English

Operating and Assembly Instructions

Electronic function module UO-EM-

EGS41

Evaluation to U-ONE® - electronic overspeed switch

certificated according EN 61508 SIL2 and DIN EN ISO 13849-1 PL d

Translation of the original

operating and assembly instructions October 2018

ID 74481

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

2

Read the Operating and Assembly Instructions prior to assembly,

starting installation and handling!

Keep for future reference!

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

3

US41_Manual_En.doc

Build:

31018

Trademark

U-ONE is a registered trademark of Johannes Hubner Fabrik elektrischer Maschinen GmbH.

Windows® is a registered trademark of Microsoft Corporation in the United States and other countries.

Viton® is a registered trademark by Du Pont.

Loctite® is a registered trademark from Henkel AG & Co. KGaA, Düsseldorf.

All other brand names and product names are trademarks or registered trademarks of their respective

owner.

Protected trademarks bearing a ™ or

However, the statutory rights of the respective owners remain unaffected.

Manufacturer / publisher

Johannes Hubner

Fabrik elektrischer Maschinen GmbH

Siemensstraße 7

35394 Giessen

Germany

Phone: +49 641 / 7969-0

Fax: +49 641 / 73645

E-Mail: info@huebner-giessen.com

www.huebner-giessen.com

Headquarters: Giessen

Court of registration: Giessen

Commercial register number: HRB 126

The manual has been drawn up with the utmost care and attention. Nevertheless, we cannot exclude

the possibility of errors in form and content. It is strictly forbidden to reproduce this publication or parts

of this publication in any form or by any means without the prior written permission of

Johannes Hubner Fabrik elektrischer Maschinen GmbH.

Subject to errors and changes due to technical improvements.

Copyright © Johannes Hubner Fabrik elektrischer Maschinen GmbH.

All rights reserved.

®

symbol are not always depicted as such in the manual.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

4

Directory

1 General ............................................................................................................................ 5

1.1 Information about the operating and assembly instructions ....................................................... 5

1.2 Scope of supply .......................................................................................................................... 5

1.3 Explanation of symbols ............................................................................................................... 5

1.4 Disclaimer ................................................................................................................................... 6

1.5 Copyright..................................................................................................................................... 6

1.6 Guarantee terms ......................................................................................................................... 6

1.7 Customer service ........................................................................................................................ 6

2 Safety ............................................................................................................................... 6

2.1 Responsibility of the owner ......................................................................................................... 6

2.2 Personnel .................................................................................................................................... 7

2.3 Special dangers .......................................................................................................................... 7

3 Technical Data ................................................................................................................ 8

3.1 Construction and function ........................................................................................................... 8

3.2 Short description ......................................................................................................................... 8

3.3 Overspeed switch-off .................................................................................................................. 8

3.4 Reset input .................................................................................................................................. 9

3.5 Other functions ........................................................................................................................... 9

3.6 Type plate /connection diagram ............................................................................................... 10

3.7 Connected loads environment .................................................................................................. 10

3.8 Connectors and Indicators ........................................................................................................ 11

3.9 Mounting the module ................................................................................................................ 11

3.10 Dimension drawing ................................................................................................................... 11

4 Functional safety ...........................................................................................................12

4.1 Characteristic safety values ...................................................................................................... 12

4.2 Timing ....................................................................................................................................... 13

4.3 Switching deviation ................................................................................................................... 13

4.4 Proper use ................................................................................................................................ 14

4.5 Improper use ............................................................................................................................. 14

4.6 Notes on configuration .............................................................................................................. 14

4.7 Switch delay .............................................................................................................................. 14

4.8 Slip angle detection .................................................................................................................. 14

4.9 Diagnostic output ...................................................................................................................... 14

4.10 Faults table ............................................................................................................................... 15

4.11 Error table ................................................................................................................................. 15

5 Transport, packaging and storage ...............................................................................16

5.1 Safety information concerning transport ................................................................................... 16

5.2 Goods inward inspection .......................................................................................................... 16

5.3 Packaging (disposal) ................................................................................................................ 16

5.4 Storing packages (devices) ...................................................................................................... 16

5.5 Returning devices (repairs/goodwill/warranty).......................................................................... 17

5.6 Disposal .................................................................................................................................... 17

6 Certificate .......................................................................................................................18

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

5

1 General

1.1 Information about the operating and assembly instructions

These operating and assembly instructions provide important instructions for working with the device.

They must be carefully read prior to starting all tasks, and the instructions contained herein must be

followed.

In addition, applicable local regulations for the prevention of industrial accidents and general safety

regulations must be complied with.

For other, non SIL certified electronic function modules please refer to the separate Operating and

Installation Instructions.

1.2 Scope of supply

The scope of supply of the electronic function module overspeed switch UO-EM-EGS41 includes the

Operating and Installation Instructions (with SIL safety instructions), the programming software

EGS41Pro (on CD) and the programming cable.

The Operating and Installation Instructions for the electronic function module is also included on the

supplied CD.

1.3 Explanation of symbols

Warnings are indicated by symbols in these operating and assembly instructions. The warnings are

introduced by signal words that express the scope of the hazard.

The warnings must be strictly heeded; you must act prudently to prevent accidents, personal injury,

and property damage.

WARNING!

Indicates a possibly dangerous situation that can result in death or serious injury if it

is not avoided.

CAUTION!

Indicates a possibly dangerous situation that can result in minor injury if it is not

avoided.

CAUTION!

Indicates a possibly dangerous situation that can result in material damage if it is not

avoided.

NOTES!

Indicates useful tips and recommendations as well as information for efficient and

trouble-free operation.

NOTES!

Do not use a hammer or similar tool when installing the device due to the risk of

damage occurring to the bearings or coupling!

DANGER!

Life-threatening danger due to electric shock!

Indicates a life-threatening situation due to electric shock. If the safety instructions

are not complied with there is danger of serious injury or death. The work that must

be executed should only be performed by a qualified electrician.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

6

1.4 Disclaimer

All information and instructions in these operating and assembly instructions have been provided under due consideration of applicable guidelines, as well as our many years of experience.

The manufacturer assumes no liability for damages due to:

Failure to follow the instructions in the operating and assembly instructions

Non-intended use

Deployment of untrained personnel

Opening of the device or conversions of the device

In all other aspects the obligations agreed in the delivery contract as well as the delivery conditions of

the manufacturer apply.

1.5 Copyright

NOTE!

Content information, text, drawings, graphics, and other representations are protected

by copyright and are subject to commercial property rights.

It is strictly forbidden to make copies of any kind or by any means for any purpose

other than in conjunction with using the device without the prior written agreement of

the manufacturer. Any copyright infringements will be prosecuted.

1.6 Guarantee terms

The guarantee terms are provided in the manufacturer´s terms and conditions.

1.7 Customer service

For technical information personnel is available that can be reached per telephone, fax or email. See

manufacturer´s address on page 2.

2 Safety

DANGER!

This section provides an overview of all the important safety aspects that ensure protection of personnel, as well as safe and trouble-free device operation.

If these safety instructions are not complied with significant hazard can occur.

2.1 Responsibility of the owner

The device is used in commercial applications. Consequently the owner of the device is subject to the

legal occupational safety obligations, and subject to the safety, accident prevention, and environmental protection regulations that are applicable for the devices area of implementation.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

7

2.2 Personnel

Qualified personnel only are permitted to install, mount, program, commission, operate, maintain and

take out of service the devices.

Qualified personnel are people who have received

training to qualify as an electrician or

instructions from qualified trades personnel

entitling them to work with and on devices, systems, machinery and plant in accordance with generally

accepted standards and safety engineering guidelines.

In addition, the owner is obliged to deploy only personnel who

are familiar with the fundamental regulations covering work safety and accident prevention,

have read and understood the chapter "Safety" in these Operating and Installation

Instructions,

and are familiar with the basic and specialist standards that apply to the specific application.

2.3 Special dangers

Residual risks that have been determined based on a risk analysis are cited below.

DANGER!

Life-threatening danger due to electrical shock!

There is an imminent life-threatening hazard if live parts are touched. Damage to insulation or to specific components can pose a life-threatening hazard.

Therefore:

Immediately switch off the device and have it repaired if there is damage to the insulation of the power supply.

De-energize the electrical equipment and ensure that all components are connected

for all tasks on the electrical equipment.

Keep moisture away from live parts. Moisture can cause short circuits.

DANGER!

Life-threatening danger if restarted without authorization!

When correcting faults there is danger of the power supply being switched on without authorization.

This poses a life-threatening hazard for persons in the danger zone.

Therefore:

Prior to starting work, switch off the system and safeguard it from being switched on

again.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

8

3 Technical Data

3.1 Construction and function

Block diagram:

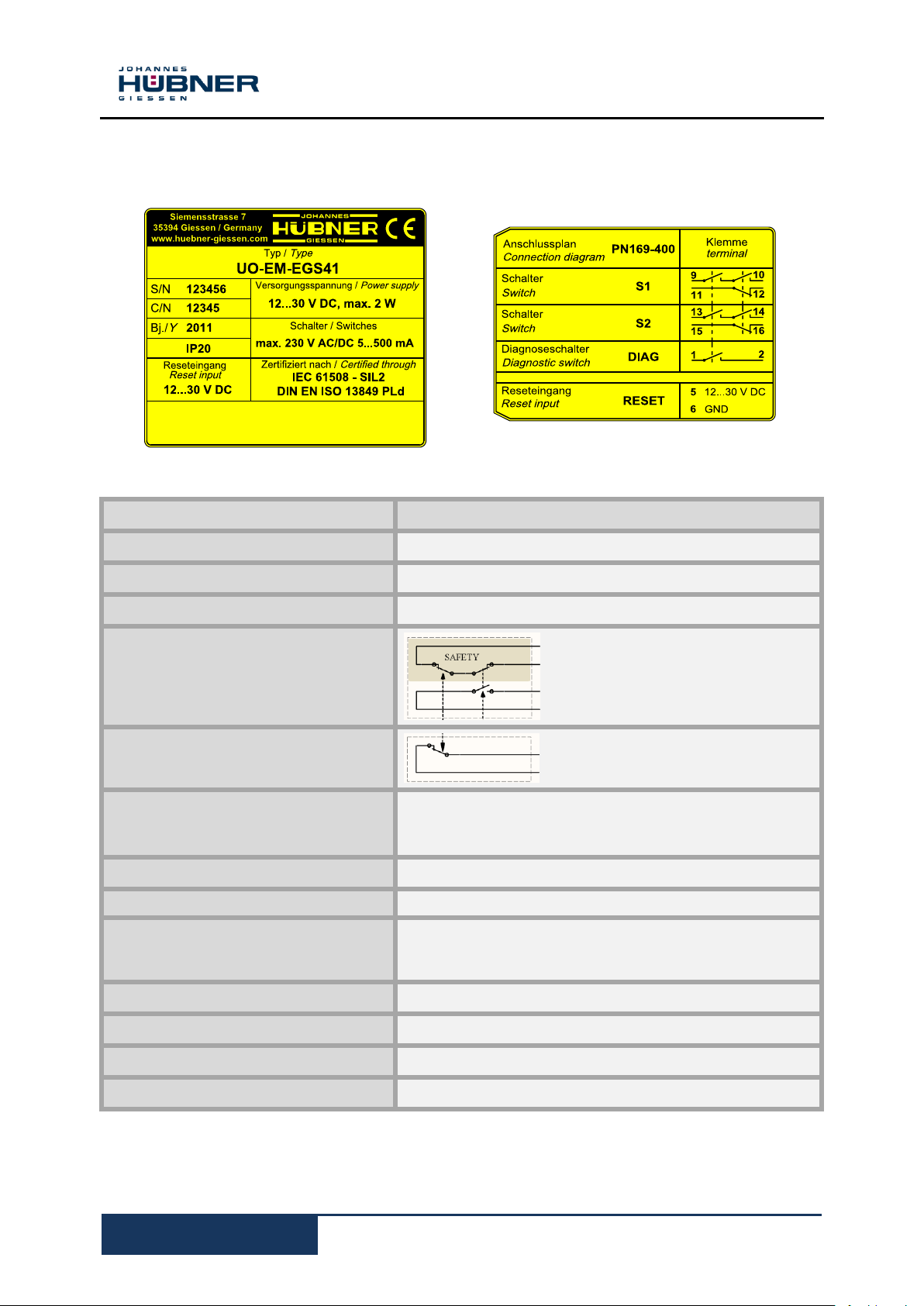

3.2 Short description

The U-ONE universal encoder system including the basic device UOM(H) 41L-1212 and the electronic

function modules UO-EM-D41 and UO-EM-EGS41 is an overspeed switch (certified to EN 61508 SIL2

and EN 13849-1 PLd).

The function module is configured using a PC running a Windows® operating system (XP, Vista and

7) in conjunction with the programming software EGS41Pro included in the scope of supply. The physical interface is USB.

The overspeed switches S1 and S2 are switched according to the set speed parameters.

The switches S1 terminal 9/10 and S2 terminal 13/14 are envisaged for safety-relevant switching. A

separate diagnostic switch is connected in series. An auxiliary contact is also available for each respective switch S1 (terminal 11/12) and S2 (terminal 15/16).

The outputs of the switches are electrically isolated from the electronics and the PC interface.

3.3 Overspeed switch-off

The incremental signal is utilized to determine the speed. The switch opens reliably if the speed exceeds the user-defined switching point

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

9

The device is equipped with a safety relay with positively driven

contacts for each switching output. That facilitates 2-channel evaluation

of the switching status with line monitoring by a downstream control.

The module incorporates 2 identical switching channels (S1 and S2).

Green LEDs indicate the switching status of the safety switches (lit LED

= switch closed).

A separate diagnostics switch (Diag) closes when no errors are diagnosed. This is also indicated on the front of the module by a green LED.

If an error is established the switch opens and a red LED lights up.

3.4 Reset input

The reset input is electrically isolated and triggers a module restart (hardware reset) when a DC voltage (12...30 VDC) is applied. The module performs an complete self-test. An established error is reset.

3.5 Other functions

The following additional, non safety-relevant functions are available:

Adjustable release point:

The user is able to select the release point (hysteresis) as required across the entire operating

range.

Restriction: the difference between the speed of the release point and the switching point must be

at least 10%.

Underspeed

To facilitate underspeed switch-off it is possible to activate a further switching point (underspeed

switch-off). The switch opens if the speed falls below the set switching point (see configuration

Guide).

Slip detection

The slip detection function closes a switch if the set slip angle is exceeded

(see configuration Guide).

Rotation direction dependent switching

It is possible to select a variety of switching speeds, depending on the direction of rotation. This

function can be combined with all other functions (see configuration Guide).

Switch delay

Briefly overshooting the switching speed (1 ms...300 ms) will not trigger overspeed switch-off (see

configuration Guide).

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

10

Description

Worth

Supply voltage

Supply via bus connections (12 … 30 V DC)

Power consumption

max. 2 W

Connection

COMBICON®-terminal strips

Switching outputs S1/2

Switching output Diag

Switching power

(max. switching cycles: approx. 2 x 106)

5 … 230V AC 5 … 500 mA

5 … 30V DC 5 … 500 mA

230V DC 5 … 150 mA

Reset input

potential free, reset voltage 12 … 30 V DC / ca. 7 mA

Programmable switching speeds

0,5 … 2700 rpm

Switching differential

(see. chapter. 4.3)

Measuring angle approx.1°

Accuracy: 2%

Switching time TSw: < 20 ms

Programming interface

USB

Connecting diagram

PN169-400

Device temperature range

-25 … + 70 °C

Degree of protection

IP20

Relays with forcibly guided contacts

max. 230V AC/DC 5 … 500mA

Relay contact

max. 230V AC/DC 5 … 500mA

3.6 Type plate /connection diagram

3.7 Connected loads environment

Install a back-up fuse (2A) to protect the relay contacts against overcurrents.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

11

Indicators

S1, S2, Diag

LEDs light up when

switches are closed

State

Green LED

Lit: Operational

Flashes 1x Absolute signal

not detected (FOC 2)

Flashes 2x Speed signal

not detected (FOC 1)

Red LED lit: Error condition

Reset

Red LED lit: Reset condition

A = 114,50 mm

B = 45 mm

3.8 Connectors and Indicators

3.9 Mounting the module

Snap the modules onto the top-hat rail and slide together.

ATTENTION!

Ensure you do not damage the connectors when you snap the modules onto the rail

and push them together!

Ensure the modules contact reliably when joining them together on the top-hat mounting rail.

Fit the supplied shrouding covers to both ends of the mounted terminals.

Follow the connection diagram!

3.10 Dimension drawing

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

12

Characteristic safety values

Safety class / standard

SIL2 to EN 61508

Performance level 'd' to EN ISO 13849-1

Category 2

System structure

1 channel with diagnostics (1oo1D)

Device type

Type B (complex components)

Hardware fault tolerance (HFT)

0

Type of operating mode

'High demand' to EN 61508

(high demand rate)

Probability of a dangerous failure per

hour (PFHd)

1,44 x 10-7 [1/h]

Failure rate:

safe detected (λSD)

safe undetected (λSU)

Dangerous detected (λDD)

Dangerous undetected (λDU)

λ

SD

: 8,40 x 10-7 [1/h]

λ

SU

: 2,22 x 10-7 [1/h]

λ

DD

: 1,13 x 10-6 [1/h]

λ

DU

: 1,44 x 10-7 [1/h]

Mean time to a dangerous failure

(MTTFd)

89.9 years (high)

Diagnostic coverage on average

(DC

AVG

)

medium

Proportion of safe failure fraction (SFF)

93,8%

Service life or

proof test interval to EN 61508

10 years

Thereafter the components must be replaced with

new components

Safe state

Switch S1 (terminals 9 / 10) open

Switch S2 (terminals 13 / 14) open

Diagnostic switch open.

Safety function

Safe overspeed switch-off switch S1 (terminals 9 /

10) and switch S2 (terminals 13 / 14).

4 Functional safety

4.1 Characteristic safety values

The details below refer to the overall system consisting of:

Electronic function module UO-EM-EGS41 (overspeed switch)

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

13

min/1

1000

)(

0

DSmess

Fehler

TTT

nnn

n0: Programmed switching

speed [rpm]

: Acceleration

s

min/1

T

D:

Adjustable switch delay [s]

T

Sys

: System time [s]

n

error

: 0.02 (2%)

ms

n

T

mess

0

6

1000

4.2 Timing

Chapter 7.4.3.2.5 of

EN 61508-2 should also be taken into consideration with regard to the process safety time of the application.

Power-on time T

After the power supply is turned on initial internal diagnostic checks are carried out before the device

is ready for operations.

The power-on time is approx. 1.6 s.

Diagnostic time T

The diagnostic time is 200 ms. If a diagnosis is flawed the diagnostics are carried out again (repeat

measurement). The max. repeat measurement time is 500 ms. If the repeat measurement is also

flawed the device is put into a 'safe state'.

Switching time T

The switching time TS of the switching contacts S1 and S2 is composed of:

TS = T

4.3)

In addition, the optionally adjustable switch delay (delay = 0 ... 300 ms) must be added.

4.3 Switching deviation

Switching deviation consists of:

(speed measurement time) + T

meas

Measuring accuracy (errors when determining the speed):

N

error =

Pw

Diag

s

2%

(system time) + TD (adjustable switch delay see Chapter

Sys

Speed measurement time (time required to identify the speed)

System time T

T

Adjustable switch delay

TD = 0 ... 300 ms

Max. switching deviation:

(calculation time + switching time of relay)

Sys

= max. 20 ms

Sys

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

14

4.4 Proper use

The universal encoder system from the series UOM 41L-1212 which includes the electronic

function modules

UO-EM-D41 and UO-EM-EGS41 has been designed and built solely for the intended purpose

described in these Operating and Installation Instructions.

It is designed to detect overspeeds (programmable), for example in electric and mechanical

drives, lifting equipment and winding plant.

The electronic function module UO-EM-EGS41 is a safety switching device that generates a

switching signal (opens the switching contact) for the higher-level controls. This is responsible

for necessary actions, such as shutting down plant components.

We do not accept liability of any kind for damages arising from improper use of the device. The

owner bears sole responsibility for any improper use.

4.5 Improper use

Do not use the device in potentially explosive areas.

It is not permitted to use the device in locations higher than 3000 m above sea level.

4.6 Notes on configuration

It is only possible to configure the device with password authorization (user rights: administrator). The factory-set administrator password is: huebner. For reasons of safety it is strongly advised that you create a user-defined password (max. 12 characters). Information on how to

change the password is available on Parameters 2.

4.7 Switch delay

Activating switch delay leads to higher switch-off speeds when speeds are accelerating in the

switching point. Before activating switch delay ensure the switch-off speed is not able to reach

dangerously high speeds

(please refer to Chapter 4.3 switching deviation).

4.8 Slip angle detection

The switch remains open if the switch-off speed is reached within the set slip angle.

4.9 Diagnostic output

The diagnostic output is not a safety output.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

15

Faults

Possible cause

Remedy

Diagnostic switch

does not close

No power supply

Check basic unit:

Green LED in terminal box not

lit.

Check electronic modules:

No LEDs lit

Check connection cable and voltage supply

No fault detected.

Red LED on the EGS module

lit.

Read out fault memory with EGS41Pro and

implement corresponding corrective measures,

if necessary. Finally, reset the fault. Please

refer to the error table for a list of individual

errors (Chapter 4.10)

Contact Hubner-Service (page 2) if none of the actions listed above provide a solution!

Error message

Description

Dg_Intern

[FFxx]

Device error

Dg_TempMain

[0601, FE01]

Overtemperature in

device

Dg_TempKK

[0602, FE02]

Overtemperature in

switch

Dg_ExtOv

[0603, FE03]

Max. permissible

supply voltage

exceeded

Dg_n_Fatal

[0604, FE04]

Non-permissible

high speed

Dg_ExtUv

[0605, FE05]

Below lowest permissible supply

voltage

Dg_AbsErr

[0606, FE06]

Flawed absolute

value

Dg_IncErr

[0607, FE07]

Flawed incremental

value

Error

[FExx]

Error

FatalError

[FFxx]

Fatal error

4.10 Faults table

4.11 Error table

Error category:

Error:

The switches S1, S2 and Diag

are opened. To reset to the

normal state interrupt the

power supply via the reset

input or click 'Delete error' in

the software 'EGS41Pro'.

The 'Delete error' command

initiates a restart. If the error

persists the device remains in

the error state.

Fatal error:

The switches S1, S2 and

Diag are opened. To reset to

the normal state click "Delete

error" in the software

'EGS41Pro'.

The 'Delete error' command

initiates a restart. If the error

persists the device remains

in the error state.

The device enters a 'safe state' in the

event an error or fatal error occurs. In

addition, the error causing the problem is displayed.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

16

5 Transport, packaging and storage

5.1 Safety information concerning transport

CAUTION!

Material damage caused by improper transport!

Observe the symbols and information on the packaging:

Do not throw - risk of breakage

Keep dry

Do not expose to heat above 40 °C or direct sunlight.

5.2 Goods inward inspection

Check the delivery immediately upon receipt for transit damage or short delivery.

Inform the carrier immediately on receipt if you determine that damage has occurred during transit

(take photos as proof).

5.3 Packaging (disposal)

The packaging is not taken back; dispose of according to the respective valid statutory provisions and

local regulations.

5.4 Storing packages (devices)

If you intend to store the device for a longer period of time (> 6 months) we recommend you use

protective packaging (with desiccant).

Keep dry

Keep packages dry and free from dust; protect from moisture.

Protect against heat

Protect packages from heat above 40 °C and direct sunlight.

NOTES!

Turn the shaft of the device every 6 month to prevent the bearing grease solidifying!

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

17

5.5 Returning devices (repairs/goodwill/warranty)

Devices that have come into contact with radioactive radiation or radioactive materials are not taken

back.

Decontaminate devices that have may come into contact with harmful chemical or biological

substances before returning.

They must also be accompanied by a safety clearance certificate.

5.6 Disposal

The manufacturer is not obliged to take back the device.

The device is classed as electronic equipment and subject to the WEEE Directive; observe local,

country-specific laws when disposing of the device.

For information on environmentally sound disposal please contact your local authority or a specialist

disposal company.

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

18

6 Certificate

Universal encoder system U-ONE

®

Electronic function module UO-EM-EGS41

19

Loading...

Loading...