Huck BTT35LS Instruction Manual

04-06-2010

HK1107

INSTRUCTION MANUAL

BOBTAIL INSTALLATION SYSTEM

BTT35LS

BTT35LS

2

BTT35LS BOBTAIL Installation Tool Alcoa Fastening Systems

3

BTT35LS BOBTAIL Installation Tool Alcoa Fastening Systems

SAFETY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

DESCRIPTION AND PRINCIPLE OF OPERATION

. . . . . . . . . . . . . . . . . . . . .5

TOOL SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PREPARATION FOR USE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERATING INSTRUCTIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

WRENCHING-UP OF PIPE THREADS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

MAINTENANCE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

TOOL ASSEMBLY PARTS LIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

TOOL ASSEMBLY DRAWING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

OPTIONAL EQUIPMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

C

C

ONTENTS

ONTENTS

4

BTT35LS BOBTAIL Installation Tool Alcoa Fastening Systems

S

S

AFETY

AFETY

This instruction manual must be read,

with particular attention to the following

safety guidelines, by any person servicing or operating this tool.

1. Glossary

Notes - are reminders of required procedures.

Bold, Italic type and underlining

- empha-

sizes a specific instruction.

2. A half hour long hands-on training session with

qualified personnel is recommended before using

Huck equipment.

3. Huck equipment must be maintained in a safe

working condition at all times. Tools and hoses

should be inspected at the beginning of each

shift/day for damage or wear. Any repair should be

done by a qualified repairman trained on Huck procedures.

4. Repairman and Operator must read manual prior to

using equipment. Warning and Caution stickers/labels supplied with equipment must be understood before connecting equipment to any primary

power supply. As applicable, each of the sections

in this manual have specific safety and other information.

5. Read MSDS Specifications before servicing the

tool. MSDS Specifications are available from the

product manufacturer or your Huck representative.

6. When repairing or operating Huck installation

equipment, always wear approved eye protection.

Where applicable, refer to ANSI Z87.1 - 2003

7. Disconnect primary power source before perform-

ing maintenance on Huck equipment or changing

Nose Assembly.

8. Tools and hoses should be inspected for leaks at

the beginning of each shift/day. If any equipment

shows signs of damage, wear, or leakage, do not

connect it to the primary power supply.

9. Mounting hardware should be checked at the

beginning of each shift/day.

10. Make sure proper power source is used at all

times.

11. Release tool trigger if power supply is interrupted.

12. Tools are not to be used in an explosive environ-

ment unless specifically designed to do so.

13. Never remove any safety guards or pintail deflec-

tors.

14. Ensure deflector or pintail collector is installed and

operating prior to use.

15. Never install a fastener in free air. Personal injury

from fastener ejecting may occur.

16. Always clear spent pintail out of nose assembly

before installing the next fastener.

17. There is possibility of forcible ejection of pintails or

spent mandrels from front of tool.

18. If there is a pinch point between trigger and work

piece, use remote trigger. (Remote triggers are

available for all tooling).

19. Unsuitable postures may not allow counteracting of

normal expected movement of tool.

20. Do not abuse tool by dropping or using it as a ham-

mer. Never use hydraulic or air lines as a handle

or to bend or pry the tool. Reasonable care of

installation tools by operators is an important factor

in maintaining tool efficiency, eliminating downtime,

and in preventing an accident which may cause

severe personal injury.

21. Never place hands between nose assembly and

work piece. Keep hands clear from front of tool.

22. There is a risk of crushing if tool is cycled without

Nose Assembly installed.

23. Tools with ejector rods should never be cycled with

out nose assembly installed.

24. When two piece lock bolts are being used always

make sure the collar orientation is correct. See fastener data sheet of correct positioning.

25. Tool is only to be used as stated in this manual.

Any other use is prohibited.

Product complies with requirements

set forth by the relevant European

directives.

Read manual prior to using

equipment.

Eye protection required while

using this equipment.

Hearing protection required while

using this equipment.

WARNINGS - Must be understood to

avoid severe personal injury.

CAUTIONS - show conditions that will

damage equipment and or structure.

5

BTT35LS BOBTAIL Installation Tool Alcoa Fastening Systems

An electric trigger switch controls the PULL and

RETURN strokes of the tool. As the trigger is pressed,

hydraulic PULL pressure is directed to front sides of

both pistons, moving them rearward. Fastener

Installation begins.

When the fastener installation is complete, the trigger

is released, causing the hydraulic units combination

valve to redirect the hydraulic RETURN pressure to the

rear side of the front piston moving it forward. The nose

assembly, with the tool, is pushed off the installed fastener.

As the pistons reach the end of the RETURN stroke,

hydraulic pressure increases causing the hydraulic unit

idler valve to move to idle position (in Model 918) or

automatically shut off (in Model 940). The tool is now

ready to install another fastener.

P

P

RINCIPLE

RINCIPLE

OF

OF

O

O

PERATION

PERATION

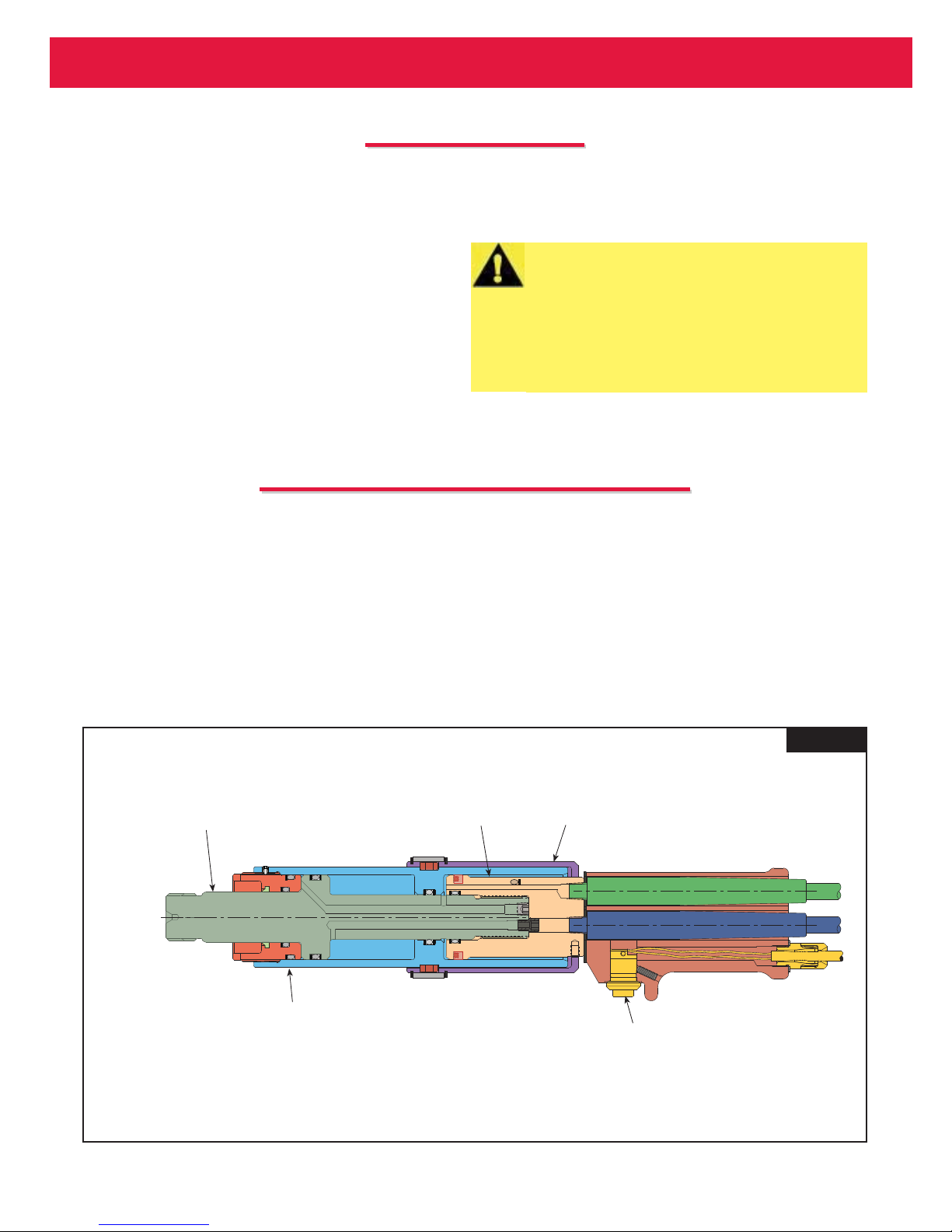

HUCK Model BTT35LS is a Hydraulic Installation Tool

that installs and removes BOBTAIL fasteners in limited clearance applications.

This tool design consists of a cylinder housing with

two chambers to accommodate two tandem pull pistons. This feature increases pull capacity while maintaining optimum centerline-to-edge clearance and

lightweight.

The tool is intended for use with Huck standard industrial POWERIG® Hydraulic Units (models 913H, 918,

d 940, and 968) or equivalent - sold separately.

Except for nose assembly, tool is complete with

hydraulic hoses, couplings and electric control cord

ready to be attached to POWERIG® Hydraulic Units

hoses and control cord.

D

D

ESCRIPTION

ESCRIPTION

CAUTION: Huck recommends that only Huck

POWERIG® Hydraulic Unit be used as the

power source for Huck installation equipment. Hydraulic power units that deliver

high pressure for both PULL and RETURN,

and are not equipped with relief valves are

specifically not recommended, and may be

dangerous.

Figure 1

Front Piston

Front of Tool

Main Housing

Rear Piston

Rear Piston Shield

Trigger

Loading...

Loading...