Secondary Throttle Lever

Lockout Adjustment

With choke wide open, hold throttle closed.

Close choke slowly ; the lockout step on secondary lock-

FIGURE 22—Secondary Throttle Lever

(First) Adjustment

out-lever should freely engage tang on secondary throttle

lever. Adjust by bending tang

(Second) Adjustment

CARBURETOR SPECIFICATIONS

DIMENSIONS:

VENTS:

GASOLINE INTAKE

:LOW SPEED JET TUBE:

Figure 24 —Secondary Throttle Lockout

Adjusstment

Flange Four Bore-4 bolt type.

Throttle bore 17A 6".

Primary venturi size, l%2" I.D.

Main venturi size, 1-3/16" I.D.

Outside, 4. Inside, 5.

Size No. 42 (.0935") drill hole in needle seat.

(Primary side only). Jet, size No. 68 (.031") drill.

By-Pass, in body, size No. 54 (.055") drill.

Economizer, in screw plug, size .0492" diameter.

Idle Bleed, in body, size .065" diameter.

Page 23

FUEL—CARBURETION

21

IDLE PORT:

IDLE PORT OPENING:

LOWER PORT:

SET IDLE ADJUSTMENT SCREW:

MAIN NOZZLE:

METERING ROD:

METERING ROD JET:

ACCELERATING PUMP:

(Upper) slot type. Primary, length .185"; width .030". Secondary, none.

Primary, .130" to .136" above top edge of valve with valve tightly closed.

Secondary, none.

Primary (for idle adjustment screw), size No. 53 (.0595") drill.

Secondary, none.

3/4 to 13/4 turns open. For richer mixture, turn screw out. Do not

idle engine below 425 RPM Automatic Trans. in Neutral (With Air

Conditioning "ON" 475 RPM) ; 550 RPM for Standard and Overdrive Trans.

Installed permanently. NO NOT REMOVE. Antipercolating jet,

primary size No. 70 (.028") drill, Secondary size No. 72 (.025") drill.

Primary economy step .074" diameter. Middle step tapers to .050" diameter.

Power step, .044" diameter. Secondary, none.

Primary size .098"; secondary size .070" diameter.

Discharge jet (Twin) primary side only, size No. 72 (.025") drill.

Intake ball check seat, size .115" to .120" diameter. Discharge

needle seat, size .070" diameter.

CHOKE:

VACUUM SPARK PORT:

Carter Climatic ® Control set on index. Choke heat suction hole in piston

housing, No. 43 drill.

Horizontal slot .130" x .040". Top of port .040" to .046" above top edge of

tightly closed throttle valve.

Page 24

22

A 10-1/2” clutch plate assembly is used with standard or overdrive transmissions. Refer to the 1955 Techncial

CLUTCH SPRING SPECIFICATIONS

CLUTCH

Service Manual for service procedures.

Stamdard

Number of

Springs (12)

6

6

Heavy

Number of

Springs (12)

3

9

Pressure

148 ± 5 Lbs.

167 ± 5 Lbs.

Pressure

182 ± 5 Lbs.

167 ± 5 Lbs.

Compressed

Length

1-23/32"

1-23/32"

Compressed

Length

1-23/32"

1-23/32"

Identification

No Paint

Light Green

Identification

Dark Blue

Light Green

Location

Adjacent to Clutch Release

Levers

Two Springs Centrally

Located Between

Clutch Release

Levers

Location

In a Clockwise

Direction the

Springs Should

Be in the #3

Position from

Each Clutch

Release Lever

Three Springs

Located Between

Clutch Release

Levers

CLUTCH LEVER ADJUSTMENT

Clutch levers are adjusted to 1/8" below the hub of gauge

plate J-1507 or J-5490.

CLUTCH PEDAL LINKAGE

ADJUSTMENT

Adjustment for free pedal play is made by varying the

length of the beam to the throwout lever rod. Lengthening

this rod reduces the free pedal play. Shortening the rod

increases the pedal play. In order to provide sufficient free

movement of the clutch throwout bearing when the clutch

is engaged and the clutch pedal fully released, free pedal

play should be 1/2" to 3/4" at all times.

The clutch pedal to beam rod adjustment (adjusted in

production)is made to provide proper leverage. The outer

end of the lever projects 5A6" from the beam, toward the

rear, with the clutch pedal against the floor board. The

pedal to beam rod should never be disturbed in service.

LUBRICATION

To lubricate the linkage, disconnect the throwout lever

spring and apply lubriplate to the ends of the pedal rod and

lever rod. The clutch beam lever pivot pin is pressure

lubricated; the lubricating fitting is located at the bottom

of the pin. Lubricate at 1,000 mile intervals.

Page 25

TRANSMISSION—OVERDRIVE

\TABLE OF CONTENTS

23

SUBJECT

Operation of Overdrive

Electrical Circuits

Diagnosing Overdrive Troubles

Transmission Removal

Disassembly

PAGE

24

24

25

26

26

SUBJECT

Inspecting Overdrive Parts

Inspecting Transmission Parts

Reassembly

Lubrication

PAGE

29

32

33

36

Figure 1—Standard Transmission

The standard transmission is supplied with or without

the overdrive unit as optional equipment).

The standard transmission without overdrive utilizes

a overdrive adapter housing, case, and torque tube

Figure 1—Standard Transmission

and oil seal adapter for attachment to the torque tube. The transmission main shaft on the standard transmission is longer to compensate

for the overdrive main shaft and overdrive operating parts which are

not installed.

Figure 1—Overdrive Transmission

Page 26

24 TRANSMISSION —OVERDRIVE

Due to the similarity between the two units, service

procedures will only be outlined on overdrive equipped

units.

OPERATION OF OVERDRIVE

The overdrive unit, when in operation above the governor

cut-in speed, automatically reduces the engine to rear axle

ratio approximately 30%.

When overdrive operation is desired, the control button

is pushed to the forward position. The car speed is then

increased to a point higher than the cut- in speed, which is

determined by the point setting of the overdrive governor.

As the governor points close, at approximately 26 miles

per hour, the solenoid is energized. This allows the locking

pawl to engage the sun gear hub and balk ring assembly

when the accelerator is momentarily released. When the

accelerator is again depressed the overdrive is in operation. As this takes place, free wheeling becomes inoperative, since free wheeling is possible only below the cut-in

speed determined by the overdrive governor.

To lock out the overdrive the control button must be

pulled all the way out. This can be done either when the

car is in motion or when it is parked. Locking. out the

overdrive while the car is in motion can he done while the

car is in the free wheeling stage.

The accelerator is depressed slightly so that the engine

is driving the car. The control button can then be pulled out

without depressing the clutch. While still applying pressure to the control button, the accelerator should be momentarily released to complete the shift.

An alternate method permits pulling the control button

back into conventional position during the time the accelerator pedal is fully depressed in the overtake position.

Solenoid Circuit

The solenoid circuit starts at the positive terminal of the

battery and continues to the "B" terminal of the voltage

regulator. At this point, it continues to the "Battery" termi-

nal on the overdrive relay, through a 30 ampere fuse, and

to the relay contacts. The circuit is resumed at the

"Solenoid" terminal of the overdrive relay and continues

to the No. "4" terminal of the solenoid and closed contacts

to ground.

Kickdown Circuit

The kickdown circuit starts from the (—) or distributor

side of the ignition coil. It continues to the applied side of

the kickdown switch and resumes at the opposite terminal

on to the No. "6" terminal of the solenoid.

FIGURE 3—Schematic Drawing Overdrive

Electrical Circuits

THE ELECTRICAL CIRCUITS

The electrical system consists of the three following circuits:

Governor Circuit—Light Line

Solenoid Circuit-Heavy Line

Kickdown Circuit—Dotted Line

The governor, solenoid, and kickdown circuits are basically outlined in Figure 3.

Governor Circuit

The governor circuit starts from the armature terminal of

the voltage regulator. It continues to terminal No. "2"

(Ignition) on the overdrive relay. The current passes

through the relay coil which magnetically controls the

contact points of the solenoid circuit. It continues through

terminal "C" (KD) of the relay through the normally

closed contacts of the kickdown switch on to the governor

terminal and its open contact points.

The Circuits in Action

When the car attains a speed of approximately 26 miles per

hour, the centrifugal action of the weights in the governor

closes the contact points, thus completing the circuit from

the ignition switch to the ground.

The relay coil, being energized, closes the relay contacts of the solenoid circuit now being completed and

immediately energizes the actuating and holding coils of

the solenoid moving the pawl into the balk ring and lock

plate.

As soon as the solenoid plunger has been permitted to

enter the lock plate, the pull-in winding contacts in the

solenoid actuating circuit are opened, permitting a decreased flow of .current through the holding coil to retain

the plunger in position during the time when the overdrive

is in operation.

The inward movement of the solenoid plunger, in addition to operating the pull-in winding contacts in the solenoid actuating circuit. also closes the ground-out contacts

Page 27

TRANSMISSION —OVERDRIVE

25

in the kickdown circuit through the release of the spring

lever on the outer end of the solenoid. The circuits are now

in normal condition for continuing the overdrive operation.

In order to understand the overdrive control system, the

first thing to remember is that any time there is an open

switch in a circuit, that entire circuit is open and inactive.

When all three switches in the governor circuit are

closed. the relay coil is energized, closing the relay points.

This completes the solenoid circuit and energizes the

solenoid, which through the locking pawl, locks the sun

gear and places the overdrive in cruising gear. Also, any

time any one of the three governor circuit switches is open,

the relay coil is de-energized, the points open, and the

solenoid circuit is broken.

At Speeds Below 26 Miles Per Hour

With the cruising gear control forward at speeds below 26

miles per hour, every switch in the governor circuit is

closed except the governor switch. But this one open

switch is enough to keep the entire governor circuit and the

solenoid circuit open, and the solenoid remains de- energized.

At Speeds Above 26 Miles Per Hour

should always check the control system before disassembling the overdrive.

If the trouble is not found after a thorough inspection of

the control system, then the transmission and overdrive

should be removed for examination.

Unsatisfactory Overdrive Operation. Look for:

Burnt relay fuse in solenoid circuit.

Loose terminals on any of the connecting wires. Incorrect terminal locations of connecting wires. Circuits

grounded by water, dirt, or deformation. Defective

solenoid points.

Dirty or sticking relay contacts.

Insufficient travel or unsatisfactory contacts in the

kickdown switch. (Adjust or replace.)

Excessive end play in the governor shaft. Improper

adjustment of governor control springs. Burnt contact

points in governor.

Damage to cap and contacts.

Absence of rubber cover to exclude water and dirt.

Insufficient travel of shift rod. (Adjust control cable to

operating lever.)

CHECKING INOPERATIVE OVERDRIVE

Mechanical Checks

As the speed of car passes 26 miles per hour, the governor

points automatically close. This completes the governor

circuit, energizes the relay, and closes the relay points,

thus energizing the solenoid.

Then, with the momentary release of the accelerator

pedal, engine torque is released just long enough for the

solenoid pawl to move off the step of the balk ring and

engage the notch of the lock plate locking the sun gear.

This places the car in cruising gear.

Kickdown Operation

With the car in cruising gear at speeds above 26 miles per

hour, depressing the foot accelerator all the way to the

floor places the overdrive in overtake position.

The accelerator pedal now in the wide open position

breaks the governor circuit and completes the kickdown

circuit. The break in the governor circuit de- energizes the

solenoid. The closing of the kickdown circuit momentarily

"shorts out" the distributor (for approximately two crankshaft revolutions) releasing engine torque just long enough

for the solenoid pawl to disengage. The instant the solenoid disengages, the solenoid ground-out points automatically open, restoring the distributor circuit. The car then

remains in direct gear as long as the engine is kept under a

pulling load.

DIAGNOSING OVERDRIVE TROUBLES

Since overdrive troubles may originate not only in the

mechanical operation of the unit but also in the electrical

circuit which controls that unit, the service man

Determine if the overdrive control button is pushed forward to the limit of travel.

Check to insure that the overdrive cable is adjusted to

move the overdrive lever firmly against the stop on the

overdrive housing in the engaged position.

Electrical Checks

With the ignition switch on, and the overdrive button

pushed forward, use a test wire or a 12-volt test light as

follows:

Check the 30 ampere fuse in the overdrive relay for live

circuits and clean contacts.

Connect test lead directly from the "B" terminal on the

voltage regulator to the terminal "SOL" on the overdrive

relay mounted on the front of the cowl. This will supply

current to the solenoid which should operate. If it does not,

check for a possible defective connecting wire or connection at the solenoid terminal before condemning the solenoid.

Ground the relay terminal "KD" or "C". If the relay is

functioning properly, the points of the relay will close and

the solenoid will operate.

Ground the overdrive relay terminal on the kickdown

switch. If all circuits are correct to this point, the solenoid

should operate.

With the kickdown switch governor terminal grounded,

push the plunger in. This breaks the circuit and the solenoid should release.

If the solenoid operates in the above tests, all circuits up

to this point are correct and further investigation must be

conducted underneath the car.

Page 28

26 TRANSMISSION —OVERDRIVE

Ground the terminal on the governor. The solenoid should

operate.

Governor Operation Inspection: Suspend the axle and

operate the engine at low speed in high gear. Apply a test

lamp across the governor contact from the live terminal to

the ground strap. The test lamp should light. Now increase

engine speed. The governor cut-in speed will be indicated

when the light goes out.

Summary

By following the above procedure in the proper sequence,

the defective portion of the electrical circuit can be readily

located. If all the preceding items are functioning correctly, the trouble may lie in the solenoid itself, such as burned

points, or the connecting wires may be grounded to the

case.

The kickdown switch should be carefully inspected to

see that none of its four terminals are touching each other.

If the governor circuit is grounded at the kickdown switch,

the grounded circuit will supply current to the relay, operating the solenoid without the possibility of disengagement. This is usually the case when the car will not free

wheel or shift into reverse.

If the kickdown circuit is internally shunting to the governor circuit, the engine will not run upon reaching governor cut-in speed, as the ignition will obtain a shunt ground

through the governor contact points.

A rubber boot has been provided to exclude water and

dirt from the governor. Moisture or an accumulation of

foreign matter may ground the line terminal on the governor and cause the solenoid to operate as soon as the

ignition is turned on.

If the mechanical and operating checks do not reveal the

difficulty, internal trouble should be suspected and the

transmission and overdrive removed for examination.

TRANSMISSION AND OVERDRIVE DISASSEMBLY

Secure the transmission assembly into a stand and completely drain its lubricant.

Removing the Torque Tube and

Rear Oil Seal Adapter

Detach the adapter from the overdrive case by removing

the four attaching cap screws. Note that the rear face of

this adapter has a vent groove located on the bottom side.

Separate the adapter and gasket from the overdrive case;

discard the gasket.

Remove the rear oil seal from the adapter with Tool

J-2626 (Fig. 4).

TRANSMISSION REMOVAL

To remove the transmission, disconnect the hydraulic

brake tube bracket that is fastened to the underside of the

body; then disconnect the torque tube at the rear of the

transmission.

Disconnect the hand brake cable at the bellcrank and the

brake cable housing at the bellcrank bracket. Move the rear

axle to the rear to separate the universal joint from the

overdrive main shaft.

Disconnect the speedometer cable, shifter rods, overdrive control cable, and electrical control wires from the

solenoid and governor.

When removing the transmission from the car, care must

be taken not to damage the transmission clutch shaft.

Always use two guide pins (Tool J-1434) in place of the

two upper attaching cap screws so the transmission clutch

shaft will slide out far enough to clear the clutch pilot

bearing and clutch disc.

FIGURE 4—Removing Rear Oil Seal

Disengaging the Shift Shaft

Drive out the tapered lock pin which retains the overdrive

shift shaft assembly in the overdrive case I Fig. 5 .

After the lock pin has been removed, work the shaft

assembly outward to disengage it from the shift rail. Do

not remove the shaft assembly from the overdrive case

unless the oil seal requires replacement. Pulling the shaft

through the seal may damage the sealing lip.

Removing Governor and Solenoid

With a 1-3/8" open end wrench, remove the governor from

the overdrive case.

Page 29

TRANSMISSION —OVERDRIVE

Remove the four cap screws that hold the overdrive case

to the transmission case. Separate the overdrive case from

the transmission case at the rear of the overdrive bearing

adapter housing (Fig. 7).

FIGURE 7—Removing Overdrive Case

27

FIGURE 5—Drive Out Tapered Lock Pin

Detach the two solenoid attaching screws and turn the

solenoid one-quarter turn clockwise to release the solenoid

plunger from the overdrive locking pawl.

Removing the Overdrive Case

Remove the rear bearing snap ring and spacer washer from

the overdrive main shaft (Fig. 6).

NOTE: On the standard transmission, the rear

bearing is a press fit between the overdrive case

and torque tube and oil seal adapter.

As the overdrive case is being removed, keep tapping the

end of the overdrive main shaft with a plastic hammer.

This will keep the shaft from coming out and will prevent

the free wheeling rollers from dropping out of position.

NOTE: If the transmission does not require com-

plete disassembly, insert a holding bolt through

the adapter and thread it into the transmission

case to retain the transmission main shaft and its

components in position.

The rear bearing which remained in the overdrive

case can now be removed, using a brass drift.

Removing Speedometer and Governor Drive Gears

The speedometer and governor drive gears which remained on the overdrive main shaft are retained by a

Woodruff Key (Fig. 8). Removal only involves sliding

them off the main shaft.

1. Spacer Washer 2. Snap Ring

FIGURE 6—Removing Rear Bearing Snap Ring

and Spacer Washer

1. Governor Gear 3. Speedometer Gear

2. Woodruff Key

FIGURE 8—Removal of Governor and

Speedometer Drive Gears

Page 30

28 TRANSMISSION —OVERDRIVE

NOTE: On a standard transmission, the speedom-

eter drive gear is retained in position by two lock

Removing the Cam and Pinion Cage

rings in addition to the Woodruff Key.

To remove the cam from the transmission main shaft,

The Woodruff Key is a pressed fit into the main shaft. It

remove the cam snap ring with snap ring pliers (Fig. 11).

may be tapped out of position if necessary.

Removing the Main Shaft and Ring Gear

As the main shaft and ring gear is moved to the rear, the

free wheeling rollers will drop out. Keep one hand underneath to catch them (Fig. 9).

FIGURE 11—Removing Cam Snap Ring

The pinion cage at that time can also be removed from

the transmission main shaft.

With snap ring pliers, remove the remaining lock ring on

the transmission main shaft (Fig. 12).

FIGURE 9—Removing Main Shaft and

Ring Gear

To remove the ring gear from the main shaft, remove the

large ring gear snap ring. The gear may then be separated

from the main shaft (Fig. 10).

FIGURE 10—Remove the Snap Ring to Separate

the Ring Gear from the Main Shaft

FIGURE 12—Removing Pinion Cage Lock Ring

Removing the Sun Gear and

Shifter Rail Assembly

Remove the overdrive shifter rail and sun gear and collar

from the main shaft as a unit. When the sun gear is free of

the sun gear hub, the shifter rail assembly can be separated

from the sun gear shifting collar (Fig. 13).

Removing the Cover Plate, Sun Gear Hub and Balk

Ring Assembly, and

Locking Pawl

Using a pair of pliers,- remove the large snap ring that

holds the sun gear cover plate, hub, and overdrive balk

ring in place (Fig. 14).

Remove the cover plate and trough assembly and the sun

gear hub assembly. Then the overdrive locking pawl can

be lifted out (Fig. 15).

Page 31

TRANSMISSION —OVERDRIVE

Removing the Lockout Spring and Control Lever

If necessary, the control lever and shaft assembly may be

removed from the overdrive case. Discard the oil seal; a

new one will be used on reassembly. Remove the retracting spring from the overdrive case.

INSPECTING PARTS

There are no internal adjustments to be made in the overdrive. However, for assurance of good operation, every

part should be inspected carefully to be sure it is in good

condition. If all parts are up to standard and correctly

assembled, the unit will operate properly.

Pinion Cage and Gears

29

FIGURE 13—The Overdrive Shifter Rail

Assembly and the Sun Gear and Collar are

Removed Together

FIGURE 14—Removing Cover Plate Snap Ring

Examine the pinion gears in the planetary pinion cage for

worn, cracked, or chipped teeth. Rotate each gear to see

that it does not bind on the pinion shaft. Then examine the

oil slinger which is a part of the pinion cage. This slinger

supplies lubrication to the pinion gears. H it is bent or

otherwise damaged, it will not operate efficiently.

Sun Gear Hub and Balk Ring

Test the fit and tension of the balk ring on the sun gear hub.

When pressure is applied in a direction that tends to close

the ring, it should bind against the hub so that it will not

turn. When pressure is applied on the end of the ring in a

direction that tends to spread or open the ring, it should

slide around the hub (Fig 16).

A spring scale may be used to measure balk ring tension-3-1/2 to 5-1/2 pounds pull required (Fig. 17).

1. Locking Pawl 3. Cover Plate

2. Sun Gear Hub and Balk

Ring Assembly

FIGURE 15—Removing the Cover Plate Allows

the Sun Gear Hub Assembly and the Locking

Pawl to be Removed

FIGURE 16—Testing Balk Ring Tension. Left:

When You Push One End Toward the Other,

the Ring Should Grab and Hold. Right:

When You Push One End of the Ring

Away from the Other, the Ring Should

Slide Around the Hub

Free Wheeling Rollers, Housing, and Cam

Examine each of the free wheeling rollers and the overdrive main shaft housing in which they turn for wear,

scoring, rough surfaces, or any indications that the rollers

may be slipping in the housing. Inspect the roller cams on

the free wheel hub for wear or grooving (Fig. 18).

Page 32

30 TRANSMISSION —OVERDRIVE

FIGURE 17—Measuring Balk Ring Tension

with Spring Scale-3-1/2# to 5-1/2# Pull

FIGURE 19—When You Twist the Cam Roller

Retainer Counter-clockwise, the Two Springs

Should Snap it Back Quickly

FIGURE 18—Inspection of Overdrive Parts is

Important. The Free Wheeling Rollers Will

Slip if these Parts Are Worn

Test the action of the two cam retaining springs. These

springs are designed to twist the cam in a clockwise direction, thus holding the rollers up on the cam. If this spring

action is slow or retarded, it will result in a loud thump

whenever the free wheeling unit engages on acceleration.

To test it, grasp the cam roller retainer and turn it counterclockwise. Then release it suddenly. If the retainer springs

quickly back in a clockwise direction, the springs are all

right. If the action is sluggish, replace the springs (Fig. 19).

Transmission Cover and Shift Fork Assembly

Interlock Sleeve End Clearance

Place one shift shaft in gear and with the other in the neutral position measure the clearance between the interlock

sleeve and cam of the shift shaft at the in-gear side (Fig.

20).

FIGURE 20—Measuring Interlock Sleeve

End Clearance

To remove the transmission cover and shift fork assembly,

simply remove the nine attaching cap screws and slide the

assembly including the shift forks away from the transmission case. Remove the gasket and discard.

This clearance should be maintained at .002" to .008".

Four different length sleeves are serviced in .005" variations.

Disassembly of the cover and shift fork assembly

Page 33

TRANSMISSION —OVERDRIVE

31

involves removal of the shift levers and forks and tapping

out the shift shafts from the cover. Care should be taken to

prevent, loss of interlock sleeve, balls, spring or pin (Fig.

21).

FIGURE 21—Transmission Cover and

Shift Lock Assembly

Removing Clutch Shaft Bearing

After removing the bearing cap and gasket, remove the

clutch shaft snap ring, spacer washer, and the bearing lock

ring.

The front bearing can be removed from the clutch shaft

by using bearing puller (J-6654) together with a thrust

yoke (J-6652) to prevent damage to the synchronizer

clutch (Fig. 22).

Grasp the main shaft and its components and separate

the main shaft from the clutch shaft (Fig. 23). When

separated, slide the main shaft and its components out the

rear of the transmission case (Fig. 24).

FIGURE 23—Separate Clutch Shaft and Main

Shaft Assembly

1. Bearing Puller (J-6654) 2. Thrust Yoke (J-6652)

FIGURE 22—Use Bearing Puller and Thrust

Yoke to Pull the Front Bearing to Prevent

Damage to the Synchro Clutch

Removing Transmission Main Shaft

With the front bearing removed from the clutch shaft, pull

the shaft as far forward as possible.

NOTE: The clutch shaft cannot be removed

from the front of the transmission case.

FIGURE 24—Removing Main Shaft Assembly

from the Transmission Case

Disassembly of Transmission Main Shaft

Set the main shaft assembly on a bench and remove the

synchro-clutch spacer washer and lock ring. The synchroclutch, second speed, and first and reverse sliding gears

may then be removed from the transmission main shaft

(Fig. 25 ).

FIGURE 25—Transmission Main Shaft

Assembly

Page 34

32 TRANSMISSION —OVERDRIVE

Where the ball bearing in the adapter requires replacement, remove the large snap ring in the bearing adapter.

Tap out the main shaft and bearing from the adapter.

Remove the oil baffle from the adapter. Then remove the

main shaft snap ring and press the bearing from the main

shaft.

Removing the Clutch Shaft

Remove the clutch shaft from the rear of the transmission

case and remove the 14 needle bearings and oil baffle.

Removing Countershaft and Reverse Idler Gears

The countershaft and reverse idler gear shaft are a press

fit into the case. They are also locked into position at the

rear by Woodruff Keys.

To maintain the position of the 80 needle bearings in

the countershaft gear, drive the countershaft out of the

rear of the case using a dummy shaft machined to .870" x

81/B" (Fig. 26).

1. Dummy Shaft 2. Woodruff Key

FIGURE 26—Removing Countershaft

With the countershaft removed, the countershaft gear

will drop to the bottom of the case. The countershaft gear

with needle bearings, spacer, washers, and thrust washers

may then be removed through the rear of the transmission

case as an assembly. If necessary, disassemble for inspection and parts replacement.

With the use of a brass drift, knock out the reverse

idler gear shaft through the rear of case (Fig. 27).

1. Woodruff Key

FIGURE 27—Removing Reverse Idler Gear

Bearings

Bearings must be handled with great care. Wrap them in

a clean cloth or paper until they can be washed.

To wash a bearing, submerge it in a cleaning solution

that is absolutely free of dirt and rotate it to flush away all

oil and dirt. Dry the bearing with care.

Carefully examine each bearing for cracked races,

worn, or scored balls.

Main Shaft

Install the gears onto the main shaft to be sure they slide

on and off easily. The should fit smoothly without excessive play between the splines. If the fit is tight, look for

burred edges on the splines.

Synchro-Clutch and Friction Rings

Carefully inspect the synchro-clutch and friction rings.

Slide the rings on the cones of the second speed gear and

the clutch shaft. Replace rings if there is excessive wear

on the taper.

Transmission Case

CLEANING AND INSPECTING PARTS

With the transmission completely disassembled, all parts

should be carefully cleaned so that they can be thoroughly

examined.

Gears

Wash all gears in a cleaning solution. Inspect for worn or

chipped teeth. Slide each gear onto a new shaft. If it

appears to be loose, it must be replaced.

NOTE: Whenever any transmission gear re-

quires replacement, the gear with which it

meshes should be replaced also.

Examine the surfaces of the bearing recesses in the transmission case for wear or scoring which indicates that the

bearing has been revolving in its housing. Examine the

case for cracks or other defects.

Be certain that all parts of the case are thoroughly clean

before and during assembly.

Clutch Housing.

Examine the housing for cracks or other defects.

Check the rear face of the clutch housing with a dial

indicator. The total run-out should not exceed .005".

The total run-out of the clutch housing bore should not

exceed .003".

Page 35

TRANSMISSION —OVERDRIVE

33

REASSEMBLY

When reassembling the transmission, always use new

gaskets and oil seals.

Reinstalling the Countershaft Gear and

Shaft

To hold the countershaft needle bearings, spacer, and

washers in place while installing the countershaft gear, use

a dummy shaft machined to .870" x 8-1/16" (Fig. 28).

the transmission case, therefore, care must be taken to

prevent damage to the shaft. Install and align the Woodruff

Key prior to driving the shaft flush to the rear face of the

case.

Assembling Main Shaft Assembly

Install the transmission center bearing on the main shaft

using Tool J-2995 (Fig. 29).

1. Needle Bearings 2 . Dummy Shaft

FIGURE 28—Reassembly Countershaft

Gear Needle Bearings

After installing the bearings in the countershaft gear

and holding it in such a manner so as not to drop the

dummy shaft, install the thrust washers. The two small

projections on the face of the bronze rear thrust washer

must index with the grooves in the countershaft gear. The

front bronze thrust washer must index with the transmission case. Position the large thrust washer and install the

assembly in the bottom of the case.

Reinstalling the Reverse Idler Gear

Install the reverse idler gear with the chamfered side of the

teeth to the front of the ease.

Align the gear and install the reverse idler gear shaft

from the rear of the case. The shaft is a press fit into the

case, therefore, care must be taken to prevent damage to

the shaft. Install and align the Woodruff Key into the shaft

prior to driving the shaft flush to the rear face of the case.

Lift and properly align the countershaft gear. Prior to

installing the shaft, check the front and rear thrust washers

for proper alignment. The countershaft is a press fit into

the transmission case,

FIGURE 29—Installing Center Bearing on

Transmission Main Shaft

Install the main shaft snap ring. This snap ring is serviced in four different sizes .087", .090", .093", and .096".

Select the thickest ring which will fit into the retaining

groove. Proper snap ring selection will reduce end play to

a minimum.

Place the oil baffle into the overdrive adapter housing

with concave side facing forward.

Tap the main shaft and center bearing assembly into the

housing.

Install the large snap ring into the retaining groove of

the adapter housing. This snap ring is serviced in five

different sizes, .088", .091", .094", .097", and .100". Select

the thickest ring which will fit into the retaining groove.

Proper snap ring selection will reduce end play to a minimum.

Page 36

34 TRANSMISSION —OVERDRIVE

Install the first and reverse sliding gear on the main shaft

with the shifting collar to the front.

Install the second speed gear on the main shaft with the

tapered cone to the front.

If the synchro-clutch was disassembled, check for

proper assembly. The hub section and the outer ring of the

synchro-clutch assembly are matched and lapped when

fabricated by the manufacturer and are marked accordingly. The etching marks will correspond when properly

assembled (Fig. 30) . This will insure smooth sliding

action when shifting into second and third speeds.

FIGURE 31—Installing Main Shaft Assembly

Check the synchro-clutch friction rings for proper location

and freeness.

REASSEMBLING THE OVERDRIVE

When all parts have been carefully inspected the unit is

ready for reassembly. As each part is assembled, be sure it

is absolutely clean and lubricated with light engine oil.

Always use new gaskets, oil seals and snap rings in reassembly.

FIGURE 30—Transmission Synchro-Clutch

Unit Etching Marks

Install the synchro-clutch including friction rings onto

the main shaft.

Install the lock ring and spacer washer on the main

shaft. Refer to Figure 25 for proper parts sequence.

Installing Clutch Shaft Assembly

Insert the fourteen clutch shaft needle bearings in the rear

of the clutch shaft. A coating of heavy lubricant will retain

them in proper position.

Insert the clutch shaft into the transmission case from

the rear. Position the shaft as shown in Figure 31.

Installing Main Shaft Assembly

Insert the main shaft assembly from the .rear of the transmission case. It will be necessary to tilt the rear portion of

the assembly downward to provide the necessary clearance to allow the synchro-clutch and second speed gear to

pass over the countershaft gear (Fig 31).

When the synchro-clutch just clears the countershaft

gear, place the clutch shaft in a horizontal position and

slide it onto the main shaft. Care must be taken to prevent

mislocation of the clutch shaft roller bearings. At that time,

place the clutch shaft and main shaft assembly in its proper

position in the transmission case.

Reinstalling the Hub and Balk Ring,

Locking Pawl, and Cover Plate

Install the hub and balk ring assembly with the chamfered

side of the ring against the sun gear hub.

Install the locking pawl, positioning the pawl and balk

ring in the "locked-out" position, with the pawl on the step

of the ring for correct installation of the solenoid.

Install the cover plate and trough in position and lock it

in place with the large snap ring.

This snap ring is serviced in three different sizes .0625",

.0665", and .0705". Select the thickest ring which will fit

into the retaining groove. Proper selection of the snap ring

will reduce end play to a minimum.

Reinstalling the Sun Gear and Shifter

Rod Assembly

Install the fork of the shifter rod in the sun gear shift collar.

Then hold them together as you slide the sun gear onto the

main (spline) shaft and the shifter rod into the opening in

the bearing adapter (Fig. 13).

Reinstalling the Pinion Cage and Cam

Install the pinion cage lock ring on the main shaft (Fig. 12).

Install the pinion cage assembly on the main shaft being

careful not to distort the oil slinger. The pinion cage

pinions mesh with the sun gear and the cage will butt up

against the lock ring previously installed.

Position the free wheeling cam on the main shaft so that

the counter bore of cam slides over the machined surface

of the pinion cage.

Page 37

TRANSMISSION —OVERDRIVE

35

Install the free wheeling cam snap ring on the main

shaft. This snap ring is serviced in three different sizes

.063", .068", and .073". Select the thickest ring which will

fit into the retaining groove (Fig. 11). Proper selection of

the snap ring will reduce end play to a minimum.

Reinstalling the Ring Gear and Main Shaft

Replace the ring gear on the overdrive main shaft and lock

it in place with a snap ring (Fig. 10).

This ring is serviced in three different sizes .055",

.057", and .059". Select the thickest ring which will fit into

the retaining groove. Proper selection of the snap ring will

reduce end play to a minimum.

The Free Wheeling Rollers

Replace the free wheeling rollers in the free wheeling cam

retainer. A rubber band placed around the rollers will help

to keep the rollers from dropping out while the main shaft

and ring gear is being installed (Fig. 32).

NOTE: On a standard transmission, the speed-

ometer drive gear is retained in position by two

lock rings in addition to the Woodruff Key.

Reinstalling the Overdrive Case, Control

Lever, and Shift Shaft Assembly

Install the shift shaft oil seal and retractor spring in the

overdrive case.

Holding the bearing adapter to the transmission case

work the overdrive case onto the overdrive assembly.

Secure the assembly with the four attaching cap screws.

Push the shift shaft into the case so that the operating

cam will engage with the slot in the shift rod. Then install

the lock pin to hold the shaft in position.

NOTE: Inspect the operation of the shift lever

as follows: With the lever against the machined

stop on the boss of the case, a slight free movement with no tension should be evident. Excessive movement with no tension indicates that the

shift rod is binding in the case.