Page 1

Page 2

Page 3

OWNER'S MANUAL

THE GREATER

HUDSON 8

FOR 1932

SERIAL NUMBERS

119" W. B.-930770

126" W. B.- 62884

132" W. B.-250001

AND

UP

HUDSON MOTOR CAR COMPANY

DETROIT, MICHIGAN, U. S. A.

Page 4

Page 5

Foreword

Hudson automobiles are equipped with locks

which have been approved by the Underwriters

Bureau as satisfactory means of preventing theft.

The presence of these locking devices reduces the

insurance rate to the owner, but does not reduce the

possibility of loss by theft unless you LOCK

YOUR CAR.

Protection against loss by damage to the mechanism has been provided in Hudson automobiles by

providing adequate means of lubrication for all

working parts. Although the system of lubrication

used is as positive and complete as any in use

today, its protection depends to a large extent on

how regularly you LUBRICATE YOUR CAR.

This instruction book is intended only as a guide

to the owner in the operation and care of his car

and not as a service manual. Do not attempt adjustments or repairs with which you are not thoroughly

familiar or for which you do not have equipment

to handle properly. Both for periodic inspection

and for adjustments TAKE YOUR CAR TO AN

AUTHORIZED HUDSON SERVICE STATION.

Protect your car when making replacements and

preserve the original performance—USE ONLY

GENUINE HUDSON PARTS.

Page 6

INDEX

General

BREAKING-IN INSTRUCTIONS

CARE OP THE FINISH

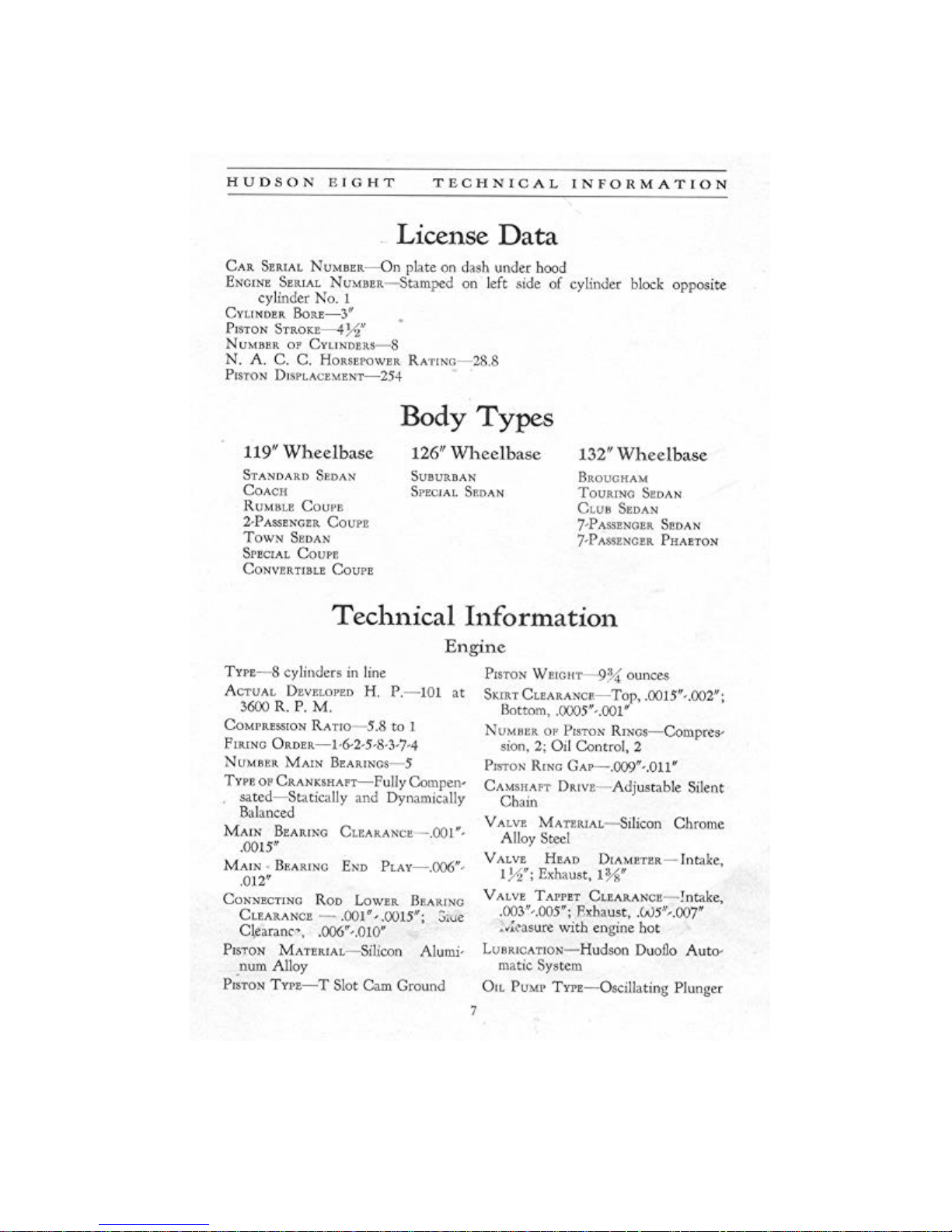

LICENSE DATA AND TECHNICAL INFORMATION

OPERATION

STARTING THE ENGINE

WARRANTY

Lubrication

BRAKE CROSS SHAFT

CHASSIS LUBRICATION CHART

CLUTCH

DISTRIBUTOR

DOOR DOVETAILS

DOOR LOCKS

ENGINE

FRONT WHEEL BEARINGS

GENERATOR

HOOD LEDGE LACINGS

HOOD LOCKS

REAR AXLE

REAR WHEEL BEARINGS

STARTING MOTOR

STEERING GEAR

THROTTLE CONTROL RODS AND LEVERS

TRANSMISSION

UNIVERSAL JOINTS

WATER PUMP

Page

13

35

7

10

12

6

23

14

17

16

23

23

15

21

16

23

23

21

22

17

22

23

20

20

16

Adjustment

ADJUST DISTRIBUTOR POINTS

BATTERY

BRAKES

CARBURETOR

CLUTCH PEDAL ADJUSTMENT

DISTRIBUTOR

FAN AND WATER PUMP

FRONT WHEEL ALIGNMENT

FRONT WHEEL BEARINGS

HEADLAMPS

IGNITION TIMING

RADIATOR

REAR WHEEL BEARINGS

SHOCK ABSORBERS

SPARK PLUGS

SPRING MOUNTINGS

STEERING GEAR

SYNCHRONIZE BREAKER POINTS

TAPPETS

TIMING CHAIN

TIRES

VACUUM TANK

WHEELS-REMOVAL AND INSTALLATION

WIRING DIAGRAM

24

29

32

27

28

24

27

32

30

35

24

34

30

34

25

33

29

25

26

26

31

28

31

18.19

Page 7

Warranty

"We warrant each new passenger automobile manufactured by us to be free from defects in material and

work- manship under normal use and service, our obligation under this warranty being limited to making good at

our factory any part or parts thereof, including all equipment or trade accessories (except tires) supplied by the

Car Manufacturer, which shall, within ninety (90) days

after making delivery of such vehicle to the original

purchaser or bfore such vehicle has been driven 4000

miles, whichever event shall first occur, be returned to us

with transportation charges prepaid, and which our examination shall disclose to our satisfaction to have been thus

defective, this warranty being expressly in lieu of all other

warranties expressed or implied and of all other obligations or liabilities on our part, and we neither assume nor

authorize any other person to assume for us any liability

in connection with the sale of our vehicles.

"This warranty shall not apply to any vehicle

which shall have been repaired or altered by other than

an authorized Hudson and Essex Distributor or Dealer

in any way so as, in the judgment of the Manufacturer,

to affect its stability or reliability nor which has been

subject to misuse, negligence or accident."

HUDSON MOTOR CAR COMPANY

Detroit, Michigan, U. S. A.

Page 8

Page 9

Page 10

Page 11

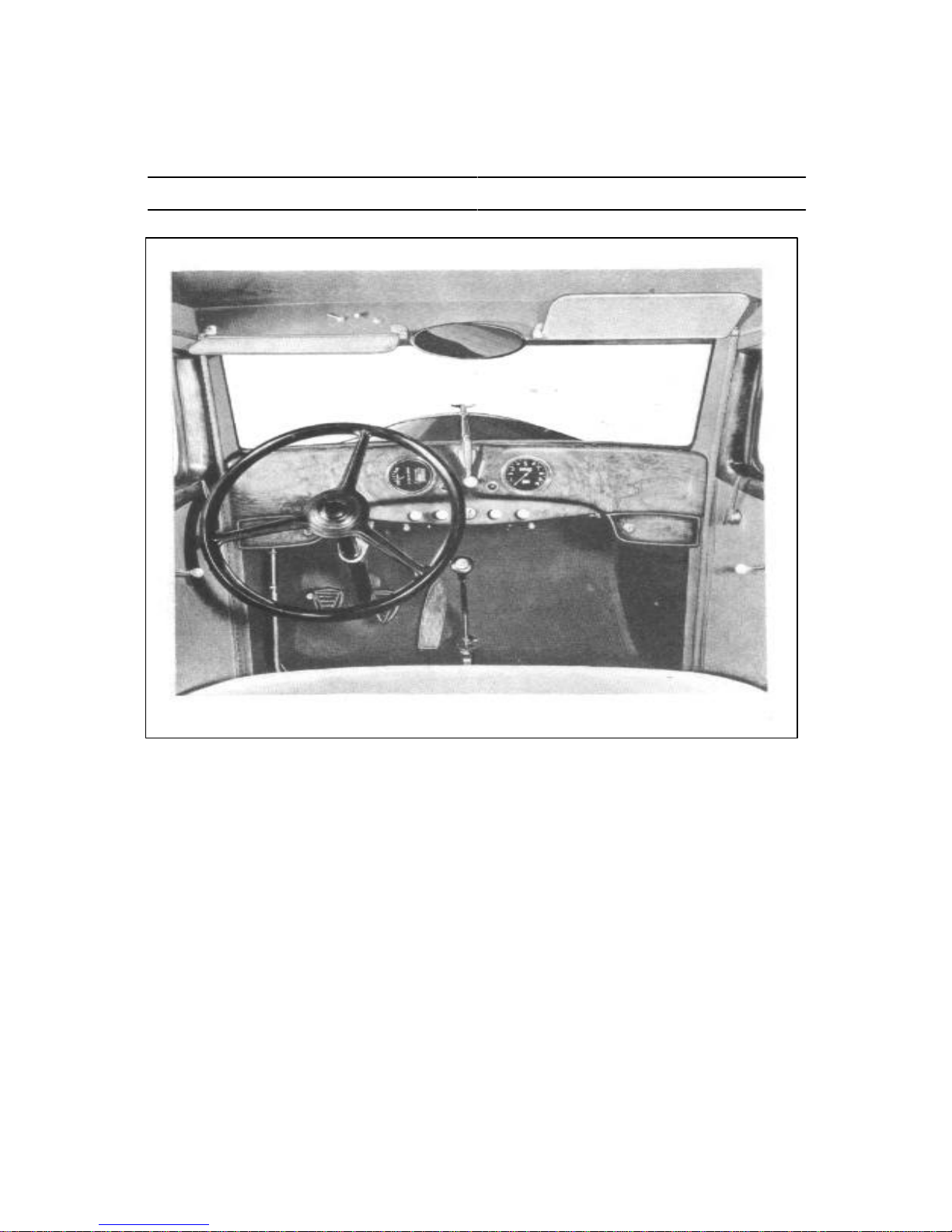

The operation of the Hudson Eight follows standard practice in many respects; however, even

those accustomed to Hudson products may refresh their memories on some of the details by

The clutch is disengaged in the conventional manner by depressing the left foot pedal to

release the engine drive from the transmission. Form the habit of keeping the foot off the clutch

The transmission operation conforms to the standard shift. The clutch must be disengaged to

HUDSON EIGHT OPERATION

Operation

reading the following paragraphs:

pedal except when shifting gears or coming to a stop.

shift gears except when the car is in motion and "free wheeling."

10

Page 12

HUDSON EIGHT OPERATION

Free wheeling is obtained by pressing the button on top of the shifting lever knob and pulling

the knob up until the button comes out flush with the top of the knob. To revert from free

wheeling" press the button and push down on the knob until the button comes out flush.

It is possible to change to "free wheeling" at any time. To change from "free wheeling" to

conventional drive when the engine is driving the car simply depress the button and knob. If the

knob does not come out flush, release the accelerator pedal slightly while still pushing down on

the knob.

If the car is in motion and the engine is running at idling speed, increase the speed of the

engine so that it drives the car, or depress the clutch before changing from "free wheeling" to

conventional drive.

The brakes are operated either by depressing the right foot pedal or pulling backward on the

hand lever located on the driver's left just ahead of the front door.

The engine speed can be controlled either by the foot accelerator or the throttle knob which is

located on the instrument panel directly to the right of the ignition lock.

The light control knob is located directly to the left of the ignition lock. Pulling the knob out

to the first position gives side lights and head lights in the second position. The head light control

is located on the toe board to the left of the clutch pedal. If the head lights are on "bright" they

are "dimmed" by pressing this foot control. A second depression of this control returns the lights

to "bright."

The dash lights are controlled by the switch extending below the instrument panel, slightly to

the right of the throttle control knob.

The starter is controlled by the ignition lock. When the ignition key is turned to the right, the

ignition is turned "on" and the starter is brought into operation. Should the engine stop while the

key is turned to the right, the automatic starter will immediately engage and re-start the engine.

If the car is in gear when the engine stalls, the clutch pedal should be depressed until the engine

starts.

If it is not desired to use the automatic starter after the engine has been started, the ignition

key can be turned to the left. Turning the key to the left will also permit reading the gasoline or

oil gauge and timing of the ignition without starting the engine. If it is desired to turn the engine

by the starter without starting the engine push the plunger which extends out of the rear face of

the automatic starter relay box (under hood at left of engine). Hold the plunger down firmly and

11

Page 13

plunger stick so that the engine continues to turn, push it in again and release quickly.

HUDSON EIGHT OPERATION

release quickly by sliding the finger off sidewise to prevent the plunger sticking. Should the

The carburetor choke control knob is located to the left of the light control knob. (See "Starting

the Engine" for use of choke.)

The oil pressure signal is the red jewel located to the left of the center of the instrument panel.

When the ignition switch is turned "on" this signal will be lighted and should stop glowing when

the engine is running. If it remains lighted or flashes while the engine is running above idling

speed, the engine should be stopped and the oil level in the reservoir checked. If necessary, check

the oil lines. Do not run the engine until the trouble is corrected.

The generator signal is the red jewel located to the right of the center of the instrument panel.

When the ignition switch is turned "on" this signal will be lighted and should stop glowing when

the engine reaches a speed slightly above normal idling. If the signal flashes when the car is

being driven above twenty miles per hour, it indicates that the battery is not being charged. Your

electrical system should be checked by your Hudson dealer.

The "gasoline or oil" gauge indicates the quantity of gasoline in the tank when the ignition

switch is turned either to the right or left position. By pushing upward on the button located

below the instrument panel and slightly to the left of the light control knob, the hand of this

gauge indicates the quantity of oil in the reservoir of the engine.

The engine temperature indicator should show a reading within the driving range at all times

when the car is being driven.

The ride control knob on the instrument panel to the right of the throttle knob gives maximum

shock absorber control when pushed in and a "boulevard control" when pulled out. Any desired

control can be obtained by moving the control knob.

Starting the Engine

The proper procedure in starting the engine is as follows: See that the throttle control knob is

in. Do not open throttle with the accelerator until the engine starts. Pull the choke knob out as far

as possible. Insert the ignition key in the lock and turn clockwise. When the engine "fires" push

the choke in until it runs evenly. If the engine is cold, the choke can only be pushed in about

three-eighths of an inch. Never leave the choke out farther than necessary to keep the engine

running smoothly. It should be pushed in to the limit of its travel as soon as possible after starting

the engine.

12

Page 14

HUDSON EIGHT OPERATION

Breaking-in Instructions

Keep Radiator Full Keep Oil Reservoir Full

Heat is a major consideration in a new engine. Do not allow the engine to

overheat. Although the heat indicator on the instrument panel shows the general

temperature of the engine, it will not show a sudden rise in temperature of an

individual part.

The pressure imposed on parts such as bearings and pistons due to rapid

acceleration or hard pulling will cause them to overheat if the car has not been

driven sufficiently to break them in. Avoid fast acceleration and hard pulling

while breaking in.

High speed also develops higher operating temperatures and to avoid damage

the car speed should be kept within the following recommendations:

0-250 MILES

Do not exceed 40 miles per hour in high gear or 20 miles per hour in second.

Do not accelerate rapidly. Use second gear on steep grades. Keep motor

temperature within "driving range" on dash heat indicator.

250-500 MILES

Do not exceed 50 miles per hour in high gear or 25 miles per hour in second.

500-1000 MILES

During this period the speed should not exceed 60 miles per hour.

IMPORTANT

Do not UNDER ANY CONSIDERATION attempt to maintain a high rate of

speed unless the crankcase is full of good oil, and until the engine is thoroughly

warmed up. Cold oil is not able to flow freely into the small clearances between

working parts so that damage may occur if sufficient time is not allowed for

warming up before attempting high speeds.

13

Page 15

Page 16

HUDSON EIGHT LUBRICATION

Lubrication

Engine

Use High-Grade Oil—Medium Heavy Body or S. A. E. 30

Consult your dealer if you are in doubt as to what

oil to use.

When the ignition switch is turned "on" the red

jewel to the left of the center of the instrument board

should flash red. If it does not, the bulb is either

burned out, the circuit to the oil relief valve broken

or the oil relief plunger sticking.

As soon as the engine is running, the light should

go out. A flash of the red jewel while the engine is

running above idling speed indicates interruption of

the oil supply. The engine should be stopped immediately and the lubrication system inspected.

The amount of oil in the reservoir is shown on the gauge on the instrument panel marked "Gas

or Oil" when the ignition electrolock is turned "on" (turn to left to read gauges without starting

engine) and the button under the instrument panel below the gauge is pressed up.

A bayonet gauge is also provided at the oil filler. See illustration.

The Hudson Duoflo oiling system provides not only purification from dilution but also double

screening and cooling of the oil. The oil is therefore maintained in good condition for a longer

time than in other lubricating systems. Oil should be added as necessary to maintain the quantity

in the reservoir. The reservoir should he drained and refilled with eight (8) quarts of oil at least

every 2500 miles.

It is, however, recommended to drain the initial supply of oil after the first 500 miles of

driving. To drain the reservoir remove the plug from the rear of the oil reservoir. Be sure the

drain plug is tightened securely when replaced.

15

Page 17

HUDSON EIGHT LUBRICATION

Water Pump

Use Motor Oil

Supply three or four drops of light motor oil in the

oil cup "A," shown in the illustration, every 1000

miles. This is the only point on the pump requiring

lubrication. Do not over-lubricate, and wipe off excess oil as this may get on the belt and cause slippage

on the pump and fan pulleys.

Distributor

Use Motor Oil

Fill distributor base to the level of the oil cup "C"

with motor oil every 2000 miles.

Coat rotor cam "B" lightly with vaseline or light

cup grease every 2000 miles.

Apply a drop of oil at breaker arm pivots "A"

every 2000 miles. Note: One breaker arm pivot not

shown in illustration.

Care should be taken not to get oil on any parts of the

distributor other than those specifically referred to as

requiring lubrication. Do not over- lubricate.

Generator

Use Motor Oil

Three or four drops of light motor oil at points "A"

and "B" in the illustration every 1000 miles.

Do not attempt to supply more oil than is required

to fill the cups once as excess oil may praevent

proper operation of the unit.

16

Page 18

HUDSON EIGHT LUBRICATION

Starting Motor

Use Motor Oil

Three or four drops of light motor oil at points "A"

and "B" in the illustration every 1000 miles.

The oil cups on the starting motor have been made

small to prevent overlubrication, which might find

its way to the windings or commutator and eventually cause failure of the unit. Do not attempt to

supply more oil than is required to fill the cups once.

Clutch

Use 1/6 Pint of Light Motor Oil

and 1/6 Pint of Kerosene

The clutch lubricant is sealed into the clutch and

supplies the driving surfaces as well as the throwout

bearing with oil.

The life of the lubricant is largely dependent on

the usage of the clutch. Harsh clutch action indicates

the need of fresh oil and the clutch should be

promptly inspected by your Hudson dealer if this

condition develops. In any event the oil should be

changed at least every 15,000 miles.

To drain the clutch, crank the engine by hand until the oil filler plug "A" on the front side

of the flywheel is visible through the timing inspection hole. Remove the plug and turn

engine slowly to allow lubricant to drain. Bring plug hole back to opening and insert new

lubricant. Replace the drain plug securely.

17

Page 19

Page 20

HUDSON EIGHT LUBRICATION

Transmission

The lubricant in the transmission and free

wheeling units should be maintained to the level

of the filler plugs "A" and "B."

The plugs "C" and "D" should be removed

every 5000 miles and the lubricant drained out.

Replace the plugs and fill through plug "B" with

one quart of kerosene. Run engine with transmission in neutral and clutch engaged for one minute. Drain kerosene, replace drain plugs and fill

through "B" with three pints of S. A. E. No. 90

gear oil (in winter use S. A. E. No. 80), allowing

the oil to drain into the main transmission housing. If the full three pints cannot be

put in at "B," add the balance at "A."

It is essential that good oil of the proper body be used to insure proper protection

against wear and permit proper gear changing. Buying according to the S. A. E.

specifications (this is shown on most oil containers) will insure you of obtaining a

satisfactory lubricant.

Universal Joints

Use Fiber Grease

Remove the plug "A," shown in the illustra-

tion, of the rear universal joint and inject good

fiber grease until grease appears at vent hole in

shaft opposite filler hole. There is a plug simi-

larly located just back of the front universal joint

for filling.

The use of a proper grease at these points is

very important in order to insure lubrication.

These units should be filled every 2000 miles.

The universal joints are often neglected until wear has occurred to such an extent

that replacement is necessary. Wear at these points throws the propeller shaft out

of balance, causing vibration, and thus offsets the care taken in manufacture to

obtain accurate balance which is necessary for smooth operation at high speeds.

20

Page 21

HUDSON EIGHT LUBRICATION

Rear Axle

Use High-Grade Gear Oil—

Heavy Body or

S. A. E. 90 in Summer—

S. A. E. 80 in Winter

The oil supply in the axle housing should be kept level with

the lower edge of the filler plug opening "A."

There are special oil passages and baffles in the differential

carrier housing which catch oil thrown from the ring gear and

carry it to the pinion bearings and return the overflow to the axle housing. This keeps the pinion

bearings under a constant bath of oil and eliminates the necessity of oiling them separately.

Every 5000 miles drain, flush out with kerosene and refill.

Housing may be drained by removing cover "B."

Front Wheel Bearings

Use Cup Grease

The front wheel bearings should be lubricated every 5000

miles. Jack up the front of the car and remove the wheel from

the hub. (See page 31 for method of removing and installing

wheels.)

Unscrew the inside hub cap and withdraw the cotter key

holding the nut "B." Unscrew the nut "B" and remove the

washer "C." The hub and brake drum can then be removed and

the bearing and inside of the hub and drum washed out with

kerosene. Pack the bearings and hub with three ounces of cup

grease. Replace the felt washer at the inner end of the hub, if necessary. Replace wheel. (See

page 30 for bearing adjustment.)

21

Page 22

HUDSON EIGHT LUBRICATION

Rear Wheel Bearings

Use Cup Grease

The rear wheel bearings should be lubricated every

5000 miles. Jack up rear of car and remove the wheel

from the hub. (See page 31 for method of removing and

installing wheels.) Withdraw cotter key and remove nut

from end of axle shaft. Pull hub and brake drum off the

shaft.

Unscrew four screws holding grease deflector "A" and

remove deflector. Remove four screws from bearing cap

"B" and remove cap and shims "C." Remove bearing and

insert ten (10) ounces of grease in the housing.

Wash the cap and bearing in kerosene and replace bearing after filling with grease. Renew the

felt washer in the bearing cap, if necessary. Replace shims and bearing cap. Replace the grease

deflector. See that all brake parts and the brake drum are free from grease before replacing the

hub and wheel.

Steering Gear

Use High-Grade Gear Oil—Heavy Body

Remove plug "A" and fill the steering gear housing every

2000 miles. The use of a good grade heavy bodied gear oil is

necessary to provide free operation under all climatic conditions. (Do not use grease.)

If the steering becomes stiff and complete lubrication of

the unit and the attached parts connecting with the front

wheels does not correct the condition, follow the instructions

on page 29 for adjustment and alignment of the steering gear.

Noise in the unit may be due to use of oil of insufflcient body.

Stiff operation ma, be experienced in cold weather if poop oil

or grease is used.

22

Page 23

HUDSON EIGHT LUBRICATION

Miscellaneous

THROTTLE CONTROL RODS AND LEVERS—Oil or grease all accelerator connections.

Throttle linkage should work with a snap. Grease choke and throttle wires occasionally to

eliminate sticking.

BRAKE CROSS SHAFT—Coat brake cross shaft pivot pins with light cup grease every 1000

miles. Do not allow oil or grease to collect inside of brake drum.

HOOD LEDGE LACINGS—Use motor oil. Saturate with motor oil frequently to remove

squeaks and preserve lacing.

HOOD LOCKS—Use motor oil. Lubricate occasionally by injecting a few drops of oil through

hole in the barrel just below the handle.

DOOR LOCKS—Use motor oil. Lubricate occasionally with a few drops of oil on the latch

bar. Work lock several times to spread oil, then wipe off excess.

DOOR DOVETAILS—Lubricate with grease or soap. Wipe off excess.

DOOR HINGES—Lubricate with light oil. Wipe off excess.

23

Page 24

HUDSON EIGHT ADJUSTMENT

Adjustment

Ignition Timing

Should it be necessary to reset the ignition

timing, loosen the distributor adjusting plate

lock screw "B." If the adjustment is being made

because of sluggish performance, turn the distributor counterclockwise one division of the

scale on the locking plate. Tighten screw "B"

and try the performance of the car on the road.

A slight spark knock should be heard when the

car is being accelerated on a level road in high

gear at ten to twenty-five miles an hour with

the throttle wide open. This gives the best

performance and fuel economy.

If a spark knock is not heard, turn the distribu-

tor one division counterclockwise as before and

test again. If the knock is too loud, turn the distributor clockwise one-half division at a time to

reduce the knock until it can just be heard by the driver.

Should the distributor require any other adjustments, the car should be taken to an authorized

Hudson or Electric Auto-Lite Service Station. The following instructions are given for use in

case of an emergency, but should not be attempted by the owner unless absolutely necessary.

The results obtained from these adjustments depend entirely on the accuracy with which they are

performed.

Adjust Distributor Points

Breaker points should be clean, flat and spaced .020" when at their maximum opening.

Remove distributor cap and inspect points and clean if necessary. A special breaker point file

or stone should be used. Place file or stone between points and move straight up and down,

dressing both points at the same time.

Crank engine by hand until the breaker arm fiber block of points "H" is on the highest point

of the cam, giving the points their maximum opening. Adjust the opening to exactly .020" by

loosening the lock nut and turning the adjusting screw on which the stationary point is mounted.

Tighten lock nut.

24

Page 25

HUDSON EIGHT ADJUSTMENT

just begin to open. This point must be determined accurately. Tighten screws "G."

polish or equal parts of ammonia and water, and allow it to stand for a few seconds. Take a piece

Crank the engine by hand until the breaker arm fiber block of points "D" is on the highest

point of the cam. Loosen screws "E" one-half turn and adjust points "D" to exactly .020" by

turning the eccentric screw "F." Tighten screws "E" and recheck opening to be sure it is exactly

.020".

Synchronize Breaker Points

Remove the spark plug from number one cylinder and

hold a finger over the plug hole. Crank the engine by hand

until a rush of air is felt. Continue to turn engine slowly

until the D. C. 1 and 8 mark is exactly in line with the

pointer on the inspection hole as shown at "A."

Loosen clamp screw "B" and turn distributor clockwise

to the full limit permitted by the slot in the clamping plate

"C." Turn the distributor slowly counterclockwise until

the points "D" have just begun to open. Care must be

taken to determine this position accurately. Tighten lock

screw "B."

Turn the engine slowly with the hand crank until the D.

C. 3 and 6 mark is exactly in line with the pointer on the inspection hole. This should require

only one-quarter (90°) turn of the crank.

Loosen screws "G" one-half turn and turn breaker point support plate clockwise to the extreme

limits of the screw holes. Turn breaker point support plate counterclockwise until the points "H"

The illustration shows the rotor arm in the proper position for firing on number one cylinder.

The cable to number one spark plug should be in the cap socket directly above the rotor point.

The spark plug cables should be in the cap in the order 1-6-2-5-8-3-7-4, following in a clockwise

direction.

Spark Plugs

When setting the gap of the spark plugs, make all adjustments by moving the side wire. Do

not bend center wire as this may break the porcelain.

To clean the carbon from the porcelain, fill the lower part of the plug with alcohol, liquid metal

of wire covered with one thickness of cloth and rub the carbon from the insulator, wiping

thoroughly dry before replacing the plug in the engine.

Spark plugs should be changed every 10,000 miles for better engine performance. New spark

plugs give quicker starting, increased power, smooth running and a saving in gasoline.

25

Page 26

HUDSON EIGHT ADJUSTMENT

Tappets

Before adjusting tappets see that the tappet clamp cap

screw "C" is tight. Adjust tappet by loosening lock nut

"B" and turning adjusting screw "A." Lock adjustment

by tightening

lock nut "B" while holding screw "A."

Measure clearance between adjusting screw and end

of valve stem with a feeler gauge as shown at "D" in the

illustration. This measurement should be made while

the engine is at its normal operating temperature.

Adjust exhaust valve tappets to .006" and intake tappets to .004" clearance. Counting from the

front the exhaust tappets are 1-4-5-8-9-12-13-16 and the intake tappets are 2-3-6-7-10-11-14-15.

Always adjust tappets after grinding valves.

Timing Chain

The timing chain should be inspected at the expiration

of the first 1500 miles and at intervals of 5000 miles

there-after.

A to and fro movement of approximately 1/8" on the

circumference of the coupling "A" (after the slack around

the coupling bolt is taken up) should be maintained.

To adjust, loosen retaining bolts "B." The inside top bolt

and the bottom bolt (not shown) pass through the notches

in the eccentric, necessitating their removal. Insert special

tool "C" in notch and pull toward you until only the

required movement of the coupling is present. If trouble is

experienced in replacing the bolts, back off the adjustment

slightly, allowing them to slide into place:

One-half pint of motor oil should be introduced through the pipe plug opening "D" whenever

the distributor support housing has been removed.

26

Page 27

HUDSON EIGHT ADJUSTMENT

Fan and Water Pump

To adjust the belt, loosen the nut "A" and raise the fan

until the belt can be deflected 5/8" below a straight edge

laid on the fan and pump pulleys. This measurement of

deflection is indicated in the illustration at "B."

Do not adjust the belt too tight as it will throw an

excessive load on the fan and pump bearings.

Adjust the water pump packing gland "C" finger tight.

Do not tighten with a wrench as the packing may bind the

shaft and throw a heavy load on the belt.

Carburetor

Spark plugs and breaker points should be cleaned, spark

gaps properly spaced and all residue in gasoline passages

removed before adjusting the carburetor.

See page 28 for removal of vacuum tank filter to stop

flow of gasoline while cleaning carburetor.

Clean carburetor filter screen "B."

Adjust set screw "C" for correct idling speed of seven

miles per hour.

Turn air screw "A" until the end is flush with the end of

the ratchet spring bearing against it. This is the normal

mixture adjustment and the final setting should be within

turn of this point. Warm engine to proper operating temperature. Turn air screw counterclockwise until the engine

hesitates, then clockwise one notch at a time until the

engine runs smoothly.

The heat supplied to the carburetor from the exhaust is automatically controlled by a

thermostat and requires no adjustment.

The air cleaner unit should be cleaned every 2500 miles, except under extremely dusty

operating conditions when the cleaning should be more frequent. The unit can be lifted off the

carburetor silencer after removing the thumbscrews "D." Wash in gasoline and then soak with

motor oil. Drain off excess oil and replace.

27

Page 28

HUDSON EIGHT ADJUSTMENT

Vacuum Tank

The glass sediment chamber at the bottom of the

vacuum tank should be removed and cleaned whenever

its contents show an accumulation of water or dirt. The

water, due to the fact that it is heavier than gasoline,

settles to the bottom of the glass and is easily distinguished.

The flow of gasoline is automatically shut off as soon

as the glass is removed, so that it is only necessary to

hold the glass "A" in one hand, loosen the thumbscrew

and swing the bracket "C" to one side to empty the glass.

The removal of the sediment chamber also acts as a

cut-off so that the carburetor feed line can be removed

without loss of gasoline from the vacuum tank.

Clutch Pedal Adjustment

A clearance of 3/4" must be maintained between the

clutch pedal shank and the toe board, as shown in the

illustration at "A."

This adjustment should be made accurately as too

much clearance will reduce the pedal movement and

may prevent complete clutch disengagement, causing

hard shifting. Too little clearance may, after slight wear

of the clutch disc facing, permit the clutch pedal to rest

against the toe board and hold the clutch in partial

disengagement. This will cause slippage and rapid wear.

To adjust, remove the clevis pin "B." and loosen the

lock nut "C." Turn the yoke on the link to obtain proper length. Lengthening the link increases

the clearance between the clutch pedal shank and the toe board, while shortening the link reduces

it.

Page 29

HUDSON EIGHT ADJUSTMENT

Steering Gear

The bearings on the steering gear worm shaft are

preloaded by the pressure of a spring located between

the outer race of the upper bearing and cover plate. This

spring pressure prevents development of end play in the

worm, so that no adjustment is necessary to take care of

normal wear.

To remove side play in cross shaft: The adjustment for

cross shaft "F” is on the opposite end to that shown in

the illustration. Loosen the lock nut and with a screwdriver turn the adjusting screw down as tightly as possible, then back up slightly. Tighten lock nut.

To remove play in mesh of worm and cross shaft

sector: Locate wheels in straight-ahead position, disconnect drag link from steering arm and shake arm to

determine the amount of play. Loosen four stud nuts "D"

(VI turn only). Turn eccentric sleeve "C" to right or

clockwise direction only in gradual stages, noting result by shaking steering arm at each step and

using care at last stage to turn sleeve just sufficiently to remove play and no further. Securely

tighten cover stud nuts "D."

To change position of steering wheel to suit requirements of driver: It is necessary to loosen

frame bracket stud nuts "E," as well as cowl bracket nut under cowl, then set steering wheel at

desired position.

Keep the steering column to dash clamp bolt, the cross shaft nut "G" and the frame stud nuts

"E" tight.

Battery

Periodically disconnect terminals "A" from the

battery. Clean thoroughly, coat with vaseline, replace

and tighten securely.

Battery must be kept securely fastened in tray.

Tighten at "B."

Inspect battery liquid at least every two weeks in

warm weather (required less frequently in cooler

weather) and add distilled water at openings "C" to

29

Page 30

HUDSON EIGHT ADJUSTMENT

Front Wheel Bearings

The adjustment of the front wheel bearings is important, as it affects braking and steering, as well as the free

running of the car.

To adjust the front wheel bearings, jack up the front

wheel, remove the inner and outer hub caps and withdraw cotter key holding nut "B." Tighten nut "B" until a

slight drag is felt when turning the wheel slowly by

hand. Loosen the nut just sufficiently to permit the wheel

to turn freely, insert cotter key and replace hub caps.

Rear Wheel Bearings

To adjust rear wheel bearings, jack up rear of car and

remove both rear wheels. (See page 31 for method of removing wheels.) Remove wheel hubs as described under "Rear

Wheel Bearings." (See page 22.)

Unscrew four screws holding grease deflector "A" and

remove deflector. Remove four screws from bearing cap "B"

and remove cap. By reducing the number of shims under the

cap, the end play of the axle shaft is decreased, and the

installation of additional shims increases the end play.

Total end play between the axle shafts should be from .004" to .010", which amount is

perceptible when pulling the axle shaft in and out.

Approximately the same thickness of shims should be used under each bear, ing cap so that

the brake drums will be evenly spaced from the brake dust shields.

30

Page 31

HUDSON EIGHT ADJUSTMENT

place with the wrench, start at least two of the cap screws. Remove the wrench and start the

Removal and Installation of Wheels

To remove either the demountable wood or wire wheels,

place a screwdriver behind the hub cap and pry off.

Loosen the five cap screws "A" with the socket wrench

provided in the tool kit. Remove the cap screw "A" which

is at the lowest position on the wheel and insert the handle

of the wrench through the screw hole in the wheel into the

hub. While holding the wheel in position with the wrench,

remove the other cap screws "A" and lift off the wheel.

When reinstalling the wheel, jack up the car so that there

is just sufficient clearance for the wheel to slide

onto the hub. Place the handle of the wrench through the

lower cap screw hole in the wheel and the drum. Lift up on

the wrench so that the wheel will clear the ground and

push the wheel in place. Align the screw holes by moving

the wrench back and forth. While holding the wheel in

remainder of the screws.

Tighten every other cap screw until all are down just enough to hold the wheel in place to be

sure it is square on the hub. Tighten every other cap screw, continuing around until all screws

are securely tightened.

Tires

Check tires once a week and keep inflated to 32 pounds pressure. For fast driving inflate tires

to 40 pounds. Be sure front tire pressures are equalized.

To remove the tires from the wheels, let all air out of the tube. Push valve stem up into tire.

Starting at the valve stem press the beads of the tire together and into the base of the rim for about

one foot in each direction. Insert an iron under both beads directly opposite the valve and force

the tire over the rim. The tire can then be lifted off.

To install a tire, inflate the tube until it is barely round and place it in the casing with the valve

stem in line with the red dot on the side wall of the casing to preserve the tire balance. Press the

beads of the tire together at the valve stem and place tire on wheel so that the beads go to the

bottom of the rim well and the valve stem enters the hole in the rim. Working both ways from

the valve stem, press the beads together and down into the rim well until the portion of the tire

opposite the valve can be forced over the rim. Raise tire up and allow beads to spread until the

tire is centered on the rim. Inflate tube to five pounds pressure and work tire back and forth to

insure proper seating of tire on rim. Inflate to proper operating pressure.

31

Page 32

HUDSON EIGHT ADJUSTMENT

Brakes

When the brake pedal travels to within 1-1/2" of the

toe board, the brakes should be adjusted as follows:

Jack up all four wheels and remove the inspection

cover "A" from the brake drum. Turn the brake drum as

necessary and insert a .014" feeler between the drum and

the lining 1

from the adjusting screw end (rear of front brakes—

front of rear brakes) of the lining of the upper shoe.

Loosen the eccentric lock nut "B" and turn the

eccentric "C" in the direction the wheel rotates when the

car is moving forward until the feeler is held snugly.

Adjust all four wheels as outlined above. Depress the

brake pedal to within 3 of the toe board. Try the braking

effect by pulling each wheel over by hand. If the braking effect is unequal, or insufflcient, adjust

by removing the adjusting hole cover "D" and inserting adjusting tool or screwdriver in hole "E"

and engaging adjusting screw ratchet. Move hand end of tool toward the axle to increase, and

away from axle to decrease, braking effect.

Front Wheel Alignment

Measure the distances "A" and "D" as shown in the

illustration. The distance "A" should be the same as "D"

or not over 1/8" longer—never shorter.

A special tool should be used for this purpose and the

measurement taken between the rims at a height about

even with the hubs. Loosen clamp bolts "B" and turn tie

rod "C" clockwise as viewed from the right to increase

"A" and counterclockwise to decrease "A."

32

Page 33

HUDSON EIGHT ADJUSTMENT

Spring Mountings

Chassis noise, erratic spring action and wandering of

the car on the road can often be attributed to spring

mountings.

Adjust the spring shackles to remove end play of

spring on shackle bolt by loosening the locking nut,

"A" and turning the bolt "B" until tight, then turn back

one-sixth turn and tighten nut "A."

This operation should be performed every 5000

miles on both upper and lower shackle bolts at the rear

of both the front and rear springs and on the anchor

bolts (not illustrated), holding the front ends of front

and rear springs to the frame brackets.

The spring clip nuts (front and rear) shown in the

illustration should be tightened every 5000 miles.

When making the above adjustments the body holddown bolts should also be tightened. There are eight of

these, four on each side, located just outside the frame

side members and under the body sills. Draw the nuts

tight after the first 1500 miles and every 5000 miles

thereafter.

33

Page 34

HUDSON EIGHT ADJUSTMENT

purpose can be obtained from your dealer. Do not use any other liquid as there is a possibility of

Shock Absorbers

The shock absorbers should be refilled every 2000 miles. The special fluid required for this

destroying the unit, especially in cold weather, should the liquid become thick or frozen.

Keep the shock absorbers tight on the frame at all times and do not permit any play to develop

in the linkage.

All repairs and adjustments, including refilling of the shock absorbers, should be made by an

authorized Hudson or Gabriel Service Station.

Radiator

Drain, flush out and refill frequently.

Filler is located under the hood to eliminate possibility

of anti-freeze ruining the finish.

About every four months a solution consisting of one

pound of washing soda to four gallons of water should be

poured into the radiator and allowed to slowly circulate

through the system by running the engine at idling speed.

Leave drain cock open and thoroughly flush out after

cleaning.

See that hose is in good condition and all hose clamps

are tight.

Do not allow mud, etc., to clog air passages through

radiator.

Repair dents and leaks when they occur.

Add an anti-freeze solution to the radiator in cold weather.

Drain enough water from the radiator so that after the anti-freeze has been added there will

still be room for a slight expansion of the liquid without its running over the overflow pipe.

Add Anti-Freeze as Follows :

Ethylene

For

32° to 10° above 0°

10° to 0

9

0° to 10° below 0°

10° to 20° below 0°

34

Glycol or

5-1/2 qts.

7 qts.

8-1/3 qts.

9-1/2 qts.

6-2/3 qts.

8-2/3 qts.

10 qts.

11-1/4 qts.

Alcohol or

Radiator

Glycerine

9-1/4 qts.

11-1/2 qts.

13-2/3 qts.

15-1/3 qts.

Page 35

HUDSON EIGHT ADJUSTMENT

Headlamps

Place the vehicle under normal load on a level floor squarely facing a smooth wall 25 feet

from the headlamps.

Measure the height of the lamp bulbs from the ground and draw a horizontal line on the wall

at the same height as the bulbs.

Sight through windshield along hood rod and radiator cap to determine the center line of the

vehicle. Locate center lines of lamps on the wall from this line.

With the light control in the position throwing the light beam farthest from the vehicle, cover

left lamp to obscure its light beam.

Loosen the right mounting nut (under fender apron) and aim the right lamp so that the top of

the beam is just even with the horizontal line and equal portions on each side of line on the

wall indicating the center line of the right lamp.

Repeat operations with the left lamp and the headlamps will be properly aligned.

Care of the Finish

The same care should be exercised in washing and cleaning cars finished in lacquer or

enamel as is employed in the handling of varnished surfaces. Dry dirt accumulations should

not be wiped off but should be softened and removed by thoroughly soaking the body with

flowing water, applied under light pressure.

Careful washing of the car, followed by the use of a polish especially prepared for lacquer or

enamel finishes, will maintain a high luster and preserve the finish. The use of polishes containing strong abrasives should he avoided, as they are particularly destructive to the striping.

Anti-freeze solutions con- taining alcohol when accidentally spilled on the finish should be immediately washed off with clear water to prevent spotting, as alcohol is a solvent of lacquer.

It is recommended that every new car purchaser apply a coat of wax while lacquer is still

clean and unmarked. If this is done and the application periodically renewed, it will be an important factor in the life of the finish.

35

Page 36

Loading...

Loading...