Hudson Year 1947, 1947 SUPER SIX, 1947 COMMODORE SIX, 1947 3/4-TON COMMERCIAL, 1947 SUPER EIGHT Owner's Manual

...Page 1

Page 2

Page 3

WHEN YOUR

NEW HUDSON

IDENTIFICATION CARD completely filled in on both

sides. BE SURE THAT KEY NUMBERS ARE

IS DELIVERED TO YOU

SEE THAT THESE THINGS ARE DONE

OWNER'S SERVICE POLICY properly filled in and

its provisions fully explained to you.

RECORDED.

BATTERY properly registered with National Battery

Dealer.

RADIO WARRANTY REGISTRATION CARD filled

in by dealer and attached to radio if car is so

equipped.

Page 4

Welcome

As the purchaser of a new Hudson car we welcome

you into the fast growing family of Hudson owners.

This may be your first Hudson—or possibly you have

had previous experience with this fine product. In

either event you will have many pleasant reactions in

Naturally, you will want to keep it trouble free and

derive from it the many pleasures for which it was

pared this Owner's Manual. In its pages you will find

Before you drive your car take a few minutes to study

this manual. It contains a wealth of information--

just the things you will want to know. Then place

its ownership.

purchased. With this thought in mind we have pre-

many suggestions to fully acquaint you with its construction, operating features and maintenance requirements.

it in the locker box for convenient future reference.

HUDSON MOTOR CAR COMPANY

Service Department

Page 5

WARRANTY

judgment of the Manufacturer, to affect its stability

"We warrant each new car manufactured by us to be

free from defects in material and workmanship under

normal use and service, our obligation under this warranty being limited to making good at our factory any

part or parts thereof, including all equipment or trade

accessories ( except tires) supplied by the Car Manufacturer, which shall, within ninety (90) days after

making delivery of such vehicle to the original purchaser, or before such vehicle has been driven 4,000

miles, whichever event shall first occur, be returned

to us with transportation charges prepaid, and which

our examination shall disclose to our satisfaction to

have been thus defective ; this warranty being expressly

in lieu of all other warranties expressed or implied, and

of all other obligations or liabilties on our part, and we

neither assume nor authorize any other person to assume for us any other liability in connection with the

sale of our vehicles.

"This warranty shall not apply to any vehicle which

shall have been repaired or altered by other than an

Authorized Hudson Dealer in any way so as, in the

or reliability, nor which has been subject to misuse,

negligence or accident."

HUDSON MOTOR CAR COMPANY

Detroit, Michigan, U.S, A.

The Hudson Motor Car Company reserves the right to make

any changes in or improvements on its products without incurring any liability or obligation whatever, and without being

required to make any corresponding changes or improvements

on products theretofore manufactured or sold.

Page 6

OWNER'S SERVICE POLICY

sions of the Hudson Owner's Service Policy which was

We cannot too greatly impress you with the need for

reading fully and becoming acquainted with the provi-

furnished with this automobile.

AUTHORIZED

HUDSON SERVICE

STATIONS

HUD

SON

PARTS SERVICE

Page 7

AUTHORIZED

The majority of automobile owners are conscientious in the service

requirements of their cars and unhesitatingly call on their car dealer

for service as and when it is required. These car owners realize that

their Hudson Dealer is in a position to render the satisfactory and

When touring or away from familiar surroundings the occasion may

arise for service needs. Look for the Hudson Authorized Service sign,

illustrated above. The Hudson Dealer displaying this sign is your

assurance of the same efficient, friendly service you receive at home.

It is your further assurance that his Service Department stocks only

HUDSON SERVICE

STATIONS

efficient service to which they are entitled.

genuine Hudson parts; uses factory approved service tools and methods and employs careful and courteous mechanics.

Page 8

6 HUDSON OWNER’S MANUAL

INSPECTION AND ADJUSTMENT SERVICE

The Hudson Owner's Service Policy provides that at the expiration of 1,000

miles and again at 2,000 miles of driving the Hudson Dealer from whom you purchased your car will perform an Inspection and Adjustment Service without

charge, except for supplies or lubricants used.

Should either of these inspections be performed by another Authorized Hudson

Dealer (one who did not sell the car) a charge of not to exceed :$5.00 will be

made for either the 1,000-mile inspection or the 2,000-mile inspection. In this

event the owner should secure a receipted bill and present it with the Owner's Policy to his own Dealer (who sold the car) and that Dealer will provide for one or

two additional inspections, whichever the case may be, without charge, except for

supplies and lubricants used.

We urge you to carefully read the provisions of the Owner's Service Policy so

that you will fully understand this procedure.

The Inspection and Adjustment Service consists of the following :

1,000 Mile

1. Check Operation of All Locks.

2. Check Signals and Instruments.

3. Check Operation of Lights.

4. Check Battery and Connections.

5. Tighten Cylinder Head Stud Nuts.

6. Tighten Manifolds.

7. Check Cooling System and Coolant.

8. Check Clutch Pedal Clearance.

2,000 Mile

1. Check Operation of Signals and In

struments.

2. Check Operation of All Lights.

3. Check Operation of Windshield

Wipers.

4. Inspect Cooling System and Conn-

ections (Anti-Freeze in Winter).

5. Check Battery and Connections

9. Check Axle Shaft Nut Tightness.

10. Check Wheel Hub Bolts.

11. Check Rear Spring Clips.

12. Check Body Bolts.

13. Check Hand and Foot Brakes.

14. Check Drive-Master.

15. Road Test.

6. Adjust Tappets—Engine Hot.

7. Tune-Up Engine.

8. Check Generator Charging

Rate.

9. Check Wheel Hub Bolts.

10. Check Hand and Foot Brakes.

11. Check Drive-Master.

12. Road Test

Page 9

HUDSON OWNER’S MANUAL 7

1947 MODELS

MODEL DESIGNATION AND SERIAL NUMBERS

To simplify identification of the various models referred to in this Owner's Manual, model

reference is made to series numbers listed below.

The car serial number which is also the engine number is stamped on a small plate attached to the

right front door hinge pillar post. These serial numbers are based on a system which codes the first

three digits to the series : e.g. 171101 indicates series 171 while 172101 and 173101 indicate

series 172 and 173 respectively. The first three digits remain unchanged regardless of the number

of cars produced. Cars are also numbered consecutively as they leave the production line without

regard to series. As an example, the car built after car serial 171999 would be numbered 1711000,

1721000, 1731000, 1741000 or 1781000, instead of 172000.

The engine number is stamped on the top of the cylinder block between Nos. 1 and 2 exhaust

manifold flanges.

CAUTION: Do not confuse engine number with casting or other numbers appearing at

different locations on engine.

When ordering service parts or corresponding with your dealer always refer to this number.

Also be sure this number corresponds to the one shown on your Owner's Service Policy,

Identification Card, and Car Registration Card.

The car color option code letter is stamped on the upper hinge of the right front door.

LICENSE INFORMATION

HUDSON SUPER SIX MODEL—SERIES 171

5”

5”

5”

5”

5”

5”

5”

4½

4½

4½

4½

4½

A.M.A.

H.P.

Rating

21.6

21.6

21.6

21.6

21.6

21.6

21.6

28.8

28.8

28.8

28.8

28.8

Body Types

4 Door Sedan

Brougham

3 Pass. Coupe

Club Coupe

Convertible

Brougham

4 Door Sedan

Club Coupe

Cab Pick-Up 6 128” 3” 5” 21.6 178101 3110

4 Door Sedan

Club Coupe

4 Door Sedan

Club Coupe

Convertible

Brougham

The above weights include spare tire, tube and wheel, but do not include water, oil

or gasoline.

No. of

Cyls.

HUDSON COMMODORE SIX MODEL—SERIES 172

HUDSON ¾-TON COMMERCIAL MODEL—SERIES 178

HUDSON SUPER EIGHT MODEL—SERIES 173

HUDSON COMMODORE EIGHT MODEL—SERIES 174

Wheel-

base Bore Stroke

6

6

6

6

6

6

6

8

8

8

8

8

121”

121”

121”

121”

121”

121”

121”

121”

121”

121”

121”

121”

3”

3”

3”

3”

3”

3”

3”

3”

3”

3”

3”

3”

Starting

Serial

No.

171101

and

up

172101

and up

173101

and up

174101

and

up

Dry

Weight

Pounds

3110

3055

2975

3040

3220

3175

2090

3260

3210

3330

3260

3435

Page 10

8 HUDSON OWNER’S MANUAL

TECHNICAL INFORMATION

ENGINE

Series No.

171, 172, 178............... 6 3"

173, 174 ..................... 8 3"

Compression Ratio

All Models

Horsepower (Actual)

171, 172, 178....................102 0 4000 R.P.M.

173, 174.........................128 4200 R.P.M.

Main Bearings (Number)

6 cylinder............................................ 3

8 cylinder............................................ 5

Pistons

Material ..........................Aluminum Alloy

Skirt Clearance—

Bottom................................ .0005" to

.001

CARBURETOR AND FUEL SYSTEM

Carburetor

Make .............................................Carter

Series Size Type

171, 172, 178................l" Duplex Down-draft

173, 174.................13/4" Duplex Down-draft

Choke Control

All

Models...............................Automatic

STARTING, LIGHTING AND IGNITION

Make.......................................................................................................................................Auto-Lite

Generator

Type ..................................................................................3rd brush—voltage regulated

Charging Rate—

Cold—All Models.............................................................................................Max.

Hot—All Models...................................................................Max. 38 Amperes

Distributor

Spark Control. Automatic (Additional

vacuum control on 6 cylinder models)

Contact Point Gap

6 cylinder..........................................020"

8 cylinder..........................................017"

Ignition Timing

6 cylinder.............½" on flywheel B.T.D.C.

8 cylinder......................................................T.D.C.

Firing Order

6 cylinder................................l-5-3-6-2-4

8 cylinder..........................1-6-2-5-8-3-7-4

Cyls. Bore

6.

50 to 1

A.M.A. Piston

Stroke H.P. Displacement

21.6 212 cu. in.

4½" 28.8 254 cu. in.

Oil Rings—

Number ...............................................2

Oil Rings-

Upper—Width ...............................3/16"

Oil Rings-

Lower—Width.......................................5/32"

Compression Rings—

Number ...............................................2

Compression Rings—

Width..................................................................3/32"

Camshaft Drive

Type Silent Helical Gears

Manifold Heat Control Type

All Models .......................................Automatic

Air Cleaner

Standard ..........................................Oil wetted

Optional ............................... .Oil bath

44

Amperes

Spark Plugs

Make and .type...Champion Hudson J-9

Size ..........................................14 M.M.

Point Gap......................................................062"

Battery

Make ........................................National

Dimensions-6 cylinder, Length-10½"

Width-7½”

Height-7

8 cylinder, Length-11¾"

Width-7¼"

Height-713/16"

Number of plates

6 cylinder ........................................51

8 cylinder ........................................57

Terminal grounded..........................Positive

-1 3

/16"

Page 11

HUDSON OWNER’S MANUAL 9

Sealed Beam Type

Semi-floating

Helical bevel

LAMP BULB SPECIFICATIONS

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C.

S.C

Volt-

age

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

6-8

Position Mazda No. C.P. Base

Headlamp

Bonnet Lamp

Fender Lamp (with Direction Indicator)

Fender Lamp (without Direction Indicator)

Tail and Stop Lamp

License Lamp

Dome Lamp

Generator and Oil Indicator

Clock

Speedometer—Series 171, 173, 178

Speedometer—Series 172, 174

Radio

Direction Indicator

Headlamp Beam

Ignition Lock

Courtesy Lamp

Fog Lamp

Spot Light

55

1158

63

1154

63

88

51

55

51

55

44

51

51

55

88

121lS

1209S

2

21-3

3

21-3

3

15

1

2

1

2

1

1

1

2

15

50

32

D.C.

D.C.

D.C.

D.C.

CLUTCH

Type

Series

Fluid cushioned, cork-insert disc

Disc Size

171, 172 without Overdrive, Vacumotive Drive, and Hudson Drive Master 9”

171, 172 with Overdrive, Vacumotive Drive, and Hudson Drive-Master,

and all 173, 174 and 178 models 10”

TRANSMISSION

Type

Speeds

Gear Ratios

All Models

288.1 to 1

Synchronized Silent Mesh—All helical gear

3 forward-1 reverse

Low

Second

1.82 to 1

High

1 to 1

Reverse

3.50 to 1

TRANSMISSION OVERDRIVE

Final rear axle ratio when car is equipped with Overdrive—All Series

Actual Axle Ratio In Overdrive

4 5/9 to 1 3.28 to 1

4 1/9 to 1 2.96 to 1

FRONT SUSPENSION

Type

Camber

Caster

Toe-in

Independent Coil Spring

½° to 1½°

½º to 1½º

0 to 1/16"

Type

Gear Type

Gear Ratio:

Standard Ratio

Optional Ratio

Standard Ratio with Overdrive

Optional Ratio wlth Overdrive

Standard Ratio with Hudson Drive-Master

Optional Ratio with Hudson Drive-Master

REAR AXLE

Series

172 172 173 174 178

4 l/9

4 5/9

4 5/9

4 l/9

4 5/9

4 l/9

4 l/9

4 5/9

4 5/9

4 1/9

4 5/9

4 l/9

4 1/9

4 5/9

4 5/9

4 1/9

4 l/9

4 5/9

4 l/9

4 5/9

4 5/9

4 l/9

4 l/9

4 5/9

4 5/9

—

4 5/9

—

4 5/9

—

Page 12

BRAKES

Type

Size:

Series

171, 172

173, 174, 178

Lining Clearance .075" Pedal to Floor Board Clearance ¼"

Mechanical Follow-up Clearance 1¼"

Diameter

10"

11"

STEERING GEAR

Width

1¾"

1¾"

Type

Worm and roller tooth

Gear Ratio

6 cylinder

18.2 to 1 8 cylinder 18.4 to 1

CHASSIS DIMENSIONS

Series

171, 172, 173, 174

178

Wheelbase

121"

128"

Over-all Length—Including

Bumpers

171, 172, 173, 174 207"

178 214"

Over-all Height—Free Height

68¾"

171, 172, 173, 174

Over-all Width—Including

Fenders

Froont—All Models 71"

Rear—All Models 72¾"

Series

171, 173

172, 174

178

Cold Hot

Tire Pressures

Size

6.00" x 16"

6.50" x 16"

6.50" x 15"

7.00" x 15" (Opt.)

26 lbs.

26 lbs.

26 lbs.

26 lbs.

TIRES

6.00" x 16"

6.50" x 15"

6.50" x 16"

Front

29 lbs.

29 lbs.

29 lbs.

29 lbs.

171, 173

172, 174, 178

Turning Radius

171, 172, 173, 174

178

Tread

Front—All Models

Rear—All Models

Size

Series

Road Clearance

Front

Rear

95/8" 83/8"

9¾" 8½"

Cold Rear

Rear

30 lbs.

40 lbs.

30 lbs.

30 lbs.

21’ 1"

21’ 10"

56¼"

59½"

Ply

4

4

6

33 lbs.

44 lbs.

33 lbs.

33 lbs.

Gasoline Tank

All Models

Cooling System

6 cylinder

8 cylinder

Engine Crankcase

6 cylinder—dry

—refill

8 cylinder—dry

—refill

Clutch

All Models

CAPACITIES

U. S.

Measure

16½ gal.

13 qts.

18 qts.

5½ qts.

4½ qts.

9 qts.

7 qts.

1

/3 pint

Imperial

Measure

13¾ gal.

10¾ qts.

15 qts.

4½ qts,

3¾ qts.

9 qts.

7 qts.

¼ pint

Metric

Measure

62½ liters

12½ liters

17 liters

5¼ liters

4¼ liters

8½ liters

6½ liters

160 c.c.

Page 13

Present day sustained high speed driving, fast acceleration, and closer fitting

precision machined parts, place chassis and engine lubrication in the category of a

highly specialized operation. A very definite plan of application is necessary to

provide the various working parts with the right amount of the correct lubricant at

the proper time. Quite contrary to ordinary belief one lubricant will not suffice for all

chassis parts. Varying load demands and peculiarities of operation of the various parts

require different types of lubricants to prevent friction and reduce wear to a minimum.

cation specifications for your car, as well as the definite plan of application. This

is your assurance that the lubrication requirements of your automobile will be met

For your guidance a copy of the Chassis Lubrication Chart is attached to the front

cover of this manual. Another quick reference chart will be found on the left side of

the dash in the engine compartment. Following is a Lubrication Schedule covering

the lubrication requirements from 500 to 10,000 miles. Careful study of these charts

The lubricants placed in your car at the time of assembly are of the finest quality

procurable and NEED NOT be changed until the recommended change period

HUDSON OWNER’S MANUAL 11

Transmission

Without Overdrive

With Overdrive

Rear Axle

All Models

Shock Absorbers

All Models

U. S.

Measuure

2 lbs.

3¼ lbs.

2½ lbs.

Front Rear

3¾ oz. (112 c.c.) 6¼ oz (187 c.c.)

Imperial

Measure

2 lbs

3¼ lbs

2¾ lbs.

Metric

Measure

.91 kgs.

1.47 kgs.

1.24 kgs.

LUBRICATION

Your Authorized Hudson Dealer has been provided with the correct factory lubri-

with the greatest care. Be sure to consult him on this most important matter.

and the schedule is recommended.

shown in the Lubrication Schedule has been reached.

LUBRICATIONS SCHEDULE

AT 500 MILES

See "The Proper Engine Oil to Use," page 14.

l,000 MILES

Upper Support Arm Eccentric Bushing..............Viscous Chassis Lubricant2 fittings

Upper Support Arm Pivot Bushing.................... Viscous Chassis Lubricant 4 fittings

Lower Support Arm to Support Pivot

Bushing ............................................................ Viscous Chassis Lubricant 2 fittings

Lower Support Arm Pivot Bushing................... Viscous Chassis Lubricant 4 fittings

Spindle Pivot Pin.................................................. Viscous Chassis Lubricant 2 fittings

Tie Rod End......................................................... Viscous Chassis Lubricant 4 fittings

Steering Center Arm Bearings............................ Viscous Chassis Lubricant 1 fitting

Drag Link ............................................................ Viscous Chassis Lubricant 2 fittings

Clutch and Brake Pedal Shaft Bushings............ Viscous Chassis Lubricant 1 fitting

Drive-Master Transfer Key (Opt. Equip.).........Viscous Chassis Lubricant 1 fitting

Page 14

Clutch Throwout Bearing

Universal Joint Spline

Universal Joint Roller Bearing

Rear Spring Rear Shackle Bushing

Water Pump

Viscous Chassis Lubricant 1 fitting

Viscous Chassis Lubricant 1 fitting

Viscous Chassis Lubricant 2 fittings

Viscous Chassis Lubricant 4 fittings

Aluminum Soap Base Grease 1 fitting or other water-resistant grease

Distributor-6 cylinder

Engine

Battery

Radiator

*Transmission

*Rear Axle

Steering Gear

Brake Master Cylinder

Front Door Hinge Pins

Water Pump Grease Turn grease cup 1

turn

Check Oil Level

Add water if less than % inch above plates

Check Water Level or Anti-Freeze

Check level and add lubricant if necessary

Cheek level and add lubricant if necessary

Check level and add lubricant if necessary

Check level and add fluid if necessary

Light Engine Oil Hole in each lower

hinge

Door Dovetail and Striker

Light Engine Oil Two places each

door

Front Door tipper and Rear Door Lower

Hinge Tension Springs

Striker Pawls

Water Pump Grease. Apply by hand

Pencil lubricant. Coat lightly

2,000 MILES

Perform operations listed under 1,000-mile lubrication in addition to the following:

Engine

See "Proper Oil to

Drain and Refill

Use"—page 14

Generator

Starting Motor

Distributor-6 and 8 cylinder

Distributor-6 cylinder

Light Engine Oil

Light Engine Oil

Water Pump

Grease

Light Engine Oil

2 cups

2 cups

Cam lobes

Contact arm pivot

and wick in top

of rotor shaft

Distributor-8 cylinder

Light Engine Oil

Oil cup, contact arm

pivot and wick in

Throttle Linkage

Bonnet Support and Lock Shaft

Brake Operating Linkage

Carburetor Air Cleaner

•Drive-Master Linkage

•Vacumotive Drive Linkage

Light Engine Oil

Light Engine Oil

Light Engine Oil

Engine Oil

Light Engine Oil

Light Engine Oil

top of rotor shaft

All joints

All joints

All joints

Clean and re-oil

All joints

All joints

5,000 MILES

Perform the operations listed under 1,000 and 2,000-mile lubrication (except change

engine oil) in addition to the following:

Rear Brake Cables Viscous Chassis Lubricant Coat Cables

Distributor-6 cylinder Water Pump Grease Fill Cup

Oil Filter Replace Cartridge

Drain and Refill These Units:

Transmission S.A.E. 90 E.P. Summer 2 lbs.—with

S.A.E. 80 E.P. Winter overdrive 3% lbs.

Rear Axle S.A.E. 90 E.P. Summer and Winter 2¾ lbs.

Clutch Hudsonite

1

/3 pint

• Optional equipment.

Page 15

*Important: When checking transmission and rear axle oil level care should

be taken that the oil foam has subsided. If the car has been run for any length

of time it should be permitted to stand long enough to allow the oil to reach

The S.A.E. 90 E.P. and S.A.E. 80 E.P. gear oils specified should be of a mild extreme

pressure, non-corrosive type. When adding lubricant to or refilling the transmission or

Special "break-in" oils or compounds are not necessary in Hudson engines. Your

decision to use them should be based on the manufacturer's assurance that they contain

The capacity of the oil reservoir in SIX cylinder engines is five and one-half

quarts ; in EIGHT cylinder engines nine quarts. When oil is drained in the

conventional manner, refill SIX cylinder engines with four and one-half quarts of

When the oil reservoir is removed for cleaning, pour one and one-half quarts of oil

into the upper tray of SIX cylinder engines before the reservoir is reassembled.

Then pour the additional four quarts through the oil filler hole. On EIGHT

cylinder engines pour two quarts of oil into the upper tray before reassembling it

It is not unusual to add oil between change periods. Its rate of usage is governed

by the individual engine and is dependent on operating speeds, temperatures,

HUDSON OWNER’S MANUAL 13

Perform the operations listed under 1,000, 2,000 and 5,000-mile lubrication in addition to

Front Wheel Bearings Milled Sodium Base 4 ounces per wheel

Lubricant

Rear Wheel Bearings Milled Sodium Base 1½ ounces per

Lubricant wheel

Spring Covers Viscous Chassis Lubricant

Vacumotive Drive Cylinder Hudson Shock Absorber 1 ounce

(Optional Equipment) Fluid

Drive-Master Cylinder Hudson Shock Absorber 1 ounce

(Optional Equipment) Fluid

10,000 MILES

the following:

its actual level before checking.

rear axle be sure the lubricants used meet these requirements for satisfactory operation.

BREAK-IN OILS NOT REQUIRED

no harmful ingredients.

CRANKCASE CAPACITIES

oil and EIGHT cylinder engines with seven quarts.

to the engine and pour the additional seven quarts in through the oil filler hole.

CHECKING ENGINE OIL LEVEL

viscosity of oil used, etc.

The level should be checked each time f uel is added. The oil gauge, illustrated in

Page 16

placed in the engine at the factory.

14 HUDSON OWNER’S MANUAL

Fig. 1, is located on the left side of the

engine. It is divided off at the lower end

into two divisions — Oil Level Range and

Low.

For normal operation the oil level is

satisfactory when it is within the Oil Level

Range. For high speed operation the level

should be maintained at the full mark, that

is the top line on the Oil Level Range.

To make an accurate check of the oil

level it is best to wait a minute or two after

the engine has been shut off to permit the

oil on the engine parts to drain back into the

reservoir.

Two and one-half quarts of oil are required

Figure 1

to restore the level from low to full in both six and eight cylinder engines. If the level

is low, and the speedometer reading indicates that the oil change period is near at

hand, it is more economical to have the oil changed.

WHEN TO CHANGE ENGINE OIL

During the first 500 miles of driving it is satisfactory to use the oil which was

Thereafter at intervals of 2,000 miles the oil reservoir should be drained and

refilled with the proper grade of oil. If the car is operated constantly in dusty areas or

for short distances at slow speeds in the winter, which permits foreign matter to

accumulate in the oil and contaminate it, the oil should be changed more frequently.

The actual change period, however, depends largely on the individual circumstances.

To drain the oil remove the plug at the rear of the oil reservoir. Always drain the

oil when it is warm as it will then flow more freely.

It is good practice to remove the oil reservoir at least twice a year, preferably in

the fall and spring, to permit cleaning the screens and removing all traces of sludge

which may have accumulated in the lower pan.

Caution: When flushing oils or compounds are used in the engine, it is important

to remove the oil reservoir and thoroughly clean it out before installing the new oil.

THE PROPER ENGINE OIL TO USE

There are two important factors to consider when buying engine oil. The first is

the selection of a well-known, dependable brand. There are many good, well-bodied,

long-lived oils on the market and your selection should be based on the reputation of

the refiner or marketer. He is responsible for the quality of his product and his

reputation is the car owner's best indication of quality.

Page 17

The first requisite is closely related to the

second factor, in that the oil should have the

ability to flow at low temperatures, to permit

easy starting, and at the same time afford ade-

quate lubrication when the engine reaches nor-

mal operating temperatures. The oil used should

be based on its ability to perform these two

functions at the lowest anticipated temperatures

expected before the next oil change period. See

The following table will he helpful in making

Note: Kerosene should be added only when

HUDSON OWNER’S MANUAL 15

S.A.E. 20

20 W

10 W

10 W, plus 10%

Fig. 2.

this selection :

Use

Use 90° Average temperature S.A.E. 30

Minimum anticipated

temperatures

32°

10°

—10°

Below —10°

kerosene.

temperatures below minus 10° are expected for long periods

Your Authorized Hudson Dealer, who has had

long experience with the brands of oils available

in your locality, will be glad to help you with

your lubrication problems

OIL FILTER

A Hudson Oil Filter, see Fig. 3, which aids in

removing foreign matter and impurities under

low pressure, and at the same time maintains a

normal flow of oil through the engine is available

through your Authorized Hudson Dealer. This

filter will keep the oil cleaner for longer periods

and help minimize wear on engine parts.

The cartridge should be replaced every 5,000

to 6,000 miles or whenever the oil shows definite

signs of becoming cloudy. Replacement cartridges should be secured from your Authorized

Hudson Dealer

Figure 3

Page 18

16 HUDSON OWNER’S MANUAL

prevent damage to it and avoid oil leaks.

prevent twisting the hose.

period.

present day automobile are self-evident to the driver, nevertheless a review of their

purposes and operation, and a full knowledge of the newer controls before driving your

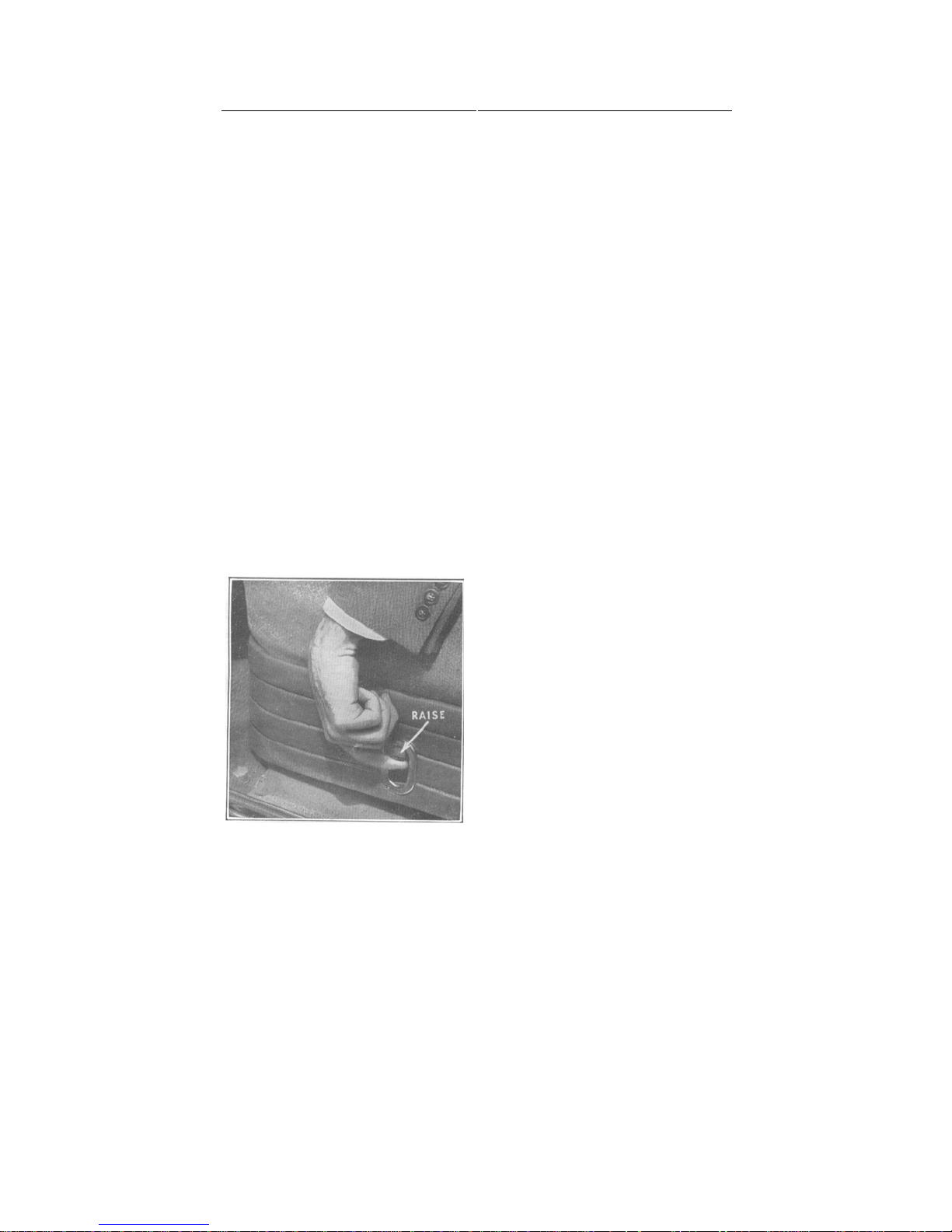

SEAT ADJUSTING LEVER is located

on the left side of the seat to secure fore

and aft movement of the seat for greater

comfort. On long drives, periodically

changing the seat position will prove

restful. The small knob shown in Fig. 4,

is raised with the finger to unlock the

seat. Simply releasing the knob locks it

ACCELERATOR PEDAL (A), Fig. 5,

controls the speed of the car. Never

pump the accelerator when starting the

engine as it will result in flooding. When

starting a cold engine, the accelerator

pedal should be pressed down one-half

1Replace the cartridge by turning the handle on the cover in a counterclockwise direction.

Lift out the old cartridge and replace it with the new one. Be sure to use the new cover

gasket furnished with the cartridge. The gasket must set squarely on the filter body to

Note : Whenever tightening hose connections be sure to

use two

wrenches to

It is also good policy to change the engine oil at this time. Using new oil with the new

cartridge will help keep the oil cleaner for a longer

CRANKCASE VENTILATION

Diluents, consisting mainly of water resulting from condensation and unburned gasoline,

contaminate the engine oil. If these diluents were permitted to remain in the engine oil for

any length of time, early deterioration of parts would result.

In the Hudson engine a ventilating system is provided whereby the diluents are drawn

out of the crankcase by vacuum through ventilator tubes on the right side of the engine.

The violent agitation of the oil by the connecting rod dippers tends to vaporize the water,

unburned fuel and other harmful diluents, allowing them to be withdrawn from the

engine by the vacuum created when the car is in motion.

OPERATING CONTROLS

From year to year new devices are introduced by the automobile industry to make

driving easier, safer, and to provide more comfort. While many of the controls on the

new Hudson will be helpful. It is, therefore, recommended that you carefully read these

instructions.

Figure 4

in position.

way and released slowly. With a warm

Page 19

HUDSON OWNER’S MANUAL 17

quarter to one-half way and hold in this

position when cranking. On cars equipped

with Hudson Drive-Master, Overdrive, or

Vacumotive Drive the accelerator pedal is

used to engage or disengage the clutch for

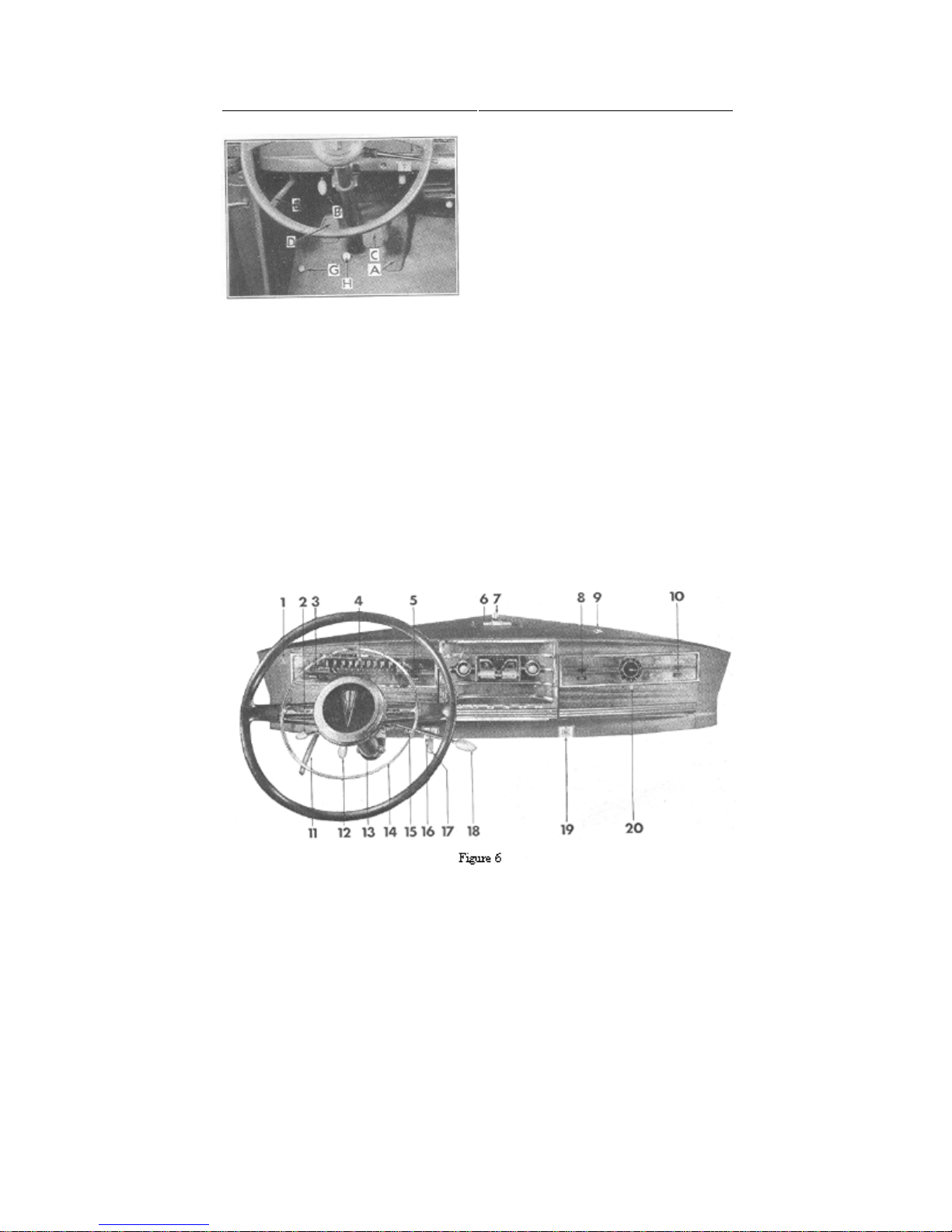

ASH RECEIVER (6), Fig. 6, may be

BONNET LOCKING HANDLE (12),

Fig. 6, should be pushed fully forward to

unlock the bonnet. Pull handle back all the

BRAKE PEDAL (C), Fig. 5, hydraulically operates brakes on all wheels. In event

of disablement of the hydraulic system, continued pressure on the pedal automatically

CLOCK (20), Fig. 6. Mechanical clock requires winding every day. Turn knob

clockwise to wind. Pull knob out to reset. Electric clock requires no attention. Fuse is

CLUTCH PEDAL (D), Fig. 5, should be depressed fully to floor board when

shifting gears. The clutch pedal must be depressed before pressing the starter button

or the starter will not operate on cars equipped with Hudson Drive-Master. When

starting the engine, particularly when it is cold, depressing the clutch pedal manually

will disconnect the load of the transmission from the starting motor and facilitate

engine, depress the accelerator pedal one-

gear shifting.

opened by lifting the knob.

Figure 5

way to lock it.

applies the brakes on the rear wheels mechanically.

located in back of clock. Pull out knob to reset.

starting.

Page 20

COURTESY LAMPS, at bottom of door lock pillar, are standard on Series 172 and

174. These lamps are lighted by switches operated by the doors when they are opened, day or

COWL VENTILATOR HANDLE (17), Fig. 6, should be pushed forward to open

DIRECTION INDICATOR (2) is optional on all models. Push lever up for right

turn and push it down for left turn. Lever returns to off position automatically when

turn is completed. Pilot light (1) on instrument panel flashes with front and rear indicator

DRIVE-MASTER (optional equipment) control switch. Pressing in "HDM" button

permits operation with Hudson Drive-Master. Pressing in "VAC" button permits

power clutch operation with conventional gear shifting. Pressing in "OFF" button

permits conventional operation of clutch and gear shifting. For more complete details, see

page 51. Control buttons are located at lower center on face of panel.

FRONT DOME LAMP SWITCH (Series 172 and 174) is of the sliding type located

FUEL GAUGE (3) indicates the fuel level in the gasoline tank when the ignition is

turned on. When needle reaches empty mark, approximately 2 gallons of fuel remains in

GENERATOR CHARGING INDICATOR (10) shows red when ignition is turned

on or when engine is idling at low speed. Light should go out as speed is increased. If

difficulty is encountered in the electrical system or generator is not charging, the light will

either flash or stay on as a warning. Have the electrical system checked by your nearest

HAND BRAKE HANDLE (11), Fig. 6, should be applied by pulling straight back

and at the same time depressing the brake pedal. Release by turning 1/4 turn to right

HEADLAMP BEAM INDICATOR (4), Fig. 6, shows red when heal lamp beam

HEADLAMP FOOT SWITCH (G), Fig. 5, controls country (upper) and traffic

(lower) beams. When meeting oncoming traffic and headlamp beam indicator shows red,

depress foot switch once and release for lower beam. Pressing switch the second time restores

HORN BUTTON RING (14), Fig. 6 (Opt. equipment on Series 171, 173, and 178 ;

LIGHTING SWITCH (19) controls instrument lights, headlamps, bonnet lights,

fender lamps, tail and license lamps. Pressing button once and releasing it turns on

instrument lights, bonnet light, fender lamps, when used, tail and license lamps. Second

position of button turns on headlamps in addition to other lamps previously lighted.

18 HUDSON OWNER’S MANUAL

night.

ventilator and pulled back to close it.

signals.

DOOR LOCKS—see page 63.

at bottom of instrument panel on right side.

reserve.

Authorized Hudson Dealer.

and pushing downward as far as it will go.

is in upper or country driving position.

beam to upper position.

std. on Series 172 and 174). Press down from any position to operate horns.

IGNITION SWITCH (15) key should be turned to the right to turn ignition "on."

Pressing the button the third time turns off all lights.

Page 21

HUDSON OWNER’S MANUAL 19

LOCKER BOX LOCK (9) is opened by pressing down to open door. Lock by inserting

OIL PRESSURE INDICATOR (8) shows red when ignition is turned on and engine is

not running. Light should go out when engine is started. Should the light flash or stay on when

the engine is running it indicates lack of oil in the reservoir, or some derangement of the

OVERDRIVE CONTROL KNOB (Opt. equipment). Push knob in for overdrive

operation and pull it out for conventional driving. See page 49 for more complete details.

RADIO FOOT SWITCH (H), Figure 5, (optional equipment). Press lightly to reduce

RHEOSTAT (13), Figure 6, located at bottom of instrument panel, is standard on Series

172 and 174. It controls the brilliancy of instrument lights. Turning knob to right decreases

SPEEDOMETER MILEAGE INDICATOR shows accumulated mileage. It is

STARTER SWITCH BUTTON (16) must be pressed in to operate starting motor.

The clutch pedal must be depressed before pressing the starter button or the starter will not

operate on cars equipped with Hudson Drive-Master. Do not press button when

engine is running, or car is in gear. Switch will not operate unless ignition is turned on.

TRANSMISSION CONTROL LEVER (Handy Shift), Fig. 7, should always be

placed in neutral position before starting en-

perature of cooling fluid only when ignition

tional to automatic clutch operation press the "VAC" button located at lower center on face

oughly to be sure that all adjustments were in order ; that all lubrication fittings and units

key and turning it 1/4 turn counter-clockwise.

oiling system. Engine should be stopped at once and source of difficulty determined.

volume and press hard to change station.

light and turning it to the left increases brilliancy. Extreme left position turns out instrument lights.

located below the speedometer.

gine. For cars with Hudson Drive-

Master, see page 51. Raise knob and

move it forward for reverse gear and rearward for low gear. Move to neutral, depress

and slide it forward for second gear and

rearward for high gear.

WA T E R T E M PE R A TU R E

GAUGE (5), Fig. 6, indicates tem-

is turned on. Needle returns to "H" position

at right side of dial when ignition is turned

oil.

Figure 7

WINDSHIELD WIPER KNOB (7)

should be turned to the left to operate wipers.

VACUMOTIVE DRIVE CONTROL (optional equipment). To change from conven-

of panel. Revert to conventional by pressing the "OFF" button. Refer also to page 46.

DRIVING YOUR NEW CAR

Before your new Hudson automobile was delivered to you, your Dealer checked it over thor-

of the car were properly lubricated ; that the cooling system was filled to the proper

Page 22

At the time your car was built, a speed governor was installed on the carburetor and sealed

to restrict top speed and fast acceleration during the initial break-in period. This governor

When the speedometer indicates 500 miles, the car should be returned to your Dealer to

have the governor removed. There is no charge for this service. At this time the engine oil

should be changed, as car speeds will be increased from this point and it is good practice

Although the governor has been removed it does not necessarily mean that the bars

should be let down on car speed. The first 500 miles is commonly called the initial

break-in period. Until the car has been driven at least another 1,000 miles it should be

driven at moderate speeds to give the close fitting, precision machined working parts an

opportunity to assume smooth operating surfaces. The following table will be helpful in

All models are fitted with automatic choke type carburetors. The automatic choke

proportions the correct mixture of air and gasoline for starting and warm-up period.

NOTE : The clutch pedal must be depressed before pressing the starter button or the

starter will not operate on cars equipped with Hudson Drive-Master.

Before starting the engine be sure the Handy Shift transmission control lever is placed

in neutral position (this applies to all models). Depress clutch pedal to release load of

transmission. Turn on ignition switch. If engine is completely cold from standing for

several hours or overnight, depress the accelerator pedal at least half way and release

slowly. Then press starter button. Depressing the accelerator pedal in this manner places

the throttle in proper position for cold starting. This will result in a higher than normal

engine idle speed. Depressing the accelerator pedal again slightly and releasing it will

permit the engine to run at the normal high idle speed to prevent stalling during the warm-up.

Do not allow the engine to run continuously at the starting speeds as it will load up and

stall if left for a minute or two.

If the engine is warm from previous running and has not been standing long enough to

become completely cold, depress the accelerator pedal one-quarter to one-half way and hold

20 HUDSON OWNER’S MANUAL

level, and that the tires were inflated to the proper pressures.

causes a slight increase in carburetor intake noise as long as it is in place.

to have clean, fresh oil in the engine.

guiding you as to the highest speeds that should be attained.

0— 250 Miles—Do not exceed 40 miles per hour in high gear.

250— 500 Miles—Do not exceed 50 miles per hour in high gear.

500— 1000 Miles—Do not exceed 60 miles per hour in high gear.

STARTING THE ENGINE

in this position while cranking. Then press starter button.

Should the engine fail to start when following these instructions, it may be due to-

1. Improper engine tune-up.

2. In cold weather, improper lubricants.

3. A combination of 1 and 2.

Page 23

REAR COMPARTMENT DOOR—To safeguard the spare tire, tools,

and any luggage that you may be carrying, always lock the rear compartment

HUDSON OWNER’S MANUAL 21

In such an event it is recommended that you consult your Authorized Hudson Dealer.

CARBON MONOXIDE GAS

CARBON MONOXIDE, A DEADLY, COLORLESS, ODORLESS

GAS IS ALWAYS PRESENT IN THE EXHAUST OF THE INTERNAL COMBUSTION ENGINE. GARAGE DOORS SHOULD

ALWAYS BE FULLY OPENED WHEN STARTING OR RUNNING

THE ENGINE.

LOCKING YOUR CAR

When your car was delivered to you it was provided with two sets of keys. The

keys with round handles fit the ignition and both front door outside locks. The keys

with the octagonal shaped handles fit the locker box door and rear compartment

locks.

All keys are numbered and these numbers should be registered on your Ownership Card

as well as some other suitable place where they will be available should the keys become

lost. As insurance regulations prohibit the stamping of key numbers on lock cylinders, misplaced or lost keys can be obtained from your Hudson Dealer only by

referring to key change number.

Many cars are driven away by unscrupulous persons simply because the ignition

key was left in the lock. Make it a practice to remove the key from the lock if the

car is to be left unattended even for only a few minutes. This is also assurance

against accidentally locking yourself out of the car.

DOOR LOCKS—All doors can be locked from the inside by pulling up on the rubber

knob (B) protruding from the door finish

moulding, see Fig. 8. To unlock the door

press down the knob. Both the right and left

front doors may be locked or unlocked

from the outside with the ignition switch

key. Turning the key one-quarter turn in a

clockwise rotation and back to the starting

position locks the door. To unlock, turn the

key one-quarter turn in counter-clock-

wise rotation and then back to starting

position.

LOCKER BOX DOOR—To lock the

Figure 8

door turn key one-quarter turn clockwise and

remove key. To unlock it turn key onequarter turn counter-clockwise and remove

key.

When door is unlocked it can be opened by pressing down on lock cylinder face.

Page 24

22 HUDSON OWNER’S MANUAL

handle. Turning the key one-half turn clockwise unlocks the lock. To lock it turn

the key one-half turn in counter-clockwise rotation.

To open the rear compartment door grasp the handle and turn it to the right. To

prevent damaging the lock be sure the handle is held to the extreme right when closing

the door.

LOCKING THE BONNET

The bonnet on your car is designed to

prevent it from being blown open if the

locking handle is accidentally left unlocked, and to prevent the engine parts and

accessories being tampered with when

locked.

To raise the bonnet first unlock it by

pushing forward on handle, Fig. 9. Then

grasp the bonnet upper moulding at the

rear end and raise the bonnet. Strong,

self-locking supports hold the bonnet it’s

raised position.

To lower the bonnet, pull it

Figure 9

downward and then draw the handle back and nap it into place.

TIRES

INFLATION PRESSURES

Maintaining proper tire pressures is important in obtaining maximum tire life,

proper car handling, and best riding qualities.

Because tires get hot due to frictional contact with the road surface and internal

friction within the tire, tire pressures will increase as much as three to four pounds.

As it is hard to check and maintain proper pressures when tires are hot, always make

it a point to check and inflate them when they are cold. Both cold and hot pressures are

given. Cold pressures should be used when the car has only been driven a few

blocks to the service station. Hot pressures should be used when the car has been

driven at high speed and if the tires are warm to the hand.

Ordinarily tire pressures should be checked at least once a week. However, when

touring, or if the car is driven extensively, they should be checked every morning

before starting out.

Tire valve caps should be finger tight to prevent loss of air which may be escaping

from a leaky valve and also preclude the possibility of dust and dirt getting into

the valve. Replace missing valve caps promptly.

Recommended tire pressures are as follows :

Front Rear

Size Cold Hot Cold Hot

6.00" x 16"

6.50" x 16"

6.50" x 15"

7.00" x 15" (Opt.)

26 lbs.

26 lbs.

26 lbs.

26 lbs.

29 lbs.

29 lbs.

29 lbs.

29 lbs.

30 lbs.

40 lbs.

30 lbs.

30 lbs.

33 lbs.

44 lbs.

33 lbs.

33 lbs.

Page 25

HUDSON OWNER’S MANUAL 23

MINIMIZING TIRE WEAR

To obtain maximum tire life it is good practice to

change tire positions at intervals of from 2,500 to 3,000

miles. This involves placing the left front tire and wheel

assembly on the left rear hub, moving the right front

assembly to the spare wheel carrier, right rear to left

front, left rear to the right front and the spare to the

right rear hub. Switching the tires in this manner changes

their direction of rotation and equalizes the tread wear over

5 tires instead of 4.

TIRE AND WHEEL BALANCE

Proper tire and wheel balance is essential to prevent

low speed thumping and high speed wheel tramp, both of

which contribute to poor handling, certain riding discomforts and excessive

wear of front end parts. Tires and tubes are balanced at the time of assembly

at the factory. The balancing marks are indicated on the tire by a small red

mark. Whenever a tire is removed from the wheel it should always be reinstalled

with the red mark aligned with the valve stem.

Although tires and wheels are balanced when they leave the factory, subsequent

tire wear causes them to go out of balance. To maintain proper balance and

assist in prolonging tire life, it is the tire manufacturers' recommendation that

the wheel and tire assemblies be checked for balance every 2,500 miles and

whenever a tire ha repaired or recapped. Your Authorized Hudson Dealer has the

necessary equipment to perform this work.

DISMOUNTING AND REMOUNTING TIRES

TO DISMOUNT—Deflate the tube completely. Stand on the tire with both feet

to force the bead away from the rim. Push the valve stem back into the tire. With

two tire tools inserted about eight inches apart between the bead and the rim,

raise the bead over the rim. Be careful not to pinch the tube with the tools. With

one tool in position, move the other tool around the rim and remove the remainder

of the bead. Then remove the tube.

Stand wheel in upright position with inner bead in rim well. Apply liquid soap

around both sides of rim. Insert both tire tools between bead and rim and pry tire

out of rim.

TO REMOUNT TIRE—Coat both beads of tire with liquid soap to help

slide them over the rim. Inflate tube just enough to round it out, then insert it

in the tire, placing the valve stem directly in line with the red balancing mark

on the tire. Place the tire on the wheel, carefully guiding valve stem into the hole

in the rim. Push the inner bead over the rim and into well at valve stem and force

balance of bead over the rim. It may be necessary to force a small remaining

portion of the bead over the rim with the tire tool.

Insert the tire tool between outer bead and rim at a point opposite

the valve stem and work bead over the rim. Leave tool in place and work

Page 26

Engage the lifting lug of the jack on the bottom of bumper bar and between the

24 HUDSON OWNER’S MANUAL

other tool around bead and force remainder of the bead over the rim. Be careful not

to damage the tube with the tool.

Inflate tire slowly, carefully checking beads to see that they both are seating properly

on the rim. The tire may be centered by bouncing it a few times. Inflate tire to

recommended pressure.

TOOL KIT

The tool kit is stored in the rear compartment. It contains a wheel hub bolt wrench,

which can also be used as a jack wrench or as a jack handle, pliers, screw driver, and a

ratchet type or a screw type bumper jack and base. Cab Pickup models are provided

with an axle lift type jack with handle extension.

SPARE TIRE AND WHEEL

To remove the spare tire and wheel mounted in the well in the rear compartment,

take out the clamp bolt and clamp, using the wheel hub bolt wrench. Tilt the top of

the tire slightly to the left and remove it from the well.

On models on which the spare tire and wheel is mounted on the partition board, behind

the front seat, remove the clamp bolt and clamp, using the wheel hub bolt wrench and roll

the tire out of the body.

USING THE BUMPER JACK

Set the parking brake securely and apply blocks at wheels to prevent any movement

of car. The jack should be placed on a level and solid place with lifting shaft as near

vertical as possible.

The lift on the bumper must be from the point where it is mounted to the frame and

amply strong to carry the car weight. Figure 10 shows the correct position of jack at

the front or rear bumper.

inner and outer mounting bar bolts on bumper

bar. CAUTION : Do not attempt to engage

jack or raise the car from the ends of bumpers.

Raise the car sufficiently to lift the tire off

the ground by using the crank shaped hub bolt

socket wrench as a handle for the ratchet type

bumper jack.

USING THE AXLE JACK

The axle lift jack should be placed under

the front suspension control arm as near to the

wheel as possible. The rear end is raised by placing the jack under the rear spring pad. Raise

the jack by placing the crank extension in the jack

and rotating the extension clockwise with the

hub bolt wrench.

Figure 10

Page 27

HUDSON OWNER’S MANUAL 25

CHANGING THE WHEEL AND TIRE

Before raising the car, remove the hub cap with a screw driver and with the hub

bolt wrench (jack wrench) loosen the hub bolts one turn. Raise the car sufficiently to

clear the ground and then remove all hub bolts and take off tire and wheel.

When installing the spare, be sure the pilot stud in the hub is in the top position, then

slide wheel onto hub using pilot stud as a guide. After wheel has been installed and car

lowered, again check tightness of hub bolts and replace hub cap.

ENGINES

THE ENGINES used in six and eight cylinder Hudson cars are of "L" head type,

designed for maximum efficiency and smoothness of operation. Live rubber cushions

are used at both front corners and at the rear center of the engine to provide flexibility

in the engine mountings. These cushions prevent engine sound or vibrations from being

transmitted to the chassis and body.

THE CRANKCASE AND CYLINDER BLOCK, cast integrally for maximum rigidity, is of high chrome iron alloy. The use of this hard material permits

seating the valves directly in the block which allows better transfer of heat from the

valve seats. Valve life is accordingly prolonged and frequent valve grinding is unnecessary.

THE PISTONS are of cast aluminum alloy, cam ground and are closely fitted in

smoothly finished cylinders.

PISTON RINGS are of the pinned type, to prevent ring rotation and permit their

maintaining greater efficiency over a longer period of operation.

TWO COMPRESSION RINGS and one oil ring are assembled above the piston

pin and one wiper oil ring is located below the piston pin. The compression rings are

specially processed to promote quick seating and freedom from scuffing.

THE PISTON PINS are of the full floating type, pressed in the diamond bored pin

bosses. Round spring steel lock rings set in grooves in the bosses hold the pins in place.

THE CONNECTING RODS are of drop-forged steel, I-beam construction, shimless type, with lower end bearings of spun bearing alloy. Integral dippers on the lower

ends of the rods passing through the oil troughs serve to circulate the oil, by splash,

throughout the engine.

PISTONS AND CONNECTING RODS are selected for uniform weight to

assure engine balance. They may be removed from the top on six cylinder models and

from the top or bottom on eight cylinder cars.

THE CRANKSHAFT is of heavy drop-forged steel with integral counterweights. It is balanced both statically and dynamically to maintain maximum bearing

life and smoothness of operation. A vibration dampener pressed on and keyed to the

front end of the crankshaft dampens out torsional vibration.

Page 28

pump, a check valve located at the right rear corner of the engine, accessible

pan.

26 HUDSON OWNER’S MANUAL

THE CRANKSHAFT BEARINGS are of the shimless, bronze back, bearing

alloy type. They are attached to the crankcase and caps with brass screws. Three

bearings are used in six cylinder engines and five in eight cylinder engines.

THE CAMSHAFT is of electric furnace alloy, specially processed for maximum life and quiet valve operation.

CAMSHAFT BEARINGS are of the large steel-back, babbitt-lined, replaceable

type. Three bearings are used in six cylinder engines and five in eight cylinder

engines.

VALVE TAPPETS are of the roller cam type and operate in replaceable guides

clamped in the cylinder block. They are adjustable to maintain proper valve

operating clearances.

VALVES. Exhaust valves are of silchrome alloy steel to withstand the high

temperatures encountered. The intake valves are of nickel chromium steel. Both

exhaust and intake valves operate in replaceable guides.

TIMING GEARS are of silent helical tooth design. The camshaft gear is

attached to the front face of the camshaft by three cap screws. The crankshaft gear

is of cast iron and is pressed on and keyed to the front end of the crankshaft.

FLYWHEEL is of highly polished cold rolled steel, closely balanced to assist in

maintaining smooth engine performance. The starter gear is pressed on the flywheel and is replaceable.

VALVE TAPPET ADJUSTMENT

Valve tappets are adjustable to provide correct operating clearances.

Correct valve clearance for six cylinder engine is .010" on intake and .012" on

exhaust. The eight cylinder engine valve clearance is .006" on intake and .008" on

exhaust valves.

Measurement should be made with flat feeler stock of the proper thickness and

with the engine idling at normal operating temperature.

Valve locations, counting from the front, are as follows:

Model Exhaust Intake

6 cylinder l-3-6-7-10-12 2-4-5-8-9-11

8 cylinder l-4-5-8-9-12-13-16 2-3-6-7-10-11-14-15

ENGINE LUBRICATION

The Duo-Flo or double circulating lubrication system is employed in all Hudson

engines. This provides adequate, positive lubrication under all operating conditions.

The system consists of a large capacity, gear driven oscillating plunger oil

external oil lines and an oil reservoir having an upper tray in addition to the storage

When the engine is started the oil pump immediately draws oil from the lower

reservoir and delivers it positively to the front and rear ends of the engine from

whence it is poured into the front and rear troughs of the oil reservoir upper tray.

The action of the connecting rod dippers

Page 29

HUDSON OWNER’S MANUAL 27

Page 30

passing through the oil in the troughs causes it to be violently sprayed against the inside of the

crankcase. The mist thus created heavily coats all working parts, providing them with a

protective film of oil. See Fig. 11. A portion of this oil is caught in channels cast in the side

of the crankcase and is fed by gravity into large reservoirs located directly over the crankshaft

and camshaft bearings. The rotating action of the crankshaft and camshaft draws the oil into the

The overflow of oil from the front and rear troughs toward the center of the engine

provides oil to the adjoining troughs. As this oil reaches the center of the tray it is

returned to the lower reservoir where it is cooled and strained by circulating through a

A pressure pump circulating type cooling system, incorporating thermostatic control, is

Series 171, 172, 173 and 178 use the choke type thermostat which is located in outlet (C),

pump, is equipped with a by-pass type thermo-

pump and back into the cylinder blo ck.

of the drain cock located a I the lower left corner of the radiator, counter-clockwise. To

drain the complete cooling system also remove the pipe plug located at the left rear

corner of the cylinder block. Note: If it becomes necessary to drain the radiator when it

contains anti-freeze and it is desired to save it, a 7/16" inside diameter hose may be fitted

PROPER CARE of the cooling system is highly essential to maintain efficient engine

operation. Rust and scale in the cylinder block is a natural product of water and iron.

Therefore, unless the necessary precautions are taken to prevent this accumulation, which acts as an

insu-

28 HUDSON OWNER’S MANUAL

bearings, affording a constant, positive supply of lubricant.

series of labyrinthian passages and fine mesh screens.

COOLING SYSTEM

used on all Hudson models.

Fig. 12, and prevents circulation of the coolant through the radiator core until such

time as the water reaches a temperature of 150°

to 155°, when the thermostat begins to open.

At 185° the thermostat should be fully opened.

The path of water circulation is as illustrated.

Series 174, which uses a by-pass type water

stat, located in outlet (D ), Fig. 13. This type

thermostat, although restricting water circulation through the radiator core, does permit circulation through the by-pass (C) in the

This t hermostat also begins to open

at 150° to 155° and is fully opened at 185°.

Figure 12

TO DRAIN the radiator only, turn handle

over the end of the drain cock and the loose end placed in a container.

Page 31

HUDSON OWNER’S MANUAL 29

lator, so-called "hot spots" may result

through the inability of the water to cool

the cylinders and the area adjacent to the

valve seats.

The use of Hudson Rust and Corrosion

Inhibitor in the cooling system prior to

adding anti-freeze in the fall and after

draining in the spring will assist to a

large measure in keeping the system clean

and permit efficient circulation. This

product is available through all Authorized Hudson Dealers.

Reverse flushing is an approved method

of removing foreign accumulation from

the radiator core and water jacket in

Figure 12

the cylinder block. As this method requires the use of special equipment, it is recommended that the work be performed

by your Authorized Hudson Dealer.

FAN BELT

The fan belt, Fig. 14, is of the "V" type and drives the water pump and generator through the vibration dampener pulley.

The belt is adjustable by means of a swinging generator mounting. Moving

the generator away from the engine increases the belt tension while moving it

towards the engine decreases its tension. Belt adjustment is correct when it is

possible to depress the belt approximately 3/4", as shown in the illustration.

Page 32

prepar ing for wi nter operation it is

Figure 15

30 HUDSON OWNER’S MANUAL

Adjustment is made by loosening cap screws and nuts (D), (E), and (F).

When proper position has been obtained be sure to tighten screws

and nuts.

WATER PUMP

A six vane impeller packless type water pump, Fig. 15, driven by the fan belt,

is used on all models. No attention, other than periodic lubrication is required.

LUBRICATION — At intervals of 1,000

miles the water pump should be lubricated

through the metered grease fitting, located on

the top of the body, with a high grade

aluminum soap base lubricant, or other suitable water resistant grease.

ANTI-FREEZE

Before installing any anti-freeze when

good practice to always drain and flush the

cooling system to insure unrestricted circulation. Also carefully check all hose and gaskets

for leaks or signs of deterioration.

The use of Hudson Anti-Freeze,

available through all Authorized Hudson

Dealers, is recommended, as it adequately

meets all the requirements of a good, reliable

anti-freeze.

Avoid the use of anti-freeze solutions containing calcium salts, or other

ingredients which promote electrolytic action. Glucose and honey clog the

radiator ; kerosene and fuel oil when hot expel inflammable vapors and,

therefore, solutions containing these ingredients should never be used.

The following anti-freeze table will be helpful in determining the quantity of

anti-freeze required for proper protection :

6-CYLINDER MODELS

Hudson

Anti-Freeze

Temper-

ature U.S. Imp.

+20°

+10°

0°

-10°

-20°

-30°

+20°

+10°

0°

-10°

-20°

-30°

Quarts

2½

3¼

4½

5

5¾

6½

3½

5¼

6¼

7

8

9½

Liters

Metric U.S. Imp.

2½

3¼

3¾

4¾

5½

4½

5¼

6½

2½

3½

4¼

4

4¾

5

6

3

31/

3

5

6

8

6

6½

7½

9

Ethylene Glycol

(Prestone or Equivalent

Quarts

2

3

4

5

5½

6

8-CYLINDER MODELS

3

4½

6

7

7¾

8

1½

2½

3½

4½

4¾

2½

3¾

6-1/

6½

5

5

6

3

Methanol or

Denatured Alcohol

3½

4¼

5¼

6¾

4¾

71/

8½

9½

2

6

3

6

Quarts

3

1½

3

3½

4½

5

5½

2½

4

5

6

7

8

Liters

Metric Qts. Imp

1¾

2¾

3¾

4¾

5

5½

2¾

4¼

5½

6½

7¼

7½

Liters

Metric

1¾

31/

5½

61/

2¾

4½

5½

3

4

5

3

7

8

9

Page 33

HUDSON OWNER’S MANUAL 31

purchased. The lower grades should be avoided in the present day high compression

permit the use of a more advanced spark timing without knock or "pinging." This

permitted.

per hour 43% more fuel is required than at 2'0 miles per hour. At 60 miles per hour 68%

CARBURETOR AND FUEL SYSTEM

FUEL RECOMMENDATIONS

The engine in your Hudson car is designed to give maximum performance and

economy with regular grades of gasoline. One of the most important factors in

getting the most out of the fuels available is correct ignition timing.

Regular grades of gasoline have octane ratings of 72 or higher while Ethyl fuel has

an octane rating of 80 and higher. In the regular brands several grades may be

engines as they tend to cause "pinging" under normal load conditions, which requires

that the spark be retarded for quieter operation. Retarding the spark naturally affects

the performance of the car as well as economy of operation and, therefore, no saving

in operation is obtained. Also avoid the use of fuels which tend to gum up quickly

as they materially affect the operation of the engine.

Premium grades of fuel, such as Ethyl, which have an octane rating of 80 or higher,

will result in improved performance and economy. It should be remembered, however, that these extra advantages cannot be obtained from this type of fuel unless the

spark timing is advanced.

For information on "Ignition Timing" see pages 37 and 39.

FUEL ECONOMY

This subject is probably foremost in the minds of all motorists. We hear

considerable about the results obtained by certain owners which may cause others

to wonder how these claims are substantiated. Unless we understand the conditions

under which these figures were obtained they mean very little to us.

Traffic conditions, the terrain, wind conditions, the driver's characteristics as to

speed, idling at traffic lights and many other factors influence the final results. It

should be understood that the conditions under which maximum results are obtained

by the manufacturer are most ideal. By this we mean the cars are driven under

fixed throttle conditions, they are not interrupted by cross traffic, they are driven

against the wind as well as with the wind and no idling and erratic operation is

High speed operation requires the use of more fuel as evidenced by the following

data compiled on a representative group of cars.

At 20 miles per hour good gasoline mileage can be expected. At 40 miles per

hour approximately 24% more fuel is required than at 20 miles per hour. At 50 miles

more fuel is required than at 20 miles per hour. At 70 miles per hour the percentage of

increase in fuel rises to the point where 98% more is used than at 20 miles per hour.

From these figures it may be clearly seen that as speed increases, wind resistance

becomes greater and fuel economy decreases proportionately.

In the final analysis it is evident that excessive idling, frequent stopping, quick

acceleration and high speed operation have a marked effect on the gasoline mileage

actually obtained.

Page 34

jets in the carburetor.

32 HUDSON OWNER’S MANUAL

Figure 15

CARBURETORS

The carburetors used on all models are of the down-draft, automatic choke type, incorporating vacuum controlled metering rods, anti-percolator valve, accelerating pump, and

fast idle features. A filter screen is also incorporated at the fuel inlet to prevent the

entrance of foreign particles which would otherwise clog the small drilled passages and

All models use a Duplex (double barrel) type carburetor, Fig. 16, incorporating two

metering rods, one for each barrel.

ADJUSTMENTS--There are no adjustments on the carburetor that will affect high

speed operation. Therefore, any servicing the carburetor may require, other than minor

adjustments that affect operation at idle speed only, should be performed by your Authorized

Hudson Dealer who has the special tools and gauges required to service these units.

IDLE MIXTURE ADJUSTMENT—This adjustment is made by turning both idle

adjusting screws (A), Fig. 16. The normal position of these screws is 1/4 to 1 turn off

their seats. To adjust them turn both screws into their seats and then out exactly 3/4 of a turn.

Readjust for smooth idling. Turning the screws in a clockwise direction produces a leaner

mixture and turning them in a counter-clockwise direction results in a richer mixture.

THROTTLE ADJUSTING SCREW (B), Fig. 16, controls the engine idle speed.

This screw should be adjusted to give a speed of 71/2 to 8 miles per hour in high gear.

Note: Before making the Idle Mixture

and Throttle Adjusting Screw Adjustments

be sure the engine has been run, long enough

to reach normal operating temperature.

Never make the adjustments when engine is cold.

If these adjustments do not produce

satisfactory results, the engine may require

an Engine Tune-up and you should consult

your Authorized Hudson Dealer.

AUTOMATIC CHOKE CONTROL

automatically proportions the fuel and air

requirements for both starting and engine

warm-up.

The thermostatic housing spring which is

contained within the thermostat housing (C),

Fig. 16, is calibrated to hold the choke valve

closed at a temperature of 75° F. when it is set at the factory. As the engine warms

up the hot air drawn into the thermostat housing through a stove attached to the

exhaust manifold on 6 cylinder models and through a pipe passing through the

exhaust manifold with the opening below the floor of the manifold on 8 cylinder

Page 35

models causes the thermostatic coil spring to release its tension on the choke valve,

permitting it to open gradually. Thus as the engine temperature increases, the choke

valve gradually opens, resulting in a leaner mixture being fed into the engine to meet

Any service required on the Automatic Choke should be referred to your Authorized

MANIFOLD HEAT CONTROL VALVE on all models is automatic and requires

FILTER SCREEN CAP (D) should be removed and the screen cleaned every

THE OIL WETTED type air cleaner, Fig. 17, is used as standard equipment on all

models. In this type cleaner the wire gauze is oil soaked and as the air passes through it,

HUDSON OWNER’S MANUAL 33

Figure 15

operating requirements.

Hudson Dealer.

no adjustment.

2,000 miles.

CARBURETOR AIR CLEANERS

foreign particles are removed thereby permitting only clean air to enter the carburetor.

At periods of 2,000 miles, or oftener if

local conditions warrant, the filter unit (C)

should be taken out by removing wing nut

(A) and lifting off cover (B). Clean

off old oil and dirt by dipping it in kerosene.

Blow it dry and re-oil by dipping it in engine

oil, using the same grade as used in the en-

gine. Permit excess oil to drain off and

reinstall it in the cleaner.

For unusually dusty areas, or when cars

are driven extensively on dusty roads, the

OIL BATH air cleaner, Fig. 18, should be

used. This is available as an option or may

be installed by your Authorized Hudson

Dealer. In this unit dirt is washed out of the air

by the oil spray created as the incoming air

strikes the oil in the sump.

Every 2,000 miles, or oftener if local conditions warrant, the unit should be removed from

the carburetor and cleaned. Filter unit (E)

should be taken out by removing wing nut

(D). If heavily coated, the filter unit should

be dipped in kerosene and blown dry. Remove all old oil and clean out sump with kerosene. Refill sump with one measured pint

Page 36

clockwise and swing strap "C" to one side.

This permits removal of bowl and screen.

When reassembling parts, carefully inspect

This type of pump, illustrated in Fig. 20, assures steady windshield wiper action under

performance. To restore these units to their highest point of efficiency a Major Engine

Tune-up is recommended at intervals of 5,000 miles. As special equipment and tools are

34 HUDSON OWNER’S MANUAL

Figure 19

Figure 20

of engine oil, using the same grade as used in the engine. Reinstall cleaner on carbure-

tor, being careful not to distort air horn when tightening clamp bolt (B).

FUEL PUMP

At intervals of 2,000 miles or oftener if

conditions warrant, the bowl and screen of

the mechanical pump, illustrated in Fig.

19, should be cleaned.

To remove bowl, turn nut "B" counter-

screen and gasket: replace them if necessary.

COMBINATION FUEL AND VACUUM PUMP

wide open throttle operation when engine vacuum is low.

To clean the gasoline filter screen,

which is recommended every 2,000 miles, remove the lower cap screw (A) and bowl (B).

Before replacing screen (C) and bowl gasket

(D), carefully examine them and renew if

necessary.

The air filter screen should also be cleaned

at 2,000-mile intervals. This is accomplished by

removing top cover screw (E) and cover (F).

Before replacing the screen and cover, carefully examine screen (G) and gasket (H)

and renew if necessary.

ENGINE TUNE-UP IS NECESSARY

In the normal operation of your ca r cer ta i n c h a nges take p l a c e in

ur e 20

the electrical system, carburetor and

Fi g-

engine which gradually decrease efficiency of

the engine and affect gasoline mileage and car

necessary for these operations, your Authorized Hudson Dealer should be consulted.

Page 37

National dealer. If not, this should be done

plates.

HUDSON OWNER’S MANUAL 35

Figure 19

STARTING, LIGHTING and IGNITION

BATTERY

The battery on all models is located in the left front corner of the engine compartment, Fig. 21, where it is easily accessible for

servicing.

A National 51-plate type battery is used in

SIX cylinder cars ; 57- plate type in EIGHT

cylinder cars. The positive post is grounded.