Page 1

Page 2

Page 3

FOREWORD

I

This edition of the Mechanical Procedure Manual

will serve as a guide and reference for Hudson servicemen in the proper servicing of Hudson Jet and Super Jet

models.

available from our service tool source, the Kent-.

Moore Organization, Inc., 5-105 General Motors

Building, Detroit 2, Michigan, with whom order

should be placed directly by Distributors and

Dealers.

The data contained in this Manual includes information covering specifications, adjustments and detailed operations involved in maintenance an d repair

procedures. The operations listed herein are predicated

on the use of special service tools developed for the

purpose where necessary and with the work done by

mechanics of average ability.

The Hudson Service Merchandiser is published each month by the Service Department to

keep servicemen supplied with up-to-date information including suggestions and short cuts received from the Field, dealing with the servicing

of Hudson cars. Read this publication regularly

and make full use of the help it affords.

The special service tools illustrated or referred to

in this book are indispensable to good workmanship

and in meeting standard flat rate times. They have been

developed by and are

For easy reference, the Index at the front of the

book is made up of sections in alphabetical order

and with each section alphabetically arranged.

ALPHABETICAL INDEX

Group Page Group Page

BRAKES 136-143 COOLING SYSTEM 53-59

Adjustment-Brakes

Bleeding Brake Lines

Brake Fluid

Brake-Front

Brake Pedal

Brake -Rear

Construction

Lubrication

Master Cylinder

Parking Brake

Specifications

Trouble Shooting

Wheel Cylinder-Front

Wheel Cylinder-Rear

CLUTCH

Assembly-Clutch

Construction

Disassembly-Clutch

Installation-Clutch

Pedal Adjustment

Release Bearing

Removal-Clutch

Flywheel

Operation of Clutch

Release Lever Adjustment

Specifications

142

141

141

140

142

140-141

136

143

136-138

136,142

136

143

139

139-140

72-80

78

72

76-78

80

72

79

76

78

72

78

72

Anti-Freeze Chart

Anti-Freeze Solution

Cooling System Diagnosis

Draining System

Fan Belt Adjustment

Inhibitor

Radiator

Reverse Flushing

Temperature Gauge

Thermostats

Water Pump

Installation

Removal

ELECTRICAL

Battery

Breaker Points

Circuit Breakers and Fuses

Coil

Condenser

Distributor

Breaker Points

Generator

Circuit Resistance Check

Motorizing Draw

Head Lamps

Horn

Spark Plugs

Specifications

53

54

59

53

57

54

59

54

57-58

57

54

56

55

60-71

62

66-67

69

68

67

66-68

66

63-64

64

64

68

69

68

60-61

Page 4

II

ALPHABETICAL INDEX - CONTINUED

Group Page Group Page

ELECTRICAL - Continued

Starter Motor

Voltage Regulator

Wiring Diagram

ENGINE

Camshaft and Bearings

Connecting Rods

Alignment

Bearing Sizes

Installation

Removal

Rod Bushings

Construction

Crankshaft

Installation

Removal

Cylinder Head

Engine Removal

Lubrication

Main Bearings

Oil Check Valve

Oil Pan

Oil Pressure Switch

Oil Pump

Piston Fitting

Piston Pins

Pistons, Pins and Rings

Rear Bearing Oil Seal

Rear Main Bearing

Specifications

Timing Chain and Sprockets

Timing Gear Cover

Timing Gear Cover Oil Seal

Valve Maintenance

Valve System

Valve Tappets

Valve Tappets-Adjustment

Valve Timing

Vibration Dampener

ENGINE TUNE UP

Battery

Carburetor:

Anti-Percolator Adjustment

Fast Idle Adjustment

Float Level Setting

Idle Adjustment

Metering Rod Setting

Pump Travel Adjustment

Unloader Adjustment

Coil Test

Compression

Condenser

Cylinder Balance Test

62-63

65-66

69-70

21-40

39-40

29-32

33-34

33

37

29

31-32

23

34

36

34

27

34

23

36

24

25,27

23

25-27

30

31

29-30

36,39

39

21-22

37

38

38

40

28

29

28

40

38

8-20

11

19

20

18

20

19

19

20

13

9

12

10

ENGINE TUNE UP - Continued

Distributor

Fan Belt Adjustment

Fuel Pump Test

Generator Test

Ignition Timing

Manifold Heat Control

Spark Plugs

Specifications

Starter Motor

Starter Solenoid

Vacuum Test

Valve Tappets

Voltage Regulator

FRONT SUSPENSION

Center Steering Arm

Front Suspension

Installation

Removal

Front Wheel Alignment

Adjustment

Camber

Caster

Pivot Pin Inclination

Toe-In

Lower Support Arm

Lower Support Arm Pivot & Bushing

Riding Height

Specifications

Spindle Pivot Pin

Steering High Point

Steering Spindle Pivot Pin

Upper Support Arm

Upper Support Arm Pivot & Bushing

Tie Rod

Tie Rod Ends

FUEL SYSTEM

Air Cleaner

Carburetor

Accelerating Pump

Anti-Percolator Valve

Anti-Percolator Adjustment

Assembly

Climatic Control (Choke)

Disassembly

Fast Idle

Fast Idle Adjustment

Installation

Metering Rod

Pump Travel

Removal

Specifications

Unloader Adjustment

11-12

15

18

15

13

18

9

8

13-14

14

10

10

16-17

116-124

121

116

118

116

122-123

124

123

124

124

124

116

118

122

116

120

123

116

116

119

122

121

41-52

48

41-48

42

42

44

46

42

45

42

44

47

43

43

45

41

41

Page 5

ALPHABETICAL INDEX - CONTINUED

Group Page Group Page

III

FUEL SYSTEM - Continued

Exhaust and Intake Manifold

Exhaust Pipe

Fuel Level Indicator

Fuel Pump

Gasoline Tank

Gas Tank Gauge Unit

Manifold Heat Control Valve

LUBRICATION

Engine Oil

Engine Oil Circuit

Engine Oil Level

Lubrication

Lubrication Charts

Lubrication Schedules

OVERDRIVE

Overdrive

Assembly

Cleaning and Inspection

Disassembly

Overdrive Housing Installation

Overdrive Main Shaft Oil Seal

Overdrive Shift Rail

Transmission and Overdrive

Assembly

Disassembly

Installation

Removal

52

52

51-52

48-50

52

52

52

1-7

1-3

5-6-7

92-103

92-97

97

96-97

92

98

97

97

98

100

99

103

98

SPRINGS, SHOCK ABSORBERS

AND STABILIZERS

Front Coil Springs

Front Shock Absorbers

Front Stabilizer

Rear Shock Absorber

Rear Springs

Rear Spring Shackle Identification

Riding Height and Spring Sag

4

4

5

4

Shock Absorbers

Specifications

STEERING GEAR

Steering Gear

Adjustment

Assembly

Construction

Disassembly

Installation

Lubrication

Removal

Specifications

Center Steering Arm

Drag Link

Jacket Tube Bearing

Steering Gear Jacket Tube

Steering Wheel

Trouble Diagnosis

TRANSMISSION

132-135

132

134-135

135

134-135

133

134

132

134-135

132

125-131

125

130

128

126

128

129

126

128

126

130

129

127

127

127

131

81-91

PROPELLER SHAFT

Assembly

Construction

Disassembly

Inspection

Installation

Removal

Universal Joints

REAR AXLE

Rear Axle

Assembly

Construction

Disassembly

Inspection

Installation

Removal

Specifications

Differential Assembly

Drive Pinion

Removal

Installation

104-105

105

104

104

104

105

104

105

106-115

106

115

106

109

111

115

109

106

109

109

110

112

Assembly

Construction

Countershaft

Countershaft Gear Cluster

Disassembly

Drive Gear Bearing Retainer

Inspection

Installation

Main Drive Gear

Mainshaft Assembly

Rear Bearing Retainer

Removal

Reverse Idler Gear

Shift Shafts and Interlock

Specifications

Transmission Control (Handy Shift)

WHEELS AND TIRES

Front Wheel Bearing Adjustment

Specifications

Tightening Wheel Hub Bolts

Tire Inflations

Wheel and Tire Balance

Wheel and Tire Run-Out

86

88

89

87

84

88

86

89

88

88

89

83

88

86

83

91

144-145

145

144

145

144

144

145

Page 6

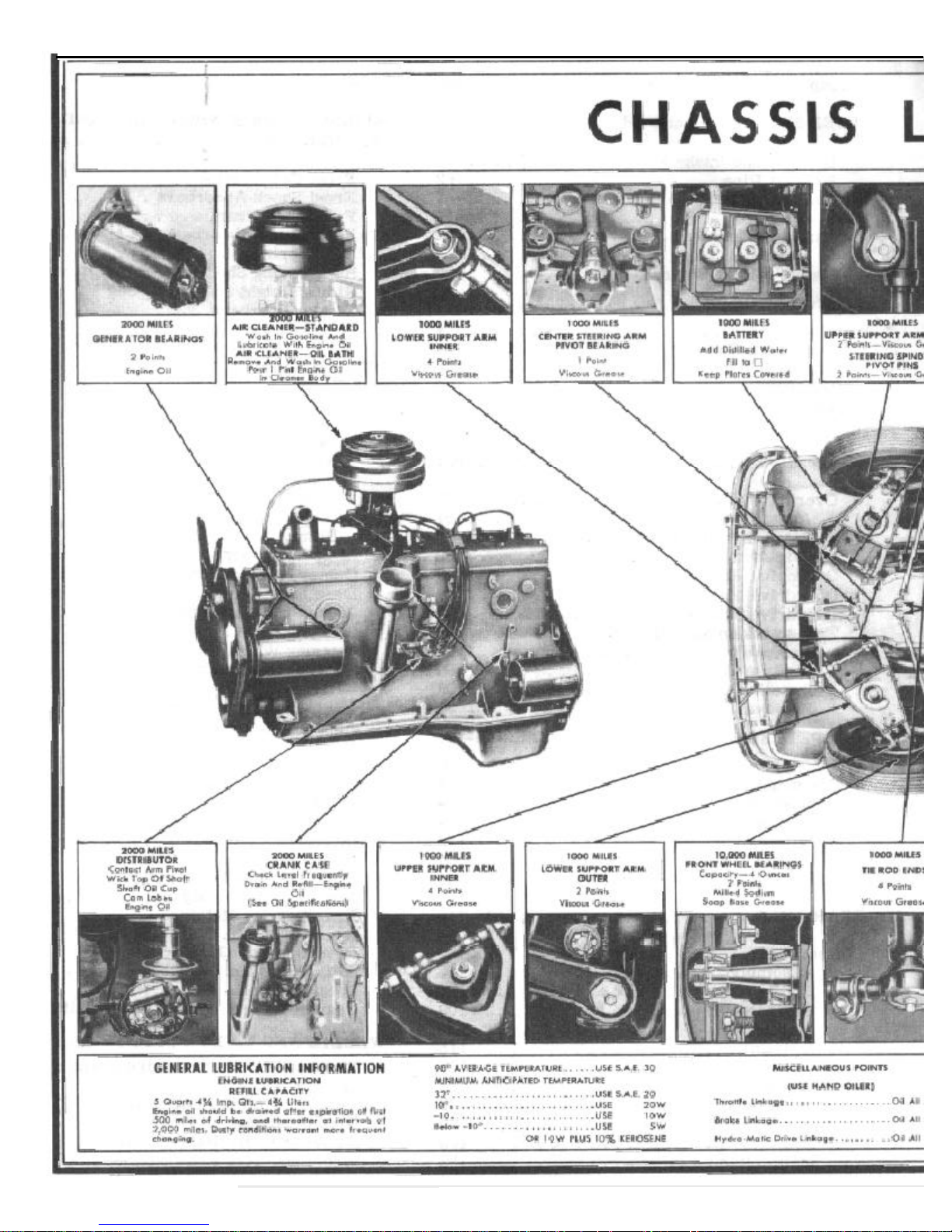

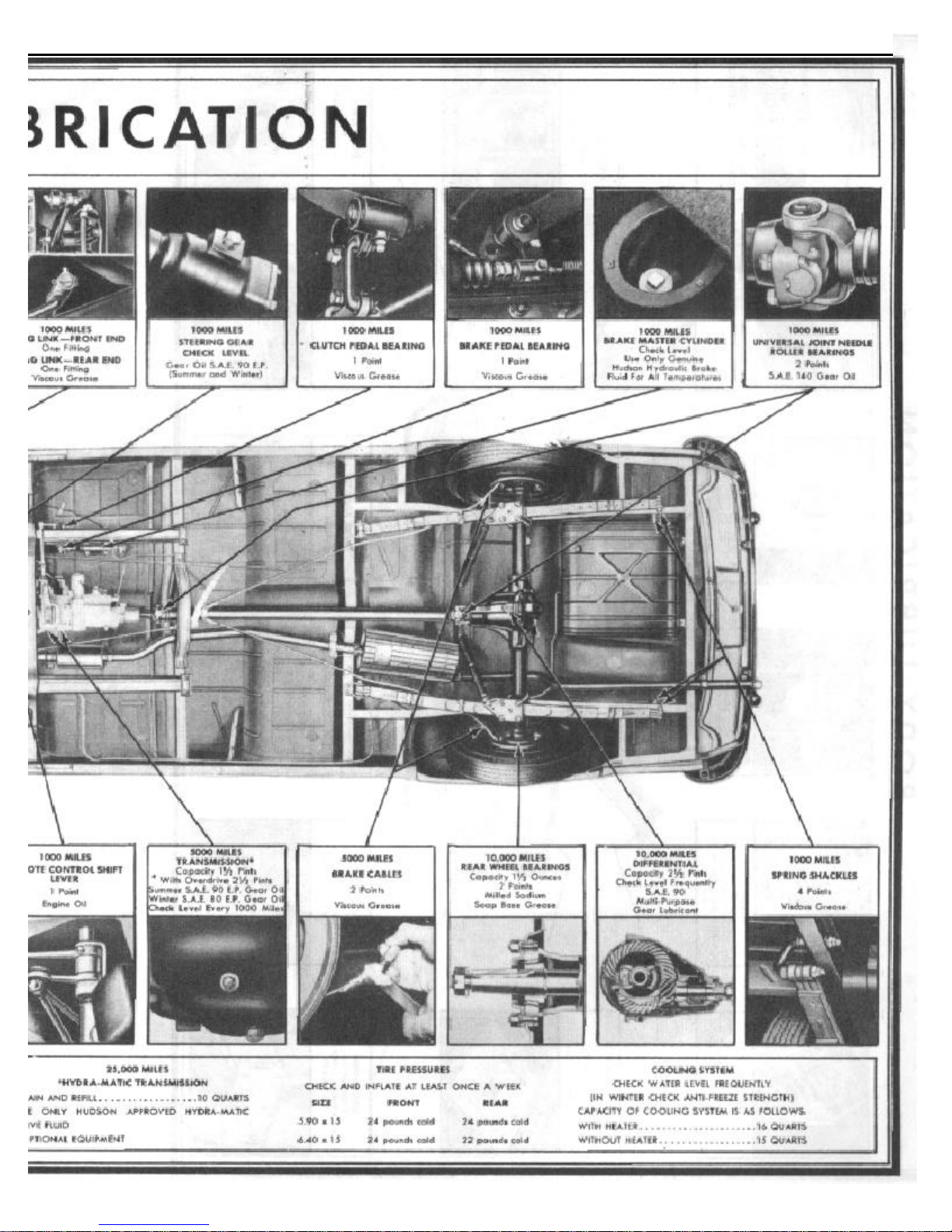

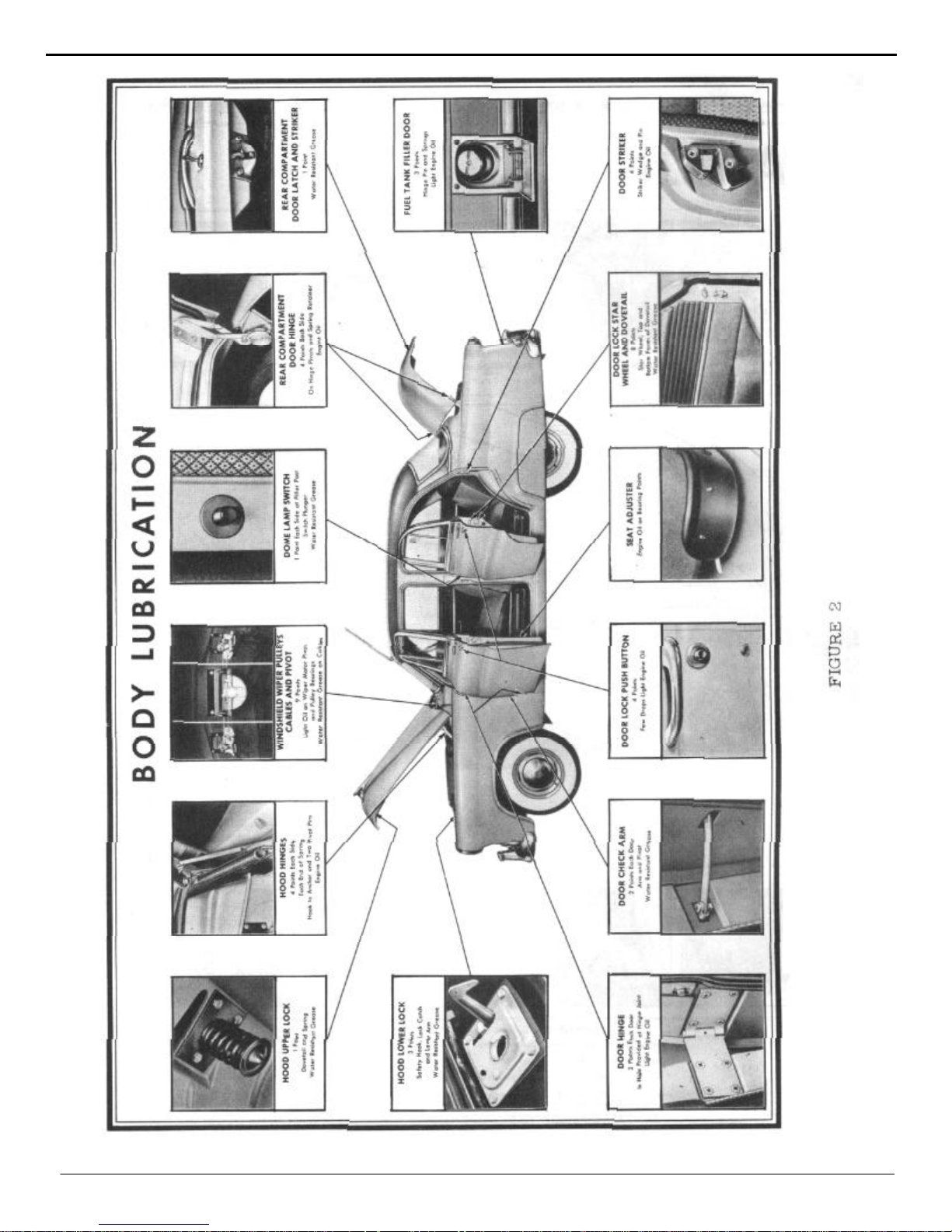

1 LUBRICATION

Page 7

LUBRICATION 2

Page 8

3 LUBRICATION

Page 9

LUBRICATION 4

SECTION

LUBRICATION

Proper lubrication is the life of every piece of

mechanism. This is particularly true of the motor car.

Correct lubrication spells the difference between long

life or rapid and premature wear.

For this reason, a definite plan and schedule for

application is necessary in order to provide the various

bearing surfaces with the right amount of the correct

lubricant at the proper intervals.

It is a well-known fact that one type of lubricant

will not suffice for all applications. The degree of load

carried and operating conditions make necessary the

use of different types of lubricants.

In order to familiarize Hudson mechanics on the

proper lubrications of the engine, chassis and body;

lubricating charts indicating points to be lubricated,

type of lubricant to be used and the frequency of

application are shown in this Manual.

NOTE: Quality lubricants are used in the course of

assembling every new car. These need not be

changed until the recommended mileage period

shown in the Lubricating Schedule.

1

the oil filter passageway and permits full pump flow

direct through the main oil gallery, extending the

full length of the crankcase. This oil gallery is

intersected by drilled leads to all main and camshaft

bearings and the valve tappets.

Through the drilled crankshaft, oil pressure from

the main bearings is distributed to each connecting

rod bearing. An angular hole drilled through the

large end of each connecting rod and upper half of

bearing shell deposits a uniform spray of oil on all

cylinder walls.

Fitted in the front end of main oil gallery is an oil

trough that conducts a small stream of oil to the

timing chain and sprockets.

The oil measuring gauge seats on a tube pressed

in the crankcase at the left rear side. A pressure type

oil signal switch mounted above the oil pump and

connected with the main oil gallery operates the

dash oil signal light which shows red when the oil

pressure drops below approximately 13 pounds

ENGINE OIL

ENGINE OILING CIRCUIT

Pressure lubrication to all engine bearings is maintained by a rotor type oil pump m o u n t e d on the right

side of crankcase and driven by a worm gear on the

camshaft. Oil is drawn by the suction side of the pump

through a pipe connecting with a floating screen fixed

in the oil pan.

The oil pump parts consist of an inner and outer

rotor, a shaft and the body and cover. No adjustment

of the pump is required. Oil pressure is regulated by a

built-in, nonadjustable release valve and spring. These

are accessible for inspection or cleaning through a plug

opening at the left rear side of engine.

When the engine is started, the release valve has

moved to a position that closes the oil passage-way to

Select oils from the well-known brands and of

the proper viscosity to suit your seasonal and driving requirements.

The oil refiners or marketers supplying oils are

responsible for the quality of their product and their

reputation is the car owner's assurance of receiving

high-grade lubricants.

It is most important that the oil should have the

ability to flow at low temperatures to permit easy

starting and at the same time, afford adequate lubrication when the engine is a t normal operating temperatures. The oil selected should be based on its ability to

perform these two functions at the lowest anticipated

temperatures expected before the next oil change period. The following table will be helpful in making this

selection.

Page 10

5 LUBRICATION

FOR USE

90° Average Temperature S.A.E. 30

32° Minimum Temperature S.A.E. 20

10° Minimum Temperature 20W

-10º Minimum Temperature 10W

Below -10° Temperature, 5W. or 10W plus

10% Kerosene

Your Authorized Hudson Dealer, who has had

long experience with the brands of oil available

in your locality, will be glad to help you with

your lubrication problems.

ENGINE OIL LEVEL - The level should be

checked each time you purchase gasoline. The

oil level gauge is located on the left side of the

engine.

WHEN TO CHANGE ENGINE OIL

The oil which is placed in the engine at the

factory should b e drained and replaced after the

first 500 miles of operation.

Thereafter, at intervals of 2,000 miles the

reservoir should be drained and refilled with

new oil of good quality. If the car is operated

constantly in dusty areas or for short distances at

low speeds during cold weather, which permits

foreign matter and sludge to accumulate, it

should be changed more frequently. However,

the actual change period is largely dependent on

the individual driving circumstances.

NOTE: Darkening or discoloration of oil does

not always mean that it is unsatisfactory. But

evidence of dilution or dirt is good indication

that the oil should be changed and the filter

cartridge should be replaced.

CAUTION: The use of flushing oils or compounds is not recommended. However, in the

event they are used, the oil reservoir should

be thoroughly drained before installing new

oil.

FIGURE 3

For normal operation, the oil level is satisfactory when it is within the "Oil Level Range."

For high speed operation, the level should be

maintained near the full mark. (Top line on the

"Oil Level Range.") Figure 3.

To make an accurate check, it is best to wait a

minute or two after shutting off the engine to

permit the oil to drain back into the reservoir

(oil pan). Oil is added through the oil filler

opening by removing the filler cap.

ENGINE OIL CAPACITIES - The total engine

oil capacity is 5-1/2 quarts. When the oil is drained

in the conventional manner, the refilling quantity is

5 quarts.

Approximately two quarts of oil are required

to bring the level from the "Low" to "Full" mark.

BREAK-IN OIL - Should the use of so called

"break- in" oils or special compounds for breaking in new engines be decided upon, make sure

the supplier guarantees that they contain no

harmful ingredients.

LUBRICATION SCHEDULE

The lubricants placed in your car at the time

of assembly are of the best quality and need

not be changed until the recommended change

period shown in the Lubrication Schedule has

been reached.

Page 11

LUBRICATION 6

AT 500 MILES

Drain engine oil reservoir and refill with new oil of good quality. See "Engine Oil" - Page 4.

EVERY 1,000 MILES

VISCOUS CHASSIS LUBRICANT

Points Points

Drag Link

Upper Support Arm Outer

Upper Support Arm Inner

Lower Support Arm Outer

Lower Support Arm Inner

Brake Pedal Bearing

Engine

Door Lock Push Button

Door Hinge

Door Striker Wedge

Fuel Tank Filler Door Hinge and

Spring

Windshield Wiper Cables at Pulleys

Door Lock Star Wheel and Dovetail

..

Rear Compartment Door Latch and

Striker

Door Check Arm

Check Oil Level

WATER RESISTANT LUBRICANT

2

2

4

2

4

1

ENGINE OIL

Points Points

4

8

4

3

Points Points

4

8

1

4

Center Steering Arm Pivot Bearing.

Tie Rod End

Steering Spindle Pivot Pins

Clutch Pedal Bearing

Rear Spring Shackle Bushing

Hood Hinge

Windshield Wiper Pulley

Remote Control Shift Lever

Rear Compartment Door Hinge

Dome Light Switch

Door Striker

Hood Upper Lock

Hood Lower Lock

1

4

2

1

4

8

4

1

8

2

4

1

2

E. P. GEAR LUBRICANT - S.A.E. 80 WINTER, S.A.E. 90 SUMMER

Transmission

Overdrive

Hydra-Matic Drive Transmission Check Level

MULTI-PURPOSE GEAR LUBRICANT - S.A.E. 140

Rear Axle Check Level

Universal Joint Needle Rollers 2 Points

Check Battery Electrolyte Level and Gravity.

Check Coolant Level and Anti-Freeze Strength.

Check Level

Steering Gear Check Level

Check Level

HYDRA-MATIC DRIVE FLUID

GEAR OIL - S.A.E. 140

DISTILLED WATER

WATER OR ANTI-FREEZE

Page 12

7 LUBRICATION

HUDSON HYDRAULIC BRAKE FLUID

Check Brake Master Cylinder Fluid Level

.

EVERY 2,000 MILES

Perform operations included in 1,000 mile lubrication, in addition to the following:

ENGINE OIL

Engine - Drain Oil Reservoir and Refill.

See "Engine Oil," Page 4.

Generator 2 Points

Distributor 4 Points

Air Cleaner - Standard - Wash and Re-oil

Air Cleaner - Oil Bath - Remove, wash and add

new oil.

Oil Filler Pipe Cap - Wash and Re-oil.

Throttle Operating Linkage All Joints

Brake Operating Linkage All Joints

EVERY 5,000 MILES

Perform operations included in 1,000 and 2,000mile lubrications, in addition to the following:

Oil Filter Renew cartridge

E. P. LUBRICANT - S.A.E. 80 WINTER, S. A. E. 90 SUMMER

Transmission Drain and Refill Overdrive Drain and Refill

VISCOUS CHASSIS LUBRICANT

Brake Cables Clean and Lubricate

EVERY 10,000 MILES

Perform operations included in 1,000 mile, 2,000 mile and 5,000 mile lubrications, in addition to the

following:

VISCOUS CHASSIS LUBRICANT

If springs are equipped with metal covers use Viscous Chassis Lubricant using special lubricating

clamp. If springs do not have metal covers, do not lubricate.

MULTI-PURPOSE GEAR LUBRICANT - S.A.E. 90

Rear Axle Drain and Refill

IMPORTANT: When checking the level of the lubricant in the rear axle and transmission, make

sure that the lubricant has stopped foaming. If the car has been run for a considerable length of

time, it should be permitted to stand long enough to allow the oil to reach the true level before

checking.

Hydra-Matic Oil Level Indicator Clean

SODIUM SOAP BASE LUBRICANT

Front Wheel Bearings Remove, Clean and Repack

Rear Wheel Bearings Remove, Clean and Repack

VERY 25,000 MILES

HYDRA-MATIC DRIVE FLUID

Hydra-Matic Drive Transmission Drain and Refill

Page 13

ENGINE TUNE-UP 8

SECTION 2

ENGINE TUNE-UP

SPECIFICATIONS

Cylinder Compression

Vacuum, Intake Manifold

Valve Tappet Clearance (Hot)

Battery Specific Gravity

Starting Motor

Cranking Voltage

Cranking Amperage

Stall Test:

Volts

Amperes

Torque

Coil Amperage Draw:

Engine Stopped

Engine Idling

Distributor:

Point Gap

Cam Angle - (Dwell)

Spring Tension

Condenser Capacity

Advance: Automatic

0° at 300 R.P.M.

1° at 350 R.P.M.

4.5° at 500 R.P.M.

12° at 1325 R.P.M.

13.5° at 1500 R.P.M.

Minimum 100 lbs.

17-20" Hq.

Intake .010" - Exhaust .012"

1.270

5 0 Volts

Approximately 160 Amps

2 0 Volts

Maximum Amps 280

Min. Ft. Lbs. 4.4

5.0 Amps

1 5 - 2.0 Amps

.020"

39º

17 to 20 oz.

21-25 Mfd.

Vacuum

0° at 5-1/4"

1° at 5-3/4"

4° at 7-1/2"

6° at 8-3/4"

7.5° at 9-1/2"

Generator Output:

Cold - at 870 to 970 R.P.M

Cold - at 1925 to 2125 R.P.M.

Hot - at 950 to 1050 R.P.M

Hot - at 2350 to 2550 R.P.M.

Voltage Regulator:

Contact Point Gap

Contact Close

Contact Open (After 15 Amp Charge)

Voltage Regulator Operates

Spark Plug Gap

Fuel Pump (Carter)

Pressure

Volume

Carburetor

Float Setting

Pump Travel

Idle Adjustment

Climatic Control

6 4 Volts 0 Amps

8.0 Volts 45.0 Amps

6.4 Volts 0 Amps

8.0 Volts 45.0 Amps

Minimum .015"

6.3 to 6.8 Volts

4.1 to 4.8 Volts

7.25 Volts 22 Amps at 100° F.

.032"

4 lbs. min. - 5 lbs. max. @ 1800 R.P.M.

1 quart 60 seconds 500 R.P.M.

Carter - Model WAI-2009S

1/2"

16/64"

1/2 to 1-1/2 turns open

Set one point lean

Page 14

9 ENGINE TUNE-UP

ENGINE TUNE-UP

Engine tune-up is important in maintaining

engine performance, fuel economy, dependability, and complete owner satisfaction. Modern high

speed engines demand accurate diagnosis and

adjustments. It is recommended that the engine be

tuned every 5,000 miles.

The tune-up procedure that follows is arranged in the usual order of performance, which

is generally: compression, ignition, carburetion.

Various manufacturers of testing equipment have

set up specific procedures for their units which

may be followed.

Many of the tests involved in the tune-up are

dependent upon a battery in good condition. If the

battery is below standard it should be recharged,

or replaced with a fully charged battery before the

tune-up.

ENGINE

COMPRESSION

An engine that fails to develop proper compression cannot be tuned. Compression should be

checked with the engine at operating temperature

with a reliable compression gauge. Test is made

with ignition switch off and all plugs removed.

valve. If two adjacent cylinders show low compression readings, check for a leaking cylinder

head gasket or loose cylinder head.

To differentiate between ring and valve leak,

place a small quantity of oil on top of each piston

and re-test. Oil will temporarily seal a ring leak

and result in near normal compression. Little or no

improvement will be noted if valve is leaking.

Correct any unsatisfactory condition found

during the compression test before continuing with

the tune-up.

SPARK PLUGS

Upon satisfactory completion of the compression

test, inspect, clean and adjust spark plugs.

1. Spark plugs with burned, blistered or cracked

porcelains, o r with pitted o r burned electrodes,

should be replaced with new plugs of the same

type. For cast iron and aluminum cylinder

heads, use Champion H-8 spark plugs. See

"Electrical Section".

2. Adjust spark plug gaps to .032" using a bending

tool and wire loop gauge.

1. Loosen spark plugs to break free any accumulated

carbon.

2. Use an air hose and blow out all dirt and carbon

from spark plug cavities before removing

plugs.

3. Remove all plugs.

4. Insert compression gauge in each spark plug

hole in turn and crack engine with starter at least

4 compression strokes.

NOTE : Check reading on first and final stroke.

5. Compression at each cylinder should be at least

100 pounds and should not vary more than 10

pounds.

NOTE: If compression gauge moves up in

jerky steps of 10 or 20 pounds at a time, it

generally indicates a sticking or leaking

valve.

3. Install new gaskets on the plugs and replace

plugs in cylinder head. Tighten to 25 to 30

pounds with a torque wrench.

4. Examine spark plug wires for loose terminals,

cracked or broken insulation. Replace defective

wires.

Page 15

ENGINE TUNE-UP 10

VACUUM TEST

An engine in good :condition - will show a

steady, or slight fluctuating , high vacuum

reading from 18" to 21". Vacuum readings

are affected by altitude. Over 2000 feet the

vacuum gauge will show about one inch lower

for each 1000 feet of elevation.

1. Remove wiper hose at intake manifold and

connect vacuum gauge hose. (If the engine

has a combination fuel and vacuum

pump,disconnect the booster pump line at intake

manifold.)

2. Check carburetor and intake manifold nuts

for tightness.

3. Connect one lead of tachometer to the distributor

primary terminal and the other lead to engine for

ground. Adjust carburetor to obtain a smooth idle

at 540 to 580 R.P.M. If car is equipped with

Hydra-Matic Transmission, set idle speed at 490-

510. Vacuum readings at sea level may be interpreted generally as follows:

TAPPET ADJUSTMENT

1. Raise front of car, place stand jack under

frame cross member and remove right front

wheel.

2. Remove bolts on the fender side dust shield

and attaching parts and take out shield from

under the fender.

3. Remove front and rear tappet covers and

breather pipe . Take out the rear tappet cover

by sliding cover forward and out.

4. Adjust tappets and re-install parts.

CYLINDER BALANCE TEST

The Cylinder Balance Tester compares the eveness of the power output of each cylinder in the

engine.

1. Connect the vacuum gauge in Figure 2 and

set the throttle until engine is running at

1500 R.P.M.

18 - 21" Steady or with slight fluctuation: En gine in good condition.

15" Steady: Incorrect ignition timing.

10" Steady: Incorrect valve timing, or

burned valves.

15 - 21" Fluctuating: Sticking valves or com pression leak.

12 - 16" Drifting: Carburetor too rich or too

lean

.

Any number of engine conditions may

cause the same action of the vacuum gauge.

The exact cause must be established by process

of elimination.

VALVE TAPPETS

Check the valve tappets clearance when

the engine is at normal operating temperature.

Correct valve clearances are .010" for

intake valves, .012" for exhaust valves.

FIGURE 2

2. Ground the master clip of the cylinder balance

tester and connect individual leads to the spark

plugs 2-3-4 and 5. Engine will now run on 1 and 6.

3. Note the reading on the vacuum gauge. Make

the same test on each pair of cylinders in the

following sequence. 6 Cylinders 1-6, 2-5, 3-4.

Page 16

11 ENGINE TUNE-UP

NOTE: A variation of more than 1 inch of

vacuum or 40 R.P.M. between pairs of cylinders being tested indicates either a defective

plug or unequal compression in a cylinder.

To isolate one weak cylinder, short out half the

cylinders. The half giving the lower reading will

include the weak cylinder.

Air bubbles prevalent in the radiator filler neck

(radiator filled with coolant to th e overflow pipe)

indicates a leaking cylinder head gasket, cylinder

head or internal cracks in the water jackets.

An extreme blow-by at the oil filler pipe indicates defective piston rings. (Compression pressure by-passing the piston rings.)

BATTERY SPECIFIC GRAVITY

Check the battery specific gravity with a hydrometer. A battery when fully charged should

read 1.270 specific gravity at 70° F. A uniform

hydrometer reading below 1.225 at 70° F. indicates a low battery that should be recharged.

it will crank the engine for 1/2 minute and the

voltage does not drop below 4-1/2 volts. Slow

cranking speed or lower voltage may be due to

high resistance in the starter circuit. Check cables

and retest. (DO NOT crank for more than 1/2

minute at a time.)

A standard cell tester may be used to make the

load test. The cell tester has a shunt across the

terminals which places each cell under load. Each

cell should show 1-1/2 volts or over, and the variation between cells should not exceed .15 volts.

If a Starter-Battery Tester is not available, a

voltmeter can be connected across the battery terminals while cranking t he engine with the starting

motor. The battery is in good condition if the

starter cranks the engine at a good speed for 1/2

minute and the voltage does not fall below 4-1/2

volts. DO NOT crank for more than 30 seconds

without allowing starter motor to cool.

NOTE: A slow cranking speed or voltage lower

than 4-1/2 volts indicates a weak cell or high

resistance in the connections to the starter.

Check battery cables and connections and repeat the "Load Test".

FIGURE 3

BATTERY LOAD TEST

Battery may be tested under load by connecting a voltmeter across the terminals and cranking

the engine. Battery is satisfactory if

DISTRIBUTOR

1. Remove wires from cap anu inspect cap and

rotor for cracks and burned or corroded contacts.

Replace defective parts.

2. Clean spark plug cable sockets with tool No.

KMO-230.

CONTACT POINTS

1. Inspect distributor contact points f o r alignment,

corrosion, burning o r pitting and clean with

carbon tetracholoride.

2. Replace burned or corroded points. If points are

badly pitted, check condenser for over or under

capacity.

3. With a feeler gauge set the points for the proper

gap. Correct gap is .020".

NOTE: Contact points adjustment is made by

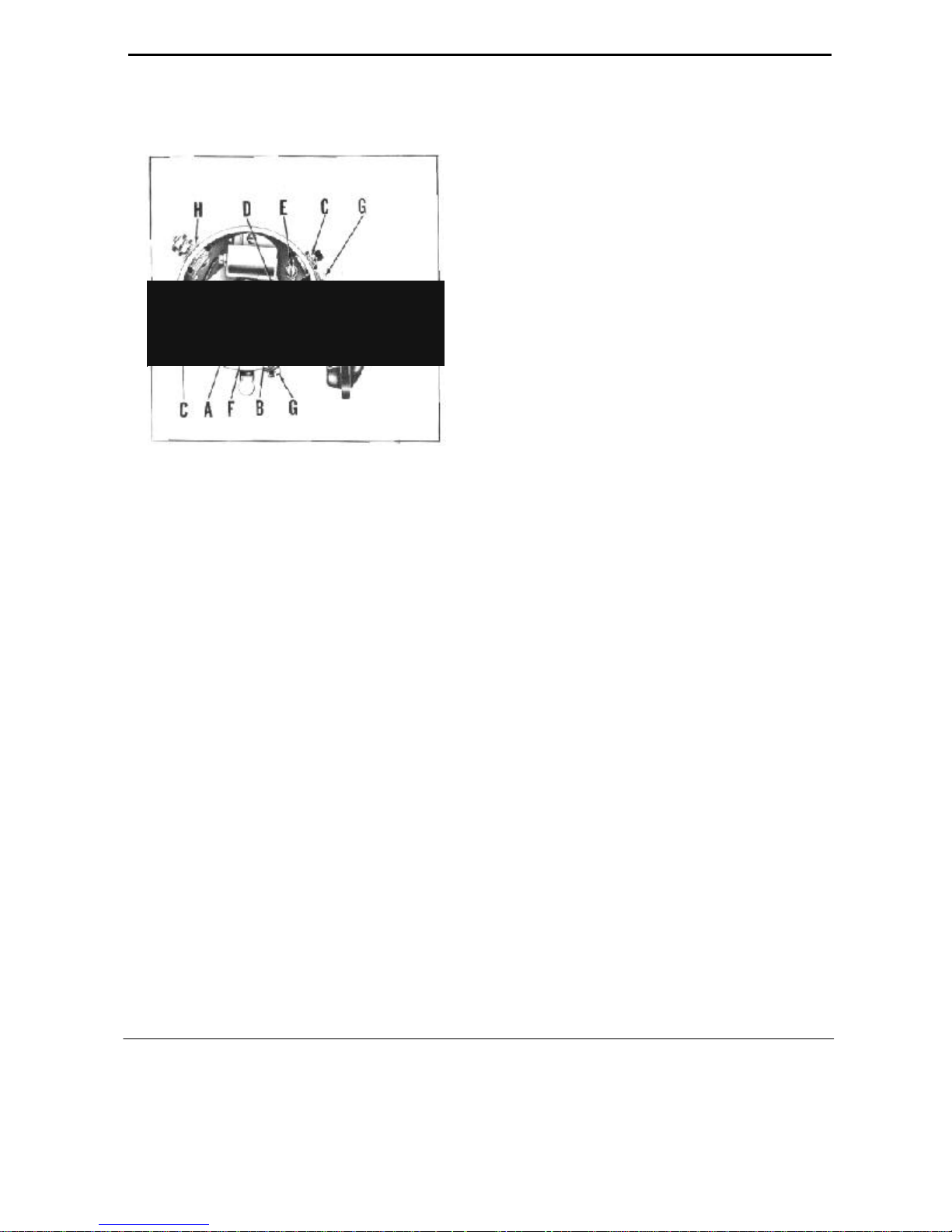

loosening the clamp screw (B) Figure 4, holding

Page 17

ENGINE TUNE-UP 12

the stationary contact plate, then turning

eccentric adjusting screw (D) to move the

contact point. Tighten clamp screw when

correct gap is secured.

FIGURE 4

4. Bend stationary contact point if necessary

to secure correct alignment.

BREAKER ARM SPRING TENSION

1. Hook a spring scale to the breaker arm at the

contact and pull at right angles to the contact

surfaces. Tension should be 17 to 20 ounces

just as the points open.

2. Adjust spring tension by loosening screw

attaching breaker arm spring to plate and

move end of spring in or out of clip as

necessary.

CONDENSER

1. Inspect condenser lead to see that it is not

frayed or broken and is connected securely to

breaker arm clip. Condenser mounting screw

must make tight ground to breaker plate.

Ground wire from breaker plate to subplate

must be securely connected.

DISTRIBUTOR DWELL TEST

Check distributor cam angle or dwell on a distributor tester to determine the cam angle or degrees of

dwell of the distributor point. This should be 39 degrees with distributor contact point set at .020".

If the dwell angle is too great, the contact point gap

is set too close. If the dwell angle is too small, the

contact gap is too wide. An erratic reading of the

Dwell Meter will indicate faulty contact, a faulty

breaker plate, a worn distributor shaft and bearings. A

change of dwell angle when accelerating or deaccelerating, the engine will indicate a faulty breaker plate,

bearing or support plate.

VACUUM ADVANCE ADJUSTMENT

Vacuum should be checked on a distributor tester

that has a controlled source of vacuum and a vacuum

gauge

.

If the vacuum advance range does n ot conform

with specifications, it may be varied by inserting or

removing washers under the sp r in g in the vacuum

chamber. Carefully check for leaky diaphragm and

sticking linkage.

AUTOMATIC ADVANCE

Place distributor on tester and check the advance

curve R.P.M.'s against the degree of advance.

If the degree of advance is more than specifications

call for at the same R.P.M., it indicates that the governor spring tension is too weak and the advance is too

rapid.

If the degree of advance is less than specifications,

call for at the same R.P.M., the spring tension is too

stiff and the advance is too slow.

In most cases, the tension of the spring may be

increased or decreased by bending the brackets on the

weight plates to which the springs are attached, in

order to make the springs conform to specifications.

Check the advance both up and down the speed

range so that the sluggish action of the governor will

be indicated and may be corrected by cleaning and

lubrication.

Check condenser with suitable equipment and

if capacity is not within range of .20 to .25 MFD,

replace with new part.

NOTE: Every 2,000 miles, lubricate contact arm

pivot, wick top of shaft, cam lobes and 3 to 5 drops

of medium engine oil at oiler.

Page 18

13 ENGINE TUNE-UP

COIL

If a faulty coil is ,suspected, the coil should be

tested with a test light or approved coil testing

equipment.

A quick test with the coil on the car can b e

made by removing the high-tension wire from the

center of distributor cap and hold end of wire 1/4"

from cylinder head and while cranking engine, if

a spark occurs regularly the coil can be considered satisfactory.

IGNITION TIMING

1. Place a chalk mark on the long line before No.

1-U.D.C. on the vibration dampener, Figure 5.

1 piston starts up on compression stroke. Continue

cranking until long line on dampener lines up with

pointer. Loosen distributor quadrant screw and

rotate distributor clockwise to the limit of the slot

in the quadrant. Remove secondary wire from

center of distributor cap and hold bare end of wire

about 1/8" from the cylinder head. With ignition

switch on, slowly rotate the distributor counterclockwise just until a spark jumps from the wire to

the cylinder head; then tighten quadrant screw.

Spark setting may be advanced with fuels of

high octane rating.

Correct ignition timing is indicated by a slight

"ping" at about 15 M.P.H. when accelerating at full

throttle from 10 M.P.H. in high gear. If no "ping"

is heard, timing should be advanced one quadrant

graduation mark at a time until the "ping" is heard.

CRANKING VOLTAGE

1. Connect the negative voltmeter lead to the

starter switch terminal (where the battery to

starter cable is connected), Figure 6.

FIGURE 5

2. Connect one lead of the power timing light to

No. 1 spark plug and the other lead to the

negative terminal of the battery.

3. With the engine idling properly, the timing

light flash should occur when the chalk mark

is in line with the pointer on the timing chain

cover.

If timing is off, make the necessary correction

by loosening the distributor advance arm screw

(on octane selector) and rotate distributor clockwise for retard and counterclockwise for advance.

4. Increase engine speed. The vacuum advance

should be at full retard position but should

advance readily when the engine speed is in

creased.

To set the timing without a timing light, remove No. 1 spark plug and crank engine until No.

FIGURE 6

2. Connect the positive voltmeter lead to engine

for a ground.

3. With the ignition key off, engage the starter

motor and note the reading on the voltmeter.

The cranking voltage should read 5 volts or

more.

CAUTION: Crank engine intermittently (not

more than 30 seconds) to prevent starter motor

from overheating.

Page 19

volts, check the battery and engine ground cables,

starter cable and the starter solenoid to determine

the low reading.

BATTERY AND ENGINE GROUND STRAPS

1. Connect the voltmeter positive lead to the

battery ground terminal, Figure 7.

FIGURE 7

2. Connect the voltmeter negative lead to engine

ground and a jumper to the frame.

3. With ignition off, crank engine and make volt

meter reading, (should not be more than .2).

4. If more than .2, check ground strap connections

from battery to engine. Replace defective ground

straps.

ENGINE TUNE-UP 14

FIGURE 8

AMPERAGE DRAW TEST

1. Turn battery starter test know to "off" position

and the voltmeter "selector switch" to the 15

volt position and connect test leads, Figure 9.

STARTER CABLE

1. Connect the positive voltmeter lead to the

"BAT" terminal of the starter and the negative

lead to negative battery post.

2. Crank engine again (ignition off). If the

voltmeter reading is more than .2, check

for loose connections or frayed cables.

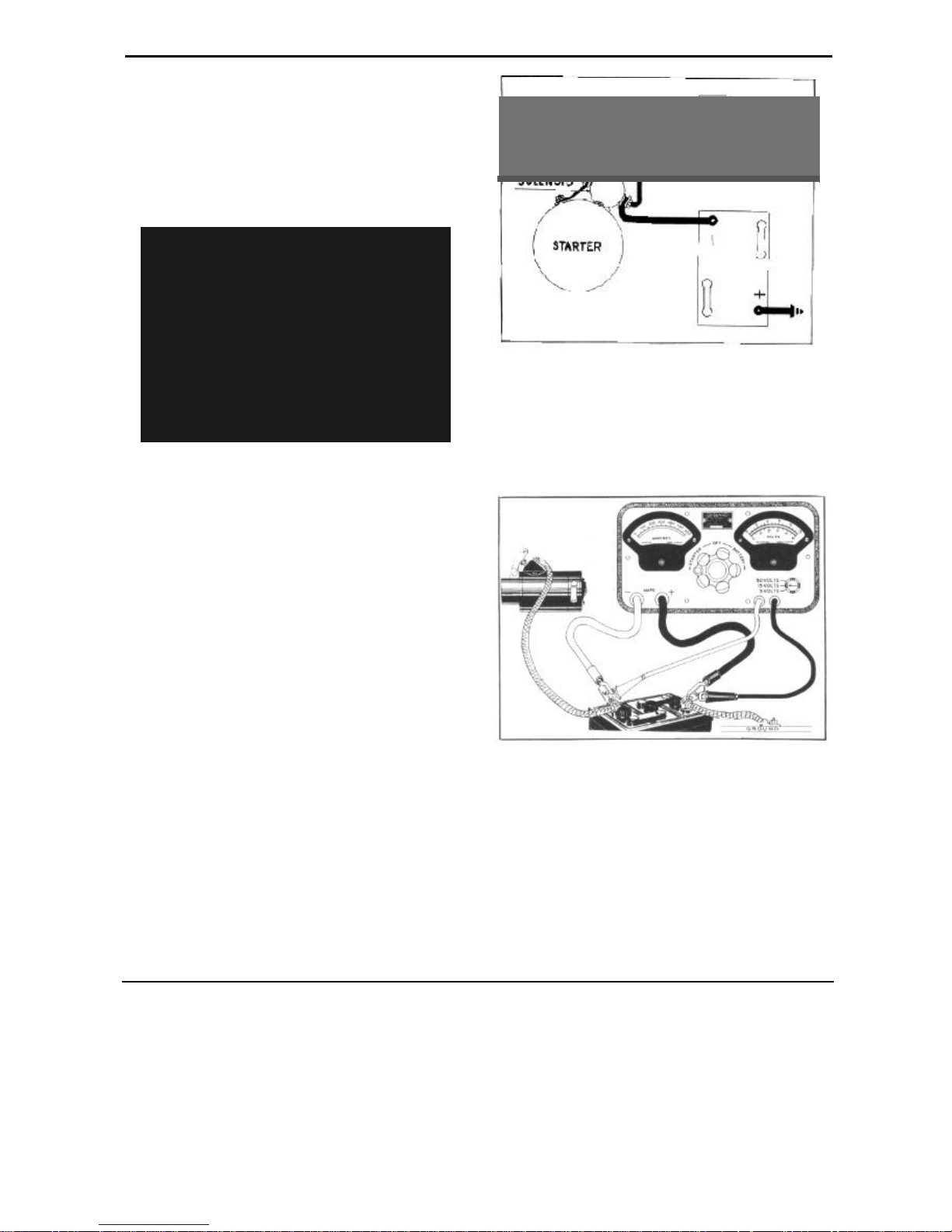

STARTER SOLENOID

1. Connect negative voltmeter lead to "BAT" terminal of starter solenoid switch and positive lead to

motor terminal of the solenoid switch, Figure 8.

2. Close the solenoid electrically to crank the

engine; and if the reading is more than .2

volts, replace solenoid switch.

FIGURE 9

2. Press starter switch and crank engine for

approximately 15 seconds and note the

"exact" reading on voltmeter.

3. Release Starter Switch and turn Starter-Battery

Tester knob clockwise until the voltmeter

reads "exactly" the same as when cranking the

engine. Ammeter reading should be 140 to

160 amperes (engine warm).

Page 20

15 ENGINE TUNE-UP

4. Turn tester to off position after completing test.

NOTE: Excessively high readings indicate a short

in the starting motor circuit or an excessive drag

on the motor due to a bent armature shaft or the

field coils touching the armature. Low readings

indicates excessive resistance in the circuit caused

by loose connections, worn brushes, or weak brush

spring tension.

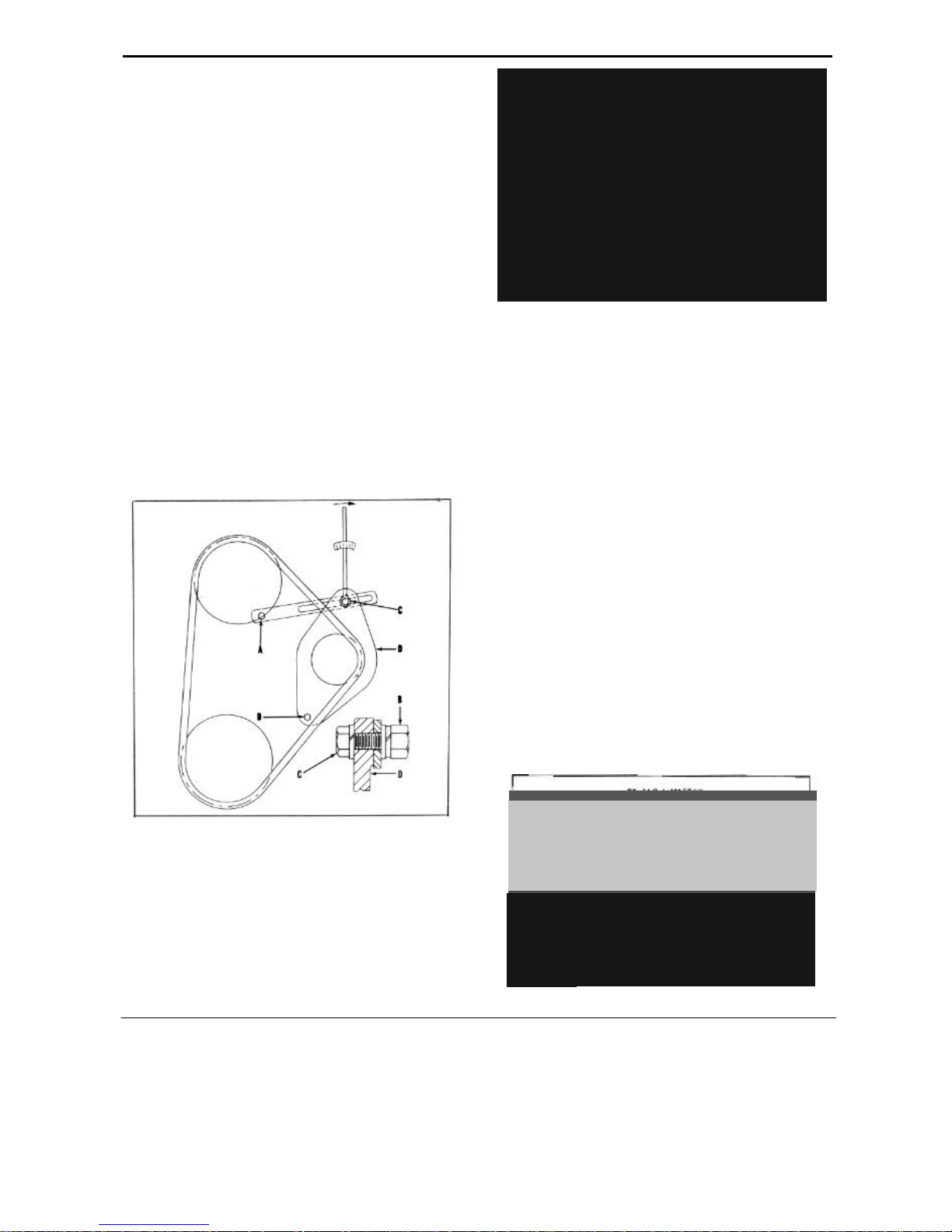

FAN BELT ADJUSTMENT

1. Loosen generator adjusting bracket bolt (A Figure 10), Nut (B) and 2 generator support

bracket bolts (D), three to four turns.

2. Apply a torque wrench approximately 12"

long and as nearly vertical as possible to head

of generator adjusting bracket bolt (C) and

pull generator against fan belt.

3. With torque wrench indicating 10-1/2 foot

pounds tighten generator adjusting nut (B)

securely. Remove torque wrench and tighten remaining 3 bolts securely.

FIGURE 11

2. Install a jumper from generator field terminal to

a ground. Momentarily raise the engine to about

1250 R.P.M. the reading on the ammeter should

read 45 amperes minimum output.

CAUTION: The engine MUST NOT be run for

more than a few seconds while making the

above test, due to danger of burning out the

generator. All lights and accessories must be

turned off also to prevent damage due to excessive voltage.

FIGURE 10

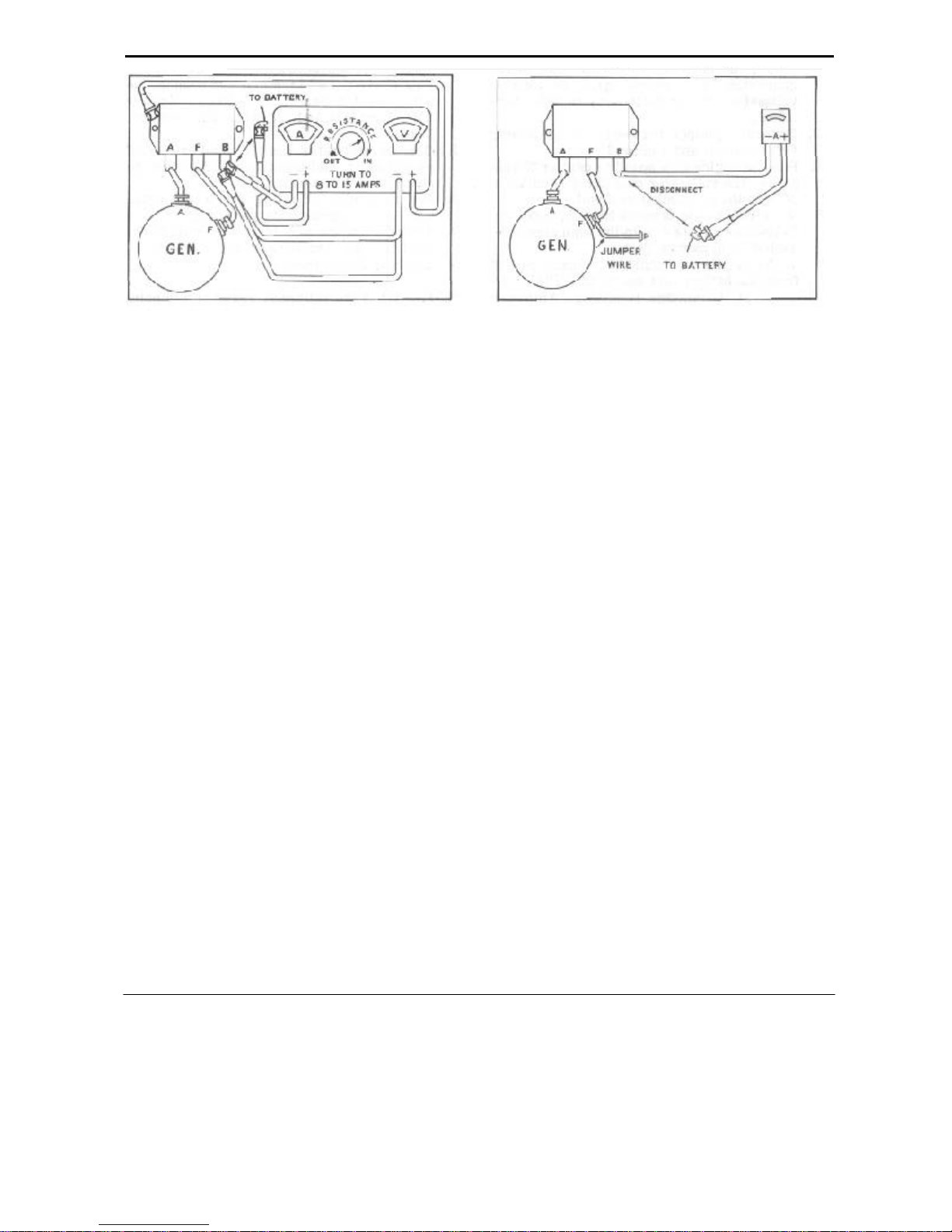

GENERATOR

GENERATOR OUTPUT CHECK

1. Disconnect battery lead at voltage regulator

"B" terminal; connect the ammeter negative

lead to the regulator "B" terminal and the

positive lead to the wire disconnected from

the regulator, Figure 11.

NOTE: A 11 generator tests should be made

with the generator circuit at normal operating

temperature.

GENERATOR CIRCUIT RESISTANCE CHECK

1. Disconnect battery lead at voltage regulator "B"

terminal; connect the ammeter negative lead to

the regulator "B" terminal and the positive lead

to the wire disconnected from the regulator,

Figure 12.

FIGURE 12

Page 21

ENGINE TUNE-UP 16

2. Install the negative voltmeter lead to the generator "A" terminal an d the positive voltmeter

lead to the battery negative terminal.

3. Connect a jumper between t he generator "F"

terminal and a ground.

4. Run the engine at a speed to deliver 20amperes.

The voltmeter should not read more or less than

8 (tenths) of a volt.

5. If the resistance is more than .8, make the

following checks with the ammeter connected

as in paragraph 1.

a. Remove the positive voltmeter lead from the

battery and install to the "A" terminal at the

voltage regulator. Ammeter should show less

than .1 (tenth).

b. Connect the voltmeter negative lead to the

regulator "A" terminal and the volt- m e t e r

positive lead to the regulator "B" terminal.

Ammeter should not show more than .3

(tenths).

c. Next, connect the voltmeter positive lead to

the battery negative terminal, negative lead to

"B" terminal on regulator. Ammeter should not

show more than .5 (tenths).

d. Connect the voltmeter positive leads to en g

in e ground, negative wire to base of regulator.

Ammeter should show .2 (tenths) or less.

CIRCUIT BREAKER CHECK

1. Disconnect the battery wire at the voltage regulator "B" terminal and connect the ammeter

between the voltage regulator " B" terminal and

the wire disconnected, Figure 13.

2. Connect voltmeter positive lead to base of

regulator and negative voltmeter to the generator "A" terminal.

3. Set carburetor adjusting screw so engine will

idle at approximately 400 R.P.M.

4. Increase engine R.P.M. by carefully rot a t in g

the accelerator bellcrank while watching the

voltmeter.

NOTE: When the voltmeter reads at any point

between 6.3 to 6.8 volts the circuit breaker

points should close and the ammeter will show

the generator is charging. When the circuit

breaker points close, a slight drop back of the

voltmeter needle will be noticed. In the eve nt

the drop back is not evident, slightly discharge

the battery and recheck.

5. Next, slowly reduce engine speed and watch the

ammeter.

NOTE: When the ammeter reads 4 to 6 amperes, negative side of zero, the circuit breaker

should open and the ammeter needle will return

to zero. Perform operation 4 and 5 several times

until you are sure your readings are correct.

To determine whether the circuit breaker

points are closing at the proper generator voltage

and also whether they will open upon deceleration by amperage from the battery proceed as

follows:

FIGURE 13

6. Proper adjustments can be made by bending the

spring hanger on the circuit breaker. Increasing

the tension raises the opening voltage; decreasing the tension lowers the opening voltage.

Contact gap must not be less than .015".

VOLTAGE REGULATOR CHECK

1. Disconnect the battery wire at the voltage regu-

lator "B" terminal and connect the test ammeter

between the voltage regulator "B" terminal and

the wire disconnected, Figure 14.

2. Connect the voltmeter positive lead to the regu-

lator base and the negative lead to the regulator

"B" terminal.

3. Run engine at approximately 2,000 R.P.M.

4. Vary resistance until ammeter reads 19 amperes

and then check the voltmeter reading which

should be 7.25 volts. (Hot, cover in place.)

Page 22

17 ENGINE TUNE-UP

FIGURE 14

NOTE: If the car is out of warranty the voltage

regulator can be set by bending the spring

hanger to get this necessary reading. The unit

must be final-checked with the voltage regulator cover in place as generally it will change

the reading from .1 to .2 of a volt and must be

compensated for in making this adjustment.

5. Stop engine, disconnect battery negative terminal and then proceed to remove the tester leaks

from the voltage regulator and install the wires

back on the "B" terminal of the regulator.

6. Install voltage regulator cover.

VOLTAGE REGULATOR ADJUSTMENT

1. Remove cover and change the armature spring

tension by bending the lower spring hanger.

Increasing the tension raises the operating voltage; decreasing the tension lowers it.

2. Replace cover and recheck.

FIGURE 15

2. Connect a Starter-Battery Tester directly across

the battery and set load to 45 amperes or use the

equivalent in sealed beam lamps.

3. Run engine to approximately 2000 R.P.M. amperage reading should be 36 amperes. If it is not

within a tolerance of one or two amperes of this

reading, the unit should be taken to an authorized Auto-Lite dealer for replacement.

NOTE: If car is out of warranty, remove the

voltage cover and adjust the current regulator

spring hanger to the necessary 36 ampere output. To prevent operation of the voltage regulator unit place a jumper across voltage regulator

points during this test. For final test always

replace the cover on the unit.

CAUTION: Momentarily touch t he negative

battery cable to the battery negative post to

determine that there is no spark between the

battery negative post and cable terminal then

connect negative cable.

3. After each adjustment, stop the engine and

restart. Bring up engine speed to deliver 15

amperes before taking a reading.

CURRENT REGULATOR CHECK

1. Disconnect the battery wire terminal "B"and

connect the test ammeter between the voltage

regulator "B" terminal and the wire disconnected,

Figure 15.

CURRENT REGULATOR ADJUSTMENT

1. Remove cover and change armature spring tension by bending the lower spring hanger. Increasing the tension raises the operating

amperage, decreasing the tension lowers it.

2. Replace cover and recheck. Stop and start engine

after each adjustment. Take readings with cover

in place.

Page 23

ENGINE TUNE-UP 18

FUEL PUMP

FUEL PUMP TEST

To determine if the fuel pump is operating properly, make the following tests:

1. Be sure fuel lines are not blocked, leaking or

have a stricture that would retard the flow of fuel

to the pump. The flexible hose should be carefully

checked for deterioration or cracks.

2. Remove and clean sediment screen.

NOTE: If the combination fuel and vacuum

pump is used, in addition, remove and clean

the air filter screen located under the cover at

the top of the pump.

3. Make sure all connections are tight after replacement.

4. Disconnect the fuel line at the carburetor and

connect the fuel pump gauge, Figure 16.

5. Start engine and run at 1800 R.P.M. normal

pressure should be 4 lbs. minimum to 5 lb s .

maximum. Stop engine and watch pressure

gauge. Pressure should not fall perceptible after

engine is stopped.

VACUUM BOOSTER CHECK

To check the action of the vacuum portion of the

combination fuel and vacuum pump, connect a

vacuum gauge to the inlet port and disconnect

outlet. Gauge should show 8-1/2" of mercury at

120 R.P.M. and 12" at 1800 R.P.M.

MANIFOLD HEAT CONTROL

Check the manifold heat control valve to see

that spring is in good condition and valve is free.

If damper shaft is stuck, remove the thermostat and

spring, apply penetrating oil or kerosene and tap

shaft for end play to break carbon or corrosion.

The shaft should not be oiled. When properly

freed, check springs and thermostat before installing and replace them if weak.

CARBURETOR

CLIMATIC CONTROL

1. Remove t he carburetor Climatic Control Cover.

Check the heat control tube for leaks or obstruction and the choke valve and piston for free

movement. Choke valve should open of its own

weight when cover is removed.

2. Reinstall the cover with graduations down and

rotate counter clockwise to one point lean of

center graduation.

FIGURE 16

6. If pressure falls; leaking pump valves are indicated.

7. If pressure is below specifications, attach the

vacuum gauge to the inlet port of the pump and

operate the engine. Gauge should show a minimum of 6 inches of mercury for satisfactory

operation.

CARBURETOR INLET STRAINER

1. Remove bowl cover strainer nut, gasket, and

strainer screen. Clean screen and replace if corroded or damaged.

CARBURETOR FLOAT LEVEL

1. Remove air cleaner, carburetor dust cover and

screws attaching carburetor air horn.

2. Disconnect throttle connector r o d, bowl cover

and check float level with gauge J-818-1 Figure

17. Float level should be 1/2".

3. To adjust, make sure needle is seated, raise float

and press down on float lever lip with a screw

driver. Bend only a small amount at a time and

do not disturb the curvature of the lip.

Page 24

19 ENGINE TUNE-UP

1. With throttle valve seated and connector link i n

lower hole (short stroke) pump travel should be

FIGURE 17

PUMP TRAVEL

16/64". Use Carter Pump stroke gauge T-109117-S if available.

2. Adjust pump travel by bending throttle connecting link at lower angle.

METERING ROD SETTING

NOTE: The correct setting of metering rod is

important and must be made after pump adjustment o r when leaner than standard rods

are installed.

FIGURE 18

1. Crack throttle valve .020" by placing gauge

J-1633 (Carter No. T-109-29) between throttle

valve and bore of carburetor on side opposite

the idle port, Figure 19.

1. With air cleaner and dust cover off remove

hairpin clip and disconnect spring from metering rod, remove metering rod and disc.

2. Insert metering rod gauge, J-1265 (Carter No.

T-109-102). Hold gauge vertical and be sure

gauge is seated in metering rod jet, Figure 18.

3. Press down on vacuum piston link directly over

piston until it contacts the pump arm. Clearance

between metering r o d pin and shoulder of

gauge should be less than .005" with throttle

valve seated. Gauge must not drag on pin.

4. Adjust by bending lip on piston link at (A). 5.

Re move gauge and install metering rod and

disc and connect metering rod spring.

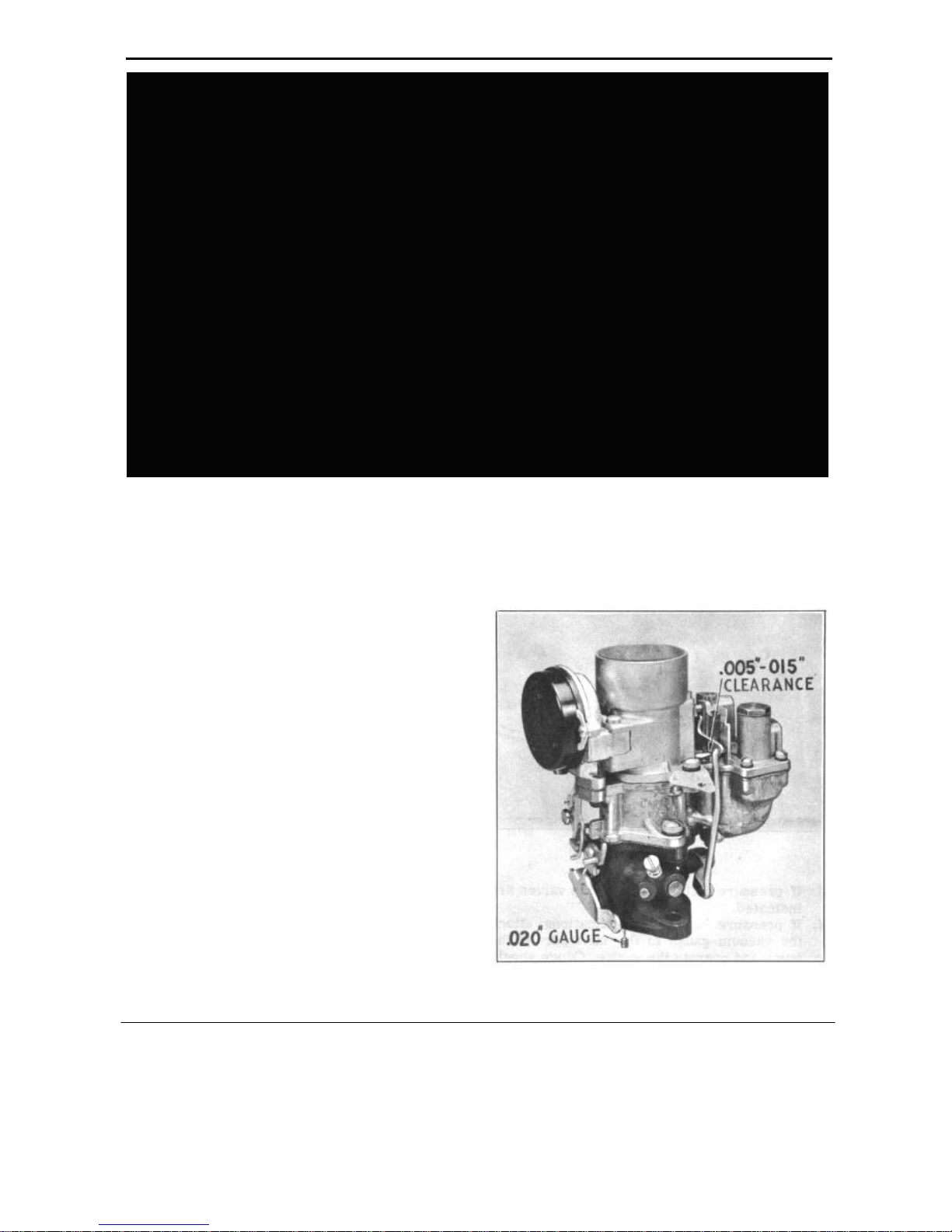

ANTI-PERCOLATOR ADJUSTMENT

NOTE: Carburetor must be removed from en-

gine.

FIGURE 19

Page 25

2. Clearance between percolator rocker arm lip

and pump arm should be .005" to .015"

3. Adjust by bending the rocker arm, using Bending Tool J-1389 to make this adjustment.

FAST IDLE ADJUSTMENT

1. With fast idle cam in normal idle position,

tighten throttle lever adjusting screw (A), Figure 20, until it just seats against the cam.

ENGINE TUNE-UP 20

FIGURE 21

IDLE ADJUSTMENT

FIGURE 20

2. Hold throttle lever closed an d pull cam back

until low step is against but not on set screw

(B), Figure 20.

3. Clearance between lower edge of choke valve

and air horn should be 5/8" as shown at (A),

Figure 21.

4. Adjust by bending fast idle link at offset.

UNLOADER ADJUSTMENT

I. Open throttle wide and check clearance be-

tween lower edge of choke valve and air horn.

Clearance should be 7/16" (A), Figure 21.

1. Start engine and allow to warm up.

2. See that choke valve is wide open.

3. Set idle adjustment screw (A), Figure 22, 1/2 to

1-1/2 turns open to obtain smooth idle. Cars

equipped with Hydra-Matic; set idle at 490-510

R.P.M., 540 to 560 for standard transmission

and 575 for overdrive.

2. Adjust by bending cam (B) on throttle lever.

FIGURE 22

Page 26

MAIN BEARING SIZE

21 ENGINE

SECTION 3

ENGINE

SPECIFICATIONS

ENGINE - GENERAL

Arrangement

No. Cylinders

Compression Pressure

Firing Order

Serial No. Location

Bore

Stroke

Piston Displacement .

Horsepower - Taxable

Horsepower - Actual.

Torque

CRANKSHAFT

Drive

Bearings

Type

No.

1.

2.

3.

4.

Radial Clearance

End Play

Timing Marks

Timing Chain

Timing Chain Width

Camshaft Sprocket

Crankshaft Sprocket

CRANKSHAFT

No.

1.

2.

3.

4.

1.

2.

3.

4.

Diameter

2.4988" to 2.4998" 1.530"

2.4988" to 2.4998" 1.500"

2.4988" to 2.4998" 1.500"

2.4988" to 2.4998" 1.750"

2.5006" to 2.5010"

2.5006" to 2.5010"

2.5006" to 2.5010"

2.5006" to 2.5010"

L Head

6

100 lbs. minimum

1-5-3-6-2-4

Right Hand Front

of Block

3"

4-3/4"

202 Cu. In.

21.6

104

158 ft. lbs. @ 1400

R.P.M.

Silent - Chain

4

Interchangeable -

Steel Back Babbitt

Diameter Length

2.375"

1.997"

1.965"

1.497"

.0005"

.003 to .005

On Sprockets and Chain

60 Links 3/8" Pitch

1"

42 Teeth

21 Teeth

x

x

x

x

x

Journal

Length

x 1.312"

x 1.250"

x 1.494"

x 1.500"

1"

11/16"

11/16"

1-1/8"

.0015"

Diametral Clearance

Adjusting Shims

Crankpins

End Play

Thrust

CONNECTING RODS

Material

Weight

Length - Center to Center

Bearing - Lower End

Type

Diameter & Length

End Play

Diametral Clearance.

Shims

Bushing - Upper End:

Material

Diameter & Length

Diametral Clearance

PISTON

Type

Material

Weight

Length (Overall)

Length - Pin Center to

Top

Piston Clearance

Ring Groove Depth

PISTON PIN

Type

Length

Diameter

Fit in Piston

Fit in Rod

PISTON RINGS

Material

Compression Rings

Width

Oil Rings

Width - Upper

Width - Lower

Gap Clearance

.0005" to .0015" None

1.937" to 1.938"x

1.125"

.003" to .009"

On No. 3 Bearing

Forged Steel

26 ozs.

8.183" to 8.193"

Precision Insert

Removable

Steel Back Babbitt

1.9375" x .962"

.007" to .013"

.0005" to .0015"

None

Steel Back Babbitt

.8465" x .870"

0" to .0003"

Cam Ground

Aluminum Alloy

10-1/4 oz.

3.1875"

1.6875"

.0015" to .002"

.148"

Floating

2.4375"

.7497" to .750"

.000" to .0003" Hand

Push Fit at 70° F.

Cast Iron

Two (Pinned)

5/64"

Two (Pinned)

3/16"

5/32"

.004" to .009"

Page 27

ENGINE 22

INTAKE VALVES

Angle of Seat

Head Outside Diameter

Port Diameter

Lift

Length

Stem Diameter

Stem to Guide Clearance

Operating Clearance Hot

Inserts

EXHAUST VALVES

Angle of Seat

Head Outside Diameter .

Port Diameter

Lift

Length

Stem Diameter

Stem To Guide Clearance

Operating Clearance Hot

Valve Angle.

Inserts

45°

1.500"

1.418"

.356"

.5.045"

.3412" to .3422"

.0015" to .0025"

.010"

None

45°

1.395"

1.315"

.356"

5.022"

.3402" to .3412"

.003" to .004"

.012"

7°

None

VALVE TIMING

Inlet Opens

Inlet Closes

Exhaust Opens

Exhaust Closes

Timing Marks

26.8° BTC 9

9.7° ABC

64.9° BBC 4

5.7° ATC

On Vibration

Dampener

LUBRICATION

Engine Lubricating

Method

Normal Pressure

Oil Pump Type

Oil Pump Drive

Oil Capacity

Pressure

40 lbs. @ 30 M.P.H.

Rotor

Worm on Camshaft

5-1/2 qts.

Total

5 qts. refill.

TORQUE SPECIFICATIONS - ENGINE

VALVE GUIDES

Type

Length:

Intake

Exhaust

Inside Diameter

VALVE SPRINGS

Free Length

With Valve Closed

With Valve Open

Total Coils

Spring Pressure -Closed

Open

VALVE TAPPETS

Type

Guides

Guide Size

Tappet Size

Fitting Clearance

Length

Removable

2-5/8"

2-5/8"

.3435"

2-3/16"

.1.953"

1.607"

8-½

40-48 lbs.

.116-124 lbs.

Mushroom

Integral with Block

.6245" to .625"

.62325" to .62375"

..00075" to .00175"

2.310"

Camshaft Gear Bolt

Connecting Rod Bolt

Crankshaft Bearing Cap

Screw

Cylinder Head Cap Screw

Cylinder Head Water

Outlet Bolt

Engine Mounting Bolt

(Front)

Engine Mounting Bolt

(Rear)

Engine Mounting to

Frame Bolt (Rear)

Manifold (Exhaust)

Manifold (Intake)

Oil Pan Bolt

Spark Plugs

Timing Gear Cover Bolt

Vibration Dampener

Screw

Water Pump To Cylinder

Bolt

SIZE

3/8-16

3/8-24

1/2-13

7/16-14

3/8-16

7/16-20

7/16-14

5/16-18

3/8-16

5/16-18

5/16-18

14 M.M.

5/16-18

5/8-18

3/8-16

FT. LBS.

20-30

40-50

75-80

20-30

40-45

40-50

12-15

20-30

12-15

15-20

25-30

15-20

80-90

20-30

Page 28

23 ENGINE

GENERAL CONSTRUCTION

The Hudson Jet and Super Jet engines are

of the "L" head design.

Crankcase and cylinder block are integra1,

made of chrome alloy iron to provide maximum

strength with minimum cylinder wear and weight.

The engine is cushioned against shock and vibration by rubber mountings at three points in cars e

quipped with standard synchromesh transmissions.

One cushion is mounted on the frame side rail at each

side of the engine front support plate. The rear of the

engine assembly is supported on the No. 3 frame

crossmember, the cushion being attached to the under

side of the clutch bell housing. Models equipped with

Hydra-Matic transmissions have four rubber engine

mountings, - one at each side of the transmission

supporting the engine at the rear at the No. 3 crossmember. Front engine mountings are identical for

both types of transmissions.

A fully counter balanced crankshaft of forged

alloy steel is balanced statically and dynamically.

Four precision insert type steel back babbitt main

bearings support the shaft. Main bearing inserts of

several undersize dimensions are available for

service 'requirements. (See Parts Book) Crankshaft end thrust is taken at the No. 3 main bearing.

Connecting rods have replaceable precision

insert steel back babbitt bearing shells which are

interchangeable.

The camshaft is made of especially heat treated

alloy iron mounted in four steel back babbitt bearings. A Morse chain and sprockets are utilized to

drive the camshaft.

Mushroom type rotating valve tappets are used.

The tappets are fitted directly in the crankcase and may

be removed from the bottom of the crankcase after

removal of the oil pan and camshaft.

Valves seat directly in the engine block with no

valve seat inserts required. The exhaust valves have

welded stems with the valve head and upper stem

made of Austenetic Alloy steel to provide maximum

heat transfer from the exhaust valve. Removable valve

guides are provided for both intake and exhaust valves.

LUBRICATION

Engine lubrication is provided by pressure to friction surfaces of the engine, Figure 4. A positive

rotor type oil pump is mounted on the right side of

the cylinder block. The pump is driven by a worm

gear integral with the camshaft.

Oil is drawn through a floating oil screen in the oil pan

and the intake pipe to the pump. From the pump oil

under pressure is forced up into the horizontal oil

gallery. From the oil gallery, oil is distributed to valve

tappets and camshaft bearings. Circulation is also provided through oil laterals to engine main bearings and

through holes in the crankshaft to the connecting rod

bearings which also provide cylinder wall lubrication.

The oil check valve located in the crankcase on the left

side regulates oil pressure.

Aluminum alloy cam ground pistons are provided. Four piston rings are utilized on each

piston, steel stake pinned at the ring gaps to prevent ring rotation in the ring grooves.

Piston pins are of the full floating type held in

position with steel lock rings fitted into grooves

machines near each end of the piston pin bore.

Piston pins operate in steel backed bronze bushings pressed in the upper ends of the rods.

NOTE: Normal oil pressure is 40 pounds at 30

M.P.H.

OIL PRESSURE SWITCH

An oil pressure switch assembly is used in conjunction with the rotor type pressure pump. The

function of the pressure switch is to Indicate by

means of an instrument panel light when there is

no oil pressure.

Page 29

ENGINE 24

The unit consists of a spring loaded diaphragm

and a set of electrical contact points normally

closed when the engine is not operating. The

closed contact completes a ground connection to

the instrument panel lighting the lamp. When the

oil pump begins to operate, oil pressure breaks the

ground contact, and the lamp goes out.

OIL CHECK VALVE

Oil pressure is maintained by a non-adjustable

oil check valve consisting of a plunger, spring,

plug retainer and plug gasket. The assembly is

located in the left side of the crankcase slightly

below the distributor. Oil pressure against the end

of the plunger and spring forces the plunger off its

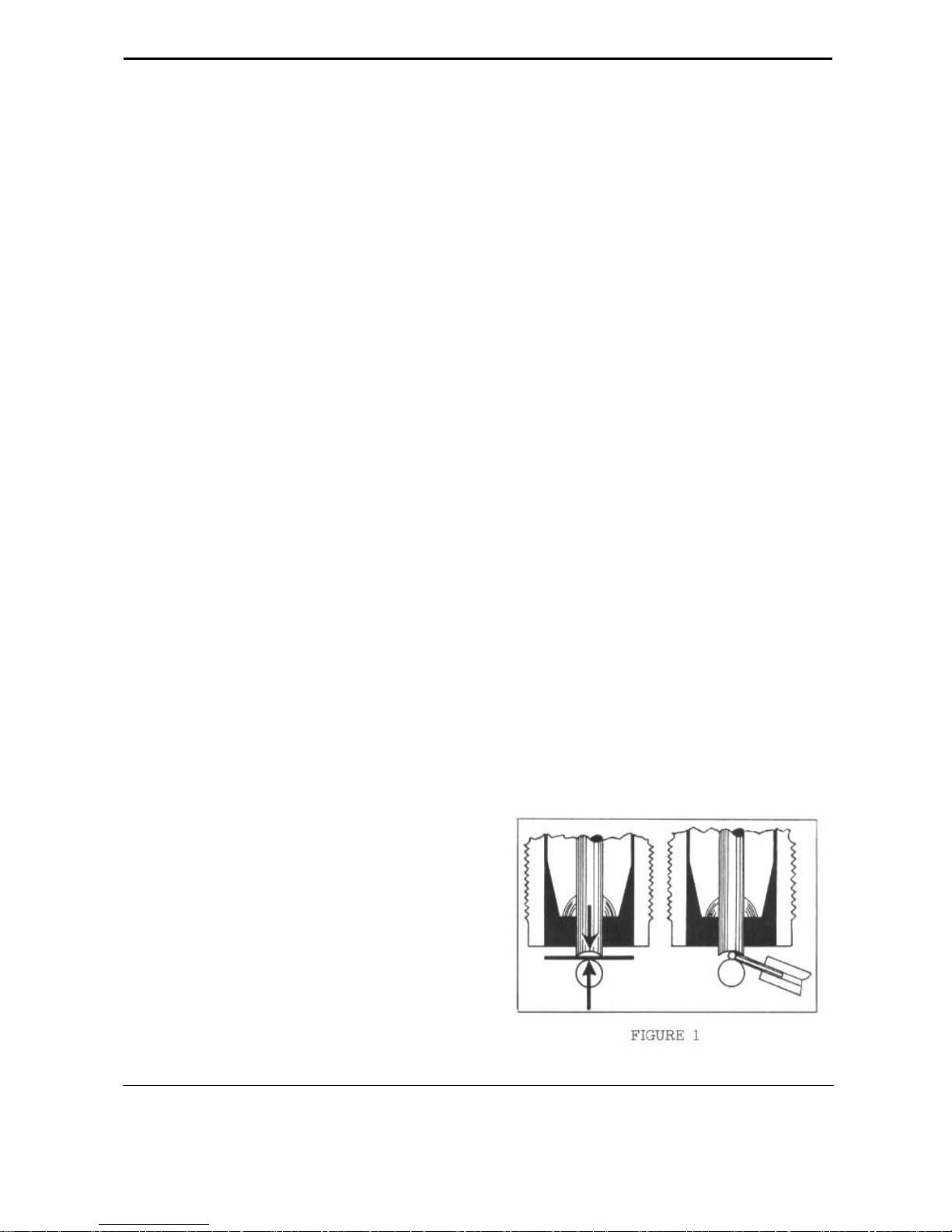

seat allowing oil to return to the oil pan, Figure 1.

one cylinder. Do not disturb this position of the

engine while the oil pump is removed.

2. Remove the two oil pump to block attaching

screws and remove the oil pump.

FIGURE 2

DISASSEMBLY

1. Remove the cover screws (1), Figure 2, cover

(2) and gasket (3).

2. Hold hand over cover opening and with the

pump upside down, turn shaft until the pump

rotor (4) falls out in the hand.

3. Drive out straight pin (10) which holds

pump drive gear to pump shaft.

4. Press shaft (7) out of gear (9) by supporting the

oil pump body (8) on the cover face in an arbor

press allowing the inner rotor and shaft to clear

when pressing the shaft out of the pump gear.

5. Wash all parts in cleaning solvent and dry

with compressed air.

FIGURE 1

OIL PUMP

The oil pump is of simple construction and

very efficient providing high volume. It is a rotor

type pressure pump. Service is seldom required.

REMOVAL

Care must be exercised to maintain correct

engine ignition timing when it is necessary to

remove the pump for servicing. The recommended procedure is as follows:

1. Lift off the distributor cap and rotate the engine

crankshaft until the distributor rotor is in firing

position for the number

INSPECTION

1. Install rotors and shaft in pump body with the

inner rotor located so that one lobe of the inner

rotor contacts the corresponding notch in the

outer rotor. Measure the clearance between the

opposite lobe of the inn e r and outer rotor. This

clearance should be .010" or less. If more than

this, replace both rotors and shaft.

2. With rotors and shaft assembled in the pump

body place a straight edge across the pump

body between the screw holes and using a feeler

gauge, measure the clearance between the top

of the rotors an d the straight edge. This clearance should be .004" or less. If the clearance is

greater than this limit, the pump body must be

replaced.

Page 30

25 ENGINE

3. With the outer rotor (4) pressed against one

side of the pump body, with a feeler gauge

measure the clearance between the outer rotor

and pump body at the opposite side. If this

clearance is more than .008", replace the pump

body.

4. Body cover (2) should be smooth. It should be

replaced if scratched, grooved or worn. Lay a

straight edge across the inner surface of cover

and check with .002" feeler gauge between the

cover and straight edge. If the feeler gauge can

be inserted, the cover is worn and must be

replaced.

ASSEMBLY

1. Install the outer. rotor (4) in the pump body (8),

Figure 2.

2. Slide the pump shaft (7) and rotor (5) assembly

into the pump body.

3. Support oil pump body, shaft and rotors assembly

on a clean surface and press pump drive gear (9)

on pump shaft (7). End play between the hub of

the drive gear and pump body should be .004" to

.008".

NOTE: The slot in the end of the oil pump

shaft is machined off center as is the tongue on

the end of the distributor shaft, Figure 4.

4. Install the oil pump, engaging the oil pump

drive gear with the camshaft worm gear teeth.

The pump shaft must be aligned to engage the

shaft slot with the tongue on the end of the

aligning tool. Then push the tool out as the

pump is seated against the block mounting

face.

5. Remove aligning tool J-2794'.

6. Set distributor in No. 1 firing position and

install.

7. In stall distributor mounting screw, distributor c a p , distributor vacuum control tube

and connect the coil lead wire.

4. In stall gear pin and peen over both ends

securely.

5. After inspecting to see that pump is thoroughly

clean, install cover gasket (3) in the recess in

the pump body.

6. Install cover (2). Tighten cover screws (1)

evenly and securely.

INSTALLATION

If the engine crankshaft has been rotated inadvertently during the interval the oil pump was out

being repaired, ignition timing will be incorrect.

The following steps will then be necessary to

remedy the improper timing.

1. Remove the distributor mounting screw, dis

connect the distributor vacuum control tube,

disconnect the coil lead wire and remove the

distributor.

2. Set dampener timing with the No. 1 piston on

T.D.C.

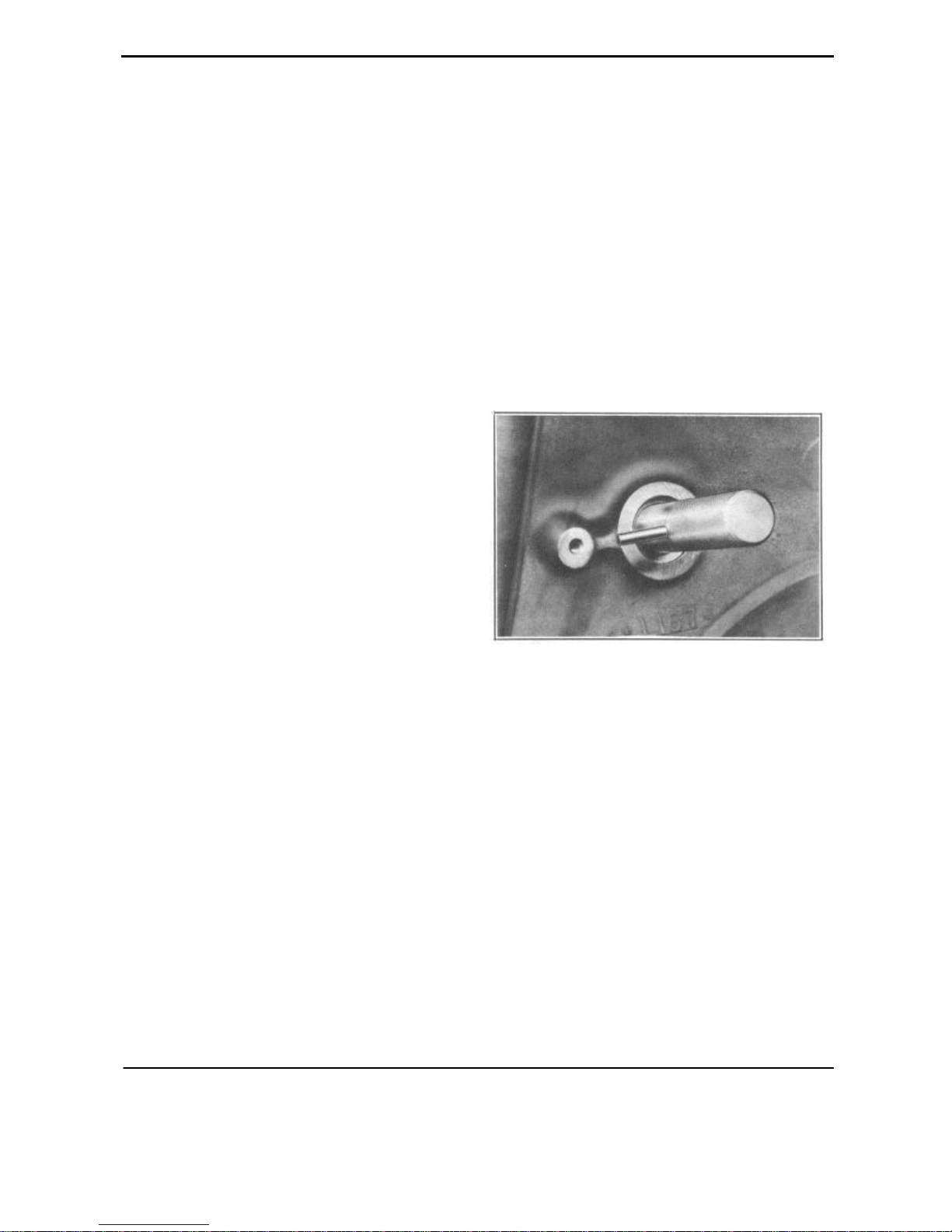

3. Insert aligning tool J-2794 in the distributor

shaft hole with the aligning pin in line with the

distributor mounting screw hole, Figure 3.

FIGURE 3

OIL PAN

REMOVAL

1. Raise car and place stand jacks under the No. 2

frame crossmember.

2. Remove the three bolts attaching the center

steering arm support bracket to the No. 2 crossmember. This permits the center steering arm

and tie rods to drop.

3. Remove the two attaching bolts, flywheel dust

cover to bell-housing, and remove dust cover.

4. Remove oil pan drain plug and drain oil. 5. Re-

move bolts and lockwashers attaching oil pan

to cylinder block and remove oil pan.

NOTE: Do not lose the round rubber gasket at

the oil outlet tube.

Page 31

ENGINE 26

FIGURE 4

Page 32

27 ENGINE

INSPECTION

1. Remove all traces of old gaskets from the pan

and crankcase. In s t all new gasket, applying a

light coat of Hudson Perfect Seal Gasket Paste

on both sides of the new gasket.

2. Remove cotter pin (1) Figure 5, attaching oil

pan screen to the outlet pipe. Clean screen

thoroughly or replace.

3. Install oil pan screen to outlet pipe. Check to be

certain there is no binding action and screen

swivels freely.

4. Secure ends of cotter pin.

3. Disconnect and remove vacuum advance control

tube.

4. Disconnect top radiator hose.

5. Disconnect heater hoses (if so equipped).

6. Disconnect throttle rod at carburetor.

7. Disconnect temperature gauge wire at cylinder

head sender unit.

8. Disconnect spark plug wires and remove spark plugs.

9. Remove cylinder head cap screws and lift off

cylinder head.

10. Remove temperature gauge sender unit

from cylinder head.

INSTALLATION

1. Make certain cylinder head is free of -carbon

and dirt. Check cylinder head with a straight

edge to detect roughness or warping, especially

in those instances of frequent "blowing" of head

gaskets. With a .010" feeler gauge, check between the straight edge and the machined surface of the cylinder head. If the feeler gauge

enters at any point, the head must be remachined

or replaced.

2. In stall new head gasket with lettering on gasket

up. (Apply a light coating of "Hudson Perfect

Seal Gasket Paste".)

FIGURE 5

INSTALLATION

1. Install rubber gasket on outlet tube.

2. Install the oil pan to the engine, using two

screws on each side until all screws have been

started.

3. Tighten oil pan screws evenly to 15 to 20

pounds torque.

4. Install oil pan drain plug.

5. Install flywheel dust cover.

6. Install center steering arm support bracket and

tighten bolts securely.

7. Fill oil pan with 5-1/2 quarts of motor oil

of the recommended viscosity

CYLINDER HEAD

REMOVAL

1. Drain cooling system.

2. Loosen carburetor a i r horn attaching screw

and clamp and lift off air cleaner.

NOTE: Cylinder head and gasket installation

can be facilitated by using two J-2969 cylinder

head locating studs t o align the gasket and

head. These studs have a screw driver slot for

easy removal after the cylinder head has been

aligned, Figure 6.

3. Cylinder head cap screws should be tightened to

75-80 foot pounds, (Cold) using a torque wrench

and retighten when engine is at normal operating

temperature.

FIGURE 6

Page 33

ENGINE 28

4. Cylinder head cap screws should be tightened

in the sequence illustrated in Figure 7.

FIGURE 7

CAUTION: Always clean out threads in cylinder

block before installing cylinder head. If threads

in the block are corroded or filled with dirt, an

incorrect torque wrench reading will be indicated, as a percentage of the torque will be absorbed

by the threads. Apply "Hudson Perfect Seal Gasket Paste" to threads to facilitate tightening of

the cap screws to the proper tension.

VALVE SYSTEM

VALVE TAPPET ADJUSTMENT

1. Remove right front wheel.

2. Remove fender side shield.

3. Remove valve covers and breather. Adjust

tappets as follows:

Intake .010" hot

Exhaust .012" hot

VALVE REMOVAL

The engine block is of hard chrome alloy iron and

the valves seat directly in the block with no valve seat

inserts required. The following procedure is recommended for removing valves:

NOTE: Place corks or wood plugs in valve

chamber oil return holes to prevent valve locks

from dropping through those holes into the oil

pan.

6. Remove valve s from engine and place them in

proper sequence in a valve rack to assure their

installation on the seats from which they were

removed.

7. Check all valves and replace those badly

burned, warped or cracked.

REFACING VALVES

Remove enough metal to clean up pits and

burns. Grind until a clean metal surface is obtained

to provide a good seal on the seat. Do not grind to

a knife edge at the top of the valve. At least 1/16"

of metal should remain, measured from the upper

edge of the valve seat to the top of the valve shown

at (D), Figure 9. If this thickness of metal does not

remain after grinding, replace the valve.

REFACING VALVE SEATS

Before refacing valve seats, it is necess a r y to

clean all carbon and varnish from valve guides.

Cleaning can be quickly accomplished using a

KMO-122 Valve Guide Cleaner Metal Brush

mounted in a small electric drill. Place a cloth

below the valve guides in the valve chamber to

catch dirt and excess thinner and prevent it from

dropping into the oil pan.

The valve guides must also be checked for excessive wear before attempting to reface the valve

seats. Excessive valve guide wear can usually be

detected by an oily deposit on the under side of the

intake valve heads or in the intake valve ports.

STANDARD CLEARANCES

1. Drain cooling system.

2. Remove cylinder head. See 'Cylinder Head

Removal", Page 27.

3. Raise car and remove right front wheel and

fender shield with extension.

4. Remove front an d rear valve covers and crank

case breather tube.

5. Compress valve springs and remove s p ring

keepers an d retainers (use tool KMO-484

Valve Spring Lifter).

VALVE GUIDES & VALVE STEMS

INTAKE EXHAUST

Valve Guide Bore .3437 .3437

Valve Stem Diameter .3417 .3407

Clearance .002 .003

When valve guides must be replaced, they may

be removed by driving them out with J-267 valve

guide remover after taking out tappet adjusting

screws.

Page 34

29 ENGINE

Valve guides can be properly installed with

the J-883-A Valve Guide Installer using pilot

I-883-10. The installer consists of the driven handle, stop collar and a pilot calibrated to limit the

depth to which the guides are driven. The valve

guides are inserted to a depth of 1-9/32" from the

top of the valve seat to the top of the guides for

both intake and exhaust valve guides. (See Figure

8.)

FIGURE 8

Before starting to reface the valve seat, be sure

that the stone is clean and true. Touch the valve

seat lightly with the stone to avoid chatter o f the

grinder. Grind seat until all pits are removed and

the seat is clean.

Seats should be held to a width of from 1/16" to

3/32" inch. When the seat is too wide, difficulty is

encountered trying to obtain a good seal. If a wide

seat is found, grind the edge with a 20° stone until

proper seat width is obtained. If necessary, an

additional cut can be taken at the port end with a

75° stone if the valve does not contact the valve

seat within the gauge line limits. (See Figure 9.)

VALVE TAPPETS

Valve tappets are of the mushroom rotating

type with self-locking tappet adjusting screws.

The valve tappets must be removed from the

bottom of the cylinder block. To accomplish this,

the oil pan, and camshaft must be removed, while

holding the valves wide open with J-1612-3 tappet

and valve holders.

FIGURE 9

INTAKE EXHAUST

A - 45° 45°

B - 1.831" 1.561"

C - .1135" .1525"

D - .0495" .0496

E - .083" .103"

F - .016" .008"

G - .054" .075"

H - 1-11/16" 1-3/8"

Valve tappets should be carefully inspected f or

pitting and scratches on t he mushroom faces that

might damage the cam lobes. Replace any tappets

that are pitted or scratched.

If the valve tappet guides are worn excessively,

the tappets should be removed, the guides reamed

and oversize tappets installed. Tappets available