Huchez MOTORBOX 150, MOTORBOX 300, MOTORBOX 500 Instruction Manual

© 2011 by Huchez Treuils S.A.S.

Electric winch

Electric winches

MOTORBOX® 150, 300 and 500 kg

Instruction manual _________________________ EN

140-225.13/3

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 2

EN

Reproduction prohibited

To ensure the constant improvement of its products, HUCHEZ reserves the right to change the equipment as

described below and, in this case, to supply products which differ from the illustrations in this instruction manual.

All rights reserved

Contents

1 - Conditions of use ............................................................................................................ 2

2 - Safety instructions .......................................................................................................... 3

3 - Warranty ....................................................................................................................... 4

4 – Reception of the equipment ............................................................................................. 4

5 – Obligatory regulatory checks by the user ........................................................................... 5

6 – Presentation of the machines ........................................................................................... 5

6.1 - General information

6.2 - Dimensions

6.3 – Models available

6.4- FEM classification

7 – Handling - Storage ......................................................................................................... 7

8 - Installation and set-up ..................................................................................................... 8

8.1- Installation

8.2-Place of installation

8.3 – Rope outlets

8.4 – Power supply

8.4.1 – Electrical connections

8.4.2 – Connection

8.5 - Work rope

9 – Servicing and maintenance ............................................................................................ 13

9.1 -Before switching on

9.2 – Periodic servicing

10 – Taking out of use ........................................................................................................ 15

11 – Spare parts ................................................................................................................ 15

12 – Operating faults .......................................................................................................... 16

13 – Declaration of EC conformity ........................................................................................ 17

14 – Annexes .................................................................................................................... 17

A – Part references

. Limit switch MOTORBOX® 150 kg

. Limit switch MOTORBOX® 300/500 kg

. MOTORBOX® 150 kg

. MOTORBOX® 300 kg

. MOTORBOX® 500 kg

B – Electrical diagrams

C - Limit switch adjustment.

D - Maintenance booklet.

1 - Conditions of use

Users must read the set-up instructions carefully before using the product for the

first

time. These

instructions should enable the user to familiarise themselves with the winch and use it to its full

capacity. The set-up instructions contain important information about how to use the winch in a

safe and correct manner. Compliance with these instructions helps to avoid danger, reduce repair

costs, reduce stoppage time and improve the reliability and service life of the winch. The

instruction manual must always be available in the place where the winch is being used. In

addition to the set-up instructions and regulations concerning the prevention of accidents, the

work safety and trade rules in force in each country must also be respected.

This equipment is governed by European regulations and more specifically Directive 2006/42/EC

on machinery, EMC Directive 2004/108/EC and LVD 2006/95/EC, as well as the EN 14492/1

standard.

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 3

EN

Reproduction prohibited

These winches are designed to move loads using a suitable steel rope. They have been designed to

perform lifting and pulling operations within the defined load capacity limit and with safety factor 5

(static against sudden failure).

For use in lifting, the European regulation makes certain equipment obligatory, such as a limit

switch system and, for loads of 1,000 kg or more, a load limiter.

The operator must check that this equipment is present (available as an option from the

manufacturer) before using the product for lifting purposes.

The capacity indicated on the winch corresponds to the maximum capacity of use (MCU); in no

event should this capacity be exceeded.

THIS WINCH CAN, UNDER NO CIRCUMSTANCES, BE USED TO LIFT PEOPLE.

Do not begin moving the load until you have attached it correctly and checked that all

personnel are outside the danger zone.

Before use, the operator must always check that the machine, rope, hook, markings and

moorings are in good working order.

The operator must check that the load is attached in such a way that the winch, the cable and

the load place neither the operator nor any other person in danger.

The winches can be used at ambient temperatures ranging from -10°C to +50°C. Please

consult the manufacturer in the event of extreme conditions of use.

Important: In the event of an ambient temperature below 0°C, the brake must be tested to ensure

that there are no operating faults resulting from the freezing conditions.

Use of winches requires strict compliance with the accident prevention and safety measures in

force in the country.

The data concerning the resistance of the steel rope and its fastenings to heat must be available

on request from the manufacturer and must be respected.

HUCHEZ accepts no liability for the consequences resulting from the use or installation of

equipment not provided for in the present instructions or for the consequences of disassembly,

modifications or replacement of original parts or components with parts or components from

other sources without the written agreement of HUCHEZ.

YOU MUST ALSO RESPECT THE REGULATIONS APPLICABLE IN YOUR COUNTRY.

2 - Safety instructions

Before using the equipment, check that there are no causes of overloading such as: adhesio n to

the ground, suction, jamming, etc. of the load.

As the operator of the winch, you are responsible for your own safety and the safety of your

colleagues in the work area of the machine.

The operator must respect all the following safety information, without exception, concerning the

handling and operation of the winch as well as the references to other sections of this instruction

manual. Non-compliance with these instructions increases the level of risk.

Only the people designated by the company are authorised to operate the winch

Before using the winch for the first time, familiarise yourself with its conditions of use. Read

the present instruction manual carefully and in its entirety and perform all the operations

described herein one after the other.

Inform your departmental manager or the safety officer of any malfunction so that the fault

can be repaired immediately.

Respect the directives of the industrial accident prevention organisations such as, in France,

the Caisse d'Assurance Retraite et de la Santé au Travail (C.A.R.S.A.T.) and the Health and

Safety Committee (HSC) of your company, if one exists.

You must scrupulously respect the information in the sections concerning the CONDITIONS OF

USE (below) and the WORK ROPE (page 10)

The operator(s) must have an unimpeded view of the load.

Please ensure that the operator is qualified to operate the machine in the conditions provided

for in this manual. This will ensure the safety of both people and the environment.

Do not lift or transport loads when there are personnel inside the danger zone.

Do not authorise the personnel to walk under a suspended load.

Do not leave a load suspended or with the rope taut unsupervised.

In addition to the above instructions, we must warn you against all incorrect use or handling listed

below. It is dangerous and prohibited to:

unwind the drum completely (retain 2 to 3 residual windings).

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 4

EN

Reproduction prohibited

pull at an angle.

swing the load.

use ropes with a diameter and texture which do not correspond to the specifications in this

manual (FEM 1dm – ISO M1).

use damaged ropes or ropes with splices.

grab or touch a moving cable or a rotating drum.

use hooks without a latch, which do not correspond to the loads indicated on the winch or which

are in poor condition.

insert objects into moving parts.

work on loaded winches or when the rope is taut

use the winch rope as a towing chain.

drum on the control box (overheating of the motor and electrical equipment).

place hands or clothes, etc. in contact with moving parts, in particular the areas where the rope

is wound in/out.

3 - Warranty

Our electric winches are guaranteed for 1 year from the date of shipment (ex-works).

The seller undertakes to repair any operating fault resulting from a fault in the design, execution,

components or materials themselves.

The warranty does not cover wear and tear or damage resulting from a lack of regular or periodic

maintenance. It does not cover damage resulting from a lack of supervision, incorrect handling or

an incorrect use of the machines, in particular overloading, pulling at an angle, under or

overvoltage or incorrect connection.

The warranty does not apply to any disassembly, modification or replacement of mechanical or

electrical parts undertaken without our agreement or by a non-approved operator. The warranty

only applies to the manufacturer's original spare parts. During the warranty period, the seller must

replace or repair any parts recognised as faulty after inspection by the qualified and approved

department, all free of charge.

The warranty excludes all other services or compensation.

Repairs undertaken within the framework of the warranty are, in principle, performed in the

seller's workshops or the workshop of their representative approved by the manufacturer. When

the intervention on the equipment occurs outside their workshops, the seller must cover the labour

costs related to the disassembly or reassembly of these parts if these operations are performed

exclusively by their personnel or their representative approved by the manufacturer. The parts

replaced become the property of the seller and must be returned to them at their cost.

In the case of components with a particular relative importance not manufactured by the seller

themselves and which carry the brand of specialist manufacturers, the warranty, which may vary

according to the manufacturer, is the same as that agreed by this manufacturer.

4 – Reception of the equipment

Conduct a visual inspection of the packaging to ensure that it is in good condition.

In the event of an anomaly, issue the usual reserves.

Check that the winch corresponds to your order.

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 5

EN

Reproduction prohibited

5 – Obligatory regulatory checks

by the user

This equipment has been designed to be tested:

In a dynamic situation, with coefficient 1.1

In a static situation, with coefficient 1.25

The users are required to comply with the standards in force in their country.

With regard to France:

Order of 1st March 2004 relating to the verification of lifting machines and accessories:

The modifications to the regulation relating to the use and verification of lifting machines and

accessories, which came into effect on 1st April 2005, impose new obligations on all users:

The suitability inspection which involves checking that the lifting machine is suitable for the

work that the user intends to carry out as well as for the risks to which workers are exposed

and that the intended operations are compatible with the conditions of use for the machine

defined by the manufacturer.

The assembly and installation inspection, which involves ensuring that the lifting machine is

assembled and installed in a safe way in accordance with the manufacturer's instruction manual,

The general periodic visits, which involve an inspection of the state of preservation and the

operating tests.

The set-up or renewed set-up inspections: in the event of a change in the place of use, the

configuration or the conditions of use on the same site; following the disassembly and

subsequent reassembly of the lifting machine; after any major replacement, repair or

transformation concerning the essential components of the lifting machine; following any

accident caused by the failure of an essential component of the lifting machine.

The maintenance booklet (Order of 2nd March 2004 applicable from 1st April 2005) which must

be used to record the maintenance operations carried out in accordance with the

recommendations of the manufacturer of the machine as well as any other inspection,

maintenance operation, repair, replacement or modification carried out on the machine. For

each operation, it is essential to record the date of the work, the names of the people and,

where appropriate, the companies which carried out the work, the nature of the operation and,

if it is a periodic operation, the frequency. If the operations involve the replacement of certain

components of the machine, the references of these components are indicated. The English

version of the maintenance booklet for our lifting winches can be downloaded from our website

www.huchez.fr/ uk under the heading "After sales services”. A copy is however proposed in the

annexes of this manual.

The inspections must be carried out in accordance with a protocol and are intended to ensure

preventive maintenance aimed at detecting any damage or defectiveness liable to result in a

danger.

6 – Presentation of the machines

6.1 - General information

These winches are available in 150 kg, 300 kg and 500 kg versions, with limit switch. They are

intended for an occasional use for pulling or lifting loads.

. Rigid steel structure

. Mechanically welded steel drum with wide flanges for safe and sound fastening of the rope.

. 230 volt, 50 Hz single-phase lifting-type self-braking motor. P = 0.25 kW (MOTORBOX® 150 kg)

or P=0.37 kW (MOTORBOX® 300/500 kg) – Insulation class F – IP 44 (MOTORBOX® 150 kg) or IP

54 (MOTORBOX® 300/500 kg).

. The FEM category is 1 dm (ISO: M1).

. 230 V single-phase control box. – IP 65 double insulation.

. Emergency stop as standard

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 6

EN

Reproduction prohibited

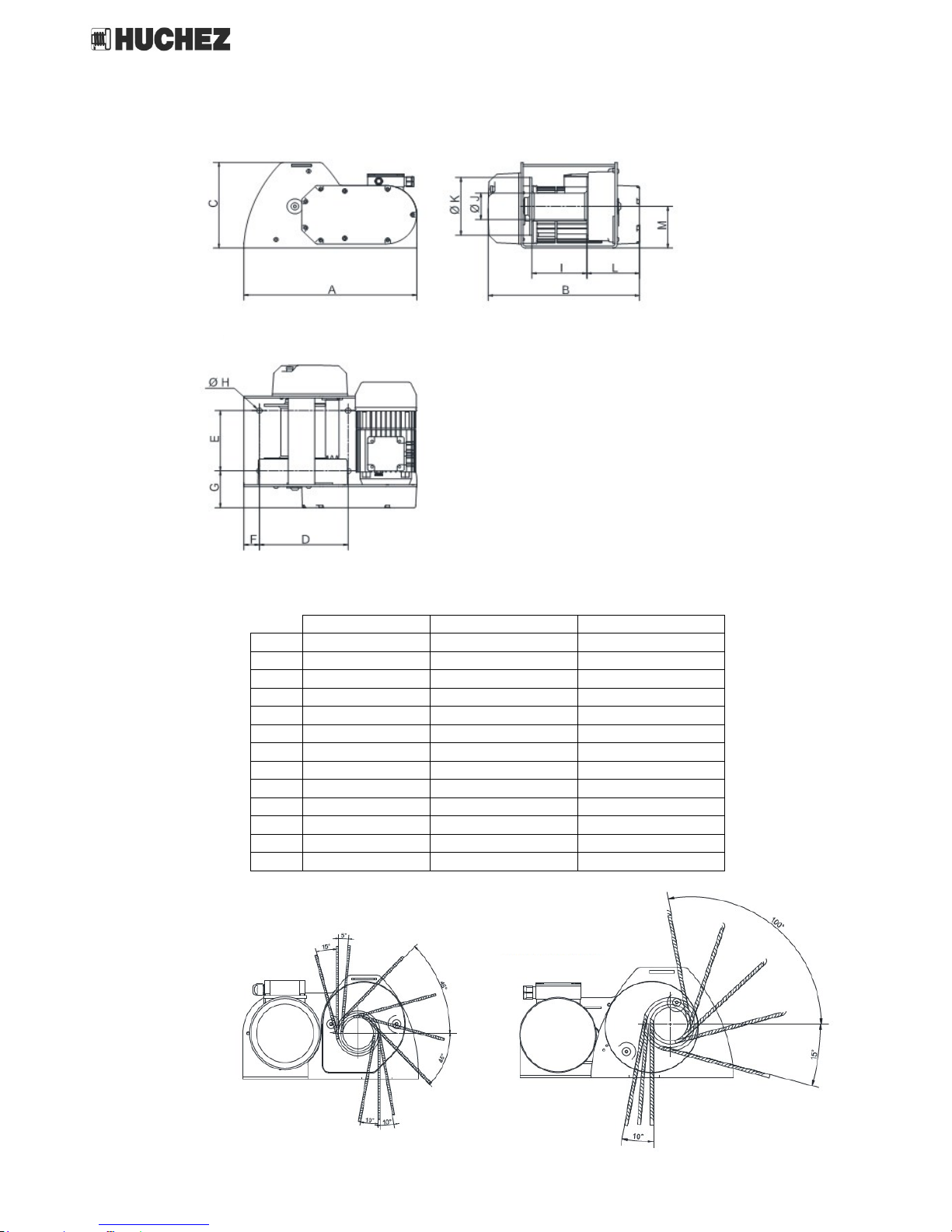

6.2 - Dimensions

MOTORBOX 150

MOTORBOX 300

MOTORBOX 500

A

310

390

390

B

281

341

341

C

179

205

205

D

154

200

200

E

114

144

144

F

15

35

35 G 68

88

88

Ø H 9 13

13

I

105

124

124

Ø J

54

63,5

63,5

Ø K

122

138

138

L

76

118,5

118,5

M

79

100

100

Fixation

Wire rope outlets

MOTORBOX150

Wire rope outlets

MOTORBOX300/500

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 7

EN

Reproduction prohibited

6.3 – Models available

References MOTORBOX®

150 CD 6

300 CD 5

500 CD 3

Force on the 1st layer kg

150

300

500

Force on the upper layer kg

150

300

500

No. of layers

3 3 3

Rope cap. on the 1st layer m *

4 4 4

Rope cap. on the upper layer m *

15

16

13,5

Rope mm

4 5 6

Speed on the 1st layer m/min.

5,5

4,6

2,6

Speed on the upper layer m/min.

7 6 3,5

FEM

1Dm

1Dm

1Dm

Motor kW

0,25

0,37

0,37

Power supply

1Ph - 230 V

1Ph - 230 V

1Ph - 230 V

Weight (bare winch, without rope) kg

14

27

27

Important: the rope diameter indicated above corresponds to rope established in the FEM 1 Dm / ISO M1

classification. It also corresponds to the capacity on the last layer.

Important: it must be ensured that the cable strength coefficient matches the load lifted (FEM 1 Dm / ISO M1)

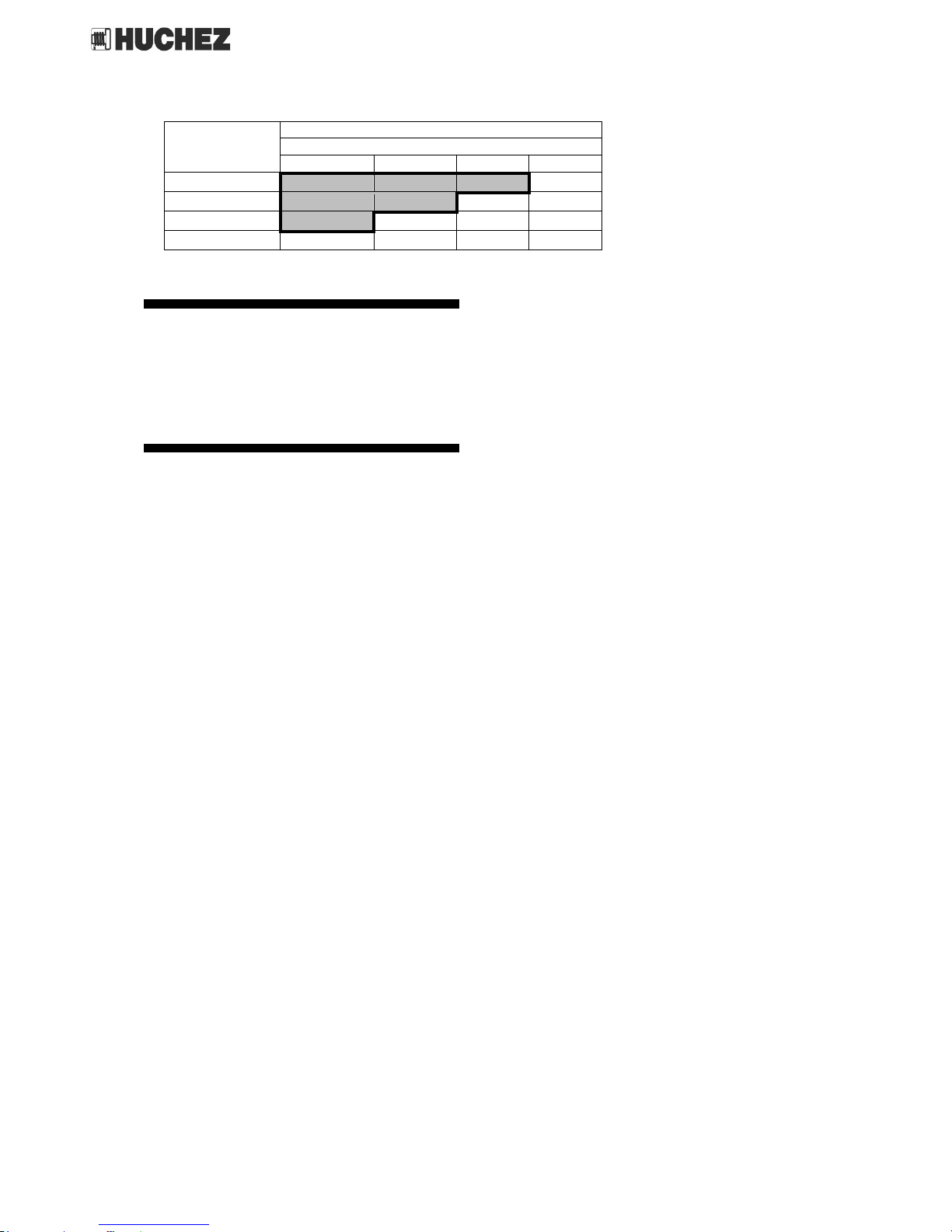

6.4- FEM classification

There are eight groups of mechanisms:

FEM

1 Dm

1 Cm

1 Bm

1 Am

2m

3m

4m

5m

ISO

M 1

M 2

M 3

M 4

M 5

M 6

M 7

M 8

To determine the group for a lifting machine, winch or hoist, three essential parameters must be

considered:

The maximum load to be lifted

Including the weight of the rope and any lifting accessories present (hook etc.), except if they

have a total weight less than or equal to 5% of the load to be lifted.

The usage rate

Indicates the extent to which the lifting machine is used at maximum load or with a reduced load.

There are four different usage rates:

Light

Lifting machines rarely subject to maximum load and

regularly used for very light loads.

k ≤ 0.5

Medium

Lifting machines quite often subject to maximum load

and regularly used for light loads.

0.5 < k ≤ 0.63

Heavy

Lifting machines often subject to maximum load and

regularly used for medium loads.

0.63 < k ≤ 0.8

Very

heavy

Lifting machines regularly subject to loads close to the

maximum load.

0.8 < k ≤ 1

For an exact classification, it is preferable to calculate the average cubic value using the following

formula:

where:

ß = payload or partial load

rated capacity

t = operating time with payload or partial load + dead weight

total operating time

Y = dead weight

maximum load

t Δ= operating time with dead weight only

total operating time

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 8

EN

Reproduction prohibited

FEM classification

Usage rate

MOTORBOX 150 - 300 - 500

Average operating time per day in hours.

7’30’’

15’

30’

1 h

Light

1 Dm

1 Dm

1 Dm

1 Cm

Medium

1 Dm

1 Dm

1 Cm

1 Bm

Heavy

1 Dm

1 Cm

1 Bm

1 Am

Very heavy

1 Cm

1 Bm

1 Am

2m

7 – Handling - Storage

Given their weight MOTORBOX winches require no special handling equipment.

When stored, these winches must be protected from bad weather in a clean and dry place at a

temperature between -10°C and +50°C.

8 - Installation and set-up

8.1- Installation

The service life of a winch depends on its installation and set-up.

It is essential that you read this manual carefully before installing, using and servicing your

machine.

Any use which contravenes our instructions may create risks. In this case, the manufacturer

cannot accept any liability.

Do not use this machine before having read and understood the instruction manual in its

entirety

Always keep the manual close to the machine, available to the operator and the

maintenance officer

Comply and ensure compliance with the safety rules

Connect to the power supply (see 8.4 Power supply)

Check the rope and hook

While ready to press the emergency stop button at all times and with no load attached, check

that the movement of the hook corresponds to the direction of the arrows indicated on the

control unit.

Check that the brake works: with a nominal load attached, lift the load and lower it again or, in

the case of pulling, pull this load.

Check that the limit switch works.

The winch has been subjected to the dynamic and static tests in the factory (cf. Test record).

8.2-Place of installation

These winches must be installed and bolted to a flat, solid and secure surface capable of

bearing the loads to which it will be subjected. An unsuitable installation site may lead to

serious accidents.

To assess the suitability of the place of installation and its resistance to loads, you must take

into account any possible overloading, the weight of the winch itself and the weight of the

options and/or accessories fitted to it, including all dynamic forces. The winch user is

responsible for determining the place of installation. If in doubt with regard to the suitability of

a place of installation, contact a civil engineer or a statics specialist.

©2011 by Huchez Treuils S.A.S.

Translation of the original instructions 9

EN

Reproduction prohibited

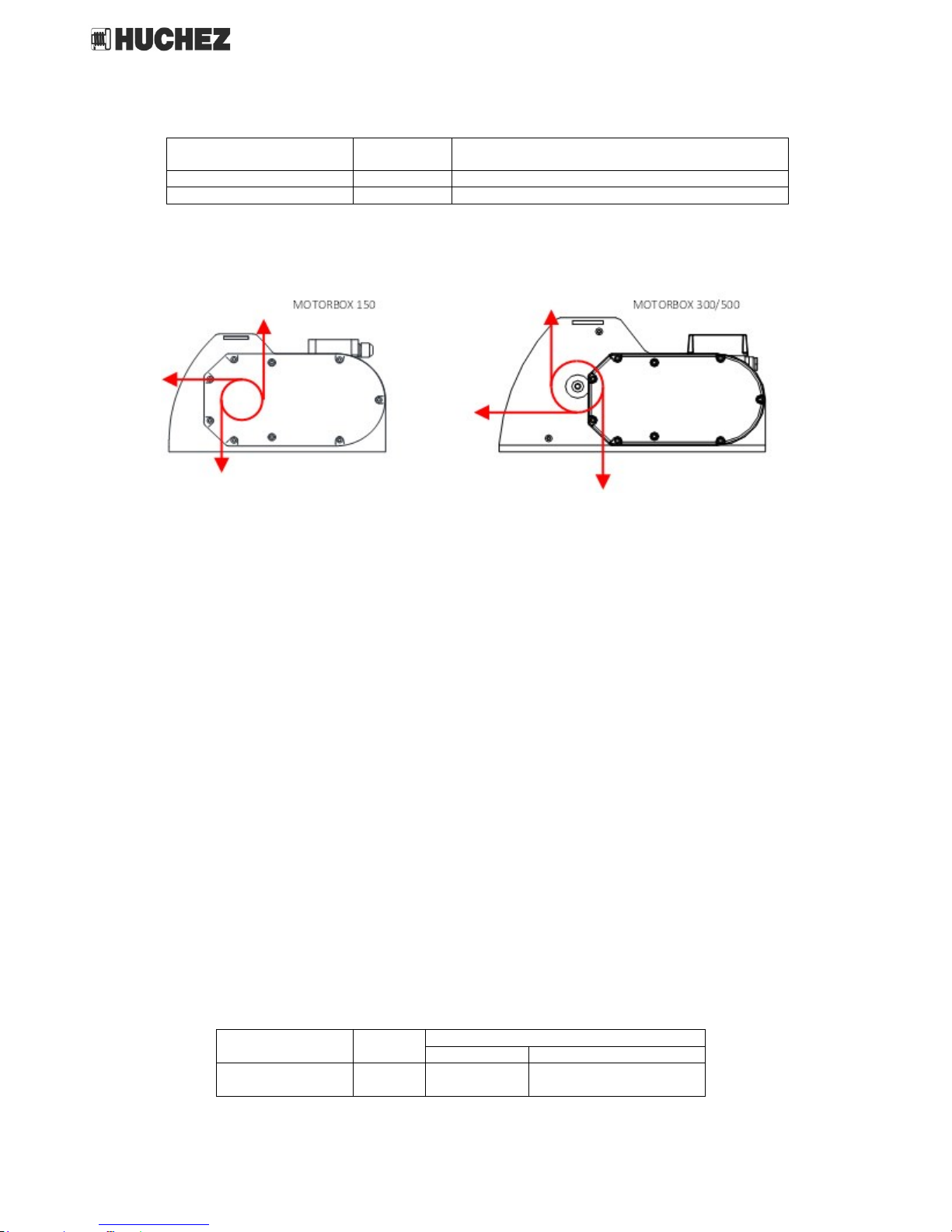

Tighten the clamping bolts correctly

Models

Bolt / nut

Grade 8.8 bolt / nut tightening torque

Nm

MOTORBOX 150 kg

M8

27

MOTORBOX 300/500 kg

M12

90

8.3 – Rope outlets

8.4 – Power supply

Before undertaking any operation on the electrical assembly, check that the power supply to

the machine is off.

A disconnecting switch must be placed no more than 10 metres from the place of use.

Very important: the winch will provide full power only if the motor is supplied by a cable with

fully suitable cross-section.

Provide personal protection in front of the winch.

8.4.1 – Electrical connections

The power supply cable, the protective fuses and the main disconnecting switch (see

wiring diagram) must be provided by the customer.

Check that the power supply network is right for the machine.

Check the type of current; there must not be more than about 5% deviation from the

rated voltage.

Neutralise power sources.

Check that the main power supply switch on the winch is in the off position.

Do not connect the power supply cable to the machine using connection terminals (split

fittings etc.).

Do not use a cable with a smaller cross-section to supply power to the machine.

Never "shunt" the disconnecting switches, electrical switches, prevention or limitation

equipment.

Never block, adjust or remove switches or end stops in order to go beyond the levels that

they allow.

A disconnecting switch must be placed no more than 10 metres from the place of use.

Recommended rope section:

VOLTAGE

TYPE

Length of supply cable

10 m max.

30 m max.

230 V single

phase

2 + T

1.5 mm²

2.5 mm²

Loading...

Loading...